Craftsman 919.174410 User Manual

ISears]

OWNERS

MANUAL

MODEL NOS.

919.174212

919.174311

919.174320

919.174410

AiR

COMPRESSOR

iMPORTANT:

Read the Safety

Guidelines Before

Operating

DESCRIPTION

ASSEMBLY

OPERATION

MAINTENANCE

REPAIR PARTS

Record in the spaces provided

below the model number, code

number and manufacturers hum=

bet of this air compressor. The

model number can be found on

the label on the front of the air

tank. The code number can be

found on the for label on the rear

of the air tank. The manufacturers

number (ASIVlE Code outfits only)

is located on the metal data plate

on the backside of the air tank.

Model No.

Code No.

Mfgs. No.

Motor Mfg. Name

Motor Mfg. No.

Retain these numbers for future

references.

SI-30-14-2-A

Sears, Roebuck and Co., Chicago, IL 60684 U.S.A.

% % %

2!85

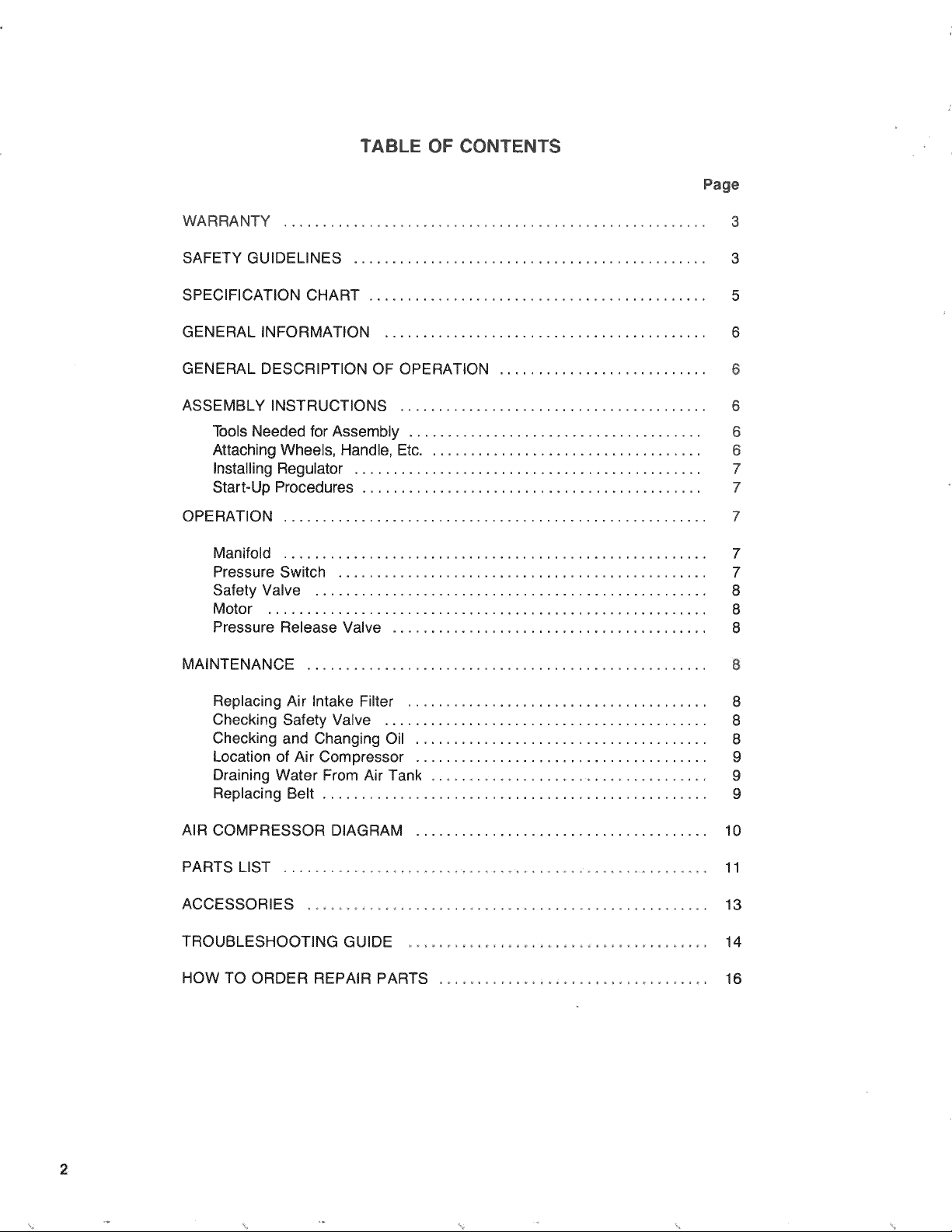

TABLE OF CONTENTS

WARRANTY ....................................................... 3

SAFETY GUIDELINES .............................................. 3

SPECIFICATION CHART ............................................ 5

GENERAL INFORMATION .......................................... 6

GENERAL DESCRIPTION OF OPERATION ........................... 6

ASSEMBLY INSTRUCTIONS ........................................ 6

Tools Needed for Assembly ...................................... 6

Attaching Wheels, Handle, Etc.................................... 6

installing Regulator ............................................. 7

Start-Up Procedures ............................................ 7

OPERATION ....................................................... 7

Manifold ....................................................... 7

Pressure Switch ................................................ 7

Safety Valve ................................................... 8

Motor ......................................................... 8

Pressure Release Valve ......................................... 8

MAINTENANCE .................................................... 8

Replacing Air Intake Filter ....................................... 8

Checking Safety Valve .......................................... 8

Checking and Changing Oil ...................................... 8

Location of Air Compressor ...................................... 9

Draining Water From Air Tank ................................... 9

Replacing Belt .................................................. 9

AIR COMPRESSOR DIAGRAM ...................................... 10

PARTS LIST 11

ACCESSORIES ................................................... 13

TROUBLESHOOTING GUIDE ............................................... 14

HOW TO ORDER REPAIR PARTS ........................................ 16

FULL ONE YEAR WARRANTY

AIR COMPRESSOR

if this compressor fails due to a defect in material or workmanship within one year from the

date of purchase, return it to the nearest Sears Service Center/Department throughout the

United States and Sears will repair it, free of charge.

if this air compressor is used for commercial or rental purposes, the warranty will apply for

ninety days from date of purchase.

This warranty gives you specific legal rights and you may also have other rights which vary

from state to state.

Sears, Roebuck and Co., Sears Tower, Dept. 698/731A, Chicago, IL 60684

SAFETY GUIDELINES

This manual contains information that is important for you to know and understand.

This information relates to YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS.

To help you recognize this information, we use the following symbols. Please read the manual and

pay attention to those sections.

iMPORTANT iNFORMATiON FOR PRE-

VENTmNG mNJURY OR LOSS OF LIFE.

information for preventing damage to

equipment.

Note

information that you should pay special atten-

tion to.

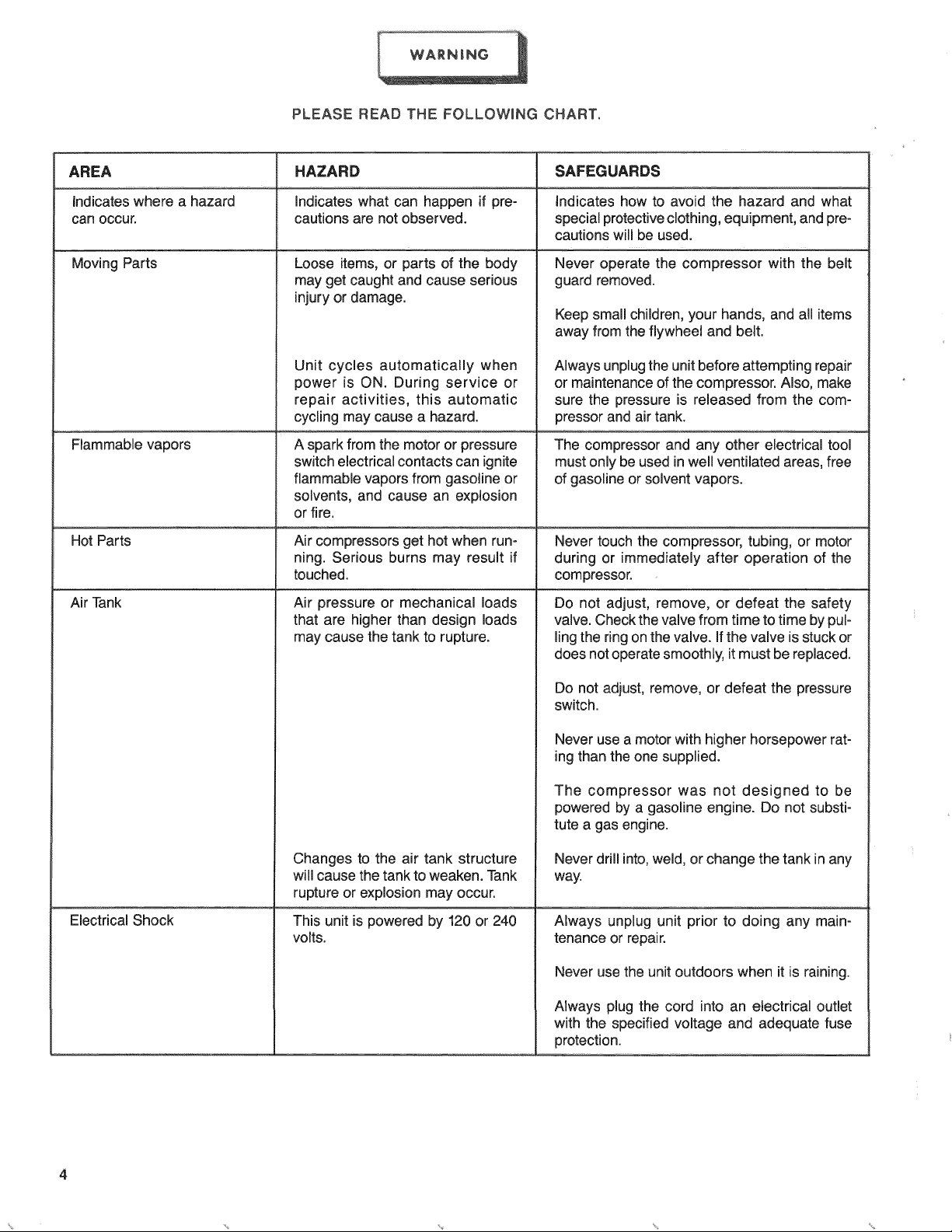

PLEASE READ THE FOLLOWmNG CHART.

AREA

indicateswhere a hazard

can occur.

Moving Parts

Flammable vapors

Hot Parts

Air Tank

HAZARD

Indicateswhat can happen if pre-

cautions are not observed.

Loose items,or parts of the body

may get caught and cause serious

injuryor damage.

Unit cycles automatically when

power is ON. During service or

repair activities, this automatic

cycling may cause a hazard.

A spark from the motor or pressure

switch electrical contacts can ignite

flammable vapors from gasoline or

solvents, and cause an explosion

or fire.

Air compressors get hot when run-

ning. Serious burns may resuk if

touched.

Air pressure or mechanical loads

that are higher than design loads

may cause the tank to rupture.

SAFEGUARDS

indicates how to avoid the hazard and what

special protectiveclothing, equipment, and pre-

cautions will be used.

Never operate the compressor with the belt

guard removed.

Keep small children, your hands, and all items

away from the flywheel and belt.

Always unplugthe unit before attempting repair

or maintenance of the compressor. Also, make

sure the pressure is released from the com-

pressor and air tank.

The compressor and any other electrical tool

must only be used in well ventilated areas, free

of gasoline or solvent vapors.

Never touch the compressor, tubing, or motor

during or immediately after operation of the

compressor.

Do not adjust, remove, or defeat the safety

valve. Check the valve from time to time by pul-

ling the ring on the valve. If the valve is stuck or

does not operate smoothly, it must be replaced.

Electrical Shock

Do not adjust, remove, or defeat the pressure

switch.

Never use a motor with higher horsepower rat-

ing than the one supplied.

The compressor was not designed to be

powered by a gasoline engine. Do not substi-

tute a gas engine.

Changes to the air tank structure

will cause the tank to weaken. Tank

Never drill into, weld, or change the tank in any

way.

rupture or explosion may occur.

This unit is powered by 120 or 240 Always unplug unit prior to doing any main-

volts, tenance or repair.

Never use the unit outdoors when it is raining.

Always plug the cord into an electrical outlet

with the specified voltage and adequate fuse

protection.

4

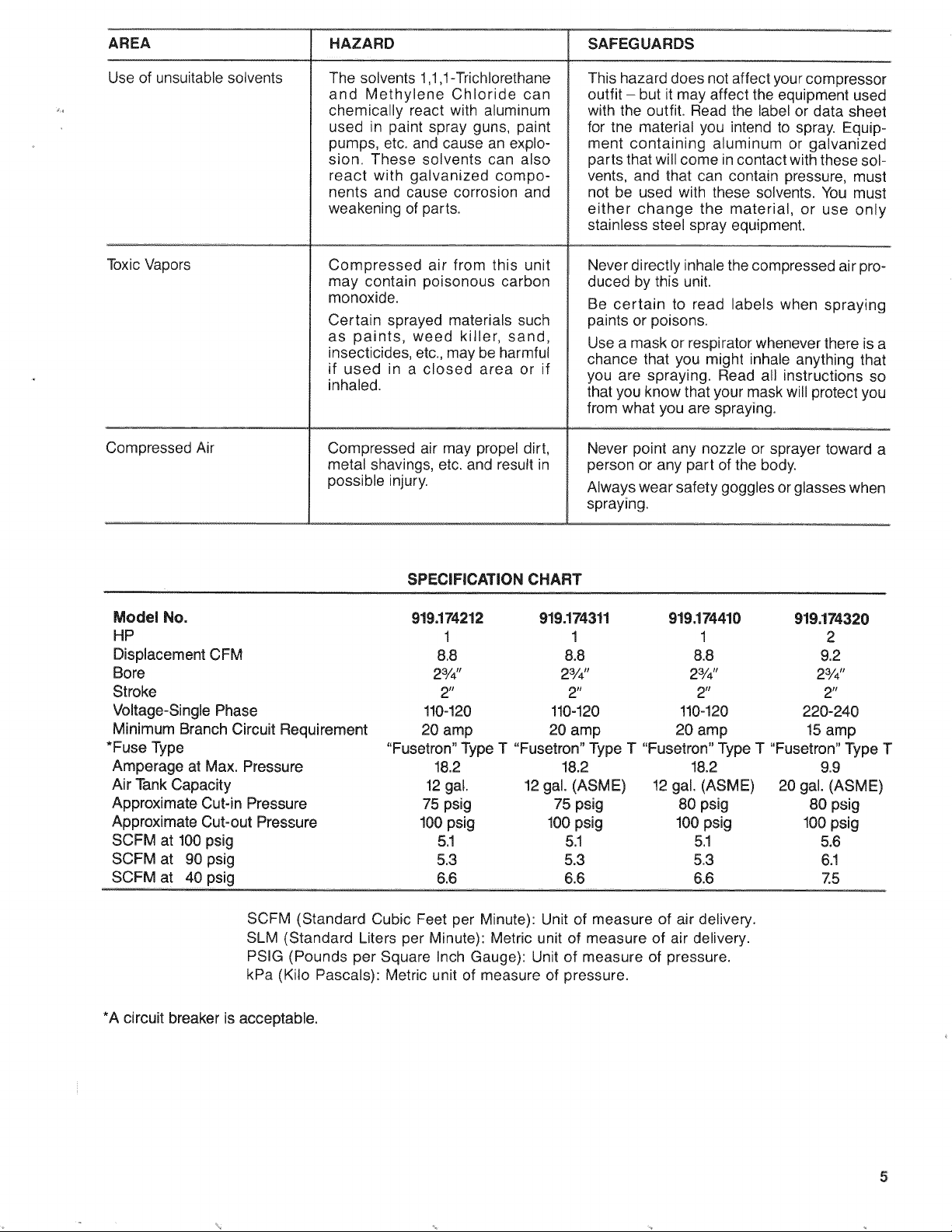

AREA HAZARD SAFEGUARDS

Use of unsuitable solvents

Toxic Vapors

Compressed Air

The solvents 1,1,1-Trichlorethane

and Methylene Chloride can

chemically react with aluminum

used in paint spray guns, paint

pumps, etc. and cause an explo-

sion. These solvents can also

react with galvanized compo-

nents and cause corrosion and

weakening of parts.

Compressed air from this unit

may contain poisonous carbon

monoxide.

Certain sprayed materials such

as paints, weed killer, sand,

insecticides, etc., may be harmful

if used in a closed area or if

inhaled.

Compressed air may propel dirt,

metal shavings, etc. and result in

possible injury.

This hazard does not affect your compressor

outfit - but it may affect the equipment used

with the outfit. Read the label or data sheet

for the material you intend to spray. Equip-

ment containing aluminum or galvanized

parts that will come in contact with these sol-

vents, and that can contain pressure, must

not be used with these solvents. You must

either change the material, or use only

stainless steel spray equipment.

Never directly inhale the compressed air pro-

duced by this unit.

Be certain to read labels when spraying

paints or poisons.

Use a mask or respirator whenever there is a

chance that you might inhale anything that

you are spraying. Read all instructions so

that you know that your mask will protect you

from what you are spraying.

Never point any nozzle or sprayer toward a

person or any part of the body.

Always wear safety goggles orglasses when

spraying.

SPECIFICATION CHART

Model No. 919.174212 919.174311 919.174410 919.174320

HP 1 1 1 2

Displacement CFM 8.8 8.8 8.8 9.2

Bore 23/4" 23/4" 23/4'' 23/4''

Stroke 2" 2" 2" 2"

Voltage-Single Phase 1!0-120 110-120 !10-120 220-240

Minimum Branch Circuit Requirement 20 amp 20 amp 20 amp 15 amp

*Fuse Type "Fusetron" Type T "Fusetron" Type T "Fusetron" Type T "Fusetron" Type T

Amperage at Max. Pressure 18.2 18.2 18.2 9.9

Air Tank Capacity 12 gal. 12 gal. (ASME) !2 gal. (ASME) 20 gal. (ASME)

Approximate Cut-in Pressure 75 psig 75 psig 80 psig 80 psig

Approximate Cut-out Pressure 100psig 100 psig 100 psig 100 psig

SCFM at 100 psig 5.1 5.1 5.1 5.6

SCFM at 90 psig 5.3 5.3 5.3 6.1

SCFM at 40 psig 6.6 6.6 6.6 Z5

SCFM (Standard Cubic Feet per Minute): Unit of measure of air delivery.

SLM (Standard Liters per Minute): Metric unit of measure of air delivery.

PSIG (Pounds per Square Inch Gauge): Unit of measure of pressure.

kPa (Kilo Pascals): Metric unit of measure of pressure.

*A circuit breaker is acceptable.

5

Loading...

Loading...