Page 1

OWNER'S MANUAL

CRAFTSMAN

6.5 Horsepower 2500 PSI 2.7 GPIVI High Pressure Washer

Model No;

919.678250

WARNING: Before using this

product, read this manual

and follow all Safety Rules

and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

1S622 MGP-67B250A Rev. 4/B/S8

PRESSURE WASHER /

CUSTOMER

r HELPLINE

1-800-245-5873

• Safety

• Assembly

• Operation

• Maintenance

• Parts List i

• Français

Page 2

Page 3

TABLE OF CONTENTS

Warranty

Safety Guidelines

Assembly..................................

Operation..................................

Maintenance.............................

Service and Adjustments

...................................

....................

........

........

........

........

........

........

........

2

3-5

5-7

7-11

12-14

15

Storage ..........................

Troubleshooting............

Parts

...............................

EPA Codes

How to Order Parts

Español

....................

.......

..........................

LIMITED ONE YEAR WARRANTY ON CRAFTSMAN HIGH PRESSURE WASHER

For one year from the date of purchase, when this Craftsman High Pressure Washer is maintained

and operated according to the instructions in the owner’s manual, Sears will repair, free of charge,

any defect in materiai and workmanship.

If your Craftsman Pressure Washer is used for commericai or rental purposes, this warranty

appiies only for 90 days from the date of purchase.

.......................15

.......................16

.................17-28

................. 29-30

.......

Back Cover

................. 32-50

LIMITED ONE YEAR WARRANTY ON CRAFTSMAN ENGINE

Maintenance, replacement or repair of the emission control devices and systems may be per

formed by any nonroad engine repair estabiishment or individuai. However, to obtain no charge

repairs under the terms and provisions of Craftsman warranty statement, any service or emission

controi part repair or replacement must be performed by an factory authorized dealer.

For one year from the date of purchase, when this Craftsman engine is maintained and operated

according to the instructions in the owner’s manual. Sears will repair, free of charge, any defect in

materiai and workmanship.

If your Craftsman engine is used for commericai or rentai purposes, this warranty applies only for

90 days from the date of purchase. This warranty does not cover; Expendable items such as

spark plugs and air filters, which become worn during normal use.

Repairs necessary because of operator abuse or negligence, inciuding damage resuiting from no

water being supplied to pump or failure to maintain the equipment according to the instructions

contained in the owner’s manuai, are not covered under warranty.

WARRANTY SERViCE IS AVAILABLE BY RETURNING THE HIGH PRESSURE WASHER TO THE

NEAREST SEARS SERVICE CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

This, warranty gives you specific legai rights and you may also have other rights, which vary from

state to state.

Sears, Roebuck and Co., D/817 WA, Hoffman Estates, IL 60179

Page 4

Page 5

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This information relates to protecting

YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the symbols

below. Please read the manual and pay attention to these sections. SAVE THESE DEFINITIONS/INSTRUCTIONS.

A WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious iniurv.

A CAUTION indicates a potentially hazardous situation

A DANGER indicates an imminently hazardous

situation which, if not avoided, win result in

death or serious iniurv.

which, if not avoided, mav result in minor or moderate

iniurv.

lo/s/gy

IMPORTANT SAFETY INSTRUCTIONS

AWARNING

Tiproper operation or maintenance of this product couid result in serious injury and property damage. Read

md understand ail warnings and operating instructions before using.

HAZARD

A DANGER

RISK OF EXPLOSION

OR FIRE

WHAT CAN HAPPEN HOW TO PREVENT IT

• Spilled gasoline and its vapors can

become ignited from cigarette

sparks, electrical arcing, exhaust

gases, and hot engine components

such as the muffler.

• Heat will expand fuel in the tank

which could result in spillage and

possible fire explosion.

Operating the pressure washer in an

explosive environment could result

in a fire.

Materials placed against or near the

pressure washer can interfere with

its proper ventilation features

causing overheating and possible

ignition of the materials.

Improperly stored fuel could lead to

accidental ignition. Fuel improperly

secured could get into the hands of

children or other unqualified persons.

Shut off engine and allow it to cool

before adding fuel to the tank.

Use care in filling tank to avoid

spilling fuel. Move pressure washer

away from fueling area before

starting engine.

Keep maximum fuel level Vi" below

top of tank to allow for expansion.

Operate and fuel equipment in well

ventilated areas free from obstruc

tions. Equip areas with fire

extinguishers suitable for gasoline

fires.

Never operate pressure washer in an

area containing dry brush or weeds.

• Store fuel in container approved for

gasoline, in a secure location away

from work area.

Adanger

RISK TO BREATHING

Breathing exhaust fumes will cause

serious injury or death.

• Some cleaning fluids contain sub

stances which could cause injury to

skin, eyes, or lungs.

Operate pressure washer in a well

ventilated area. Avoid enclosed areas

such as garages, basements ,etc.

Never operate unit in a location

occupied by humans or animals.

Use only cleaning fluids specifically

recommended for high pressure

washers. Follow manufacturers

recommendations.

Page 6

Page 7

IMPORTANT SAFETY INSTRUCTIONS (contad)

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

^WARNING

RISK OF UNSAFE

OPERATION

RISK OF INJURY FROM

SPRAY

• Unsafe operation of your pressure

washer could lead to serious injury

or death to you or others.

• The spray gun/wand is a powerful

cleaning tool that could look like a

toy to a child.

• Reactive force of spray will cause

gun/wand to move, and could cause

the operator to slip or fall, or

misdirect the spray. Improper control

of gun/wand can result in injuries to

self and others.

• High velocity fluid spray can cause

objects to break, propelling particles

at high speed.

• Light or unsecured objects can become

hazardous projectiles.

Become familiar with the operation

and controls of the pressure washer.

Keep children away from the

pressure washer at all times.

Never defeat the safety features of this

product.

Do not operate machine with missing,

broken, or unauthorized parts.

Never leave wand unattended while

unit is running.

Keep work area free of obstaoles.

Stand on a stable surface and grip gun/

wand firmly. Expect the gun to kick

when triggered.

Always wear ANSI approved Z87 safety

glasses. Wear protective clothing to

protect against accidental spraying.

Never point wand at, or spray people or

animals.

Always secure trigger lock when wand

is not in service to prevent accidental

operation.

Never permanently secure trigger in pull

back (open) position.

Awarning

RISK OF

ELECTRICAL

SHOCK

Awarning

RISK OF FLUID INJECTION

Awarning

RISK OF CHEMICAL BURN

• Spray directed at electrical outlets or

switches, or objects connected to an

electrical circuit, could result in a fatal

electrical shock.

• Your washer operates at fluid

pressures and velocities high enough

to penetrate human and animal flesh,

which could result in amputation or

other serious injury. Leaks caused by

loose fittings or worn or damaged

hoses can result in injection injuries.

DO NOT TREAT FLUID INJECTION AS

A SIMPLE CUT! See a physician

immediately!

• Relieve system pressure before

attempting maintenance or disassem

bly of equipment.

Use of acids, toxic or corrosive

chemicals, poisons, insecticides, or

any kind of flammable solvent with this

product could result in serious injury

or death.

Unplug any electrically operated

product before attempting to ciean it.

Direct spray away from electric outlets

and switches.

Never place hands in front of nozzle.

Direct spray away from self and others.

Make sure hose and fittings are

tightened and in good condition. Never

hold onto the hose or fittings during

operation.

Do not allow hose to contact muffler.

Never attach or remove wand or hose

fittings while system is pressurized.

Use only hose and high pressure

accessories rated for 2500 PSi service.

To relieve system pressure, shut off

engine, turn off water supply, and pull

gun trigger until water stops flowing.

• Do not use acids, gasoline, kerosene, or

any other flammable materials in this

product. Use only household

detergents, cleaners and degreasers

recommended for use in pressure

washers.

• Wear protective clothing to protect

eyes and skin from contact with

sprayed materials.____________________

Page 8

Page 9

HAZARD

IMPORTANT SAFETY INSTRUCTIONS (cont’d)

WHAT CAN HAPPEN

HOWTO PREVENT IT

Awarning

RISK OF HOT SURFACES

iternational

ymbols

m

Contact with hot surfaces, such as

engines exhaust components, could

result in serious burn.

Safety Alert - Read

Owner’s Manual

[ O Of Of* (®)Stop 05

During operation, touch only the control

surfaces of the pressure washer. Keep

children away from the pressure washer

at all times. They may not be able to

recognize the hazards of this product.

Fuel

Shutoff

Fuel

0

N

Choke

IMPORTANT:

'he powerful spray from your pressure washer is capable of causing damage to fragile surfaces such as: wood, glass,

lutomobile paint, auto stripping and trim, and delicate objects such as flowers and shrubs. Before spraying, check the

tern to be cleaned to assure yourself that it is robust enough to resist damage from the force of the spray. Avoid the

jse of the concentrated spray stream except for very strong surfaces like concrete and steel.

Operating unit with water supply shut off without flow of water will result in equipment damage. You should never run

!hls pressure washer for more than 2 minutes without pulling the trigger to allow cool water to enter the pump and the

leated (recirculated) water to exit. Running the pressure washer with water supply shut off will void your warranty.

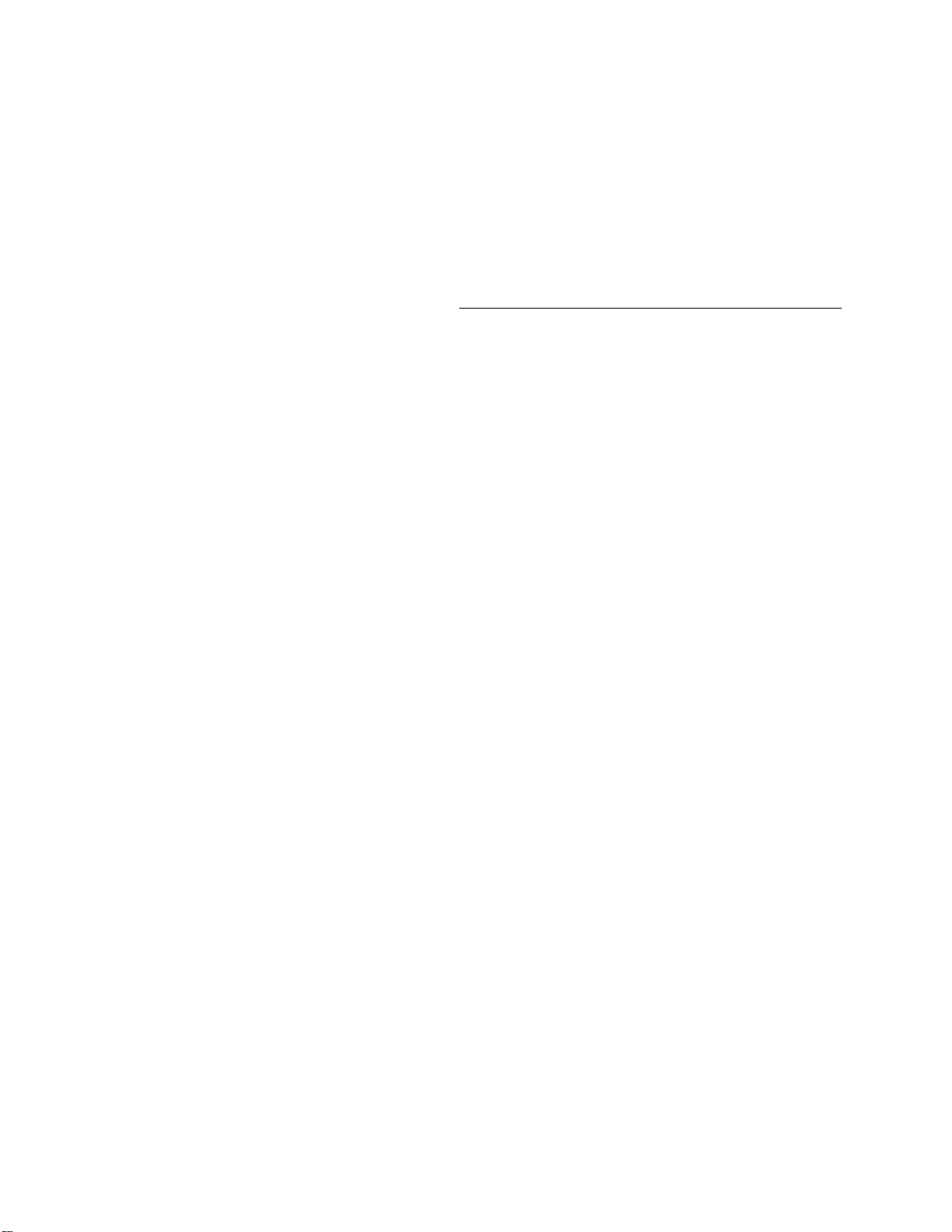

ASSEMBLY

Carton Contents

• Main Unit pressure washer with wheels

• Handle

• High Pressure Hose

• Chemical Pickup Hose and Filter

• Gun

• Wand

Bag Containing

• Video Cassette

• Owners’ Manual

• Nozzle Cleaning Kit and Replacement 0-Rings

• Engine Oil

• Rubber Isolator and Mounting Hardware

• Handle Mounting Hardware

Main Unit pressure washer Handle

with wheels

Chemical Pickup Hose and Filter

Video Cassette Owners’ Manual Nozzle Cleaning Kit

o

High Pressure Hose

Gun and Wand

o

<SBt>

Handle Mounting

Hardware

Engine Oil Rubber Isolator and

Mounting Hardware

0®

Replacement 0-Rings

Page 10

Page 11

Tools Required for Assembly

Adjustable wrench Pliers

1 /2” Socket wrench Funnel

Remove Pressure Washer from Carton

• Open box from the top. Locate and remove from

box, the parts box, which includes gun, handle,

wand,oil, knobs and J bolts. Next remove the parts

bag and the handle.

• Cut carton along dotted lines.

• Remove all carton inserts.

• Roll unit through opening in carton.

NOTE: The high pressure and chemical hose are

located at the bottom of the box.

Preparing the Pressure Washer for First Use

• Note: Included with your pressure washer is a video

tape on how to prepare your unit for operation. It is

recommended you view this tape before performing

the next steps.

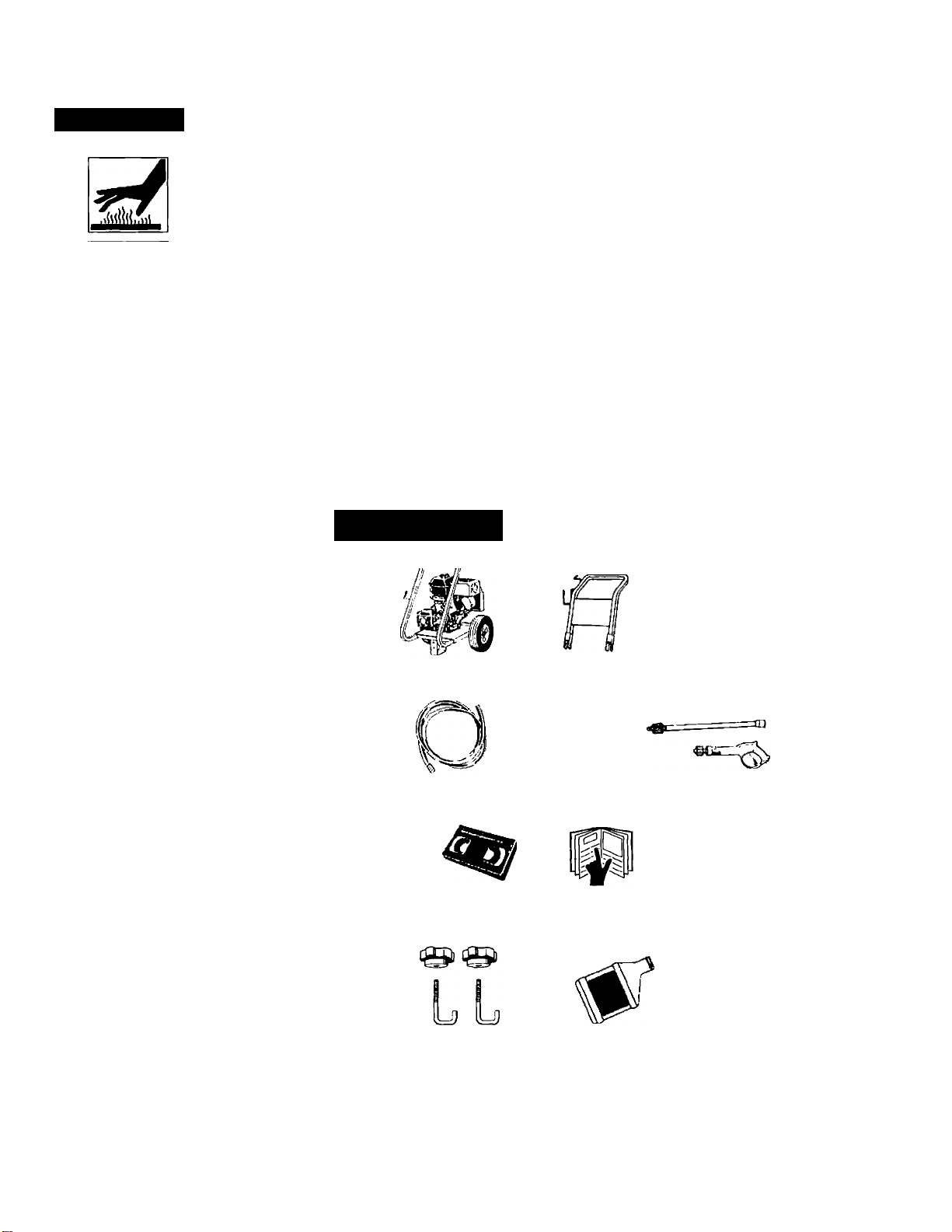

1. • Insert handle onto frame.

• Slide J bolts into frame.

• Tighten knobs turning in clockwise direction.

/0^^2237//trighton knob in clockwise

' direction to threaded end of J boit.)

Ilneert J boit here. Threaded end

goes in bottom hole)

Page 12

2. • Remove wood plank from the frame of the unit.

An adjustable wrench is required. Discard nut,

bolt and board.

3. • Mount the rubber isolator to the frame. To moun

isolator place threaded end of bolt through the

washer. Next with washer on bolt, place threader

end of bolt through the rubber isolator. Place

threaded portion of isolator through the front

hole location where the wood plank was mounter

on to the pressure washer. Next place lockwashc

over threaded portion of nut that has been placer

through the mounting hole in the pressure washei

and use nut to tighten isolator to the frame.

Tighten nut with an adjustable wrench. All isolatoi

parts are supplied in parts bag.

BOLT

LOCKWASHER

------

A

NUT

PRESSURE , ,

WASHER l„f-|SOLATOR

FRAME C-^WASHER

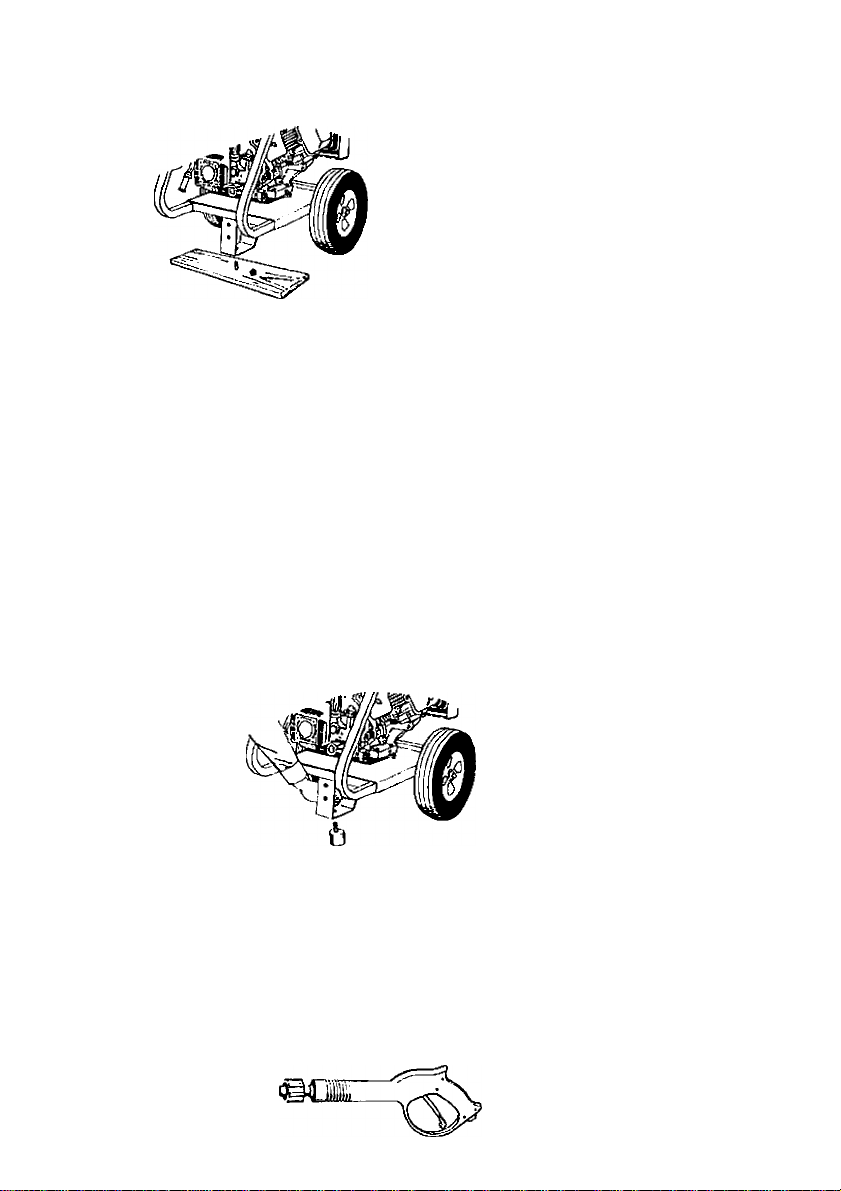

4. • Connect wand with nozzle extension to gun. To

tighten, turn knob in clockwise direction. Hand

tighten.

Page 13

Cut tie wrap off of high pressure hose. Unwind

high pressure hose to attach the threaded end to

the gun.

Connect chemical hose to the chemical injector

hose barb on pump.

CHEMICAL

INJECTOR

HOSE

PUMP

8.

Your units pump is shipped with a

temporary plug that must be replaced with a

breather cap. This plug is located over the

pump’s oil port. Unscrew and remove this plug.

Remove the breather cap from the bag attached

to the plug and install it in the pump’s oii port.

BREATHEI

CAP

9. • Piace assembied gun and wand on pressure

handle bracket as shown.

7. • Connect high pressure hose to the quick connect

outlet on pressure washer.

QUICK

CONNECT

NOTE: Always keep hose away from engine

muffler.

CAUTION: Failure to replace the plug will result

in serious pump damage.

Checklist

Before going any further piease review the foiiowing:

• Be sure you have completed assembly instruction.

• Double check all fittings to be sure they are tight.

IMPORTANT: Before any attempt to start your pres

sure washer be sure to check engine oii (See Operation

under Engine Oii, page 9.)

Page 14

Page 15

OPERATION

Know Your High Pressure Washer

Read this Owner’s Manual and Safety Rules before

operation of your High Pressure Washer Compare

this illustration with our pressure washer to familiarize

yourself with the location of various controls and

adjustments. Save this manual for future reference.

PUMP- Develops high pressure.

ENGINE OIL FILL- Place where engine oil is poured.

PRESSURE REGULATOR- Allows you to adjust the

pressure of the outlet stream.

ENGINE RUN/STOP SWITCH- Sets engine in starting

mode for recoil starter — Stops running engine.

RECOIL STARTER- Used for starting the engine

manually.

SPRAY GUN ASSEMBLY- Controls the application of

water onto cleaning surface with trigger device.

PUMP OIL FILL- Port where pump oil Is poured and

breather cap is located.

GAS TANK/CAP- Cap is removed and unleaded

gasoline is poured.

CHEMICAL INJECTION TUBE AND FILTER- Mixes

water and detergent in outlet water flow.

HIGH PRESSURE OUTLET- Connection for high pres

sure hose.

CHOKE- Lever used for starting unit.

CHEMICAL

ADJUSTMENT

KNOB

Page 16

Page 17

topping Your Pressure Washer

4 CAUTION; Do not run pump without the water

supply connected and turned on. Failure to do so

will result in pump damage.

To turn pressure washer off place the on/stop switch

to the stop position.

Simply shutting OFF engine will not release pressure

in the system. Squeeze the trigger on the spray gun

for about 3 seconds to relieve pressure. Spray

stream will decrease in length.

MPORTANT: This unit is equipped with a thermal relief

alve. If unit is allowed to run for several minutes

(/ithout pressing the trigger on the spray gun, several

Irops of water may be released through this valve to

;ool the unit. The heated water will be purged from the

)ottom of the pump.

BEFORE STARTING THE ENGINE

fo operate the engine you will need to do the following.

A CAUTION: Always check engine oil level before

every start. Running engine low of oil or out of oil

could result In serious damage.

A CAUTION; Always check pump oil level before

every start. Running pump low on oil could result

in pump damage.

Adding Pump Oil

Before running the high pressure washer, check the

pump oil level by viewing the sight glass on the side of

the pump. When properly filled, the oil will be at the

half way point marked by the two triangles. Your pres

sure washer pump is shipped with oil. Add oil only if oil

level is lower than the half way point on the sight glass.

Do not overfill. Use 30 weight non-detergent oil if

necessary.

A CAUTION: Do Not use engine oil that has been

shipped with your unit in your pump. Engine oil

is detergent and your pump uses a non-detergent

oil. Detergent oil can cause damage to your pump.

Page 18

Engine Oil

Your unit has been shipped without oil in the engine.

A bottle of SAE 30 weight oil is included in the carton.

Remove oil plug located on the side of engine. Using a

funnel, fill engine crankcase up to the last thread in the

oil port. Pour slowly. Oil reading will be inaccurate on

unlevel ground.

NOTE: When adding oil to the engine crankcase, use

a high quality detergent oil classified “For Service SF,

SG, SH rated SAE 30 weight. Use no special addi

tives. Select the oil’s viscosity grade according to

you expected operating temperatures.

SAE viscosity Grades

STAHTIwe TCMPEHATJRE mWQE ANTICIPATEO BEFORE NEXT OLCmNOE

Aircooled engines run hotter than automotive engines.

The use of multi-viscosity oil such as (10W-30, etc.) in

ambient temperatures above 40°F (4°C) will result in

higher than normal oil consumption. If multi-viscosity

oil is used, check the oil level more frequently to

prevent any posssible engine damage due to lack or

lubrication.

Use of SAE30 oil below 40°F (4°C) will result in hard

starting and possible engine damage due to inad

equate lubrication.

Gasoline

Your pressure washer engine is 4 cycle. Use unleaded

fuel only.

A CAUTION: Do not overfill the fuel tank. Always

allow room for fuel expansion.

A WARNING: Never fill fuel tank indoors. Never

fill fuel tank when engine is running or hot. Do

not smoke or have open flame when filling fuel

tank.

Use clean, fresh, regular unleaded gasoline with a

minimum of 85 octane. Do not mix oil with gasoline.

If unleaded fuel is not available, leaded fuel may be

used.

Page 19

IMPORTANT: It is important to prevent gum deposits

from forming in essential fuel system parts such as the

carburetor, fuel filter hose or tank during storage. Also,

experience indicates that alcohol-blended fuels (called

gasohol or using ethanol or methanol) can attract mois

ture which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel system

of an engine while in storage. To avoid engine problems,

the fuel system should be emptied before storage of 30

days or longer. Never use engine or carburetor cleaner

products in the fuel tank or permanent damage may

occur.

NOTE: Never start pressure washer with cutwater

source turned on and connected to pressure washer.

To Start Your Pressure Washer

Make sure fuel shutoff valve is turned to the open

position.

• Remove gas cap

• Add unleaded gasoline, slowly, to fuel tank.

• Do not overfill.

Connect garden hose to the water inlet on the

pressure washer. Tighten by turning water inlet

counterclockwise.

Connect high pressure hose to discharge on pump.

• Connect the garden hose to the water spout and turn

Page 20

• Squeeze trigger on pressure washer wand to relieve a

pressure caused by turning on the water. Water will

spew out of the gun in a thin stream. This will make it

easier to start the engine.

• Engage the safety latch on the spray gun. This locks

the trigger in place and keeps you from accidentally

spraying a high pressure stream.

On the engine there is a choke/run lever. Place lever

to the choke position.

• On the engine there is a throttle control lever. Place

throttle to the rabbit position. Always start engine

with throttle in the rabbit position. Place on/stop

switch to the “on” postion.

• Make sure fuel shut off valve is to the open position.

• Grasp the starter grip and pull slowly until resistance

is felt, then pull firmly to start engine.

• When engine starts, gradually move choke lever to

RUN position.

• If engine does not start after 5 pulls, place choke

back to run position.

• For hot engine starts make sure choke/run lever is in

the run position. Make sure fuel shut off valve is open

and throttle is in the run position.

NOTE: If any leaks are present shut unit down and

tighten fittings.

10

Page 21

(low To Use Your Pressure Washer

Dn the end of your spray gun is a nozzle that you can

wist from side to side. With the adjustable nozzle you

3an adjust the nozzle to either high pressure or low

jressure.

Turn the nozzle in a counter clockwise direction to

achieve low pressure. Turn nozzle clockwise for high

pressure.

For most effective cleaning, keep spray nozzle

between 8 and 24 inches of cleaning surface.

IMPORTANT: If you get spray nozzle too close,

especially on high pressure, you may damage the

cleaning surface.

• The pressure control knob is located on the pump.

You can increase the pressure by turning the knob

clockwise or decrease the pressure by turning the

knob counterclockwise.

NOTE: The maximum pressure for the unit is set at it’s

maximum setting at the factory. Do not attempt to adjust

the pressure higher than this factory setting.

Using Soaps/Chemicals

IMPORTANT: Use soaps and chemicals that are

designed specifically for use with pressure washers. To

apply soap/chemicals follow these steps:

Prepare the soap/chemical as required by your job.

Insert soap/chemical line into your container (soap/

chemicals not included).

Page 22

NOTE: The first step involves applying an appropriate

soap/chemical solution to penetrate and loosen grime.

The soap/chemicai is applied at low pressure to avoid

splashing, over spray and waste. Leave the solution

on surface for 3 to 5 minutes to allow solution to work.

NOTE: The second step involves cleaning the surface

you have prepared with the pressure washer and then

rinsing it clean.

• Turn the adjustable nozzle counterclockwise to low

pressure mode. Soap/chemicals cannot be applied

with nozzle in high pressure position.

• Review the use of the adjustable nozzle.

• Connect garden hose to water inlet (see “To Start Your

Pressure Washer”), check that high pressure hose is

connected to spray gun and pump (see Assembly),

and start engine.

• Apply soap/chemicals to dry surface, starting from the

bottom and working up.

• Allow the soap/chemicals to soak in between 3-5

minutes before washing and rinsing.

• For cleaning, start at lower portion of area to be

washed and work upward, using long, even over

lapping strokes.

Your pressure washer is equipped with a chemical

injector adjustment knob. With the knob fully opened

you will get maximum chemical draw. With knob fully

closed you will get no chemical draw. Turn knob in

counterclockwise direction to achieve more chemical

draw and clockwise for less chemical draw.

After using the pressure washer, it is recommended

the pump, chemical injector and chemical line be

flushed with clear water. To do so, simply place

chemical injector hose in water and siphon for 1 to 2

minutes.

11

Page 23

MAINTENANCE

CUSTOMER RESPONSIBILITIES TABLE

Every 25

MAINTENANCE TASK

PRESSURE WASHER

Check/clean inlet screen. X

Check high pressure hose.

Check soap and chemical hose and filter X

Check gun and wand for leaks. X

Purge pump ofairand contaminants X

Check pump oil X

Change pump oil X

ENGINE

Check oil level X

Change engine oil X

Before each use

X

hours oryearly

Every 50

hours oryearly

Every 100

hours oryearly

Product Specifications

Pressure Washer Specifications

Pressure

Flow Rate

Cleaning Units (psi x GPM)

Engine Specifications

RPM 3600

Rated Horsepower 6.5

Spark Plug Gap

Gasoline Capacity

Oil

0.030” (0.76mm)

2.7 GPM

3 Quarts

SAE 30 weight

2500

6750

General Recommendations

The warranty of the high pressure washer does not

cover items that have been subjected to operator

abuse or negligence. To receive full value from the

warranty, operator must maintain high pressure

washer as instructed in this manual.

Some adjustments will need to be made periodocally to maintain your high pressure washer.

All adjustments in the Maintenance section of this

manual should be made at least once each season.

Once a year you should clean or replace the spark

plug and clean or replace the air filter and check

the gun and wand assembly for wear. A clean

spark plug and clean air filter assure proper

fuel-air mixture and help your engine run better

and last longer.

NOTE: Over time the o-rings in the gun assembly

become worn. Attached to your owners manual is a

replacememt o-ring and split backup ring.

12

Page 24

Page 25

Pressure Washer Maintenance

Check and Clean Inlet Screen: Examine inlet screen

on pump inlet fitting. Clean if clogged replace if torn.

Check High Pressure Hose: High pressure hose can

develop leaks from wear, kinking, abuse. Inspect hose

each time before use. Check for cuts, leaks, abrasions

or bulging of cover, damage or movement of couplings.

If any of these conditions exist, replace hose

immediately.

Check Chemical/Soap Hose: Examine the chemical/

soap hose and clean if clogged. Hose should fit tightly

on pump fitting. Check for leaks and tears. Replace

filter or hose if either is damaged.

Check Gun and Wand: Examine hose connection to

gun making sure it is secure. Test trigger by pressing it

and making sure it springs back into place when you

release it.

Pump Oil

Pump oil level should be checked before each use.

Changing Pump Oii

Oil should be changed after the first 10 hours of opera

tion. Subsequent changes after each 50 hours of opera

tion. To drain oil, simply remove oil plug with a adjust

able wrench. The oil plug is located at the bottom of the

pump. Dispose of used oil. Properly remove pump oil fill

plug. Add 30 weight non-detergent oil. Fill until oil level is

at the mid point on the sight glass.

Purge Pump of Air and Contaminants

To remove the air from the pump, follow these steps:

• Set up the pressure washer as described in

Assembly section and connect the water supply.

• Remove the wand extension from the spray gun.

• Pull the trigger on the gun and hold.

To remove the contaminants from the pump, follow

these steps:

• Set up the pressure washer as described in

ASSEMBLY section, connect the water supply.

• Remove the wand extension from the spray gun.

Start the engine according to instructions in the

OPERATION section.

Page 26

• Pull the trigger on the gun and hold.

• When the water supply is steady and constant,

disengage trigger and refasten the wand extension.

Engine Maintenance Oil

• Oil level should be checked prior to each use

or at least every 5 hours of operation. To check oil see

Adding Engine OH on page 9.

Changing Engine Oil

For a new engine, change oil after the first 5 hours of

operation. Thereafter, change oil after every 50 hours of

operation.

Change the oil while the engine is still warm. The oil will

flow freely and carry away more impurities. Make sure

the engine is level when filling, checking, or changing oil.

Change the oil as follows:

• To keep dirt, grass, etc., out of the engine, clean the

area around the drain plug and oil plug before

removing it.

• Remove the oil drain plug and oil plug. Tilt the engine

slightly towards the oil drain to obtain better drainage.

Be sure to allow ample time for complete drainage.

• Reinstall the drain plug. Make sure it is tightened

securely.

• Fill the crankcase with new oil of the proper type, to

up to the thread in the oil port. Pour slowly.

13

Page 27

Reinstall the oil fill cap or plug and tighten securely.

Service Air Cleaner

To service pre-cleaner, wash in liquid detergent and

water. Allow to dry thoroughly before using. Do not oil

pre-cleaner. Replace if very dirty or damaged.

NOTE: Do not use petroleum solvents, e.g., kerosene,

which will cause the cartridge to deteriorate. Do not use

pressurized air to clean cartridge. Pressurized air can

damage the cartridge.

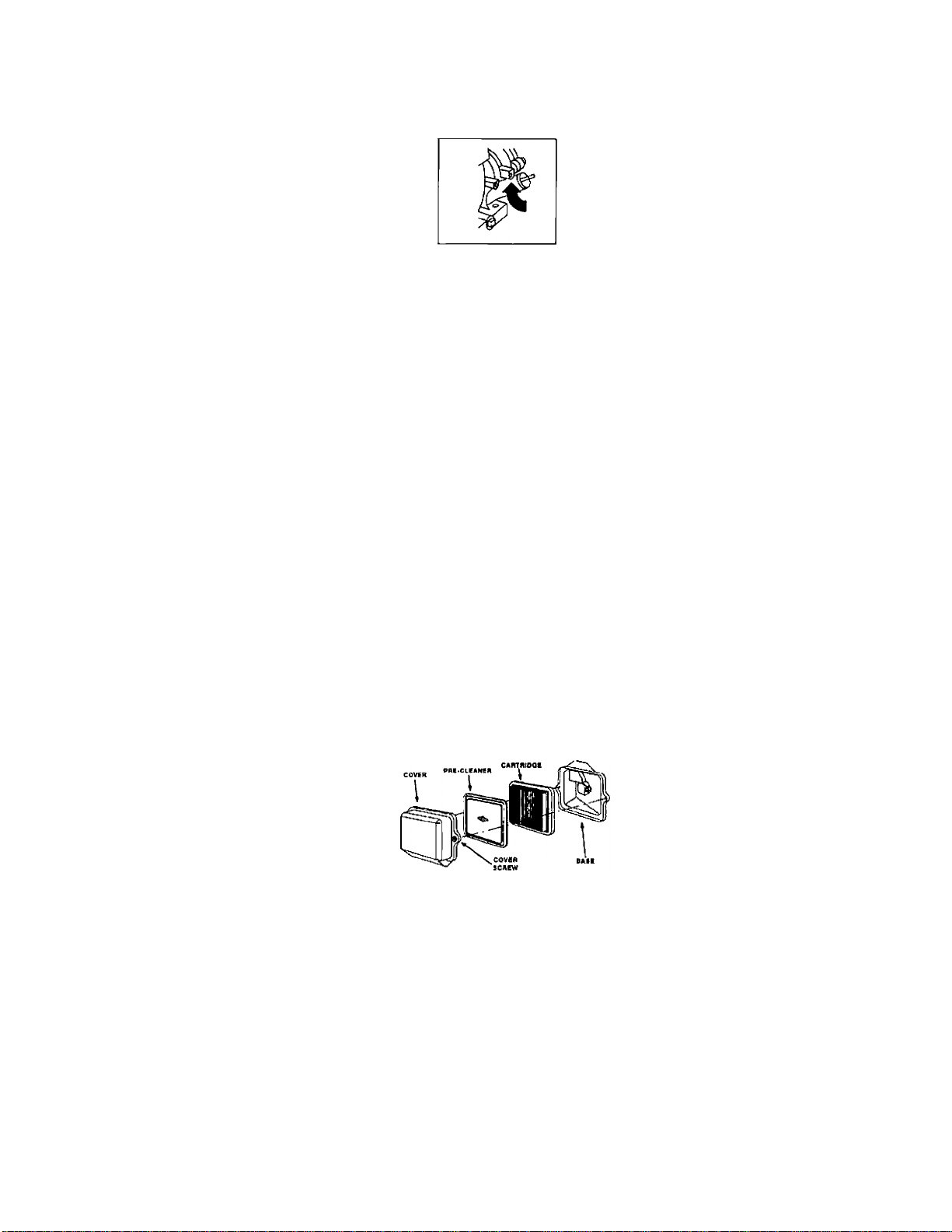

To service air cleaner follow these steps:

1. Unscrew cover screws. Remove cover and air cleaner

assembly.

2. Remove cartiridge from cover, then retainer

(if equipped) and pre-cleaner.

NOTE: Do not use petroleum solvents, e.g., kerosene,

which will cause the cartridge to deteriorate. Do not use

pressurized air to clean cartridge. Pressurized air can

damage the cartiridge.

3. Reassemble pre-cleaner or retainer (if equipped.)

Place in cover with pre-cleaner mesh side toward

cartridge. Place cartridge in retainer in cover.

4. Push cover and air cleaner assembly squarely onto

base (tabs must be in slots, if equipped) and hold

firmly. Tighten cover screws securely.

Keep engine and parts dean!

Page 28

Do not clean engine with a forceful spray of water

because water could contaminate fuel system. With

a brush or cloth clean finger guard after every use to

prevent engine damage caused by overheating.

Before running engine, clean muffler area to remove all

combustible debris.

Clean and Replace Spark Plug

Change the spark plug every 100 hours of operation or

once each year, whichever comes first. This will help

your engine to start easier and run better.

14

Page 29

SERVICE AND ADJUSTMENTS

Carburetor

The carburetor of your high pressure washer is pre-set

at the factory. The carburetor should not be tampered

with. If you pressure washer is used at an altitude in

excess of 5000 feet consult with your nearest Sears

Service Center regarding high altitude set changes.

A CAUTION: Engine speed was properly adjusted

at the factory and should require no additional

adjustment. Do not attempt to change engine

speed. If you believe the engine is running too fast

or too slow, take your pressure washer to a Sears

Authorized Service Center for repair and adjustment.

AWARNING: High engine speeds are dangerous and

increase the risk of personal injury or damage to

equipment.

AWARNING: Low engine speeds impose a heavy

load on the engine and when sufficient engine

power is not available could shorten engine life.

____________________________________

STORAGE

Nozzle Maintenance Hi-Low Lance:

1. Shut off the pressure washer and turn off the water

supply.

2. Disconnect spark plug wire.

3. Pull trigger on gun handle to relieve any water

pressure.

4. Disconnect the wand/lance from the gun.

5. Remove the high-pressure nozzle from the lance.

Remove any obstructions with the nozzle cleaning

tool provided and backflush with clean water.

6. Direct water supply into nozzle end to backflush

loosened particles for 30 seconds.

7. Reassemble the nozzle to the lance using teflon tape

to prevent leaks. Tighten securely.

8. Reconnect wand/lance to gun and turn on water

supply.

9. Start pressure washer and place wand/lance into

high pressure setting to test.

This pressure washer should be stored in such a way to

protect it from freezing. Do not store this unit outdoors

or in an area where temperatures will fall below 32° F.

This can cause extensive damage to this unit.

If unit has to be stored under freezing conditions a non

toxic R.V. anti-freeze can be used to protect from

freezing.

Preparing Pressure Washer for Storage

NOTE: If you do not plan to use your unit for 30 days or

more, unit should be prepared for storage.

Engine Preparation

• First add a fuel stabilizer to the fuel tank.

• Run pressure washer for full 5 minutes to allow fuel

stabilizer to enter the fuel system.

NOTE: While doing this procedure make sure water

supply is turned on and flowing to the unit. NEVER run

unit without water supply running through pump.

• Next shut off engine and disconnect the water supply.

• Disconnect the spark plug wire and remove the spark

plug.

Add one teaspoon of oil through the spark plug hole.

Place rag over spark plug hole and pull the recoil a

few times to lubricate the combustion chamber.

Replace the spark plug, but do not connect the spark

plug wire.

Pump Preparation

• Be sure engine switch is in “OFF” position and spark

plug wire has been removed from spark plug.

• Pull the trigger on the spay gun to release the

pressure in the high pressure hose. Detach high

pressure hose and garden hose from the unit.

• Pull the recoil on the engine 4 to 6 times to discharge

remaining water in pump.

• Tip the unit on the end with the water inlet fitting

pointing upward.

• Pour approximately 1/4 cup of non-toxic R.V. anti

freeze down the fitting where the water hose attaches

to the pump.

• Set unit upright and pull starter handle on engine 4 to

6 times to circulate anti-freeze in pump until anti

freeze is discharged from the pump.

15

Page 30

Page 31

TROUBLESHOOTING

SYMPTOM CAUSE

Engine won’t

start

Won’t Draw

Chemical

Pump running

normaliy but

pressure does

not achieve

rated vaiues

1. Engine throttle is in "OFF" Position.

2. Choke iever has not been piaced to

choke.

3. Pressure buildup after initial use.

1. Nozzle not in chemical draw position.

2. Chemicai screen is obstructed.

3. Chemical screen not working.

4. Chemicai injector orifice obstructed

or stuck.

5. Chemicai injector ciosed.

1. Water suppiy restricted.

2. Nozzie is in iow PSl position.

3. Nozzie incorrect or worn. 3. Check and replace.

4. Pump sucking air. 4. Check that hoses and fittings are air-tight.

5. Nozzie blocked. 5. Clean nozzle.

SOLUTION

1. Slide throttle to "Rabbit" position.

2. Slide choke lever to choke position.

3. Depress trigger gun.

1. Place nozzle to low pressure.

2. Check chemical screen; clean if obstructed.

3. Make sure chemical screen is submerged in

chemical/water.

4. Check and clean.

5. Open chemical injector by turning adjustment

knob.

1. Check water supply and filter screen for.

blockage. Check hoses for blockage, kinks,

leaks, etc.

2. Twist nozzle at end of wand clockwise the high

pressure position.

Fluctuating

Pressure

Pressure drops

after period of

normai use

Pump noisy 1. Water too hot. 1. Reduce temperature below 63° C or 145° F.

Presence of

water in oii (oii

milky).

Water dripping

from pump 2. Fittings Loose.

1. Pump sucking air. 1. Check that hoses and fittings are air tight. Purge air

from garden hose.

2. Garden hose inlet strainer ciogged.

3. Worn Seáis or Packing.

4. Inadequate water supply.

5. Fouled or dirty iniet or discharge

vaives.

6. Leaky discharge hose.

1. Nozzie clogged, partially obstructed. 1. Use nozzle cleaning kit to clear obstruction. (See

2. Nozzle worn.

3. Pump Valves worn, dirty or stuck.

4. Worn pump piston packing.

2, Pump sucking air.

3. Valves dirty or worn.

4. Worn bearings.

1. High humidity.

2. Piston packing and oii seal worn.

1. Thermal relief functioning normal.

3. 0-rings of piston guide or retainer

worn.

4. Piston packing worn.

2. Clean. Check filter frequently.

3. Check and replace.

4. Check hose for kinks.

5. Check flow available to pump. Check for

excessive heat, 145° F or above.

6. Clean inlet and discharge valve assemblies.

Replace if damaged.

Nozzle Maintenance under Service Adjustment.)

2. Clean or replace.

3. Check and replace.

4. Check and replace.

2. Check that hoses and fittings are air tight.

3. Check, clean or replace.

4. Check and replace if necessary.

1. Change Oil.

2. Check and replace oil seals.

1. Protecting pump, if not using pressure washer for

a long period of time, shutoff engine.

2. Tighten.

3. Check and replace.

4. Check and replace.

Oil Dripping

1. Oil seal worn

2. Loose drain plug or worn drain plug

o-ring.

1. Check and replace

2. Tighten drain plug or replace O-ring. Do not overtorque.

16

Page 32

Page 33

PARTS

CRAFTSMAN 2 00 PSI HIGH PRESSURE WASHER 919.762500

22—(g)

----23

KEY# PART NUMBER

1

2

16498 Handle

16471

3 16396

4

5

6

16504

16371

16470 JBolt

DESCRIPTION

Knob

Gun

Tire Simi-Pnuematic

Foot Rubber

7 16503 Frame

8

9

10

11

12

900

16830 0-ring Kit

H100

16823

15111

16501

Chemical Hose

Lance Hi/Low

High Pressure Hose

Decal Front Craftsman

Engine (Refer to Engine Breakdown

Briggs #121432-0112-El)

15

16

17

18

19

20

16727

PK16642 Pump

F035

16829

F464

F064

Decal Operation

High Pressure QC

Adapter- Garden Hose

Nut Pal 1/2"

Srew Hex HDC

KEY# PART NUMBER DESCRIPTION

21

22

23

24

N03515

F119

F078

F112

PARTS NOT ILLUSTRATED

MGP-762500

F078

F119

F066

FI 07

15167

F078

NCT001

F039

17091

17

Nozzle

Hex Nut

Lock Washer

Flat Washer

Owners Manual

Lockwasher, Engine to Frame

Nut Hex 5/16 Engine to Frame

Screw 5/16 Engine to Frame

Lockwasher-Pump to Engine

Srew, Hex- Pump to Engine

Lockwasher- Pump to Engine

Nozzle Cleaning Kit

QC Socket for HP Hose

Nozzle 3 pack 0°, 25°, 40°

Spray Pattern

Page 34

Page 35

PUMP PARTS

CRAFTSMAN 2500 PSI HIGH PRESSURE WASHER 919.678250

^73

f i

PUMP BREAKDOWN MODEL PK16642

rfYPE~F2^

18

Page 36

PUMP PARTS

CRAFTSMAN 2500 PSI HIGH PRESSURE WASHER 919.678250

REF.

NO.

1

2 AR-1260162

3 AR-1269050

4

5

6

7 AR-1260130

8

9

10 AR-1266740

11

12 AR-1780550 Snap ring

13

14

15

16

17 AR-1200430

18 AR-1789010

19 AR-1780040

20 AR-1780060

21

22

PART

NO. DESCRIPTION QTY.

AR-960160 0-Ring 6

Plug 6 24 AR-1260100 Piston washer 3

Complete valve 6

AR-880830 0-Ring 6 27 AR-740290

AR-620301

AR-1780130

AR-1780090

AR-1780010 Pump body

AR-1260790 Circiip

AR-1780490

AR-880130 Oil cap 1 40

AR-1780050

AR-1780510 0-Ring

AR-480480

AR-1260091 Spacer disc

Plug 1

Support ring 3 28

Gasket 3 30 AR-1260460 Seal 3

Piston guide 3

1 32

Cap 1 33

1 36 AR-1780380

1 37

Bearing 1 38

Piston pin 3 41

1 42

Screw 6

Compiete cover 1 67 AR-820440 Grub screw

Con rod 3 68

Guiding piston

0-Ring 3 70

3 69

3 71

REF.

NO.

23

25

31

44

72

73

PUMP BREAKDOWN PK16642

PART

NO.

AR-1780070 Piston

AR-1260110 Nut

AR-880530 Plug

AR-1780100 Rear Piston guide 3

AR-770260 0-Ring

AR-1260440

AR-1381550

AR-680570 Screw 8

AR-1321190

AR-1321080 Snap ring

AR-480671 Seal 1

AR-180030 Screw 4

AR-1789200 Pump head pre-ass. 1

AR-1380580 Gas engine flange

AR-1780590

16747

AR-2973

16506 Thermal Relief Valve 1

DESCRIPTION QTY.

3

3

0-Ring

Gasket

Head 1

Washer

Bearing 1

Hollow shaft %” 1

Chemical Injector 1

Unloader 1

2

2

3

3

8

1

1

1

A=KIT 16739

Valves

Pos. Qty.

3 6

4 6

D=KIT 16745

Water Seals

Pos.

7 3 13

32 3 40

33

Qty. Pos,

3

PARTS KITS

B=KIT 16746

Pistons

Pos. Qty. Pos. Qty.

23 3

F=KIT 16749

Bearings

Qty.

1 71 1

1

C=KIT 16748

Oil Seals for

D Version

10 1

16 1

30 3

42 1

G=KiT 16747

Injector Kit

Pos. Qty.

19

H=KiT 16744

Unioader 0-Ring

Kit

Pos. Qty.

Page 37

Page 38

ENGINE PARTS

CRAFTSMAN 2500 PSI HIGH PRESSURE WASHER 919.678250

21^

22.

BRIGGS ENGINE MODEL #121432-0112-E1

529 @

306

307

REF. PART

NO. NO.

690045(F)

1

399269 Bushing 18

2

692266

3

692549

12

691696 Plug-Oil

15

DESCRIPTION

Cylinder Assembly 17

Seal-Oil 20

Gasket-Crankcase 21 692261

REF. PART

NO. NO. DESCRIPTION

692510 Bearing-Ball 306

22

690047

692550

692551

Cover-Crankcase

Seal-Oil

Cap-Oil Fill 1019

Screw-Hex. 1058 273700 Owner’s Manual

20

REF. PART

NO. NO.

692552

307 690345 Screw-Hex.

529 692553 Grommet

690035

DESCRIPTION

Shield-Cylinder

Label Kit

Page 39

Page 40

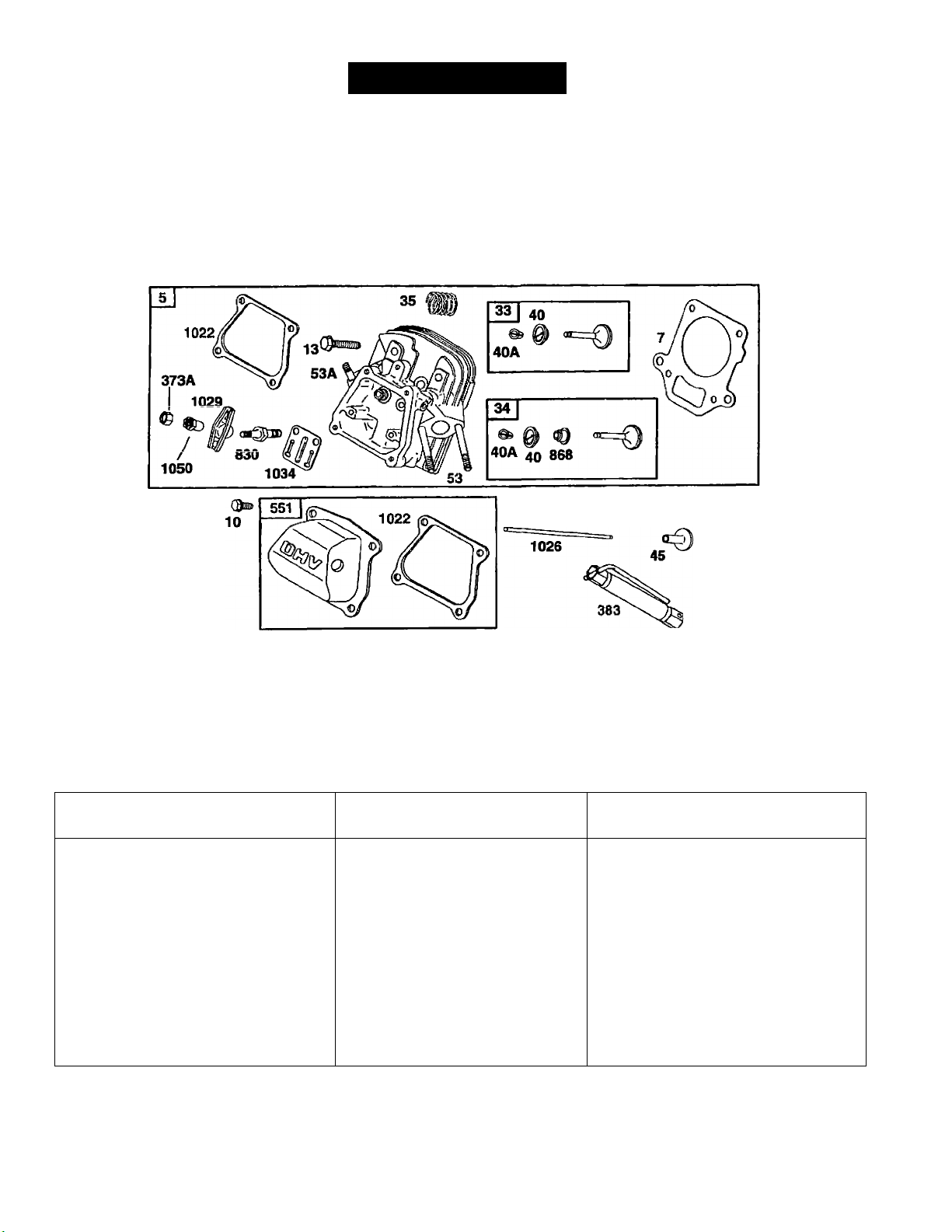

ENGINE PARTS

CRAFTSMAN 2500 PSI HIGH PRESSURE WASHER 919.678250

635

337

BRIGGS ENGINE MODEL #121432-0112-El

13^

REF.

NO.

5 499922

7 692554

33

34 499641

35 691304 Spring-Valve

40 692194

45 690977 Tappet-Valve

51 692555

PART

NO.

11 692600

13 691137 Screw-Hex.

499642

124

692568

DESCRIPTION

Head-Cylinder

Gasket-Cylinder Head

Tube-Breather

Valve-Exhaust

Valve-Intake

Retainer-Valve

Gasket-Intake

Screw-Hex.

REF.

PART

NO. DESCRIPTION

NO.

692556

155

691295

189

238 691300 Cap-Valve 1022

305 691108

692557 Screw-Hex. 1026

305A

337 690965

692558

353

19374

383

692186

635

692559 Screw-Hex.

830

Plate-Cylinder Head

Ball-Rocker Arm

Screw-Hex.

Plug-Spark

Nut-Hex.

Wrench-Spark Plug

Boot-Spark Plug

21

REF.

NO.

868

978 691892 Gasket-Plate

1023

1029

1034

PART

NO.

692044 Seal-Valve

691890

499924

692560 Rod-Push

691230

691343

DESCRIPTION

Gasket-Rocker Cover

Cover-Rocker

Arm-Rocker

Guide-Push Rod

Page 41

Page 42

ENGINE PARTS

CRAFTSMAN 2700 PSI HIGH PRESSURE WASHER 919.678270

635

337

ENGINE NUMBER 138432-0035-A1

REF.

NO.

40A

•Included in Gasket Set-Part No. 715482

★ Included inValve Overhaul Kit-Part No. 715483

Aincluded in Carburetor Kit-Part No. 715484

♦Included in Gasket Gasket Set -Part No. 715485

PART

NO. DESCRIPTION

715444 Head-Cylinder

5

7 **710624 Gasket-Cylinder Head

710023 Screw-Hex

10

710020 Screw-Hex

13

715445 Valve-Exhaust

33

34 715446 Valve-Intake

710011 Spring-Valve

35

40

710012

715130

Retainer-Valve

Retainer-Valve Plug

REF.

NO.

45 710008 Tappet-Valve 635 710634

53 710148 Stud-Carburetor 830

53A 710099

337 491055

373A

383 19374 Wrench-Spark

551 715450

PART

NO.

710007 Nut-Lock 1029

DESCRIPTION

Mounting 868 •710019

Stud

(Muffler Mounting)

Plug-Spark

Cover-Rocker

22

REF.

NO.

1022 **710626 Gasket-Rocker

1026 710622 Rod-Push

1034

1050 710015 Adjuster-Rocker Arm

PART

NO. DESCRIPTION

Boot-Spark Plug

710016

710014

710017

Stud-Rocker Arm

Seal-Valve

Cover

Arm-Rocker

Guide-Push Rod

Page 43

Page 44

ENGINE PARTS

CRAFTSMAN 2500 PSI HIGH PRESSURE WASHER 919.678250

141 I

124

634A

131

©634

BRIGGS ENGINE MODEL #121432-0112-El

ImT

%

1331

104

975

137

110®

117I110O

REF.

REF.

NO.

51 692555

95

98

PART

NO. DESCRIPTION

Gasket-Intake

(2 Required)

691636

398185 Screw-Idle Speed (Sold in Kit Only)

104 691242 Pin-Float Hinge 130 691181 Valve-Throttle

692567

108

110

111 690572

Screw-Slotted

Valve-Choke

Washer-Seal 133

(Sold in Kit Only)

Spring-Friction

(Choke)

PART

NO. DESCRIPTION

NO.

117 690048 Jet-Main (Standard)

690043

122

127 Plug-Welch

699024 Shaft-Throttle

131

398187 Float-Carburetor

134 398188

Spacer-Carburetor

Valve-Needle

23

REF.

PART

NO.

NO. DESCRIPTION

137 Gasket-Float Bowl

(Sold in Kit Only)

141 699023

163 691887

186 692317 Connector-Hose

634

634A

493640

975

Shaft-Choke

Gasket-Air Cleaner

Washer

(Sold in Kit Only)

Washer

(Sold in Kit Only)

Bowl-Float

Page 45

Page 46

ENGINE PARTS

CRAFTSMAN 2500 PSI HIGH PRESSURE WASHER 919.678250

2221

_75j

©

©

188 f

98A|

%

202

334

232

2651

BRIGGS ENGINE MODEL #121432-0112-E1

843^

663^

211

663^

209

356

356A

PART

REF.

NO.

NO.

495659 Washer Set 232

75

493280 Screw-Idle Speed 265

98A

690877 Screw-Hex.

188

692569 Link-Mechanical

202

692569

209

691798

211

692572 Bracket-Control

222

692573

227

DESCRIPTION

Governor 333

Spring-Governor 334

Spring-Governor 347

Lever-Governor 356

PART

REF.

NO.

NO.

692570

691024

267 690804

692574 Panel-Control 615 692576

281

692605 Armature-Magneto 616

691061

692599 Switch-Rocker 843

692575 Nut-Lock

354

692602 Wire-Stop

DESCRIPTION

Spring-Link

Clamp-Casing 562 691112 Bolt-Governor Level

Screw-Slotted Hex. 592 691251 Nut-Hex.

Screw-Hex.

347

REF.

NO.

356A

663

PART

NO.

692603

692547 Crank-Governor

692577 Screw-Slotted Hex.

692578 Sleeve-Lever

851 493880

DESCRIPTION

Wire-Stop

Retainer-Governor

Terminal-Cable

24

Page 47

Page 48

ENGINE PARTS

CRAFTSMAN 2500 PSI HIGH PRESSURE WASHER 919.678250

967

176 ^

958

BRIGGS ENGINE MODEL #121432-0112-E1

526

373

REF.

NO.

298 690453 Locknut-Muffler 601

300 692580 Muffler-Exhaust

PART

NO. DESCRIPTION

692579 Base-Air Cleaner 346

161

163 691887

176 692127 Screw-Shoulder 373 692582

187 298049 Line-Fuel (Cut to 526 691127

187A

692601 Line-Fuel (Molded)

Gasket-Air Cleaner 346A 692581 Screw-Hex.

Required Length)

PART

REF.

NO.

NO.

690661 Screw-Hex. 863 692595

534

692583

535

691710

692201

642 692584

819 692598

692584

832

819

PART

REF.

DESCRIPTION

Nut-Tinnerman 864

Screw-Hex.

Screw-Slotted Hex.

Filter-Air 967

Clamp-Hose

Cover-Air Cleaner 972 692587 Tank-Fuel

Screw-Hex.

Guard-Muffler

NO.

NO.

863A

692596

692548

957 691654 Cap-Fuel Tank

958 692586

691706

971

691106

DESCRIPTION

Bracket-Muffler

Bracket-Muffler

Adapter-Muffler

Valve-Shutoff

Filter-Air (Pre-Filter)

Screw-Shoulder

25

Page 49

Page 50

ENGINE PARTS

CRAFTSMAN 2500 PSI HIGH PRESSURE WASHER 919.678250

BRIGGS ENGINE MODEL #121432-0112-El

363

332

188 A

PART

REF.

NO.

NO.

692588 Flywheel

23

692608

65

692590

188A

PART

REF.

DESCRIPTION

Screw-Hex.

Screw-Shoulder 332 690662

NO.

NO.

304 692589

691108

305

REF.

PART

DESCRIPTION

Housing-Blower

Screw-Hex. 455 692591 Cup-Flywheel

Nut-Flywheel 1005

26

NO.

NO.

363 19069

692592

DESCRIPTION

Flywheel Puller

Fan-Flywheel

Page 51

Page 52

ENGINE PARTS

CRAFTSMAN 2500 PSI HIGH PRESSURE WASHER 919.678250

608

BRIGGS ENGINE MODEL #121432-0112-E1

623^

REF.

55

PART

NO.

NO.

691422 Housing-Rewind 60 393152

498144 Pulley-Starter 65A 690837

56

58 692593

692594 Insert-Grip

59

REF.

DESCRIPTION

Starter 60A

Rope-Starter (Cut To

Suit)

NO.

373A 690800

456

PART

NO.

691930

692299

373A

65A'^

REF.

DESCRIPTION

Grip-Starter Rope 459

Grip-Starter Rope 608

Screw-Hex. 623

Nut-Hex.

Retainer-Spring

NO.

689

PART

NO.

692260

497830

691696

691855

DESCRIPTION

Pawl-Ratchet

Starter-Rewind

Screw-Shoulder

Spring-Friction

27

Page 53

Page 54

ENGINE PARTS

CRAFTSMAN 2500 PSI HIGH PRESSURE WASHER 919.678250

BRIGGS ENGINE MODEL #121432-0112-E1

REF.

PART

NO.

NO.

3

692266 Seal-Oil 127

7

692554 Gasket-Cylinder Head

12 692549 Gasket-Crankcase

20 692550 Seal-Oil

51

692555

104 691242 Pin-Float Hinge 163

110 Washer-Seal 358

121 690032 Carburetor Kit

122

690043

DESCRIPTION

Gasket-Intake

(2 Required)

(Sold in Kit Only)

Spacer-Carburetor

REF.

NO.

134

137

634

PART

NO. DESCRIPTION

Plug-Welch

(Sold in Kit Only)

398188 Valve-Needle

(Includes Seat)

Gasket-Float Bowl

(Sold in Kit Only)

691887 Gasket-Air Cleaner

690031 Gasket Set

Washer-Shaft

(Throttle Shaft)

(Sold in Kit Only)

28

REF.

PART

NO.

NO.

634A

868

692044

977

690033

978 691892

1022 691890

1033 690034 Kit-Valve Overhaul

DESCRIPTION

Washer-Shaft

Choke Shaft

(Sold in Kit Only)

Seal-Valve

Gasket Set-Carburetor

Gasket-Plate

Gasket-Rocker Cover

Page 55

Page 56

Briggs & Stratton Corporation (B&S), the California Air Resources Board (CARB)

and the United States Environmental Protection Agency (U.S. EPA)

Emission Control System Warranty Statement (Owner’s Defect Warranty Rights and Obligations)

In the interest of the environment, B&S engines that meet strict emis

sion requirements are labeled, ‘This engine conforms to 1995 -1998

California emission regulations for ULGE engines and U.S. EPA

Phase I regulations for small non-road engines.”

EMISSION CONTROL WARRANPr COVERAGE IS APPLICABLE

TO CERTIFIED ENGINES PURCHASED IN CALIFORNIA IN 1995

AND THEREAFTER, WHICH ARE USED IN CALIFORNIA, AND

TO CERTIFIED MODEL YEAR 1997 AND LATER ENGINES

WHICH ARE PURCHASED AND USED ELSEWHERE IN THE

UNITED STATES.

California and United States Emission Control Defects Warranty Statement

CARB, U.S, EPA and B&S are pleased to explain the Emission

Control System Warranty on your 1996 and later utility or lawn and

garden equipment (ULGE) engine. In California, new ULGE engines

produced on or after August 1,1995 must be designed, built and

equipped to meet the State's stringent anti-smog standards/ Else

where in the United States, new non-road, spark-ignition engines

certified for model year 1997 and later, must meet similar standards

set forth by the U.S. EPA. B&S must warrant the emission control

there has been no abuse, neglect or improper maintenance of your

ULGE engine.

Your emission control system includes parts such as the carburetor,

air cleaner, ignition system, muffler and catalytic converter. Also

Included maybe connectors and other emission related assemblies.

Where a warrantable condition exists, B&S will repair your ULGE

engine at no cost to you including diagnosis, parts and labor.

system on your engine for the periods of time listed below, provided

Briggs & Stratton Emission Control Defects Warranty Coverage

ULGE engines are warranted relative to emission control parts below. If any coveredpart on yourengine is defective, the partwill be

defects for a period of two years, subject to provisions set forth repaired or replaced by B&S.

Owner’s Warranty Responsibilities

As the ULGE engine owner, you are responsible tor the performance

of the required maintenance listed in your Operator/Owner Manual.

B&S recommends that you retain all your receipts covering mainte

nance on your ULGE engine, but B&S cannot deny warranty solely

(or the lack of receipts or for your failure to ensure the performance of

all scheduled maintenance.

As the ULGE engine owner, you should however be aware that B&S

may deny you warranty coverage if your ULGE engine or a part has

failed due to abuse, neglect, improper maintenance or unapproved

modifications.

You are responsible (or presenting your ULGE engine to an Autho

rized B&S Service Dealer as soon as a problem exists. The undis

puted warranty repairs should be completed in a reasonable amount

of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and

responsibilities, you should contact a B&S Service Representative

at 1-414-259-5262.

The emission warranty is a defects warranty. Defects are judged on

normal engine performance. The warranty is not related to an in-use

emission test.

Briggs & Stratton Emission Controi Defects Warranty Provisions

The following are specific provisions relative to your Emission Control Defects Warranty Coverage. It is in addition to the B&S engine warranty

for non-regulated engines found in the Operator/Owner Manual.

1.

Warranted Parts 3.

Coverage under this warranty extends only to the parts listed

below (the emission control systems parts) to the extent these

parts were present on the engine purchased.

Fuel Metering System

a.

• Cold start enrichment system (soft choke)

• Carburetor and internal parts

• Fuel Pump

Air Induction System

• Air cleaner

• Intake manifold

Ignition System

c.

• Spark plug(s)

• Magneto ignition system

Catalyst System 5.

d.

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

Miscellaneous Items Used in Above Systems

e.

• Vacuum, temperature, position, time sensitive valves

and switches

• Connectors and assemblies

Length of Coverage

B&S warrants to the initial owner and each subsequent purchaser

that the Warranted Parts shall be free from defects in materials 6.

and workmanship which caused the failure of the Warranted

Parts for a period of two years from the date the engine is deliv

ered to a retail purchaser.

No Charge

Repair or replacement of any Warranted Part will be performed

at no charge to the owner, including diagnostic labor which leads

to the determination that a Warranted Part is defective, if the

diagnostic work is performed at an Authorized B&S Service

Dealer. For emissions warranty service contact your nearest

Authorized B&S Service Dealer as listed in the “Yellow Pages”

under "Engines, Gasoline,” "Gasoline Engines,” “Lawn

Mowers,” or similar category.

4.

Claims and Coverage Exclusions

Warranty claims shall be filed in accordance with the provisions

of the B&S Engine Warranty Policy. Warranty coverage shall be

excluded for failures of Warranted Parts which are not original

B&S parts or because of abuse, neglect or improper mainte

nance as set forth in the B&S Engine Warranty Policy. B&S is not

liable to cover failures of Warranted Parts caused by the use of

add-on, non-original, or modified parts.

Maintenance

Any Warranted Part which is not scheduled for replacement as

required maintenance or which is scheduled only for regular

inspection to the effect of “repair or replace as necessary” shall

be warranted as to defects for the warranty period. Any

Warranted Part which is scheduled for replacement as required

maintenance shall be warranted as to defects only for the period

of time up to the first scheduled replacement for that part. Any

replacement part that is equivalent in performance and durability

may bo used in the performance of any maintenance or repairs.

The owner Is responsible for the performance of all required

maintenance, as defined in the B&S Operator/Owner Manual.

Consequential Coverage

Coverage hereunder shall extend to the failure of any engine

components caused by the failure of any Warranted Part still

under warranty.

29

Page 57

Page 58

Briggs & Stratton welcomes warranty repair and apologizes

to you for being inconvenienced. Any Authorized Service

Dealer may perform warranty repairs. Most warranty repairs

are handled routinely, but sometimes requests for warranty

service may not be appropriate. For example, warranty would

not apply if engine damage occurred because of misuse, lack

of routine maintenance, shipping, handling, warehousing or

improper installation. Simiiarly, warranty is void if the serial

number of the engine has been removed or the engine has

been altered or modified.

If a customer differs with the decision of the Service*Dealer, an

investigation wili be made to determine whether the warranty

appiies. Ask the Service Dealer to submit ail supporting facts to

his Distributor or the Factory for review, if the Distributor or the

Factory decides that the ciaim is justified, the customer will be

fully reimbursed for those items that are defective. To avoid

misunderstanding which might occur between the customer

and the Dealer, listed below are some of the causes of engine

failure that the warranty does not cover.

Improper maintenance;

The life of an engine depends upon the conditions under

which it operates, and the care it receives. Some applications,

such as tiilers, pumps and rotary mowers, are very often used

in dusty or dirty conditions, which can cause what appears to

be premature wear. Such wear, when caused by dirt, dust,

spark plug cleaning grit, or other abrasive material that has

entered the engine because of improper maintenance, is not

covered by warranty.

This warranty covers engine reiated defective materiai

and/or workmanship oniy. and not repiacement or refund

of the equipment to which the engine may be mounted.

Nor does the warranty extend to repairs required

because of:

1. PROBLEMS CAUSED BY PARTS THAT ARE

ORIGINAL BRIGGS & STRATTON PARTS.

2. Equipment controls or installations that prevent starting,

cause unsatisfactory engine performance, or shorten

engine life. (Contact equipment manufacturer.)

3. Leaking carburetors, ciogged fuel pipes, sticking vaives,

or other damage, caused by using contaminated or stale

fuel. (Use clean, fresh, lead-free gasoline and Briggs &

Stratton gasoline stabilizer. Part No. 5041.)

NOT

Page 59

4. Parts which are scored or broken because an engine was

operated with insufficient or contaminated lubricating oil,

or an incorrect grade of lubricating oil (check oil level daily

or after every 8 hours of operation. Refill when necessary

and change at recommended intervals.) Read "Owner’s

Manual.”

5. Repair or adjustment of associated parts or assemblies

such as clutches, transmissions, remote controls, etc.,

which are not manufactured by Briggs & Stratton.

6. Damage or wear to parts caused by dirt, which entered

the engine because of improper air cleaner maintenance,

re-assembly, or use of a non-original air cleaner element

or cartridge. (At recommended intervals, clean and re-oil

the Oil-Foam® element or the foam pre-cleaner, and

replace the cartridge.) Read “Owner's Manual.”

7. Parts damaged by overspeeding, or overheating caused

by grass, debris, or dirt, which plugs or clogs the cooling

fins, or flywheel area, or damage caused by operating the

engine in a confined area without sufficient ventilation.

(Clean fins on the cylinder, cylinder head and flywheel at

recommended intervals.) Read “Owner’s Manual.”

8. Engine or equipment parts broken by excessive vibration

caused by a loose engine mounting, loose cutter blades,

unbalanced blades or loose or unbalanced impellers,

improper attachment of equipment to engine crankshaft,

overspeeding or other abuse in operation.

9. A bent or broken crankshaft, caused by striking a solid

object with the cutter blade of a rotary lawn mower, or

excessive v-belt tightness.

10. Routine tune-up or adjustment of the engine.

11. Engine or engine component failure, i.e., combustion

chamber, valves, valve seats, valve guides, or burned

starter motor windings, caused by the use of alternate

fuels such as, liquified petroleum, natural gas, altered

gasolines, etc.

30

Page 60

OWNERS MANUAL FOR

CRAFTSMAN

MODEL NO.

919.678250

SERVICE

High Pressure Washer

The model number of your Sears Air Compressor can be found on the

maintenance label on the top of the shroud or on the bar code label on

the rear of the air tank.

SERVICE AND REPAIR PARTS

CALL 1-800-665-4455*

Keep this number handy should you require a service call or need to

order repair parts.

If ordering parts make sure you have the name, make and model no. of

the merchandise and the name and number of

the part you wish to order.

HOW TO ORDER

REPAIR PARTS

'^If calling locally, please use one of the following numbers:

Regina - 566-5124 Montreal -333-5740

Toronto - 744-4900 Halifax - 454-2444

Kitchener - 894-7590 Ottawa - 738-4440

Vancouver - 420-8211

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION:

PART NUMBER

MODEL NUMBER

All parts listed may be ordered from any Sears Service Center

and most Sears stores.

If the parts you need are not stocked locally, your order will be

electronically transmitted to a Sears Repair Parts Distribution

Center for handling.

PART DESCRIPTION

NAME OF ITEM

Sold By Sears Canada, Inc., Toronto, Ont. MSB 2B8

Page 61

Page 62

SERVICE NOTES

Page 63

SERVICE NOTES

Page 64

SERVICE NOTES

Loading...

Loading...