Page 1

r o u t i n g t e c h n o l o g y

R

trend

ROUTER TABLE

for the Craftsman

Instruction

Manual

Model Numbers:

CRT/A

CRT/B

CRT/C

CRT/D

CRT/E

CRT/X

Trend Machinery & Cutting Tools Ltd.

Penfold Works Imperial Way Watford

Hertfordshire WD2 4YF England

Sales: _________________ 01923 249911

Technical Enquiries:____ 01923 224681

Fax: ___________________ 01923 236879

Email: _______ mailserver@trend.co.uk

WWW: ____ http://www.trendm.co.uk

Page 2

Router Table for the Craftsman

Routing Products from the UK Leader

Dear Customer

Thank you for purchasing the Trend Router Table for the Craftsman. We hope you

enjoy many years of creative and productive use of this product.

Trend welcomes comments on this and all our products in our aim to develop and

improve what we do to meet the needs of you, the customer.

Please contact our Technical Department in the first instance if you have any

comments or queries.

Trend is the UK's leading supplier of router cutters, equipment and accessories.

Our Craft Range of Cutters referred to in this manual, is designed specifically to meet

the needs of amateur craftsmen and woodworking enthusiasts in quality and value.

MANU/RTv5

For the professional woodworker, the Trend Professional Range of Routing Products

has become the industry's standard guide to the most comprehensive range of router

cutters and related products available in the UK.

Please contact your nearest Trend stockist to obtain any of our products and for a

copy of the latest Trend Routing Catalogue.

-1-

Page 3

Router Table for the Craftsman

CONTENTS ________________________ Page

Contents, Introduction, Tools Required _______ 1

Safety Precautions, Specs, Cutter Care, Advice 3

Assembly Instructions

A.

Assembly of Legs ________________________ 5

B.

Mounting Table to Workbench or Workboard___ 5

C.

Mounting Table to a Workmate _____________ 5

D.

Identification of Mounting Holes and Screws ___ 8

E.

Re-Drilling of Router Base _________________ 8

F.

Re-Drilling of Insert Plate __________________ 9

G.

Re-Drilling of Insert Plate and Router base ____ 9

H.

Fitting Insert Plate to Table Surface _________ 10

I.

Fitting Router to Insert Plate_______________ 10

J.

Selecting & Fitting Insert Plate Rings ________ 11

K.

Fitting Lead-on Pin ______________________ 11

L.

Assembly & Mounting of Tenon Push Block __ 13

M.

Assembly of Safety Dust Guard to Back Fence 13

N.

Assembly of Back Fence _________________ 15

P.

Attachment of Back Fence to Table _________ 15

Q.

Assembly & Alignment of Mitre Fence _______ 17

R.

Fitting of No-Volt Release Switch___________ 17

Optional Accessories

S.

Dust Extraction Equipment________________ 18

T.

Assembly of Spring Pressure Clamp ________ 19

U.

Assembly of Profiling Top Guard ___________ 20

Operation

V.

Edging & Profiling using the Back Fence _____ 21

W.

Using Router Table for Grooving ___________ 22

X.

Using Mitre Fence ______________________ 22

Y.

Using the Profiling Top Guard _____________ 24

Z.

End Cutting with the Tenon Push Block ______ 26

Spare Parts Diagram ____________________ 28

INTRODUCTION

This Router Table is designed for the woodworking

Craftsman and especially those new to the art of routing.

The Router Table has the necessary features to extend

the versatility of most portable routers when profiling,

edging, rebating and jointing.

The table includes the following features:

●

A large machined aluminium Table Surface

●

A Back Fence with Workpiece Support and Dust

Extraction Point

●

A clear Retractable Safety Dust Guard

●

An adjustable sliding Mitre Fence

●

A sliding Push Block for producing tenons

●

A pre-drilled Insert Plate to fit most popular routers

●

Insert Rings to reduce the 2 1/8" (54mm) cutter

aperture

●

A Lead-on pin for safer profiling with bearing

guided cutters without a Back Fence

●

No-Volt Release Switch - 230 volts

●

Plastic Pushstick

The following Optional Extras are also available

through your Trend stockist:

●

Spring Pressure Clamps

●

Safety Profiling Top Guard

●

Extraction Hose and Adaptor

TOOLS REQUIRED FOR ASSEMBLY OF TABLE

A set of spanners and a screwdriver are required for the

initial assembly of the table. Additional screws or nuts/

bolts will be required for mounting the table to a suitable

surface.

Spanners 8mm, 10mm

and 11mm

Screwdriver with flat head

MOUNTING OF ROUTERS

Appendix

Plan for base of Hitachi TR12 _________________ 30

Plan for base of Ryobi R600, RE600 ___________ 31

Plan for base of Skil 1835U, 1875U1 ___________ 32

Plan for base of Elu MOF96(E) Mk1

and other similar makes _____________________ 33

Plan for the Elu OF97(E) gasket _______________ 34

Plan for the Bosch POF52, 400A, 500A

& 600 ACE gasket__________________________ 35

Most popular makes of router can be mounted to the

table, providing the correct model of table is purchased.

Additional modification may be required for certain

models of router and are described in sections E to

G. Additional tools may be required to make these

modifications.

Choice of router will depend on shank size of cutters that

will be used. Higher powered routers will be required for

using larger diameter cutters or for making heavier cuts.

Additional plates can be purchased if more than one type

of router is to be mounted to the table.

-2-

Page 4

Router Table for the Craftsman

SAFETY PRECAUTIONS

Always switch off the power and unplug the router when

1.

changing cutters or when making adjustments.

2.

Always wear protective goggles when routing.

3.

Wear sound protective ear muffs when routing for long

periods of time.

4.

Do not wear loose clothing. Make sure baggy sleeves are

rolled up and ties are removed.

5.

Always remove spanners and allen keys from the table

surface before switching router on .

6.

Keep hands well clear of the router cutter when routing.

7.

Avoid accidental starting of the router. Make sure the

power switch is in the 'Off' position before plugging in and

connecting to the electrical supply. Fit the no-volt release

switch for ultimate safety.

8.

Never leave the router unattended when running. Always

wait until the router comes to a complete stop before

making any adjustments.

9.

Do not switch the router on with the cutter touching the

workpiece.

10.

Make a push stick and use it to move narrow workpieces

across the cutting area.

11.

Mount the Router Table securely to a work bench or to a

workboard fitted to a suitable surface.

CUTTER CARE

Do not drop cutters or knock them against hard objects.

1.

2.

Cutters should be kept clean. Resin build-up should be

removed at regular intervals with a wire brush. The use of

a dry lubricant will act as a preventative eg Trendicote

spray. Take care not to allow excessive quantities of

lubricant to come into contact with the Router Table.

3.

Cutter shanks should be inserted into the collet at least 3/4

of shank length to prevent distortion. A distorted collet

should be discarded, as it can cause vibration and damage

the shank.

4.

Do not overtighten collet as this will score the shank and

create a weakness there.

5.

It is also advisable to periodically check the router collet

nut for wear.

USEFUL ADVICE

Judge your feed rate by the sound of the motor.

1.

In time, the operator will acquire a ‘feel’ for the router, and

a feed speed relative to the work will come naturally.

Too slow a feed will result in burning.

2.

Do not take too deep a cut in one pass. Take light cuts

with many passes to maintain cutter speed and improve

finish.

12.

Check the function of the retractable safety guard before

each use, to ensure it rides easily over the workpiece.

13.

Always use the back fence to guide the work. Do not work

freehand unless using bearing guided or pin guided

cutters.

14.

Always feed the workpiece against the rotation of the cutter

15.

Periodically check all nuts and bolts to make sure they are

tight and secure.

16.

Use dust extraction equipment.

SPECIFICATIONS:

Table surface 359mm (14") x 610mm (24")

Table height 349mm (13

1

/2")

Aperture opening 54mm (2 1/8")

Back Fence opening 73mm (2 7/8")

Height of Back Fence 100mm (4")

3.

Apply the normal precautions as with any electric power

tool.

4.

The main abuse of routing machines is the inclination for

operators to overload them. The motto is 'Keep the revs

up'. The drop in revolutions should not exceed, if possible,

more than 20% of full running speed.

5.

The motor of a router is susceptible to the accumulation of

sawdust and wood chips, and should be blown out, or

‘vacuumed’ , frequently to prevent interference with normal

motor ventilation.

6.

Do not store the Router Table with router fitted on the

floor, as chips, panel pins or dirt could drop into the air

intake of the router.

7.

Refer to the Instruction Manual supplied with your router

for full details of it's features and safety information.

8.

The use of a fine height adjuster is highly recommended

(if available for your router) for accurately adjusting the

height of the cutter.

9.

Do not use strong detergents or organic solvents to clean

the Router Table or any of its components.

-3-

Page 5

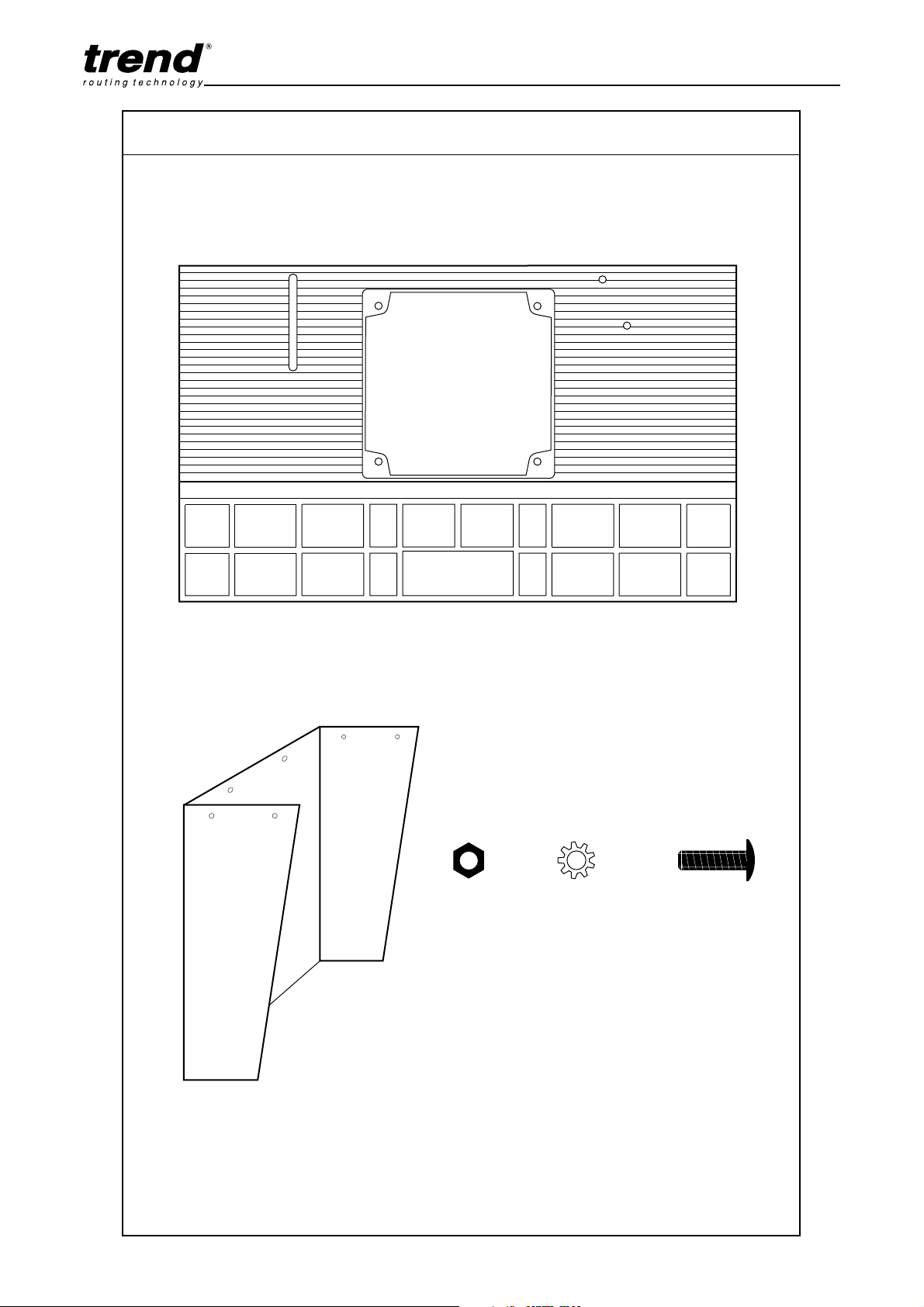

Table Components

Router Table for the Craftsman

Table Leg

x 2

Nuts

x 12

Star

Washers

x 12

Table Surface

x 1

Dome Headed

Screws

x 12

-4-

Page 6

Router Table for the Craftsman

L

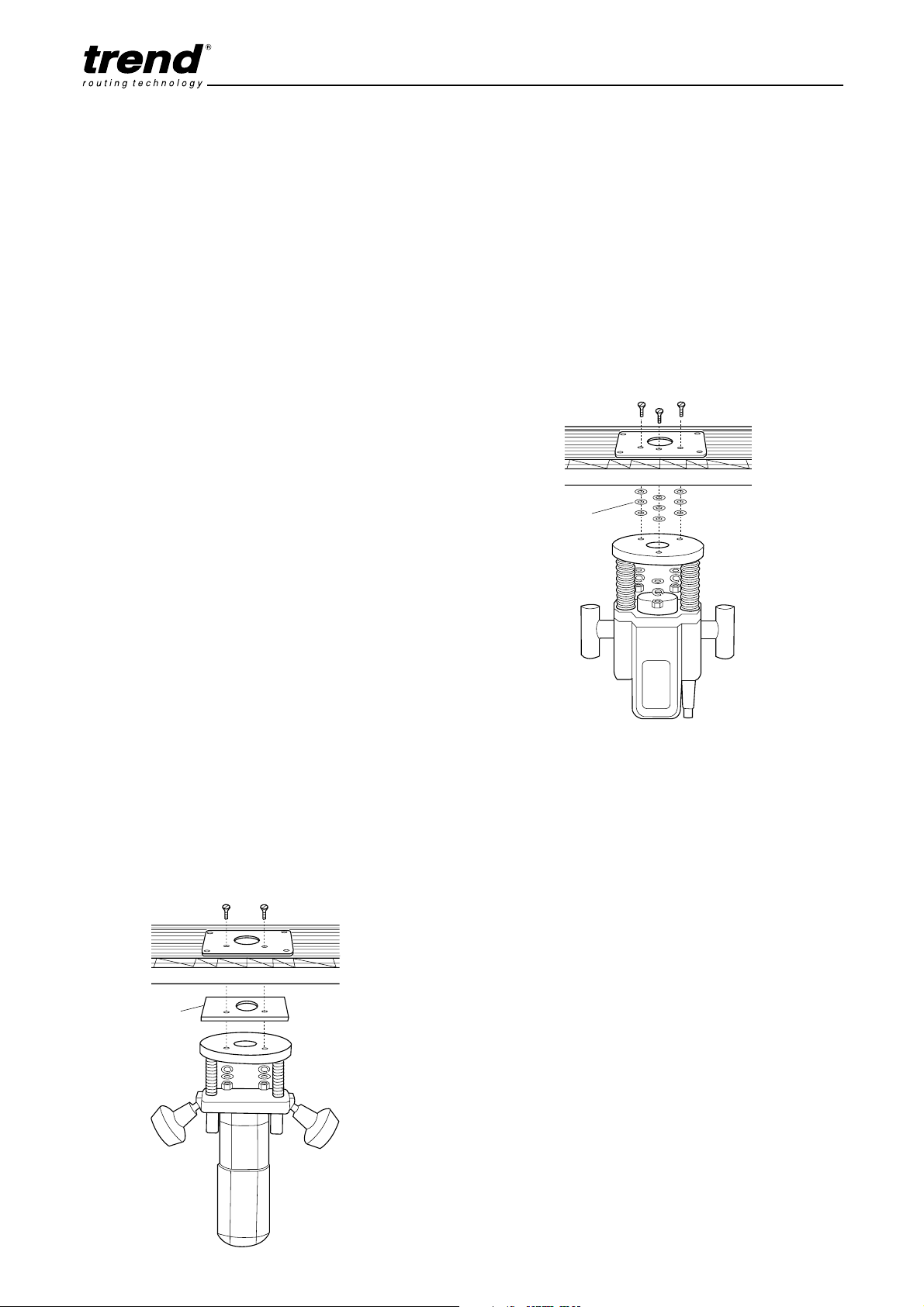

ASSEMBLY INSTRUCTIONS

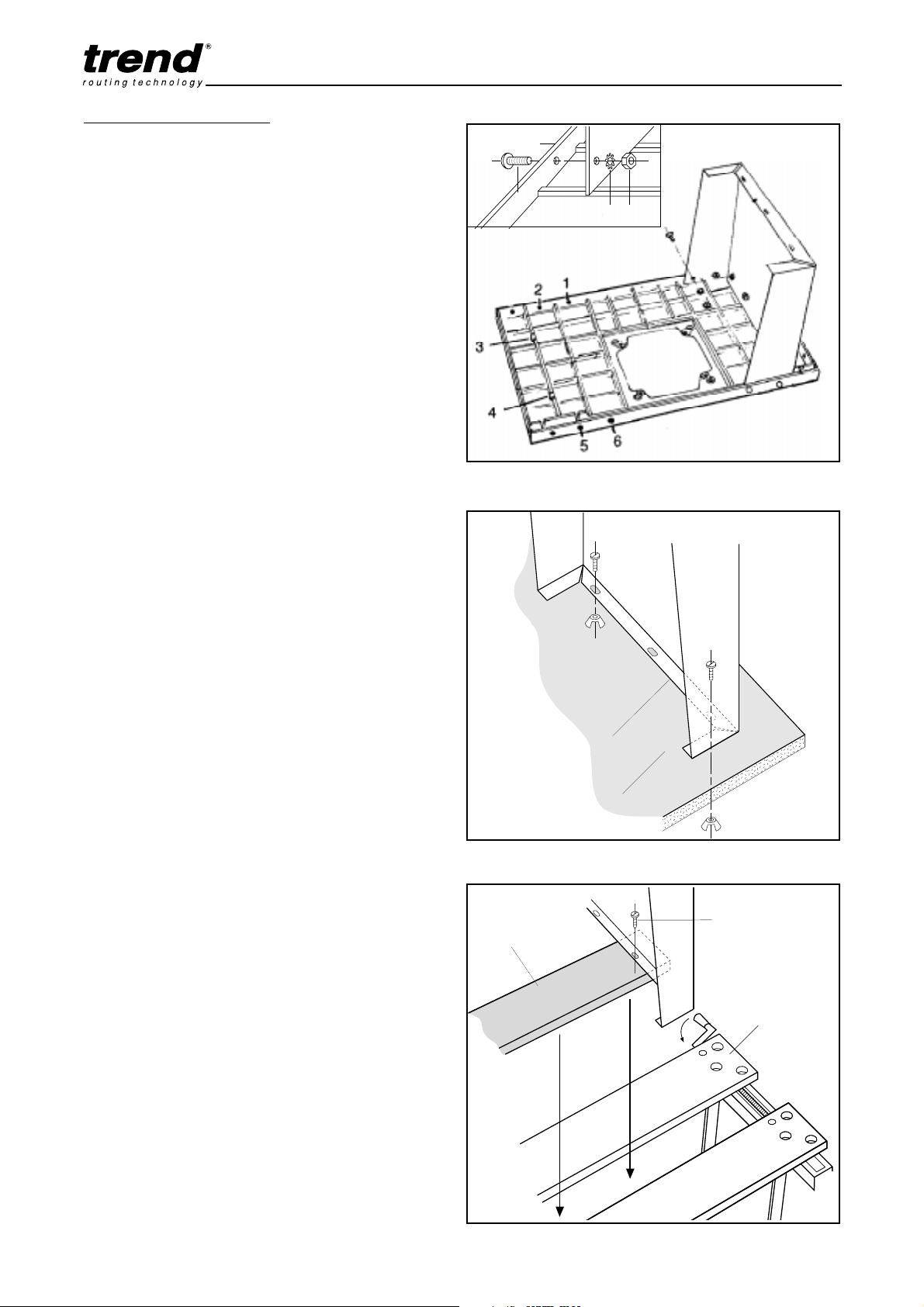

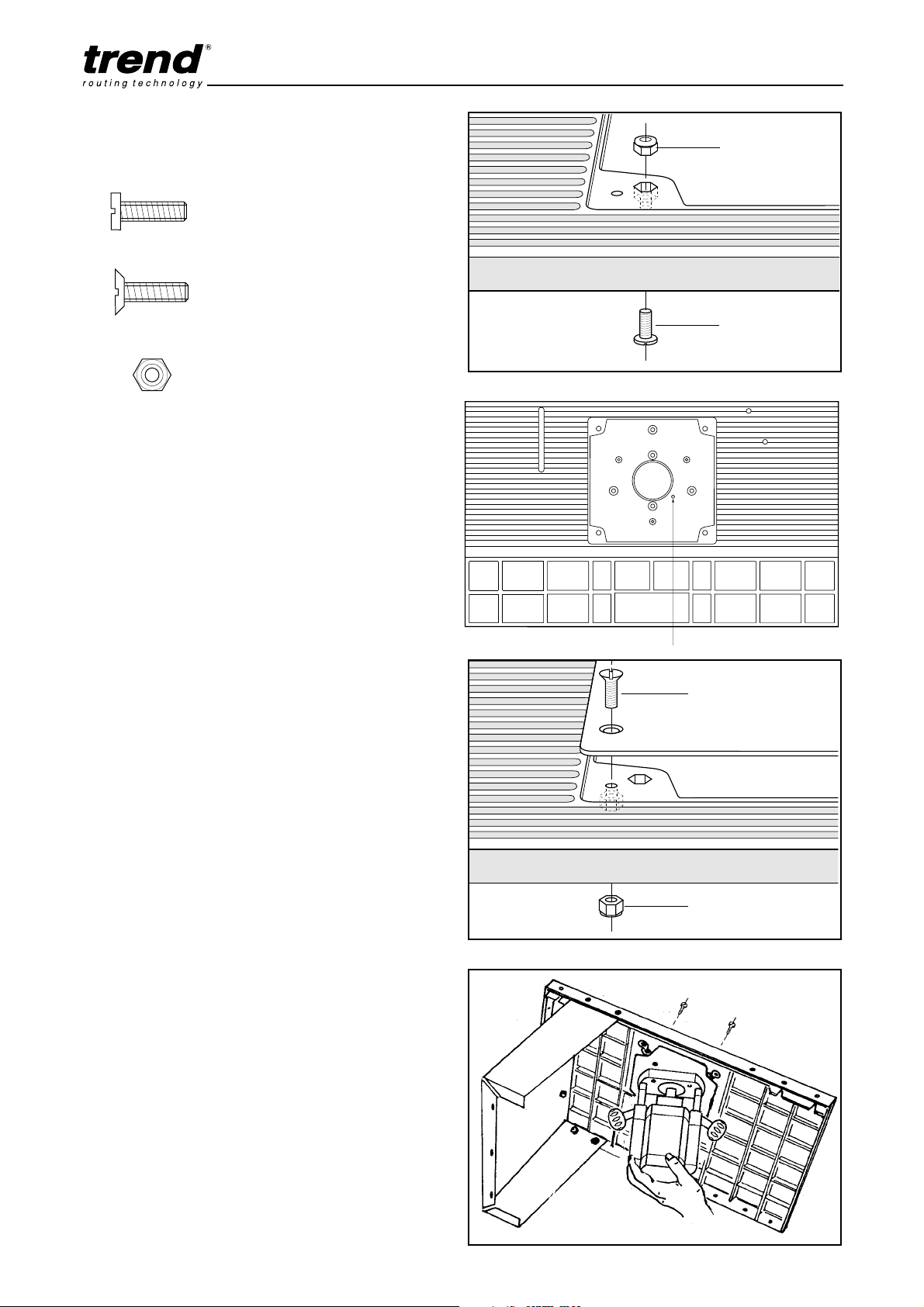

A.

Assembly of Legs

Identify the components required, see opposite

1.

2.

Turn the Table Surface face down.

3.

Locate one of the Table Legs at one end of the

Table Surface as shown in figure A.

4.

Insert the Dome Headed Screws through the six

holes in the Table Surface and Table Leg. Six

screws are required for each of the two Table Legs.

5.

Lightly tighten the Nuts and Star Washers on to

each Dome Headed Screw. The Star Washers

should be against the inside of the Table Leg.

6.

Repeat for the second Table Leg.

7.

Turn the table assembly the correct way and tighten

all 12 Nuts with a 10mm spanner (not provided).

Fig. A

Table

screw

eg

Star

washer

Nut

B.

Mounting Table to Workbench or Workboard

The Router Table must always be mounted onto a

suitable workbench or workboard for stability.

Each Table Leg has three slotted holes at the bottom

mounting. Firmly secure the table assembly to a workbench or workboard, using appropriate bolts and wing

nuts (not provided) as shown in fig. B. The slots are 6mm

wide x 16mm long and will accommodate bolt sizes up to

M6.

If a workboard is used, this will allow quick mounting and

removal from a workbench by using G clamps.

C.

Mounting Table to a Workmate

The Router Table can also be fiited by using No. 12 selftapping screws (not provided) through the centre holes in

the legs to a 125mm (5") batten, which will enable the

Router Table to be quickly mounted and removed from a

Black & Decker Workmate® or similar workmate by

simple clamping the batten between the jaws. See

fig. C.

Fig. B

(125mm) 5"

wide Batten

Table leg

Workboard or

Workbench

Self tapping

screw

Workmate®

Fig. C

-5-

Page 7

Router Table for the Craftsman

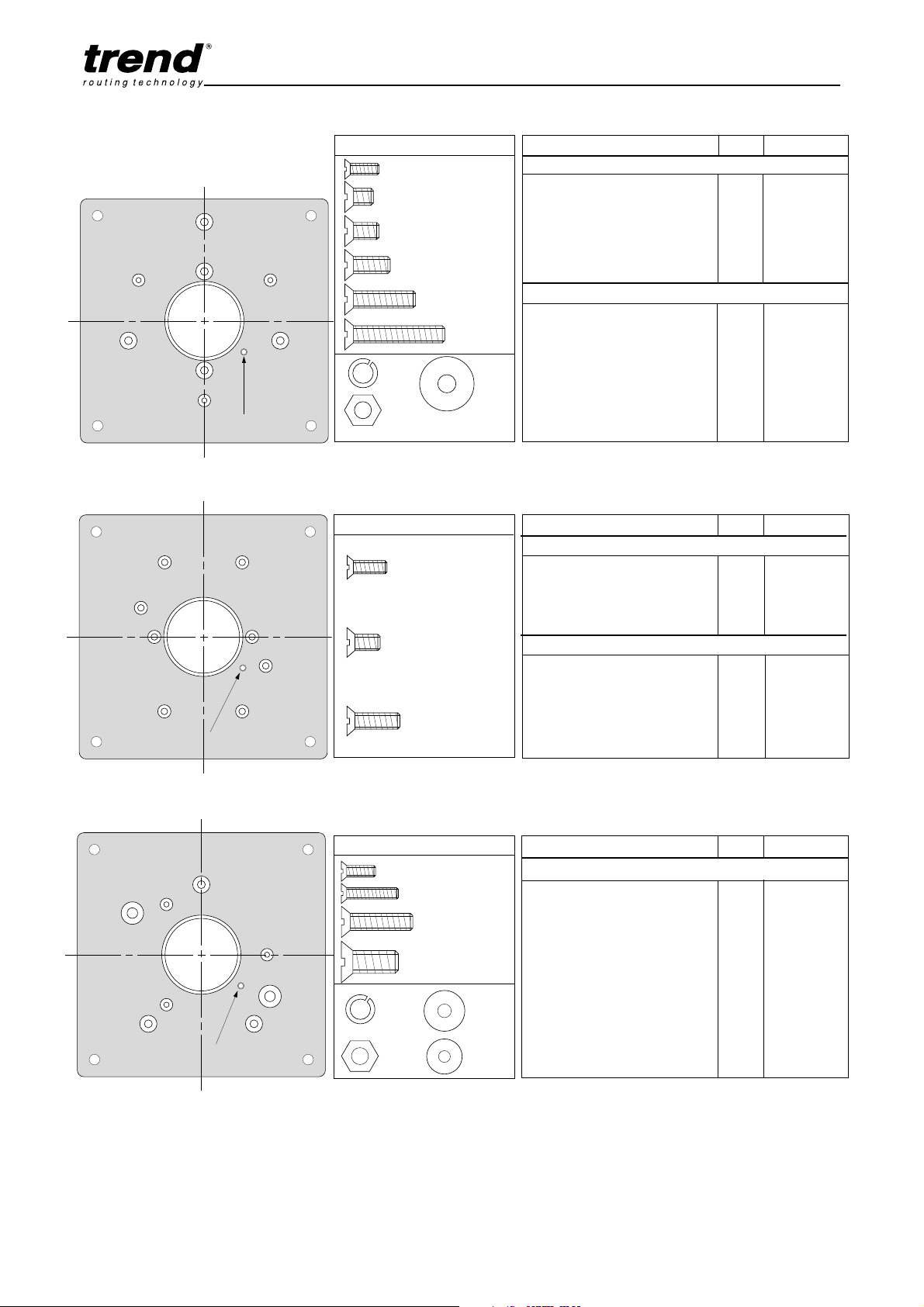

CRT/PLATE A (inc. Fixing Pack) supplied with Router Table CRT/A

Fixing Pack Router Models Holes Fixings

M4 x 12mm (3)

(3)

(3)

M6 x 10mm (2)

M6 x 12mm (3)

M6 x 25mm (3)

M6 x 16mm (3)

M6 x 35mm

3/4"

x1/4"

Washer

(3)

A2

B

CC

A1A1

B

Spring

washer

C

Threaded hole

for Lead-On pin

M6 nut

CRT/PLATE B (inc. Fixing Pack) supplied with Router Table CRT/B

Following models will fit insert plate

Elu MOF 69, 96(E) Mk 2 A1 M6 x 10

Elu OF97(E)

Elu MOF 131, 177(E) A1, A2 M6 x 12

Bosch POF 52,400,500A,600ACE

●

A1 M6 x 16

●

B M6 x 12

Bosch GOF 1600A, 1700ACE A1, A2 M6 x 12

Black & Decker

BD780(E), KW780(E)

C M4 x 12

Dewalt DW613 A1 M6 x 10

Require re-drilling of router base, see Section E

Elu MOF 96(E) Mk 1* B M6 x 25

Black & Decker SR100* B M6 x 25

AEG OFS450S, OFS50, OFS720 &

(3)

OFSE850* B M6 x 25

Metabo OF1028◆, OFE1229

Perles OF808, Stayer PR50* B M6 x 25

Ryobi R500◆, R502

◆

◆

A1 M6 x 35

A1 M6 x 35

Kango R8550S, Holzher 2335, 2355 B M6 x 25

Virutex FR77C, 78C B M6 x 35

*

see page 33

▲

▲

▲

▲

▲

▲

▲

▲

Fixing Pack

D

D

M4 x 12mm (4)

Router Models Holes Fixings

Following models will fit insert plate

Hitachi M8◆, M8V

Peugeot DF55E, DEF570E E M5 x 16

E

FF

M5 x 10mm (4)

E

Ryobi RE120, R150, R151 E M5 x 16

Makita 3620 F M5 x 16

Require re-drilling of insert plate, see Section F

Hitachi TR12

(see page 30)

DD

Threaded hole

for Lead-On pin

M5 x 16mm (2)

Ryobi R600◆, RE600

(see page 31) - M5 x 16

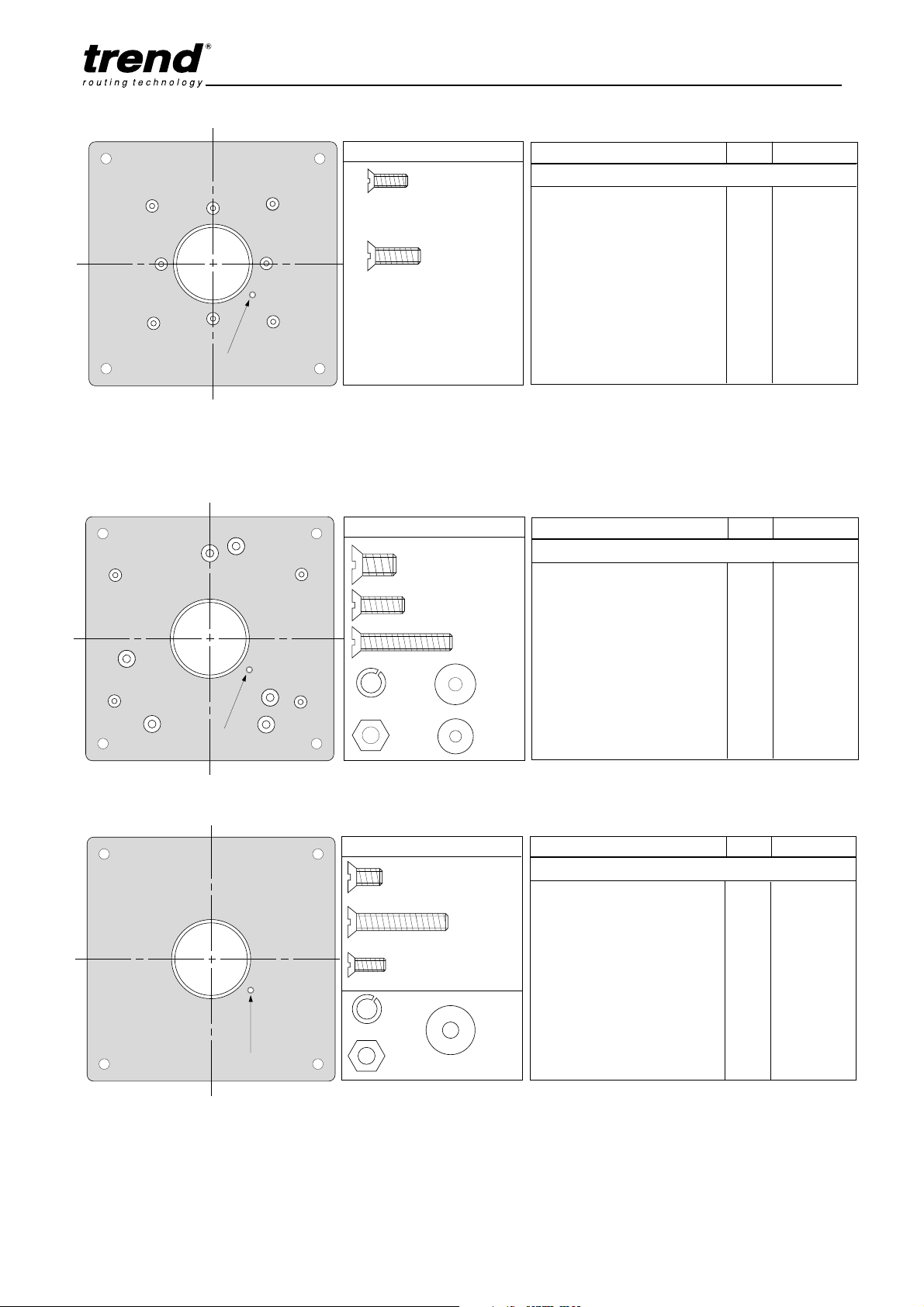

CRT/PLATE C (inc. Fixing Pack) supplied with Router Table CRT/C

Fixing Pack

H

G1

I

M4 x 12mm (2)

M4 x 20mm (1)

M6 x 25mm (3)

G2

M8 x 20mm (2)

G1

H

Threaded hole

for Lead-On pin

I

Spring

H

washer

(3)

M6

nut

(3)

3/4"x1/4"

Packing

Washer

6mm

Washer

Router Models Holes Fixings

Following models will fit insert plate

Black & Decker BD66

Bosch GOF 900A, 900ACE H M6 x 35

Ryobi RE600N◆, R600N

(9)

(3)

◆

◆

◆

◆

D M5 x 10

- M5 x 10

- M4 x 12

G1 M4 x 12

G2 M4 x 20

■

◆

I M8 x 20

◆

Remove plastic base of router before fitting router to insert plate

▲

Requires fitting of washer, spring washer and nut

●

Requires user made packing piece/gasket, please see end of

section D.4.(i) on page 8

■

Requires fitting of washer, spring washer, nut and three

3/4"x1/4" packing washers which are placed between

plate and router base for each fixing

-6-

Page 8

Router Table for the Craftsman

CRT/PLATE D (inc. Fixing Pack) supplied with Router Table CRT/D

J2,K2 J2,K2

K1

J1

Fixing Pack

M4 x 12mm (4)

M5 x 16mm (2)

J1

Router Models Holes Fixings

Following models will fit insert plate

Makita 3612BR J1 M5 x 16

Makita 3612, K1 M5 x 16

Makita 3612C K2 M4 x 12

J2,K2 J2,K2

K1

Threaded hole

for Lead-On pin

CRT/PLATE E (inc. Fixing Pack) supplied with Router Table CRT/E

L

M

N

N

L

N

M

Threaded hole

for Lead-On pin

L

N

M

Fixing Pack

Spring

washer

(3)

M6

nut

(3)

M5 x 10mm (4)

M6 x 12mm (3)

M6 x 35mm (3)

3/4"x1/4"

Packing

Washer

6mm

Washer

Router Models Holes Fixings

Following models will fit insert plate

AEG OFSE2000 L M6 x 25

Bosch GOF1300ACE M M6 x 35

Freud FT2000(E) L M6 x 12

Hitachi M12V/M12SA N M5 x 10

(9)

(3)

J2 M4 x 12

■

CRT/PLATE X (inc. Fixing Pack) supplied with Router Table CRT/X

Threaded hole

for Lead-On pin

Fixing Pack

Spring

washer

(3)

M6 nut

(3)

M6 x 12mm (3)

M6 x 35mm (3)

No.10-32UNF

x 3/8" (3)

3/4"x1/4"

Washer

Router Models Holes Fixings

Require re-drilling of insert plate, see Section F

Skil 1835, 1875UI - see p.32 - No.10 - 32

Festo OF900(E), OF2000(E) - M6 x 35

Hitachi FM8, ZK2008 - M6 x 35

(3)

◆

Remove plastic base of router before fitting router to insert plate

▲

Requires fitting of washer, spring washer and nut

●

Requires user made packing piece/gasket, please see end of

section D on page 8

■

Requires fitting of washer, spring washer, nut and three 3/4"x1/4"

packing washers which are placed between plate and router base

for each fixing

UNF x 3/8"

▲

▲

-7-

Page 9

Router Table for the Craftsman

D. Identification of Mounting Holes and Screws

See previous page to:

1. Identify which Insert Plate has been supplied with

your Router Table.

2. Identify the mounting holes and fixing screws

(including washers & nuts if applicable) which will be

required to suit your router.

3. Identify whether your router or the Insert Plate

requires re-drilling.

If at this point, you realise you have ordered the incorrect

model of Router Table for your router, an exchange of

the Insert Plate can be made direct with Trend, see

address on front cover. Ensure that the fixing pack, insert

rings and insert plate are returned. Please quote part

number of plate required in the exchange.

Additional Insert Plates can be purchased through your

nearest Trend stockist if you wish to fit other models of

router to your router table. See prevoius page for

selection, and spare parts diagram for price details.

Your Router should fall into one of the following

catagories:

base. The fixing screws can then be used to secure.

The use of a gasket serves two purposes, firstly it

allows for secure fixing of the router, and secondly,

due to the small aperture in the router it allows the

tabs of the insert rings to fit tightly to the plate.

Enlarging the aperture in the base of the router is also

advised if large diameter tooling is to be used.

(iii) For Bosch GOF900A and 1300ACE, three 3/4"x1/4"

packing washers are used on each screw to pack out

the base of the router from the underside of the insert

plate. These packing washers allow the tabs of the

inset rings to fit tightly in the plate.

3/4" & 1/4"

packing

washers

(i) No adjustment necessary - Proceed to section H.

Please note for Elu OF97(E) see section (i) below.

For Bosch POF 52, 400A, 500A and 600ACE see

section D4 (ii) and for Bosch GOF900A and 1300ACE

see section D4 (iii).

(ii) Router base requires re-drilling - Proceed to section E

(iii) Insert Plate requires re-drilling - Proceed to section F

4.(i)For the Elu OF97(E) a 6.35mm (1/4") thick MDF or

plywood gasket is required. The central hole should

be drilled out to 60mm in diameter and with two

Bosch GOF900A & 1300ACE

further holes of 8mm diameter and at 115mm centres.

Please see page 34 for plan.

(ii) For the Bosch POF DIY range of DIY routers a

special gasket must be made in 3mm to 6mm thick

plywood or MDF made. Please see page 35 for plan.

This gasket is then placed between the underside of

the plate in the table and the underside of the router

Packing

piece

E. Re-drilling of Router Base

1. Invert your router onto a suitable surface.

2. Place the Insert Plate facing upwards onto the base

of your router.

3. Identify holes A1 and A2, or holes B on the Insert

Plate.

4. Fit a large diameter cutter (max. 53mm diam.) into

your router and tighten collet.

5. Retract plunge mechanism and lock off allowing

cutter to protrude through the base.

Bosch POF52, 400A, 500A & 600ACE

6. Adjust position of the Insert Plate to centralise the

cutter within the centre hole of the Insert Plate.

7. Ensure that the threaded hole in the Insert Plate

faces the same side as on/off switch and fine height

adjuster (if fitted) so as these are easily accessible

when the router is fitted to the table.

8. Ensure that the holes you are about to drill in the

base do not interfere with any of the features on the

-8-

Page 10

Router Table for the Craftsman

router or any webbings in the casting of the router

base. A slight turning of the plate may be required to

miss such obstructions.

(i) The base of the following routers must be drilled

with two 6mm diameter holes:

MOF96(E) Mk1

Black & Decker SR100

AEG OFS450S, OFS50, OFS720, OFSE850

Perles OF808, Stayer PR50

Kango R8550S, Holzher 2335, 2355

Virutex FR77C, 78C

Please see page 33 for plan. Holes B on the plate

will be used.

(ii) The base of the following routers must be drilled

with two 6mm diameter holes:

Metabo OF1028, OFE1228

Ryobi R500, R502

Holes A1 on the plate will be used.

9. Mark the centre of the holes onto the base.

10. Remove plate and mark the centre of the holes with

a centre punch.

11. Drill a hole at these points with a 6mm diameter

drill bit.

12. Clean up edges of holes if required.

10. Countersink the hole with a countersink bit to a

depth so the heads of the screws are slightly below

the top surface. Clean off any burrs created.

Note

If you do not have the necessary equipment to carry out

operations 7 and 8, then a local engineering shop will be

able to carry them out accurately.

G. Re-drilling both Insert Plate and Router Base

1. Invert the router and lay the insert plate onto the

upturned base, ensuring threaded insert hole is in

the correct position.

2. Clamp the insert plate and router base together

with two cramps.

3. Ensuring that the drill bit will not foul any

webbing or fixtures on the router base, drill

with a 6mm diameter drill bit into the insert plate

and through the router base two holes approximately 75mm apart.

4. Unclamp the router base and insert plate.

5. Countersink the insert plate holes with a countersink bit to a depth so the screw heads are slightly

below the top surface. Clean off any burrs created

on both the insert plate and router base.

F. Re-drilling of Insert Plate

1. Remove or photocopy the plan from the appendix of

this manual.

2. Invert the router and lay the plan onto the base.

3. Identify the appropriate holes on the plan to fit your

model of router.

4. Line up the plan with the holes on the router and

check the accuracy of their positions.

5. Draw cross lines on the insert plate with a pencil.

These cross lines bi-secting the plate on both sides.

6. Cut around the plan of the router base so that the

cross lines drawn on the paper plan are dissected.

7. Line up the lines on the insert plate and the lines on

the paper plan, ensuring that the threaded insert

hole match. Stick the paper plan onto the insert

plate.

8. Using a centre punch, mark centres of holes.

9. Drill the required hole size with a suitable metal drill

bit . Best results will be obtained if your power drill is

mounted in a drill stand.

-9-

Page 11

Router Table for the Craftsman

H.

Fitting Insert Plate to Table Surface

1.

Identify the components required, see below.

Insert Plate

Adjustable Bolts

x 4

Insert Plate

Retaining Bolts

x 4

Nylock Nut

with

Nylon ring

facing up

Insert plate

adjustment bolt

Nylock Nuts x 8

2.

Assemble the four Insert Plate Adjustment Bolts

and the four Nylock Nuts to table as shown in fig.

G1.

After a few turns some resistance will be felt as the

screws are gripped by the Nylock Nuts. Screw just

enough to leave a few threads protruding through

the nut.

3.

Place the Insert Plate into the large opening in the

table. The position of the plate should be with the

Threaded Hole to the front right of the Table

Surface, see fig. G2.

4.

While pressing down on the Insert plate, gradually

adjust the Insert Plate Adjustable Bolts with a

screwdriver until the Insert Plate is level with the

Table Surface. A steel rule or T-square can be

placed on the top of the Insert Plate to help this

levelling process.

The Insert Plate must be be supported equally on

all four Insert Plate Adjustment Bolts. When

pressure is applied, the Insert Plate should be

stable.

Fig. G.1

Fig. G.2

Threaded hole for Lead-on Pin

Insert plate

retaining bolt

5.

Insert the four Insert Plate Retaining Bolts and fit

the four Nylock Nuts to secure the Insert Plate to

the Table Surface, and tighten securely, see fig.

G.3.

I.

Fitting Router to Insert Plate

1.

Turn the table onto its side, invert the router and

line up the Mounting Holes in the Insert Plate, as

identified in section D, with the appropriate securing

points in the base of the router.

2.

Insert the correct Router Fixing Bolts, as identified

in section D, through the Insert Plate and into

router base. Fit appropriate washers and nuts if

applicable, see fig. H.

Note

Some models of router will require removal of plastic

base prior to fitting, see Section D and pages 6 and 7.

Nylock Nut with

Nylon ring facing down

Fig. G.3

Fig. H

-10-

Page 12

Router Table for the Craftsman

J.

Selecting & Fitting Insert Plate Rings

The Insert Plate Rings are designed to support the

workpiece around the cutter to avoid small timber

sections tipping or flexing when being machined.

1.

First separate all Insert Plate Rings from each

other using a sharp knife and trim off all flashes,

see fig. J.1.

Selecting the correct size of Ring

2.

Select an Insert Plate Ring with an inside diameter

approximately 1/4" (6mm) larger than the maximum

diameter of the cutter to be used. This will give 1/8"

(3mm) gap around the cutter to allow the chips to

clear.

3.

An Insert Plate Ring is not required for cutters

having a diameter of 1 3/4" (45mm) or larger, as the

Insert Plate will provide enough support for the

workpiece.

4.

Do not use router cutters having diameters larger

than 50mm (2"). Always ensure the aperture on the

base of your router will allow the cutter to protrude

through it without touching it.

Fitting Insert Plate Rings

Fig. J.1

Trim flash

here

Insert Plate

Ring

The Insert Plate Rings are designed to be snapped into

the Insert Plate. Slide the large tab under the edge of

the Aperture Hole in the Insert Plate as shown in

fig. J.2.

5.

Using you thumb, press down on the Insert Plate

Ring until the small tab snaps into position. Ensure

the Insert Plate Ring is fully seated into the

Aperture Hole.

6.

To remove the Insert Plate Ring, release the small

tab from the edge of the Aperture Hole and pull the

Ring out.

K.

Fitting Lead-on Pin

The Lead-on Pin is a safety feature for profiling straight

or shaped workpieces with a bearing guided cutter

without using a back fence. It will prevent the cutter from

snatching the workpiece, especially when using larger

cutters or when making heavier cuts. The use of the

optional accessory Profiling Top Guard is highly

recommended to safely carry out this type of routing

operation. See section Y for more information.

Identify the Lead-On Pin, see below.

Insert plate ring

Fig. J.2

Guide pin

Lead-on Pin x 1

1.

Screw the Lead-on Pin by hand into the Threaded

Hole in the Insert Plate, see Fig. K.

2.

With a flat screwdriver tighten the pin securely.

3.

When you do not require the Lead-on Pin, keep it

in a safe place as it is easily misplaced.

Fig. K

-11-

Page 13

Router Table for the Craftsman

Tenon Push Block Components

Spring

Washer

x 1

Nut x 1

Clamp Rod x 1

Washer x 1

Clamp Plate x 1

Push Block x 1

Safety Dust Guard Components

Pivot Pin x 1

Wing Nut x 1

Push Nuts x 2

-12-

Dust Guard x 1

(not shown actual size)

Page 14

Router Table for the Craftsman

Hex

nut

Spring washer

Wing

nut

Flat

washer

Push block

Small threaded end

Long threaded end

Clamp

rod

Shoulder

Clamp

plate

Push block

Clamp

plate

Face of

back fence

L.

Assembly of Tenon Push Block

1.

Identify the components required, see opposite.

2.

Screw the smaller threaded end of the Clamp Rod

into threaded hole in Clamp Plate until the plate

bottoms on it’s shoulder (make sure clamp is

oriented such that letter 'C' is facing outwards as

shown in fig. L.1) and tightly secure Clamp Plate to

Clamp Rod with a 11mm AF spanner.

3.

Insert the longer threaded end of Clamp Rod

through hole in Push Block and fit the flat washer

and the Wing Nut onto it.

Mounting Push Block Assembly on Back Fence

1.

Mount assembled Push Block on the Back Fence

by aligning retaining rib on Push Block with the

groove in the face of Back Fence. See fig. L.2.

Fig. L.1

2.

Slide push block assembly back and forth along

entire length of Back Fence to ensure that it slides

freely. Occasional application of furniture spray wax

on the sliding surfaces of the Push Block will

improve the sliding motion.

Removing dust and chips from sliding surfaces of

Push Block and Back Fence will ensure a good

sliding motion.

M.

Assembly of Safety Dust Guard to Back Fence

1.

Identify the components required, see opposite.

2.

Position the guard on the Back Fence as shown in

fig. M.

3.

Fit one of the Push Nuts onto one end of the Pivot

Pin. (To ensure a secure fitting it will be necessary

to tap it onto the pin with a hammer).

4.

Align the holes in the Back Fence with those on the

Dust Guard.

5.

Insert the Pivot Pin through the holes.

6.

Fit the remaining Push Nut onto the other end of

the Pivot Pin. It will be necessary to support the

other end of the Pivot Pin onto the corner of a hard

surface in order to tap the Push Nut securely onto

the Pivot Pin with a hammer.

Fig. L.2

7.

Ensure the guard pivots freely.

Note

Once the guard has been installed, it is recommended

that the Push Nuts are not removed.

Fig. M

-13-

Page 15

Router Table for the Craftsman

Back Fence Components

Back Fence x 1

Workpiece Support x 1

Medium Size Knob x 1

Large Size Knob x 2

Washer x 1

Washer x 2

Workpiece Support

Adjustment Bolt x 1

Back Fence

Fixing Bolts x 2

-14-

Page 16

Router Table for the Craftsman

Knob (medium size)

Workpiece support

adjustment bolt

Workpiece

support

Slot

Aperture

Flat washer

N.

Assembly of Back Fence

1.

Identify the components required, see opposite.

2.

Slide Workpiece Support through rectangular

opening in the aperture provided in the Back

Fence.

The V-guide on the Back Fence should engage in

the V-guide on the under side of Workpiece

Support, see fig. N and page 21 for use.

3.

Insert the Workpiece Support Adjustment Bolt

through the hole in the underside of the Back

Fence and through the slot in the Workpiece

Support.

4.

While holding the head of the bolt in the hex recess

on the underside of Back Fence, place the flat

washer over the bolt and screw on the Medium

Size Knob.

When knob is loosened, the Workpiece Support should

slide back & forth in the aperture for take-up adjustment.

Fig. N

Back Fence

Fixing Bolt

P.

Attachment of Back Fence to Table

The Back Fence is provided as a guide against which

the workpiece should be held for accurate routing.

Freehand routing (not holding work against the fence)

should be avoided unless the cutter has a bearing guide

or pin. Then, the Lead-on Pin should be fitted to prevent

the cutter from snatching the workpiece.

When attaching the Back fence to the Table Surface,

care should be taken not to knock the protruding cutter, if

it has already been fitted.

Two round holes on the right side of the Table Surface

and one long slot on the left hand side of the Table

Surface are provided for attaching the Back Fence.

For all edge cutting and end cutting operations, attach

fence using the front hole and the slot. This will allow

adequate adjustment of the Back Fence to suit the cutter

diameter and depth of cut. See fig. P.2.

For all routing operations away from edge on the under

side of workpiece, such as grooving, fluting, veining,

attach the Back Fence using the back hole and the slot.

See fig. P.3.

Dust extraction should be used with the Back Fence

all times to prevent clogging of wood waste, see page 18.

at

Fig. P.1

1.

2.

3.

4.

Position Back Fence assembly to Table Surface

as shown in fig. P.1.

Depending upon the type of routing operation,

insert one of the Back Fence Fixing Bolts through

one of the holes on the right side of the Table

Surface (from the underside) and the short slot in

the Back Fence. Make sure square shoulder of the

bolt fits into the square recess in the underside of

the Table Surface.

While holding the bolt in place, fit the flat washer

and large knob onto the bolt to secure loosely the

Back Fence to the Table Surface.

Repeat Steps 2 and 3 for table slot and fence slot

on the left hand side of the Table Surface.

Fig. P.2

Fig. P.3

-15-

Page 17

Router Table for the Craftsman

Mitre Fence Components

Mitre Bar x 1

Mitre Fence Head x 1

Small Size

Knob x 1

Bolt x 1

Washer x 1

Pointer x 1

Securing

Bolt x 1

Nut x 1

-16-

Page 18

Router Table for the Craftsman

Q.

Assembly of Mitre Fence

1.

Identify the components required, see opposite.

2.

Insert the pin of the Mitre Fence Head into the

Mitre Bar.

3.

Insert the Securing Bolt and fit the Flat Washer

and Securing Knob (small size).

4.

Remove any flash on the plastic pointer with a

sharp knife.

5.

Position the pointer as shown in fig. Q.1 and insert

the bolt, then fit the nut.

Alignment of Back Fence to Mitre Fence Slot

1.

Measure the distance from each end of Back

Fence to edge of Mitre Fence slot in the Table

Surface as shown in fig. Q.2. Adjust the position of

the Back Fence to ensure both distances are

equal.

fig. Q.1

Mitre fence head

Mitre bar

Knob

Flat washer

Securing bolt

Knob

Pointer

Hex nut

2.

Position Mitre Gauge in slot as shown in fig. Q.2.

R.

No-Volt Release Switch - NVRS/230V

(Standard accessory on tables made from 1/3/97)

The No-volt Release Switch can be fitted to the table

leg or workboard to provide easy access to On/Off

buttons. Should the power be turned off at source, the

router will not restart until the green start button is

pressed. The switch is for use with 230 volt routers up to

1850 watts.

1. With the fixing kit supplied, mount the No Volt

Release Switch on the right side of the router table

using the holes already drilled.

fig. Q.2

fig. U.1

workboard

to plug at

mains supply

to socket for

plug of router

-17-

fig. U.2

Page 19

Router Table for the Craftsman

OPTIONAL ACCESSORIES

R.

Dust Extraction Equipment

The Back Fence is provided with an extraction point for

fitting to suitable dust extractors. The internal hole

diameter is 57mm (2 1/4"). Suitable fittings with 57mm

outside diameter are available with most extractor units.

Only a dust extractor unit recommended for use in the

workshop should be used.

swivel freely when fitted to the hose.

Assembly of Hose Adaptor

1.

Slide Adaptor Clip onto end of the Extraction

Hose CRT/4 with tabs facing outwards.

2.

Screw the Adaptor Fitting anti-clockwise onto

hose, ensuring that the Extraction Hose is

screwed in all the way.

A suitable adaptor and extraction hose can be purchased

as optional accessories as follows:

Extraction Hose - 39mm OD - 3 metre length.........CRT/

4

Hose Adaptor - 58mm OD to 39mm ID..................CRT/3

The hose has an outside diameter of 39mm and inside

diameter of 32mm and is designed to fit the hose adaptor. The hose adaptor is a unique design allowing it to

Extraction Hose - CRT/4

Hose Adaptor - CRT/3

3.

Fit the Adaptor Tube by locating the holes with the

tabs of the Adaptor Clip.

4.

Push the assembly into the back fence connection

point with a slight twisting action to ensure a tight

fit.

5. Fit the other end of the extraction hose to your dust

extractor.

Extraction Point

Back Fence

fig. R

Extraction

Hose

CRT/4

Hose Adaptor

CRT/3

39mm

Tabs

Adaptor Clip

57mm

Adaptor Tube

Adaptor Fitting

-18-

Page 20

Router Table for the Craftsman

T.

Assembly of Spring Pressure Clamps

The Optional Spring Pressure Clamps can be mounted

to the Back Fence. When adjusted to suit the width and

thickness of the material, it ensures the material is held

down onto the surface to obtain accurate machining of

the workpiece.

The Back Fence is pre-drilled to accept both Spring

Pressure Clamps.

1.

Remove Back Fence from Table Surface

2.

Insert Vertical Pillar Bolt through the underside of

the Back Fence.

3.

Fit washer and screw on the Vertical Pillar. Tighten

screw securely to ensure pillar is vertical.

4.

Fit knobs to Connector Block and slide it onto

Vertical Pillar.

5.

Slide Horizontal Bar through Connector Block.

Spring Pressure Clamp Set - CRT/10

6.

Slide Pressure Strip into the slot in Horizontal Bar

aligning the holes. Insert the Retaining Screw

ensuring it goes in through the un-threaded side of

the hole first.

Before tightening the Vertical Pillar Bolts, ensure that

the Vertical Pillar will allow the block to be positioned

parallel to the Back Fence with the knob engaging on the

flat of the Vertical Pillar.

Adjustment

The Spring Pressure Clamps will require adjusting to

suit the height and width of material being routed. The

Pressure Strips should provide enough pressure to

prevent the material lifting from the Table Surface, but

not too much as to create friction which would prevent the

material from sliding freely. The block assembly with

Horizontal Bar and Pressure Strip can be removed

from the Vertical Pillars when not required. The Vertical

Pillars can be left in position and will not impede the

Tenon Push Block system.

Pressure

Strip

Retaining

Slot

Screw

3mm

Allen

Key

Knob

Connector

Block

Vertical

Bar

Vertical

Pillar Bolt

Horizontal

Bar

Washer

fig. S

4mm

Allen Key

-19-

Page 21

Router Table for the Craftsman

U.

Assembly of Profiling Top Guard

The use of the optional accessory, Profiling Top Guard

is highly recommended to safely carry out the profiling of

workpieces with a bearing guided cutter. It will prevent

the operator's fingers inadvertantly contacting the cutter.

1.

Fit the Bolt, Star Washer, Spring Washer and Nut

in the sequence as indicated below.

2.

Tighten nut securely with a 8mm spanner.

3.

Fit Plate, Washer and Wing Nut.

4.

Slide the Perspex Guard in between the Plate and

edge of Table Surface.

5.

Gently tighten Wing Nuts.

Profiling Top Guard - CRT/2

Adjustment

1.

The height of the Perspex Guard should be

adjusted to leave a 6mm to 12mm gap between the

top of the workpiece and the underside of the

guard. This will prevent fingers coming into contact

with the cutter.

2.

To adjust the height undo the wing nuts, re-position

the guard and retighten.

Section Y describes a typical application involving the

use of bearing guided cutters with the Router Table.

Plate

Washer

Wing Nut

Perspex Guard

M5 Bolt

Star Washer

Spring Washer

Half Nut

fig. T

-20-

Page 22

Router Table for the Craftsman

OPERATION

V.

Edging and Profiling using the Back Fence

The router table has many advantages when profiling and

edging operations are to be carried out especially on

narrow workpieces. A Fine Height Adjuster fitted to the

router will make adjustment of the height far easier and

hence is highly recommended.

Craft Range

Ref. C020

Craft Range

Ref. C072

Craft Range

Ref. C110

NOTE:

Make a test cut on a piece of waste material prior

to carrying out any routing operation.

1. Mark the width and depth of cut required onto the

end of the timber. See fig. V.1 for typical profiling

and edging operation which can be carried out.

2. Place timber up against Back Fence.

3. Release Back Fence Fixing Bolts.

4. Adjust Back Fence until required width of cut is

achieved. See fig. V.2a.

If bearing guided cutters are used, ensure that the Back

Fence is in line with the bearing or slightly behind it. The

Back Fence will give more support and provides the

retractable Safety Dust Guard and Spring Pressure

Clamp facility.

5. Lock Back Fence Fixing Bolts.

6. Release plunge mechanism on router.

7. Adjust the depth of cut using the Fine Adjuster (if

fitted), see fig. V.2b.

Craft Range

Ref. C040

fig. V.1

fig. V.2a

Craft Range

Ref. C112

Craft Range

Ref. C094

fig. V.2b

8. Lock-off plunge mechanism of router.

9. Lower Safety Dust Guard and check it will retract

freely over the workpiece.

10. Adjust the Spring Pressure Clamps (if fitted) to suit

the thickness and width of the timber.

11. Ensure that you have a Pushstick within easy reach

when routing.

12. Switch on router.

13. Pass timber over cutter with a consistant feed

speed.

Ensure even pressure is kept on the workpiece down

onto the table and against the back fence.

Always ensure that your hand positions are never near

the cutter.

Use the correct procedure as shown in figs. V.3a - c.

Use the push stick to safely maintain pressure on narrow

timbers.

14. The Workpiece Support can be used to plane an

edge. The cutter should be set approximately 2mm

proud of the Back Fence. The material should be

routed until the planed edge passes onto the outfeed

fence. Switch off router, slide or pivot material away

from cutter. Replace material and bring Workpiece

Support out until it touches the material. Tighten

knob and continue routing.

fig. V.3a

fig. V.3b

fig. V.3c

-21-

Page 23

Router Table for the Craftsman

W.

Using Router Table for Grooving

The router table can be used for operations away from

the edge of the workpiece such as grooving,

fluting, veining, etc.

Always unplug the router before making any setting,

adjustments, or changing bits.

When routing, always feed against the rotation of the

cutter. Feed workpiece in the direction of arrow in

fig. W.2.

For maximum accuracy, one edge of your workpiece

(edge sliding against the fence) must be true and

straight.

Set up your fence as follows:

1.

Raise Safety Dust Guard and rest it against the

extraction point.

2.

Position the fence behind the router bit for the

desired cutting depth (the distance of cut from the

edge of the workpiece, as shown in fig. W.1).

3.

Securely tighten Back Fence Fixing Bolts and

lower the guard over the cutter.

4.

Make the cut by sliding the straight edge of

workpiece against the fence. Use a Pushstick as

shown in fig. W.2. (For each successive cut, the

fence would need to be re-adjusted).

fig. W.1

pushstick

fig. W.2

X.

Using Mitre Fence

Your Mitre Fence will be required to give extra support

for routing small workpieces or ends of large workpieces.

See fig. X.

NOTE:

For all routing operations requiring use of the Mitre

Fence along with the fence, be sure to align fence with

mitre bar slot before making any cuts.

It is advisable to fit a waste piece of material to the Mitre

Fence or behind the component to prevent breakout of

the wood grain.

If using Mitre Fence to trim the end off a piece of material, the Workpiece Support can be brought forward with

the cutter to support the material after the cut, see fig. X.

fig. X

-22-

Page 24

Router Table for the Craftsman

Craft Range Cutter Ref. C116

Template

Table Surface

6mm

Insert Plate

Craft Range Cutter Ref. C078

Guard

Lead-on

Pin

Insert Ring

fig. Y.1

Table Surface

6mm

Insert Plate

Guard

Lead-on

Pin

fig. Y.2

-23-

Page 25

Router Table for the Craftsman

Y.

Using The Profiling Top Guard

Example

A typical application using the Profiling Top Guard is in

the routing of shields from MDF Board (Medium Density

Fibreboard) as follows:

b.

Gradually swing workpiece towards cutter until

template engages the guide bearing.

c.

Feed workpiece against the rotation of the cutter

whilst swinging the workpiece away from the

Lead-On Pin. At this point the guided bearing is

acting as the guide. Progressively feed the

workpiece anti-clockwise around the shape of

the templateensuring that the guide bearing

always stays in contact with the template.

d.

When the complete edge of the workpiece has

been machined, slide the workpiece away from

the cutter.

If you are unfamiliar with the above procedure then

the technique should be practised before switching on

the router.

Design of shield

Producing a Shield

1.

Construct an actual size template of the shield

design from 6mm MDF, hardwood or plywood

ensuring that it is accurate and free from imperfections. Remember the finished product will only be

as good as the template.

2.

Fix the template to the back of the workpiece to be

used using screws or double sided tape.

3.

Rough cut the workpiece to the shape of the

template using a band saw or jigsaw leaving 2-3mm

oversize.

4.

Remove the Back Fence assembly from the table.

5.

Fit the Lead-on Pin as described in section K.

6.

Fit the fine height adjuster if one is available for

your router. This will allow the height of the cutter to

be adjusted accurately.

7.

Fit a self-guided trimmer cutter.

8.

Lay the workpiece (with template fitted) face down

on the table surface. Adjust the height of the cutter

using the plunge and lock mechanism on the router

or use the fine height adjuster (if fitted). Ensure

that the bearing will contact the template and the

cutting edge of the cutter will machine the full edge

of the workpiece. See fig. Y.1.

Special Notes

1.

Always keep the workpiece moving in a precise

steady movement to prevent the material from

burning.

2.

Never let go of the workpiece. Always keep an even

pressure of the workpiece against the bearing. Do

not use too much pressure.

3.

If you wish to stop routing halfway through the

operation. Simply slide the workpiece away from

the cutter before switching off the router.

4.

If the template inadvertently comes away from the

bearing and so does not emulate the template, do

not stop. Complete the operation and repeat the

procedure for the edge concerned.

5.

It is advisable to repeat the operation in order to

improve the finish of the workpiece.

6.

Keeps hands away from the cutter, even if the

guard is fitted, in order to give a good safety

margin.

Minimal finishing should be required before the next

operation. If natural woods are used, consideration

should be given to breakout of short grain which will

effect your decision as to where to start the routing

operation in order to prevent it.

9.

Lock-off plunge mechanism of router to ensure that

the plunge mechanism will not inadvertently move

during routing.

10.

Fit the Profiling Top Guard as described in

Section T and adjust height to give a 6-12mm gap

between the top of cutter and underside of template.

11.

Switch router on and allow to reach full running

speed.

a.

Position the workpiece against the Lead-On Pin

as shown in fig. Y.3. The Workpiece should not

contact the cutter.

-24-

Page 26

Moulding the Shield

Router Table for the Craftsman

A suitable bearing guided cutter should be chosen to

mould the shield.

1.

Remove plug from mains.

2.

Fit chosen moulding cutter.

3.

Adjust height of cutter to achieve shape required.

If the full edge of the workpiece is to be machined

leave the template attached to the workpiece so as

to provide a guide for the bearing. Otherwise the

template can be removed, providing there is

sufficient edge for the bearing to follow. See fig Y.2.

4.

Repeat the same routing procedure as before. If the

profile required involves excessive removal of

material, it is advisable to take two passes with the

cutter. First reduce the height of the cutter protruding from the table, this in effect, reduces the

amount of material which will be removed, or fit a

larger bearing, if one is available for that particular

cutter.

The second pass can then be made to give the

required finish.

Carrying out this two stage routing operation has many

advantages.

a.

Improved finish on workpiece

b.

Less load on cutter and router

c.

Far less risk of workpiece snatching

Definition of Snatching

This can be described as the cutter catching the

workpiece and projecting it away from the direction of

rotation. The workpiece is often taken from the operator's

hands and projected across the work area. It can have

potentially dangerous consequences if the cutter is

unguarded and/or the operator's hands are too close to

the cutter. Damage to the cutter can also be caused.

The following precautions should be made to avoid a

potentially dangerous situation:

1.

Fit the Profiling Top Guard, this will prevent

fingers contacting the cutter.

2.

Always rout in the direction which opposes the

direction of rotation of the cutter. Routing with the

direction of the cutter is called back-cutting and will

cause snatching.

3.

Use the Lead-On Pin to provide support for the

workpiece during the initial start of the routing

operation, it will also ensure that you approach the

cutter from the correct side.

4.

When a deep cut is required or the material is

particularly dense, then take two or three passes.

5.

Ensure the cutter always has a sharp cutting edge.

6.

Do not reduce pressure of the workpiece or let go

of it. Always keep both hands on the workpiece and

keep an even pressure against the guide bearing.

7.

Do not use too great a feed speed. If the revolutions of the router drop, it is a good indication that

either too deep a pass is being made and/or the

cutter is blunt. Therefore reduce the depth of cut

and/or resharpen your cutter.

If the above points are followed, profile routing using

bearing guided cutters is both safe and rewarding. It is

however advisable for those new to routing to avoid using

larger diameter cutters until proficient with the technique

described. Under no circumstances should this type of

operation be carried out with cutters not having a guide

ball bearing or pin.

Workpiece

position 3

Workpiece

position 2

Top Guard

Cutter Rotation

-25-

Lead-On Pin

Workpiece

position 1

fig. Y.3

Page 27

Router Table for the Craftsman

Z.

End Cutting with the Tenon Push Block

The Push Block facility is ideal for producing tenons and

sliding dovetails.

The retractable dust guard cannot be used when carrying

our push block operations. Therefore extra care must be

taken to ensure that hands are kept well clear of the

cutter.

Ensure that the workpiece is true and the end is square

and smooth.

1.

Mount push block assembly on the Back Fence,

see section L.

2.

Fit the correct insert ring into the the insert plate to

suit the diameter of the cutter being used, see

section J.

3.

Adjust the height and depth of the cutter to suit the

cut required.

4.

Position workpiece between Clamp Plate and

Push Block so that it's side is flush against the

face of the Back Fence, the end to be cut is resting

on the edge of the insert plate hole and edge

marked with lines 'A' and 'B' is facing the router

cutter. Clamp workpiece in this position by

tightening the Wing Nut on the Clamp Rod while

making sure that Clamp Plate stays orientated on

workpiece. See fig.Z.2.

fig. Z.1

Typical width of tenon is 1/3 of

thickness of material

A

B

Shoulder

Face Side

Face Edge

5.

Slide Push Block and workpiece back to the

position as shown in fig.Z.3. When routing, always

feed against the rotation of the cutter. Feed

workpiece in the direction shown by the arrow.

6.

Switch router on. While holding Push Block and

guidig workpiece against fence with both hands and

fingers at a safe distance from cutter (fig.Z.3).

7.

Turn router off, unclamp workpiece and slide Push

Block back to original position.

8.

Position and clamp the opposite side of workpiece

(make sure the wing nut is tight just enough to

clamp workpiece in position and end to be cut is

resting on the edge of insert plate hole). Repeat

step 6 and 7.

9.

To cut ends of tenon, position and clamp workpiece

so that the edge of the workpiece is held flush

against the face of the fence and end to be cut

should be resting on edge of insert plate hole. See

fig.Z.4. Repeat steps 6 and 7.

10.

A scrap piece of timber should be placed behind

the workpiece to prevent breakout.

fig. Z.2

fig. Z.3

-26-

fig. Z.4

Page 28

Router Table for the Craftsman

36

29

23

21

26

27

22

Spare Parts for Router Table Model CRT/A, CRT/B, CRT/C and CRT/X

38

40

12

12

42

3223

3

3

33 3

43

46

47

24

12

2

93

12

3

33 3

12

44

3

45

3

75

4

3

3

3

3

48

52

51

79

243

to socket for

plug of router

to plug at

mains supply

11

15

10

9

8

7

6

16

5

53

28

4

3

933

76

3

4

3

12

39

1

39

77

78

54

18

41

30

25

31

3

19

5

32

3

30

3

25

14

20

34

17

2

-28-

4

24

33

4

Page 29

trend

r o u t i n g t e c h n o l o g y

80

R

Router Table for the Craftsman

73

Instruction

Manual

Spare Parts for

Profiling Top

Guard

Optional Accessories

60

59

58

57

56

55

62

61

Spring Pressure Clamp

67

66

65

63

71

64

68

72

74

70

KEY PART NO. DESCRIPTION

1 WP-CRT/01 Table Surface

2 WP-CRT/02 Table Leg

3 WP-CRT/03 Washer

4 WP-CRT/04 Carriage Bolt

5 WP-CRT/05 Nut

6 WP-CRT/06 Mitre Bar

7 WP-CRT/07 Pointer

8 WP-CRT/08 Bolt

9 WP-CRT/09 Groove Pin

10 WP-CRT/10 Mitre Fence Head

11 WP-CRT/11 Small Size Knob

12 WP-CRT/12 Insert Plate Ring Set

14 WP-CRT/14 Star Washer

15 WP-CRT/15 Washer

16 WP-CRT/16 Securing Bolt

17 WP-CRT/17 Back Fence

18 WP-CRT/18 Retractable Safety Guard

19 WP-CRT/19 Pivot Pin

20 WP-CRT/20 Workpiece Support

21 WP-CRT/21 Push Block

22 WP-CRT/22 Clamp Rod

23 WP-CRT/23 Clamp Plate

24 WP-CRT/24 Workpiece Support Adjustment Bolt

25 WP-CRT/25 Push Nut

26 WP-CRT/26 Wing Nut

27 WP-CRT/27 Flat Washer

28 WP-CRT/28 Dome Headed Screw

29 WP-CRT/29 Spring Washer

30 WP-CRT/30 Large Size Knob

31 WP-CRT/31 Medium Size Knob

32 WP-CRT/32 Label (Router Table)

33 WP-CRT/33 Warning Label (Fence)

34 WP-CRT/34 Label (Fence)

36 WP-CRT/36 Hex Nut

38 WP-CRT/38 Lead-on Pin

39 WP-CRT/39 Nylock Nut

40 WP-CRT/40 Insert Plate Retaining Bolt

Spare parts are available from your Trend stockist. Prices exclude VAT and are subject to change.

KEY PART NO. DESCRIPTION

41 WP-CRT/41 Insert Plate Adjustment Bolt

42 WP-CRT/42 Fixing Pack for Insert Plate A

43 WP-CRT/43 Fixing Pack for Insert Plate B

44 WP-CRT/44 Fixing Pack for Insert Plate C

45 WP-CRT/45 Fixing Pack for Insert Plate X

46 CRT/PLATE A Insert Plate Set A

47 CRT/PLATE B Insert Plate Set B

48 CRT/PLATE C Insert Plate Set C

51 CRT/PLATE X Insert Plate Set X

52 WP-CRT/50 Mitre Fence Assembly-complete

53 WP-CRT/51 Push Block Assembly-complete

54 WP-CRT/52 Back Fence Assembly-complete

55 WP-NUT/11 Wing Nut

56 WP-WASH/09 Washer

57 WP-CRT/57 Plate

58 WP-NUT/05 Nut

59 WP-WASH/29 Spring Washer

60 WP-WASH/39 Star Washer

61 WP-SCW/16 M5 Bolt

62 WP-CRT/62 Perspex Guard

63 WP-SCW/29 Bolt M6

64 WP-WASH/50 Washer

65 WP-CRT/65 Vertical Pillar

66 WP-CRT/66 Block

67 WP-KNB/01 Knob

68 WP-CRT/68 Horizontal Bar

70 WP-CRT/70 Pressure Strip

71 WP-AK/04 Allen Key - 4mm A/F

72 WP-AK/03 Allen Key - 3mm A/F

73 MANU/RT Instruction Manual

74 WP-SCW/20 Retaining Screw

75 WP-CRT/75 Fixing Pack for Insert Plate D

76 WP-CRT/76 Fixing Pack for Insert Plate E

77 CRT/PLATE D Insert Plate Set D

78 CRT/PLATE E Insert Plate Set E

79 NVRS/230V 230 Volt No Volt Release Switch

80 PUSHSTICK/1 Plastic Pushstick

-29-

Page 30

21mm

21mm

77mm

77mm

Router Table for the Craftsman

Position of

Router Handle

APPENDIX

77mm

21mm

77mm

C

FRONT OF CRT TABLE

21mm

C

Position of

Router Handle

4 holes for

M5 M/C

screws

Plan for

HITACHI TR12

-30-

Router

Page 31

-31-

Plan for

RYOBI R600, RE600

Routers

Position of

Router Handle

2 holes for

M5 M/C

screws*

59mm

37mm

C

Router Table for the Craftsman

44mm

C

Position of

Router Handle

40mm

* The plate for the CRT/B table

is pre-drilled to accept the two

central fixings M5 M/C screw

54mm

FRONT OF CRT TABLE

44mm

4 holes for

M4 M/C

screws

Page 32

3 holes for

No.10 - 3/8"

UNF M/C

screws

59.25mm

34.5mm

68mm

FRONT OF CRT TABLE

Position of

Router Handle

Position of

Router Handle

C

C

Router Table for the Craftsman

Plan for

SKIL 1835U, 1875U

Routers

-32-

Page 33

2 off 6mm dia.

through holes

required to be

drilled into base

of router.

Router Table for the Craftsman

Threaded hole

for lead-on piece

C

65°

Position

of plate

Switch Side

C

Plunge

lock

75mm

FRONT

handle

side

Plan showing positions of holes required

to be drilled in base of Elu MOF96(E) Mk1

and other similar makes

-33-

Underside view of Elu

MOF 96(E) Mk1 base

Page 34

Router Table for the Craftsman

2 through holes

8mm diameter

14.5mm

60mm Ø

approx.

100mm

MATERIAL MIN. 6.35mm (1/4") THICK.

C

approx.

145mm

115mm

Plan showing gasket

required for

ELU OF97(E)

-34-

Page 35

Router Table for the Craftsman

C

2 through holes

8mm diameter

60mm Ø

approx.

100mm

75mm

approx.

145mm

MATERIAL MIN. 3.2mm (1/8") THICK

Plan showing gasket

required for

Bosch POF52, 400A,

500A & 600 ACE

-35-

Loading...

Loading...