Page 1

Owner’s Manual

Home/Hobby

AIR COMPRESSOR

• Safety Guidelines

• Assembly

• Operation

• Maintenance

• Service and Adjustments

• Troubleshooting

• Repair Parts

Model No.

919.722020

CAUTION: Read the Safety Guidelines

and All Instructions Carefully Before

Operating.

D29495 Rev. 0 9/05/03

Sold by Sears Canada, Inc. Toronto, Ont. M5B 2B8

Page 2

2- ENG

D29495

TABLE OF CONTENTS

WARRANTY

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SPECIFICATION CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SAFETY GUIDELINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

GLOSSARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-12

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-15

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-19

REPAIR PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

FRENCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21-39

HOW TO ORDER REPAIR PARTS . . . . . . . . . . . . . . . . . . . . . .back cover

FULL ONE YEAR WARRANTY ON AIR COMPRESSORS

If this air compressor fails due to a defect in material or workmanship within

one year from the date of purchase, RETURN IT TO THE NEAREST SEARS

SERVICE CENTER THROUGHOUT CANADA AND SEARS WILL REPAIR IT,

FREE OF CHARGE.

If this air compressor is used for commercial or rental purposes, the warranty

will apply for ninety days (90) from the date of purchase.

This Craftsman Air Compressor warranty gives you specific legal rights and

you may have other rights which vary from province to province.

Sears Canada, Inc., Toronto, Ont. M5B 2B8

Page 3

Model No. 919.722020

Bore 1.875"

Stroke 1.25"

Voltage/Hertz/Phase 120V/60/1

Minimum Branch Circuit Requirement 15 amps

Fuse Type Time Delay

Air Tank Capacity (gallons) 1.5

Approx. Cut-In 120

Approx. Cut-out 150

SCFM @ 40 psig 3.0

SCFM @ 90 psig 2.0

3- ENG

D29495

SPECIFICATION CHART

SAFETY GUIDELINES - DEFINITIONS

Indicates an

imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially

hazardous situation

which, if not avoided, could

result in

death or serious injury.

Indicates a potentially

hazardous situation

which, if not avoided, may

result in

minor or moderate injury.

Used without the

safety alert symbol

indicates a potentially hazardous

situation which, if not avoided, may

result in pr

operty damage.

This manual contains information that is important for you to know and understand. This information

relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you

recognize this information, we use the symbols below. Please read the manual and pay attention to

these sections.

IMPORTANT SAFETY INSTRUCTIONS

Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known (to the State of California) to

cause cancer, birth defects or other reproductive harm. Some example of these chemicals are:

●

lead from lead-based paints

●

crystalline silica from bricks and cement and other masonry products

●

arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, always wear MSHA/NIOSH approved, properly fitting face mask or respirator when using

such tools.

When using air tools, basic safety precautions should always be followed to reduce the risk of of

personal injury.

Page 4

4- ENG

D29495

IMPORTANT SAFETY INSTRUCTIONS

Save these instructions

Improper operation or maintenance of this product could result in serious injury and

property damage. Read and understand all warnings and operation instructions before

using this equipment.

HAZARD

WARNING: Risk of explosion or fire

How To Prevent It

What Could Happen

It is normal for electrical contacts

within the motor and pressure switch to

spark.

If electrical sparks from compressor

come into contact with flammable

vapors, they may ignite, causing fire or

explosion.

Restricting any of the compressor

ventilation openings will cause serious

overheating and could cause fire.

Unattended operation of this product

could result in personal injury or

property damage. To reduce the risk of

fire, do not allow the compressor to

operate unattended.

Always operate the compressor in a well

ventilated area free of combustible

materials, gasoline, or solvent vapors.

If spraying flammable materials, locate

compressor at least 20 feet away from

spray area. An additional length of hose

may be required.

Store flammable materials in a secure

location away from compressor.

Never place objects against or on top

of compressor. Operate compressor in

an open area at least 12 inches away

from any wall or obstruction that would

restrict the flow of fresh air to the

ventilation openings.

Operate compressor in a clean, dry well

ventilated area. Do not operate unit

indoors or in any confined area.

Always remain in attendance with the

product when it is operating.

Always disconnect electrical power by

placing the Off/Auto-On to the OFF

position and drain tank daily or after

each use.

Page 5

WARNING: Risk of Bursting

Air Tank: The following conditions could lead to a weakening of the tank, and result

in a violent tank explosion and could cause property damage or serious injury.

How To Prevent It

What Could Happen

WARNING: Risk from Flying Objects

The compressed air stream can cause

soft tissue damage to exposed skin

and can propel dirt, chips, loose

particles, and small objects at high

speed, resulting in property damage or

personal injury.

Always wear ANSI Z87.1 approved safety

glasses with side shields when using the

compressor.

Never point any nozzle or sprayer

toward any part of the body or at other

people or animals.

Always turn the compressor off and

bleed pressure from the air hose and tank

before attempting maintenance, attaching

tools or accessories.

HAZARD

HAZARD

Drain tank daily or after each use. If

tank develops a leak, replace it

immediately with a new tank or replace

the entire compressor.

Failure to properly drain condensed

water from tank, causing rust and

thinning of the steel tank.

Modifications or attempted repairs to

the tank.

Unauthorized modifications to the

unloader valve, safety valve, or any

other components which control tank

pressure.

Never drill into, weld, or make any

modifications to the tank or its

attachments.

Excessive vibration can weaken the

air tank and cause rupture or

explosion

The tank is designed to withstand specific

operating pressures. Never make

adjustments or parts substitutions to

alter the factory set operating

pressures.

For essential control of air pressure, you

must install a pressure regulator and

pressure gauge to the air outlet (if not

equipped) of your compressor. Follow the

equipment manufacturers

recommendation and never exceed the

maximum allowable pressure rating of

attachments.

A

TTACHMENTS & ACCESSORIES:

Exceeding the pressure rating of air

tools, spray guns, air operated

accessories, tires, and other inflatables

can cause them to explode or fly apart,

and could result in serious injury.

How To Prevent It

What Could Happen

5- ENG

D29495

Page 6

6- ENG

D29495D29495

WARNING: Risk to Breathing

WARNING: Risk of Electrical Shock

HAZARD

HAZARD

Your air compressor is powered by

electricity. Like any other electrically

powered device, If it is not used

properly it may cause electric shock.

Repairs attempted by unqualified

personnel can result in serious injury

or death by electrocution.

Electrical Grounding: Failure to provide

adequate grounding to this product

could result in serious injury or death

from electrocution.

See grounding instructions.

Never operate the compressor outdoors

when it is raining or in wet conditions.

Never operate compressor with

protective covers removed or damaged.

Any electrical wiring or repairs required

on this product should be performed by

authorized service center personnel in

accordance with national and local

electrical codes.

Make certain that the electrical circuit to

which the compressor is connected

provides proper electrical grounding,

correct voltage and adequate fuse

protection.

The compressed air directly from your

compressor is not safe for breathing.

The air stream may contain carbon

monoxide, toxic vapors, or solid

particles from the tank. Breathing these

contaminants can cause serious injury

or death.

Sprayed materials such as paint, paint

solvents, paint remover, insecticides,

weed killers, may contain harmful

vapors and poisons.

Air obtained directly from the compressor

should never be used to supply air for

human consumption. In order to use air

produced by this compressor for

breathing, suitable filters and in-line

safety equipment must be properly

installed. In-line filters and safety

equipment used in conjunction with the

compressor must be capable of treating

air to all applicable local and federal

codes prior to human consumption.

Work in an area with good cross

ventilation. Read and follow the safety

instructions provided on the label or

safety data sheets for the materials you

are spraying. Use a NIOSH/ MSHA

approved respirator designed for use with

your specific application.

How To Prevent It

What Could Happen

How To Prevent It

What Could Happen

Page 7

7- ENG

D29495

WARNING: Risk of Burns

Touching exposed metal such as the

compressor head or outlet tubes, can

result in serious burns.

Never touch any exposed metal parts

on compressor during or immediately

after operation. Compressor will remain

hot for several minutes after operation.

Do not reach around protective shrouds

or attempt maintenance until unit has

been allowed to cool.

WARNING: Risk from Moving Parts

Never operate the compressor with

guards or covers which are damaged or

removed.

Moving parts such as the pulley, flywheel,

and belt can cause serious injury if they

come into contact with you or your

clothing.

WARNING: Risk of Falling

A portable compressor can fall from a

table, workbench, or roof causing

damage to the compressor and could

result in serious injury or death to the

operator.

Always operate compressor in a stable

secure position to prevent accidental

movement of the unit. Never operate

compressor on a roof or other elevated

position. Use additional air hose to

reach high locations.

HAZARD

HAZARD

HAZARD

Any repairs required on this product

should be performed by authorized

service center personnel.

Attempting to operate compressor with

damaged or missing parts or attempting

to repair compressor with protective

shrouds removed can expose you to

moving parts and can result in serious

injury.

How To Prevent It

What Could Happen

How To Prevent It

What Could Happen

How To Prevent It

What Could Happen

Page 8

8- ENG

D29495D29495

Review and understand all instructions

and warnings in this manual.

Become familiar with the operation and

controls of the air compressor.

Keep operating area clear of all persons,

pets, and obstacles.

Keep children away from the air

compressor at all times.

Do not operate the product when

fatigued or under the influence of

alcohol or drugs. Stay alert at all times.

Never defeat the safety features of this

product.

Equip area of operation with a fire

extinguisher.

Do not operate machine with missing,

broken, or unauthorized parts.

WARNING: Risk of Unsafe Operation

Unsafe operation of your air compressor

could lead to serious injury or death to

you or others.

HAZARD

SAVE THESE INSTRUCTIONS

How To Prevent It

What Could Happen

Page 9

9- ENG

D29495

GLOSSARY

ACCESSORIES

Become familiar with these terms

before operating the unit.

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per

minute; a unit of measure of air

delivery.

PSIG: Pounds per square inch

gauge; a unit of measure of pressure.

Code Certification: Products that

bear one or more of the following

marks: UL, CUL, ETL, CETL, have

been evaluated by OSHA certified

independent safety laboratories and

meet the applicable Underwriters

Laboratories Standards for Safety.

Cut-In Pressure: While the motor is

off, air tank pressure drops as you

continue to use your accessory.

Accessories

• In Line Filter

• In Line Oiler

• In Line Regulator

• Tire Air Chuck

• Quick Connector Sets

(various sizes)

• Air Hose: 1/4", 3/8" OR 1/2" I.D. in

various lengths

Tools

• Inflator/Blow Gun

• Air Brush

• Multi-Purpose Spray Gun

• Touch Up Spray Gun

• Brad Nailer

• Stapler

• Finish Nailer

• Grease Gun

• Engine Cleaning Gun

• Liquid Siphon Transfer

• Caulk Gun

• Smaller Impact Wrenches

• Smaller Ratchet Wrenches

• Mini-Rotary Grinder/Polisher/Cutter

This unit is capable of powering the following Accessories. The accessories are

available through the current Power and Hand Tool Catalog or full-line Sears stores.

When the tank pressure drops to a

certain low level the motor will restart

automatically. The low pressure at

which the motor automatically

restarts is called "cut-in" pressure.

Cut-Out Pressure: When an air

compressor is turned on and begins

to run, air pressure in the air tank

begins to build. It builds to a certain

high pressure before the motor

automatically shuts off, protecting

your air tank from pressure higher

than its capacity. The high pressure

at which the motor shuts off is called

"cut-out" pressure.

Branch Circuit: Circuit carrying

electricity from electrical panel to

outlet.

Page 10

10- ENG

D29495

ASSEMBLY

Assemble Hose

1. Assemble hose to air outlet.

IMPORTANT: The hex fitting on

the air outlet MUST be held in

place with a wrench when

tightening hose onto air outlet.

Tools Required for Assembly

1 - 9/16" open end wrench or

adjustable wrench

1 - adjustable wrench

Unpacking

1. Remove unit from carton and

discard all packaging. NOTE:

Save all parts bags.

Contents of Carton

1 - Air Compressor

1 - Air Hose

1 - Inflator Accessory Kit

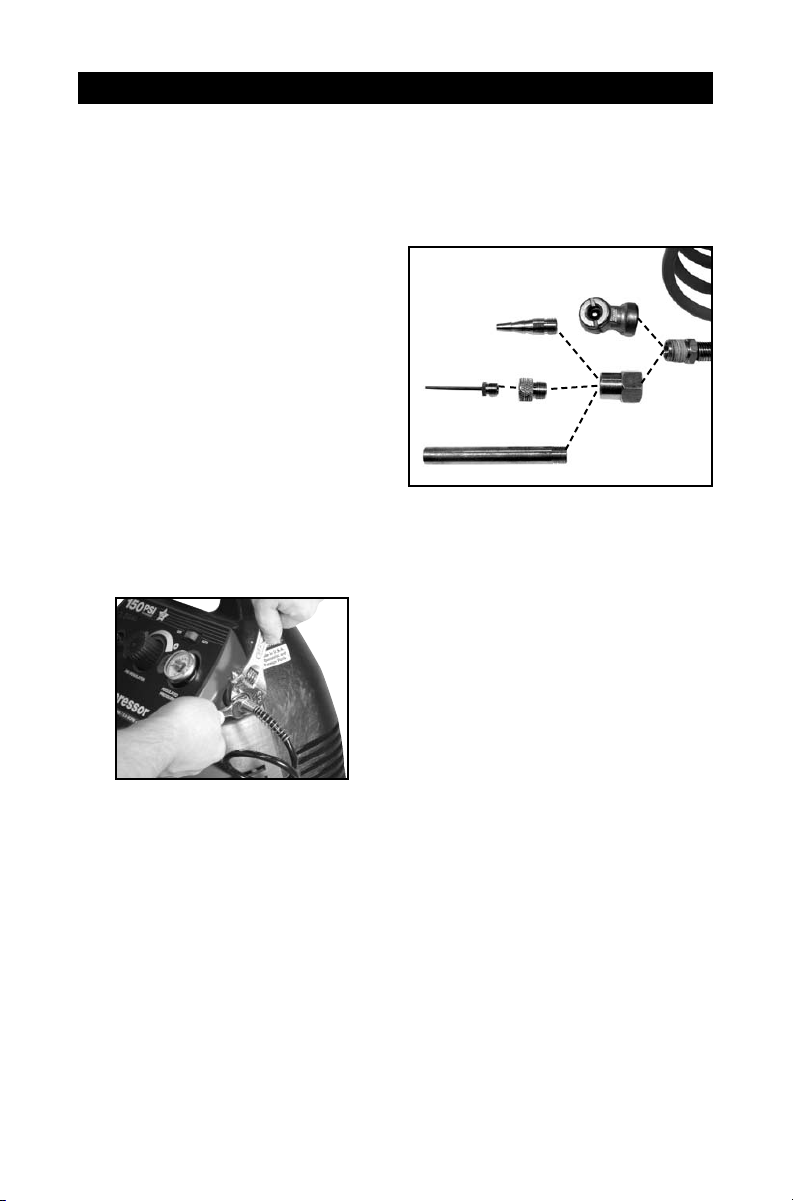

Assemble Other Accessories

1. Attach the hose adapter to hose.

2. Choose the needed accessory.

Attach the tapered nozzle,

extension tube, or blow gun

adapter to the hose adapter. The

inflating needle attaches to the

blow gun adapter. NOTE: The

tapered nozzle, extension tube,

and blow gun adapter can also

be attached to a blow gun (sold

separately, not shown).

Assemble Accessories

Choose the accessory needed.

Assemble Female Tire Chuck

1. Assemble female tire chuck to

hose and tighten securely with

wrenches.

Female Tire

Chuck

Hose

Adapter

Hose

End

Ta pe r ed

Nozzle

Blow Gun

Adapter

Inflating

Needle

Extension Tube

Page 11

11- ENG

D29495

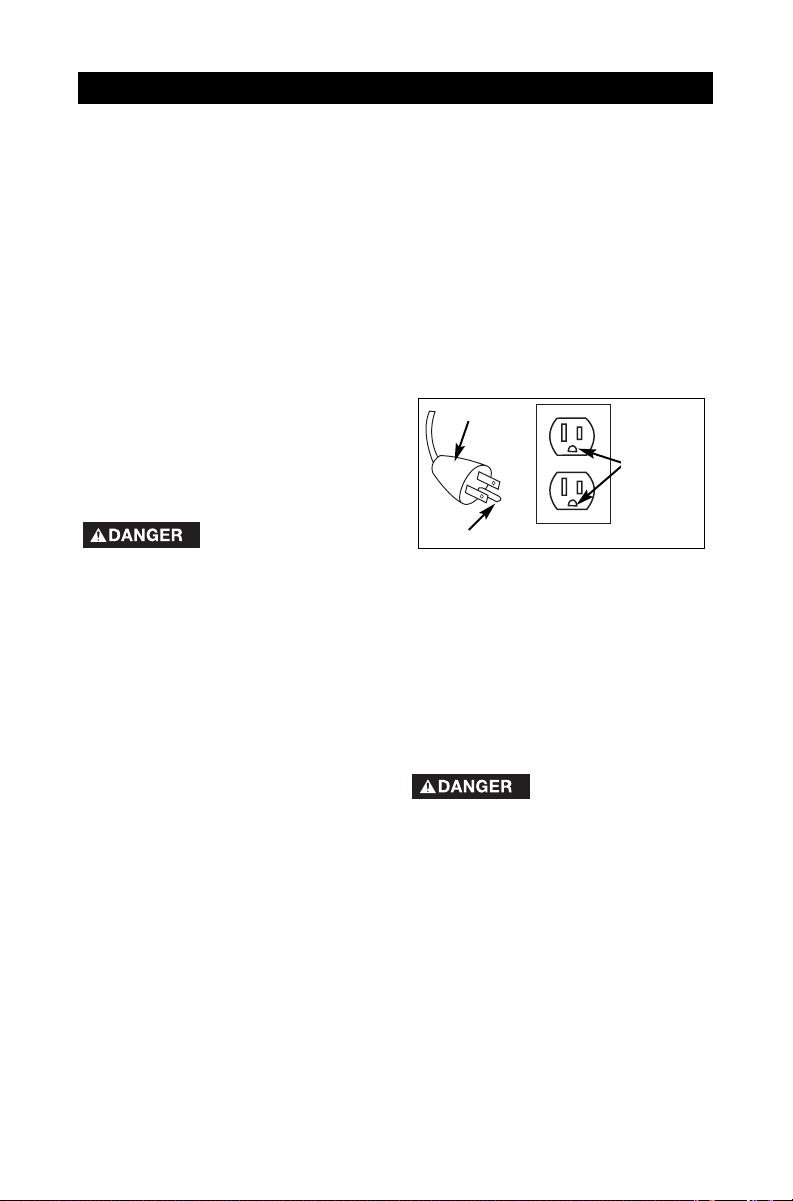

1. The cord set and plug with this

unit contains a grounding pin.

This plug MUST be used with a

grounded outlet.

IMPORTANT: The outlet being used

must be installed and grounded in

accordance with all local codes and

ordinances.

2. Make sure the outlet being used

has the same configuration as

the grounded plug. DO NOT

USE AN ADAPTER. See

illustration.

3. Inspect the plug and cord before

each use. Do not use if there are

signs of damage.

4. If these grounding instructions

are not completely understood,

or if in doubt as to whether the

compressor is properly

grounded, have the installation

checked by a qualified

electrician.

Risk of Electrical

Shock. IMPROPER

GROUNDING CAN RESULT IN

ELECTRICAL SHOCK.

Do not modify the plug provided. If

it does not fit the available outlet, a

correct outlet should be installed

by a qualified electrician.

Repairs to the cord set or plug

MUST be made by a qualified

electrician.

INSTALLATION

GROUNDING INSTRUCTIONS

Risk of Electrical

Shock. In the event

of a short circuit, grounding

reduces the risk of shock by

providing an escape wire for the

electric current. This air

compressor must be properly

grounded.

The portable air compressor is

equipped with a cord having a

grounding wire with an appropriate

grounding plug (see following

illustrations). The plug must be used

with an outlet that has been installed

and grounded in accordance with all

local codes and ordinances.

HOW TO SET UP YOUR

UNIT

Location of the Air Compressor

Locate the air compressor in a clean,

dry and well ventilated area. The air

compressor should be located at

least 12" away from the wall or other

obstructions that will restrict the flow

of air. The air compressor pump and

shroud are designed to allow for

proper cooling. The ventilation

openings on the compressor are

necessary to maintain proper

operating temperature. Do not place

rags or other containers on or near

these openings.

Grounding Pin

Grounded

Outlets

Plug

Page 12

12- ENG

D29495

Extension Cords

If an extension cord must be used, be

sure it is:

• a 3-wire extension cord that has

a 3-blade grounding plug, and a

3-slot receptacle that will accept

the plug on the product

• in good condition

• no longer than 50 feet

• 16 gauge (AWG) or larger. (Wire

size increases as gauge number

decreases. 14, 12, 10, and 8

AWG may also be used.

Voltage and Circuit Protection

Refer to the specification chart for the

voltage and minimum branch circuit

requirements.

Risk of Unsafe

Operation. Certain

air compressors can be operated

on a 15 amp circuit if the following

conditions are met.

1. Voltage supply to circuit must

comply with the National

Electrical Code.

2. Circuit is not used to supply any

other electrical needs.

3. Extension cords comply with

specifications.

4. Circuit is equipped with a 15

amp circuit breaker or 15 amp

time delay fuse. NOTE: If

compressor is connected to a

circuit protected by fuses, use

only time delay fuses. Time delay

fuses should be marked "D" in

Canada and "T" in the US.

If any of the above conditions cannot

be met, or if operation of the

compressor repeatedly causes

interruption of the power, it may be

necessary to operate it from a 20

amp circuit. It is not necessary to

change the cord set.

Page 13

13- ENG

D29495

safety valve will protect against high

pressure by "popping out" at its

factory set pressure (slightly higher

than the pressure switch "cut-out"

setting).

Outlet Pressure Gauge: The outlet

pressure gauge indicates the air

pressure available at the outlet side

of the regulator. This pressure is

controlled by the regulator and is

always less than or equal to the tank

pressure.

Regulator: Controls the air pressure

shown on the outlet pressure gauge.

Turn knob clockwise to increase

pressure and counterclockwise to

decrease pressure.

Description of Operation

Become familiar with these controls

before operating the unit.

Off/Auto Switch: Turn this switch

to"Auto" to provide automatic power

to the pressure switch and "OFF" to

shut off power at the end of each use.

Pressure Switch (not shown): The

pressure switch automatically starts

the motor when the air tank pressure

drops below the factory set "cut-in"

pressure. It stops the motor when the

air tank pressure reaches the factory

set "cut-out" pressure.

Safety Valve: If the pressure switch

does not shut off the air compressor

at its "cut-out" pressure setting, the

OPERATION

Know Your Air Compressor

READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR UNIT. Compare the illustrations with your unit to familiarize yourself with the

location of various controls and adjustments. Save this manual for future reference.

Air

Outlet

Air

Hose

Safety Valve

Regulator

Outlet

Pressure Gauge

Female

Air Chuck

Drain Valve,

not shown

Off/Auto

Switch

Power Cord

Hose Adapter

Ta pe r ed

Inflator

Blow Gun

Adapter

Extension

Tube

Inflating

Needle

Page 14

14- ENG

D29495

Female Tire Chuck: Attaches to the

hose end to be used to inflate tires.

Note: To ensure correct tire pressure

use a tire pressure gauge.

Hose Adapter: Attaches to hose end

to allow the use of accessories.

Blow Gun Adapter: Attaches to hose

end or blow gun (sold separately, not

shown) to allow the inflating needle

to be used.

Inflating needle: Attaches to blow

gun adapter to be used to inflate

sport balls.

Tapered Inflator: Attaches to hose

adapter or blow gun (sold separately)

to be used to inflate toy inflatables/air

mattresses.

Extension Tube: Attaches to hose

adapter or blow gun (sold separately)

to be used for air blowing, drying,

and for specialized inflating.

Drain Valve (not shown): The drain

valve is located at the base of the air

tank and is used to drain

condensation at the end of each use.

Cooling System (not shown): This

compressor contains an advanced

design cooling system. At the heart

of this cooling system is an

engineered fan. It is perfectly normal

for this fan to blow air through the

vent holes in large amounts. You

know that the cooling system is

working when air is being expelled.

Air Compressor Pump (not shown):

Compresses air into the air tank.

Working air is not available until the

compressor has raised the air tank

pressure above that required at the

air outlet.

Check Valve (not shown): When the

air compressor is operating, the

check valve is "open", allowing

compressed air to enter the air tank.

When the air compressor reaches

"cut-out" pressure, the check valve

"closes", allowing air pressure to

remain inside the air tank.

How to Use Your Unit

How to Stop:

1. Set the Off/Auto switch to "OFF".

Before First Start-up

Break-in Procedure

Risk of Unsafe

Operation. Serious

damage may result if the following

break-in instructions are not

closely followed.

This procedure is required before the

air compressor is put into service.

1. Make sure the Off/Auto switch is

in the "OFF" position.

2. Turn the regulator knob

counterclockwise until it stops.

3.

Plug the power cord into the

correct branch circuit receptacle.

(Refer to Voltage and Circuit

Protection paragraph in the

Installation section of this

manual.)

4. Open the drain valve fully

(counterclockwise) to permit air

to escape and prevent air

pressure build up in the air tank

during the break-in period.

5. Move the Off/Auto switch to

"AUTO" position. The

compressor will start.

6. Run the compressor for 15

minutes. Make sure the drain

valve is open and there is

minimal air pressure build-up in

tank.

7. After 15 minutes, close the drain

valve (clockwise). The air receiver

will fill to "cut-out" pressure and

the motor will stop.

The compressor is now ready for use.

Page 15

15- ENG

D29495

How to Start:

1. Turn the Off/Auto switch to

"AUTO" and allow tank pressure

to build. Motor will stop when

tank pressure reaches "cut-out"

pressure.

2. Turn the regulator knob

clockwise until desired pressure

is reached.

3. The compressor is ready for use.

Before Each Start-Up:

1. Place Off/Auto switch to "OFF"

and close air regulator.

2. Turn the regulator knob

counterclockwise until it stops.

3. Attach hose and accessories.

Risk of Bursting.

Too much air

pressure causes a hazardous risk

of bursting. Check the

manufacturer’s maximum pressure

rating for air tools and accessories.

The regulator outlet pressure must

never exceed the maximum

pressure rating.

Page 16

4. Place unit on blocks to lift unit off

of ground.

5. Place suitable container under

unit to catch water.

6. Slightly tilt unit and turn drain

valve counter clockwise to open.

7. Place unit back onto blocks to

drain water from air tank.

Risk of Bursting.

Water will

condense in the air tank. If not

drained, water will corrode and

weaken the air tank causing a risk

of air tank rupture.

8. After the water has been drained,

close the drain valve (clockwise).

The air compressor can now be

stored.

16- ENG

D29495

MAINTENANCE

Customer Responsibilities

Daily or

after

each

use

Before

each

use

●

●

Check Safety Valve

Drain Tank

NOTE: See "Operation" section for

the location of controls.

Risk of Unsafe

Operation. Unit

cycles automatically when power is

on. When performing maintenance,

you may be exposed to voltage

sources, compressed air, or

moving parts. Personal injuries can

occur. Before performing any

maintenance or repair, disconnect

power source from the compressor

and bleed off all air pressure.

To Check Safety Valve

Risk of Bursting. If

the safety valve

does not work properly, overpressurization may occur, causing

air tank rupture or an explosion.

1. Before starting compressor, pull

the ring on the safety valve to

make sure that the safety valve

operates freely. If the valve is

stuck or does not operate

smoothly, contact a trained

service technician.

To Drain Tank

NOTICE: Allow unit to cool before

draining tank, drain valve becomes

hot during operation.

1. Set the Off/Auto switch to "OFF".

2. Turn the regulator knob counter-

clockwise to set the outlet

pressure to zero.

3. Pull and hold ring on safety valve

allowing air to bleed from the

tank until air pressure is

minimized.

Page 17

17- ENG

D29495

STORAGE

Before you store the air compressor,

make sure you do the following:

1. Drain tank, see "To Drain Tank"

paragraph in the "Maintenance"

section of this manual for the

correct procedure.

Risk of Bursting.

Water will

condense in the air tank. If not

drained, water will corrode and

weaken the air tank causing a risk

of air tank rupture.

2. Store accessories in the storage

bag located on back of unit. The

storage bag has a smaller

compartment to hold smaller

accessories.

3. Wrap the electrical cord loosely

around the unit and snap it into

itself for storage.

4. Secure air hose to hose snap.

5. Store the air compressor in a

clean and dry location.

Smaller

Compartment

Page 18

18- ENG

D29495

It is normal for "some"

pressure drop to occur.

If there is an excessive

amount of pressure drop

when the accessory is used,

adjust the regulator following

the instructions in the

"Description of Operation"

paragraph in the "Operation

Section.

NOTE: Adjust the regulated

pressure under flow

conditions (while accessory

is being used).

Pressure reading

on the regulated

pressure gauge

drops when an

accessory is

used.

TROUBLESHOOTING

Risk of Unsafe Operation. Performing repairs may expose

voltage sources, moving parts or compressed air sources.

Personal injury may occur. Prior to attempting any repairs, unplug the air

compressor and bleed off all air tank air pressure.

PROBLEM

CAUSE

CORRECTION

Pressure switch does not

shut off motor when

compressor reaches "cutout" pressure.

Pressure switch "cut-out"

too high.

Move Off/Auto switch to the

"OFF" position, if the unit

does not shut off contact a

Trained Service Technician.

Contact a Trained Service

Technician.

Excessive tank

pressure - safety

valve pops off.

Tube fittings are not tight

enough.

Tighten fittings where air can

be heard escaping. Check

any exposed fittings with

soapy water solution. Do Not

Overtighten.

Air leaks at

fittings.

Possible defect in safety

valve.

Operate safety valve

manually by pulling on ring.

If valve still leaks, Contact a

Trained Service Technician.

Air leak from

safety valve.

Possible defect in safety

valve.

Knocking Noise.

Operate safety valve

manually by pulling on ring.

If valve still leaks, Contact a

Trained Service Technician.

Apply sealant tape to threads

of exposed fittings.

Page 19

19- ENG

D29495

PROBLEM

CAUSE

CORRECTION

Compressor is

not supplying

enough air to

operate

accessories.

Prolonged excessive use of

air.

Compressor is not large

enough for air requirement.

Hole in hose.

Air leaks.

Decrease amount of air

usage.

Check the accessory air

requirement. If it is higher

than the SCFM or pressure

supplied by your air

compressor, you need a

larger compressor.

Check and replace if

required.

Tighten any exposed fittings.

Check fuse box for blown

fuse and replace as

necessary. Reset circuit

breaker. Do not use a fuse or

circuit breaker with higher

rating than that specified for

your particular branch circuit.

Check for proper fuse. You

should use a time delay fuse.

Check for low voltage

problem.

Check the extension cord.

Disconnect the other

electrical appliances from

circuit or operate the

compressor on its own

branch circuit.

Have checked by a Trained

Service Technician.

Fuse blown, circuit breaker

tripped.

Extension cord is wrong

length or gauge.

Loose electrical

connections.

Faulty motor.

Check the extension cord.

Check wiring connection

inside terminal box.

Motor will not

run.

Page 20

21- FR

D29495

GARANTIE COMPLÈTE D'UN AN SUR LES COMPRESSEURS D'AIR

Si ce compresseur d'air ne fonctionne pas à cause d'un défaut de matériau ou de

fabrication dans une période d'un an à compter de la date d'achat, RETOURNEZ-LE

AU CENTRE DE SERVICE APRÈS-VENTE SEARS LE PLUS PROCHE AU CANADA ET

SEARS LE RÉPARERA SANS FRAIS.

Si ce compresseur d'air est utilisé à des fins commerciales ou comme appareil de

location, cette garantie s'applique pour une période de quatre-vingt-dix (90) jours à

compter de la date d'achat.

Cette garantie sur le compresseur d'air de Craftsman vous donne des droits

particuliers. Il se peut que vous ayez d'autres droits qui varient d'une province à l'autre.

Sears Canada, Inc., Toronto, Ont. M5B 2B8

GARANTIE

GARANTIE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

TABLEAU DES SPÉCIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

MESURES DE SÉCURITÉ - DÉFINITIONS . . . . . . . . . . . . . . . . . . . . . .22

CONSIGNES DE SÉCURITÉ IMPORTANTES . . . . . . . . . . . . . . . . .22-27

LEXIQUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

ACCESSOIRES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

ASSEMBLAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30-31

UTILISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32-34

ENTRETIEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

RANGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

DÉPANNAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37-38

PIÈCES DE RECHANGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

COMMANDE DE PIÈCES DE RECHANGE . . . . . . . . .couverture arrière

TABLE DES MATIÈRES

Page 21

22- FR

D29495

CONSIGNES DE SÉCURITÉ IMPORTANTES

La poussière produite par le ponçage électrique, le sciage, le

meulage, le perçage et autres activités de construction peut

contenir des produits chimiques qui sont reconnus, par l'état de la Californie, de causer

le cancer, les anomalies congénitales ou autres maux de reproduction. Ces produits

chimiques comprennent, entre autres :

●●

le plomb provenant des peintures à base de plomb

●●

la silice cristalline provenant de briques, de béton ou d'autres produits de

maçonnerie

●●

l'arsenic et le chrome provenant du bois de charpente traité chimiquement

Le risque d'exposition à ces produits dépend de la fréquence d'exécution de ce genre de

travaux. Afin de réduire l'exposition à ces produits chimiques, travaillez dans un endroit

bien aéré et utilisez de l'équipement de sécurité approuvé, portez toujours un masque

facial ou respirateur homologué MSHA/NIOSH bien ajusté lorsque vous utilisez de tels

outils.

Lorsque vous utilisez un outil pneumatique, il faut toujours suivre les mesures de sécurité

de base afin de réduire le risque de blessures corporelles.

MESURES DE SÉCURITÉ - DÉFINITIONS

Indique un danger

imminent qui, s'il n'est

pas évité, causera de graves blessures

ou la mort.

Indique la

possibilité

d’un danger qui, s’il n’est pas évité,

pourrait causer de graves blessures ou

la mort.

Ce guide contient des renseignements importants que vous devez bien saisir. Cette

information porte sur VOTRE SÉCURITÉ et sur LA PRÉVENTION DE PROBLÈMES

D'ÉQUIPEMENT. Afin de vous aider à identifier cette information, nous avons utilisé les

symboles ci-dessous. Veuillez lire attentivement ce guide en portant une attention

particulière à ces symboles.

Indique la

possibilité d'un

danger qui, s'il n'est pas évité, peut

causer des blessures mineures ou

moyennes.

Sans le symbole

d’alerte. Indique la

possibilité d’un danger qui, s’il n’est pas

évité, peut

causer des dommages à la

propriété.

TABLEAU DES SPÉCIFICATIONS

Modèle n

o

919.722020

Alésage 1,875 po (47,6 mm)

Course 1,25 po (31,8 mm)

Tension/ Hertz/ Phase 120

Exigence minimale du circuit de dérivation 15 A

Genre de fusibles À retardement

Capacité du réservoir d'air 5,7 litres (1,5 gal.)

Pression l'amorçage approx. 120

Pression de rupture approx. 150

pi³/min standard (SCFM) à 40 psi 3,0

pi³/min standard (SCFM) à 90 psi 2,0

Page 22

23- FR

D29495

AVERTISSEMENT : Risque d'explosion ou d'incendie

Prévention

Risque

DANGER

Les étincelles qui proviennent des contacts

électriques du moteur et du manostat sont

considérées normales.

Si des étincelles électriques du compresseur

entrent en contact avec des vapeurs

inflammables, elles peuvent s'enflammer,

provoquant un incendie ou une explosion.

Toute obstruction des orifices d'aération du

compresseur entraînera une surchauffe

dangereuse et risque de causer un incendie.

Si cet appareil fonctionne sans supervision,

cela risque de causer des blessures graves

ou des dommages à la propriété. Pour

réduire le risque d'incendie, ne jamais laisser

le compresseur d'air fonctionner sans

supervision.

Toujours utiliser le compresseur dans un

endroit bien aéré, loin de toute matière

combustible et des vapeurs d'essence ou de

solvants.

Si des matières inflammables doivent être

vaporisées, situer le compresseur à une

distance d'au moins 6 m (20 pieds) de la

zone de vaporisation. Il peut s'avérer

nécessaire d'utiliser un boyau supplémentaire.

Entreposer les matières inflammables dans

un endroit sécuritaire, loin du compresseur.

Ne jamais placer des objets contre ou sur le

compresseur. Utiliser le compresseur dans un

endroit ouvert, à au moins 30 cm (12 pouces)

de tout mur ou obstruction qui réduit le débit

d'air frais vers les orifices d'aération.

Utiliser le compresseur dans un endroit propre,

sec et bien aéré. Ne pas utiliser l'appareil à

l'intérieur ou dans un endroit clos.

Toujours rester à proximité de l'appareil

lorsqu'il est en fonction.

Toujours débrancher l'alimentation électrique

en plaçant le commutateur « Arrêt/marche

auto » (« Off/Auto-On ») en position d'arrêt

(« Off ») et vidanger le réservoir chaque jour

ou après chaque usage.

Conserver ces directives

Un emploi ou un entretien non appropriés de ce produit peut causer des blessures

graves et des dommages à la propriété. Lire attentivement tous les avertissements et les

directives d'utilisation avant d'utiliser cet appareil.

CONSIGNES DE SÉCURITÉ IMPORTANTES

Page 23

24- FR

D29495

AVERTISSEMENT : Risque d'éclatement

Réservoir d'air : Les conditions suivantes peuvent affaiblir les parois du réservoir et provoquer

une explosion violente du réservoir qui risque de causer des dommages à la propriété ou des

blessures graves.

Le défaut de vidanger de façon appropriée

l'eau condensée dans le réservoir risque de

causer la rouille et l'amincissement des parois

en acier du réservoir.

Des modifications ou tentatives de réparation

faites sur le réservoir.

Des modifications non autorisées apportées à

la soupape de décharge, à la soupape de

sûreté ou à toute autre composante qui

contrôle la pression du réservoir.

Des vibrations excessives peuvent affaiblir le

réservoir et causer une rupture ou une

explosion.

FIXA

TIONS ET ACCESSOIRES :

Le fait d'excéder la pression nominale des

outils pneumatiques, pistolets vaporisateurs,

accessoires pneumatiques, pneus et autres

objets gonflables risque de provoquer

l'explosion de ces derniers et la projection de

pièces, ce qui risque de causer de graves

blessures.

AVERTISSEMENT : Risque de projection d'objets

Le jet d'air comprimé peut causer des

lésions aux tissus de la peau exposée et peut

projeter de la saleté, des copeaux, des

particules libres et de petits objets à haute

vitesse, ce qui risque de causer des dommages

à la propriété ou des blessures.

Porter toujours des lunettes de protection

homologuées ANSI Z87.1 avec des écrans

latéraux lors de l'utilisation du compresseur.

Ne jamais diriger la buse ou le vaporisateur

vers soi, vers d'autres personnes ou vers des

animaux.

Toujours mettre le compresseur hors fonction

et purger la pression du boyau d'air et du

réservoir avant d'entamer l'entretien ou

d'attacher des outils ou accessoires.

Prévention

Risque

Prévention

Risque

DANGER

DANGER

Purger le réservoir quotidiennement ou après

chaque utilisation. Si le réservoir accuse une

fuite, le remplacer immédiatement par un nouveau

réservoir ou remplacer le compresseur au

complet.

Ne jamais perforer avec une perceuse, souder

ou faire une modification quelconque au

réservoir ou à ses accessoires.

Le réservoir est conçu pour subir des pressions

de service particulières. Ne jamais effectuer

des réglages ni substituer des pièces pour

modifier les pressions de service établies à

l'usine.

Pour le contrôle essentiel de la pression d'air, il

faut poser un régulateur de pression et un

manomètre à la sortie d'air du compresseur

« s'ils ne sont pas déjà posés ». Suivre les

recommandations du fabricant de l'équipement

et ne jamais excéder la valeur nominale de

pression spécifiée des accessoires.

Page 24

25- FR

D29495

DANGER

AVERTISSEMENT : Risque de choc électrique

Ne jamais faire fonctionner le compresseur à

l'extérieur lorsqu'il pleut ou dans des

conditions humides.

Ne jamais faire fonctionner le compresseur

sans les couvercles de protection ou lorsque

ceux-ci sont endommagés.

Tout câblage électrique ou toute réparation

requis sur cet appareil devrait être effectué par

le personnel d'un centre de service aprèsvente autorisé, conformément aux codes

électriques nationaux et locaux.

S'assurer que le circuit électrique alimentant

le compresseur fournit une mise à la terre

électrique appropriée, une tension appropriée

et une protection adéquate par fusibles.

Votre compresseur d'air est alimenté par

électricité. Comme avec tous les appareils

électriques, si l'appareil n'est pas utilisé de

façon appropriée, il peut causer des chocs

électriques.

Toute réparation effectuée par une personne

non qualifiée peut entraîner des blessures

graves ou la mort par électrocution.

Mise à la terre : Le défaut d'établir une mise à

la terre appropriée pour cet appareil peut

entraîner des blessures graves ou la mort

par électrocution. Voir les directives de mise à

la terre.

Prévention

Risque

Prévention

Risque

L'air obtenu directement du compresseur ne

devrait jamais être utilisé comme source d'air

pour les être humains. Si l'air produit par ce

compresseur sera utilisé pour la respiration, il

faut installer des filtres appropriés ainsi que

du matériel de sécurité. Les filtres en ligne et

le matériel de sécurité utilisés avec le

compresseur doivent être dans la mesure de

traiter l'air de façon à ce qu'il réponde à

toutes les normes nationales et locales

applicables avant d'être utilisé pour les êtres

humains.

L'air comprimé de votre compresseur d'air

n'est pas sécuritaire pour l'inhalation. Le jet

d'air peut contenir du monoxyde de

carbone, des vapeurs toxiques ou des

particules solides du réservoir. L'inhalation de

ces contaminants peut causer des blessures

graves ou la mort.

Les matières vaporisées telles que la peinture,

les solvants de peinture, les décapants, les

insecticides et les herbicides contiennent des

vapeurs nocives et toxiques.

Travailler dans un endroit où il y a une bonne

ventilation transversale. Bien lire et respecter

les directives de sécurité indiquées sur

l'étiquette ou la fiche signalétique de la matière

qui est vaporisée. Porter un respirateur

homologué par le NIOSH/MSHA et conçu pour

l'application en question.

DANGER

AVERTISSEMENT : Risque par inhalation

Page 25

26- FR

D29495

AVERTISSEMENT : Risque de brûlures

Le fait de toucher aux surfaces de métal

exposées telles que la tête du compresseur ou

les tubes de sortie peut causer de graves

brûlures à la peau.

Ne jamais toucher aux pièces de métal

exposées du compresseur durant ou

immédiatement après le fonctionnement. Le

compresseur demeure chaud pendant

plusieurs minutes après le fonctionnement.

Ne pas tenter d'atteindre les composantes

derrière les gardes de protection et ne pas

effectuer de l'entretien avant d'avoir laissé

refroidir l'appareil.

AVERTISSEMENT : Risque relié aux pièces mobiles

Ne jamais faire fonctionner le compresseur

sans les gardes ou les couvercles ou lorsque

ceux-ci sont endommagés.

Toute réparation requise sur cet appareil devrait

être effectuée par le personnel d'un centre de

service après-vente autorisé.

Les pièces mobiles telles que la poulie, le

volant-moteur et la courroie peuvent entraîner

des blessures graves si elles entrent en

contact avec une partie du corps ou des

vêtements.

En tentant de faire fonctionner le

compresseur avec des pièces manquantes

ou endommagées, ou de réparer le

compresseur sans les gardes de protection, on

s'expose aux pièces mobiles, ce qui peut

entraîner des blessures graves.

AVERTISSEMENT : Risque de chute

Un compresseur portatif peut tomber d'une

table, d'un établi ou d'un toit. L'impact peut

causer des dommages au compresseur et

des blessures corporelles ou la mort de

l'utilisateur.

Toujours s'assurer de la stabilité du

compresseur avant de le faire fonctionner afin

de prévenir tout mouvement accidentel de

l'appareil. Ne jamais utiliser un compresseur

sur un toit ou dans une position élevée ;

utiliser plutôt un boyau d'air supplémentaire

pour atteindre les endroits élevés.

Prévention

Risque

Prévention

Risque

Prévention

Risque

DANGER

DANGER

DANGER

Page 26

27- FR

D29495

DANGER

AVERTISSEMENT : Risque d'une utilisation dangereuse

Une utilisation dangereuse de votre

compresseur d'air pourrait causer des

blessures graves ou la mort de l'utilisateur ou

d'autres personnes.

Prévention

Risque

Lire attentivement tous les instructions et les

avertissements figurant dans ce guide.

Se familiariser avec le fonctionnement et les

commandes du compresseur d'air.

Garder les personnes non-autorisées, les

animaux de compagnie et les obstacles éloignés

de l'aire de travail.

Garder les enfants éloignés du compresseur

d'air en tout temps.

Ne pas utiliser le produit lorsque vous êtes

fatigué ou sous l'influence d'alcool ou de

drogues. Rester alerte à tout moment.

Ne jamais tenter d'annuler les caractéristiques

de sécurité de ce produit.

S'assurer qu'un extincteur d'incendie est

disponible dans l'aire de travail.

Ne pas utiliser l'appareil avec des pièces

brisées, manquantes ou non autorisées.

CONSERVER CES DIRECTIVES

Page 27

28- FR

D29495

Veuillez vous familiariser avec ces termes avant

d'utiliser l'appareil.

CFM : pieds cubes par minute (pi3/min).

SCFM : pieds cubes par minute (pi

3

/min)

standard. Une unité de mesure de débit d'air.

PSIG: jauge indiquant le nombre de livres par

pouce carré (lb/po

2

). Une unité de mesure de

pression.

Codes de certification : Les produits portant

une ou plusieurs des mentions suivantes (UL,

CUL, ETL, CETL) ont été évalués par des

laboratoires indépendants de sécurité certifiés

par l'OSHA et répondent aux normes de

sécurité applicables des Underwriters

Laboratories.

Pression d'amorçage : Lorsque le moteur est

arrêté, la pression du réservoir d'air s'abaisse

tandis qu'on continue d'utiliser l'accessoire.

Quand la pression du réservoir tombe à un

certain niveau bas, le moteur se remet

LEXIQUE

automatiquement en marche. La basse

pression à laquelle le moteur se remet

automatiquement en marche s'appelle la

« pression d'amorçage ».

Pression de rupture : Lorsqu'on met un

compresseur d'air en marche et qu'il

commence à fonctionner, la pression d'air dans

le réservoir commence à s'accumuler. La

pression monte et atteint un certain niveau

élevé, avant que le moteur ne s'arrête

automatiquement, protégeant ainsi le réservoir

d'air d'un taux de pression qui excèderait sa

capacité. La haute pression à laquelle le moteur

s'arrête s'appelle la « pression de rupture ».

Circuit de dérivation : Le circuit acheminant

l'électricité du tableau électrique vers la

prise murale.

ACCESSOIRES

Cet appareil peut alimenter les accessoires suivants. Les accessoires figurent dans le Catalogue

actuel des outils électriques et manuels et sont également disponibles des magasins Sears

vendant nos gammes complètes.

Accessoires

• Filtre en ligne

• Huileur en ligne

• Régulateur en ligne

• Mandrin de gonflage pour pneus

• Jeux de raccords rapides

(dimensions diverses)

• Boyau d'air : Diamètre interne de

1/4 po, 3/8 po OU 1/2 po - longueurs

diverses

Outils

• Accessoire de gonflage/Soufflette

• Aérographe

• Pistolet de vaporisation à usages

multiples

• Pistolet de vaporisation pour retouches

• Cloueuse pour clous à tête de diamant

• Agrafeuse

• Cloueuse de finition

• Pistolet graisseur

• Pistolet de nettoyage de moteur

• Appareil de transfert de liquide par

siphonnage

• Pistolet de calfeutrage

• Clés à chocs plus petites

• Clés à cliquet plus petites

• Meuleuse/polisseuse/coupeuse rotative

miniature

Page 28

29- FR

D29495

Déballage

1. Retirez l'appareil de sa boîte et jetez

tout l'emballage. REMARQUE :

Conservez tous les sacs de pièces.

Contenu de l'emballage en carton

1 - Compresseur d'air

1 - Boyau d'air

1 - Trousse d'accessoires pour le

gonflage

Outils requis pour l'assemblage

1 - Clé ouverte de 14 mm (9/16 po) ou

clé à molette

1 - Clé à molette

Assemblage du boyau

1. Fixez le boyau à la sortie d'air.

IMPORTANT: le raccord hexagonal

de la sortie d'air doit être tenu en

place avec une clé lorsque le boyau

est serré à la sortie d'air.

Assemblage des accessoires

Choisissez les accessoires requis.

Assemblage du mandrin de

gonflage femelle

1. Fixez le mandrin de gonflage femelle

au boyau et serrez bien le tout avec

des clés.

Mandrin de

gonflage femelle

pour pneus

Adaptateur

de boyau

Extrémité

du boyau

Buse

conique

Adaptateur

de soufflette

Aiguille de

gonflage

Tube de rallonge

Assemblage des autres

accessoires

1. Attachez l'adaptateur de boyau au

boyau.

2. Choisissez l'accessoire approprié.

Attachez la buse conique, le tube de

rallonge ou l'adaptateur de soufflette

à l'adaptateur de boyau. L'aiguille de

gonflage s'attache à l'adaptateur de

soufflette. REMARQUE : La buse

conique, le tube de rallonge et

l'adaptateur de soufflette peuvent

également être attachés à une

soufflette (vendue séparément, non

illustrée).

ASSEMBLAGE

Page 29

30- FR

D29495

2. Assurez-vous que la prise de courant

utilisée a la même configuration que la

fiche de mise à la terre. NE PAS

UTILISER UN ADAPTATEUR. Voir

l'illustration.

3. Inspectez la fiche et le cordon avant

chaque utilisation. Ne pas les utiliser s'il y

a des signes de dommages.

4. Si vous ne comprenez pas tout à fait ces

directives de mise à la terre, ou s'il y a

des doutes que le compresseur soit mis

à la terre de manière appropriée, faire

vérifier l'installation par un électricien

qualifié.

Risque de choc

électrique

! UNE MISE À

LA TERRE INAPPROPRIÉE PEUT

ENTRAÎNER DES CHOCS ÉLECTRIQUES.

Ne modifiez pas la fiche fournie. Si elle ne

convient pas à la prise de courant

disponible, une prise appropriée doit être

installée par un électricien qualifié.

Toute réparation du cordon ou de la fiche

DOIT être effectuée par un électricien

qualifié

INSTALLATION

Broche de mise à la terre

Prises de

courant

mises à la

terre

Fiche

DIRECTIVES DE MISE À LA TERRE

Risque de choc

électrique

! En cas de

court-circuit, la mise à la terre réduit le

risque de choc en fournissant un fil de fuite

pour le courant électrique. Ce compresseur

d'air doit être adéquatement mis à la terre.

Ce compresseur d'air portatif est doté d'un

cordon muni d'un fil de mise à la terre et d'une

fiche appropriée de mise à la terre (voir

l'illustration ci-dessous). La fiche doit être

insérée dans une prise de courant installée et

mise à la terre conformément à tous les codes

et ordonnances locaux.

1. Le cordon fourni avec cet appareil

comprend une fiche avec broche de mise

à la terre. La fiche DOIT être insérée dans

une prise de courant mise à la terre.

IMPORTANT : La prise de courant utilisée doit

être installée et mise à la terre conformément à

tous les codes et ordonnances locaux.

MONTAGE DE L'APPAREIL

Emplacement du compresseur d'air

Le compresseur d'air doit être situé dans un

endroit propre, sec et bien aéré. Le

compresseur d'air doit être situé à une

distance d'au moins 30 cm (12 po) du mur ou

de toute autre obstruction qui pourrait nuire au

débit d'air. La pompe et la tôle de protection

du compresseur sont conçus pour permettre

un refroidissement approprié. Les ouvertures

d'aération du compresseur sont nécessaires

pour maintenir la température de

fonctionnement appropriée. Ne placez pas de

chiffons ou de contenants sur ou à proximité

de ces ouvertures.

Page 30

31- FR

D29495

Rallonges

Si une rallonge doit être utilisée, s'assurer :

• d'utiliser une rallonge à trois fils, munie

d'une fiche à trois lames avec mise à la

terre et une prise de courant à trois

fentes qui accepte la fiche de la rallonge;

• qu'elle est en bon état;

• qu'elle n'excède pas 15,2 m (50 pi);

• que les fils sont d'un calibre minimum de

16 AWG. (La grosseur du fil augmente

comme le numéro de calibre diminue).

Les fils de calibre 14, 12, 10 et 8 AWG

peuvent également être utilisés.

Protection contre la surtension et

protection du circuit

Consulter le tableau des spécifications

pour connaître les exigences minimums

concernant la tension et le circuit de

dérivation.

Risque d'une

utilisation

dangereuse. Certains modèles de

compresseur d'air peuvent fonctionner

sur un circuit de 15 ampères si les

conditions suivantes sont satisfaites :

1. la tension d'alimentation au circuit

doit être conforme au code national

d'électricité ;

2. le circuit n'est pas utilisé pour

alimenter d'autres dispositifs

électriques ;

3. les rallonges sont conformes aux

spécifications ;

4. le circuit est muni d'un coupe-circuit de

15 A ou d'un fusible à retardement de

15 A.

REMARQUE : Si un compresseur

est relié à un circuit protégé par des

fusibles, n'utilisez que des fusibles à

retardement. Les fusibles à retardement

portent un « D » au Canada et un « T »

aux États-Unis.

Si une des conditions ci-dessus ne peut

être satisfaite, ou si l'utilisation du

compresseur entraîne continuellement une

panne de courant, il sera peut être

nécessaire de brancher le compresseur

sur un circuit de 20 ampères. Il n'est pas

nécessaire de remplacer le cordon dans

un tel cas.

Page 31

32- FR

D29495

UTILISATION

Familiarisez-vous avec votre compresseur d'air

LISEZ CE GUIDE DE L'UTILISATEUR ET TOUTES LES MESURES DE SÉCURITÉ AVANT

D'UTILISER CET APPAREIL. Comparez les illustrations à votre appareil pour vous

familiariser avec l'emplacement des commandes et boutons de réglage. Conservez ce

guide pour références ultérieures.

Soupape de sûreté : Si le manostat

n'arrête pas le compresseur d'air lorsque

la «pression de rupture» est atteinte, la

soupape de sûreté protège contre toute

surpression en «sautant» à la valeur de

pression établie à l'usine (une pression

légèrement supérieure à la «pression de

rupture» établie pour le manostat.

Manomètre de sortie : Le manomètre de

sortie indique la pression d'air disponible

à la sortie du régulateur. Cette pression

est contrôlée par le régulateur et est

toujours inférieure à ou égale à la pression

du réservoir.

Régulateur : Contrôle la pression d'air

indiquée sur le manomètre de sortie.

Tournez le bouton dans le sens des aiguilles

d'une montre pour hausser la pression et

dans le sens contraire des aiguilles d'une

montre pour la réduire.

Description du fonctionnement

Familiarisez-vous avec ces commandes

avant d'utiliser l'appareil.

Interrupteur arrêt/auto « off/auto » :

Placez cet interrupteur à la position « Auto »

pour obtenir une alimentation automatique

au manostat et à la position « OFF » pour

couper l'alimentation après chaque

utilisation.

Manostat (non illustré) : Le manostat

démarre automatiquement le moteur

lorsque la pression dans le réservoir d'air

tombe à une valeur inférieure à la

«pression d'amorçage» réglée à l'usine. Il

arrête le moteur lorsque la pression dans

le réservoir d'air atteint la «pression de

rupture» réglée à l'usine.

Sortie

d'air

Adaptateur

de boyau

Accessoire

de gonflage

conique

Adaptateur

de

soufflette

Tube de

rallonge

Soupape de

sûreté

Cordon

d'alimentation

Régulateur

Boyau

d'air

Manomètre de sortie

Interrupteur

arrêt/auto

Mandrin de

gonflage

femelle

Robinet de vidange,

(non illustré)

Aiguille de

gonflage

Page 32

33- FR

D29495

Mandrin de gonflage femelle : Se fixe à

l'extrémité du boyau pour gonfler les pneus.

Remarque : Pour assurer que les pneus

sont gonflés au niveau de pression voulue,

utilisez un manomètre.

Adaptateur de boyau : S'attache à

l'extrémité du boyau pour permettre

l'utilisation d'accessoires.

Adaptateur de soufflette : S'attache à

l'extrémité du boyau ou à la soufflette

(vendue séparément, non illustrée) pour

permettre l'utilisation de l'aiguille de

gonflage.

Aiguille de gonflage : S'adapte à

l'adaptateur de boyau pour gonfler les

ballons de sport.

Accessoire de gonflage conique :

S'attache à l'adaptateur de boyau ou à la

soufflette (vendue séparément) pour le

gonflage de jouets gonflables/matelas

pneumatiques.

Tube de rallonge : S'attache à l'adaptateur

de boyau ou à la soufflette (vendue

séparément) pour le soufflage à air, le

séchage et le gonflage spécialisé.

Robinet de vidange (non illustré) : Le

robinet de vidange est situé à la base du

réservoir d'air et est utilisé pour vidanger la

condensation après chaque utilisation.

Système de refroidissement

(non illustré) : Ce compresseur d'air offre

un système de refroidissement de pointe.

Le cœur de ce système de refroidissement

est un ventilateur. Il est tout à fait normal

que ce ventilateur souffle une grande

quantité d'air à travers les trous d'aération.

L'expulsion d'air indique que le système de

refroidissement est en fonction.

Pompe du compresseur d'air (non

illustrée) : La pompe comprime l'air pour

le forcer dans le réservoir d'air. L'air n'est

pas disponible pour travailler avant que le

compresseur n'ait élevé la pression du

réservoir d'air au niveau requis à la sortie

d'air.

Soupape de retenue (non illustrée) :

Lorsque le compresseur fonctionne, la

soupape de retenue est «ouverte»,

permettant à l'air comprimé d'entrer dans le

réservoir d'air. Quand le compresseur d'air

atteint la «pression de rupture», la soupape

de retenue «se ferme», permettant à l'air

pressurisé de demeurer à l'intérieur du

réservoir d'air.

Avant le premier démarrage

Procédures de rodage

Risque d'une

utilisation

dangereuse. Le compresseur d'air peut

subir d'importants dommages si les

procédures de rodage ne sont pas

suivies à la lettre.

Cette procédure doit être exécutée avant

d'utiliser le compresseur d'air pour la

première fois.

1. Assurez-vous que l'interrupteur

« Off/Auto » est en position d'arrêt

« Off ».

2. Faites tourner le bouton du

régulateur dans le sens contraire des

aiguilles d'une montre jusqu'à ce

qu'il s'arrête.

3. Branchez le cordon d'alimentation

dans la prise de courant du circuit de

dérivation approprié. (Consultez le

paragraphe sur la protection contre la

surtension et la protection du circuit de

la section sur l'installation de ce guide.)

4. Ouvrez complètement le robinet de

vidange (en tournant dans le sens

contraire des aiguilles d'une montre)

afin de permettre à l'air de sortir et

pour empêcher une accumulation de

pression dans le réservoir d'air lors

de la période de rodage.

5. Placez l'interrupteur « Off/Auto » à la

position «Auto». Le compresseur se

mettra en marche.

6. Faire fonctionner le compresseur

pendant 15 minutes. Assurez-vous

que le robinet de vidange est ouvert

et que la pression d'air accumulée

dans le réservoir est minimale.

7. Après 15 minutes, fermez le robinet

de vidange (en tournant dans le sens

des aiguilles d'une montre). Le

réservoir d'air se remplira jusqu'à ce

que la «pression de rupture» soit

atteinte et le moteur s'arrêtera

ensuite.

Le compresseur d'air est maintenant prêt

pour l'utilisation.

Utilisation de l'appareil

Arrêt de l'appareil :

1. Réglez l'interrupteur « Off/Auto » à la

position d'arrêt « Off ».

Page 33

34- FR

D29495

Mise en marche :

1. Réglez l'interrupteur « Off/Auto » à la

position « Auto » et attendez jusqu'à

ce que la pression augmente. Le

moteur s'arrêtera lorsque la pression

dans le réservoir atteint la "pression

de rupture".

2. Tournez le bouton du régulateur dans

le sens des aiguilles d'une montre

jusqu'à ce que la pression désirée

soit atteinte.

3. Le compresseur d'air est maintenant

prêt pour l'utilisation.

Avant chaque mise en marche :

1. Réglez l'interrupteur « Off/Auto » à la

position d'arrêt « Off ».

2. Faites tourner le bouton du

régulateur dans le sens contraire des

aiguilles d'une montre jusqu'à ce

qu'il s'arrête.

3. Raccordez le boyau et les

accessoires.

Risque

d'éclatement.

Une pression d'air trop élevée conduit à

un risque dangereux d'éclatement.

Vérifiez la pression nominale maximum

du fabricant pour tous les outils

pneumatiques et accessoires utilisés.

La pression de sortie du régulateur ne

doit jamais excéder la pression

nominale maximum.

Page 34

35- FR

D29495

Vidange du réservoir

AVIS : Laissez refroidir l'appareil avant de

vidanger le réservoir : la soupape de

vidange devient chaude pendant l'usage.

1. Placez l'interrupteur « Off/Auto » à la

position « Off ».

2. Tournes le bouton du régulateur dans

le sens contraire des aiguilles d'une

montre pour régler la pression de sortie

à zéro.

3. Tirez et tenez en place l'anneau de la

soupape de sûreté pour permettre à

l'air de s'échapper du réservoir

jusqu'à ce que la pression soit

réduite.

4. Placez l'appareil sur des blocs pour

soulever l'appareil du sol.

5. Placez un contenant approprié sous

l'appareil pour que l'eau puisse s'y

égoutter.

6. Inclinez légèrement l'appareil et faites

tourner la soupape de vidange dans

le sens contraire des aiguilles d'une

montre pour l'ouvrir.

7. Remettez l'appareil sur les blocs pour

vidanger l'eau contenue dans le

réservoir à air.

Risque

d'éclatement.

L'eau dans le réservoir d'air peut

condenser. Si l'eau n'est pas vidangée,

cela risque de corroder et d'affaiblir le

réservoir d'air, produisant ainsi un

risque de rupture du réservoir d'air.

8. Une fois la vidange de l'eau terminée,

fermez le robinet de vidange (tournez

dans le sens des aiguilles d'une

montre). Le compresseur d'air peut

maintenant être rangé.

ENTRETIEN

Responsabilités du client

●

●

Vérifier la soupape de sûreté

Vidanger le réservoir

À chaque

jour ou

après

chaque

utilisation

Avant

chaque

utilisation

Risque d'une

utilisation

dangereuse. L'unité fonctionne

automatiquement en cycles quand le

courant est présent. Durant l'entretien,

vous pourriez être exposé à des

sources de tension, à l'air comprimé ou

à des pièces mobiles. Avant de faire

l'entretien de l'unité, débranchez

l'alimentation électrique au

compresseur d'air et purgez la pression

du réservoir.

REMARQUE : Pour connaître

l'emplacement des commandes, voir la

section « Utilisation ».

Vérification de la soupape de sûreté

Risque

d'éclatement.

Si la soupape de sûreté ne fonctionne pas

correctement, une surpression pourrait

avoir lieu et causer une rupture ou une

explosion du réservoir d'air.

1. Avant de mettre en marche le

compresseur, tirez sur l'anneau de la

soupape de sûreté pour vous assurer

que la soupape fonctionne librement. Si

la soupape est coincée ou qu'elle ne

bouge pas librement, contactez un

technicien qualifié.

Page 35

36- FR

D29495

Avant de ranger le compresseur d'air,

assurez-vous de suivre les étapes

suivantes :

1 Vidangez le réservoir (la procédure à

suivre est précisée dans le

paragraphe « Vidange du réservoir »

de la section « Entretien » de ce

guide).

Risque

d'éclatement.

L'eau dans le réservoir d'air peut

condenser. Si le réservoir n'est pas

vidangé, l'eau corrodera et affaiblira les

parois du réservoir d'air, causant ainsi

un risque d'éclatement du réservoir.

2. Entreposez les accessoires dans le

sac de rangement situé à l'arrière de

l'appareil. Le sac de rangement est

muni d'un compartiment plus petit

pour ranger les petits accessoires.

3. Enroulez le cordon électrique

légèrement autour de l'appareil et

enclenchez-le dans sa fiche pour le

ranger.

4. Enclenchez le boyau d'air dans le

porte-boyau.

5. Rangez le compresseur d'air dans un

endroit propre et sec.

RANGEMENT

Compartiment

plus petit

Page 36

37- FR

D29495

Une légère chute de pression est

considérée normale.

S'il y a une chute excessive de

pression lorsqu'un accessoire est

utilisé, ajustez le régulateur en

suivant les directives du paragraphe

intitulé « Description du

fonctionnement » de la section sur

l'utilisation.

REMARQUE : Ajustez la pression du

régulateur lorsqu'il y a un débit d'air

(c.-à-d. pendant l'utilisation d'un

accessoire).

Le relevé de pression

sur le manomètre du

régulateur tombe

lorsqu'un accessoire

est utilisé.

DÉPANNAGE

PROBLÈME

CAUSE

CORRECTION

Le manostat n’arrête pas le moteur

lorsque le compresseur d'air atteint

la « pression de rupture ».

La « pression de rupture » du

manostat est trop élevée.

Déplacez l'interrupteur «

Off/Auto »

à la position « Off ». Si l'appareil ne

s'arrête pas, contactez un technicien

qualifié.

Contactez un technicien qualifié.

Pression excessive la soupape de sûreté

se soulève.

Les raccords des tubes ne sont pas

assez serrés.

Resserrez les raccords là où on peut

entendre l'air s'échapper. Vérifiez les

raccords à l'aide d'une solution

d'eau savonneuse. Ne pas trop

serrer.

Fuites d'air aux

raccords.

Fuite d’air à la

soupape de sûreté.

Défectuosité possible dans la

soupape de sûreté.

Faites fonctionner la soupape

manuellement en tirant sur l'anneau.

Si les fuites ne sont pas éliminées,

contactez un technicien qualifié.

Cognements.

Risque d'une utilisation dangereuse. En effectuant des

réparations, vous pourriez être exposé à des sources de

tension, à l'air comprimé ou à des pièces mobiles. Avant de tenter toute

réparation, débranchez l'alimentation électrique au compresseur d'air et purgez la

pression du réservoir.

Appliquez du ruban scellant sur

les filetages des joints exposés.

Défectuosité possible dans la

soupape de sûreté.

Faites fonctionner la soupape

manuellement en tirant sur l'anneau.

Si les fuites ne sont pas éliminées,

contactez un technicien qualifié.

Page 37

38- FR

D29495

Le compresseur d'air

ne fournit pas

suffisamment d'air

pour faire fonctionner

les accessoires.

Utilisation prolongée et excessive de

l'air.

Le compresseur n'est pas assez gros

pour la quantité d'air requise.

Trou dans le boyau.

Fuites d'air.

Diminuez la quantité d'air utilisé.

Vérifiez les exigences en air de

l'accessoire. Si elles sont plus

élevées que la valeur SCFM (pi

3

/min)

ou la pression produite par le

compresseur, vous avez besoin d'un

compresseur plus gros.

Vérifiez et remplacez le boyau au

besoin.

Serrez les raccords.

PROBLÈME

CAUSE

CORRECTION

Le moteur ne tourne

pas.

Fusible sauté ou coupe-circuit

déclenché.

Rallonge de longueur ou de calibre

inapproprié.

Connexions électriques desserrées.

Moteur défectueux.

Vérifiez s'il y a un fusible sauté dans la

boîte à fusibles et remplacez-le au

besoin. Rétablissez le coupe-circuit.

Ne pas utiliser un fusible ou un coupecircuit à valeur nominale supérieure à

la valeur spécifiée pour le circuit de

dérivation utilisé.

Vérifier si le fusible est du type

approprié. Vous devriez utiliser un

fusible retardé.

Vérifier s'il y a une condition de

tension basse.

Vérifiez la rallonge.

Déconnectez tout autre appareil

électrique du circuit ou branchez le

compresseur sur son propre circuit

de dérivation.

Vérifiez la rallonge.

Vérifiez les connexions de câblage

dans la boîte à bornes.

Faire vérifier par un technicien

qualifié.

Page 38

e

Get it fixed, at your home or ours!

Your Home

For repair – in your home – of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner’s manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

®

1-800-4-MY-HOME

(1-800-469-4663) (U.S.A. and Canada)

www.sears.com www.sears.ca

Our Hom

For repair of carry-in products like vacuums, lawn equipment,

and electronics, call or go on-line for the nearest

Sears Parts and Repair Center.

1-800-488-1222

To purchase a protection agreement (U.S.A.)

or maintenance agreement (Canada) on a product serviced by Sears:

1-800-827-6655

Anytime, day or night (U.S.A. only)

www.sears.com

(U.S.A.) 1-800-361-6665 (Canada)

Anytime, day or night

Para pedir servicio de reparación

Au Canada pour service en français:

a domicilio, y para ordenar piezas:

1-888-SU-HOGAR

(1-888-784-6427)

© Sears, Roebuck and Co.

® Registered Trademark /

® Marca Registrada /

MC

Marque de commerce /MD Marque déposée de Sears, Roebuck and Co.

TM

SM

TM

Trademark /SMService Mark of Sears, Roebuck and Co.

Marca de Fábrica /SMMarca de Servicio de Sears, Roebuck and Co.

1-800-LE-FOYER

(1-800-533-6937)

www.sears.ca

MC

Loading...

Loading...