Page 1

T.Nr. 40284

Operating and Installation Instructions for

CRAMER Baking Oven

Model CBC

versions CBCG (with grill) and CBCO (without grill)

GB

GB, IE, IS

Product-ID-Number

CE-0085BN0171

Page 2

Important warnings

This appliance of class 3 is designed to be built in a kitchen block.

This appliance is produced in two versions (with and without grill):

1. Oven

Model description See schene of installation

Oven with grill, without chimney, front flue of waste gas Page 7, Fig. 3

Oven with grill, with chimney horizontal – vertical Page 7, Fig. 4

Oven with grill, with chimney vertical and box for waste gas Page 8, Fig. 5

Oven with grill, with chimney horizontal and box for waste gas Page 8, Fig. 6

with grill

version CBCG (door down hinged

)

Oven output (Hs) 1,2 kW (Mn = 85 g/h, propane/butane)

Grill output (Hs) 1,6 kW (Mn = 115 g/h, propane/butane)

(It is technically ensured that both parts cannot be switched on at the same time).

2. Oven

Oven without grill, without chimney, front flue of waste gas Page 7, Fig. 3

Oven without grill, with chimney horizontal – vertical Page 7, Fig. 4

Oven without grill, with chimney vertical and box for waste gas Page 8, Fig. 5

Oven without grill , wi th chimney horizonta l an d box for waste gas Page 8, Fig. 6

2. Oven

Oven without grill, without chimney, front flue of waste gas Page 7, Fig. 3

Oven without grill, with chimney horizontal – vertical Page 7, Fig. 4

Oven without grill, with chimney vertical and box for waste gas Page 8, Fig. 5

Oven without grill, with chimney horizontal and box for waste gas Page 8, Fig. 6

without grill

Model description See scheme of installation

without grill

Model description See scheme of installation

version CBCO (door down hinged)

version CBCO (door hinged on the left side)

Oven output (Hs) 1,2 kW (Mn = 85 g/h, propane/butane)

If the gas tap is scarcely moving or seizing it is necessary either to replace it or to disas semble

the appropriate tap cone, to clean it with benzoline, to grease it with a special lubricant for taps,

for example one produced by Klüber, Muni ch, type „Staburgas No 32“ and to assemble it. This

work may be carried out only by a gas specialist.

The appliance may be installed by a qualified person only!

Before installing the appliance it is necessary to check whether local connection conditions (kind

and pressure of gas) are in accordance with appliance settings. Appliance settings values are

shown on the instruction label (on the appliance plate).

This appliance has to be installed and connected in accordance with the valid installation

conditions. Special attention has to be paid to the measures for sufficient ventilation.

Gas supplying parts and waste gas connected lines (waste gas pipe) have to be tested by

specialist according to valid norms before the initial operation and every two years thereafter.

2

Page 3

The user is responsible for arranging the test. The installer of the appliance has to inform in

writing the user about this compulsory test.

The appliance can be only used for baking and grilling under conditions mentioned hereinafter. It

must not be used for other purposes than described in this manual (e.g. heating, etc.).

Use of the appliance can cause creation of warmth and/or humidity in the room, where it is

placed. It is necessary to supervise the ventilation of the kitchen: natural venting air-openings or

mechanical ventilations.

Intensive and longstanding use of appliance may require auxiliary ventilation, for example

opening of a window or run of a ventilation device at a higher performa nc e l e vel.

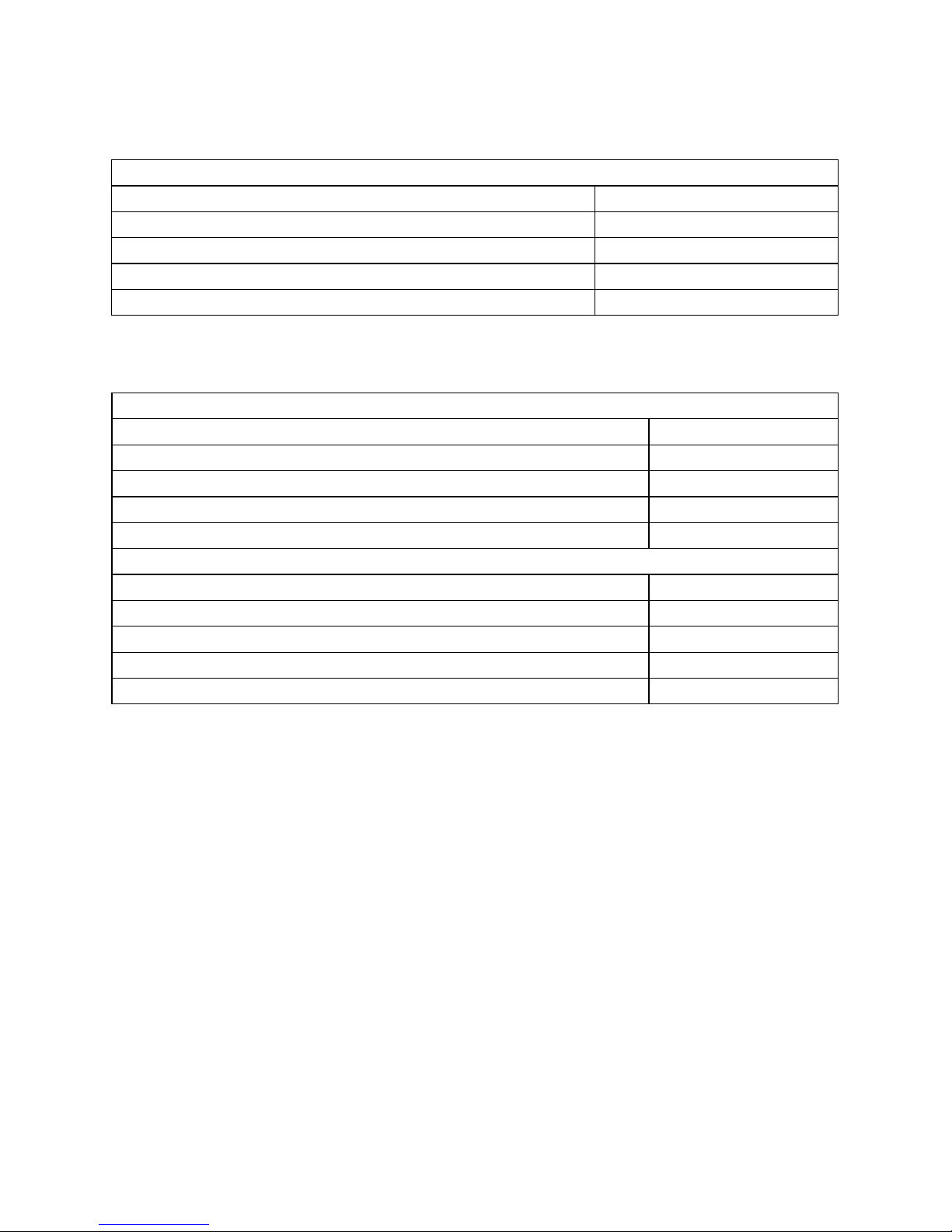

Pressure reducers between gas cylinder and appliance have to respond to categories as follows:

Category mbar Gas Output pressure reducer

G 30 (Butane) 1,5 Kg/h

I 3 (50) 50

G 31 (Propane) 1,5 Kg/h

I 3+ (28-30/37) 28-30

G 30 (Butane) 1,5 Kg/h

I 3 (30) 30

I 3+ (28-30/37) 37

G 31 (Propane) 1,5 Kg/h

I 3 (30) 30

ATTENTION: THE APPLIANCE HAS TO BE INSTALLED BY A SPECIALIST IN

ACCORDANCE WITH THE VALID NORMS.

IMPORTANT: IN ORDER TO PREVENT ANY ACCIDENT IT IS NECESSARY TO

INSTALL THE APPLIANCE IN ACCORDANCE WITH THE PRESENTED

INSTRUCTIONS. UNQUALIFIED INSTALLATION CAN RESULT IN THE LOSS OF

GUARANTEE.

„EACH MODIFICATION OF THE APPLIANCE CAN BE DANGEROUS!“

1. VENTILATION OF THE ROOM

Each room, where one or more appliances are intended to be installed, has to be equipped

with one or more openings allowing input of fresh air with a minimum total available crosssection 100 cm2. These openings may be situated at various points of the room, have to be

placed near the floor at a height of maximum 10 cm above the floor.

One or more openings with a minimum cross-section 150 c m2 have to be placed above the

appliance.

3

Page 4

These openings have to be from time to time checked and/or cleaned by the user (e.g. clea n

the waste-gas output from snow and the combustion air inlet from melting snow in winter).

The opening of the waste gas outlet must not be placed at the entry door and under

ventilation openings.

If waste gas is discharged through the roof it is necessary to check whether the waste gas line

is installed in the upward position.

2. CONNECTING THE APPLIANCE TO THE GAS SUPPLY

Connecting the appliance to the gas supply can be only executed using gas-tight conn ector or

standardised tubing connection (max. length 1.5 metres), which have to be replaced before

their expiration date.

When laying rubber tubings it is necessary to make sure that they do not touch metal parts,

which become extremely hot during the use of appliance, e.g. ones under the burners.

When using pipes to connect the appliance they have to be made of galvanised iron or

copper. These pipes have to be used with a gas-tight connector. After completion of the gas

connections the gas lines has to be tested for gas leakage by applying soapy water over

connection points and gas lines; gas leaks will show up as bubbles where the gas leak occurs.

ATTENTION: DURING INSTALLATION AND CONNECTION OF APPLIANCE

THE GAS PIPE CANNOT BE TURNED, PULLED OR IN A DIFFERENT WAY

STRAINED.

3. GAS CYLINDERS

Gas cylinders usually used in the country where the appliance was sold have to be used. The

usable gastype is clearly definied on the package and on the wipe resistant label on the

backside of the appliance.

USE OF PRESSURE OR GAS DIFFERENT FROM INSTRUCTIONS CAN CAUSE

AN UNSTABLE RUNNING CONDITIONS OF THE APPLIANCE; THEREFORE

THE PRODUCER REFUSES ANY RESPONSIBILITY CONCERNING THE

CONNECTION WITH UNQUALIFIED HANDLING OF THE APPLIANCE.

In any case the following instruction have to be followed:

Gas cylinders with tap and pressure reducer have to be positioned in vertical position in

a case intended for this purpose. Input of cylinders must not be obstructed.

Replacement of the gas cylinder has to be fluent and without any difficulties.

AFTER USE THE GAS CYLINDER HAS TO BE ENCLOSED

4

Page 5

ATTENTION!

When replacing a gas cylinder the following safety measures have to be carried out:

a) Close the taps on the appliance (turn the knob into position 0);

b) Make sure that no flame or flaming articles are located close to it;

c) Close the tap of the cylinder being repla c ed;

d) Unscrew the pressure reducer from the empty cylinder, take the last one out of the

case and replace it with a new gas cylinder – when connecting a new gas cylinder

proceed in the reverse sequence.

Test theleakage by applying of soapy water in the above mentioned way.

e) Fire up the burner and check the proper run; otherwise refer to a specialised

technician.

3.1 CASE FOR GAS CYLINDERS

The case for gas cylinders has to be spacious enough for the intended type of cylinder with

installed pressure regulator.

4. VISUAL CONTROL OF FLAME

a) The flame has to burn still. It has to be predominantly blue coloured and with clear

contours.

b) If the flame does not burn steady, it is necessary to check whether air inlet openings

(Venturi tube) are free of obstacles. Otherwise the obstacles have to be removed.

5. POWER SUPPLY AND ELECTRICAL CONNECTION:

The electronic ignition of the grill and oven burners requires a 12 V DC power supply.

ELECTRICAL CONNECTION

To connect the appliance a twin core, 1,5 mm2 red and black cable shall be used and

connected to the terminal board on the back of the appliance. This terminal board has both

poles marked with + and -. The + pole is to be identified with the red colour cable. When

connecting the cables it is absolutely necessary to observe the right polarity! The electric

circuit has to be protected against fusion with a 3 A fuse (not supplied with the appliance).

5

Page 6

UNDER NO CIRCUMSTANCES MUST THE APPLIANCE BE CONNECTED TO 220

V POWER SUPPLY! IT MAY CAUSE TOTAL DAMAGE OF ELECTRICAL

COMPONENTS AND DANGER FOR USERS.

6. GAS LEAKAGE

To check gas leakage we recommend to use an electric gas detector of a verified type. In

case of an accident close the gas inlet tap and refer to a gas-fitter, seller or specialised

technician.

7. FIXATION OF THE APPLIANCE TO FURNITURE

To build the appliance ino furniture a space with dimensions shown on fig. 1 - 6 must be

available depending to model (see label of appliance). Arbitrary position can be chosen.

The appliance has to be placed on a firm, stable base in furniture. The front of the appliance

must be fixed firmly to the furniture by means of supplied screws and 4 mounting frames.

For fixation it is not allowed to use gas lines, taps or parts of burners.

Fig 1

Fig 2

C

Max30mm

7m m

Min15 m m

Fixation to furniture

Oven

Detail D

Furniture

D

SECTION A-A

6

Page 7

Fig 3

Installation of oven without chimney, front flue of waste gas.

Fig 4

Installation of oven with chimney horizontal – vertical.

Minimum distamce from combustible

areas backward and towards right and

left sides: 20 mm.

Minimum distance from combustible

areas upward: 50 mm.

Section: the front side horizontally

with building in (see installation

drawing No. 39986)

Minimum distamce from

combustible areas backward and

towards right and left sides: 20 mm.

Minimum distance from combustible

areas upward: 50 mm.

Section: the front side horizontally

with building in (see installation

drawing No. 39986)

7

Page 8

Fig 5

Installation of ovens with chimney vertical and with box for waste gas.

Fig. 6

Minimum distance from combustible

areas backward and towards right and

left sides: 20 mm.

Minimum distance from combustible

areas upward: 50 mm.

Minimum distance of waste gas line

box from combustible areas: 50 mm

Section: the front side horizontally

with building in ( see installation

drawing No. 39986)

Installation of ovens with chimney horizontal and with box for waste gas

.

Minimum distamce from

combustible areas backward and

towards right and left sides:

20 mm.

Minimum distance from

combustible areas upward: 50 mm.

Minimum distance of waste gas

line box from combus t ible areas:

50 mm

Section: the front side horizontally

with building in (see installation

drawing No. 39986)

8

Page 9

ATTENTION: Installation of baking oven with chimney horizontal is allowed only with the

waste gas line box, partnumber 43661 (new version ) and without chimney-adapter.

ATTENTION: For the reason of saving of weight the oven for an OEM (producer of

caravans or motorhomes) might be also delivered without the outer housing.

The waste gas line through chimney pipe has to be in upward position. Maximum length of the

waste gas line i s 2.000 mm. The max imum eleva tion difference between the upper edge of oven

and the point of waste gas outlet from the chimney is 1.500 mm.

Walls and components closer than 50 mm to the waste gas exhaust have to be wrapped or

protected with materials belonging to M0 fire-resistant group.

Ø 50 mm flexible pipe of the waste gas exhaust made of a high-grade steel has always to be

fixed at the outlet from the oven and at the inlet to the chimney adapter by means of one strap

with a screw thread Ø 50 - Ø 60 mm (Truma´s thread appertaining to the pipe).

7.1 THE APPLIANCE HAS TO BE INSTALLED IN A SAFE DISTANCE FROM

INFLAMMABLE MATERIALS.

7.2 PROTECTION AGAINST OVERHEATING

All walls or components which are closer to the appliance than the minimum distance in the

drawin g (see Fi gures 3 - 6) have to be wrap ped or pr otecte d with mat erial s belongi ng to M0

fire-resistant group.

7.3 REMOVAL OF THE APPLIANCE FROM FURNITURE

a) Close the main gas tap

b) Release fastening screws

c) Disconnect gas adapter and/or electrical cables.

8. USE THE APPLIANCE ONLY IN A SUFFICIENTLY VENTED ROOM

If the appliance is being used, venting openings shall to be without obstructions.

9

Page 10

9. USE OF THE APPLIANCE

9.1 IGNITION OF THE APPLIANCE

AUTOMATIC IGNITION: OVEN – GRILL

a) To ignite the oven or grill the oven door has to be completely open.

b) Push the knob gently and turn into the ignition position. Getting the oven into

operation is possible in all positions 1-6 of the knob (after pushing turn the knob to the

left). Getting the grill into operation (for ovens with grill only) is possible if the knob

is in the position Grill (after pushing and turning the knob to the right).

c) Release the knob and turn into the chosen position.

GRILL

GRILL

Notice:

When operating the grill the sheet protecting against heat has to be completely drawn

out (see 9.3a too).

Various positions of the knob correspond approximately to the following temperatures of the

oven (in oC)

POSITION 1 2 3 4 5 6

TEMPERATURE 140 170 190 210 230 250

If an excessive deviation of the oven temperatures is experienced it may be necessary to

repair or replace the thermostat.

IMPORTANT:

If the ignition of the burner is not successful at the first attempt, repeat the

process from the beginning. If necessary, check the gas or current supply to the appliance. If

the appliance does not work in spite of all that, close the gas inlet tap and refer to your seller.

Before the initial operation of the oven, let it run empty (without food) for app. ½ hour at the

maximum temperature. If the flame of burner blows out mistakenly, close the burner

regulator and before repeating the ignition of the burner let it extinct f o r minimum 1 minute.

„IT IS A SAFETY REQUIREMENT THAT OVEN GLOVES ARE USED WHEN

HANDLING THE HOT OVEN TRAY OR ROTISSERIE. “

9.2. USING THE OVEN

a) The pan has to be inserted in the oven so that the

perforated (front) edge is at the front

Front edge

10

Pan

Back edge

Page 11

b) The pan has 3 optional levels.

Notice:

When grilling using the rotisserie the pan has to be in the position „1“..

c) The grill shelf can be turned, thus allowing 2 levels

9.3. Handling of the grill (only for appliances with grill).

a) The heat protecting sheet must be pulled out as far as possible during grilling.

b) To ignite the grill burner the oven door must be completely open.

c) When operating the grill the oven door has to be half-open.

Sheet protecting against heat

Position of the door during grilling

11

Page 12

ATTENTION: When operating the grill the appliance reaches high temperatures.

Keep children away.

9.3.1. USING THE ROTISSERIE (only for appliances with grill).

a) Place the pan with the assembled left-hand holder of the rotisserie in the oven.

Insert the rotisserie ino the the grill motor shaft hole. Insert the left side of the

rotisserie into the rack holder. Switch on the rotisserie motor by means of the

switch for this purpose.

Left-hand holder of the

grill rack

b) When grilling using the rotisserie the pan has to be in the position „1“ (see 9.2.a).

10. FAILURES OF THE APPLIANCE

In the event of failure of the appliance please contact the dealer you purchassed the

appliance from or the distributor.

11. CLEANING INSTRUCTIONS

The appliance needs little maintenance other than cleaning. To clean the appliance use

only warm soapy water and recommended household cleaning agents. Do not use

abrasive cleaners, steel wool or cleansing powders.

Insert into the grill motor shaft

CRAMER SR s. r. o.

● Tehelná 8 ● SK – 986 01 Fiľakovo ● Telephone: +421-47-4319100 ●

● Fax: +421-47-4319133, 4319166 ●

● E-mail: cramer@cramer.sk ●

● Internet: www.cramer.sk ●

07/2004

12

Loading...

Loading...