Page 1

OPERATOR’S MANUAL

WORKBENCH

MAINTENANCE

• Periodically the surfaces should be cleaned with a mild

detergent and water.

• Grease and oil can be removed with most standard cleaning

uids. For safety, use a nonammable cleaning uid.

• Auto wax will preserve the unit’s luster nish. Apply the wax

as to a car. The wax will also help protect the unit against

scratches.

SAFETY

DANGER is used to indicate a hazardous situation which,

if not avoided, will result in serious injury or death.

WARNING indicates a hazardous situation which,

if not avoided, could result in serious injury or death.

CAUTION is used to indicate a hazardous situation which, if not

avoided, may result in minor injury, moderate injury, or property

damage.

CAUTION: Read and follow all Safety Rules and Operating

Instructions before rst use of this product.

DANGER

• DO NOT stand on this product. You may fall or cause product

to tip.

• DO NOT mount this product on a truck bed or any other moving

object. This may cause personal injury or product damage.

• Appropriately secure this product before moving with a forklift.

• DO NOT tow with power equipment. The product could tip,

which may cause personal injury or product damage.

* Product you purchased may vary from picture shown

SERVICE PARTS

CALL 1-800-469-4663 FOR SERVICE PARTS. Refer to Service

Parts Drawing for full listing of Service Parts.

LOCATING MODEL # INFORMATION

Model numbers and other information required for service parts is

located on a label on the interior right side of the frame weldment.

CAPACITIES

• The maximum combined weight limit should not exceed

3,000 lbs.

WARNING

• Use appropriate safety equipment when using power

and hand tools. Failure to do so may cause personal

injury or product damage.

• Use adequate manpower when assembling and moving

this unit. Failure to do so may cause personal injury or

product damage.

• DO NOT alter this product in any manner. This may cause per-

sonal injury or product damage.

• Unit must be located on a level surface. The product may become unstable and tip if stored or moved on an un-level surface,

which may cause personal injury or product damage.

Distributed by Sears Brands Management Corporation, Hoffman Estates, IL 60179

F1984

Page 2

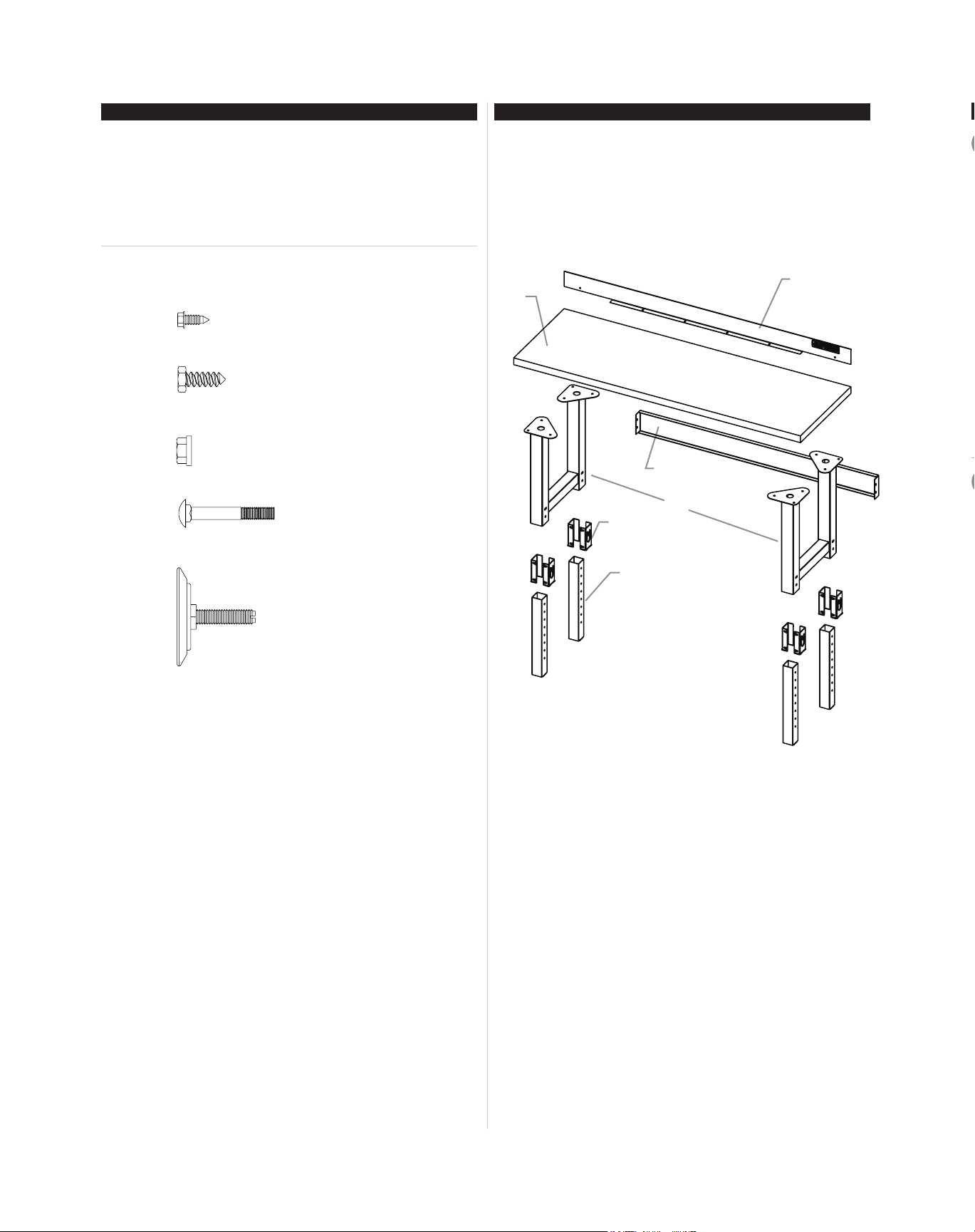

HARDWARE CARTON CONTENTS

#14-10 x 5/8" Hex Screw

(Qty:4)

5/16-18 x 2-1/4" Carriage Bolt

(Qty:4)

5/16-18 Flange Nut

(Qty:4)

3/8-7 x 1" Hex Screw

(Qty:12)

Screw Leveler (Qty:4)

TOOLS REQUIRED:

Socket Wrench

5/8" Socket or 5/8" Wrench

5/16" Socket or 5/16" Wrench

HARDWARE INCLUDED:

#14-10 x 5/8" Hex Screw

(Qty: 6)

3/8-7 x 1" Hex Screw (Qty: 12)

5/16-18 Flange Nut (Qty: 8)

5/16-18 x 3-1/2" Carriage

Bolt (Qty: 8)

A. Back Stop

B. Workbench Top

C. Frame Weldment (2)

D. Leg Weldment (4)

E. Rail

F. Leg Spacer (8)

A

B

E

C

F (8)

D (4)

Screw Leveler (Qty: 4)

2

Page 3

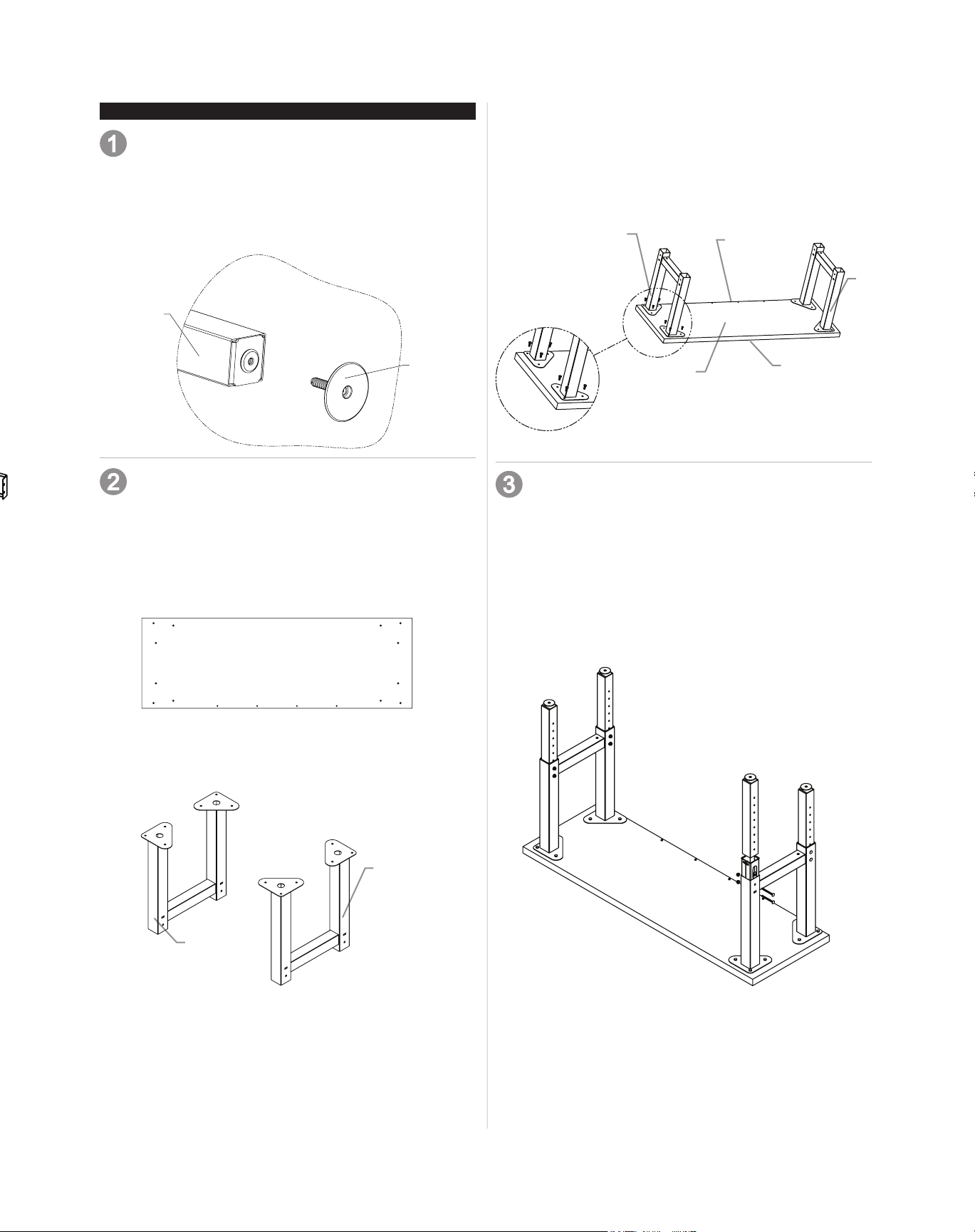

ASSEMBLY

Items Needed:

Leg Weldment (Qty: 4)

Screw Leveler (Qty: 4)

Process:

• Assemble (2) Screw Levelers in each Leg Weldment.

Some adjustments may be necessary after workbench is

in desired position.

Leg

Weldment

Process:

• Assemble Frame Weldment as shown to the bottom of

the Workbench Top following the illustration below and

aligning the pre-drilled holes using (12) 3/8-7 x 1" Hex

screws.

• Tighten screws so frames do not fall, but are still

adjustable.

C

Workbench

Back

C

Leveler

Items Needed:

Frame Weldment (Qty: 2)

Process:

• Place Workbench Top, with top side down. (Use

packaging material to prevent scratches.)

Underside of Workbench Top

Back of Workbench

B

Workbench

Front

Items Needed:

Leg Spacer (Qty: 8)

Leg Weldment (Qty: 4)

5/16-18 x 3-1/2” Carriage Bolt (Qty :4)

5/16-18 Flange Nut (Qty:4)

Process:

• Assemble Leg Spacers (2) into each Frame Weldment by

sliding into frame until spacer snaps into rectangular hole

in Frame Weldment. Repeat 3 times.

• Slide Leg Weldment into Leg Spacers to desired height.

Repeat 3 times. Ensure all legs are at the same position.

Frame

Weldment

Square Holes on Back

Leg

Frame

Weldment

• Attach front Leg Weldments using (2) 5/16-18 x 3-1/2”

carriage bolt and (2) 5/16-18 ange nuts.

NOTE: Do not assemble carriage bolts to back Leg

Weldment. See Step 4.

3

Page 4

Items Needed:

Rail (Qty:1)

5/16-18 x 3-1/2" Carriage Bolt (Qty :4)

5/16-18 Flange Nut (Qty:4)

Process:

• Attach Rail as shown using (4) 5/16-18 x 3-1/2" carriage

bolts and (4) 5/16-18 Flange nuts. Flanges of rail should

face towards the front of the workbench. Adjust back Leg

Weldment to desired height before attaching bolts.

OPERATION

Leveling Foot Adjustment

• Adjust leveling foot to desired position with a 5/8" open

end wrench as shown.

Items Needed:

Back Stop (Qty: 1)

#14-10 x 5/8" Hex Screw (Qty: 6)

Process:

• Place the workbench in its upright position.

• Attach Back Stop to back of workbench top using (6)

#14-10 x 5/8" Hex screws by aligning the holes in the

backstop with the pre-drilled holes in the bottom of the

workbench top.

NOTE: On some units two of the holes required are not

pre-drilled. You will need to predrill the holes prior to

attaching the screws. Using the back stop as a guide, use

a 7/32" DIA drill and drill a 1" deep hole at each end of the

back splash.

• Wrench tighten all screws securely. Do not over tighten.

Some units may need

to have these holes

added

4

Page 5

Product questions or problems?

1-888-331-4569

Customer Care Hot Line

Get answers to questions, troubleshoot problems,

order parts, or schedule repair service.

Para respuestas a preguntas o problemas, y ordenar piezas o pedir

servicio para la reparación de su equipo.

To help us help you, register your product at www.craftsman.com/registration

Para poderte ayudar mejor, registra tu producto en www.craftsman.com/registration

Join the Craftsman Club today!

www.craftsman.com/signup

Receive exclusive member benets including special pricing and offers, project sharing, expert

advice, and SHOP YOUR WAY REWARDS!

Como miembro exclusivo, recibe diversos benecios como ofertas, precios especiales,

proyectos nuevos, consejos de expertos y nuestro programa de puntos SHOP YOUR

WAY REWARDS!

® Registered Trademark / TM Trademark of KCD IP, LLC in the United States, or Sears Brands, LLC in other countries

® Marca Registrada / TM Marca de Fábrica de KCD IP, LLC en Estados Unidos, o Sears Brands, LLC in otros países

Page 6

MANUAL DE USUARIO

BANCO DE TRABAJO

MANTENIMIENTO

• Las supercies deben limpiarse periódicamente con un detergente

suave y agua.

• La grasa y el aceite pueden retirarse con la mayoría de los líquidos

estándar para limpieza. Por razones de seguridad, utilice un líquido

incombustible para limpieza.

• La cera para automóviles preservará el acabado brilloso de la unidad.

Aplique la cera como lo haría al carro. La cera también ayudará a proteger la unidad contra raspones.

SEGURIDAD

PELIGRO se utiliza para indicar una situación

peligrosa que, de no evitarse, resultará en lesiones graves o la muerte.

ADVERTENCIA indica una situación peligrosa que, de no

evitarse, podría producir lesiones graves o la muerte.

PRECAUCIÓN se utiliza para indicar una situación peligrosa que, de

no evitarse, puede derivar en lesiones leves o moderadas, o en daño a la

propiedad.

ATENCIÓN: Lea y siga todas las Normas de Seguridad y las

Instrucciones de Funcionamiento antes de utilizar por primera vez este

producto.

* El producto que compraste puede variar de la imagen que se muestra

PIEZAS DE SERVICIO

EN ESTADOS UNIDOS LLAME AL 1-800-659-7084 PARA

PIEZAS DE REPUESTO. FUERA DE ESTADOS UNIDOS

LLAME A SU DISTRIBUIDOR LOCAL. Suministre el número de

modelo al comunicarse.

UBICACIÓN DE INFORMACIÓN DEL NO. DE MODELO

Los números de modelo y otra información requerida para obtener piezas de repuesto están ubicados en una etiqueta en la

parte interior derecha del ensamblaje del armazón.

CAPACIDAD

PELIGRO

• NO se ponga de pie sobre esta unidad. Puede caerse u ocasionar que

el producto se vuelque.

• NO montes este producto en la cama de un camión o sobre cualquier

otro objeto en movimiento. Esto puede causar lesiones físicas o daños

al producto.

• NO monte este producto en una cama de carro o ninguÌn otro objeto

móvil.

• NO mueva la unidad antes de cerrar y asegurar todas las gavetas. Las

gavetas podrían abrirse y hacer que la unidad se vuelva inestable y se

vuelque.

ADVERTENCIA

• USA EQUIPOS DE SEGURIDAD ADECUADOS

al trabajar con herramientas eléctricas y manuales. No hacerlo puede

causar lesiones físicas o daños al producto.

• BUSCA LA AYUDA NECESARIA al ensamblar y

trasladar esta unidad. No hacerlo puede causar lesiones

físicas o daños al producto.

• UTILICE LOS FRENOS cuando el producto no esté en

movimiento. Esto impedirá que se deslice.

• NO altere la unidad en modo alguno. Por ejemplo, no suelde las

barras de sujeción externas ni le incorpore equipos eléctricos.

• El peso máximo combinado no debe exceder los 1362 kg.

Distribuido cerca Sears Brands Management Corporation, Hoffman Estates, IL 60179

F1984

Page 7

FERRETERÍA CONTENIDO DE LA CAJA DE CARTÓN

#14-10 x 5/8" Hex Screw

(Qty:4)

5/16-18 x 2-1/4" Carriage Bolt

(Qty:4)

5/16-18 Flange Nut

(Qty:4)

3/8-7 x 1" Hex Screw

(Qty:12)

Screw Leveler (Qty:4)

HERRAMIENTAS NECESARIAS:

Llave de dado

Dado de 5/8" o llave de 5/8"

Dado de 5/16" o llave de 5/16"

PIEZAS INCLUIDAS:

Tornillo hexagonal

núm. 14-10 x 5/8" (Cant.: 6)

Tornillo hexagonal 3/8-7 x 1"

(Cant.: 12)

Tuerca de brida 5/16-18

(Cant.: 8)

Perno de carro 5/16-18 x 3-1/2"

(Cant.: 8)

A. Tope posterior

B. Supercie del banco de trabajo

C. Ensamblaje del armazón (2)

D. Ensamblaje de las patas (4)

E. Riel

F. Espaciador de las patas (8)

A

B

E

C

F (8)

D (4)

Nivelador de tornillo (Cant.: 4)

2

Page 8

Artículos Necesarios:

Ensamblaje de las patas (Cantidad 4)

Nivelador de tornillo (Cant.: 4)

Proceso:

• Ensambla 2 niveladores de tornillo en cada ensamblaje

Ensamblaje

de las patas

ENSAMBLAJE

de las patas. Pueden ser necesarios algunos ajustes

después de que el trabajo esté en la posición deseada.

Proceso:

• Ensambla el ensamblaje del armazón en la parte inferior

de la supercie del banco de trabajo, como se muestra,

siguiendo la ilustración a continuación y alineando

los oricios pretaladrados usando los 12 tornillos

hexagonales de 3/8-7 x 1".

• Aprieta los tornillos de manera que los armazones no se

caigan, pero que puedan ajustarse.

C

Parte posterior

del banco de

trabajo

C

Nivelador

Artículos Necesarios:

Ensamblaje del armazón (Cant: 2)

Proceso:

• Coloca la supercie del banco de trabajo con el lado

superior hacia abajo. (Usa el material de empaque para

evitar rayones).

Parte inferior de la supercie del

banco de trabajo

Parte posterior del banco de trabajo

B

Parte frontal

del banco de

trabajo

Artículos necesarios:

Espaciador de las patas (Cant.: 8)

Ensamblaje de las patas (Cant.: 4)

Perno de carro de 5/16-18 x 3-1/2” (Cant.: 4)

Tuerca de brida 5/16-18 (Cant.:4)

Proceso:

• Ensambla los espaciadores de las patas (2) en cada

ensamblaje del armazón deslizándolos en el armazón hasta

que los espaciadores encajen en el oricio rectangular del

ensamblaje del armazón. Repite 3 veces.

• Desliza el ensamblaje de las patas en los espaciadores de las

patas a la altura deseada. Repite 3 veces. Asegúrate de que

todas las patas estén en la misma posición.

Ensamblaje

del armazón

Oricios cuadrados en

la pata trasera

Ensamblaje

del armazón

• Instala el ensamblaje de las patas usando 2 pernos de

carro de 5/16-18 x 3-1/2” y 2 tuercas de brida de 5/16-18

NOTA: No ensambles los pernos de carro en el

ensamblaje de las patas posterior. Consulta el paso 4.

3

Page 9

Artículos Necesarios:

Riel (Cant.: 1)

Perno de carro de 5/16-18 x 2-1/4" (Cant.: 4)

Tuerca de brida 5/16-18 (Cant.:4)

Proceso:

• Instala el riel como se muestra, usando 4 pernos de

carro de 5/16-18 x 2-1/4" y 4 tuercas de brida de 5/16-

18. Las bridas del riel deben apuntar hacia la parte

frontal del banco de trabajo. Ajusta el ensamblaje de las

patas posterior a la altura deseada antes de instalar los

pernos.

Artículos Necesarios:

Tope posterior (Cant.: 1)

Tornillo hexagonal núm. 14-10 x 5/8" (Cant.: 6)

Proceso:

• Coloca el banco de trabajo en posición vertical.

• Instala el tope posterior en la parte posterior del banco

de trabajo usando 6 tornillos hexagonales núm. 14-10

x 5/8", alineando los oricios del tope posterior con los

oricios pretaladrados de la parte inferior de la supercie

del banco de trabajo.

NOTA: En algunas unidades dos de los oricios

requeridos no están pretaladrados. Tendrá que pretaladrar

los agujeros antes de jar los tornillos. Usando el tope

posterior como una guía, utilice un taladro DIA de 7/32" y

taladre un agujero de 1" de profundidad en cada uno de

los extremos de la parte posterior.

• Aprieta con llave todos los tornillos hasta que estén

seguros. No sobreapriete.

Algunas unidades

pueden necesitar que

añadan se estos

agujeros

FUNCIONAMIENTO

Ajuste de la Pata Niveladora

• Ajusta la pata niveladora a la posición deseada con

una llave de extremo abierto de 5/8" como se muestra.

4

Page 10

Product questions or problems?

1-888-331-4569

Customer Care Hot Line

Get answers to questions, troubleshoot problems,

order parts, or schedule repair service.

Para respuestas a preguntas o problemas, y ordenar piezas o pedir

servicio para la reparación de su equipo.

To help us help you, register your product at www.craftsman.com/registration

Para poderte ayudar mejor, registra tu producto en www.craftsman.com/registration

Join the Craftsman Club today!

www.craftsman.com/signup

Receive exclusive member benets including special pricing and offers, project sharing, expert

advice, and SHOP YOUR WAY REWARDS!

Como miembro exclusivo, recibe diversos benecios como ofertas, precios especiales,

proyectos nuevos, consejos de expertos y nuestro programa de puntos SHOP YOUR

WAY REWARDS!

® Registered Trademark / TM Trademark of KCD IP, LLC in the United States, or Sears Brands, LLC in other countries

® Marca Registrada / TM Marca de Fábrica de KCD IP, LLC en Estados Unidos, o Sears Brands, LLC in otros países

Loading...

Loading...