Craftsman 919.769020 User Manual

OWNER'S MANUAL

6.5 Horsepower

2600 PSI 2.7 GPM

High Pressure Washer

Model No:

919.769020

WARNING: Before using this

product, read this manual

and follow all Safety Rules

and Operating instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

MGP-769020 12/1/93

\

PRESSURE WASHER

CUSTOMER

HELPLINE

1-800-245-5873

/fA

• Safety

• Assembly

• Operation

• Maintenance

• Parts List

• Español

i

TABLE OF CONTENTS

.

..........

Warranty

Safety Guidelines..........................

Assembly

Operation................................................

Maintenance

Service and Adjustments.....................

.................................................

.

.............................................

.....................................

.

2

...........

3-5

.......... 5-7 Parts........................................

...........

7-11 ERA Codes...............................

...........

12-14 Espahoi

.

..........

15

FULL ONE YEAR WARRANTY ON CRAFTSMAN HIGH PRESSURE WASHER

For one year from the date of purchase, when this Craftsman High Pressure Washer is maintained

and operated according to the instructions In the owner’s manual, Sears will repair, free of charge,

any defect in material and workmanship.

Storage

Troubleshooting

How to Order Parts

...............................

......................

....

.................................

.

.................

.............................

..............................

......................17-28

.

.....................

......................31-51

.........

29-30

Back Cover

15

16

If your Craftsman Pressure Washer is used for commençai or rental purposes, this warranty

applies only for 90 days from the date of purchase. If this washer is used for rented purposes this

warraty applies for only 30 days from the date of purchase.

FULL TWO YEAR WARRANTY ON CRAFTSMAN ENGINE

For two years from the date of purchase, when this Craftsman engine is maintained and operated

according to the instructions in the owner’s manual, Sears will repair, free of charge, any defect In

materia! and workmanship.

if your Craftsman engine is used for commençai or rental purposes, this warranty applies only for

one year from the date of purchase. This warranty does not cover expendable items such as spark

plugs and air filters, which become worn during normal use.

Repairs necessary because of operator abuse or negligence, including damage resulting from no

water being supplied to pump or failure to maintain the equipment according to the instructions

contained in the owner’s manual, are not covered under warranty.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE HIGH PRESSURE WASHER TO THE

NEAREST SEARS SERVICE CENTER THROUGHOUT THE UNITED STATES. This warranty gives you

specific legal rights and you may also have other rights, which vary from state to state.

Sears, Roebuck and Co., D/817 WA, Hoffman Estates, IL 60179

SAFETY GUIDELINES - DEFINITIONS

' This manual contains information that is important for you to know and understand. This information relates to protecting

YQUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the symbols

below. Please read the manual and pay attention to these sections. SAVE THESE DEFINITIONS/INSTRUCTIONS.

A WARNING indicates a potentially hazardous

.situation which, if not avoided, could result in

death or serious iniurv.

A CAUTION indicates a potentially hazardous situation

A DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious iniurv.

■

.......

.......................................................

....... ...................

which, If not avoided, may resuit in minor or moderate

iniurv.

iO,'S/97 ^

IMPORTANT SAFETY INSTRUCTIONS

AWARNING

Improper operation or maintenance of this product could result in serious injury and property damage. Read

and understand all warnings and operating instructions before using.

HAZARD

A DANGER

RISK OF EXPLOSION

OR FIRE

WHAT CAN HAPPEN

Spilled gasoline and its vapors can

become ignited from cigarette

sparks, electrical arcing, exhaust

gases, and hot engine components

such as the muffler.

Heat will expand fuel in the tank

which could result in spillage and

possible fire expiosion.

Operating the pressure washer in an

explosive environment could result

in a fire.

Materials placed against or near the

pressure washer can interfere with

its proper ventilation features

causing overheating and possible

ignition of the materials.

improperly stored fuel could lead to

accidental ignition. Fuel improperly

secured could get into the hands of

children or other unqualified persons.

HOW TO PREVENT IT

Shut off engine and allow it to cool

before adding fuel to the tank.

Use care in filling tank to avoid

spilling fuel. Move pressure washer

away from fueling area before

starting engine.

Keep maximum fuel level I/2” below

top of tank to allow for expansion.

Operate and fuel equipment in well

ventilated areas free from obstruc

tions. Equip areas with fire

extinguishers suitable for gasoline

fires.

Never operate pressure washer in an

area containing dry brush or weeds.

Store fuel in container approved for

gasoline, in a secure location away

from work area.

Adanger

RISK TO BREATHING

Breathing exhaust fumes will cause

serious injury or death.

Some cleaning fluids contain sub

stances which could cause injury to

skin, eyes, or lungs.

Operate pressure washer in a well

ventilated area. Avoid enclosed areas

such as garages, basements ,etc.

Never operate unit in a location

occupied by humans or animals.

Use only cleaning fluids specifically

recommended for high pressure

washers. Follow manufacturers

recommendations.

IMPORTANT SAFETY INSTRUCTIONS (cont’d)

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

AWARNINO

RISK OF UNSAFE

OPERATION

Awarning

RISK OF INJURY FROM

SPRAY

Unsafe operation of your pressure

washer could lead to serious injury

or death to you or others.

The spray gun/wand is a powerful

cleaning tool that could look like a

toy to a child.

Reactive force of spray will cause

gun/wand to move, and could cause

the operator to slip or fall, or

misdirect the spray. Improper control

of gun/wand can result in injuries to

self and others.

High velocity fluid spray can cause

objects to break, propelling particles

at high speed.

Light or unsecured objects can become

hazardous projectiles.

Become familiar v^/ith the operation

and controls of the pressure washer.

Keep children away from the

pressure washer at ati times.

Never defeat the safety features of this

product.

Do not operate machine with missing,

broken, or unauthorized parts.

Never leave wand unattended while

unit is running.

Keep work area free of obstacles.

Stand on a stable surface and grip gun/

wand firmly. Expect the gun to kick

when triggered.

Always wear ANSI approved Z87 safety

glasses. Wear protective clothing to

protect against accidental spraying.

Never point wand at, or spray people or

animals.

Always secure trigger lock when wand

is not in service to prevent accidental

operation.

Never permanently secure trigger in pul!

back (open) position.

Awarning

RISK OF

ELECTRICAL

SHOCK

Awarning

RISK OF FLUID INJECTION

Awarning

RISK OF CHEMICAL BURN

Spray directed at electrical outlets or

switches, or objects connected to an

electrical circuit, could result in a fatal

electrical shock.

Your washer operates at fluid

pressures and velocities high enough

to penetrate human and animal flesh,

which could result in amputation or

other serious injury. Leaks caused by

loose fittings or worn or damaged

hoses can result in injection injuries.

DO NOT TREAT FLUID INJECTION AS

A SIMPLE CUT! See a physician

immediately!

Relieve system pressure before

attempting maintenance or disassem

bly of equipment.

Use of acids, toxic or corrosive

chemicals, poisons, insecticides, or

any kind of flammable solvent with this

product could result in serious injury

or death.

Unplug any electrically operated

product before attempting to clean it.

Direct spray away from electric outlets

and switches.

Never place hands in front of nozzle.

Direct spray away from self and others.

Make sure hose and fittings are

tightened and in good condition. Never

hold onto the hose or fittings during

operation.

Do not allow hose to contact muffler.

Never attach or remove wand or hose

fittings while system is pressurized.

Use only hose and high pressure

accessories rated for 2600 PSI service.

To relieve system pressure, shut off

engine, turn off water supply, and pull

gun trigger until water stops flowing.

Do not use acids, gasoline, kerosene, or

any other flammable materials in this

product. Use only household

detergents, cleaners and degreasers

recommended for use in pressure

washers.

Wear protective clothing to protect

eyes and skin from contact with

sprayed materials.

IMPORTANT SAFETY INSTRUCTIONS (cont’d)

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

RISK OF HOT SURFACES

Internationa!

Symbois

• Contact with hot surfaces, such as

engines exhaust components, could

result in serious burn.

Safety Alert - Read

Owner's Manual

O On OH (s^Stop

• During operation, touch only the control

surfaces of the pressure washer. Keep

children away from the pressure washer

at ail times. They may not be able to

recognize the hazards of this product.

Fuel

Shutoff

0

Fuel

V!

Choke

ACAUnON

The powerful spray from your pressure washer is capable of causing damage to fragile surfaces such as: wood, glass,

automobile paint, auto stripping and trim, and delicate objects such as flowers and shrubs. Before spraying, check the

item to be cleaned to assure yourself that it is robust enough to resist damage from the force of the spray. Avoid the

use of the concentrated spray stream except for very strong surfaces like concrete and steel.

Operating unit with water supply shut off without flow of water will result in equipment damage. You should

never run this pressure washer for more than 2 minutes without pulMng the trigger to allow cool water to enter

the pump and the heated {recirculated} water to exit. Running the pressure washer with water supply shut off

will void your warranty.

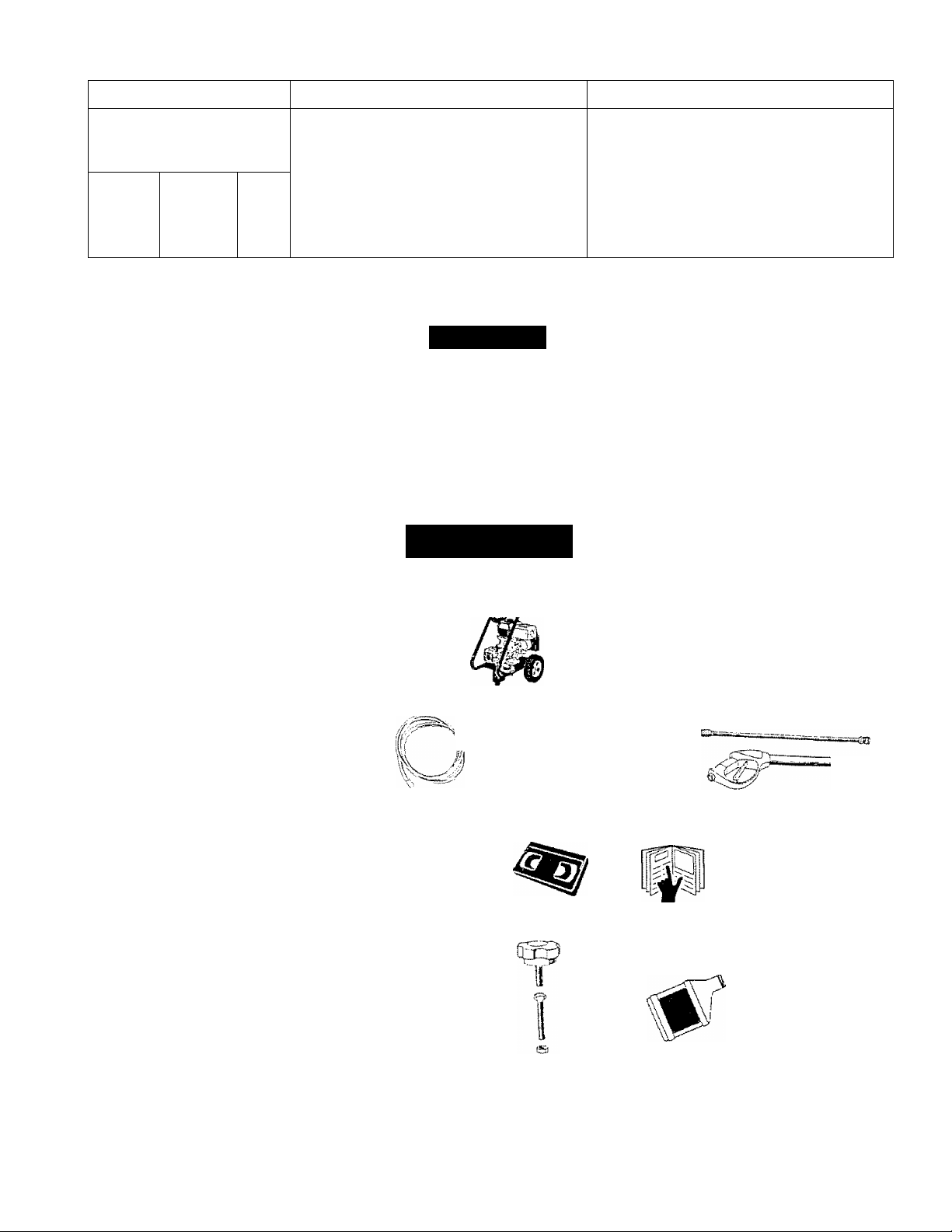

ASSEMBLY

Carton Contents

• Main Unit pressure washer with wheels

• Handle

• High Pressure Hose

• Chemical Pickup Hose and Filter

• Quick Connects (5 included)

• Gun

• Wand

Chemical Pickup Hose and Filter

Bag Containing

Video Cassette

Owners’ Manual

Nozzle Cleaning Kit and Replacement 0-Rings

Engine Oil

Rubber isolator and Mounting Hardware

Handle Mounting Hardware

Main Unit pressure washer

with wheels

I

Video Cassette Owners’ Manual Nozzle Cleaning Kit

A

itr

Handle

Quick Connects

Nozzles

S

o

High Pressure Hose

Gun and Wand

a

Handle Mounting Engine Oil Rubber Isolator and

Hardware

Mounting Hardware

0

Replacement 0-Rings

Tools Required for Assembly

Adjustable wrench

1/2” Socket

Remove Pressure Washer from Carton

• Open carton from the top. Locate and remove from

carton, the parts box, which includes gun, handle,

wand,oil, knobs and bolts. Next remove the parts

bag and the handle.

• Cut carton along dotted lines.

• Remove ail carton Inserts.

• Roll unit through opening in carton.

Note: The pressure and chemical hose are located at

the bottom of the box.

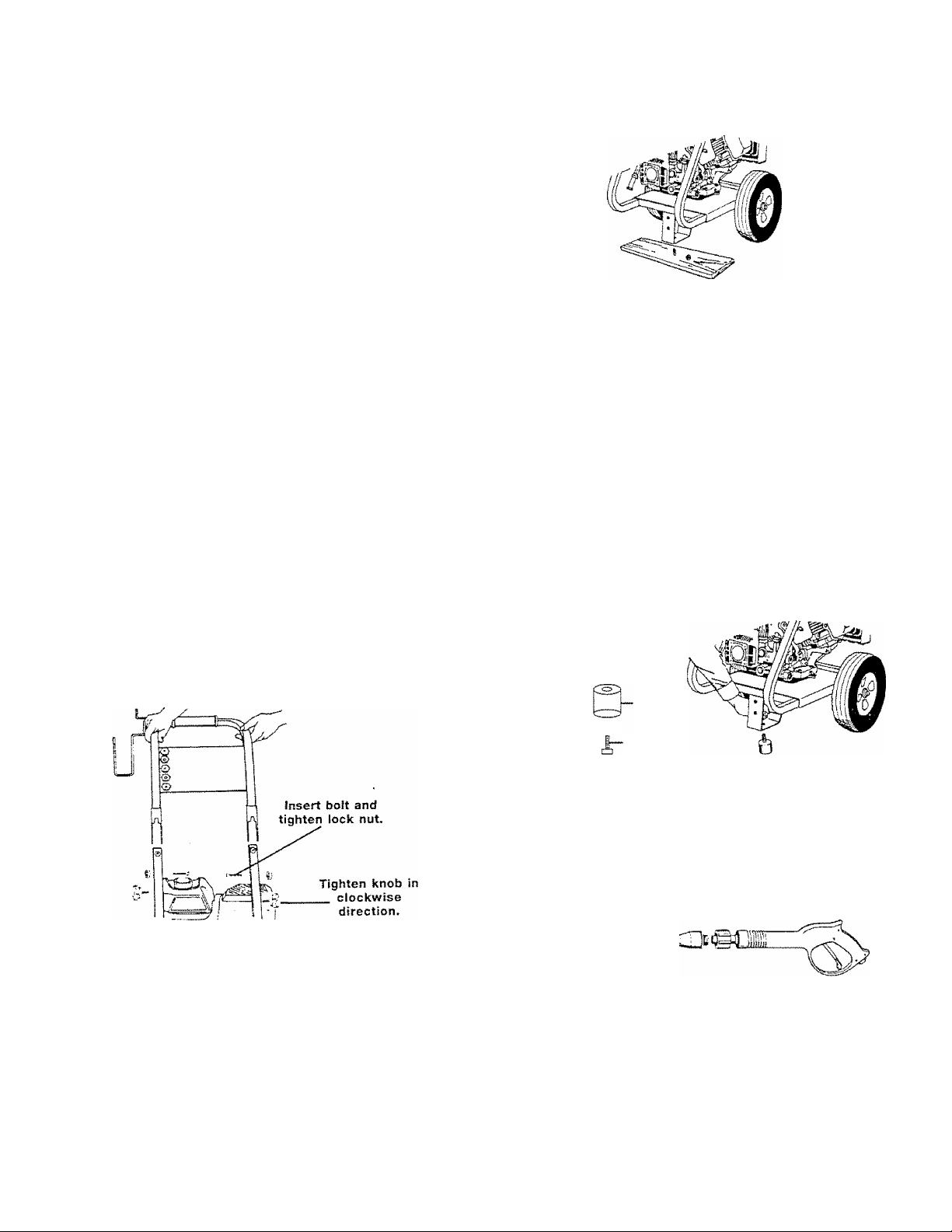

Preparing the Pressure Washer for First Use

Note: included with your pressure washer is a video

tape on how to prepare your unit for operation, it is

recommended you view this tape before performing

the next steps.

1. insert handle onto frame.

• insert knobs into the threaded slot in front of the

frame handle and tighten by turning in a clockwise

direction.

'v

^ • Slide bolts into the slot in the side of the frame

handle and tighten the nut by turning in a clockwise

direction.

2.

Remove wood plank from the frame of the unit.

An adjustable wrench is required. Discard bolt

and board.

3. Mount the rubber isolator to the frame.

• To mount isolator place threaded end of bolt

through the washer.

• Next with washer on bolt place threaded end

of bolt through larger hole in bottom of the

rubber isolator. Place threaded portion of

isolator through the front hole location where

the wood plank was mounted on the pressure

washer.

• Next place lockwasher over threaded portion

of bolt that has been placed through the

mounting hole in the pressure washer and use

nut to tighten isolator to the frame.

• Tighten nut with an adjustable wrench.

NUT

¿

LOCKWASHER

/ /

PRESSURE

WASHER

FRAME

WASHER—<S>

4.

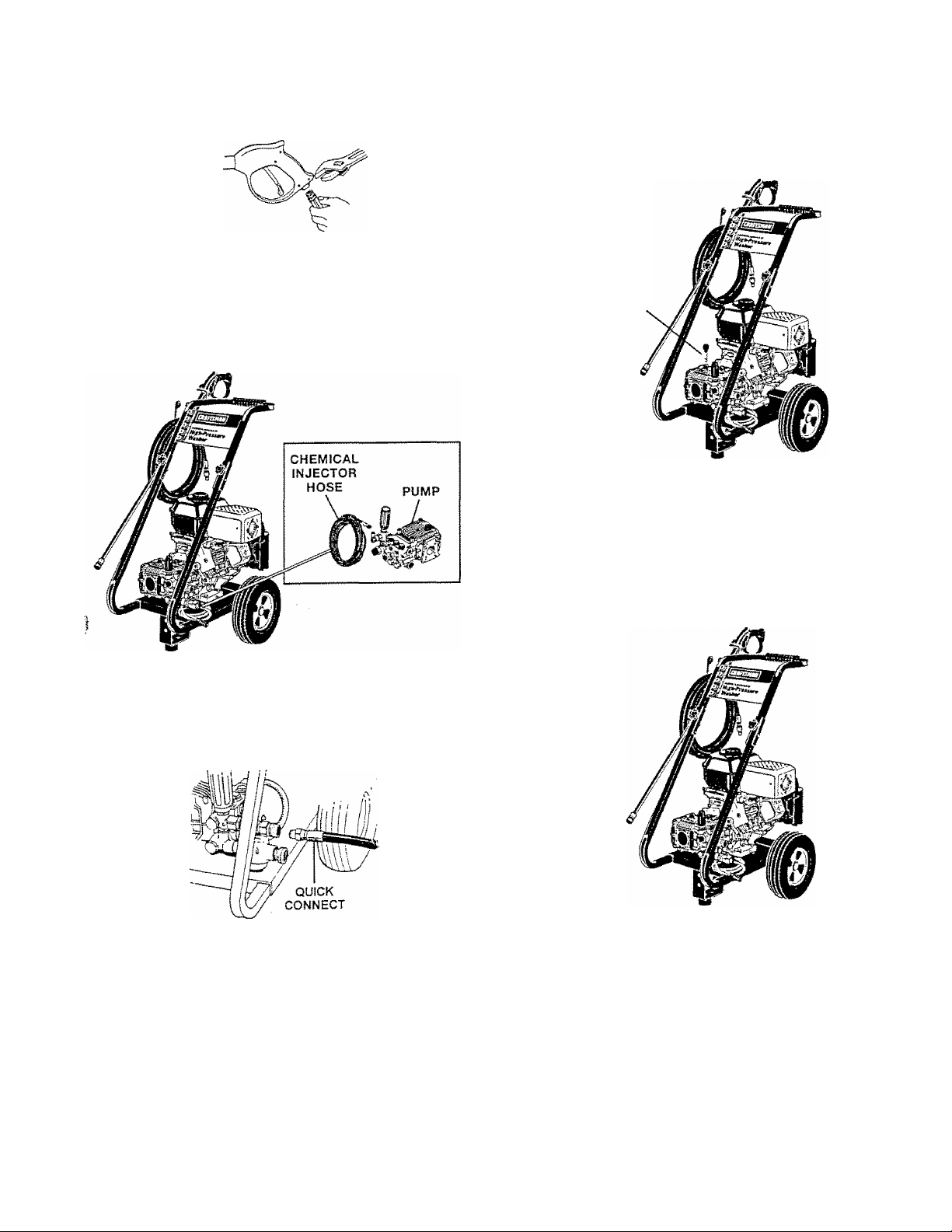

Connect wand with nozzle assembly to gun. To

BOLT

tighten, turn knob in clockwise direction. Hand

tighten.

Cut tie wrap off of high pressure hose. Unwind

5\

high pressure hose to attach the threaded end to

the gun. Tighten with adjustable wrench.

8.

Your units pump is shipped with a

temporary plug that must be replaced with a

breather cap. This plug is located over the

pump’s oil port. Unscrew and remove this plug.

Remove the breather cap from the bag attached

to the plug and install it in the pump’s oil port.

6. Connect chemical hose to the chemical injector

hose barb on pump.

7. Connect high pressure hose to the quick connect

outlet on pressure washer.

BREATHER

CAP

A CAUTION: Failure to replace the plug will result

in serious pump damage.

9. Place assembled gun and wand on pressure

handle bracket as shown.

NOTE: Always keep hose away from engine

muffler.

Checklist

Before going any further please review the following:

• Be sure you have completed assembly instruction.

• Double check all fittings to be sure they are tight.

IMPORTANT: Before any attempt to start your pres

sure washer be sure to check engine oil {See Operation

under Engine Oil, page 9.)

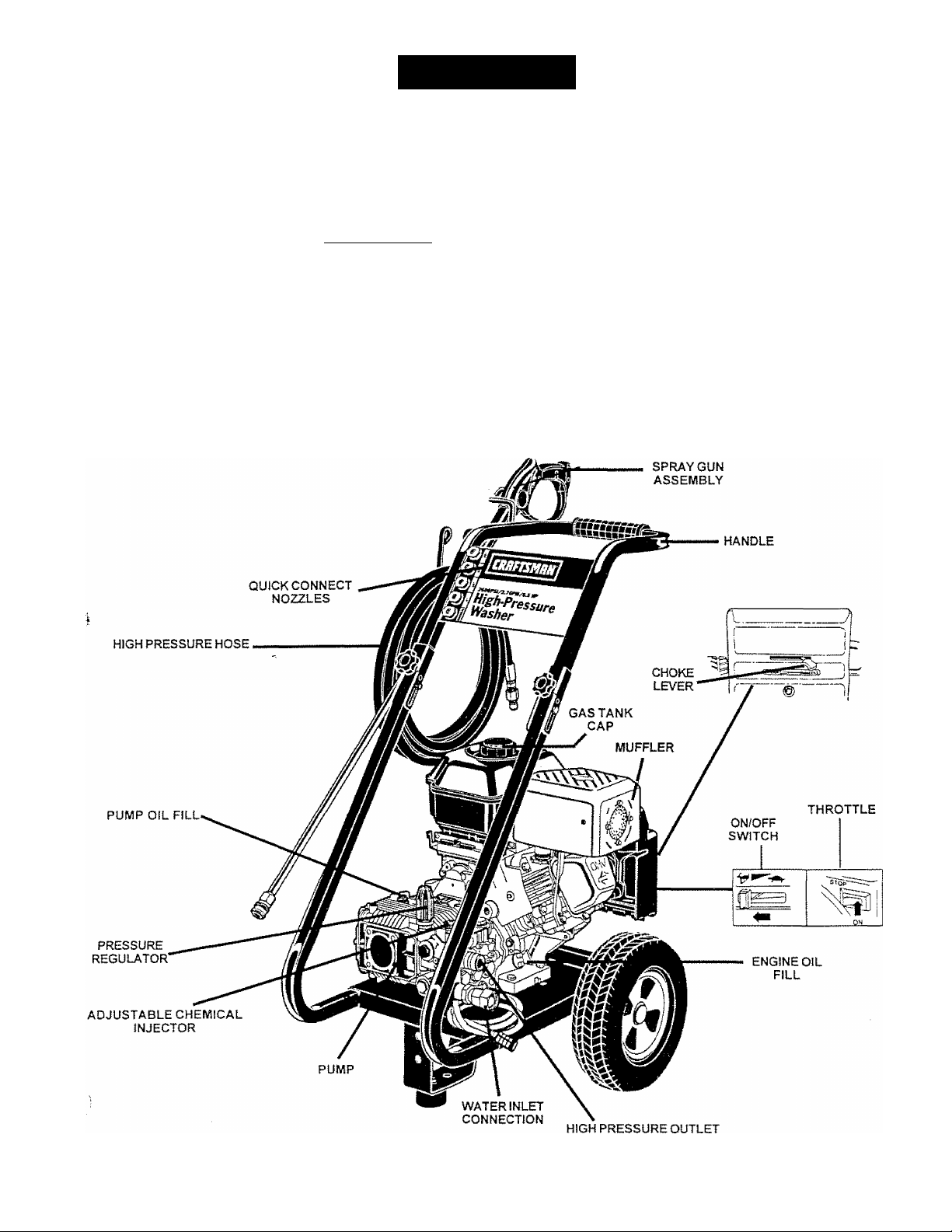

OPERATION

Know Your High Pressure Washer

' Read this Owner’s Manual and Safety Rules before

operation of your High Pressure M/as/jer Compare

this illustration with our pressure washer to familiarize

yourself with the iocation of various controls and

adjustments. Save this manual for future reference.

PUMP- Develops high pressure.

ENGINE OIL FILL- Place where engine oil is poured.

PRESSURE REGULATOR- Allows you to adjust the

pressure of the outlet stream.

ENGINE RUN/STOP SWITCH- Sets engine in starting

mode for recoil starter — Stops running engine.

RECOIL STARTER- Used for starting the engine

manually.

SPRAY GUN ASSEMBLY (Contains Gun and Wand)-

Controls the application of water onto cleaning surface

with trigger device.

PUMP OIL FILL- Port where pump oil is poured and

breather cap is located.

GAS TANK/CAP- Cap is removed and unleaded

gasoline is poured.

CHEMICAL INJECTION TUBE AND FILTER- Mixes

water and detergent in outlet water flow.

HIGH PRESSURE OUTLET- Connection for high pres

sure hose.

CHOKE- Lever used for starting unit.

QUICK CONNECT NOZZLES- Tips used for various

degrees of spray patterns.

stopping Your Pressure Washer

Engine Oil

A CAUTION; Do not run pump without the water

supply connected and turned on. Failure to do so

will result in pump damage.

' To turn pressure washer off place the on/stop switch

to the stop position.

• Simply shutting OFF engine will not release pressure

in the system. Squeeze the trigger on the spray gun

for about 3 seconds to relieve pressure. Spray

stream will decrease in length.

IMPORTANT: This unit is equipped with a thermal relief

valve. If unit is allowed to run for several minutes

without pressing the trigger on the spray gun, several

drops of water may be released through this valve to

cool the unit. The heated water will be purged from the

bottom of the pump.

Your unit has been shipped without oi! in the engine.

A bottle of SAE 30 weight oi! is included in the carton,

Remove oii plug located on the side of engine. Using a

funnel, fill engine crankcase up to the last thread in the

oil port. Pour slowly. Oil reading will be inaccurate on

unlevel ground.

NOTE: When adding oii to the engine crankcase, use

a high quality detergent oii classified “For Service SF,

SG, SH rated SAE 30 weight". Use no speciai addi

tives. Select the oil’s viscosity grade according to

your expected operating temperatures.

SAE Viscosity Grades

latsMa

'i'hO

i-U

BEFORE STARTING THE ENGINE

To operate the engine you will need to do the following.

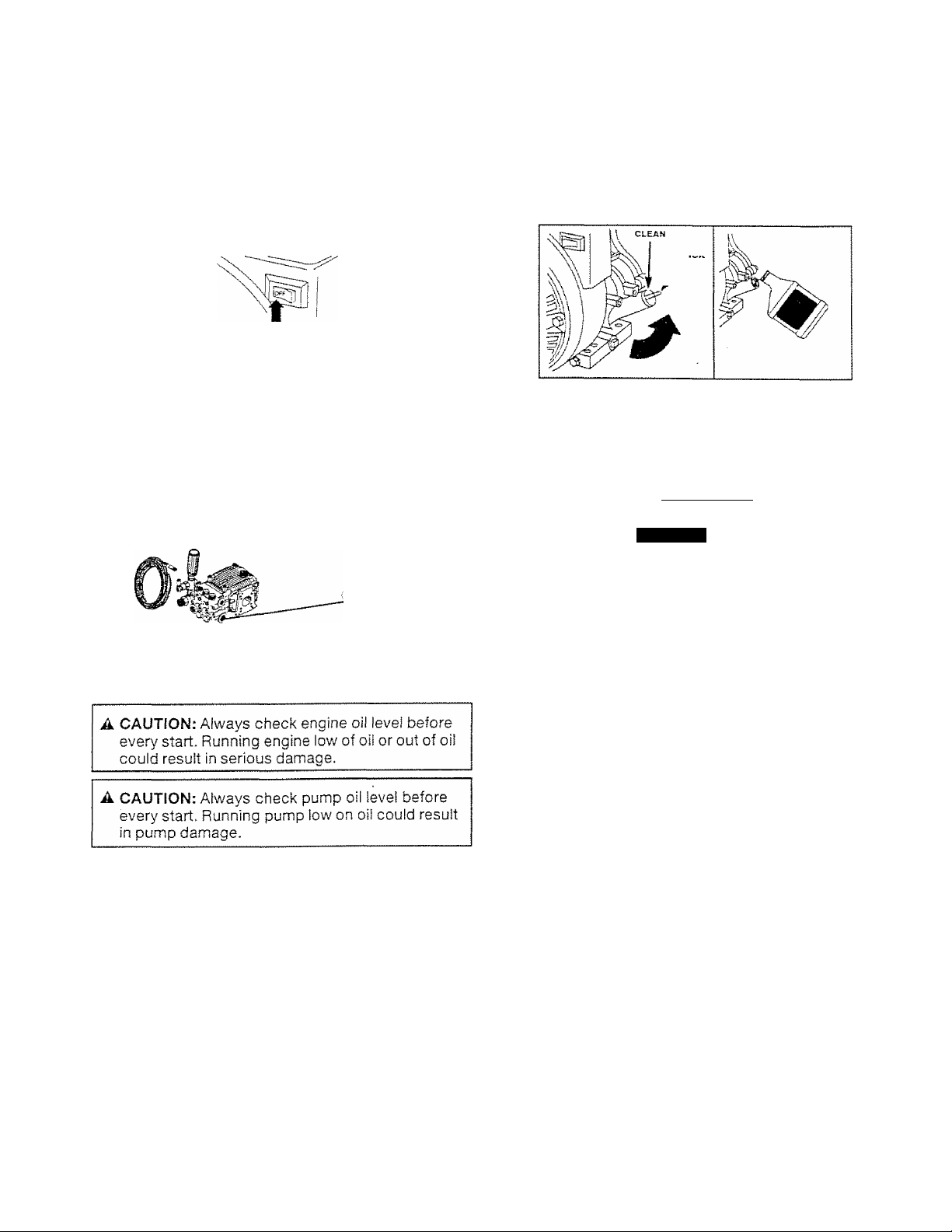

Adding Pump Oil

Before running the high pressure washer, check the

pump oi! level by viewing the sight glass on the side of

the pump. When properly filled, the oil will be at the

half way point marked by the two triangles. Your pres

sure washer pump is shipped with oil. Add oil only if oil

level is lower than the half way point on the sight glass.

Do not overfill. Use 30 weight non-detergent oii if

necessary.

STARTING TEMPgPATüRE RANGE ANTICIPATED BEFORE N£>T OtL CHANGE

Air cooled engines run hotter than automotive engines.

The use of multi-viscosity oi! such as (10W-30, etc.) in

ambient temperatures above 40°F (4°C) will result in

higher than normal oil consumption. If multi-viscosity

oi! lo used, check the oil level more frequently to

prevent any posssibie engine damage due to lack or

lubrication.

Use of SAE30 oil below 40°F (4°C) will result in hard

starting and possible engine damage due to inad

equate lubrication.

Gasoline

Your pressure washer engine is 4 cycle. Use unleaded

fuel only.

A CAUTION: Do not overfill the fuel tank. Always

allow room for fuel expansion.

A'^ARNING: Never fill fuel tank indoors. Never

fill fuel tank when engine is running or hoi. Do

not smoke or have open flame when filling fuel

tank.

A CAUTION: Do Not use engine oil that has been

shipped with your unit in your pump. Engine oii

Is detergent and your pump uses a non-detergent

oil. Detergent oii can cause damage to your pump.

Use clean, fresh, regular unleaded gasoline with a

minimum of 85 octane. Do not mix oil with gasoline.

If unleaded fuel is not available, leaded fuel may be

used.

Loading...

Loading...