Page 1

D30333 Rev. 0 11/03/03

Owner’s Manual

5.5 Horsepower

2500 PSI

2.5 GPM

PRESSURE WASHER

• Safety Guidelines

• Assembly

• Operation

• Maintenance

• Storage

• Troubleshooting

• Repair Parts

Model No.

919.672190

CAUTION: Read the Safety Guidelines

and All Instructions Carefully Before

Operating.

Sold by Sears Canada, Inc. Toronto, Ont. M5B 2B

Page 2

2- ENG

D30333

TABLE OF CONTENTS

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SPECIFICATION CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SAFETY GUIDELINES- DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . .3

CONSUMER SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . .3

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . .3-7

BOX CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-15

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-18

STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-20

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21-23

REPAIR PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24-39

HOW TO ORDER REPAIR PARTS . . . . . . . . . . . . . . . . . . . . . .Back Cover

WARRANTY

FULL ONE YEAR WARRANTY ON PRESSURE WASHERS

If this pressure washer fails due to a defect in material or workmanship within

one year from the date of purchase, RETURN IT TO THE NEAREST SEARS

SERVICE CENTER THROUGHOUT CANADA AND SEARS WILL REPAIR IT,

FREE OF CHARGE.

If this pressure washer is used for commercial or rental purposes, the warranty

will apply for ninety days (90) from the date of purchase.

This Craftsman pressure washer warranty gives you specific legal rights and you

may have other rights which vary from province to province.

Sears Canada, Inc., Toronto, Ont. M5B 2B8

Page 3

3- ENG

D30333

This product may not be equipped with a spark arresting

muffler. If the product is not equipped and will be used

around flammable materials, or on land covered with materials such as

agricultural crops, forest, brush, grass, or other similar items, then an approved spark arrester must be installed and is legally required in the state of

California. It is a violation of California statutes section 130050 and/or sections 4442 and 4443 of the California Public Resources Code, unless the

engine is equipped with a spark arrester, as defined in section 4442, and

maintained in effective working order. Spark arresters are also required on

some U.S. Forest Service land and may also be legally required under other

statutes and ordinances.

Engine exhaust contains chemicals known, in certain

quantities, to cause cancer, birth defects or other

reproductive harm.

CONSUMER SAFETY INFORMATION

Model No. 919.672190

Pressure Washer

Pressure 2500 PSI

Flow Rate 2.5 GPM

Cleaning Units (PSI x GPM) 6250

Engine

RPM 3600

Rated Horsepower 5.5

Spark Plug Gap .030” (0.76mm)

Gasoline Capacity .29 gallons (1.1 liters)

Oil .58 quarts ( .55 liters) capacity SAE 30 weight

SAFETY GUIDELINES - DEFINITIONS

Indicates an imminently

hazardous situation

which, if not avoided, will

result in death

or serious injury.

Indicates a potentially

hazardous situation

which, if not avoided, could

result in death

or serious injury

.

Indicates a potentially

hazardous situation

which, if not avoided, may

result in minor

or moderate injury.

Used without the safety

alert symbol indicates a

potentially hazardous situation which, if

not avoided, may result in pr

operty

damage.

This manual contains information that is important for you to know and understand.

This information relates to protecting YOUR SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize this information, we use the

symbols below. Please read the manual and pay attention to these symbols.

SPECIFICATION CHART

Page 4

4- ENG

D30333

IMPORTANT SAFETY INSTRUCTIONS

Read Operators Manual. Do not operate equipment until you

have read operators Manual for Safety, Assembly, Operation, and

Maintenance Instructions.

RISK OF EXPLOSION OR FIRE

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

• Spilled gasoline and it’s vapors can become ignited from cigarette sparks,

electrical arcing, exhaust gases, and hot

engine components such as the muffler.

• Shut off engine and allow it to cool before

adding fuel to the tank.

• Use care in filling tank to avoid spilling fuel.

Move pressure washer away from fueling area

before starting engine.

• Heat will expand fuel in the tank which

could result in spillage and possible fire

explosion.

• Keep maximum fuel level ½” below top of

tank to allow for expansion.

• Operating the pressure washer in an explosive environment could result in a fire.

• Operate and fuel equipment in well ventilated

areas free from obstructions. Equip areas with

fire extinguisher suitable for gasoline fires.

• Materials placed against or near the pressure washer can interfere with its proper

ventilation features causing overheating

and possible ignition of the materials.

• Never operate pressure washer in an area

containing dry brush or weeds.

• Muffler exhaust heat can damage painted

surfaces, melt any material sensitive to

heat (such as siding, plastic, rubber, or

vinyl), and damage live plants.

• Always keep pressure washer a minimum of

four feet away from surfaces (such as houses,

automobiles, or live plants) that could be damaged from muffler exhaust heat.

• Improperly stored fuel could lead to accidental ignition. Fuel improperly secured

could get into the hands of children or

other unqualified persons.

• Store fuel in an OSHA approved container,

in a secure location away from work area.

• Use of acids, toxic or corrosive chemicals,

poisons, insecticides, or any kind of flammable solvent with this product could result in serious injury or death.

• Do not spray flammable liquids.

• Never fill cleaning solution tanks with

gasoline or other flammable solvent.

• Breathing exhaust fumes will cause serious

injury or death!

• Operate pressure washer in a well ventilated

area. Avoid enclosed areas such as garages,

basements, etc.

• Never operate unit in a location occupied by

humans or animals.

• Some cleaning fluids contain substances

which could cause injury to skin, eyes, or

lungs.

• Use only cleaning fluids specifically recommended for high pressure washers. Follow

manufacturers recommendations. Do not

use chlorine bleach or any other corrosive

compound.

RISK TO BREATHING

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

READ AND SAVE THESE INSTRUCTIONS

Page 5

5- ENG

D30333

• Fuel or oil can leak or spill and could

result in fire or breathing hazard, serious

injury or death can result. Fuel or oil leaks

will damage carpet, paint or other

surfaces in vehicles or trailers.

• If pressure washer is equipped with a fuel

shut-off valve, turn the valve to the off

position before transporting to avoid fuel

leaks. If pressure washer is not equipped

with a fuel shut-off valve, drain the fuel from

tank before transporting. Only transport fuel

in an OSHA approved container. Always

place pressure washer on a protective mat

when transporting to protect against damage to vehicle from leaks. Remove pressure

washer from vehicle immediately upon arrival

at your destination.

• Your washer operates at fluid pressures

and velocities high enough to penetrate

human and animal flesh, which could

result in amputation or other serious injury.

Leaks caused by loose fittings or worn or

damaged hoses can result in injection

injuries. DO NOT TREAT FLUID

INJECTION AS A SIMPLE CUT! See a

physician immediately!

• Never place hands in front of nozzle.

• Direct spray away from self and others.

• Make sure hose and fittings are tightened

and in good condition. Never hold onto the

hose or fittings during operation.

• Do not allow hose to contact muffler.

• Never attach or remove wand or hose

fittings while system is pressurized.

• Do not use acids, gasoline, kerosene, or

any other flammable materials in this

product. Use only household detergents,

cleaners and degreasers recommended for

use in pressure washers.

• Read and understand all warnings and

instructions supplied by cleaning solution

manufacturer.

• Wear protective clothing to protect eyes

and skin from contact with sprayed

materials.

• Use of acids, toxic or corrosive chemicals,

poisons, insecticides, or any kind of flammable solvent with this product could result in serious injury or death.

RISK OF INJURY OR PROPERTY DAMAGE

WHEN TRANSPORTING OR STORING

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

RISK TO FLUID

INJECTION

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

• Injuries can result if system pressure is not

reduced before attempting maintenance or

disassembly.

RISK OF

CHEMICAL

BURN

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

• To relieve system pressure, shut off engine,

turn off water supply, and pull gun trigger

until water stops flowing.

• Use only hoses and accessories rated for

pressure higher than your pressure

washer's p.s.i.

Page 6

6- ENG

D30333

• Reactive force of spray will cause

gun/wand to move, and could cause the

operator to slip or fall, or misdirect the

spray. Improper control of gun/wand can

result in injuries to self and others.

• Do not overreach or stand on an unstable

support. Grip gun/wand firmly with both

hands. Expect the gun to kick when triggered.

• If proper starting procedure is not

followed, engine can kickback causing

serious hand and arm injury.

• If engine does not start after two pulls,

squeeze trigger of gun to relieve pump

pressure. Pull starter cord slowly until

resistance is felt. Then pull cord rapidly

to avoid kickback and prevent hand or

arm injury.

• The spray gun/wand is a powerful cleaning tool that could look like a toy to a

child.

• Keep children away from the pressure

washer at all times.

• Contact with hot surfaces, such as

engines exhaust components, could

result in serious burn.

• During operation, touch only the control

surfaces of the pressure washer. Keep

children away from the pressure washer at all

times. They may not be able to recognize the

hazards of this product.

• Spray directed at electrical outlets or

switches, or objects connected to an

electrical circuit, could result in a fatal

electrical shock.

• Unplug any electrically operated product

before attempting to clean it. Direct spray

away from electric outlets and switches.

RISK OF UNSAFE OPERATION

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

• Unsafe operation of your pressure washer

could lead to serious injury or death to

you or others.

• Do not use chlorine bleach or any other

corrosive compound.

• Become familiar with the operation and controls of the pressure washer.

• Keep operating area clear of all persons,

pets, and obstacles.

• Do not operate the product when fatigued

or under the influence of alcohol or drugs.

Stay alert at all times.

• Never defeat the safety features of this

product.

• Do not operate machine with missing,

broken, or unauthorized parts.

• Never leave wand unattended while unit is

running.

RISK OF

ELECTRICAL SHOCK

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

RISK OF HOT

SURFACES

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

Page 7

7- ENG

D30333

BOX CONTENTS

Handle

Part No. D22316 with

Screws Part No. D22901

High Pressure

Hose

Part No. D28094

Chemical Hose

Part No. H140

The powerful spray from your pressure washer is capable of causing

damage to surfaces such as wood, glass, automobile paint, auto

striping and trim, and delicate objects such as flowers and shrubs. Before spraying,

check the item to be cleaned to assure yourself that it is strong enough to resist damage

from the force of the spray. Avoid the use of the concentrated spray stream except for

very strong surfaces like concrete and steel.

Operating without flow of water will result in equipment damage. Operating the pressure

washer with water supply shutoff will void your warranty. You should never run this pressure washer for more than 2 minutes without pulling the trigger to allow cool water to

enter the pump and the heated (recirculated) water to exit.

RISK OF INJURY FROM SPRAY

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

• High velocity fluid spray can cause

objects to break, propelling particles at

high speed.

• Light or unsecured objects can become

hazardous projectiles.

• Always wear ANSI approved Z87 safety

glasses.Wear protective clothing to protect

against accidental spraying.

• Never point wand at, or spray people or

animals.

• Always secure trigger lock when wand is not

in service to prevent accidental operation.

• Never permanently secure trigger in pull

back (open) position.

Bagged Parts

Engine Oil

Accessories Panel

Part No. D25081

Bagged Accessories Panel

Engine Frame, Wheel

Assembly, and Dual

Tank Cleaning System

English/

French

Owners

Manual

Knobs

Part No.

16471

Saddle

Bolts Part

No. D23196

Nozzle

Cleaning

Kit

Allen Wrench Part No. 16797

Cleaning Tool Part No. NCT001

Spray Gun

Part No. D27858

Multi-Adjustable Spray Wand

Part No. D23314

Page 8

8- ENG

D30333

ASSEMBLY

3. Connect wand to gun. Tighten

securely.

4. Attach high pressure hose to gun.

Tighten securely.

2. Place handle assembly onto frame

and connect handle to frame.

NOTE: Knobs are assembled to

the outside of frame.

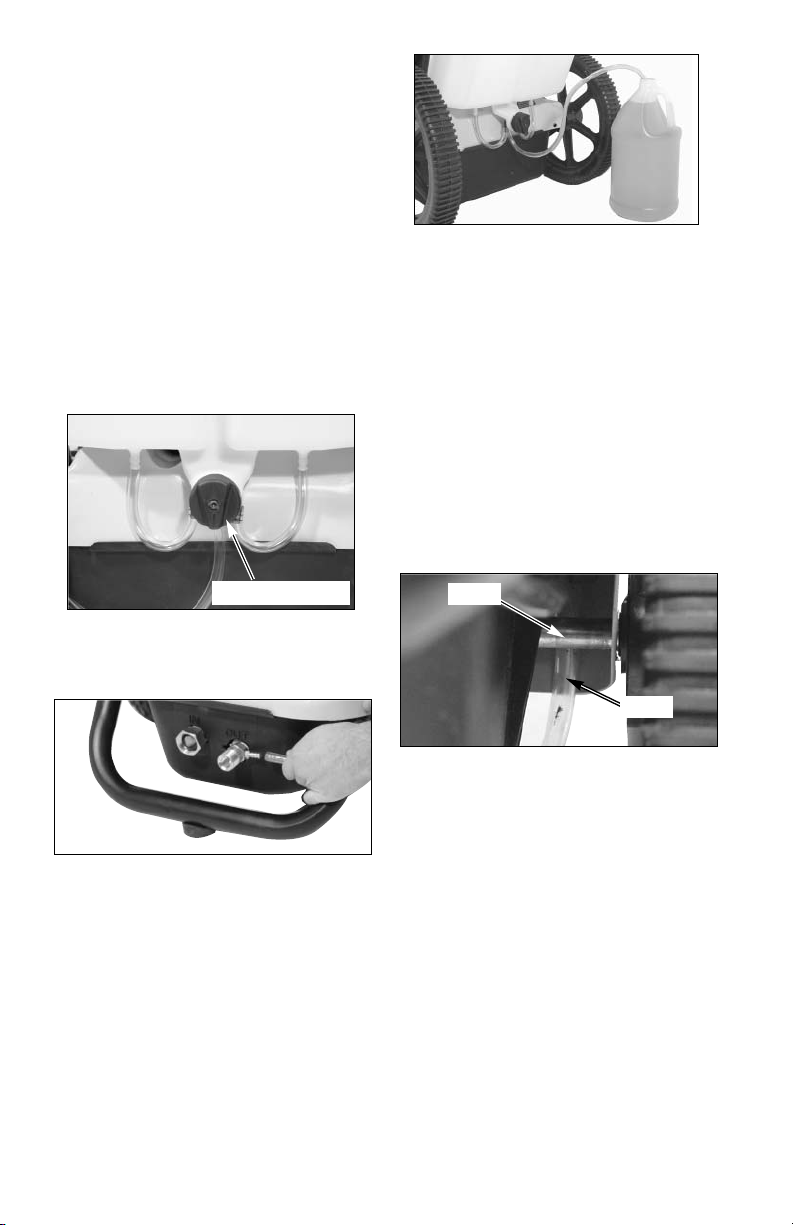

5. To Assemble Accessories Panel

a. Remove top screws on

handle assembly.

b. Loosen bottom screws on

handle assembly.

c. Place grooves in accessories

panel assembly onto screws

and slide panel assembly into

place.

Loosen

Remove

1. Remove cleaning solution tanks

from frame assembly. Slide tanks up

and away from frame assembly.

Screws

Page 9

9- ENG

D30333

7. Attach cleaning solution hose to

barb fitting on control valve located

at the rear of unit.

d. Place screws (removed

earlier) into the top holes and

secure accessories panel

assembly to handles. Do not

overtighten.

6. Reinstall cleaning solution tanks.

Tilt cleaning solution tanks toward

engine, slide onto handles, and

snap into place.

barb fitting

Page 10

10- ENG

D30333

OPERATION

High

Pressure

Pump

Engine

High

Pressure

Hose

Spray

Gun

MultiAdjustable

Spray Wand

Hand

Grip

Air Filter

Fuel Valve

Lever

Choke

Control

Throttle

Control

Chemical Injector Rinsing Hose (not

shown): Rinses the chemical injector

after use of cleaning solution.

Dual Tank Cleaning System: Allows

easily switching from one cleaning

solution to another depending on the

cleaning task by simply turning the

control valve knob.

ENGINE

Choke Control: Opens and closes

carburetor choke valve

Throttle Control Lever: Controls

engine speed.

Starter Grip: Pulling starter grip

operates recoil starter to crank engine.

Fuel Valve Lever: Opens and closes

connection between fuel tank and

carburetor.

PRESSURE WASHER

High Pressure Pump (located inside

the shroud): Increases the pressure of

the water supply.

Engine: Drives the high pressure

pump.

High Pressure Hose: Carries the

pressurized water from the pump to

the gun and spray wand.

Spray Gun: Connects with spray wand

to control water flow rate, direction,

and pressure.

Multi-Adjustable Spray Wand: Has a

spray nozzle which adjusts from a

pencil stream (0°) to a wide angle fan

spray (40°). The spray can be adjusted

by twisting the nozzle clockwise

and/or counterclockwise. Also, the

high and low pressure settings can be

controlled by moving the nozzle in and

out. See Operation section. See How

To Use Spray Wand paragraph in this

section.

READ THIS OPERATION MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR UNIT. Compare the illustrations with your unit to familiarize yourself with

the location of various controls and adjustments. Save this manual for future

reference.

Dual Tank

Cleaning

System

Page 11

11- ENG

D30333

HOW TO USE SPRAY WAND:

Your pressure washer is equipped with

a multi-adjustable spray wand with

both high and low pressure settings.

The high pressure setting is for

cleaning and rinsing, the low pressure

setting is for applying cleaning

solutions to surfaces.

When using the high

pressure setting, DO

NOT allow the jet-like spray to come

in contact with unprotected skin,

eyes, or with any pets or animals.

Serious injury can occur.

Risk of injection or

injury to person. DO

NOT direct discharge stream toward

persons.

For high pressure operation, pull back

the nozzle of the multi-adjustable

spray wand as shown.

TO ADJUST PRESSURE

The pressure setting is preset at the

factory to achieve optimum pressure

and cleaning. If you need to lower the

pressure, it can be accomplished by

these methods.

1. Back away from the surface to be

cleaned. The further away you are,

the less the pressure will be on

the surface to be cleaned.

2. Rotate the nozzle at the end of

the multi-adjustable spray wand

to widen the fan spray. The wider

fan spray will minimize the

pressure on the surface to be

cleaned.

DO NOT attempt to

increase pump

pressure. A higher pressure setting

than the factory set pressure may

damage pump.

HOW TO USE

IMPORTANT: Read and understand

how to use the pressure washer

before operating.

PRESSURE WASHER

TERMINOLOGY

PSI: Pounds per Square Inch. The unit

of measure for water pressure. Also

used for air pressure, hydraulic

pressure, etc.

GPM: Gallons Per Minute. The unit of

measure for the flow rate of water.

CU: Cleaning Units. GPM multiplied by

PSI.

Bypass Mode: In Bypass Mode, the

pump is recirculating water because

the trigger of the spray gun is not

pulled. If unit is left in bypass mode for

more than two (2) minutes, the water

temperature will rise to a dangerous

level and could damage internal

components of the pump. Any

damage to pump due to these causes

will not be covered under warranty.

DO NOT allow your

unit to operate in

bypass mode for more than two

minutes at any time. Overheating of

pump can cause damage to pump.

Thermal Relief Valve: In an effort to

prevent extreme damage, pumps are

equipped with a thermal relief valve.

This valve will open when the

temperature inside the pump rises too

high. This valve will then release a

gush of water in an effort to lower the

temperature inside the pump.

Immediately after this occurs, the

valve will close. The thermal relief

valve is part of the pump and is not

visible to the user.

Chemical Injection System: Mixes

cleaners or cleaning solvents with the

water to improve cleaning

effectiveness.

Water Supply: All pressure washers

must have a source of water. The

minimum requirements for a water

supply are 20 PSI and 5 gallons per

minute.

high

pressure

Page 12

12- ENG

D30333

3. Fill cleaning solution tanks with

desired cleaning solution. Each

tank holds approximately 1.25

gallon. NOTE: The cleaning

solution/water ratio is 7:1, for

every 7 gallons of water pumped,

1 gallon of cleaning solution will

be used.

Never fill cleaning

solution tanks with

gasoline or other flammable solvent.

4. Turn control valve knob toward

tank with desired cleaning

solution.

5. Set multi-adjustable nozzle to low

pressure setting. See How To Use

Spray Wand paragraph in this

section.

6. After use of cleaning solution the

chemical injector MUST be rinsed,

follow the instructions in the

Shutting Down paragraph after

each use.

NOTE: Cleaning solutions will not

siphon when spray wand is in the high

pressure setting.

DUAL TANK CLEANING

SOLUTION TIPS

1. Each tank may be filled with

different cleaning solutions

depending on the task to be

performed. Example: deck and

driveway. Fill one tank with deck

cleaning solution and the other

with driveway cleaning solution.

Clean the deck with the deck

cleaning solution and then simply

turn the control knob toward the

driveway cleaning solution and

clean the driveway.

The nozzle at the end of the multiadjustable spray wand can be rotated

to change the high pressure spray

pattern from a narrow jet to a 40º fan

shape, as shown. Markings have been

placed on the nozzle to help you

select the spray pattern.

For low pressure operation, extend the

nozzle of the multi-adjustable spray

wand as shown.

40º fan spray

narrow jet stream

HOW TO USE THE DUAL TANK

CLEANING SYSTEM

NOTE: Use only soaps and cleaning

solutions designed for pressure

washer use. Do not use bleach.

To apply cleaning solutions:

1. Make sure cleaning solution tanks

are assembled and all hoses are

connected.

2. Turn control valve knob arrow to

the down (off) position as shown.

Control Valve Knob

Tank to

be used

low

pressure

Page 13

13- ENG

D30333

TO SHUT DOWN

IMPORTANT: Read and understand

how to shut down the pressure

washer before operating.

1. After use of cleaning solution the

chemical injector MUST be rinsed in

order to prevent pump damage

caused by solution build up. The

warranty will not cover pumps that

are damaged because the chemical

injector was not properly rinsed.

To rinse chemical injector using

chemical injector rinsing hose

a. Remove cleaning solution

hose from chemical injector

barb fitting.

b. Push chemical injector rinsing

hose onto the chemical

injector barbed fitting.

2. If only one cleaning solution is

being used both tanks may be

filled with the same solution to

double the capacity before refilling

tanks.

3. If only one cleaning solution is

being used the second tank may

be filled with clean water to

conveniently rinse the chemical

injector after use.

c. Place other end of chemical

injector rinsing hose into

container of clean water and

depress trigger to draw at least

one gallon of clean water

through chemical injection

system to rinse system

thoroughly.

d. Before reconnecting cleaning

solution hose to chemical

injector barb fitting make sure

that any remaining cleaning

solution has been completely

drained from the cleaning

solution hose.

To rinse chemical using cleaning

solution system tank

a. Turn control valve knob arrow

to the down (off) position.

b. Fill one of the cleaning

solution system tanks with

clean water.

c. Turn control valve knob

toward tank with clean water.

d. Depress trigger to draw clean

water through chemical

injection system to rinse

system thoroughly.

2. Turn engine off by placing the

throttle control in the OFF

position.

NOTE: NEVER turn the water off

with the engine running.

Control Valve Knob

Tank to

be used

Page 14

14- ENG

D30333

1. In a well ventilated outdoor area

add fresh, high quality, unleaded

gasoline with a pump octane

rating of 86 or higher. Do not

overfill. Wipe up spilled fuel before

starting the engine.

2. Remove filler cap/dipstick and

add engine oil (supplied) to

engine. NOTE: There will be a

slight amount of oil in the engine

from factory testing. Always check

oil level before each start-up.

3. Verify the filter screen is in water

inlet of pump. NOTE: Cone side

faces out.

4. Connect high pressure hose to

pump outlet.

5. Connect water source to pump

inlet.

NOTE: Water source must provide a

minimum of 5 gallons per minute at

20 p.s.i.

Water

Source

High

Pressure

Hose

Filter Screen

BEFORE STARTING

Read and understand all Important

Safety Instructions in the front of

this manual and the following

Cautions and Warnings before

starting the pressure washer.

• Never fill fuel tank completely.

Fill tank to 1/2" below bottom of

filler neck to provide space for

fuel expansion. Wipe any fuel

spillage from engine and

equipment before starting

engine.

• Never fill fuel tank indoors.

Never fill fuel tank when engine

is running or hot. Do not smoke

when filling fuel tank.

• Never run engine indoors or in

enclosed, poorly ventilated

areas. Engine exhaust contains

carbon monoxide, an odorless

and deadly gas.

• Never turn water supply off

while pressure washer engine is

running or damage to pump will

result.

• DO NOT use hot water, use cold

water only.

• DO NOT stop spraying water for

more than two minutes at a

time.

Filler cap/dipstick

3. Turn the fuel valve to the OFF

position if engine will not be

restarted soon.

4. Turn water source off.

5. Pull trigger on spray gun to relieve

any water pressure in hose or

spray gun.

6. See Storage section in this

manual for proper storage

procedures. NOTE: Cleaning

solution must be removed from

cleaning solution tanks if storing

unit longer than 30 days, see

Storage section for correct

procedure.

Page 15

15- ENG

D30333

6. If applying a cleaning solution, see

How To Use the Dual Cleaning

Solution System in Operation

section of this manual.

7. Turn water source on.

NOTE: Failure to do so could cause

damage to the pump.

8. Turn fuel valve to the ON position,

1/4 turn counterclockwise.

9. Move the choke control lever to

the CHOKE ON position and

the throttle control to the FAST

position. NOTE: No choke is

needed to start a warm engine.

10. Pull starter grip slowly until you

feel resistance, then pull briskly.

Return starter grip gently. Pull

rope with a rapid full arm stroke.

Let rope rewind slowly. Repeat if

necessary.

Fuel Valve Knob

Choke

Control

Throttle

Control

If the engine does

not start after two

pulls, pull the trigger to relieve the

pressure.

11. If the choke was used to start the

engine, move the choke lever to

the OFF position.

12. Depress trigger on gun to start

water flow. NOTE: Stand on a

stable surface and grip

gun/spray wand firmly with both

hands. Expect the gun to kick

back when triggered.

13. Release trigger to stop water flow.

14. Adjust nozzle spray for the task

being performed. See How To

Use Spray Wand instructions in

this section.

DO NOT let hoses

come in contact with

very hot engine muffler during or

immediately after use of your

pressure washer.

MAINTENANCE

When performing maintenance, you may be exposed to hot

surfaces, water pressure, or moving parts that can cause

serious injury or death!

Before performing any maintenance or repair, disconnect spark plug wire,

let engine cool and release all water pressure. The engine contains

flammable fuel. DO NOT

smoke or work near open flames while performing

maintenance.

To ensure efficient operation and longer life of your pressure washer, a routine

maintenance schedule should be prepared and followed. If the pressure washer is

used in unusual conditions, such as high-temperatures or dusty conditions, more

frequent maintenance checks will be required.

Page 16

16- ENG

D30333

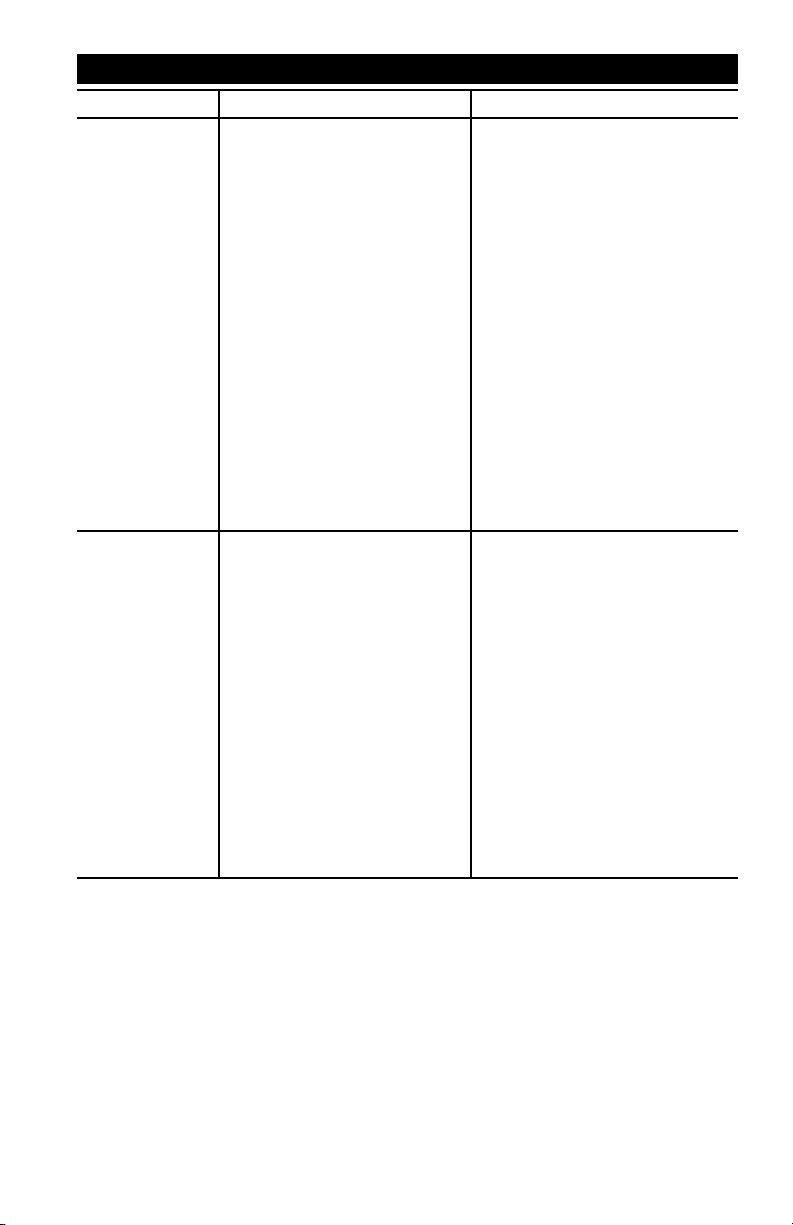

CUSTOMER RESPONSIBILITIES TABLE

MAINTENANCE TASK

PRESSURE WASHER

ENGINE

check/clean inlet screen

check high pressure hose

check soap and chemical

hose and filter

check gun and wand for leaks

check oil level

change oil

check air filter

clean/replace spark plug

prepare for storage

Before

each use

Every 25

hours or

yearly

Every 50

hours or

yearly

Every 100

hours or

yearly

Prepare unit for storage if it is to remain idle for longer

than 30 days

X

X

X

X

X

X

X

X

ENGINE

To Check Oil

1. Shut down engine and place on a

level surface.

2. Remove filler cap/dipstick and wipe

it clean.

3. Insert and remove the filler

cap/dipstick without screwing it

into the filler neck. Check the oil

level shown on the dipstick.

Filler cap/dipstick

4. If the oil level is low, fill to the edge

of the oil filler hole with the SAE

10W-30 oil.

NOTE: Other viscosities shown in the

chart may be used when the average

temperature in your area is within the

recommended range.

Oil Filler

Cap/Dipstick

Upper Limit

Lower Limit

SAE Viscosity Grades

**

*

Synthetic 5W-30, 10W-30

-20 0 20 40 60 80 100

F

-30 -20 -10 0 10 20 30 40

C

STARTING TEMPERATURES RANGE

ANTICIPATED BEFORE NEXT OIL CHANGE

32

Page 17

17- ENG

D30333

To Change Oil

Drain the engine oil when the engine is

warm. Warm oil drains quickly and

completely.

1. Turn the fuel valve to the OFF

position, 1/4 turn clockwise.

2. Place a suitable container next to

the engine to catch the used oil.

3. Remove filler cap/dipstick and

drain the oil into the container by

tipping the engine toward the oil

filler neck.

NOTE: Please dispose of used motor

oil in a manner that is compatible with

the environment. It is recommended to

take used oil in a sealed container to

your local recycling center or service

station for reclamation. Do not throw it

in the trash or pour it on the ground or

down a drain.

4. With the engine in a level position,

fill to the upper limit mark on the

dipstick with SAE 10W-30 oil.

Engine oil capacity is 0.58 quart

(.055 liter). NOTE: Other viscosities

shown in the chart in the “To

Check Oil” paragraph may be

used.

5. Replace the oil filler cap/dipstick

securely.

Upper Limit

Lower Limit

Oil Filler Neck

Oil Filler

Cap/Dipstick

Air Cleaner

A dirty air cleaner will restrict air flow to

the carburetor and cause poor engine

performance. Inspect the filter each

time the engine is operated. Clean the

filter more frequently if the engine is

operated in very dusty areas.

NOTICE: Operating the engine without

a filter, will allow dirt to enter the

engine, causing rapid engine wear. This

type of damage is not covered under

the warranty.

Inspect

1. Press the latch tabs on the top of

the air cleaner cover and remove

the cover. Check the filter to be

sure it is clean and in good

condition.

2. Reinstall the filter and air cleaner

cover.

Cleaning

1. Tap the filter several times on a

hard surface to remove dirt or

blow compressed air [not

exceeding 30 psi (207kPa, 1.2

kg/cm

2

) through the filter from the

clean side that faces the engine.

Never try to brush off dirt.

Brushing will force dirt into the

fibers.

2. Wipe dirt from the air cleaner body

and cover using a moist rag. Be

careful to prevent dirt from

entering the air duct that leads to

the carburetor.

Air Cleaner Body

Filter

Air

Cleaner

Cover

Latch

Tabs

Lower

Tabs

Air Duct

Page 18

18- ENG

D30333

3. Pull trigger on gun handle to

relieve any water pressure.

4. Disconnect the wand from the

gun.

5. Remove the nozzle from the end

of the wand with the 2mm allen

wrench provided as shown.

6. Clean the nozzle using the nozzle

cleaner provided or a straightened

paper clip. Insert into the nozzle

end and work back and forth until

obstruction is removed.

7. Direct water supply into nozzle

end to backflush loosened

particles for 30 seconds.

8. Reconnect spark plug wire.

9. Reassemble the nozzle to the

wand. Tighten securely to prevent

leaks.

10. Reconnect wand to gun and turn

on water supply.

11. Start pressure washer and place

wand into high pressure setting to

test.

NOZZLE CLEANING

If the nozzle becomes clogged with

foreign materials, such as dirt,

excessive pressure may develop. If the

nozzle becomes partially clogged or

restricted, the pump pressure will

pulsate. Clean the nozzle immediately

using the nozzle kit supplied and the

following instructions:

1. Shut off the pressure washer and

turn off the water supply.

2. Disconnect spark plug wire.

Clean and Replace Spark Plug

Change the spark plug every 100 hours

of operation or once each year,

whichever comes first. This will help

your engine to start easier and run

better.

Resistor

.030” (0.76 MM)

Wire Gauge

PUMP

This screen filter should be checked

periodically and cleaned if necessary.

1. Remove filter by grasping end and

removing it from water inlet of

pump as shown.

2. Clean filter by flushing it with water

on both sides.

3. Re-insert filter into water inlet of

pump. NOTE: Cone side faces

out.

NOTE: Do not operate pressure

washer without filter properly installed.

Filter Screen

Page 19

19- ENG

D30333

ENGINE

IMPORTANT: It is important to prevent

gum deposits from forming in essential

fuel system parts such as the

carburetor, fuel filter, hose or tank

during storage. Also, experience

indicates that alcohol-blended fuels

(called gasohol or using ethanol or

methanol) can attract moisture which

leads to separation and formation of

acids during storage. Acidic gas can

damage the fuel system of an engine

while in storage. To avoid engine

problems, the fuel system should be

emptied before storage of 30 days or

longer. Never use engine or carburetor

cleaner products in the fuel tank or permanent damage may occur.

Engine Preparation

1. First add a fuel stabilizer to the

fuel tank.

2. Run pressure washer for a full 5

minutes to allow fuel stabilizer to

enter the fuel system.

While preparing the

engine make sure

water supply is turned on and

flowing to the unit. NEVER run unit

without water supply running

through pump. Failure to do so will

cause pump damage.

3. Next shut off engine and

disconnect the water supply.

4. Disconnect the spark plug wire

and remove the spark plug.

5. Add one teaspoon of oil through

the spark plug hole.

6. Place rag over spark plug hole and

pull the recoil a few times to

lubricate the combustion chamber.

7. Replace the spark plug, but do not

connect the spark plug wire.

PUMP

1. Drain all water from high

pressure hose, coil it, and store it

in cradle of the pressure washer

handle.

2. Drain all water from spray gun

and spray wand by holding spray

gun in a vertical position with

nozzle end pointing down and

squeezing trigger. Store in

gun/hose holder.

3. Store chemical injector rinsing

hose, high pressure hose, spray

gun, and spray wand so they are

protected from damage, such as

being run over.

It is recommended that you follow

these steps to protect the internal seals

of the pressure washer when STORING

THE UNIT FOR MORE THAN 30 DAYS

AND/OR WHEN FREEZING

TEMPERATURES ARE EXPECTED.

*RV antifreeze needs to be run through

the pump as outlined in the steps

below.

4. Obtain a funnel, six ounces of *RV

antifreeze, and approximately 36

inches of garden hose with a male

hose connector attached to one

end.

Use only RV

antifreeze. Any other

antifreeze is corrosive and can

damage pump.

5. Disconnect spark plug wire.

6. Connect 36 inch length of hose

to water inlet of pump.

STORAGE

Page 20

20- ENG

D30333

4. Turn control valve toward tank to

be drained.

5. Repeat steps 3-4 to drain second

tank.

6. Turn control valve knob to the

down (off) position.

7. Fill tanks with clean water.

8. Turn valve toward tank and drain

water from tank. Repeat on

second tank. NOTE: This will rinse

cleaning solution tanks.

9. Route the cleaning solution hose

over the axle and reconnect

cleaning solution hose to chemical

injector for future use.

7. Add *RV antifreeze to hose as

shown.

8. Pull engine starter rope slowly

several times until antifreeze

comes out of high pressure hose

connection of pump.

9. Remove short hose from water

inlet of pump.

10. Reconnect spark plug wire.

* Windshield washer fluid may also be

used

DUAL TANK CLEANING

SYSTEM

1. Turn control valve knob to the

down (off) position.

2. Remove cleaning solution hose at

chemical injector and pull it over

the axle and to the rear of the unit.

3. Place end of cleaning solution

hose into a suitable container to

drain cleaning solution.

Control Valve Knob

Axle

Hose

Page 21

21- ENG

D30333

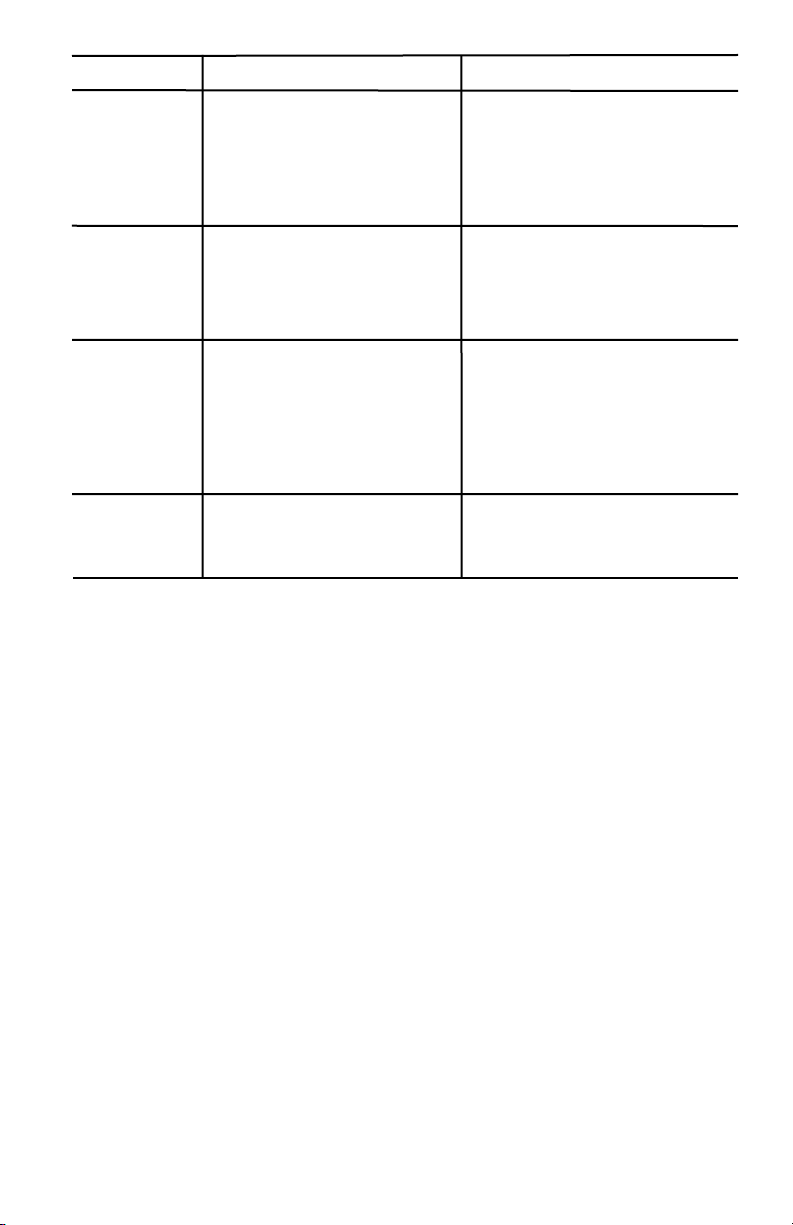

TROUBLESHOOTING GUIDE

PROBLEM

CAUSE

CORRECTION

Engine will not

start

1. No fuel.

2. Pressure builds up after

two pulls on the recoil

starter or after initial use.

4. Spark plug wire not

attached.

5. Choke lever in the

"Choke" position on a

"hot" engine or an engine

that has been exposed to

thermal heat for a long

period of time.

6. Fuel valve closed

1. Add Fuel.

2. Squeeze gun trigger to

relieve pressure.

4. Attach spark plug wire.

5. Move choke to the "No

Choke" position.

6. Move the fuel valve knob to

the "Open" position.

No or low

pressure

(initial use)

1. Wand not in high

pressure.

1. See How to Use Spray

Wand paragraph in the

Operation Section.

2. Low water supply.

2. Water supply must be at

least 5 GPM @ 20 PSI.

3. Leak at high pressure

hose fitting.

3. Tighten. Apply sealant tape

if necessary.

4. Nozzle obstructed.

5. Water filter screen

clogged.

5. Remove and clean filter.

4. See Spray Wand

paragraph in the

Maintenance section for

the correct procedure.

3. Choke lever in the “No

Choke” position.

3. Move choke to the

“Choke” position.

Page 22

22- ENG

D30333

6. Air in hose.

6. Turn off the engine, then the

water source. Disconnect

the water source from the

pump inlet and turn the

water source on to remove

all air from the hose. When

there is a steady stream of

water present, turn water

source off. Reconnect water

source to pump inlet and

turn on water source.

Squeeze trigger to remove

remaining air.

7. Choke lever in the

"Choke" position.

8. Throttle control lever is

not in the "Fast" position.

9. High pressure hose is too

long.

7. Move choke to the "No

Choke" position.

8. Move throttle control lever to

the "Fast" position.

9. Use high pressure hose

under 100 feet.

PROBLEM

CAUSE

CORRECTION

No or low

pressure

(initial use)

(continued)

6. Chemical build up in

chemical injector.

Will not draw

cleaning solution

1. Wand not in low

pressure.

2. Filter clogged on

chemical injector rinsing

hose.

3. Screen on end of

chemical injector rinsing

hose not in water

4. Chemical too thick

5. Pressure hose is too long

2. Clean filter.

3. Make sure end of chemical

injector rinsing hose is fully

submerged into clean water.

4. Dilute chemical. Chemical

should be the same

consistency as water.

5. Lengthen water supply hose

instead of high pressure

hose.

6. Have parts cleaned or

replaced by AWSC.

1. See Spray Wand paragraph

in the Maintenance section

for the correct procedure.

7. Hoses are not

connected.

7. Make sure all hoses are

connected at valve.

8. Control valve is in the

down (off) position or

pointed toward the tank

not being uses.

8. Turn control valve toward

tank being used.

Page 23

23- ENG

D30333

PROBLEM

CAUSE

CORRECTION

No or low

pressure (after

period of normal use.)

Water leaking

at gun/wand

connection

Water leaking

at pump

1. Worn seal or packing.

2. Worn or obstructed

valves.

3. Worn unloader piston.

1. Worn or broken o-ring.

2. Loose hose connection.

1. Loose connections.

2. Piston packings worn.

3. Worn or broken o-rings.

4. Pump head or tubes

damaged from freezing.

1. Have replaced by AWSC.

2. Have replaced by AWSC.

3. Have replaced by AWSC.

1. Check and replace.

2. Tighten.

1. Tighten.

2. Have replaced by AWSC.

3. Have replaced by AWSC.

4. Have replaced by AWSC.

1. Nozzle obstructed.

1. See Spray Wand paragraph

in the Maintenance section

for the correct procedure.

Pump

Pulsates

Page 24

24- ENG

D30333

REPAIR PARTS

Pressure Washer Model Number 919.672190

Key# Part # Description

2 D23124 Label, Danger

3 D23125 Label, Hot Surface

4 * Pump Kit

5 D27152 Screw, 5/16-24

10 D27956 Screw, 3/8-16-18 x 1.25

14 D22267 Plug

16 D21963 Wheel

17 D22268 Isolator

18 D23208 Screw, 1/4-20

19 W137 Pal Nut

23 D21630 Pump Shroud

26 D27959 Dual Tank Cleaning System

* See Breakdown for individual Parts

26

3

2

14

16

19

16

5

Torque to

120 - 240

in.-lbs.

10

Torque to

120 - 240

in.-lbs.

23

4

17

18

Page 25

25- ENG

D30333

Key# Part # Description

1 * Engine, Honda GCV160A

2 17050 Label, Danger

3 D23125 Label, Hot Surface

6 D22908 Frame

7 D25074 Base

8 D22904 Label, Moving Parts

9 D23099 Axle

12 D22308 Screw, 5/16-18

15 D22692 Nut, 5/16-18

24 D25087 Label, Warning

25 D27926 Cleaning Solution H ose

Not Shown

D30333 Manual, Owners

* See Breakdown for individual Parts

REPAIR PARTS

Pressure Washer Model Number 919.672190

6

24

9

15

Torque to

120-240 in.-lbs.

25

1

3

2

12

7

8

Page 26

26- ENG

D30333

REPAIR PARTS

Key# Part # Description

1 D20998 Hose, 3/8 x 18”

2 18139 Unloader Assembly

3 16848 Thermal Relief Valve

4 H061 Swivel Nut, Garden Hose

5 H068 Swivel, 3/8”

6 D29372 Chemical Injector

7 F187 Inlet ScreenFilter

8 D25006 Set Screw

Not Shown:

H140 Chemical Hose

Pressure Pump Model Number D28703

2

1

3

5

4

6

7

8

Page 27

27- ENG

D30333

REPAIR PARTS

Honda Engine Model Number GCV160A

Ref Description Part Number H/C Qty

1 Cylinder Assembly 12000-ZL8-405 6315691 1

2 Clip, Valve Guide 12216-ZE5-300 2399780 1

3 Cover, Head 12311-ZL8-000 5579990 1

4 Cover, Breather

(Breather Valve Assy) 12355-ZL8-000 5580006 1

5 Bolt, Flange (6x12) (CT200) 90013-883-000 0636845 4

6 Bolt, Flange (6x14) 90014-952-000 0803619 1

7 Oil Seal (25.4x62x6) 91201-ZL8-003 5581038 1

8 Spark Plug (BPR6ES)(NGK) 98079-56846 1441112 1

CYLINDER BARREL

Page 28

28- ENG

D30333

REPAIR PARTS

Honda Engine Model Number GCV160A

Ref Description Part Number H/C Qty

1 Pan Assembly, Oil (SAE) 11300-ZOL-820 6696686 1

2 Gasket, Oil Filler Cap 15625-ZE1-003 4497947 1

4 Shaft, Governor Holder 16508-ZM0-010 6384341 1

5 Governor Assembly 16510-ZM0-010 6384333 1

6 Weight Governor 16511-ZL8-000 5580287 2

7 Holder, Governor Weight 16512-ZM0-000 5580295 1

8 Pin, Governor Weight 16513-ZE1-000 1427244 2

9 Slider, Govenor 16531ZE1-000 1427251 1

10 Shaft, Governor Arm 16541-ZM0-000 5580303 1

11 Bolt, Flange (6x14) 90014-952-000 0803619 1

12 Bolt, Flange (6x25) 90121-952-000 0748111 8

13 Washer, Thrust (28x41.25x6) 90451-ZE1-000 2413862 1

14 Clip, Governor Holder 90602-ze1-000 2456697 1

15 Oil Seal (28x41.25x6) 91202-ZM0-V31 6315865 1

16 Washer, Plain (6mm) 94101-06800 0345900 1

17 Pin, Lock (8mm) 94251-08000 0115527 1

18 Pin, Dowel 98c20) 94301-08200 1417369 2

19 Gauge Assy., Oil Level 15650-ZM0-003 5722996 1

20 Bolt, Drain Plug 90131-896-650 1986231 1

21 Washer, Drain Plug 94109-12000 0171868 1

OIL PAN

Page 29

29- ENG

D30333

REPAIR PARTS

Honda Engine Model Number GCV160A

Ref Description Part Number H/C Qty

5 Washer, Thrust 90402-ZL8-000 5581012 1

6 Crankshaft 13310-Z0L-650 6696702 1

CRANKSHAFT

Page 30

30- ENG

D30333

REPAIR PARTS

Honda Engine Model Number GCV160A

Ref Description Part Number H/C Qty

1 Piston 13101-ZL8-000 5580014 1

2 Pin, Piston 13111-ZE0-000 1426576 1

3 Rod Assy., Connecting 13200-ZL8-000 5580022 1

4 Bolt, Connecting Rod 90001-ZE1-000 1431055 2

5 Clip, Pistion Pin (13mm) 90551-ZE0-000 2605517 2

6 Ring Set, Piston (TEIKOKU) 13010-ZL8-014 6315717 1

CRANKSHAFT

Page 31

31- ENG

D30333

REPAIR PARTS

Honda Engine Model Number GCV160A

Ref Description Part Number H/C Qty

1 Pulley, Camshaft 14320-ZL8-000 5580055 1

2 Shaft, Cam Pulley 14324-ZL8-000 5580063 1

3 Belt, Timing (84HU7 G-200) 14400-Z0J-004 6637417 1

4 Arm, In. Valve Rocker 14431-ZL8-000 5580089 1

5 Arm, EX. Valve Rocker 14441-ZL8-000 5580097 1

6 Shaft, Rocker Arm 14461-ZL8-000 5580105 2

7 Valve, In. 14711-ZL8-000 5580113 1

8 Valve, Ex 14721-ZL8-000 5580121 1

9 Spring, Valve 14751-ZL8-000 5580139 2

10 Retainer, In. Valve Spring 14771-ZE1-000 1426980 2

11 Screw, Tappet Adj. 90012-333-000 0294819 2

12 Nut, Tappet Adj. 90206-001-000 0004598 2

13 O-Ring (6.8x1.9) 91301-ZM0-V31 6315873 1

CRANKSHAFT PULLEY

Page 32

32- ENG

D30333

REPAIR PARTS

Honda Engine Model Number GCV160A

Ref Description Part Number H/C Qty

1 Starter Assy., Recoil *NH1*

(black) 28400-ZL8-013ZA 6061204 1

2 Knob, Recoil Starter 28461-ZL8-003 5580634 1

3 Rope, Recoil Starter 28462-ZL8-003 5611454 1

4 Nut, Flange (6mm) 90201-ZM0-000 6478812 3

CRANKSHAFT PULLEY

Page 33

33- ENG

D30333

REPAIR PARTS

Honda Engine Model Number GCV160A

Ref Description Part Number H/C Qty

1 Rubber, Supporter (107mm) 16854-ZH8-000 3683646 1

2 Petcock Assy. (MAN) 16950-ZG9-M02 5028923 1

3 Bracket, Petcock 16956-ZM0-000 5580394 1

4 Cap Assy., Fuel Tank 17620-ZL8-013 6673289 1

5 Tube, Fuel 17702-ZM0-000 5580469 1

6 Cover, Fan *NH1*(black) 19610-ZM0-010ZA 6132989 1

8 Collar, Fr. Turn Signal 33600-GK4-620 2499440 1

9 Bolt, Stud 90043-ZL8-000 5581004 3

10 Screw-Washer (5x10) 93891-05010-08 0671636 1

11 Bulk Hose, Fuel (5.5x800) (5.5x150) 95001-55008-40M 2449593 1

12 Clip, Tube (B8) 95002-02080 0250647 1

13 Clip, Tube (B10) 95002-02100 0250985 2

14 Clip, Tube (C9) 95002-50000 0053447 1

FAN COVER

Page 34

34- ENG

D30333

REPAIR PARTS

Honda Engine Model Number GCV160A

Ref Description Part Number H/C Qty

1 Gasket Set 16010-883-015 3088416 1

2 Float Set 16013-ZL1-003 5580162 1

3 Chamber Set, Float 16015-887-782 3465879 1

4 Screw Set 16016-ZG0-W00 4481818 1

5 Screw Set B 16028-ZE0-005 1441518 1

6 Screw Set 16029-ZG0-901 5580170 1

7 Carburetor Assembly (BB62B D) 16100-ZM0-803 6212849 1

8 Valve, Float 16155-ZM0-003 5580212 1

9 Nozzle, Main 16166-ZM0-003 5580220 1

10 Insulator, Carburetor 16211-ZL8-000 5580238 1

11 Gasket, Insulator 16212-ZL8-000 5580246 1

12 Gasket, Carburetor 16221-883-800 4581120 2

13 Gasket, Carburetor (Choke Side) 16228-ZL8-000 5580253 1

14 Guide, Air 19650-ZM0-000 5580535 1

15 Screw, Pan (5x6) 93500-05006-0H 0639419 1

16 Jet, Main (#60) 99101-124-0600 0635474 1

Jet, Main (#62) 99101-124-0620 0635482 1

Jet, Main (#65) 99101-124-0650 0636126 1

17 Screw Set, Drain 16024-ZE1-811 1672187 1

CARBURETOR

Page 35

35- ENG

D30333

REPAIR PARTS

Honda Engine Model Number GCV160A

Ref Description Part Number H/C Qty

1 Tube Breather 15721-ZM0-000 5580154 1

2 Element, Air Cleaner 17211-ZL8-000 5580402 1

3 Case Assembly, Air Cleaner 17220-ZM0-000 5580410 1

5 Gasket, Air Cleaner 17228-ZM0-000 5664560 1

6 Cover, Air Cleaner 17231-X0L-000 6673255 1

7 Bolt, Flange (6x86) (CT200) 90003-Z0L-000 5580964 2

8 Bolt, Flange (6x14) 95701-06014-08 2374742 1

AIR CLEANER

Page 36

36- ENG

D30333

REPAIR PARTS

Honda Engine Model Number GCV160A

Ref Description Part Number H/C Qty

1 Muffler 18310-ZM0-000 5580485 1

2 Protector, Muffler 18321-ZL8-000 5580501 1

3 Bolt, Flange (6x79) (CT200) 90004-ZL8-000 5580972 2

4 Bolt, Flange (6x12) (CT200) 90013-883-000 0636845 3

5 Gasket, Muffler 18381-ZL8-305 5737457 1

MUFFLER

Page 37

37- ENG

D30333

REPAIR PARTS

Honda Engine Model Number GCV160A

Ref Description Part Number H/C Qty

1 Key, Special Woodruff (25x18) 13331-357-000 0348433 1

2 Coil Assembly, Ignition 30500-ZL8-004 5580659 1

4 Wire, Stop Watch 32195-ZM0-800 6315816 1

10 Bolt, Flange (6x20) (CT200) 90022-888-010 0671552 1

11 Nut, Special (14MM) 90201-878-003 0442038 1

12 Clip, Cable (A) 90681-959-003 1824630 1

15 Plate Side 19612-ZM0-000 6315782 1

16 Bolt, Flange (6x12) (CT200) 90013-883-000 0636845 2

17 Flywheel 31110-ZL8-004 5656053 1

FLYWHEEL

Page 38

38- ENG

D30333

REPAIR PARTS

Honda Engine Model Number GCV160A

Ref Description Part Number H/C Qty

1 Arm, Governor 16551-ZM0-000 5580311 1

2 Rod, Governor 16555-ZM0-000 5580329 1

3 Spring, Governor 16561-ZM0-V30 6315725 1

4 Spring, Throttle Return 16562-ZM0-000 5580352 1

5 Spring, Lever 16574-ZE1-000 1427384 1

6 Washer, Control Lever 16575-ZE2-W00 3678679 1

7 Plate, Lever Center 16577-ZM0-V30 6315741 1

8 Spacer, Control Lever 16578-ZE1-000 1427400 1

9 Base Control 16580-ZM0-V30 6315758 1

10 Lever, Choke 16612-ZM0-V30 6315766 1

11 Rod, Choke 16674-ZM0-V30 6315774 1

12 Collar (9.2x15x20.5) 91501-ZM0-V30 6363733 1

13 Switch Assembly, Engine Stop (N.0) 35120-ZL8-003 5611520 1

14 Mark, Throttle Indication 87532-ZM0-V30 6315832 1

15 Bolt, Governor Arm 90015-ZE5-010 2418671 1

16 Bolt, Flange (6x32) 90017-883-000 0636076 1

17 Bolt, Special (6x45) 90016-ZM0-V30 6315840 1

18 Nut, Self-Lock (6MM) 90114-SA0-000 1410182 1

19 Nut, Self-Lock (5MM) 90136-SM4-901 3596095 1

20 Screw-Washer (4x12) 93892-04012-00 0485946 1

21 Nut, Flange (6MM) 94050-06000 0471623 1

22 Washer, Plain (4MM) 94103-04000 1510361 1

CONTROL (2)

Page 39

39- ENG

D30333

REPAIR PARTS

Honda Engine Model Number GCV160A

Ref Description Part Number H/C Qty

1 Mark, Emblem (5.5) 87101-ZM0-000 5580865 1

LABELS

Page 40

40- FR

D30333

TABLE DES MATIÈRES

GARANTIE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

TABLEAU DES SPÉCIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

MESURES DE SÉCURITÉ – DÉFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . .41

RENSEIGNEMENTS SUR LA SÉCURITÉ DU CONSOMMATEUR . . . . . . . . . . . . . . .41

MESURES DE SÉCURITÉ IMPORTANTES . . . . . . . . . . . . . . . . . . . . . . .42-45

CONTENU DE LA BOÎTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

ASSEMBLAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46-47

UTILISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48-53

ENTRETIEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53-56

ENTREPOSAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57-58

GUIDE DE DÉPANNAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59-61

PIÈCES DE RECHANGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62-77

COMMANDE DES PIÈCES DE RECHANGE . . . . . . . . . . . .Couverture arrière

GARANTIE COMPLÈTE DE UN AN SUR LES LAVEUSES À PRESSION

Si cette laveuse à pression arrête de fonctionner à cause d’un défaut de fabrication ou de

main-d’œuvre dans une période d’un an à compter de la date d’achat, RETOURNEZ-LA

AU CENTRE DE SERVICE APRÈS-VENTE SEARS LE PLUS PROCHE AU CANADA ET

SEARS LA RÉPARERA SANS FRAIS.

Si cette laveuse à pression est utilisée à des fins commerciales ou comme appareil de

location, la garantie ne s’applique que pour une période de quatre-vingt-dix (90) jours à

compter de la date d’achat.

Cette garantie sur la laveuse à pression de Craftsman vous donne des droits particuliers. Il

se peut que vous ayez d’autres droits qui varient d’une province à l’autre.

Sears Canada, Inc., Toronto, Ont. M5B 2B8

GARANTIE

Page 41

41- FR

D30333

N° de modèle 919.672190

Laveuse à pression

Pression 2 500 lb/po

2

Débit 2,5 gal./min

Unités de nettoyage (gal./min x lb/po

2

) 5 250

Moteur

Tr./min 3 600

Puissance nominale en chevaux 5,5

Écartement de la bougie d’allumage 0,030 po (0,76 mm)

Capacité du réservoir à carburant 0,29 gallon (1,1 litre)

Capacité d’huile : 0,58 pinte (0,55 litre) SAE 30

TABLEAU DES SPÉCIFICATIONS

Il se peut que ce produit ne soit pas équipé d’un silencieux

à pare-étincelles. Si le produit n’en est pas équipé, et s’il

est utilisé près de matériaux inflammables ou sur de la terre couverte de produits

agricoles, forêts, broussailles, gazon ou autres articles semblables, un pare-étincelles

approuvé doit être posé, et est exigé par la loi en Californie. Selon la section 130050

de la loi de la Californie, et les sections 4442 et 4443 du Code sur les ressources

publiques de la Californie, ce produit ne peut pas être utilisé en Californie, à moins

que le moteur ne soit équipé d’un pare-étincelles, tel que décrit dans la section 4442,

et à moins que l’appareil ne soit maintenu en bon état de fonctionnement. Des pareétincelles sont également requis sur certaines terres forestières des États-Unis et

peuvent être exigés légalement sous certains autres lois et arrêtés.

Les gaz d’échappement du moteur contiennent des

produits chimiques qui, dans certaines quantités, peuvent

causer le cancer, les anomalies congénitales ou d’autres maux de reproduction.

RENSEIGNEMENTS SUR LA SÉCURITÉ DU CONSOMMATEUR

MESURES DE SÉCURITÉ - DÉFINITIONS

Indique un danger

imminent qui, s'il n'est

pas évité, causera de graves blessures

ou la mort.

Indique la

possibilité

d’un danger qui, s’il n’est pas évité,

pourrait causer de graves blessures ou

la mort.

Ce guide contient des renseignements importants que vous deviez bien saisir. Cette

information porte sur VOTRE SÉCURITÉ et sur LA PRÉVENTION DE PROBLÈMES

D'ÉQUIPEMENT. Afin de vous aider à identifier cette information, nous avons utilisé les

symboles ci-dessous. Veuillez lire attentivement ce guide en portant une attention particulière

à ces symboles.

Indique la possibilité

d'un

danger qui, s'il n'est pas évité, peut causer

des blessures mineures ou moyennes.

Sans le symbole d’alerte.

Indique la possibilité d’un

danger qui, s’il n’est pas évité, peut causer

des dommages à la propriété.

Page 42

42- FR

D30333

Lisez le Guide de l’utilisateur. Ne tentez pas d’utiliser cet

appareil avant d’avoir lu les directives sur la sécurité,

l’assemblage, l’utilisation et l’entretien de ce Guide de l’utilisateur.

RISQUE

PRÉVENTION

• Ne pas vaporiser des liquides inflammables.

• Ne remplissez jamais les réservoirs de solution de

nettoyage avec de l'essence ou autres solvants

inflammables.

• Couper le moteur et le laisser refroidir avant d'ajouter

de carburant au réservoir.

• Prendre des précautions lors du remplissage du

réservoir pour éviter le déversement de carburant.

Placer la laveuse à pression loin du lieu de

remplissage avant de démarrer le moteur.

• Toujours garder la laveuse à pression à une distance

minimum de quatre pieds 1,2 m (4 pieds) des surfaces

qui pourraient être endommagées par les gaz

d'échappement du silencieux (telles que les maisons,

automobiles ou plantes).

MESURES DE SÉCURITÉ IMPORTANTES

• L'essence répandue par déversement et les vapeurs

qui en émanent risquent de s'enflammer en présence

d'étincelles provenant d'une cigarette allumée, d'un

arc électrique, de gaz d'échappement et de pièces

chaudes du moteur, telles que le silencieux.

RISQUE D'EXPLOSION OU D’INCENDIE

DANGER

RISQUE PAR INHALATION

DANGER

LISEZ ET CONSERVEZ CES INSTRUCTIONS

• La chaleur peut causer l'expansion de carburant

dans le réservoir pouvant aboutir à un déversement

et provoquer un incendie ou une explosion.

• Maintenir le niveau maximal de carburant à

environ13mm (½ po) du haut du réservoir afin de

permettre l'expansion de l'essence.

• Le fait d'utiliser la laveuse à pression dans un milieu

explosif peut aboutir à un incendie.

• Faire le plein et utiliser l'équipement dans un endroit

bien aéré et libre de toutes obstructions. Équiper ces

lieux d'extincteurs appropriés pour combattre les

incendies comprenant à base d'essence.

• Des matières placées contre ou à proximité de la

laveuse à pression peuvent nuire à une ventilation

adéquate provoquant ainsi une surchauffe et un

risque d'inflammation de ces matières.

• Ne jamais faire fonctionner la laveuse à pression dans

un endroit comprenant des herbes ou buissons secs.

• La chaleur des gaz d'échappement du silencieux

peut endommager les surfaces peintes, faire fondre

des matériaux sensibles à la chaleur (tels que le

revêtement d'extérieur, le plastique, le caoutchouc et

le vinyle) et endommager les plantes.

• Un entreposage inapproprié du carburant peut

causer une inflammation accidentelle. Le carburant

qui n'est pas rangé de façon sécuritaire peut tomber

entre les mains d'un enfant ou autres personnes non

compétentes.

• Placer le carburant dans un contenant approuvé par

l'OSHA et le ranger dans un lieu sûr, loin de l'aire de

travail.

• L'utilisation d'acides, de produits chimiques toxiques

ou corrosifs, de poisons, d'insecticides ou de toute

sorte de solvant inflammable dans ce produit pourrait

provoquer des blessures graves ou la mort.

•

Certains nettoyeurs liquides contiennent des

substances pouvant causer des lésions à la peau, aux

yeux et aux poumons.

• Utiliser la laveuse à pression dans un endroit bien

aéré. Éviter les endroits clos tels que les garages,

sous-sols, etc.

• Ne jamais utiliser l'appareil dans un endroit occupé

par d'autres personnes ou des animaux.

• N'utiliser que des liquides de nettoyage recommandés

pour des laveuses à pression. Suivre les

recommandations du fabricant. Ne pas utiliser d'eau

de Javel ou tout autre produit corrosif.

•

L'inhalation des émanations d'échappement peut

causer de graves blessures ou la mort !.

RISQUE

PRÉVENTION

Page 43

43- FR

D30333

• L'utilisation d'acides, de produits chimiques

toxiques ou corrosifs, de poisons, d'insecticides ou

de toute sorte de solvant inflammable dans ce

produit pourrait provoquer des blessures graves ou

la mort.

• Ne pas utiliser d'acides, d'essence, de kérosène ou

toute autre matière inflammable avec cet appareil.

N'employer que des détergents, nettoyeurs ou

dégraisseurs d'entretien ménager qui sont

recommandés pour une utilisation avec une laveuse à

pression.

• Lire attentivement tous les avertissements et

instructions fournis par le fabricant de la solution de

nettoyage.

• Porter un équipement et des vêtements de protection

pour se protéger les yeux et la peau contre tout

contact avec des matières vaporisées.

RISQUE DE BLESSURES ET DE DOMMAGES À LA PROPRIÉTÉ

PENDANT LE TRANSPORT OU L'ENTREPOSAGE

RISQUE D'INJECTION D'UN FLUIDE

RISQUE DE BRÛLURES CHIMIQUES

RISQUE

DANGER

RISQUE

PRÉVENTION

DANGER

RISQUE

PRÉVENTION

DANGER

• Des fuites ou des déversements de carburant ou

d'huile peuvent se produire et entraîner des risques

d'incendie ou des problèmes aux voies respiratoires,

des blessures graves ou la mort. Des fuites de

carburant ou d'huile endommagent les tapis, la

peinture et d'autres surfaces dans les véhicules et les

remorques.

• Si la laveuse à pression est munie d'une soupape

d'arrêt, tourner la soupape à la position fermée avant

le transport pour éviter tout risque de fuite. Si l'appareil

n'est pas muni d'une soupape d'arrêt, vidanger le

carburant du réservoir avant le transport. Ne

transporter le carburant que dans des contenants

approuvés par l'OSHA. Pour le transport, toujours

placer la laveuse à pression sur un tapis protecteur

pour éviter l'endommagement du véhicule par des

fuites. Retirer la laveuse à pression du véhicule

immédiatement à l'arrivée.

• La laveuse à pression fonctionne à une pression et à

une vitesse suffisamment élevées pour faire pénétrer

le fluide dans la peau de personnes ou d'animaux et

causer des blessures graves ou la nécessité d'une

amputation. Une fuite causée par des raccords

relâchés ou usés ou par un boyau endommagé peut

aboutir à une blessure par injection. NE PAS

TRAITER L'INJECTION D'UN FLUIDE COMME UNE

SIMPLE COUPURE ! Consulter immédiatement un

médecin !

• Ne jamais placer la main devant la buse.

• Diriger le jet de vaporisation loin de soi et d'autrui.

• S'assurer que le boyau et les raccords sont bien

serrés et en bon état. Ne jamais se cramponner au

boyau ou aux raccords lors de l'utilisation de

l'appareil.

• Éviter tout contact du boyau avec le silencieux.

• Ne jamais mettre ni enlever les raccords de la lance

ou du boyau lorsque l'appareil est pressurisé.

• On risque de subir des blessures si la pression du

système n'est pas diminuée avant de tenter tout

entretien ou démontage.

• Pour dégager la pression de l’appareil, couper le moteur,

couper l’alimentation d’eau et enfoncer la détente du

pistolet jusqu’à ce que l’eau arrête de s’écouler.

• N'utiliser qu'un boyau et des accessoires à haute

pression classés pour un service nominal plus élevé

que la puissance nominale (lb/po

2

) de l'appareil.

PRÉVENTION

Page 44

44- FR

D30333

•

Si le moteur ne démarre pas après deux essais,

appuyer sur la détente du pistolet afin de dégager la

pression de la pompe. Tirer lentement sur le cordon

de démarrage jusqu'à ce qu'on sente une

résistance. Tirer ensuite rapidement sur le cordon

pour éviter les contre-coups et les blessures aux

mains ou aux bras.

• La force de rétroaction du jet fait déplacer le

pistolet/la lance et peut faire glisser ou tomber

l'utilisateur ou provoquer un changement de direction

du jet. Une mauvaise maîtrise du pistolet/de la lance

peut causer des blessures à l'utilisateur ou à d'autres

personnes.

• Ne pas trop éloigner le pistolet du corps et ne pas se

tenir sur une surface instable. Saisir le pistolet/la lance

fermement avec les deux mains. S'attendre à ressentir

un contre-coup lors du déclenchement.

• Le contact avec les surfaces chaudes, telles que les

pièces d'échappement du moteur, peut provoquer

des brûlures graves.

• Durant le fonctionnement de l'appareil, ne toucher

qu'aux surfaces de commande de la laveuse à

pression. Garder les enfants loin de la laveuse à

pression en tout temps. Les enfants ne sont pas

nécessairement capables de reconnaître les dangers

que comporte cet appareil.

RISQUE D'UNE UTILISATION NON SÉCURITAIRE

DANGER

RISQUE DE CHOCS ÉLECTRIQUES

DANGER

RISQUE DE SURFACES CHAUDES

DANGER

RISQUE

PRÉVENTION

RISQUE

PRÉVENTION

RISQUE

PRÉVENTION

• Une utilisation de la laveuse à pression qui n'est pas

conforme aux mesures de sécurité peut causer de

graves blessures ou la mort de l'utilisateur ou

d'autres personnes.

• Ne pas utiliser d'eau de Javel ou tout autre produit

corrosif.

• S'habituer au fonctionnement et aux commandes de la

laveuse à pression.

• Garder toutes les personnes non autorisées, les

animaux domestiques et les obstacles loin de l'aire de

vaporisation.

• Ne pas utiliser l'appareil lorsque vous êtes fatigué ou

sous l'effet de boissons alcooliques ou de drogues.

Restez alerte à tout moment.

• Ne jamais contourner un dispositif de sécurité de cet

appareil.

• Ne jamais utiliser un appareil auquel il manque des

pièces, qui comprend des pièces brisées ou non

autorisées par le fabricant.

• Ne jamais s'éloigner de la lance lorsque l'appareil est en

marche.

• Si la procédure de démarrage appropriée n'est

pas suivie, le moteur peut provoquer des contrecoups et causer des blessures graves aux mains

ou aux bras.

• Le pistolet/la lance de vaporisation est un outil de

nettoyage puissant qui peut ressembler à un jouet

aux yeux d'un enfant.

• Garder les enfants éloignés de la laveuse à pression à

tout moment.

• Une vaporisation dirigée vers des prises de courant,

des interrupteurs ou des objets branchés sur un

circuit électrique peut causer des chocs électriques

mortels.

• Débrancher tout appareil électrique avant de tenter de

le nettoyer. Diriger le jet de vaporisation loin de toutes

prises de courant et interrupteurs.

Page 45

45- FR

D30333

CONTENU DE LA BOÎTE

Poignée

n

o

de pièce D22316

avec vis - node pièce D22901

Pièces dans un sac

Trousse de nettoyage

de la buse

Boutons de

selle n

o

de

pièce D23196

Ensemble de châssis

de moteur avec roues

Boyau à haute

pression

n

o

de pièce

D22166

Boyau de

produit chimique

n

o

de pièce H140

Huile à moteur

Pistolet de vaporisation

n

o

de pièce 17780

Lance de vaporisation à réglages multiples

node pièce D22837

Tableau d'accessoires

n

o

de pièce D25081

Boutons

node

pièce

16471

Clé Allen - no de pièce 16767

Outil de nettoyage - n

o

de pièce NCT001

Le puissant jet de la laveuse à pression est capable d'endommager les

surfaces fragiles telles que le bois, le verre, la peinture d'automobiles, les

garnitures d'auto ainsi que les objets délicats tels que les fleurs et arbustes. Avant de vaporiser,

vérifiez l'objet à nettoyer afin de vous assurer qu'il est assez robuste pour résister à la puissance

du jet sans subir de dommages. Évitez d'utiliser le jet à débit concentré sauf pour des surfaces

très résistantes telles que le béton ou l'acier.

Le fait de faire fonctionner l'appareil sans alimentation d'eau endommagera l'appareil. L'utilisation

de l'appareil sans alimentation d'eau annulera la garantie. Vous ne devez jamais faire fonctionner

l'appareil plus de deux (2) minutes sans appuyer sur la détente du pistolet afin de permettre à l'eau

fraîche d'entrer dans la pompe et à l'eau chauffée (recirculée) d'en sortir.

D

RISQUE DE BLESSURES PAR VAPORISATION

DANGER

RISQUE

PRÉVENTION

• Un fluide vaporisé à haute vélocité peut

causer le bris d’objets et la propulsion de

particules à vitesse élevée.

• Les objets légers ou qui ne sont pas fixés

peuvent devenir de dangereux projectiles.

• Toujours porter des lunettes de sécurité Z87

homologuées par l’ANSI. Porter des vêtements

de protection pour se protéger contre toute

vaporisation accidentelle.

• Ne jamais vaporiser ni pointer la lance en

direction de personnes ou d’animaux.

• Toujours s’assurer que la détente est verrouillée

lorsque la lance n’est pas utilisée afin de

prévenir toute mise en marche accidentelle.

• Ne jamais fixer la détente en position enfoncée

(ouverte) de façon permanente.

Tableau d’accessoires dans un sac

Guide de

l'utilisateur

en anglais et

français

MISE EN GAR

Page 46

46- FR

D30333

ASSEMBLAGE

3. Attachez la lance au pistolet et bien

serrer.

2. Placez l’ensemble de poignée sur le

châssis et attachez la poignée au

châssis. REMARQUE : Les boutons

doivent être fixés à l'extérieur du

châssis.

1. Retirez de l'ensemble de châssis les

réservoirs de solution de nettoyage.

Glissez les réservoirs vers le haut et

éloignez-les de l'ensemble de châssis.

4. Attachez le boyau à haute pression

au pistolet et bien serrer.

5. Assemblage du tableau

d’accessoires:

a. Retirez les vis supérieures de

l'ensemble de poignée.

b. Desserrez les vis inférieures de

l'ensemble de poignée

.

c. Positionnez les rainures du

tableau d'accessoires sur les vis

et mettez le tableau en place.

Retirer

Desserer

Vis

Page 47

47- FR

D30333

d. Insérez les vis (retirées plus tôt)

dans les trous supérieures et

fixez le tableau d'accessoires sur

les poignées. Ne pas trop serrer.

6. Remettez en place les réservoirs de

solution de nettoyage. Inclinez les

réservoirs de solution de nettoyage vers

le moteur, glissez-les sur les poignées

et enclenchez-les en place.

Raccord cannelé

7. Fixez le boyau de solution de

nettoyage au raccord cannelé de la

soupape de commande, située à

l'arrière de l'appareil.

Page 48

48- FR

D30333

MOTEUR

Commande d'étrangleur : Ouvre et ferme la

soupape de l'étrangleur dans le carburateur.

Levier de commande des gaz : Commande la

vitesse du moteur.

Poignée du démarreur : Tirer sur la poignée du

démarreur fait fonctionner le lanceur à rappel

pour démarrer le moteur.

Levier de la soupape de carburant : Ouvre et

ferme la connexion entre le réservoir de

carburant et le carburateur.

UTILISATION

LISEZ CE GUIDE DE L’UTILISATEUR ET TOUTES LES MESURES DE SÉCURITÉ AVANT

D’UTILISER CET APPAREIL. Comparez les illustrations avec votre appareil afin de vous

familiariser avec l’emplacement des commandes et des réglages. Conservez ce guide pour

les références futures.

Pompe à

haute

pression

Moteur

Boyau à

haute

pression

Pistolet de

vaporisation

Poignée du

démarreur

Levier de la

soupape de

carburant

Commande

d'étrangleur

Commande

des gaz

Boyau de rinçage d'injecteur de produit

chimique (non illustré) : Utilisé pour rincer

l'injecteur de produit chimique après

l'utilisation d'une solution de nettoyage.

Système de nettoyage à deux réservoirs :

Permet de passer facilement d'une solution

de nettoyage à une autre, selon les travaux

de nettoyage à accomplir ; il suffit de tourner

le bouton de la soupape de commande.

Filtre à air

Lance de vaporisation

à réglages multiples

Système de

nettoyage à

deux

réservoirs