Page 1

OWNER'S

MANUAL

Model No.

919.679370

IMPORTANT:

Read the Safety Guidelines

and All Instructions Carefully

Before Operating

Sold by Sears Canada, Inc., Toronto, Ont. M5B2B8

120/240 ¥OLT • 3750 WATT

GENERATOR

SAFETY GUIDELINES

ASSEMBLY

OPERATION

MAINTENANCE

TROUBLESHOOTING

REPAIR PARTS

MGP-679370A 8/12/99

Page 2

TABLE OF CONTENTS

Warranty.....................

Safety Guidelines......

Assembly....................

Operation ..................

Maintenance..............

Service Adjustments

DATE PURCHASED:.

MODEL NO:

SERIAL NO:

STORE WHERE PURCHASED:

ADDRESS

CITY

TELEPHONE;

Record the above information about your unit

so that you will be able to provide it in case

of loss or theft.

....... 2

.... 3-8

....... 8

.. 9-13

13-15

..... 15

Storage................................................... 15

Troubleshooting..................................... 16

Parts.................................................. 17-31

EPA Codes........................................ 32-33

How To Order Parts ................. Back Cover

Français

HORSE POWER 7.5 HP

GASOUNE CAPACITY 4 GALLON

OIL CAPACITY 30 OZ.

MAINTENANCE AGREEMENT

The Craftsman Warranty, plus a Maintenance Agreement,

provide maximum value for your Sears products. Contact

your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

Read and observe the safety rules.

Follow a regular schedule in maintaining, caring for and us

ing your generator.

Follow the instructions under “Customer Responsibilities”

and “Storage” sections of this owner's manual.

FULL ONE YEAR WARRANTY ON CRAFTSMAN GENERATORS

For one year from the date of purchase, when this Craftsman generator is maintained and operated according to the

instructions in this owner’s manual, Sears will repair, free of charge, any defect in material and workmanship.

If your Craftsman Generator is used for commercial or rental purposes, this warranty applies for only 90 days from the

original date of purchase.

FULL ONE YEAR WARRANTY ON CRAFTSMAN ENGINE

For one year from the date of purchase, when this Craftsman engine is maintained and operated according to the

instructions in this owner’s manual. Sears will repair, free of charge, any defect in material and workmanship.

If your Craftsman engine is used for commercial or rental purposes, this warranty applies only for 90 days from the date

of purchase. This warranty does not cover: Expendable items such as spark plugs and air filters, which become worn

during normal use.

Repairs necessary because of operator abuse or negligence, including damage resulting from no oil being supplied to

the engine or failure to maintain the equipment according to the instructions contained in this owner’s manual, are not

covered under warranty.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE GENERATOR TO THE NEAREST SEARS SERVICE CENTER.

This warranty gives you specific legal rights and you may also have other rights, which vary from PROVINCE TO

PROVINCE,

Sold by Sears Canada^ Inc., Toronto, Ont.

2 - ENG

Page 3

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that

is important for you to know and

understand. This information relates

to protecting YOUR SAFETY and

PREVENTING EQUIPMENT PROB

LEMS. To help you recognize this

information, we use the symbols to

the right. Please read the manual and

pay attention to these sections.

IMPORTANT SAFETY INSTRUCTIONS

When using this product basic precautions should always be followed

A DANGER

URGENT SAFETY INFORMATION - A HAZ

ARD THAT WILL CAUSE SERIOUS INJURY

OR LOSS OF LIFE.

AWARNING

IMPORTANT SAFETY INFORMATION - A

HAZARD THAT MIGHT CAUSE SERIOUS

INJURY OR LOSS OF LIFE.

• SAVE THESE INSTRUCTIONS •

Information for preventing damage to

equipment.

Information that you should pay

special attention to.

AWARNING

including the following:

I..............................

NOTE

3

..R..ISK

HAZARD

Attempting to connect generator directly

to the electrical system of any building

structure.

Inadequate electrical grounding of gen

erator.

A DANGER

.........

Back feeding electricity through a

building’s electrical system to the

outside utility feed lines could en

danger repair persons attempting to

restore service.

Attempting to connect to the incoming

utility service could result in electrocu

tion.

Restoration of electrical service while

the generator is connected to the in

coming utility could result in a fire or

serious damage if a isolator switch is

not installed.

The failure of one of the generator’s

electrical devices, a broken wire, wet

surfaces, etc. could result in the entire

unit becoming electrically charged.

Contact with electrically charged

surfaces could result in electrocution.

Q.F

.....

ELECTROCUIIOM

......

AM.D..FI.B..E

WHAT COULD HAPPEM HOW TO PREVENT IT

Never back feed electricity through a

structure's electrical system.

To connect to a structure's electrical

system in a safe manner and always

have a Double-Throw Transfer Switch

installed by a qualified electrician, in

compliance with local ordinances.

(When installing a Double-Throw

Transfer Switch, a minimum of 10

gauge wiring must be used.)

Make sure that the unit is connected

to an appropriate electrical ground,

in accordance with the requirement

of the National Electric Code. See

page 8 for grounding instructions.

3 - ENG

Page 4

>iUli

READ AND UNDERSTAND ALL WARNINCS BEFORE

ATTEMPTING TO OPERATE GENERATOR.

ADANGER

RISK OF ELECTROCUTION AND FIRE iconrcii

HAZARD

Operation of generator in rain, wet, icy,

or flooded conditions.

Use of worn damaged, undersized or un

grounded extension cords.

WHAT COULD HAPPEN HOW TO PREWEIT IT

Water is an excellent conductor of

electricity! Water which comes in

contact with electricity charged

components can transmit electricity to

the frame and other surfaces, resulting

in electrical shock to anyone contact

ing them.

Contact with worn or damaged exten

sion cords could result in electrocution.

Use of undersize extension cords could

result in overheating of the wires or at

tached items, resulting in fire.

Use of ungrounded cordsets could pre

vent operation of circuit breakers and

result in electrical shock.

Operate generator in a clean, dry,

well ventilated area. Make sure

hands are dry before touching unit.

Inspect extension cords before use

and replace with new if required.

Use proper size (wire gauge) cordset

for application.

Always use electrically grounded

cordset.

Placing generator on or against highly

conductive surface, such as a steel

walkway or metal roof.

Improper connection of items to gen

erator.

Operation of unit when damaged, or with

guards or panels removed.

Accidental leakage of electrical current

could charge conductive surfaces in

contact with the generator.

Exceeding the load capacity of the gen

erator by attaching too many items, or

items with very high load ratings to it

could result in overheating of some

items or their attachment wiring result

ing in fire or electrical shock.

Attempting to use the unit when it has

been damaged, or when it is not func

tioning normally could result in fire or

electrocution.

Removal of guarding could expose elec

trically charged components and result

in electrocution.

4 - ENG

Place generator on low conductivity

surface such as a concrete slab.

Read the load rating chart and in

structions on page 9, 10 and 11.

Make sure that the summation of

electrical loads for all attachments

does not exceed the load rating of

the generator.

Do not operate generator with me

chanical or electrical problem. Have

unit repaired by an Authorized Ser

vice Center.

Do not operate generator with pro

tective guarding removed.

Page 5

READ AND UNDERSTAND ALL WARNINGS BEFORE

ATTEMPTING TO OPERATE GENERATOR.

AWARNING

RISK OF FIRE

HAZARD

Attempting to fill the fuei tank while the

engine is running.

Sparks, fire, hot objects Cigarettes, sparks, fires, or other hot

Improper storage of fuel Improperly stored fuel could lead to ac

Inadequate ventilation for generator Materials placed against or nearthe gen

WHAT COULD HAPPEN HOW TO PREWEiT IT

Gasoline and gasoline vapors can

become ignited by coming in contact

with hot components such as the

muffler, engine exhaust gases, or from

an electrical spark.

objects can cause gasoline or gasoline

vapors to ignite.

cidental ignition. Fuel improperly secured

could get into the hands of children or

other unqualified persons.

erator or operating the generator in ar

eas where the temperature exceeds 104°

F. ambient can interfere with its proper

ventilation features causing overheating

and possible ignition of the materials.

Turn engine off and allow it to cool

before adding fuel to the tank. Equip

area of operation with a fire extin

guisher certified to handle gasoline

or fuel fires.

Add fuei to tank in well ventilated

area. Make sure there are no sources

of ignition nearthe generator.

Store fuel in a container designed to

hold gasoline. Store container in se

cure location to prevent use by oth

ers.

“Operate generator in a clean, dry,

well ventilated area a minimum of four

feet from any objects or wall, DO

NOT OPERATE UNIT INDOORS OR

IN ANY CONFINED AREA.

Tampering with factory set engine speed

settings.

Overfilling the fuel tank - fuel spillage. Spilled fuel and its vapors can become

Engine speed has been factory set to

provide safe operation. Tampering with

the engine speed adjustment could re

sult in overheating of attachments and

could cause a fire.

ignited from hot surfaces or sparks.

5 - ENG

Never attempt to “speedup” the en

gine to obtain more performance.

Both the output voltage and fre

quency will be thrown out of stan

dard by this practice, endangering

attachments and the user.

Use care in filling the tank to avoid

spilling fuel. Make sure fuel cap is

secured tightly and check engine

for fuel leaks before starting

engine. Move generator away from

refueling area or any spillage before

starting engine. Allow for fuel

expansion. Keep maximum fuel

level % inch below the tip of the

fuel tank. Never refuel with the

engine running.

Page 6

READ AND UNDERSTAND ALL WARNINGS BEFORE

ATTEMPTING TO OPERATE GENERATOR.

A DANGER

Risk of lniur¥ and Propertw Damage When

Transporting Generator

HAZARD

Fire, Inhalation, Damage to Vehicle

Surfaces

WHAT COULD HAPPEN

Fuel or oil can leak or spill and could

result in fire or breathing hazard, seri

ous injury or death can result. Fuel or oil

leaks will damage carpet, paint or other

surfaces in vehicles or trailers.

A DANGER

HOW TO PREVENT IT

If generator is equipped with a fuel

shut-off valve, turn the valve to the

off position before transporting to

avoid fuel leaks. If generator is not

equipped with a fuel shut-off valve,

drain the fuel from tank before trans

porting. Only transport fuel in an CSA

approved container. Always place

generator on a protective mat when

transporting to protect against dam

age to vehicle from leaks. Remove

generator from vehicle immediately

upon arrival at your destination

RISK OF BREATHING - INHALATION HAZARD

HAZARD

Gasoline engines produce toxic carbon

monoxide exhaust fumes.

WHAT COULD HAPPEN

Breathing exhaust fumes wiil cause se

rious injury or death.

6 - ENG

HOW TO PREVENT IT

Operate generator in clean, dry, well

ventilated area. Avoid enclosed ar

eas like garages, basements, stor

age sheds, etc., which lack a steady

exchange of air. Never operate unit

in a location occupied by humans or

animals. Keep children, pets and oth

ers away from area of operating unit.

Page 7

READ ÄND UNDERSTAND ALL WARNINGS BEFORE

ATTEMPTING TO OPERATE GENERATOR.

AWARNING

RISK OF UNSAFE OPERATION

HAZARD

Operation of generator in careless

manner.

Operation of voltage sensitive appli

ances without a voiiage surge protec

tor.

WHAT COÜLD HAPPEN HOW TO PREWENT IT

Ail sources of energy include the poten

tial for injury. Unsafe operation or main

tenance of your generator couid iead to

serious injury or death to you or others.

Review and understand all of the

operating instructions and warn

ings in this manual.

Become familiar with the operation

and controls of the generator.

Know how to shut it off quickly.

Equip area of operation with a fire

extinguisher certified to handle

gasoline or fuel fires.

Keep children or others away from

the generator at all times.

Any gasoline operated household gen

erator will incur voltage variations caus

ing damage to voltage sensitive appli

ances or result in fire.

Always use U.L. listed voltage pro

tector to connect voltage sensitive

appliances (TV, computer, stereo,

etc.). Failure to use a U.L. listed volt

age surge protector will void the war

ranty on your generator.

Notice: A multiple outlet strip is not

a surge protector make sure you use

a U.L. listed voltage surge protector.

HAZARD

Contact with hot engine and generator

components.

HAZARD

Contact with moving parts can result in

serious injury.

AWARNING

RISK OF HOT SURFACES

WHAT COULD HAPPEN HOWTO PREVENT IT

Contact with hot surfaces, such as en

gines exhaust components, could result

in serious burns.

During operation, touch only the con

trol surfaces of the generator. Keep

children away from the generator at

all times. They may not be able to

recognize the hazards of this prod

uct.

RISK OF MOVING PARTS

WHAT COULD HAPPEN HOW TO PREVENT IT

The generator contains parts which ro

tate at high speed during operation.

These parts are covered by guarding to

prevent injury.

7 - ENG

Never operate generator with guard

ing or cover plates removed. Avoid

wearing loose fitting clothing or jew

elry which could be caught by mov

ing parts.

Page 8

READ AND UNDERSTAND ALL WARNINGS BEFORE

ATTEMPTING TO OPERATE GENERATOR.

AWARNING

RISK FROU LIFTING

HAZARD

Lifting a very heavy object. Serious injury can result from attempt

ik WARNING

This product is not equipped with a spark arresting muffler. If the product will be used around flammable materials, or on

land covered with materials such as agricultural crops, forest, brush, grass, or other similar items, then an approved spark

arrester must be installed and is legally required in the state of California. It is a violation of California statutes section

130050 and/or sections 4442 and 4443 of the California Public Resources Code, unless the engine is equipped with a spark

arrester, as defined in section 4442, and maintained in effective working order. Spark arresters are also required on some

U.S. Forest Service land and may also be legally required under other statutes and ordinances.

Engine exhaust contains chemicals known, in certain quantities, to cause cancer, birth defects or other reproductive harm.

Read Owner’s Manual. Do not operate equipment until you have read Owner’s Manual for

Safety. Operation, and Maintenance Instructions.

WHAT COULD HAPPEN HOW TO PREWEIT IT

The generator is too heavy to be lifted

ing to lift too heavy an object.

by one person. Obtain assistance

from others before you try to move

it.

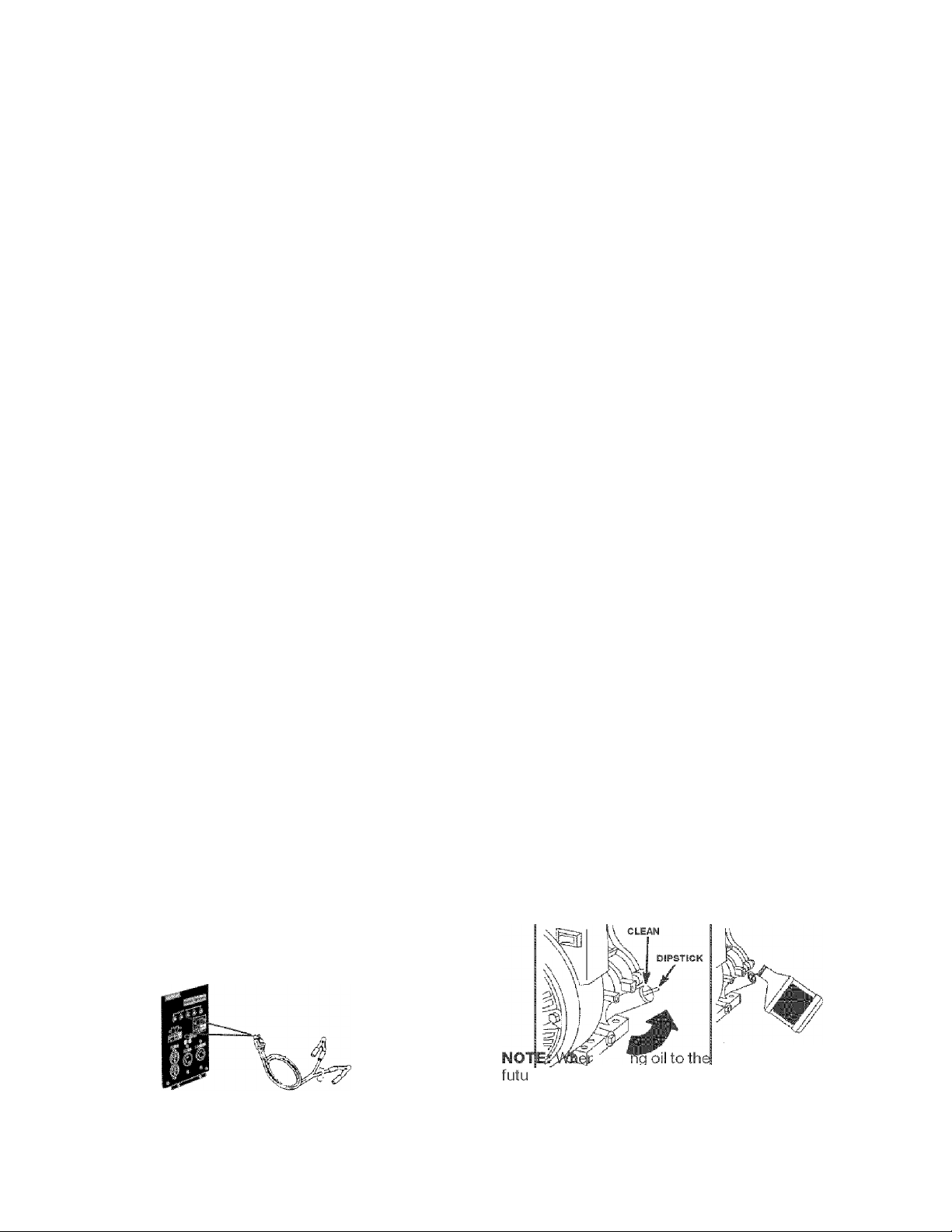

CARTON CONTENTS

® Main Unit

® Owner's Manual

• Battery Charge Cables

Owner's Manual

Battery Charge Cables

Main Generator Unit

CAUTION: Read owner’s manual. Do not attempt to

operate equipment until you have read Owner’s

Manual for Safety, Operation, and Maintenance In

structions.

REMO¥E GENERATOR FROM CARTON

® Open carton from top.

• Cut carton along dotted lines.

• Remove all carton inserts.

• Remove generator through opening in carton.

IMPORTANT: Before any attempt to start your generator

be sure to check engine oil (See OPERATION under

Engine Oil on page 11)

8 - ENG

GROUNDING THE GENERATOR

This generator should be grounded to help prevent

accidental electrical shock. Shown below is a picture of

the grounding lug supplied on your generator. First, drive

a 3/4" or 1" diameter copper pipe or rod into the ground

close to the generator set. The pipe must penetrate moist

earth. Using #10 gauge wire, connect one end of the wire

into the grounding lug. Next, connect the other end of the

wire to the copper pipe or rod using an approved ground

clamp.

o

o

Grounding Lug

o

Page 9

OPERATION

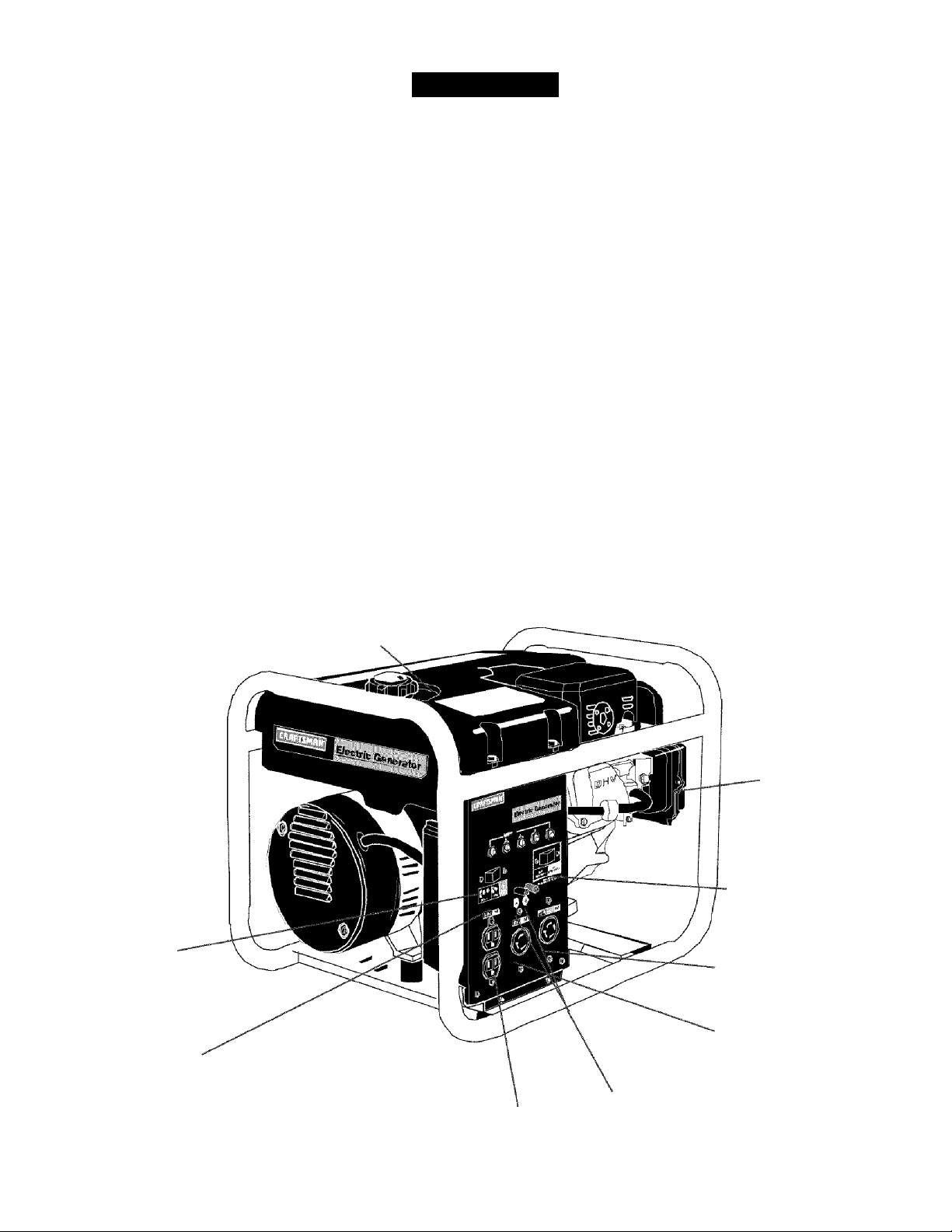

KNOW YOUR GENERATOR

Read this Owner’s Manual and Safety Rules be

fore operation of your Generator. Compare this

illustration with your generator to familiarize yourself

with the location of various controls and adjustments.

Save the manual for future references.

FUEL TANK- Capacity of 4 US gallons.

CHOKE SWITCH- Lever used to start, cold engine.

ENGINE RUN/STOP SWITCH- Sets engine in starting

mode for recoil start.er - Stops running engine.

ENGINE OIL FILL- Place where engine oil is poured.

CIRCUIT BREAKER- Each receptacle has a circuit

breaker to protect the generator from overloading.

120 ¥OLT DUPLEX RECEPTACLES- Used to supply 1800

watts of electrical power per receptacle for operations.

Protected by 15 amp circuit breaker.

120/240 VOLT TWISTLOCK RECEPTACLE- Used to

supply 1800 watts of electrical power for 120 volt operations

and for 240 volt operation 3750. Will only supply 1875 watts

each if both receptacles are being used. Protected by 15

amp circuit breaker.

120 VOLT TWISTLOCK RECEPTACLE- Used to supply

1800 watts of power per receptacle protected by a 15 amp

circuit breaker.

AIR CLEANER- Includes filter element and foam pre-cleaner

that limits the amount of dirt, that enters the engine.

FULL POWER SWITCH - Switch used to convert, every

receptacle on the panel, when placed in the 120 position,

to a 120 volt receptacle. This will allow you to receive the

full capacity of the generator by using all 120 volt recep

tacles. When in the 120/240 position, you will only be able

to use half of the 3750 watts when using the 120 volt recep

tacles. But in this position, the full 3750 watts can be re

ceived in the 240 twistlock receptacle.

IDLE CONTROL SWITCH- When on, allows the engine to

run at a lower speed when there is no load on the generator.

FULL

POWER

SWITCH

CIRCyiT

BREAKERS

FUEL TANK

120 DUPLEX

RECEPTACLES

AIR CLEANER

IDLE CONTROL

SWITCH

120/240

TWISTLOCK

RECEPTACLE

120 TWISTLOCK

RECEPTACLE

12 VOLT DC

CHARGES

9 - ENG

Page 10

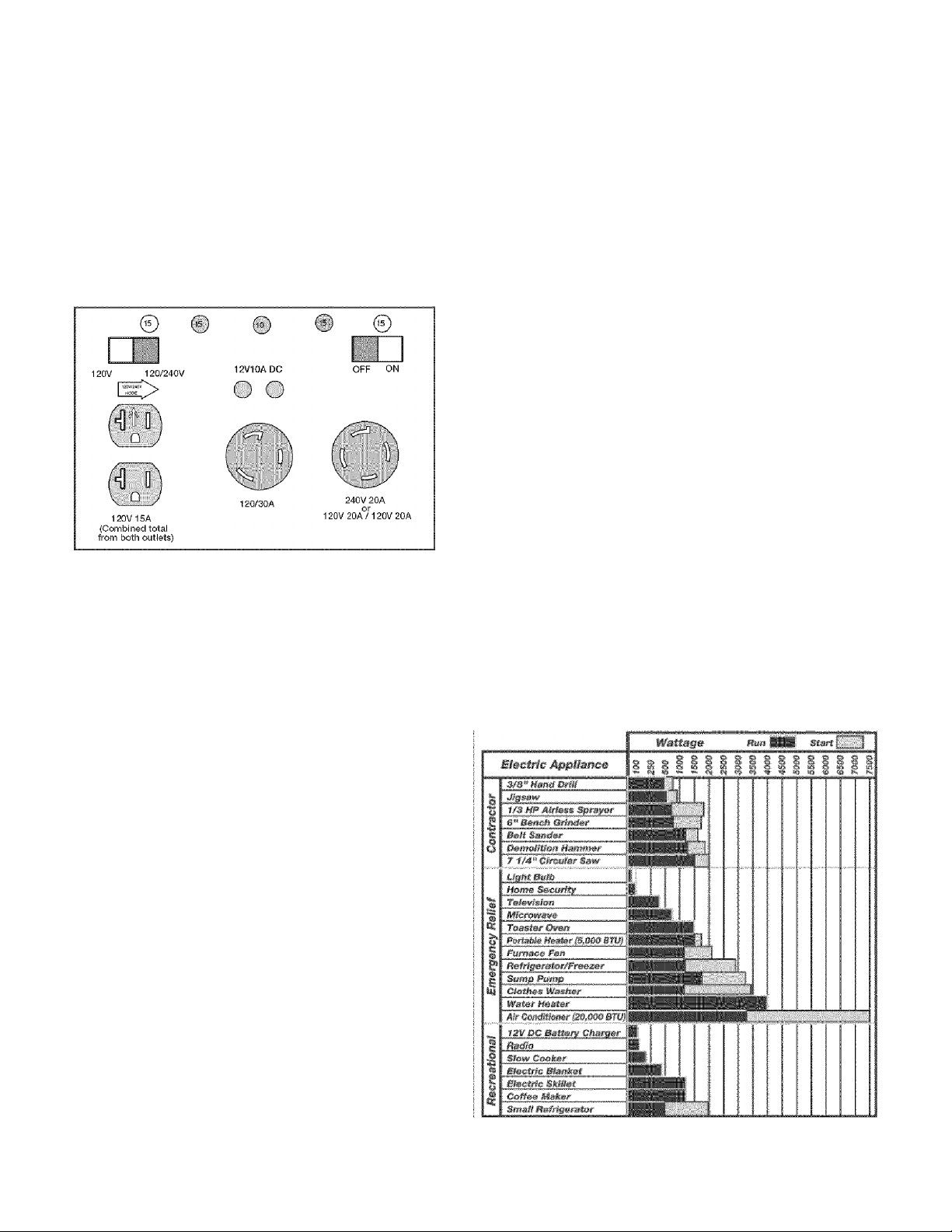

RECEPTACLES

Your generator is equipped with duplex 120 volt receptacle

a 120 twistlock and a 120/240 volt twistlock receptacle.

The unit is also equipped with a 15 amp circuit breaker for

the duplex 120 volt receptacles, a 15 amp circuit breaker

for the 120 volt twistlock receptacle and a 15 amp circuit

breaker for the 120/240 volt twistlock receptacle. If the cir

cuit breaker trips, unplug all electrical loads from the gen

erator. Let the circuit breaker cool down. Push circuit breaker

button to reset.

FULL POWER SWITCH

Your Craftsman generator has a full power switch on the

control panel. This switch has two positions: 120 VOLT

ONLY, and 120/240 VOLT.

120 Position

When placed in the 120 position, (Shown below) every re

ceptacle on the panel will be converted to a 120 volt recep

tacle. 240-volt power is not available. This position allows

full capacity of the generator to be received by using all

120-volt receptacles. While in the 120 position, each re

ceptacle has the ability to reach the maximum 4650 surge

wattage for inductive motors that require 4650 watts or be

low to start.

GENERATOR CAPACITY

Exceeding the rated capacity of your generator can

result in serious damage to your generator and connected

electrical devices. You should observe the following to

prevent overloading the unit:

® Starting and running wattage requirements must be

calculated to match your generator wattage capacity.

• Resistive load appliances such as light bulbs, TV’s

and microwaves, have the same starting and running

wattage. The wattage used for calculating the capacity

can usually be found on each of these appliances.

Some inductive appliances and tools will list on the motor

name plate, the starting and running voltage and amperage

requirements. Use the following formulato convert voltage

and amperage to wattage:

(Volts X Amp = Watts)

inductive load appliances and tools such as refrigerators,

air compressors and washers require approximately 2 to

4 times the listed running wattage for starting the equip

ment. This initial load only lasts for a few seconds on

start-up but is very important when figuring your total

wattage to be used.

NOTE: Always start your largest electric motor first, and

then plug in other items, one at a time.

The guide below is provided to assist you in determining

the appliances and tools that can be ran with the wattage

capacity of your generator.

Го s#feet thm right gmamatm for уоиг fi»ei#s, total tiii» wattmg»

mf ffte Jfe»s fe be run at tfte saw# time.

120 V 120/240V

120/240 Position

When in the 120/240 position, (Shown Below) only half of

the 3750 watts can be received when using the 120-volt

receptacles and the 120/240-volt twistlock receptacle will

be converted to allow the full 3750 watts to be received

from this one receptacle. Also in this position, the 120-volt

receptacles will only reach a maximum of 4650 surge watts.

120 V

120/240V

10 - ENG

Tim штШат mitmas wtmma шт wmrsm*. ШйШзф гтиШтФШ шаг vav

m№ dfffmmnt brands of »ррвтев».

Page 11

OBTAINING ELECTRICITY FROM GENERATOR

There are basically two ways to obtain electricity form a

generator:

® Use of extension cords directly form the generator

to the appliance, lights, tools, etc.

® Use of a double-throw transfer switch installed

directly to the main electrical supply outside of the

house.

® Start the engine. Let it run while the battery charges.

® When the battery is fully charged, stop the engine

and disconnect the battery charge cables from the

panel and battery. Batteries should not be charged

when the unit is unattended.

NOTE: Dd not use t±ifi unit to chaiga any 6-volt tatteries.Do

not use the unit to crank an engine having a discharged

tstbsty.

Extension Cord

When using an appliance or tool at a considerable distance

from the generator, a 3-wire extension cord that has a 3blade grounding plug and 3-slot receptacle that accepts

the tool’s plug should be used. A cord of adequate size

must be used. A minimum of 12 gauge wire size with at

least a 20 amp draw can be used. When amperage

exceeds 20 amps a 10 gauge wire size should be used.

Connecting Generator To Main Electrical Sypply

Potential hazards exist when a electrical generator is con

nected to the main electrical supply coming into the house.

It is at that point that the generator could feed back into the

utility company’s system causing possible electrocution of

workers who are repairing electrical lines. To avoid back

feeding of electricity into utility systems, a double-throw

transfer switch should be installed between the genera

tor and utility power. This device should be Installed by a

licensed electrician and in compliance with all local electri

cal codes.

NOTE: When installing a Double-Throw Transfer Switch,

a minimum of 10 gauge wiring must be used.

CHARGING A BATTERY

IMPORTANT: Always use safety glasses, rubber gloves

and protective clothing while charging battery.

Your generator has the capability of recharging a 12-volt

storage or automotive battery. To recharge a 12-volt

battery, proceed as follows:

® First, check the fluid level in all of the battery cells.

Add distilled water if necessary. Do not use tap

water.

® Clean battery posts if necessary.

® Connect battery charge cables to panel receptacle.

BEFORE STARTING ENGINE

CAUTION: Always check engine oil level before

every start.. Running engine low of oil or out of oil

could result in serious damage to the engine.

Automatic Idle Control

The automatic idle control switch, when in the ON posi

tion, allows the engine to run at lower speed when there

is no load on the generator. This will lower the engine

noise, save on fuel consumption and engine life. When in

the OFF position the engine will run at 3600 RPM’s

continuous with or without a load.

OFF

NOTE: The idle con mmime OFF position when

operating large motor loads (Refrigerators, freezers, etc.) or

voltage sensitive electronic equipment (TV, computers, etc.)

Engine Oil

Your unit has been shipped without oil in the engine. A

bottle of SAE 30 weight oil is included in the cart.on.

Remove oil dip stick located on the side of engine. The

oil dip stick is clearly marked with a line that tells you

when unit has enough oil. Do not fill above this point.

Pour slowly.

Connect the battery charge cable with the red handle

to the battery post indicated by POS or (+).

Connect the battery charge cable with the black

handlefo the battery post indicated by NEC or (-).

11 - ENG

raddi

rbrase-adiiglTcitrattlTTfe^

Service SF, SG, SH” rated SAE 30 weight. Use no special

additives. Select the oil’s viscosity grade according to

you expected operating temperatures.

engine crankcase iji the

^errtrnixfc

Page 12

gine damage due to lack or lubrication.

Use of SAE30 oil below 40°F (4°C) will result in hard start

ing and possible engine damage due to inadequate lubri

cation.

Low Oil Shytdown

Your Craftsman generator engine is equipped with Low

Oil Shutdown. Low Oil Shutdown is a safetydevice

designed to protect your engine from damage in the

event the oil level in the crankcase is low.

If while the engine is running, the oil gets low, it will

automatically shut itself down and will not restart until the

oil is added. If the oil is low before start-up, the genera

tor will not start until oil is added.

NOTE: The Low Oil Shutdown mechanism is very sensi

tive. You must fill the engine to the full mark on the

dipstick to inactivate this safety device.

• Remove gas cap

• Add unleaded gasoline, slowly, to fuel tank.

• Do not overfill.

• On the engine there is a choke/run lever. Place lever

to the choke position.

Gasoline

Your generator engine is 4 cycle. Use unleaded fuel only.

Never mix oil with gasoline.

CAUTION; Never fill fuel tank completely. Fill tank to

1/2" below the bottom of the filler neck to provide

space for fuel expansion. Wipe any fuel spillage from

engine and equipment before starting engine.

WARNING: Never fill fuel tank indoors. Never fill fuel

tank when engine is running or hot. Do not smoke

when filling fuel tank.

Use clean, fresh, regular unleaded gasoline with a mini

mum of 85 octane. Do not mix oil with gasoline. If unleaded

fuel is not available, leaded fuel may be used.

CHOKE

LE¥ER"~-L^,

Throttle is factory set.

• Grasp the starter grip and pull slowly until resistance

is felt, then pull firmly to start engine.

• When engine starts, gradually move choke lever to

RUN position.

• If engine does not start after 5 pulls, place choke

back to run position.

• For hot engine starts make sure choke lever is in

the run position. Make sure fuel shut off valve is open.

12 - ENG

Page 13

Connecting Electrical Loads

» Let engine run and warm up for about five minutes

after starting.

• Plug in the desired 120 or 240 volts tools.

• DO NOT connect 240 volt equipment to the 120 volt

duplex receptacles.

• DO NOT connect 3-phase loads to the panel

receptacles.

IMPORTANT: You should always add up the rated

watts of all lights, tools and appliances you are power

ing at one time. This total should not exceed the rated

capacity of your generator or circuit breaker rating of

the receptacle supplying power.

Stopping The Engine

» Disconnect all electrical loads.

• Switch the start/off switch to the off position.

IMPORTANT: Never store engine with fuel in tank,

indoors, or in enclosed, poorly ventilated areas or where

fuel fumes may reach an open flame.

MAINTENANC

CUSTOMER RESPONSIBILITIES TABLE

Before each

use

MAINTNENANCE TASK

Check oil level

Change oil

Clean Air Filter Assembly

Check Spark Plug

Prepare Unit for Storage

Note 1: Change oil after first two (2) operating hours and every 50 operating hours thereafter, more often if operated in

extreme dusty or dirty conditions.

Note 2: Check oil after 5 hours of operation {Seepage 14 - ENGINE MAINTENANCE - Changing Engine Oil.)

X See Note 2

Prepare unit for storage if it is to remain idle for more than 30 days.

Every 25

Hours of Every

Season

X

X

X

Every 50

Hours of Every

Season

See Note 1

Every 100

Hours of Every

Season

X

13 - ENG

Page 14

GENERAL RECOMMENDATIONS

The warranty of the generator does not cover items that

have been subjected to operator abuse or negligence. To

receive full value from the warranty, operator must maintain

the generator as instructed in this manual.

Some adjustments will need to be made periodically to

maintaining your generator.

GENERATOR MAINTENANCE

Your generator should be kept clean and dry at all times.

The generator should not be stored or operated in

enviroments that includes excessive moisture, dust or any

corrosive vapors. If these substances are on the generator,

clean with a cloth or soft bristle brush. Do not use a garden

hose or anything with water pressure to clean the genera

tor. Water may enter the cooling air slots and could possi

bly damage the rotor, stator and the internal windings of the

gen head.

All adjustments in the Maintenance section of this manual

should be made at least once each season.

ENGINE MAINTENANCE

Changing Engine Oil

• Reinstall the oil fill cap or plug and tighten securely.

Ser¥ice Air Cleaner

NOTE: Do not use petroleum solvents, e.g., kerosene,

which will cause the cartridge to deteriorate. Do not use

pressurized air to clean cartridge. Pressurized air can

damage the cartridge.

To sen/ice air cleaner follow these steps:

1. Unscrew cover screws. Remove cover and air

cleaner assembly.

2. Remove cartridge from cover, then retainer

(if equipped) and pre-cleaner.

To service pre-cleaner, wash in liquid detergent and

water. Squeeze dry in a clean cloth. Saturate in engine

oil. Squeeze in clean, absorbent cloth to remove all

excess oil. Replace if very dirty or damaged.

To service cartridge, clean by tapping gently on a flat

surface. Do not oil cartridge. Replace if dirty or dam

aged.

For a new engine, change oil after the first 5 hours of

operation. Thereafter, change oil after every 50 hours of

operation.

Change the oil while the engine is still warm. The oil will

flow freely and carry away more impurities. Make sure the

engine is level when filling, checking, or changing oil.

Change the oil as foHoms:

• To keep dirt, grass clippings, etc., out of the engine,

clean the area around the drain plug and dipstick

before removing it.

• Remove the oil drain plug and dipstick. Tilt the engine

slightly towards the oil drain to obtain better drainage.

Be sure to allow ample time for complete drainage.

IS mm

S inm

OIL DRAIN

OIL DRAIN OIL FILL

3. Reassemble pre-cleaner or retainer (If equipped.)

Place in cover with pre-cleaner mesh side toward

cartridge. Place cartridge in retainer in cover.

4. Push cover and air cleaner assembly squarely onto

base (tabs must be in slots, if equipped) and hold

firmly. Tighten cover screws securely.

Do not clean engine with a forceful spray of water

because water could contaminate fuel system. With

a brush or cloth clean finger guard after every use to

prevent engine damage caused by overheating.

• Reinstall the drain plug. Make sure it is tightened

securely.

• Fill the crankcase with new oil of the proper type, to

the Full mark on the dipstick. Always check the level

with the dipstick before adding more oil.

14 - ENG

Page 15

Before running engine, clean muffler area to remove all

combustible debris.

SERVICE ADJUSTMENT

Clean and Replace Spark Plug

Change the spark plug every 100 hours of operation or

once each year, whichever comes first. This will help

your engine to start easier and run better.

Carburetor

The carburetor of your generator is pre-set at the factory.

The carburetor should not be tampered with, if your gen

erator is used at an altitude in excess of 4000 feet perfor

mance may be affected. If so consult with your nearest

Sears Service Center regarding high altitude set changes.

Go¥ernor

Your engine governor maintains the constant operating

speed of your generator. DO NOT tamper with the engine

governor which is factory set for proper engine speed.

STORAG

If you are going to store your generator for more than 30

days, use the following information as a guide to prepare

the generator for storage.

STORAGE INSTRUCTIONS

CAUTION: Never store generator with fuel in the

tank indoors or in enclosed, poorly ventilated areas,

where fumes can reach an open flame, spark or pilot

light as on a furnace, water heater, clothes dryer or

other gas appliances.

Engine Preparation

• Add fuel stabilizer to fuel tank to minimize the

formation of fuel gum deposits during storage.

» Run engine at least 10 minutes after adding stabilizer

to allow it to enter the fuel system.

• Next shut off engine.

Over-speeding your engine above factory high speed set

ting can be dangerous and could possibly cause personal

injury or property damage. If you believe the engine is run

ning too fast or slow, take your generator to a Authorized

Sears Service Center for repair and adjustment.

CAUTION: Low engine speeds impose a heavy load

on the engine and when sufficient power is not avail

able the engine life could be shorten.

• Disconnect the spark plug wire and remove the

spark plug.

• Add one teaspoon of oil through the spark plug hole.

® Place rag over spark plug hole and pull the recoil a

few times to lubricate the combustion chamber.

• Replace the spark plug, but do not connect the spark

plug wire.

NOTE: if a fuel stabilizer is not used, all gasoline must

be drained from the tank and carburetor to prevent gum

deposits from forming on these parts and causing

possible malfunction of the engine.

Generator

» Clean the generator as outlined on Page 14 {Generator

Maintenance)

• Check that cooling air slots and openings on generator

are open and unobstructed.

15 - ENG

Page 16

TROUBLESHOOTING GUIDE

PROBLEM

CAUSE

Engine will not start 1. Low on fuel or oil.

2. Ignition switch in "Off" position.

3. Faulty spark plug.

4. Choke In wrong position.

5. Fuel shut-off valve in closed

position.

6. Unit loaded during start-up.

7. Spark plug wire loose.

No electrical output

1. Faulty receptacle.

2. Circuit breaker kicked out.

3. Defective capacitor.

4. Faulty power cord.

5. GFCI switch breaker kicked out (if

equipped)

CORRECTION

1. Add fuel or oil.

2. Turn to "ON" position

3. Replace spark plug.

4. Adjust choke accordingly.

5. Open fuel shut-off valve.

6. Remove load from unit.

7. Attach wire to spark plug.

1. Have Service Center replace.

2. Depress and reset.

3. Have Service Center replace

capacitor.

4. Repair or replace cord.

5. Depress and reset

Repeated circuit breaker tripping

1. Overload

2. Faulty cords or equipment.

Generator overheating 1. Generator overloaded.

2. Insufficient ventilation.

No auto idle

DC does not have power with the

circuit breaker depressed

1. Faulty solenoid

2. Faulty idle control switch

3. Faulty windings in stator

4. Faulty circuit board

5. Faulty wire harness

1. Faulty rectifier

2. Faulty windings in stator

3. Faulty wire harness

1. Reduce load.

2. Check for damaged, bare, or

frayed wires on equipment.

Replace.

1. Reduce load.

2. Move to adequate supply of

fresh air.

1. Have Service Center replace.

2. Have Service Center replace.

3. Have Service Center replace.

4. Have Service Center replace.

5. Have Service Center replace

1. Have Service Center replace.

2. Have Service Center replace.

3. Have Service Center replace.

16 - ENG

Page 17

GENERATOR PART

CRAFTSMAN 3750 WATT GENERATOR 919.679370

13

,11

TORQUE 60-70 IN-LBS

KEY

NO. DESCRIPTION PART NUMBER

1 HEAT SHI ELD GS-816

2 SCREW, 1/4-20 X .75 91895680

3 FUEL CLAMP GS-0227

4 SCREW, 5/16-18 XI.25 SSF-605

5 WASHER SSN-60-ZN

6 NUT, HEX WIZLOCK SSF-8150

7 WASHER, LOCK SSN-1619-ZN

8 GROUND STRAP GS-0118

9 CAP SCREW, 5/16-18 X 74 SS-12-SD

10 FUEL TANK (4 GALLON) GS-0650

11 ENGINE GS-0665

12 WASHER. .875 OD .35 ID .083 THK SSN-632

13 FUEL TANK CAP GS-0443

17 - ENG

Page 18

GENERATOR PART

CRAFTSMAN 3750 WATT GENERATOR 919.679370

14 FUEL HOSE GS-0225

15 DRAIN COCK GROMMET GS-0446

16 FRAME ASSEMBLY GS-0611

17 GENERATOR ASSEMBLY GS-0672

18 GROUND LUG GS^0117

19 SCREW, HEX WASHER, UNSLOTTED SSF-928

20 VIBRATION ISOLATOR GS-0033

21 VIBRATION ISOLATOR GS^0433

22 SCREW, 10^24x9/16 SSF-5530

23 DRAIN COCK GS-0437

24 END COVER GS-0077

18 - ENG

Page 19

GENERATOR PART

CRAFTSMAN 3750 WATT GENERATOR 919.679370

KEY

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

PAB.I..NMMBER.

RECTIFIER

SCREW, 10-24 X .75 T25 TORX

DRIVE END ADAPTER

LOCK WASHER 3/8

CAP SCREW, 3/8-16 X 1

ROTOR ASSEMBLY

STATOR THRU BOLT

STATOR ASSEMBLY

WASHER 11/16 OD X11/32

NUT, 5/16-24

ROTOR THRU BOLT

BEARING SUPPORT

НЕХНиТУ4-20

CAPACITOR

CAPACITOR BRACKET

SCREW 10-32

GS-0767

SSF-3158-1

GS-0830

SSN-619

SSF-577

GS-0588

GS-0110

GS-0673

SS-6506-CD

SSF-576

GS-0091 -1

GS-0793

SSF-575

GS-0748

GS-0595

SSF-553-1

ITEMS NOT SHOWN

*Diode(s) — GS-0082

19 - ENG

Page 20

GENERATOR PART

CRAFTSMAN 3750 WATT GENERATOR 919.679370

*Not Shown

KEY

la DESCRIPTION PART NUMBER

40 SCREW, 10-9 X .50 PLASTITE SSF-3156

41 SCREW, #6-32 X.5 TORX SSF-583

42 SPEED NUT #6-32 SSF-584

43 RECEPTACLE, 120V DUPLEX GS-0804

44 RECEPTACLE, 3 PRONG TWISTLOCK GS-0021

45 RECEPTACLE, 4 PRONG TWiSTLOCK GS-0445

46 FULL POWER SWITCH GS-0045

Al

48 15A CIRCUIT BREAKER GS-0024

49 10A CIRCUIT BREAKER GS-0681

50 SWITCH FACE PLATE GS-0207

51 CIRCUIT BOARD FOR IDLE CONTROL SWITCH GS-0663

52 JAM NUT 7/16 SSF-595

53 WASHER 3/8 SS-1525-CD

IDLE CONTROL SWITCH GS-0679

RESISTOR ASSY. D.C. SHUNT GS-0835

20 - ENG

Page 21

ENGINE PARTS

CRAFTSMAN 3750 WATT GENERATOR 919.679370 ENGINE NUMBER 138432-0035-A1

J

REF.

NO.

1 715461 Cylinder Assembly 10 710023 Screw-Hex 373 710059 Nut-Lock

3 •710000 Seal-Oil 15 715000 Plug-Oil Drain 505 710090 Nut-Lock

»Included In Gasket Set-Part No. 715482

★ Included inValve Overhaul Kit-Part No. 715483

Aincluded In Carburetor Kit-Part No. 715484

★ Included in Gasket Gasket Set -Part No. 715485

PART

NO. DESCRIPTION

REF.

NO.

17 710003 Bearing-Ball 614 710056 Pin-Retainer

116 •710055 Seal-O-Ring 616 710636 Crank-Governor

116A •710091 Seal-O-Ring 718 710005 Pin-Locating

227 710051 Lever-Governor 725 710102 Sheild-Heat

230 •710058 Washer-Spacer 890 715136 Bracket-Support

277 710004 Washer-Seal 1019 715031 Label Kit

306 710063 Sheild-Cylinder 1052 715353 Sensor-Oil

356 710308 Wire-Oil Sensor 1058 273126 Owner’s Manual

PART

NO. DESCRIPTION

REF.

NO.

PART

NO. DESCRIPTION

Page 22

ENGINE PART

CRAFTSMAN 3750 WATT GENERATOR 919.679370 ENGINE NUMBER 138432-0035-A1

22

22A

523

116B

J

REF. PART

NO. NO. DESCRIPTION

12 • 710628 Gasket-Crankcase

17 710003 Bearing-Ball

18 715463 Cover-Crankcase

20 #710215 Seal-Oil

22 710032 Screw-Hex.

•Included In Gasket Set-Part No. 715482

★ Included inValve Overhaul Kit-Part No. 715483

Alncluded in Carburetor Kit-Part No. 715484

♦Included In Gasket Gasket Set -Part No. 715485

REF. PART

NO. NO. DESCRIPTION

22A 710306 Screw-Hex

116B *710029 Seal-O-RIng

219 715341 Gear-Governor

220 710035 Washer-Spacer

22

REF. PART

NO. NO. DESCRIPTION

221 710027 Cup-Governor

225 710028 Shaft-Governor Gear

523 715007 Dipstick

718 710005 Pin-Locating

Page 23

ENGINE PARTS

CRAFTSMAN 3750 WATT GENERATOR 919.679370 ENGINE NUMBER 138432-0035-A1

635

337

10

J

REF.

NO.

40A 715130 Retainer-Valve Plug

»Included In Gasket Set-Part No, 715482

^Included inValve Overhaul Kit-Part No. 715483

Aincluded in Carburetor Kit-Part No. 715484

^Included in Gasket Gasket Set -Part No. 715485

PART

NO. DESCRIPTION

5 715444 Head-Cylinder 45 710008 Tappet-Valve

7 •*710624 Gasket-Cylinder Head 53 710148 Stud-Carburetor

10 710023 Screw-Hex Mounting

13 710020 Screw-Hex 53A 710099 Stud

33 715445 Valve-Exhaust (Muffler Mounting)

34 715446 Valve-Intake 337 491055 Plug-Spark

35 710011 Spring-Valve 373A 710007 Nut-Lock

40 710012 Retainer-Valve 383 19374 Wrench-Spark

REF.

NO.

PART

NO. DESCRIPTION

551 715450 Cover-Rocker

23

REF.

NO.

635 710634 Boot-Spark Plug

830 710016 Stud-Rocker Arm

868 •710019 Seal-Valve

1022 #*710626 Gasket-Rocker

1026 710622 Rod-Push

1029 710014 Arm-Rocker

1034 710017 Guide-Push Rod

1050 710015 Adjuster-Rocker Arm

PART

NO. DESCRIPTION

Cover

Page 24

ENGINE PART

CRAFTSMAN 3750 WATT GENERATOR 919.679370 ENGINE NUMBER 138432-0035-A1

J

REF. PART REF. PART REF. PART

NO. NO. DESCRIPTION NO. NO. DESCRIPTION NO. NO. DESCRIPTION

16 715426 Crankshaft 25 715456 Piston Assy. 27 710040 Lock-Piston Pin

Used on Type No(s). (Standard) 28 715455 Pin-Piston Std.

0035, 0084 715457 Piston Assy. 29 715427 Rod-Connecting

(.010” O.S.) (Standard)

715448 Piston Assy. 715502 Rod-Connecting

(.020” O.S.) (.020” Undersize)

26 715452 Ring Set 32 710041 Screw-Connecting

(Standard) Rod

715453 Ring Set 46 715451 Grear-Cam

(.010” O.S.) 718A 710616 Pin-Compression

715454 Ring Set

(.010” O.S.)

»Included In Gasket Set-Part No. 715482

^Included inValve Overhaul Kit-Part No. 715483

Aincluded in Carburetor Kit-Part No. 715484

♦Included in Gasket Gasket Set -Part No. 715485

24

1051 710039 Ring-Retaining

Page 25

ENGINE PARTS

CRAFTSMAN 3750 WATT GENERATOR 919.679370

J

ENGINE NUMBER 138432-0035-A1

163 (b

REF.

NO.

51 #*A+710060 Gasket-Intake

95 710672 Screw-Round Head

98

104

105

108 710674 Valve-Choke

117

122 715034 Spacer-Carburetor

125 715473 Carburetor

PART

NO. DESCRIPTION

715478

•

710663 Pin-Float

•

710661 Valve-Needle

•

710665 Jet-Main

710719 Jet-Main

Screw-Idle Speed

-NOTE-

(High Altitude)

REF.

NO.

130 710671 Valve-Throttle

131 715480 Shaft-Throttle

133 715477 Float-Carburetor

137 Gasket-Float Bowl

138

141 715479 Choke Shaft Kit

142 • 710664 Nozzle-Carburetor

147 • 710675 Jet-Pilot

154 710081 Nut-Hex

163**M710639 Gasket-Air Cleaner

620 710635 Bracket-Control

PART

NO. DESCRIPTION

(Sold In Kit Only)

«♦

710720 Jet-Pilot

Washer

(Sold In Kit Only)

-NO 11-

(High Altitude)

154 e

1043

REF.

NO.

634A

634B

955A 710679 Plug-Carburetor

PART

NO. DESCRIPTION

«

•

955 710667 Screw-Bowl

975 715476 Bowl-Float

Seal-Throttle Shaft

(Sold In Kit Only)

Bushing-Choke

Shaft

(Sold In Kit Only)

Mounting

#lncluded in Gasket Set-Part No. 715482

★ Included inValve Overhaul Kit-Part No. 715483

Aincluded in Carburetor Kit-Part No. 715484

♦Included in Gasket Gasket Set -Part No. 715485

25

Page 26

ENGINE PART

CRAFTSMAN 3750 WATT GENERATOR 919.679370

53

\

51

354®

J

ENGINE NUMBER 138432-0035-A1

6*31

467

REF.

NO.

11 710115 Tube-Breather

51 •★ A+710060 Gasket-Intake

53 710148 Stud-Carburetor

129 715024 Screw-Governor

161 710521 Base-Air Cleaner

»Included in Gasket Set-Part No. 715482

^Included inValve Overhaul Kit-Part No. 715483

Aincluded in Carburetor Kit-Part No. 715484

♦Included in Gasket Gasket Set -Part No. 715485

PART

NO. DESCRIPTION

Mounting

Speed

(High and Idle

Speed Adjustment)

REF.

NO.

202 710637 Link-Mechanical

209 710702 Spring-Governor

232 710638 Spring-Link

235 710522 Shield-Fuel Spray

354 710068 Nut-Hex

467 280715 Knob-Control

535 491435 Filter-Air

PART

NO. DESCRIPTION

Governor

26

REF.

NO.

620B 715025 Bracket-Control

PART

NO. DESCRIPTION

663 710057 Screw-Hex

967 491588 Air Filter

968 495872 Cover-Air Cleaner

969 93473 Screw-Hex

Page 27

ENGINE PARTS

CRAFTSMAN 3750 WATT GENERATOR 919.679370 ENGINE NUMBER 138432-0035-A1

J

REF.

NO.

53A 710099 Stud

300 715508 Muffler-Exhaust

408 710307 Screw-Phllllps

505 710090 Nut-Lock

»Included in Gasket Set-Part No. 715482

^Included inValve Overhaul Kit-Part No. 715483

Aincluded in Carburetor Kit-Part No. 715484

♦Included in Gasket Gasket Set -Part No. 715485

PART

NO. DESCRIPTION

(Muffler Mounting)

REF.

NO.

663 710057 Screw-Hex

673 93705 Screw-Hex

676 715230 Deflector-Muffler

737 710074 Screw-Hex

823 710248 Screw-Hex

PART

NO. DESCRIPTION

27

REF.

NO.

832 710565 Guard-Muffler

863 714319 Bracket-Muffler

883 **-710082 Gasket-Muffler

994 715491 Arrester-Spark

1075 710329 Screen-Outlet

PART

NO. DESCRIPTION

Page 28

ENGINE PART

CRAFTSMAN 3750 WATT GENERATOR 919.679370

J

ENGINE NUMBER 138432-0035-A1

REF.

NO.

281 710646 Panel-Control

»Included in Gasket Set-Part No. 715482

^Included inValve Overhaul Kit-Part No. 715483

Aincluded in Carburetor Kit-Part No. 715484

♦Included in Gasket Gasket Set -Part No. 715485

PART

NO. DESCRIPTION

10 710023 Screw-Hex

Used on Type No(s).

0035

305^

REF.

NO.

304 715465 Housing-Blower 356A 710120 Wire-Stop

305 710095 Screw-Hex 356B 710087 Wire-Stop

347 493521 Switch-Rocker 663A 710160 Screw-Hex

PART

NO. DESCRIPTION

(Without Lamp) 663B 710234 Screw-Hex

REF.

NO.

PART

NO. DESCRIPTION

670 710159 Spacer-Fuel Tank

813 710083 Clamp

1036 499350 Label Kit-Emission

1053 710305 Module

28

Page 29

ENGINE PARTS

CRAFTSMAN 3750 WATT GENERATOR 919.679370 ENGINE NUMBER 138432-0035-A1

737 f

J

REF.

NO.

281A 710658 Panel-Control

332A 710345 Nut-Hex

PART

NO. DESCRIPTION

23 715429 Flywheel

120 93836 Washer-Lock

154 93837 Nut-Hex

332 710048 Nut-Hex

333 715464 Armature-Magneto

332A

334

1054

455

REF.

NO.

334 710047 Screw-Hex 890A 710644 Bracket-Support

354 710068 Nut-Hex 892 493625 Key Switch

356C 710324 Wire-Ground (Includes Keys)

455 710277 Cup-Flywheel 990 392832 Key Set-Starter

475 715200 Rectifier Switch

521 710045 Shielding-Cable 1054 710349 TIe-Cabie

526 710089 Srew-Hex

729 710046 Clip-Wire

737 710074 Screw-Hex

PART

NO. DESCRIPTION

890A

REF.

NO.

3S4

PART

NO. DESCRIPTION

737

%

•Included in Gasket Set-Part No. 715482

^Included inValve Overhaul Kit-Part No. 715483

Aincluded in Carburetor Kit-Part No. 715484

♦Included in Gasket Gasket Set -Part No. 715485

29

Page 30

ENGINE PART

CRAFTSMAN 3750 WATT GENERATOR 919.679370 ENGINE NUMBER 138432-0035-A1

J

REF.

NO.

55 715132 Housing-Rewind

56 710274 Pulley-Starter

57 710270 Spring-Rewind

♦Included in Gasket Set-Part No. 715482

★ Included inValve Overhaul Kit-Part No. 715483

Aincluded in Carburetor Kit-Part No. 715484

♦Included in Gasket Gasket Set -Part No. 715485

PART

NO. DESCRIPTION

Starter

Starter

REF.

NO.

58 710275 Rope-Starter 461 805955 Screw-Shoulder

60 490652 Grip-Starter Rope 615 805952 Ring-Rewind Starter

456 710272 Plate-Pawl Friction 737 710074 Screw-Hex

459 715256 Pawl-Ratchet

PART

NO. DESCRIPTION

(Cut to Required 515 805953 Spring-Pawl

Length) 608 715133 Sta rter-RewInd

30

REF.

NO.

PART

NO. DESCRIPTION

Page 31

ENGINE PARTS

CRAFTSMAN 3750 WATT GENERATOR 919.679370 ENGINE NUMBER 138432-0035-A1

358 GASKET SET

116B0 524 0 «6A#

20/^ 617# 1160

121 CARBURETOR KIT

104

138® lOSg 147|

J

«7 1

163

REF.

NO.

3

12

20

51 #*A4.710060

104

105

116

116A

116B • 710029 Seal-O-Ring

117

PART

NO. DESCRIPTION

•

710000 Seal-Oil

7 •*

710624 Gasket-Cylinder Head

•

710628 Gasket-Crankcase

•

710215 Seal-Oil

A

710663 Pin-Float

A

710661 Valve-Needle

•

710055 Seai-OII

•

710091 Seal-O-RIng

A

710665 Jet-Main

Gasket-Intake

634A® 634B® 142|

^ 51 13?C^

377 CARBURETOR GASKET SET

51

138 <S> 163 137

REF.

NO.

121 715484 Carburetor Kit 617 *710069 Seal-O-Ring

137 A4- Gasket-Float 634A

138

142

147 A 710675 Jet-Pilot 868 * 710019 Seal-Valve

163«*A+710639 Gasket-Air Cleaner 883 •*710082 Gasket-Exhaust

277 • 710004 Washer-Seal 977 715485 Gasket Set358 715482 Gasket Set Carburetor

524 • 710072 Seal-O-RIng 1022 •*710262 Gasket-Rocker

PART

NO. DESCRIPTION

Bowl (Sold In Kit Shaft (Sold in Kit

Only) Only)

AA

A 710664

Washer 634B

(Sold In Kit Only) Shaft (Sold in Kit

Nozzle-Carburetor Only)

o

REF.

NO.

1033 715483 Kit-Valve Overhaul

PART

NO. DESCRIPTION

•

*

Seal-Throttle

Bushing-Choke

Cover

»Included in Gasket Set-Part No. 715482

★ Included inValve Overhaul Kit-Part No. 715483

Aincluded in Carburetor Kit-Part No. 715484

^Included in Gasket Gasket Set -Part No. 715485

31

Page 32

Briggs & Stratton Corporation {B&S), the California Air Resources Board (CARS)

Emission Control System Warranty Statement (Owner’s Defect Warranty Rights and Obligations)

In the interest of the environment. B&S engines that meet strict emis

sion requirements are labeled, “This engine conforms to 1995-1998

California emission regulations for ULGE engines and U.S. EPA

Phase I regulations for small non-road engines.”

EMISSION CONTROL WARRANTY COVERAGE IS APPLICABLE

GARB, U.S. EPA and B&S are pleased to expiairr the Emission

Control System Warranty on your 1996 and later utility or lawn and

garden equipment (ULGE) engine. In California, new ULGE engines

produced on or after August 1, 1995 must be designed, built and

equipped to meet the State’s stringent anti-smog standards.*Else

where in the United States, new non-road, spark-ignition engines

certified for model year 1997 and later, must meet similar standards

set forth by the U.S. EPA. B&S must warrant the emission control

system on your engine for the periods of time listed below, provided

ULGE engines are warranted relative to emission control parts below. If any covered part on your engine is defective, the part will be

defects for a period of two years, subject to provisions set forth repaired or replaced by B&S.

As the ULGE engine owner, you are responsible for the performance

of the required maintenance listed in your Operator/Owner Manual

B&S recommends that you retain all your receipts covering mainte

nance on your ULGE engine, but B&S cannot deny warranty solely

for the lack of receipts orfor your failure to ensure the performance of

all scheduled maintenance.

As the ULGE engine owner, you should however be aware that B&S

may deny you warranty coverage if your ULGE engine or a part has

failed due to abuse, neglect, improper maintenance or unapproved

modifications.

The following are specific provisions relative to your Emission Control Defects Warranty Coverage. It is in addition to the B&S engine warranty

for non-regulated engines found in the Operator/Owner Manual.

1. Warranted Parts

Coverage under this warranty extends only to the parts listed

below (the emission control systems parts) to the extent these

parts were present on the engine purchased.

Fuel Metering System

a.

• Cold start enrichment system (soft choke)

• Carburetor and internal parts

• Fuel Pump

Air Induction System

b.

• Air cleaner

• Intake manifold

Ignition System

c.

• Spark plug(s)

• Magneto ignition system

Catalyst System

d.

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

Miscellaneous Items Used in Above Systems

e.

• Vacuum, temperature, position, time sensitive valves

and switches

• Connectors and assemblies

Length of Coverage

B&S warrants to the initial owner and each subsequent purchaser

that the Warranted Parts shall be free from defects in materials

and workmanship which caused the failure of the Warranted

Parts for a period of two years from the date the engine is deliv

ered to a retail purchaser.

and the United States Environmental Protection Agency (U.S. EPA) _ _

TO CERTIFIED ENGINES PURCHASED IN CALIFORNIA IN 1995

AND THEREAFTER, WHICH ARE USED IN CALIFORNIA, AND

TO CERTIFIED MODEL YEAR 1997 AND LATER ENGINES

WHICH ARE PURCHASED AND USED ELSEWHERE IN THE

UNITED STATES.

California and United States Emission Control Defects Warranty Statement

there has been no abuse, neglect or improper maintenance of your

ULGE engine.

Your emission control system Includes parts such as the carburetor,

air cleaner, ignition system, muffler and catalytic converter. Also

included may be connectors and other emission related assemblies.

Where a warrantable condition exists, B&S will repair your ULGE

engine at no cost to you inctuding diagnosis, parts and labor.

Briggs a Stratton Emission Control Defects Warranty Coverage

Owner’s Warranty Responsibilities

You are responsible for presenting your ULGE engine to an Autho

rized B&S Service Dealer as soon as a problem exists. The undis

puted warranty repairs should be completed in a reasonable amount

of time, not to exceed 30 days.

tf you have any questions regarding your warranty rights and

responsibilities, you should contact a B&S Service Representative

at 1-414-259-5262.

The emission warranty is a defects warranty. Defects are judged on

norma! engine performance. The warranty is not related to an in-use

emission test.

Briggs & Stratton Emission Control Defects Warranty Provisions

3. No Charge

Repair or replacement of any Warranted Part will be performed

at no charge to the owner, including diagnostic labor which leads

to the determination that a Warranted Part is defective, if the

diagnostic work is performed at an Authorized B&S Service

Dealer. For emissions warranty service contact your nearest

Authorized B&S Service Dealer as listed in the “Yellow Pages”

under “Engines, Gasoline,” “Gasoline Engines,” “Lawn

Mowers,” or similar category.

4. Claims and Coverage Exclusions

Warranty claims shall be filed in accordance with the provisions

of the B&S Engine Warranty Policy. Warranty coverage shall be

excluded for failures of Warranted Parts which are not original

B&S parts or because of abuse, neglect or improper mainte

nance as set forth in the B&S Engine Warranty Policy. B&S is not

liable to cover failures of Warranted Parts caused by the use of

add-on, non-original, or modified parts.

5. Maintenance

Any Warranted Part which is not scheduled for replacement as

required maintenance or which is scheduled only for regular

inspection to the effect of “repair or replace as necessary” shall

be warranted as to defects for the warranty period. Any

Warranted Part which is scheduled for replacement as required

maintenance shat! be warranted as to defects only for the period

of time up to the first scheduled replacement for that part. Any

replacement part that is equivalent in performance and durability

may be used in the performance of any maintenance or repairs.

The owner is responsible for the performance of all required

maintenance, as defined in the B&S Operator/Owner Manual.

6. Consequential Coverage

Coverage hereunder shall extend to the failure of any engine

components caused by the failure of any Warranted Part still

under warranty.

32

Page 33

Briggs & Stratton welcomes warranty repair and apologizes

to you for being inconvenienced. Any Authorized Service

Dealer may perform warranty repairs. Most warranty repairs

are handled routinely, but sometimes requests for warranty

service may not be appropriate. For example, warranty would

not apply if engine damage occurred because of misuse, lack

of routine maintenance, shipping, handling, warehousing or

improper ¡nstallation. Similarly, warranty is void if the serial

number of the engine has been removed or the engine has

been altered or modified.

If a customer differs with the decision of the Service*Dealer, an

investigation will be made to determine whether the warranty

applies. Ask the Service Dealer to submit al! supporting facts to

his Distributor or the Factory for review. If the Distributor or the

Factory decides that the claim is justified, the customer will be

fully reimbursed for those items that are defective. To avoid

misunderstanding which might occur between the customer

and the Dealer, listed below are some of the causes of engine

failure that the warranty does not cover.

Improper maintenance:

The life of an engine depends upon the conditions under

which it operates, and the care it receives. Some applications,

such as tillers, pumps and rotary mowers, are very often used

in dusty or dirty conditions, which can cause what appears to

be premature wear. Such wear, when caused by dirt, dust,

spark plug cleaning grit, or other abrasive material that has

entered the engine because of improper maintenance, is not

covered by warranty.

This warranty covers engine related defective material

and/or workmanship only, and not replacement or refund

of the equipment to which the engine may be moynted.

Nor does the warranty extend to repairs required

because of:

4.

Parts which are scored or broken because an engine was

operated with insufficient or contaminated lubricating oil,

or an incorrect grade of lubricating oil (check oil level daily

or after every 8 hours of operation. Refill when necessary

and change at recommended intervals.) Read “Owner’s

Manual.”

5.

Repair or adjustment of associated parts or assemblies

such as clutches, transmissions, remote controls, etc.,

which are not manufactured by Briggs & Stratton.

6.

Damage or wear to parts caused by dirt, which entered

the engine because of improper air cleaner maintenance,

re-assembly, or use of a non-original air cleaner element

or cartridge. (At recommended intervals, dean and re-oil

the Oil-Foam® element or the foam pre-cleaner, and

replace the cartridge.) Read “Owner’s Manual.”

7.

Parts damaged by overspeeding, or overheating caused

by grass, debris, or dirt, which plugs or clogs the cooling

fins, or flywheel area, or damage caused by operating the

engine in a confined area without sufficient ventilation.

(Clean fins on the cylinder, cylinder head and flywheel at

recommended intervals.) Read “Owner's Manual.”

8

Engine or equipment parts broken by excessive vibration

caused by a loose engine mounting, loose cutter blades,

unbalanced blades or loose or unbalanced impellers,

improper attachment of equipment to engine crankshaft,

overspeeding or other abuse in operation.

9. A bent or broken crankshaft, caused by striking a solid

object with the cutter blade of a rotary lawn mower, or

excessive v-belt tightness.

10. Routine tune-up or adjustment of the engine.

11. Engine or engine component failure, i.e., combustion

chamber, valves, valve seats, valve guides, or burned

starter motor windings, caused by the use of alternate

fuels such as, liquified petroleum, natural gas, altered

gasolines, etc.

1. PROBLEMS CAUSED BY PARTS THAT ARE NOT

ORIGINAL BRIGGS & STRATTON PARTS.

2. Equipment controls or installations that prevent starting,

cause unsatisfactory engine performance, or shorten

engine life. (Contact equipment manufacturer.)

3. Leaking carburetors, dogged fuel pipes, sticking valves,

or other damage, caused by using contaminated or stale

fuel. (Use clean, fresh, lead-free gasoline and Briggs &

Stratton gasoline stabilizer, Part No. 5041.)

33

Page 34

Dear Customer,

In manufacturing this product, many steps have been taken to provide you with the highest quality.

Unfortunately, errors oromissions occasionally occur. In the event that you find a missing or defective

part, please contact your nearest Sears store.

SERVICE AND REPAIR PARTS

CALL 1-800-665-4455 *

Keep this number handy should you require a service call or

need to order repair parts.

If ordering parts make sure you have the

name, make and model no, of the merchandise and the name

and number of the part you wish to order.

* If calling locally, please use one of the following numbers:

Regina - 566-5124 Montreal - 333-5740

Toronto - 744-4900 Halifax - 454-2444

Kitchener - 894-7590 Ottawa - 738-4440

Vancouver - 420-8211

If you have any suggestions that would help us to improve our assembiy/operation instructions, or

this product, please write them down and mail it to:

Sears Canada Inc.

222 Jarvis Street

Toronto, Ontario

MSB 2B8

Attention: Buyer Dept: D671 Model No.

NAME

ADDRESS

POSTAL CODE PHONE#

COMMENTS

Loading...

Loading...