Page 1

Owner's Manual

I(RRFTSMRNq

Oil Lubricated

Single Stage

Vertical Stationary

AIR COMPRESSOR

Model No.

919.184191

• Safety Guidelines

• Assembly

• Operation

• Maintenance

• Service and Adjustments

• Troubleshooting

• Repair Parts

• Espahol

CAUTION: Read the Safety Guidelines

and All Instructions Carefully Before

Operating.

Sears, Roebuck and Co., Hoffman Estates, IL 60170 U.S.A.

Visit our Craftsman website: www.sears.com/craftsman

D30091 Rev. 0 9/26/03

Page 2

WARRANTY ................................................ 2

SPECIFICATION CHART ..................................... 3

SAFETY GUIDELINES ...................................... 3-8

GLOSSARY ................................................ 9

ACCESSORIES ............................................. 9

DUTY CYCLE .............................................. 9

ASSEMBLY ............................................... 10

INSTALLATION .......................................... 11-13

OPERATION ............................................ 14-16

MAINTENANCE ......................................... 17-19

SERVICE AND ADJUSTMENTS ............................ 20-21

STORAGE ................................................ 22

TROUBLESHOOTING GUIDE .............................. 24-27

REPAIR PARTS ......................................... 28-31

ESPAI_IOL .............................................. 32-57

NOTES .................................................. 58

REPAIR PROTECTION AGREEMENTS ......................... 59

HOW TO ORDER REPAIR PARTS ...................... back cover

FULL ONE YEAR WARRANTY AIR COMPRESSOR

If this CRAFTSMAN Air Compressor fails due to a defect in material or

workmanship within one year from the date of purchase, Sears will at its

option repair or replace it free of charge. Contact your nearest Sears Service

Center (1-800-4-MY-HOME ®)to arrange for repair, or return the Air

Compressor to the place of purchase for replacement.

If this Air Compressor is used for commercial or rental purposes, this warrant

applies for only ninety days from the date of purchase.

This warranty gives you specific legal rights and you may have other rights

which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

D30091 2- ENG

Page 3

-_".J=[a_I; [.'7,21d[1] _I i f'-1:II

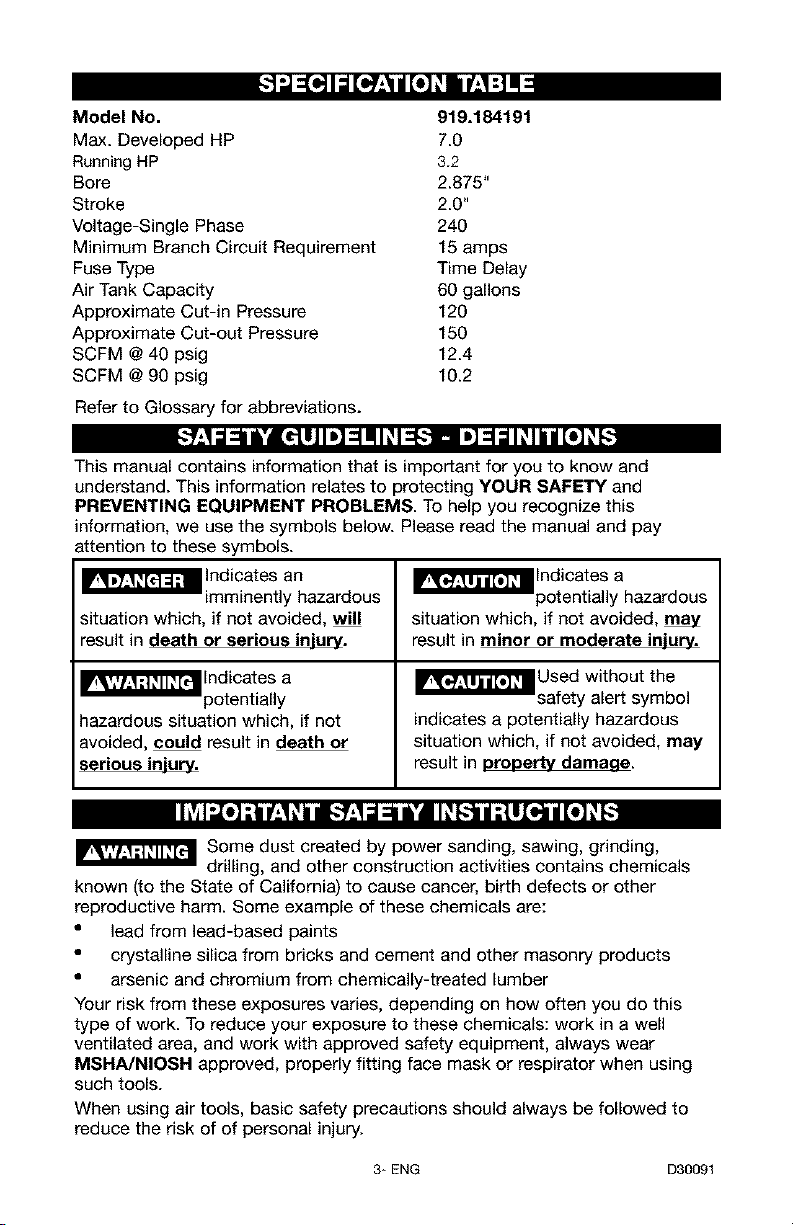

Model No. 919.184191

Max. Developed HP 7.0

Running HP 3.2

Bore 2.875"

Stroke 2.0"

Voltage-Single Phase 240

Minimum Branch Circuit Requirement 15 amps

Fuse Type Time Delay

Air Tank Capacity 60 gallons

Approximate Cut-in Pressure 120

Approximate Cut-out Pressure 150

SCFM @ 40 psig 12.4

SCFM @ 90 psig 10.2

Refer to Glossary for abbreviations.

This manual contains information that is important for you to know and

understand. This information relates to protecting YOUR SAFETY and

PREVENTING EQUIPMENT PROBLEMS. To help you recognize this

information, we use the symbols below. Please read the manual and pay

attention to these symbols.

_"_F"4'_ Indicat es an

imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

_T_llndicates a

potentially hazardous

situation which, if not avoided,

result in minor or moderate injury.

_lndicates a

potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

_J Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals

_'_lUsed without the

safety alert symbol

indicates a potentially hazardous

situation which, if not avoided, may

result in property damaee.

known (to the State of California) to cause cancer, birth defects or other

reproductive harm. Some example of these chemicals are:

• lead from lead-based paints

• crystalline silica from bricks and cement and other masonry products

• arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals: work in a well

ventilated area, and work with approved safety equipment, always wear

MSNA/NIOSR approved, properly fitting face mask or respirator when using

such tools.

When using air tools, basic safety precautions should always be followed to

reduce the risk of of personal injury.

3* ENG D30091

Page 4

II_ I_o] ;111P'.'q+IInl[,.'9'.,__1_ &'i __JL_[,._)III,_]LI_+']IIT[_o_+]L_,[,._

Save these instructions

Improper operation or maintenance of this product could result in serious injury and

property damage. Read and understand all warnings and operation instructions before

using this equipment,

,l;1"l'J "-In

WARNING: Risk of explosion or fire

What Could Happen How To Prevent It

It is normal for electrical contacts Always operate the compressor in a well

within the motor and pressure switch to ventilated area free of combustible

spark, materials, gasoline, or solvent vapors.

If electrical sparks from compressor If spraying flammable materials, locate

come into contact with flammable compressor at least 20 feet away from

vapors, they may ignite, causing fire or spray area. An additional length of hose

explosion, may be required,

Store flammable materials in a secure

location away from compressor.

Restricting any of the compressor

ventilation openings will cause serious

overheating and could cause fire,

Unattended operation of this product

could result in personal injury or

property damage. To reduce the risk of

fire, do not allow the compressor to

operate unattended.

Never place objects against or on top

of compressor. Operate compressor in

an open area at least 12 inches away

from any wall or obstruction that would

restrict the flow of fresh air to the

ventilation openings.

Operate compressor in a clean, dry wall

ventilated area. Do not operate unit

indoors or in any confined area.

Always remain in attendance with the

)roduct when it is operating.

Always disconnect electrical power by

moving pressure switch lever to the off

}osition and drain tank daily or after

each use.

D30091 4* ENG

Page 5

WARNING: Risk of Bursting

Air Tank: The following conditions could lead to a weakening of the tank, and result

in a violent tank explosion and could cause property damage or serious injury,

What Could Haopen How To Prevent It

Failure to properly drain condensed Drain tank daily or after each use. If

water from tank, causing rust and tank develops a leak, replace it

thinning of the steel tank. immediately with a new tank or replace

the entire compressor.

Modifications or attempted repairs to Never drill into, weld, or make any

the tank. modifications to the tank or its

Unauthorized modifications to the attachments.

unloader valve, safety valve, or any

other components which control tank

pressure.

Excessive vibration can weaken the The tank is designed to withstand specific

air tank and cause rupture or operating pressures. Never make

explosion adjustments or parts substitutions to

alter the factory set operating

pressures=

ATTACHMENTS & ACCESSORIES:

Exceeding the pressure rating of air

tools, spray guns, air operated

accessories, tires, and other inflatables

can cause them to explode or fly apart,

and could result in serious injury.

For essential control of air pressure, you

must install a pressure regulator and

pressure gauge to the air outlet (if not

equipped) of your compressor. Follow the

equipment manufacturers

recommendation and never exceed the

maximum allowable pressure rating of

attachments. Never use compressor to

inflate small low pressure objects such

as children's toys, footballs,

basketballs, etc.

WARNING: Risk from Flying Objects

What Could Happen How To Prevent It

The compressed air stream can cause

soft tissue damage to exposed skin

and can propel dirt, chips, loose

particles, and small objects at high

speed, resulting in property damage or

personal injury.

Always wear ANSI Z87.1 approved safety

glasses with side shields when using the

compressor.

Never point any nozzle or sprayer

toward any part of the body or at other

people or animals.

Always turn the compressor off and

bleed pressure from the air hose and tank

before attempting maintenance, attaching

to0_s Oi" accessories,

5* ENG D30091

Page 6

WARNING: Risk of Electrical Shock

What Could Happen How To Prevent It

Your air compressor is powered by Never operate the compressor outdoors

electricity. Like any other electrically when it is raining or in wet conditions.

powered device, If it is not used Never operate compressor with

properly it may cause electric shock. }retactive covers removed or damaged.

Repairs attempted by unqualified Any electrical wiring or repairs required

personnel can result in serious injury on this product should be performed by

or death by electrocution, authorized service center personnel in

Electrical Grounding: Failure to provide Make certain that the electrical circuit to

adequate grounding to this product which the compressor is connected

could result in serious injury or death provides proper electrical grounding,

from electrocution, correct voltage and adequate fuse

See grounding instructions. _retection.

accordance with national and local

electrical codes.

WARNING: Risk of Breathing

What Could Happen How To Prevent It

The compressed air directly from your

compressor is not safe for breathing.

The air stream may contain carbon

monoxide, toxic vapors, or solid

particles from the tank. Breathing these

contaminants can cause serious injury

or death.

Air obtained directly from the compressor

should never be used to supply air for

human consumption. In order to use air

)roduced by this compressor for

breathing, suitable filters and in-line

safety equipment must be properly

installed. In-line filters and safety

equipment used in conjunction with the

compressor must be capable of treating

air to all applicable local and federal

codes prior to human consumption.

Sprayed matadals such as paint, paint

solvents, paint remover, insecticides,

weed killers, may contain harmful

vapors and poisons.

D30091 6* ENG

Work in an area with good cross

ventilation. Read and follow the safety

instructions provided on the label or

safety data sheets for the materials you

are spraying. Use a NIOSH/MSHA

approved respirator designed for use with

your specific application.

Page 7

:r:_rJ:_;!m

WARNING: Risk of Burns

What Could Happen

Touching exposed metal such as the

compressor head or outlet tubes, can

result in serious burns.

Never touch any exposed metal parts

on compressor during or immediately

after operation. Compressor will remain

hot for several minutes after operation.

Do not reach around protective shrouds

or attempt maintenance until unit has

been allowed to cool.

How To Prevent It

:r:_rJ:_;!=

WARNING: Risk from Moving Parts

What Could Happen How To Prevent It

Moving parts such as the pulley, flywheel, Never operate the compressor with

and belt can cause serious injury if they guards or covers which are damaged or

come into contact with you or your removed.

clothing.

Attempting to operate compressor with Any repairs required on this product

damaged or missing parts or attempting should be performed by authorized

to repair compressor with protective service center personnel.

shrouds removed can expose you to

moving parts and can result in serious

injury.

:r:_rJ:_;!=

WARNING: Risk of Falling

What Could Happen How To Prevent It

A portable compressor can fall from a Always operate compressor in a stable

table, workbench, or roof causing secure position to prevent accidental

damage to the compressor and could movement of the unit. Never operate

result in serious injury or death to the compressor on a roof or other elevated

operator, position. Use additional air hose to

reach high locations.

7÷ ENG D30091

Page 8

WARNING: Risk of Serious Injury or Property Damage When

Transporting Compressor

(Fire, Inhalation, Damage to VehicleSurfaces)

What Could Happen How To Prevent It

Oil can leak or spill and could result in Always place COMPRESSOR on a

fire or breathing hazard; serious injury or protective mat when transporting to

death can result, oil leaks will damage protect against damage to vehicle from

carpet, paint or other surfaces in leaks. Remove COMPRESSOR from

vehicles or trailers, vehicle immediately upon arrival at your

WARNING: Risk of Unsafe Operation _1=

What Could Happen How To Prevent It

Unsafe operation of your air compressor

could lead to serious injury or death to

you or others.

destination.

Review and understand all instructions

and warnings in this manual.

Become familiar with the operation and

controls of the air compressor.

Keep operating area clear of all persons,

pets, and obstacles.

Keep children away from the air

compressor at all times.

Do not operate the product when

fatigued or under the influence of

alcohol or drugs. Stay alert at all times.

Never defeat the safety features of this

product.

Equip area of operation with a fire

extinguisher.

DO not operate machine with missing,

broken, or unauthorized parts.

SAVE THESE INSTRUCTIONS

D30091 8* ENG

Page 9

Become familiar with these terms

before operating the unit.

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per

minute; a unit of measure of air

delivery.

PSlG: Pounds per square inch

gauge; a unit of measure of pressure.

Code Certification: Products that

bear one or more of the following

marks: UL, CUL, ETL, CETL, have

been evaluated by OSHA certified

independent safety laboratories and

meet the applicable Underwriters

Laboratories Standards for Safety.

Cut-In Pressure: While the motor is

off, air tank pressure drops as you

continue to use your accessory.

This unit is capable of powering the following Accessories. The accessories are

available through the current Power and Hand Tool Catalog or full-line Sears

stores.

Accessories

• In Line Filter

• Tire Air Chuck

• Quick Connector Sets (various

sizes)

• Air Pressure Regulators

• Oil Fog Lubricators

When the tank pressure drops to a

certain low level the motor will restart

automatically. The low pressure at

which the motor automatically

restarts is called "cut-in" pressure.

Cut-Out Pressure: When an air

compressor is turned on and begins

to run, air pressure in the air tank

begins to build. It builds to a certain

high pressure before the motor

automatically shuts off - protecting

your air tank from pressure higher

than its capacity. The high pressure

at which the motor shuts off is called

"cut-out" pressure.

Branch Circuit: Circuit carrying

electricity from electrical panel to

outlet.

• Air Hose: 1/4", 5/16", or 3/8" OR

1/2" inside diameter in various

lengths

ml_Tujj_[e,_ q=1

This air compressor pump is capable

of running continuously. However, to

prolong the life of your air

compressor, it is recommended that a

50%-75% average duty cycle be

maintained; that is, the air

compressor pump should not run

more than 30-45 minutes in any given

hour.

9- ENG D30091

Page 10

Tools Required for Assembly

1 - 9/16" socket or open end wrench

1 - electric drill

Unpacking

1. Remove allpackaging.

It may be

necessary to brace

or support one side of the air

compressor when removing the

pallet because the air compressor

will have a tendency to tip.

2. Remove and discard the (4)

screws and washers holding the

compressor to the pallet.

3.

With the help of another person

carefully remove air compressor

from pallet and place on a level

surface.

Adding Oil To Pump

Compressors are

shipped without oil.

A small amount of oil may be

present in the pump upon receipt

of the air compressor. This is due

to plant testing and does not mean

the pump contains oil. Do not

attempt to operate this air

compressor without first adding oil

to the crankcase. Serious damage

can result from even limited

operation unless filled with oil and

broken in correctly. Make sure to

closely follow initial start-up

procedures.

I_[_I_ Use air compressor

Viscosity motor oils, like lOW 30,

should not be used in an air

compressor. They leave carbon

deposits on critical components,

thus reducing performance and

compressor life.

oil only. Multi-

NOTE: Use an air compressor oil

such as Sears item number 9-16426

or SAE-20 (API CG/CD) heavy duty

motor oil. Under extreme winter

conditions use SAE-10 weight oil.

To Add Oil

Drain tank to

release air pressure

before removing the oil fill cap or

oil drain plug.

1. Place unit on a level surface.

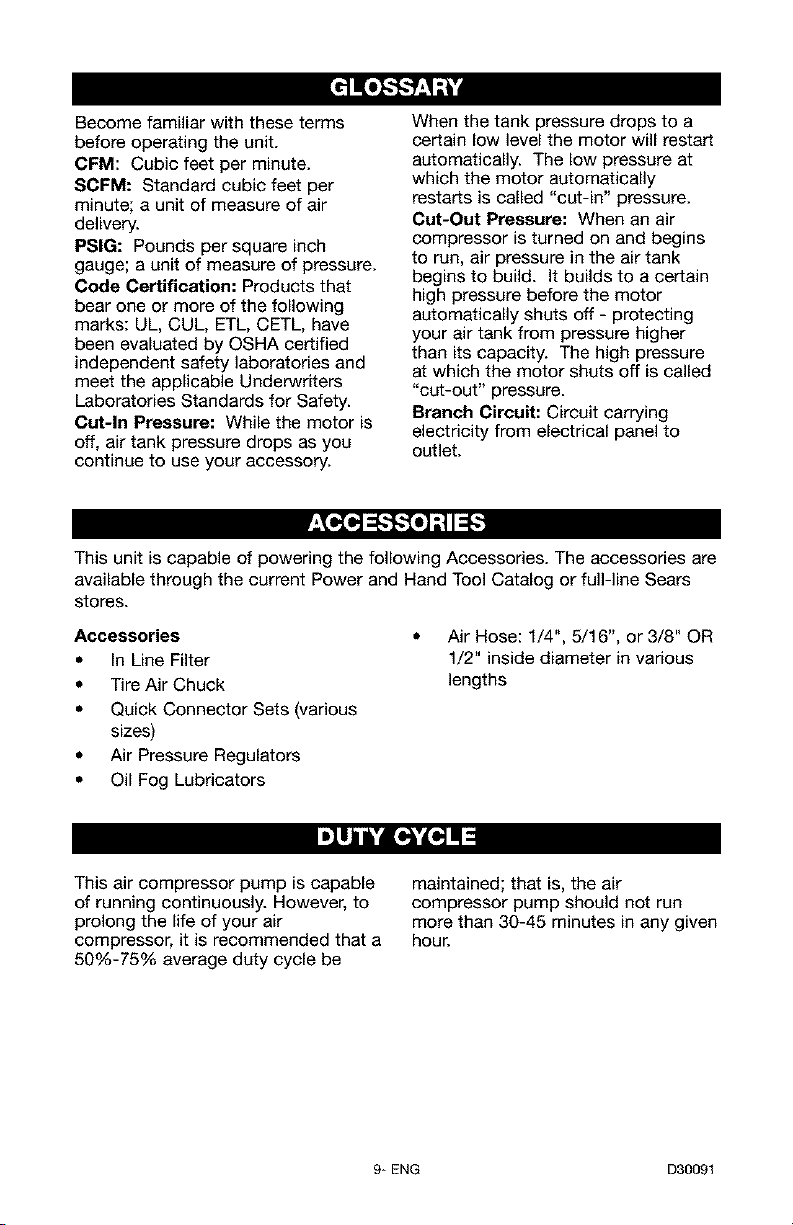

2. Remove oil fill plug (A) and

slowly add compressor oil until it

is even with the top of the oil fill

hole. NOTE: Do not allow oil to

be lower than 3/8" (6 threads)

from the top at any time. When

filling the crankcase, the oil flows

very slowly into the pump. If the

oil is added too quickly, it will

overflow and appear to be full.

NOTE: Crankcase oil capacity is

approximately 16 fluid ounces.

3. Replace oil fill plug.

D30091 10_ ENG

Page 11

HOW TO SET UP YOUR

UNIT

Air Compressor Location

• Locate the air compressor in a

clean, dry, and well ventilated

area.

• Locate the air compressor at

least 12" away from the wall or

other obstructions that will

interfere with the flow of air.

• Locate the air compressor as

close to the main power supply

as possible to avoid using long

lengths of electrical wiring.

NOTE: Long lengths of electrical

wiring could cause power loss to

the motor.

• The air filter must be kept clear

of obstructions which could

reduce air flow to the air

compressor.

Anchoring of the Air

Compressor

_ Excessive vibration

tank and cause an explosion. The

compressor must be properly

mounted,

The air compressor MUST be bolted

to a solid, level surface.

Hardware needed:

4 - Concrete anchors (not

supplied)

4 - 3/8" Lag screw to fit

concrete anchors (not

supplied)

4 - 5/8" Washer (found in parts

bag)

- shims (if needed)

1. Place the air compressor on a

solid, level surface.

2. Mark the surface using the holes

in the air compressor feet as a

template.

can weaken the air

3.

Drill holes in the surface for the

concrete anchors. Install

concrete anchors.

4.

Line up holes in surface with

holes in air compressor feet.

5.

Place the (4) washers (supplied)

between the floor and air

compressor feet. If needed, solid

shims may be placed between

the washers and floor to evenly

distribute weight on all four feet.

See next figure.

3/8" Lag

// I Screw

5/8" Washer ¢/ ,j supplied)

(supplied) [__

_ Surface Line

Shim Under

Washer Co_crete Anchor

(not supplied) (not supplied)

6.

Place the (4) 3/8" lag screws

_ _(not

through the air compressor feet,

washers, shims, and into the

anchors.

7.

Torque 3/8" lag screws to 7-10

ft.-Ibs.

Wiring Instructions

I_-J_-;_ Risk of Electrical

Shock. Improper

electrical grounding can result in

electrical shock. The wiring should

be done by a qualified electrician.

A qualified electrician needs to know

the following before wiring:

1. The amperage rating of the

electrical box should be

adequate. Refer to the

Specification Table, in this

manual, for this information.

11_ ENG D30091

Page 12

2. The supply line should have the

same electrical characteristics

(voltage, cycle, phase) as the

motor. Refer to the motor

nameplate, on side of motor, for

this information.

NOTE: The supply voltage must be

the same as the motor nameplate

voltage plus or minus 10%. Refer to

local codes for correct wire size and

maximum wire run; undersize wire

causes high amp draw and

overheating of the motor.

Risk of Electrical

Shock. Electrical

wiring must be located away from

hot surfaces such as manifold

assembly, compressor outlet tubes,

heads, or cylinders.

GROUNDING INSTRUCTIONS

This product should be connected to

a metallic, permanent wiring system,

or an equipment-grounding terminal

or lead on the product.

Grounding location is clearly

indicated on compressor.

Voltage and Circuit Protection

Refer to the specification chart for the

voltage and minimum branch circuit

requirements.

Risk of Unsafe

Operation. Certain

air compressors can be operated

on a 15 amp circuit if the following

conditions are met.

1. Voltage supply to circuit must

comply with the National

Electrical Code.

2. Circuit is not used to supply any

other electrical needs.

3. Extension cords comply with

specifications.

4. Circuit is equipped with a 15

amp circuit breaker or 15 amp

time delay fuse. NOTE: If

compressor is connected to a

circuit protected by fuses, use

only time delay fuses. Time delay

fuses should be marked "D" in

Canada and "T" in the US.

If any of the above conditions cannot

be met, or if operation of the

compressor repeatedly causes

interruption of the power, it may be

necessary to operate it from a 20

amp circuit. It is not necessary to

change the cord set.

Air Distribution System

Risk of Bursting.

Plastic or PVC pipe

is not designed for use with

compressed air. Regardless of its

indicated pressure rating, plastic

pipe can burst from air pressure.

Usa only metal pipe for air

distribution lines.

The next figure represents a typical

air distribution system. The following

are tips to remember when setting up

the air compressor's air distribution

system.

Use pipe that is the same size as

the air tank outlet. Piping that is

too small will restrict the flow of

air.

• If piping is over 100 feet long,

use the next larger size.

Bury underground lines below

the frost line and avoid pockets

where condensation can gather

and freeze. Fill lines with air

pressure before covering to

make sure pipe joints are free

from leaks.

D30091 12- ENG

Page 13

Install a flexible coupling

between the air discharge outlet

and main air distribution line to

allow for vibration.

A separate regulator is

recommended to control the air

pressure. Air pressure from the

air tank is usually too high for

individual air driven tools.

DRAIN

_'g__

LEG

TYPICAL COMPRESSED

AIR DISTRIBUTION SYSTEM

13_ ENG D30091

o%u%_

AIR D_SCHARGE J

VALVE

DRAIN COCK

VALVE

AiR

COMpReSSOR

Page 14

Know Your Air Compressor

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR UNIT. Compare the illustrations with your unit to familiarize yourself with

the location of various controls and adjustments. Save this manual for future

reference.

Tank Pressure Gauge: The air tank

pressure gauge indicates the reserve

air pressure in the air tank.

Globe Valve: Opens and closes air

discharge valve. Turn knob counter-

clockwise to open and clockwise to

close.

Drain Valve: The drain valve is

located at the base of the air tank

and is used to drain condensation at

the end of each use.

On/Auto/Off Switch: Turn this switch

ON/AUTO to provide automatic

power to the pressure switch and

OFF to remove power at the end of

each use.

Pressure Switch: The pressure

switch automatically starts the motor

when the air tank pressure drops

below the factory set "cut-in"

pressure. The pressure switch stops

the motor when the air tank pressure

reaches the factory set "cut-out"

pressure.

Safety Valve: If the pressure switch

does not shut off the air compressor

at its "cut-out" pressure setting, the

safety valve will protect against high

pressure by "popping out" at its

factory set pressure (slightly higher

than the pressure switch "cut-out"

setting).

D30091 14_ ENG

Cooling System (not shown): This

compressor contains an advanced

design cooling system. At the heart

of this cooling system is an

engineered fan. It is perfectly normal

for this fan to blow air through the

vent holes in large amounts. You

know that the cooling system is

working when air is being expelled.

Air Compressor Pump (net shown):

Compresses air into the air tank.

Working air is not available until the

compressor has raised the air tank

pressure above that required at the

air outlet.

Page 15

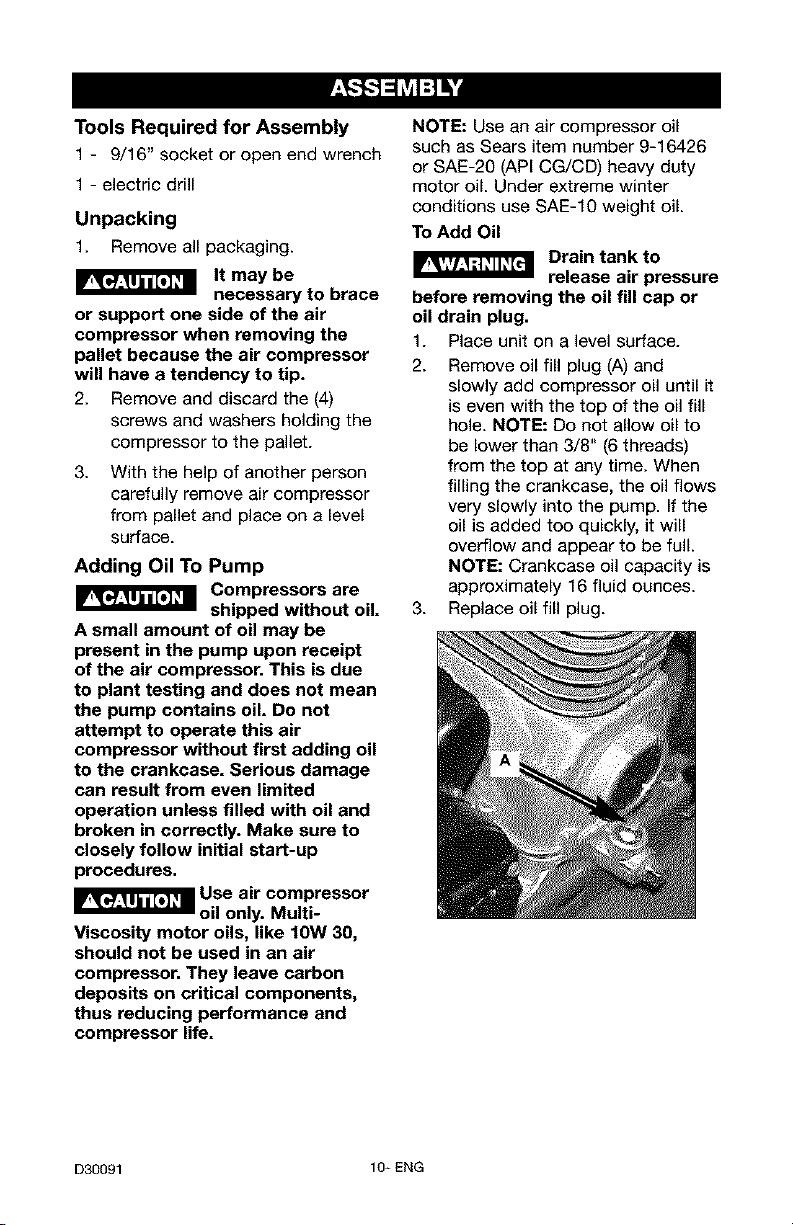

Check Valve: When the air

compressor is operating, the check

valve is "open", allowing compressed

air to enter the air tank. When the air

compressor reaches "cut-out"

pressure, the check valve "closes",

allowing air pressure to remain inside

the air tank.

Pressure Release Valve: The

pressure release valve, located on the

side of the pressure switch, is

designed to automatically release

compressed air from the compressor

head and the outlet tube when the air

compressor reaches "cut-out"

pressure or is shut off. The pressure

release valve allows the motor to

restar_ freely. When the motor stops

running, air will be heard escaping

from this valve for a few seconds.

No air should be heard leaking when

the motor is running or after unit

reaches "cut-out" pressure.

Air Intake Filter (not shown) This

filter is designed to clean air coming

into the pump. This filter must always

be clean and ventilation openings

free from obstructions. See

"Maintenance".

How to Use Your Unit

How to Stop:

1. Set the On/Auto/Off lever to

"OFF".

Before First Start-up

Risk of Unsafe

Operation. Serious

damage may result if the following

break-in instructions are not

closely followed.

This procedure is required before the

air compressor is put into service the

first time and when the check valve

or a complete compressor pump has

been replaced.

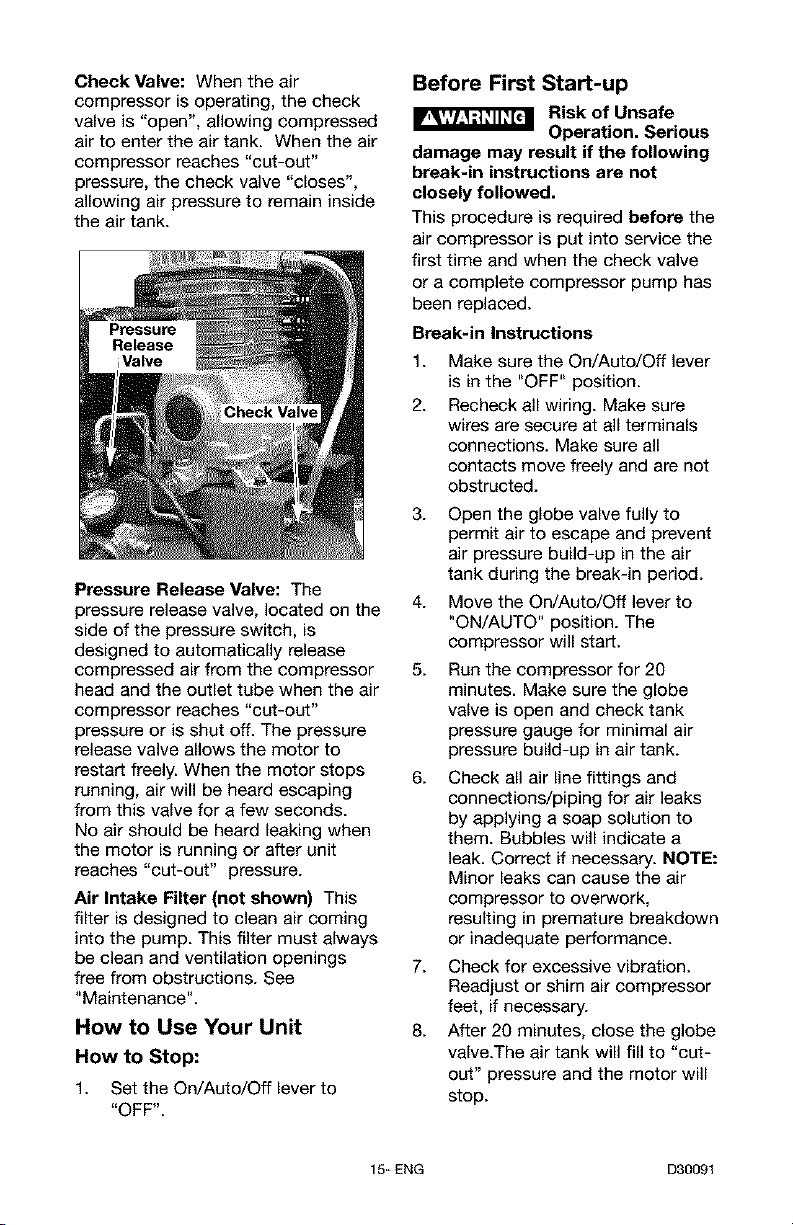

Break-in Instructions

1.

Make sure the On/Auto/Off lever

is in the "OFF" position.

2.

Recheck all wiring. Make sure

wires are secure at all terminals

connections. Make sure all

contacts move freely and are not

obstructed.

3. Open the globe valve fully to

permit air to escape and prevent

air pressure build-up in the air

tank during the break-in period.

4. Move the On/Auto/Off lever to

"ON/AUTO" position. The

compressor will start.

5.

Run the compressor for 20

minutes. Make sure the globe

valve is open and check tank

pressure gauge for minimal air

pressure build-up in air tank.

6.

Check all air line fittings and

connections/piping for air leaks

by applying a soap solution to

them. Bubbles will indicate a

leak. Correct if necessary. NOTE:

Minor leaks can cause the air

compressor to overwork,

resulting in premature breakdown

or inadequate performance.

7. Check for excessive vibration.

Readjust or shim air compressor

feet, if necessary.

8. After 20 minutes, close the globe

valve.The air tank will fill to "cut-

out" pressure and the motor will

stop.

15_ ENG D30091

Page 16

Before Each Start-Up:

f. Place On/Auto/Off lever to

"OFF".

2. Close the globe valve.

3. Attach hose and accessories.

NOTE: A regulator MUST be

installed when using accessories

rated at less than 120 PSI.

Risk of Bursting.

Too much air

pressure causes a hazardous risk

of the air tank bursting, Check the

manufacturer's maximum pressure

rating for air tools and accessories,

The regulator outlet pressure must

never exceed the maximum

pressure rating.

How to Start

1. Turn the On/Auto/Off lever to

"AUTO" and allow air tank

pressure to build. Motor will

stop when air tank pressure

reaches "cut-out" pressure.

2. When the air tank pressure

reaches "cut-out" pressure open

the globe valve.

IMPORTANT: When using regulator

and other accessories refer to the

manufacturer's instructions.

D30091 16_ ENG

Page 17

Customer Responsibilities

Before Dally or Every Every Every Every

each after 8 40 100 160 Yearly

use each hours hours hours hours

use

Check Safety Valve •

Drain Air Tank •

Check 0il •

Change Oil •

Listen for Unusual

Noise and/or •

Vibration

Check Air Filter • (1)

Check Drive Belt •

Condition

Check Motor Pulley/ •

Flywheel alignment

Check Air

compressor pump •

intake and exhaust

valves

Inspect air lines and •

fittings for leaks

1- more frequent in dusty or humid conditions

Risk of Unsafe

Operation. Unit

cycles automatically when power is

on. When servicing, you may be

exposed to voltage sources,

compressed air, or moving parts.

Before servicing unit unplug or

disconnect electrical supply to the

air compressor, bleed tank of

pressure, and allow the air

compressor to cool.

To ensure efficient operation and

longer life of the air compressor air

compressor, a routine maintenance

schedule should be prepared and

followed. The following routine

maintenance schedule is geared to

an air compressor in a normal

working environment operating on a

daily basis. If necessary, the schedule

should be modified to suit the

conditions under which your

compressor is used. The

modifications will depend upon the

hours of operation and the working

environment. Air compressors in an

extremely dirty and/or hostile

environment will require a greater

frequency of all maintenance checks.

NOTE: See "Operation" section for

the location of controls.

17_ ENG D30091

Page 18

To Check Safety Valve

Risk of Bursting.If

the safety valve

does not work properly, over-

pressurization may occur, causing

air tank rupture or explosion and

possible serious injury.

1. Before starting compressor, pull

the ring on the safety valve to

make sure that the safety valve

operates freely. If the valve is

stuck or does not operate

smoothly, it must be replaced

with the same type of valve.

To Drain Air tank

1. Set the On/Auto/Off lever to

"OFF" and disconnect electrical

supply.

2. Close the globe valve.

3. Remove the air tool or

accessory.

4. Open the globe valve and allow

the air to slowly bleed from the

air tank until tank pressure is

approximately 20 psi.

5. Close the globe valve.

6. Drain water from air tank by

opening drain valve (counter-

clockwise) on bottom of air tank.

Ip,,,,i._ ;t=,ii_[d

condense in the air tank. If not

drained, water will corrode and

weaken the air tank causing a risk

of air tank rupture and possible

serious injury.

7. After the water has been drained,

close the drain valve (clockwise).

The air compressor can now be

stored.

Risk of Bursting.

Water will

Oil

I_ Risk of Bursting.

Drain air tank to

release air pressure before removing

the oil fill cap or oil drain plug.

NOTE: Use air compressor oil such

as SAE-20 (API CG/CD) heavy duty

motor oil. Under extreme winter

conditions use SAE-10 weight oil. Oil

capacity is approximately 16 fluid

ounces.

Checking

1. Remove the oil fill plug (A). The

oil level should be even with the

top of the fill hole and no lower

than 6 threads from the top of fill

hole.

2. If needed, slowly add oil until it

reaches the top of fill hole.

Changing

1. Remove the oil fill plug (A).

2. Remove the oil drain plug (B) and

drain oil into a suitable container.

3. Replace the oil drain plug (B) and

tighten securely.

4. Slowly add compressor oil until it

is even with the top of the oil fill

hole. NOTE: When filling the

crankcase, the oil flows very

slowly into the pump. If the oil is

added too quickly, it will overflow

and appear to be full.

5. Replace oil fill plug (A) and

tighten securely.

NOTE: If drain valve is plugged,

release all air pressure. The valve

can then be removed, cleaned, then

reinstalled.

D30091 18_ ENG

Page 19

Air Filter Inspection and

Replacement

Risk of Burns.

Compressor head

and cylinder sleeve are very hot.

Do not touch. Allow compressor to

cool prior to servicing.

A dirty air filter will not allow the

compressor to operate at full

capacity. Keep the air filter clean at

all times.

1. Remove

the air filter

cover.

2. Remove

the air filter

from filter

cover.

IMPORTANT:

Do not operate

the compressor with the air filter

removed.

3. Place new air filter into filter

cover. Refer to the "Repair Parts"

for the correct part number.

4. Replace air filter cover and lock

into place.

Motor Pulley/Flywheel Alignment

NOTE: Once the motor pulley has

been moved from its factory set

location, the grooves of the flywheel

and pulley must be aligned to within

1/16" to prevent excessive belt wear.

The air compressor flywheel and motor

pulley must be in-line (in the same

plane) within 1/16" to assure belt

retention within flywheel belt grooves.

To check alignment, perform the

following steps:

1. Disconnect electrical supply to the

air compressor

2. Remove belt guard.

3. Place a straightedge against the

outside of the flywheel and the

motor drive pulley.

4. Measure the distance between the

edge of the belt and the

straightedge at points A1 and A2

in figure. The difference between

measurements should be no more

than 1/16".

19_ ENG D30091

5.

If the difference is greater or tess

than 1/16" loosen the set screw

holding the motor drive pulley to

the shaft and adjust the pulley's

position on the shaft until the A1

and A2 measurements are within

1/16" of each other.

6. Torque the motor drive pulley set

screw to 70-80 in.-Ibs.

7. Visually inspect the motor drive

pulley to verify that it is

perpendicular to the drive motor

shaft. Points B1 and B2 in figure

above should appear to be

equal. If they are not, loosen the

setscrew of the motor drive

pulley and equalize B1 and B2,

using care not to disturb the belt

alignment performed in step 4.

8. Retighten the motor drive pulley

set screw to 70-80 in.-Ibs.

9. Reinstall belt guard.

Air Compressor Pump Intake

and Exhaust Valves

Once a year have a Trained Service

Technician check the air compressor

pump intake and exhaust valves.

Inspect Air Lines and Fittings

for Leaks

1. Turn the air compressor on to

inspect for air leaks.

2,

Apply a soap solution to all air

line fittings and

connections/piping. Bubbles will

indicate a leak.

3. Correct any leaks found.

IMPORTANT: Even minor leaks can

cause the air compressor to

overwork, resulting in premature

breakdown or inadequate

performance.

Page 20

ALL SERVICE AND REPAIR

OPERATIONS NOT DESCRIBED IN

THIS MANUAL MUST BE

PERFORMED BY A TRAINED

SERVICE TECHNICIAN.

Risk of Unsafe

Operation. Unit

cycles automatically when power is

on. When servicing, you may be

exposed to voltage sources,

compressed air, or moving parts.

Before servicing unit unplug or

disconnect electrical supply to the

air compressor, bleed tank of

pressure, and allow the air

compressor to cool.

To Replace or Clean Check

Valve

1. Release all air pressure from air

tank. See "To Drain Air tank" in

the Maintenance section.

2. Disconnect electrical supply to

the air compressor

3. Using an adjustable wrench,

loosen outlet tube nut at air tank

and pump. Carefully move outlet

tube away from check valve.

4. Using an adjustable wrench,

loosen pressure relief tube nut at

air tank and pressure switch.

Carefully move pressure relief

tube away from check valve.

5. Unscrew the check valve (turn

counterclockwise) using a 7/8 "

open end wrench. Note the

orientation for reassembly.

6. Using a screwdriver, carefully

push the valve disc up and

down. NOTE: The valve disc

should move freely up and down

on a spring which holds it in the

closed position; if valve disc is

not moving freely the check valve

needs to be cleaned or replaced.

open

position

nothing is

visible.

tn closed position

disc is visible.

7. Clean or replace the check valve.

A solvent, such as paint or

varnish remover can be used to

clean the check valve.

8. Apply sealant to the check valve

threads. Reinstall the check valve

(turn clockwise).

9. Replace the pressure release

tube. Tighten nuts.

10. Replace the outlet tube and

tighten nuts.

11. Perform the Break-in Procedure.

See "Break-in Procedure" in the

Operation section.

D30091 20_ ENG

Page 21

Motor

This motor has a manual thermal

overload protector. If the motor

overheats for any reason, the

overload protector will shut off the

motor. The motor must be allowed to

cool down before restarting. To

restart:

1. Place the On/Auto/Off lever in

the Off postion.

2.

Allow the motor to cool.

3.

Depress the red reset button on

the motor.

4.

Place the On/Auto/Off lever in

the On/Auto postion to restart

the motor.

3. Loosen the wing nut on hold

down plate and tilt motor to

allow for easy removal or

installation of the belt.

To Replace Belt

_[_ Risk from Moving

Parts. Serious injury

or damage may occur if parts of

the body or loose items get caught

in moving parts. Never operate the

unit with the belt guard removed.

The belt guard should be removed

only when the compressor is

unplugged.

1. Disconnect electrical supply to

the air compressor

2. Remove the front of the belt

guard by disengaging the snaps.

Insert a flat bladed screwdriver at

each snap location and pry the

beltguard apart.

4. Remove belt.

5. Replace belt. NOTE: The belt

must be centered over the

grooves on the flywheel and

motor pulley.

6. Turn the wing nut on the hold

down plate until it makes contact

with the washer, plus one

additional turn.

7. Replace the belt guard.

21_ ENG D30091

Page 22

Before you store the air compressor,

make sure you do the following:

1. Review the "Maintenance"

section on the preceding pages

and perform scheduled

maintenance as necessary.

2. Set the On/Auto/Off lever to

"OFF" and disconnect electrical

supply.

3. Close the globe valve.

4. Remove the air tool or accessory.

5. Open the globe valve and allow

the air to slowly bleed from the

air tank until tank pressure is

approximately 20 psi.

6. Drain water from air tank by

opening drain valve (counter-

clockwise) on bottom of air tank.

Risk of Bursting.

Water will

condense in the air tank. If not

drained, water will corrode and

weaken the air tank causing a risk

of air tank rupture and possible

serious personal injury.

7. After the water has been drained,

close the drain or drain valve.

NOTE: If drain valve is plugged,

release all air pressure. The valve

can then be removed, cleaned, and

reinstalled.

8. Protect the air hose from

damage (such as being stepped

on or run over).

D30091 22- ENG

Page 23

h| -'Toll:J_oXo_

Risk of Unsafe Operation. Unit cycles automatically when

power is on. When servicing, you may be exposed to

voltage sources, compressed air, or moving parts. Before servicing unit

unplug or disconnect electrical supply to the air compressor, bleed tank

of pressure, and allow the air compressor to cool.

PROBLEM

Excessive tank

pressure -

safety valve

pops off.

Pressure switch does not

shut off motor when

compressor reaches "cut-

out" pressure.

CAUSE CORRECTION

Move On/Auto/Off lever to

the "OFF" position, if the air

compressor does

not shut off contact a Sears

or other Trained Service

Technician.

Pressure switch "cut-out"

too high.

Air leaks at

fittings.

Air leaks at or

inside check

valve

Air leaks at Defective pressure switch Contact a Sears or other

pressure switch release valve. Trained Service Technician.

release valve.

(if equipped)

Air leaks in air Defective air tank.

tank or at air

tank welds.

Air leaks Leaking seal. Contact a Sears or other

between head Trained Service Technician.

and valve plate.

Tube fittings are not tight

enough.

Check if valve seat

damaged.

23_ ENG D30091

Contact a Sears or other

Trained Service Technician.

Tighten fittings where air can

be heard escaping. Check

fittings with soapy water

solution. Bubbles will

indicate a leak. DO NOT

OVERTIGHTEN.

A defective check valve

results in a constant air leak

at the pressure release valve

when there is pressure in the

tank and the compressor is

shut off. Replace check

valve. Refer to "To Replace

or Clean Check Valve" in the

"Service and Adjustments"

section.

Air tank must be replaced.

Do not repair the leak.

Risk of

Do not drill into, weld or

otherwise modify air tank

or it will weaken. The air

tank can rupture or

explode and cause

_ossible serious injury.

Bursting.

Page 24

PROBLEM CAUSE CORRECTION

Air leak from Possible defect in safety Operate safety valve manually

safety valve, valve, by pulling on ring. If valve still

leaks, it should be replaced.

Compressor is

not supplying

enough air to

operate

accessories.

Restricted air

intake

Prolonged excessive use of

air.

Compressor is not large

enough for air requirement.

Hole in hose.

Check valve restricted.

Air leaks.

Restricted air intake filter

Loose belt.

Dirty air filter.

Decrease amount of air usage.

Check the accessory air

requirement. If it is higher than

the SCFM or pressure supplied

by your air compressor, you

need a larger compressor.

Check and replace if required.

Remove and clean, or replace.

Tighten fittings.

Clean or replace air intake

filter. Do not operate the air

compressor with the filter

removed. Refer to the "Air

Filter" paragraph in the

"Maintenance" section.

Loosen wingnut and then

tighten wingnut until it contacts

the washer, plus one turn.

Clean or replace. See Air Filter

paragraph in the Maintenance

section.

Squealing

sound.

Compressor pump has no

oil.

Loose belt.

D30091 24_ ENG

See Oil-Checking paragraph in

the Maintenace section.

Loosen wingnut and then

tighten wingnut untilit

contacts the washe£ plus one

turn.

Page 25

PROBLEM

Motor will not

run.

CAUSE

Motor overload protection

switch has tripped

Tank pressure exceeds

3ressure switch "cut-in"

3ressure.

CORRECTION

Let motor cool off and see

Motor paragraph in the

Service and Adjustment

section.

Motor will start automatically

when tank pressure drops

below "cut-in" pressure of

pressure switch.

2,heck valve stuck open.

Loose electrical

connections.

Possible defective motor

or starting capacitor.

Paint spray on internal

motor parts.

Pressure release valve on

pressure switch has not

unloaded head pressure.

Fuse blown, circuit breaker

tripped.

Remove and clean, or replace.

Check wiring connection

inside pressure switch and

terminal box area.

Have checked by a Sears or

other Trained Service

Technician.

Have checked by a Sears or

other Trained Service

Technician. Do not operate

the compressor in the paint

spray area. See flammable

vapor warning on page 4.

Bleed the line by pushing the

lever on the pressure switch to

the "off" position; if the valve

does not open, replace switch.

1. Check fuse box for blown

fuse and replace as

necessary. Reset circuit

breaker. Do not use a fuse

or circuit breaker with

higher rating than that

specified for your

particular branch circuit.

2. Check for proper fuse. You

should use a time delay

fuse.

3. Check for low voltage

conditions and/or proper

extension cord.

4. Disconnect the other

electrical appliances from

circuit or operate the

compressor on its own

branch circuit.

25_ ENG D30091

Page 26

PROBLEM

CAUSE

CORRECTION

Knocking Noise.

Possible defect in safety

valve.

Defective check valve.

Loose pulley

Loose flywheel

Compressor mounting

screws loose

Loose belt

Carbon build-up in pump

Belt to tight

Operate safety valve manually

by pulling on ring. If valve still

leaks, it should be replaced.

Remove and clean, or replace.

Tighten pulley set screw, see

Repair Parts section for torque

specifications.

Tighten flywheel screw, see

Repair Parts section for torque

specifications.

Tighten mounting screws,see

Repair Parts section for torque

specifications.

Loosen wingnut and then

tighten wingnut until it

contacts the washer, plus one

turn.

Have checked by a Sears or

other Trained Service

Technician.

Loosen wingnut and then

tighten wingnut untilit

contacts the washe£ plus one

turn.

Excessive belt

wear

D30091 26_ ENG

Loose belt.

Tight belt.

Loose pulley.

Pulley misalignment.

Loosen wingnut and then

tighten wingnut untilit

contacts the washe£ plus one

turn.

Loosen wingnut and then

tighten wingnut untilit

contacts the washe£ plus one

turn.

Have checked by a Sears or

other Trained Service

Technician.

See Motor Pulley/Flywheel

Alignment paragraph in the

Maintenace section.

Page 27

27-ENG D30091

Page 28

Air Compressor Model Number 919.184191

Torque

10_15

ft.qbs,

36

Torque 29_

70_80

414

17

s6j

lJ

57j

D30091 28_ ENG

Page 29

Air Compressor Model Number 919.184191

KEY

NO. PART NO. DESCRIPTION

1 Z-D24919 Tank

2 Z-D20659 Motor

3 D21594 Motor Mount Pin

4 D23591 Hold Down Screw

5 CAC-1011 Spring Elastomer

6 SSN-1619-ZN Lock Washer

7 SSN-56-ZN Washer 1" x 11/32 x 1/16

8 SS-2038-ZN Nut Wing 5/16-18

9 Z-D22624 Pump Assembly

10 AC-0330 Solberg Filter 1/2 NPT

11 CAC-327 Bracket

12 SSF-8113-ZN Lock Nut 3/8-16 x 9/16

13 SSP-9401 Connector Body

14 SS-1215 Pipe Plug

15 CAC-323 Beltguard, Inside

16 CAC-322 Beltguard, Outside

17 SSF-986 Screw 10-16 x 7/16 (2 used)

18 AC-0217 Manifold

19 Z-D24918 Pressure Switch

20 SSP-7811 Nut Sleeve Assembly 1/4"

21 SS-2072-1 Nipple .375 NPT x 1.50

22 D21927 Safety Valve

23 GA-360 Gauge 300 PSI

25 SSV-812 Globe Valve 200 PSI

26 SSW-7367 Strain Relief Bushing

27 SUDL-4O2-2 Motor Cord Assembly (Not Shown)

28 D21584 Pressure Relief Tube

29 C-PU-2861 Motor Pulley

30 SS-391 Set Screw

31 SUDL-9-1 Screw (3 used)

32 SSN-613 Washer Belleville

33 D21582 Outlet Tube

34 D28826 Check Valve 1/2 NPT- 1/2"

36 SSF-928 Screw Hex Washer HD (4 used)

37 SSP-7812 Nut Sleeve Assembly 1/2" (2 used)

41 C-BT-223 Belt

51 LA-3266 Label, Warning

53 D23153 Label, Application

56 LA-3105 Label, Craftsman

57 LA-3027 Label, Drain Tank

59 LA-3108 Label, Hot Surface

60 D30083 Label, Performance (Not Shown)

63 D23000 Drain Valve (Not Shown)

29_ ENG D30091

Page 30

Air Compressor Model Number 919.184191

Key No. Torque

4 9-12 ft.-Ibs.

8 25-30 ft.-Ibs.

10 25-30 ft.-Ibs.

25 15-20 ft.-Ibs.

32 13-17 ft.-Ibs.

38 7-10 ft.-Ibs.

25

9

35

_37

21

!7

D30091 30+ ENG

(oil drainm;lug)

Page 31

Air Compressor Model Number 919.184191

KEY

NO. PART NO.

1 Z-AC-02O5

2 265-16-1

3 DAC-276

4 SSF-925

5 265-6

6 AC-0322

7 AC-0333

8 SSF-955

9 SSF-935

10 SSF-6627

11 Z-CAC-4213

12 Z-CAC-291-1

13 Z-CAC-4212-1

14 CAC-207

15 265-19

16 265-410

17 Z-D22270

18 SSP-505

20 SSP-486

21 SSN-1018

22 AC-0169

23 SST-104

24 SSN-1014-ZN

25 SSF-3039-ZN

26 265-2

27 CA0-4285

28 Z-CAC-54-2

• 31 265-25

• 32 SSF-9821

33 CAC-294

• 34 Z-265-196-1

+ 35 Z-CAC-56-1

+ 36 Z-CAC-58

+ 37 Z-CAC-57

38 SSF-927

DESCRIPTION

Crankcase

Base Gasket

Base

Screw 1/4-20 x ,875

Vent Filter

Filter Plate

Felt Filter

Screw

Screw

Shoulder Stud 3/3-16

Assembly Head

Gasket Head

Valve Plate Assembly

Piston Pin Plug (4 used)

Piston Pin (2 used)

Connecting Rod Assembly (2 used)

Crankshaft

Plug

Pipe Plug 3/8 - 18 NPT (2 used)

Washer Wavy Spring

Oil Seal

Ball Bearing (2 used)

Washer .339/.344 ID 1 1/2

Screw 5/16-18X3/4

Flywheel

Piston Ring Assembly (2 used)

Valve Plate Gasket

Intake Flapper Valve (2 used)

Screw THD Forming 5-40 x 1/4 (8 used)

Restrietor Plate (2 used)

Flapper Valve-Corner Bevels (2 used)

Compression Ring (4 used)

Oil Ring (4 used)

Oil Ring Expander (2 used)

Screw 1/4" - 20 x 1-1/8" (2 used)

Kits

+

Not Illeetated

KK-4313

K-0159

KK-4275

Ring Kit

Gasket Kit

Valve Kit

D30091 Owne_ Manual

31_ ENG D30091

Page 32

GARANT|A ........................................... 32

CUADRO DE ESPECIFICACIONES ...................................... 33

DEFINICIONES DE NORMAS DE SEGURIDAD ............................. 33

IMPORTANTES INSTRUCCIONES DE SEGURIDAD ...................... 33-38

GLOSARIO .......................................................... 39

ACCESORIOS ....................................................... 39

CICLO DE SERVICIO .................................................. 39

ENSAMBLADO ....................................................... 40

INSTALACION ..................................................... 41-43

OPERACION ...................................................... 44-46

MANTENIMIENTO ................................................. 47-49

SERVICIOS Y REGULACIONES ...................................... 50-51

ALMACENAJE ....................................................... 52

GU(A DE DIAGNOSTICO DE PROBLEMAS ............................. 53-56

NOTES/NOTAS .................................................... 87-58

CONTRATOS DE PROTECCION PARA REPARACIONES ..................... 59

LISTA DE PARTES ................................................. 28-31

COMO SOLICITAR PIEZAS PARA REPARACION .................... contratapa

GARANT|A TOTAL DE UN AI_IO DEL COMPRESOR DE AIRE

Si este compresor de aire Craftsman fallase debido a defectos de materiales

o de fabricaci6n dentro del aSo de su fecha de compra, Sears, a su opei6n, Io

reparar& o reemplazar& sin eosto alguno. Comuniquese con el Centro de

Servicio Sears m&s cercano (1-800-4-MY-HOME) para coordinar su

reparaci6n, o devuelva el compresor de aire al lugar donde Io compr6 para

que Io cambien.

Si este compresor de aire se usase con fines comerciales o para alquiler, esta

garantia se aplica s61o durante los primeros noventa dias a partir de su fecha

de compra.

Esta garantia le otorga derechos especfficos y usted podrfa tener otros

derechos que varian de un estado a otto.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

D30091 32_ SP

Page 33

Modelo N °

Max. HP desarrollado

Potencia de trabajo

Di&metro interior

Carrera

Voltaje-corriente manofAsica

Circuito mfnimo requerido

Tipo de fusible

Capacidad de sire en el tanque

Presi6n de eorte de entrada

Presi6n de corte de salida

SCFM a 40 psig

919.184191

7,0

3,2 HP

2.875" (73.02mm)

2" (50.8mm)

240V

15A

Accion retardada

60 Galones (227.1 Iitros)

120 psig

150 psig

12.4 Calibre de Iibras

pot pulgada cuadrada

SCFM a 90 psig

10.2 Calibre de Iibras

pot pulgada cuadrada

Refierase al glosario para descifrar las abreviaturas.

SEGURIDAD Y PREVENCION DE PROBLEMAS DEL EQUIPO: Para ayudar al

reconocimiento de esta informaci6n, hemos utilizado los sfmbolos mostrados abajo.

Sirvase leer el manual y prestar atenci6n a dichas secciones.

_ Indicauna situaci6nde

inminente riesgo, la

cual, si no es evitada, causara la muerte

o lesionee series.

_ Indies una situaci6n

potencialmente

peligrosa, la cual, si no es evitada, podria

resultar en lesiones menores o

moderades.

_ Usado sin el sfmbolo

de seguridad de

potencialmente riesgosa, que si no es

evitada, podrfa resultar en la muerte o

lesiones serias,

alerts indica una situacion potencialmente

riesgosa la que, si no es evitada, podria

causar da_os en le propiedad.

IIlv_I_o]:i L't_i t =[--__[l_,[-._l[((o_ ID1_ [._€-!1 ]i1117,.Ii)

_ Algunos tipos de aserr[n cresdos pot m&quinas electricas de Iijado, sserrado,

materiales qu_micos conocidos (en el Estado de California) como causantes de c&ncer, defectos de

nacimiento u otros d_os del aparato reproductivo. A_gunos ejemplos de dichos productos quimicos son:

El plomo contenido en algunas pinturas con base de plomo

Sflice cristalizado proveniente de los ladrillos, el cemento y otros productos de albaSilerfa

Ars6nioo y oromo provenientes del tr_tamiento qufmico dado a la readers

Su r_esgo a dichas exposiciones variar& dependiendo de la frecuencia con la que usted realice

diferentes tipos de trabajo. Pars reducir su exposici6n a la acci6n de dichos agentes quimicos:

trabaje en zonas bien ventiladas+ y h&galo con equipo de seguridad aprobado, use siempre protecci6n

facial o respirader MSHA / NIOSH aprobados cuande deba utilizar dichas herramientas.

AI utilizar herramientas neum&tioas tambi_n deben tomarse precauciones bAsicas de seguridad, a fin

de reducir la posibilidad de riesgo de lesiones personales.

3motsdo, perforado u otras actividades de Is construcci6n, contienen

33- SP D30091

Page 34

GUARDE ESTAS INSTRUCCIONES

La operaciSn o el mantenimiento inadecuados de este producto podrian ocasionar

serias lesiones y dafios a la propiedad. Lea y comprenda todas las advertencias e

instrucciones de funcionamiento antes de utilizar este equipo.

',]=lm[_ ;{_

ADVERTENCIA: Riesgo de Explosi6n o Incendio

qud puede occurrir

Para los contaotos el_ctricos es normal la

existencia de chispas entre el motor y el

intermptor a presi6n.

Si Ias chispas el_=ctricas provenientes d_

compresor tomaran contacto con

emanaciones de materiales inflamables,

ellos podrian arder originando incendio o

explosibn.

Restringir cualquiera de las aberturas de

ventilacibn causar_ un serio recalentamiento

y podrla producir un incendio.

Dejar desatenido este producto mientras el

mismo est& en funcionamiento puede

resultar en lesiones personales o da_os a la

propiedad= Para reducir el riesgo de

incendio, no permita que el oompresor

opere desatendido.

cbmo prevenirlo

Opere siempre el compresor en un sector

bien ventilado y libre de materiales

combustibles, gasolina o emanaciones de

solvente=

En un &tea de rociado de materiales

infiamables, ubique al compresor por Io

menos a 6,1m (20 pies) de distancia del _rea

de rociado. Podrla requerirse una extensi6n de

la manguera.

Almacene los materiales inflamables en una

ubicaci6n segura, alejados del compreson

Jamds coloque objetos apoyados o sobre el

compresor. Opere el compresor en un sector

abierto, por Io menos a 30 cm (12 pulgadas)

alejado de cualquier pared u obstrucci6n que

restrinja el flujo de aim fresco alas aberturas de

ventilaci6n.

Opere el compresor en un sector limpio, seco, y

bien ventilado. NO opere la unidad en espacios

cerrados o cualquier drea confinada.

Mant_ngase siempre alerLa cada vez que el

_roducto este funcionando.

Desconecte siempre el suministro el_ctrico

moviendo la palanca conmutadora de

presi6n a la posici6n de apagado (off), y

drene el tanque diariamente o despu{_s de

cada uso=

D30091 34- SP

Page 35

'J=Ira[_ r,{q

ADVERTENCIA: Riesgo de Explosi6n

Tanque de aire: las siguientes condiciones podrian, causar el debilitamiento del tanque, y

determinar su explosion violenta, daSos a la propiedad o serias lesiones.

qud puede occurrir cbmo prevenido

Drenaje inadecuado del agua condensada Drene el tanque diariamente o despu_s de

en el tanque, siendo la causa del 6xido que cada uso. Si et tanque genera una perdida,

reduce el espesor del tanque de acero, reemplbcelo inmediatamenta con un nuevo

Modificaciones o intento de reparaciones Jam_s perfore, suelde, o efectde modificacibn

al tanque, alguna al tanque o sus accesorios.

Modificaciones no autorizadas a la v_lvula

de descarga, vblvula de seguridad o

cualquier otto componente que controle la

presibn del tanque.

La vibraci6n excesiva puede debilitar el El t_qque est_ dise_ado para resistir presiones

tanque de aire y causar su ruptura o operativas espeolficas. Jambs efectde ajustes

explosibn, o sustituya partes que alteren las

AGREGADOS YACCESORIOS

El exceso a los valores de presibn

establecidos para las herramientas

neun'_ticas, pistolas rociadoras, accesorios

activados pot aire, cubiertas y otros objetos

inflables, puede causar su explosi6n o set

arrojados, pudiendo ocasionar serias lesiones.

tanque o reemplace el compresor completo.

regulaciones de presibn originales de

fbbrica.

Para un control esencial de la presi6n, debe

usted instalar un regulader y un medidor de

presi6n a la salida del aire de su compresor. (Si

no estuviese equipado) Siga las recomendaciones

de los fabricantes de su equipo y jambs exceda

los valores m&ximos de presibn permitidos p_ra

los acc_orios, Jamds use el compresor para

inflar ob'tetcs que requieren poca o baja

presibn, tales como juguetas para los nitros,

pelotas de f(itbol, pelotas de basquet, etc.

'J=l=l[dr,{q

ADVERTENCIA: Riesgo de Objetos Arrojados pot el Aire

qu_ puede occurrir cbmo prevenido

El chorro de aire comprimido puede causar

da_os sobre los tejidos blandos de la piel

expuesta, y puede propulsar suciedad,

astiIlas, partlculas sueltas y pequeSos objetos a

aka velocidad, ocasi0nando da_os a la

propiedad o lesiones personales.

AI utilizar el compresor, use siempre anteojos

de seguridad ANSI Z87.1 aprobados, con

protecci6n lateral.

Jamds apunte ninguna boquilla o

pulverizador hacia parses del cuerpo, a otras

personas o

animales.

Apague siempre el compresor y purgue la

presibn de la manguera del aire y deI tanque,

antes de intentar eI mantenimiento, el acople

de herramientas o accesorios.

35- SP D30091

Page 36

•,,l::1nnl[_1r,{q

ADVERTENCIA: Riesgo de Descatga Eldctrica _/F

qud puede occurrir cbmo prevenirlo

Su compresor de aire estA accionado pc# Jam_s opere el compresor a la intemperie

electricidad, Como cua_quier otto dispositivo cuando est& Iloviendo o en condiciones de

el_ctrico imputsado et6ctricamente, si no se Io humedad,

utiliza adecuadamente, podria causarle una Nunca opere el compresor sin sus defensas o

descarga el_ctrica, sus cubiertas removidas o da_adas.

Las reparaciones intentadas pot personal Cualqu+er conexibn el_ctrica o _eparaci6n

no calificado podrian ocasionar serias requerida pot este producto debe ser

$esiones o la muerte por electrocuci6n, efectuada pot personal autorizado de los

CONEXI(_N A TIERRA: Dejar de proveer una Asegt_rese que el circuito el_ctrico al cual

adecuada cormxibn a tierra a este producto est& conectado el compresor, suministra

pedria ccasionar lesiones serias o la muerte apropiada conexibn a tierra, tensi6n correcta

por electrocuci6n= Vet instrucciones para la y una adecuada protecci6n de fusibles.

puesta a tierra.

servicentros de acuerdo a los c6d+gos

el_ctricos nacionales y locales.

p,.]:4unlIt1:To]

ADVERTENCIA: Riesgo de Inhalaci6n

qud puede occurrir cbmo prevenirlo

E_aire comprimido proveniente del compresor

no es sano para respirar. El chorro de aire

puede contener mon6xido de carbono,

vapores t6xicos o partlculas sblidas

provenie_es del tanque. La inhalaci6n de

dichos contaminantes peede Uegar a causar

serias lesiones o la muerte=

El tociado de materiates tales como pintura,

solventes, removedores de pintura,

insecticidas, mata hierbas, contienen

emanaciones da_inas y venenosas,

D30091 36+ SP

E_aire obtenido directamente del compresor

am_is deberd ser utilizado para proveer aim

_ara consumo humano. Para poder utilizar el

aire producido por este compresor y hacerlo

respirable, deber_in instalarse un filtro

adecuado y un equipe de seguridad

intercalado= Los filtros intercalados tanto como

el equipo de seguridad utilizado en conjunto

con el compresor, deber_n ser capaces de

}rocesar el tratamiento del aire de acuerdo a

todos los cbdigos locales y federales, previo

al consumo humano.

Trabaje en un &rea con buena ventilacibn

cruzada. Lea y siga las instrucciones de

seguridad provistas en el r6tulo o en los datos

de las hojas de seguridad del material que est_

}ulverizando. Use el respirador aprobado

NIOSH/MSHA designado para utilizarse con su

8plicaciSn especffica,

Page 37

_=ll[_r,{w

ADVERTENCIA: Riesgo de Quemaduras

qu_ puede occurrir

Tooar el metal expuesto tal como el cabezsI

del compresor o los tubos de salida del

escape, puede ocasionarle serias

quemaduras.

Jam_is toque partes de metal expuestas en el

compresor durante o inmedistamente despu_s

de la operaci6n, el compresor permanecer_

caliente pot varios minutos luego de la

operaci6n.

No Io cubra con fundas protectoras o intente el

mantenimiento hasta que la unidad haya

alcanzado su enfriamiento.

cbmo prevenirlo

_=ll[_r,{w

ADVERTENCIA: Riesgo de Partes Mbviles

que puede occurrir cbmo prevenirlo

Partes movibles tales come Ia pole& el Nunca opere el compresor sin sus defensas

volante y la correa podrlan ser la causa de o sus cubiertas removidas o da_adas.

serias lesiones si elias entraran en contacto

con usted o sus ropas.

Intentar operar el compresor con sus Cualquier reparaci6n requerida pot este

partes da_adas o faitantes, o la reparacibn producto debe ser efectuada pot personal

del compresor con sus protecciones autorizado de los servicentros.

removidas, puede exponerlo a usted a

partes movibles, que podrlan resultar en

lesiones serias=

ADVERTENCIA: Riesgo de Caida _

qu_ Duede occurrir cbmo orevenirlo

Un compresor port&til puede caerse de la

mesa, el banco de trabs_o o del techo da_ando

al compresor y pudiendo resultar en serias

lesiones o la muerte del operador=

#=ll [_ r,{,,

Opere siempre el compresor en una posici6n

estable y segura a fin de prevenir el

movimiento accidental de la unidad. Jam_s

opere el compresor sobre un techo u otra

posicibn elevada. Utilice mangueras

adicionales de aire para alcanzar posiciones

altas.

37_ SP D30091

Page 38

',1=1! It-1;{_

ADVERTENCIA: Riesgo de Serias Lesiones o Da_os a la Propiedad al

Transportar el Compresor

(Fuego, inhalaci6n, da_o a la superficie de vehiculos)

qud puede occutrit cbmo prevenirlo

El aceite puede derramarse y ello podrfa Deposite el compresor sobre una alfombrilla

resuttar en serias les+ones o la muerte debido protectora cuando Io transporte, a fin de

al riesgo de incendio o inhalaciSn. E_derrame proteger al vehiculo de p_rdides pot goteo,

de aceite daSa atfombras, pinturas u otras Retire el compresor del vehiculo

superf+cies de vehiculos o remotques, inmediatamente despu_s de su arribo al

ADVERTENCIA: Riesgo de Operaci6n Lasegura A

qud puede occurrir cbmo prevenirlo

La operation insegura de su compresor de

aire podrla ocasionarle serias lesiones o la

muerte a usted u otros.

destino.

Revise y comprenda todas las instrucciones y

advertencias contenidas en este manual.

Familiar_cese con los m_todos de operacibn

y control del compresor de aire.

Mantenga libre la zona de eperaciones de

persona 8Jguna+ animates dom_sticos y

obst&culos.

ianter_ga aEejados a los ni_os de{ compresor

de aire en todo memento.

No opere el producto cuando se encuentre

fatigado o bajo la influencia del alcohol o

drogas. Est_ alerta en todo memento.

Jam_is altere los elementos de seguridad de

este producto.

Equipe la zona de operaciones con un

extinguidor de fuego.

No opere la mdquina si _sta tiene parses

faltantes, rotas o no autorizadas.

CONSERVAR ESTAS INSTRUCCIONES

D30091 38 + SP

Page 39

Familiadcese con los siguiantes t_rminos,

antes de operar la unidad:

OFM: (Cubic feet per minute) Pies cQbicos

por minuto.

SCFM: (Stardard cubic feet per minute)

Pies ct_bicos est&ndar pot minuto; una

unidad de medida que permite medir la

cantidad de entrega de aire.

PSIG: (Pound per square inch) Libras por

pulgada cuadrada.

Obdigo de eertificaoi6n: Los productos

que usan ana o m&s de las siguientes

marcas: UL, CUL, ETL, CETL, hen sido

evaluados por OSHA, laboratorios

independientes certificados en seguridad,

y reunen los est&ndares suscriptos per los

laboratorios dedicados ala certificaci6n

de la seguridad.

Esta unidad ss suficiente para ebastecer de energie electdca ales siguientss acceserios. Estos se

encuentran dispenibles a traves del cat&logo pare herrernientas electrices y manuales, en

cualquiera de los comercios que mantiene la linea complete de SEARS.

Accesorios

• Filtro en linea

• Entrada de aire a neum&ticos

• Juegos de conectores r&pidos (varios

tama_os)

• Reguladores de presion de aire

• Lubricadores de niebla de aceite

Presibn minima de corte: Cuando el

motor est& apagado, la presi6n del tanque

de aire baja a medida que usted contint_a

usando su accesorio Cuando la presi6n

del tanque baja al valor fijado an f&brica

como punto bajo, el motor volver& a

arrancar autom&ticamante. La presion

baja a la cual el motor arranca

autom&ticamente, se llama presion

"minima de corte".

Presi6n m_xima de corte: Cuando un

compresor de aire se enciende y

comienza a funcionar, la presi6n de aire

en el tanque comianza a anmentar.

Aumanta haste un valor de presi6n alto

fijado en f&brica antes de que el motor

autom&ticamente se apague protegiando

a su tanque de aire de presiones m&s

altas que su capacidad. La presi6n atta a

la cual el motor seapaga se llama presi6n

"m&xima de "corte".

Ramal: Circuito electrico que transporta

electricidad desde el panel de control

haste el tomacorriente.

• Manguera de aire:

1/4", 5/16",3/8" o 1/2" D.L en varias

medidas

[o,][_o31 m]=1_o,] [o]

Esta bomba compresora de aire es capaz

de faneionar continuamante, sin embargo

para prolongar la vida t_til de su

compresor de aire se recomienda

mantener un ciclo promedio de servicio

que oscile entre el 50% y el 75%; ello

significa que la bomba compresora no

deberia trabajar m_s de 30 a 45 minutos

pot hora.

39* SP D30091

Page 40

Herramientas requeridas para el

Ensamblado

1 - Uave de tubo 9/16" o llave mec&nica

de boca abierta

1 - Taladro electrico

Desembalaje

I. Extraiga todo el embalaje

Podrd ser

o soportar un lado del equipo al extraer

la plataforma, porque el compresor de

aire tendera a inclinarse.

2. Extraiga y descarte los (4) tomillos y

arandelas qua sujetan el compresor a

la plataforma.

3,

Con la ayuda de otra persona,

remueva cuidadosamente el

compresor de aire de su plataforma y

colSquelo sobre una plataforma

nivelada.

Para agregar aceite a la bomba

aceite. AI tecibir el compresor de aire,

puede haber un poco de aceite en la

bomba. Esto se debe a las pruebas en

la fabrica y no significa que la bomba

tiene aceite. No intentar operar este

compresor de aire sin antes haberle

agregado aceite al carter. Pueden

ocurrir serios dafios, inclusive con

opetaciones limitadas, si no se Ilena de

aceite y no se asienta correctamente.

Cercioratse de seguir cuidadosamente

los procedimientos pata el arranque

iniciaL

necesado apuntalar

Los compresores

se envian sin

No se deben usar

aceites de

viscosidad mdltiple como 10W30 en

ningAn compresor de aire. Estos

aceites dejan depbsitos de catbono en

componentes criticos, reduciendo el

rendimiento y la vida Atil del compresor.

NOTA: Use aceite para compresor tipo

Sears, item 9-16426 6 SAE-20 (API CG/CD)

de servicio pesado para motor. Para

condiciones extremas invemales use aceite

pesado SAE-10.

Aceite

Drene el tanque

fin de liberar la

presibn de aire antes de extraer la tapa

para el relleno de aceite, o el tapbn

para drenaje del aceite.

1. Colocar la unidad en una superficie

nivelada.

2,

Extraiga el tap6n de aceite (A) y

agregue lentamente aceite para

compresor hasta qua quede a ras del

borde de[ orificio de Ilenado de

aceite. NOTA: No permita qua el

nivel de aceite Ilegue en ningQn

momento a 3/8" (6 filetes) del borde.

AI Ilenar el carter, el aceite fluye muy

lentamente. Si sele agrega aceite

muy rapido, el carter se rebalsara y

aparentara estar lieno.

NOT_ La capacidad del carter es de

16 onzas liquidas (473ml) de aceite.

3. Colocar la tapa de Ilenado de aceite.

D30091 40- SP

Page 41

COMO PREPARAR LA UNIDAD

Ubicacibn del comp_sor de aire

Instale el compresor de aire en una

zona limpia, seca y bien ventilada.

Instale el compresor de aire a una

distancia no menor de 30 cm (12")

de la pared u otras obstrucciones

que pudiesen interferir con el flujo

del aire.

Instale el compresor de aire Io m_s

cerca posible del sitio de

alimentaciSn electrica, a fin de evitar

el uso de largas extensiones de

cableado electrico. NOTA: Lss

extensiones electricas demasiado

largas pueden causar una cafda de

tension perjudicial para la

alimentaciSn del motor.

El filtro de aire debe mantenerse libre

de obstrucciones que pudiesen

reducir el flujo del aire al compresor.

4,

Haga coincidir la alineacion de los

orificios de la superficie, con el de Ins

patas del compresor de aire.

5.

Coloque las (4) arandelas

(suministradas) entre el piso y las

patas del compresor. Si fuese

necesario, pueden colocarse cu£_as

solidas entre Ins arandelas y el piso

a fin de distribuir en forma pareja el

peso sobre Ins

cuatro paras. Vea la figura siguiente.

Tornillo

Arandela de tirafondo de

5/8" 3/8" (no

suministrado

Linea de superficie

la atandela (no

suministrada)

Tarugos pars anclaje

en cemento no

sum n strados

Anclaje del compresor de aire

La vibracibn

excesiva puede