Craftsman 917O251550 User Manual

®

MODEL NUMBER 917o251550

oAssembly

oOperation

Customer Responsibilities

• Service and Adjustments

oRepair Parts

OWNER'S MANUAL

CAUTION: Read and follow all safety rules and instructions before operating this equipment.

SAFETY RULES

_it Safe Operation Practices for Ride-On Mowers &

IMPORTANT: THIS CUTTING MACHINE tS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING OBJECTS.

FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT iN SERIOUS INJURY OR DEATH.

I. GENERAL OPERATION

• Read, understand,and follow all instructionsinthe manual

and on the machine before starting_

• Only allow responsible adults, who are familiar with the

instructions,to operate the machine.

• Clear the area of objects such as rocks, toys, wire, etc.,

which could be picked up and thrown by the blade°

• Besure the areais clearof otherpeople before mowing_ Stop

machine if anyone enters the area.

• Never carry passengers.

• Do not mow in reverse unless absolutely necessary° Always

look down and behind before and while backing.

• Be aware of the mower discharge direction and do not point

itat anyone. Do not operate the mower without eitherthe

entire grass catcher or the guard in ptace.

• Slow down before turning.

• Never leave a running machine unattended. Always turnoff

blades, set parking brake, stop engine, and remove keys

before dismounting_

• Turn off blades when not mowing

,, Stop engine before removing grass catcher or unclogging

chute.

• Mow only in daylight or good artificial light.

• Do not operate the machine while under the influence of

alcohol or drugs..

• Watch for trafficwhen operating near or crossing roadways.

• Use extra care when loading or unloading the machine into

a trailer or truck.

I1, SLOPE OPERATION

Slopes are a major factor related to toss-of-control and

tipover accidents, which can result in severe injury or death_

All slopes require extra caution. If you cannot back up the

slope or if you feel uneasy on it, do not mow it.

DO:

° Mow up and down slopes, not across

• Remove obstacles such as rocks, tree limbs,etc..

,, Watch for holes, ruts, or bumps. Uneven terrain could

overturn the machine. Tall grass can hide obstacies

• Use slow speed.. Choose a low gear so thatyou will not have

to stop orshift while on the slope.

• Follow the manufacturer's recommendations for wheel

weights or counterweights to improve stability.

• Use extra care with grass catchers or other attachment&

These can change the stability of the machine.

• Keep all movement on the slopes slow and gradual Do not

make sudden changes in speed or direction°

• Avoid starting or stopping on a slope, if tires lose traction,

disengage the blades and proceed slowly straight down the

slope..

DO NOT:

• Do not turnon slopes unless necessary, and then,turnslowly

and gradually downhill, if possible.

• Do not mow near drop-offs, ditches, or embankments. The

mower could suddenly turnover if a wheel is over the edge

of a cliffor ditch, or if an edge caves in.

• Do not mow on wet grass. Reduced traction could cause

sliding.

• Do not trytostabilize the machine byputting your foot on the

ground

• Do not use grass catcher on steep slopes..

!11. CHILDREN

Tragic accidents can occur ifthe operator is not alert to the

presence of children, Children are often attracted to the

machine and the mowing activity. Never assume that

children will remain where you last saw them.

• Keepchildrenoutofthemowing area and under the watchful

care of another responsible adult.

• Be alert and turn machine off ifchildren enter the area

• Before and when backing, look behind and downfor small

children.

• Never carry children. They may fall off and be seriously

injured or interfere with safe machine operation.

• Never allow childrento operate the machine_

- Use extra care when approaching blind corners, shrubs,

trees, orotherobjectsthat may obscure vision.

IV.

SERVICE

Use extracare in handling gasolineand other fuels They are

flammable and vapors are explosive.

Use only an approvedcontainer.

Never remove gas cap or add fuel with the engine

running. Allow engine tocool before refueling Do not

smoke,

Never refuel the machine indoors

Never storethe machine or fuel container inside where

there is an open flame, such as a water heater.

o

Never run a machine insidea closed area.

Keep nuts and bolts, especially blade attachment bolts, tight

and keep equipment in good condition.

Never tamper with safety devices Check their proper

operation regularty_

Keep machine free of grass, leaves, or'other' debris build-up_

Clean oil or fuel spillage Allow machine to cool before

storing

e

Stop and inspect the equipment if you strike an object,

Repair, if necessary, before restarting,

Never make adjustments or repairs with the engine running,

Grass catcher components are subject towear, damage, and

deterioration, which could expose moving parts or aJlow

objecls to be thrown. Frequently check components and

replace with manufacturer's recommended pads. when nec-

essary_

Mower bfades are sharp and can cut, Wrap the blade(s) or

wear' gloves, and use extra caution when servicing them.

Check brake operation frequently, Adjust and service as

required

,IUI,I,H,HU,I,lllIHII/Jlll I I J I

portant safety precautions. It means

Look for this symbol to point out im-

CAUTION!!! BECOME ALERT!!! YOUR

SAFETY' IS INVOLVED.

iii ll/uli lll

,Jllllll,uuui/iull/i iii ii ,i i llll i i

CAUTION: Always disconnect spark plug

wire and place wire where it can notcontact

spark plug in order' to prevent accidental

starting when setting up, transporting,

adjusting or making repairs.

IHIJ"IIW"U II

"l'he engine exhaust from this product con-

tains cliemicals known to the State of Califor-

nia to cause cancer, birth defects, or other

repr°ductive harm. .......

2

& WARNING & I

CONGRATULATIONS on your purchase of a Sears

Tractor,, It has been designed, engineered and manufac-

tured to give you the best possible dependability and

performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Authorized

Service CentedDepartmenL We have competent, weIF

trained technicians and the proper tools toservice or repair

this tractor+.

Please read and retain this manual The instructions will

enable you to assemble and maintain your unit properly.

Always observe the "SAFETY RULES".

MODEL

NUMBER

917+251550

SERIAL

NUMBER

DATE OFPURCHASE

THE MODELAN DSERIAL NUMBERS WILLBEFOUND

ON A PLATE UNDER THE SEAT.

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE,

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this prod-

uct. Contact your nearest Sears store for details.

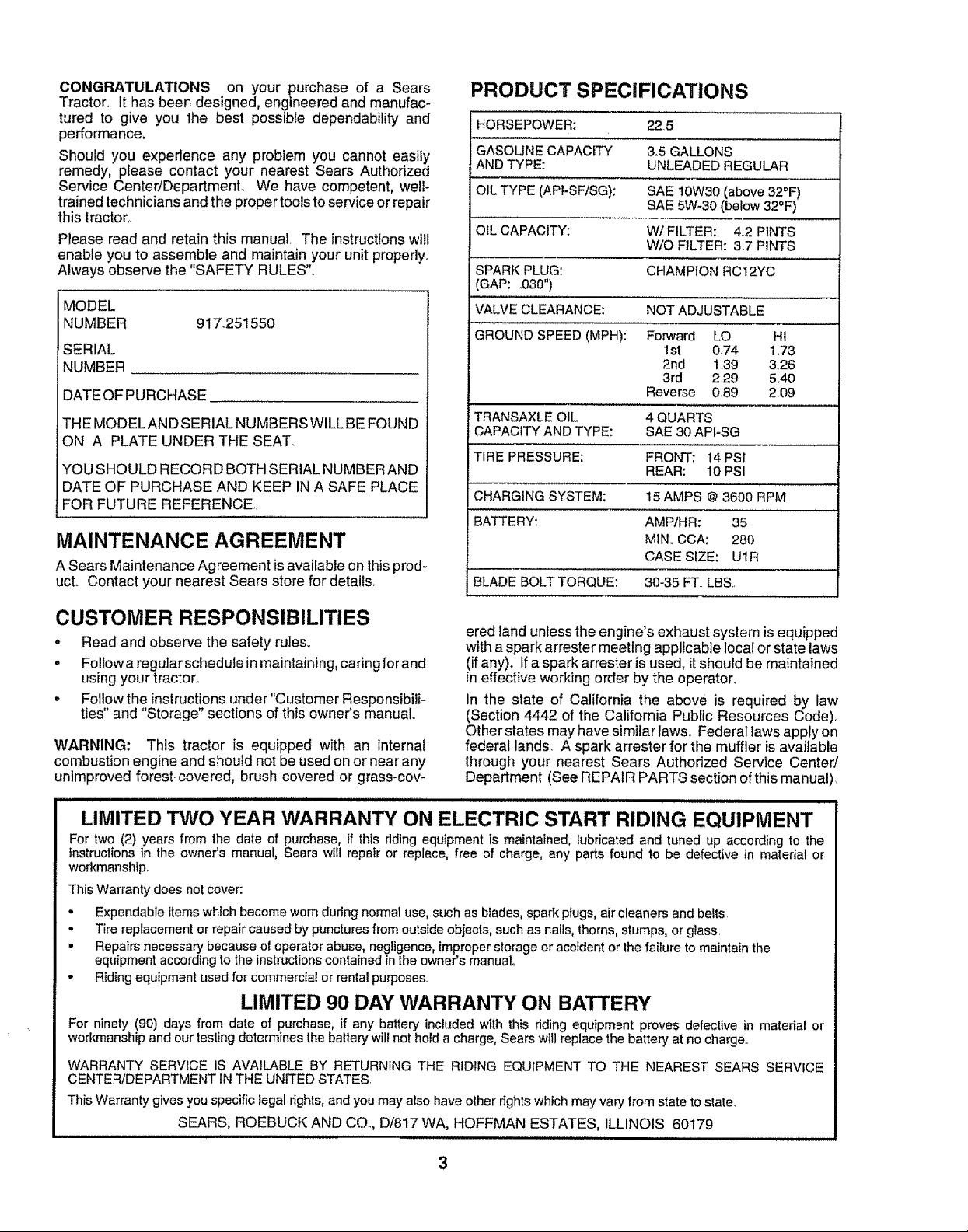

PRODUCT SPECIFICATIONS

HORSEPOWER: 225

GASOLINE CAPACITY 3+5GALLONS

AND TYPE: UNLEADED REGULAR

OIL TYPE (API-SF!SG): SAE 10W30 (above 32°F)

SAE 5W-30 (below 32°F)

OIL CAPACITY: W/FILTER: 4.2 PINTS

W!O FILTER: 3.7 PINTS

SPARK PLUG: CHAMPION RC12YC

(GAP: +030")

VALVE CLEARANCE: NOT ADJUSTABLE

GROUND SPEED (MPH):' Forward LO HI

1st 0.74 1_73

2nd 1.39 3..26

3rd 229 5.,40

Reverse 0.89 2.09

TRANSAXLE OIL 4 QUARTS

CAPACtTY AND TYPE: SAE 30 API+SG

TIRE PRESSURE: FRONT: 14 PSI

REAR: 10PSI

CHARGING SYSTEM: 15 AMPS @ 3600 RPM

BATTERY: AMP]HR: 35

MIN_.CCA: 280

CASE SIZE: U1R

BLADE BOLT TORQUE: 30-35 FT.+LBS+

CUSTOMER RESPONSIBILITIES

o Read and observe the safety rules..

, Fo!low a regular schedule in maintaining, caring for and

using your tractor.

• Follow the instructions under"Customer Responsibili-

ties and Storage sections of this owner s manual.

WARNING: This tractor is equipped with an internal

combustion engine and should not be used on or near any

unimproved forest-covered, brush-covered or grass-coy-

,IIH lUUJJJJJJIIJJlIIIIIIIIIIIIIIIII IIII ' IJJJJIJLIIIIIIIIIII IIIIIII

ered landunless the engine's exhaust system is equipped

with a spark arrester meeting applicable local or state laws

(if any),, If a spark arrestor is used, itshould be maintained

in effective working order by the operator.

In the state of California the above is required by law

(Section 4442 of the California Public Resources Code)+

Other states mayhave similar laws+ Federal laws apply on

federal lands. A spark arrester for the muffler is available

through your nearest Sears Authorized Service Center/

Department (See REPAIR PARTS section of this manual),

LIMITED TWO YEAR WARRANTY ON ELECTRIC START RIDING EQUIPMENT

For two (2) years from the date of purchase, if this dding equipment is maintained, lubricated and tuned up according to the

instructionsin the owner's manual, Sears will repair or replace, free of charge, any parts found to be defective in material or

workmanship.

This Warranty does not cover:

• Expendable itemswhich become wornduring normal use, such as btades, spark plugs, air cleaners and bells

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or glass.

• Repairs necessary because of operator abuse, negligence, improper storage or accident or the failure to maintain the

equipment according to the instructionscontained in the owner's manual

• Riding equipment used for commercial or rental purposes_

LIMITED 90 DAY WARRANTY ON BATTERY

For ninety (90) days from date of purchase, if any battery included with this riding equipment proves defective in material or

workmanship and our testingdetermines the battery will not hold a charge, Sears will replace the battery at no charge+

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE RIDING EQUIPMENT TO THE NEAREST SEARS SERVICE

CENTER/DEPARTMENT IN THE UNITED STATES,

This Warranty gives you specific legal rights, and you may also have other rights whichmay vary Irom state to state.

SEARS, ROEBUCK AND CO+, D/817 WA, HOFFMAN ESTATES, ILLINOIS 60179

3

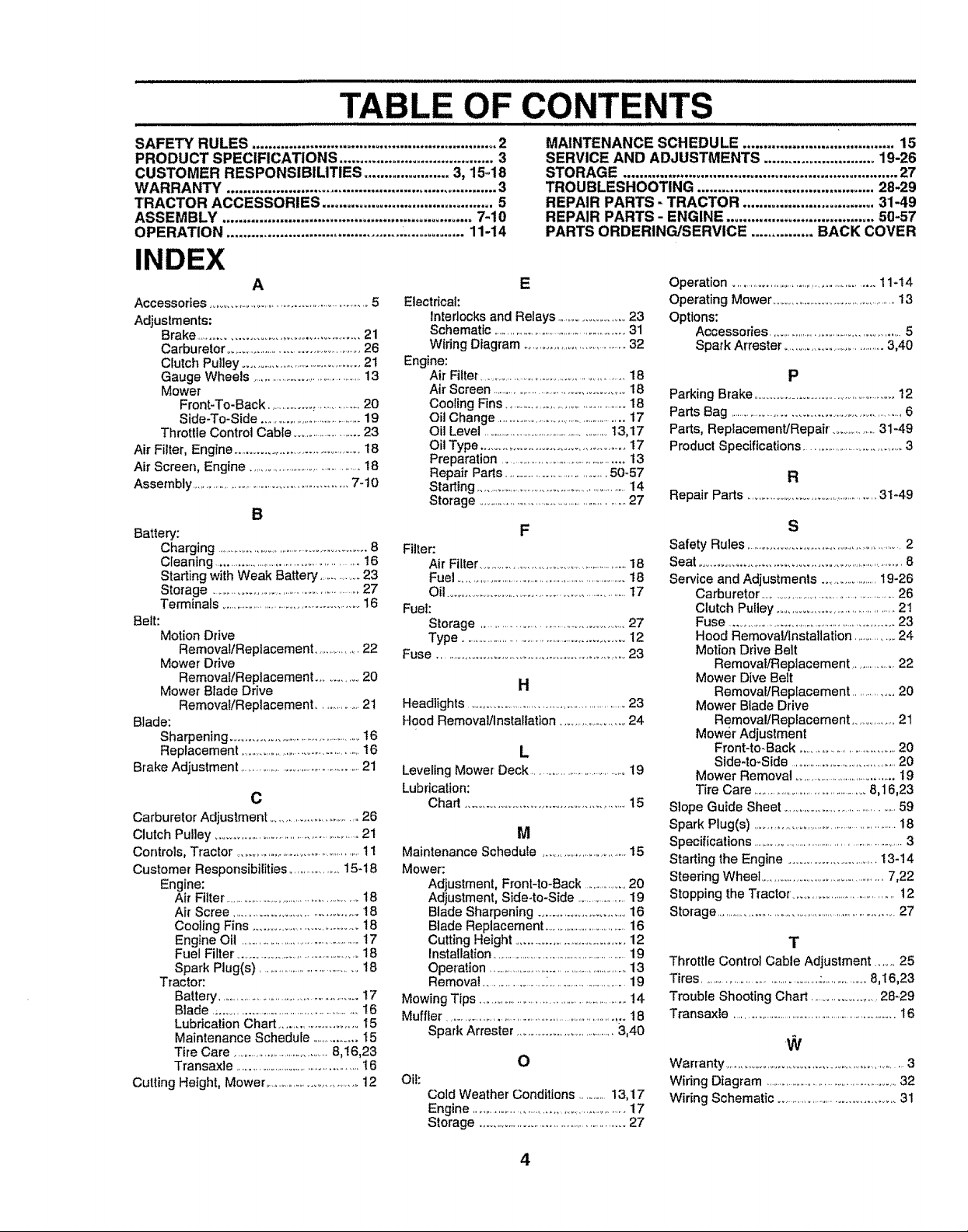

SAFETY RULES ............................................................ 2

PRODUCT SPECIFICATIONS ...................................... 3

CUSTOMER RESPONSIBILITIES ..................... 3, 1548

WARRANTY .................................................................. 3

TRACTOR ACCESSORIES .......................................... 5

ASSEMBLY ............................................................. 7-10

OPERATION .......................................... ................ 11-14

INDEX

A

Accessories ...........................................................5

Adjustments:

Brake ....................................................21

Carburetor .................................................26

Clutch Putiey ........................................21

Gauge Wheels .......................................13

Mower

Front-To-Back ................,,...............20

Side-To-Side .........................................19

Throttle Control Cable ..........................23

Air Filter, Engine...........................................18

Air Screen, Engine ...........................................18

Assembly ......................................................7-10

B

Battery:

Charging ....................................................8

Cleaninc ................................................16

Starting with Weak Battery ...............23

Storage .................................................27

Terminals ..................................................16

Belt:

Motion Drive

Removal/Replacement ...............22

Mower' Drive

Removal/Replacement ........... 20

Mower' Blade Drive

Removal/Replacement ..............2t

Blade:

Sharpening ...........................................16

Replacement ............................................16

Brake Adjustment ................................................21

C

Carburetor Adjustment ............................26

Clutch Pulley ...................................................21

Controls, Tractor .................................................11

Customer Responsibilities...................15-! 8

Engine:

Air Filter ...................................................18

A# Scree ........................................18

Cooling Fins ................................18

Engine Oil .................................................17

Fuel Filter .......................................18

Spark Plug(s) ......................................18

Tractor:

Battery ................................................17

Blade ....................................................16

Lubrication Chart ....................... 15

Maintenance Schedule ..................I5

Tire Care .....................................8,16,23

Transaxle ..................................................16

Cutting Height, Mower ..................................12

Electrical:

Interlocksand Relays ......................23

Schematic .......................................................31

Wiring Diagram .....................................32

Engine:

Air Filter.........................................................18

Air Screen ................................................18

Cooling Fins ............................................18

Oil Change ...................................................17

Oil Level ....................................................t3,17

Oil Type ...........................................17

Preparation ...............................................13

Repair Parts ......................................50-57

Starting .........................................................14

Storage .....................................................27

Filter:

Air Filter ..........................................................18

Fuel.................................................................18

Oil ................................................................17

Fuel:

Storage ..............................................27

Type ..........................................................12

Fuse ........................................................23

Headlights .........................................................23

Hood Removal/Installation ......................24

Leveling Mower Deck ...................................19

Lubrication:

Chart .............................................. 15

Maintenance Schedule .................................15

Mower:

Adjustment, Front-to-Back ..................20

Adjustment, Side-to-Side ....................19

Blade Sharpening ...........................16

Blade Replacement ....................................16

Cutting Height ............................... 12

Installation....................................................19

Operation ............................................................13

Removal ......................i..............................19

Mowing Tips .....................................................14

Muffler ..................................................................18

Spark Arrester .....................................3,40

Oi!:

Cold Weather Conditions ............13,17

Engine .........................................................17

Storage ...................................................27

MAINTENANCE SCHEDULE ..................................... 15

SERVICE AND ADJUSTMENTS ........................... 19-26

STORAGE ................................................................... 27

TROUBLESHOOTING ........................................... 28-29

REPAIR PARTS - TRACTOR ................................ 31-49

REPAIR PARTS - ENGINE .................................... 50-57

PARTS ORDERING/SERVICE ............... BACK COVER

E

Operation .....................................................11-14

Operating Mower ..........................................13

Options:

Accessories ..................................................5

Spark Ar-rester _.....................................3,40

P

Parking Brake .........................................12

PartsBag .........................................................6

Parts, Replacement/Repair. .............31-49

Product Specifications ...................................3

R

Repair Parts ..................................................31-49

F

Safety Rules ..................................................2

Seat .................................................................8

Service and Adjustments ...................19-26

Carburetor .....................................................26

Clutch Pulley ......................................21

Fuse ............................................................. 23

Hood Removal/Installation................24

Motion Drive Belt

Removal/Replacement ...................22

H

L

M

Mower Dive Belt

Removal/Rep[acement ..............20

Mower' Blade Drive

Removal/Replacement ...............21

Mower Adjustment

Front-to.Back ...............................20

Side-to-Side ......................................20

Mower Removal ......................................19

Tire Care ................................................ 8,16,23

Slope Guide Sheet ........................................59

Spark Plug(s) .................................................18

Specifications .............................................................3

Starting the Engine ......................... 13-14

Steedng Wheel .........................................7,22

Stopping the Tractor'. ...............................12

Storage .................................................................27

S

T

Throttle Control Cable Adjustment ...... 25

Tires...............................................:..................8,t6,23

TroubEeShooting Chart ......................28-29

Transaxie .....................................................................16

O

Warranty ..............................................................3

Wiring Diagram ........................................................32

Wiring Schematic .....................................31

4

ACCESSORmES

AND ATTACHIVIENTS

These accessories and attachmentswere available throughmost Sears retailoutiets and service centers when the tractor was purchased.

Most Sears stores can order these itemsfor you when you provide the model number of your tractor,

ENGINE

SPARK PLUG

GAS CAN ENGINE OIL

FUEL STABILIZER

AtR FILTER

MAINTENANCE

BLADES ] BELTS t1

PERFORMANCE

Sears offersa wide variety of attachments that fit your tractor.. Many of theseare listedbelow with bdef explanations of how they can help

you° This list was current at the time of publication; however, it may change in future years - more attachments may be added changes

may be made in these attachments, or some may no longer be available or fit your model Contact your nearest Sears store for the

accessories and attachments that are available for your tractor.

Most of these attachments do not require additional hitches or conversion kits (those that do are indicated) and are designed for easy

attaching and detaching,

AERATOR promotes deep root growth for a healthy lawn. Tapered

25-inch steel spikes mounted on 10-inch diameter discs puncture

holestnsotlatcloseintervalstoletmoisturesoakin Steelweight tray

for increased penetration

BUMPER protects front end of tractor from damage.

CARTS make hauling easy Variety of sizes available, ptus accesso-

ries such as side panel kits, tool caddy, cart cover, protective mat and

dolly,

CORING AERATOR takes small plugs out of soil to allow moisture

andnutrienlstoreachgrassroots 36-inahswath, 24 hardened steel

coring tips, 150 Ib,, capacity weight tray,

DISC HARROW has 2 gangs of 4 steel blades that angle from 10 to

20 degrees, 40 inches wide Can hook 2 units in tandem, (Requires

sleeve hitch.)

DOZER BLADE removes snow; grades dirt, sand and gravel, 48

inches wide, 17 inches high, clears 44qnch path when angled. Master

lift control lever for operator ease. Spring tdp for snow removal on

uneven pavement; built-in float for blade to follow ground contour.

Reversible, replaceable scraper bar, (Use with tire chains and wheel

weights and/or rear drawbar weight,)

EASY OIL DRAIN VALVE makes oil changes easier, taster,

FRONT NOSE ROLLER canters in front of mower deck to reduce

chances of "scalping" on uneven terrain.

GANG HITCH Iets you tow 2 or 3 pull-behind attachments at

once, such as sweepers, dethatchers, aerators (not for use with

rollers, carts or other heavy' attachments)

MULCH RAKE/DETHATCHER loosens soil and flips thatch and

matted leaves to lawn surface for easy pickup. Twenty spring tine

teeth, Usefulto prepare bare areas forseeding, Avai]ablefor front or

rear mounting. HIGH PERFORMANCE REEL-ACTION SPRING

TINE DETHATCHER covers 36-inch wide path and tosses thatch into

large hopper, Mounts behind tractor,

PLOW turns soil 6 inches deep, cuts 10-inch furrow, Crank adjust-

ment controls depth, 3-position yoke sets width. Heavy steel iandside

for straight furrowing, (Requires sleeve hitch )

RAMP TOPS AND FEET let you load and unload tractor from a

pickup truck, Use wilh 2 x 8 or 2 x 10 lumber°

REAR GRADER BLADEfs 42 inches wide and operated from drwer's

seat. Reversible steel blade can be angled at 30 degrees forgrading.

Reverses forpushing snow backwards (Requires sleeve hitch, )

ROLLER for smoother lawn surface, 36-inch wide, 18-inch diameter

water-tight drum holds up to 390 lbs, of weight. Rounded edges

prevent harm to turf, Adiustabte scraper automaticalfy cleans drum

SLEEVE CULTIVATOR is 43 inches wide. Prepares ground for

seeding, helps weed control Steel frame holds 5 adjustable sweeps.

Adjusts vertically, horizontally, (Requires sleeve hitch.) Opttonat

accessory: steel furrow opener for wider openings for potatoes,

corn, and other deep.seeded crops,

SLEEVE HITCH for use with master lift system,, Singie pin couples/

uncouples,

SNOWTHROWER has 42-inch swath., Drum-type auger handles

powdery and wellheavy snow, Mounts easilywith simple pin arrange-

ment. Discharge chute adjusts from tractor seat, 6-inch diameter

spout discharges snow 10 to 50 feet., Lift controlled at tractor seat,,

(Use with chains and wheel weights and/or rear drawbar weight,)

SPRAYERS use 12-volt DC electric motor that connects to the tractor

baltery or other 12-volt source, Includes booms for automatic

spraying and hand heldwand for spot spraying, Wand has adjustable

spray pattern For applying herbicides, insecticides, fungicides and

liquid fertilizers,

SPREADERISEEDERS make seeding, fertilizing, and weed killing

easy, Broadcast spreaders are also useful for granular de-icers and

sand.,

SWEEPERS let you collect grass clippings and leaves,,

TILLER has 8hp engine to prepare seed beds, cultivate, and compost

garden residue. Chain-ddve transmission. Six 11-inch diameter one

piece heat4reated steel tines. Tills 30-inch path° (Requires sleeve

hitch.) Or use 5 hp tow-behind TILLER with 36-inch swath to prepare

seed beds, cultivate and compost garden residue, Tiller has its own

built-in lift and depth control system and does NOT require a sleeve

hitch° Fits any lawn, yard or garden tractor. Simply hook up to the

tractor drawbar and go! Optional accessories for 5 hp tiller convert

unit for dethatching, aerating, hilling..,without tools.

TIRE CHAINS are heavy duty; closely spaced extra-large cross links

give smooth fide, oulstanding traction°

TRACTOR CAB has heavy duty vinyl fabric over tubular steel frame,

ABS plastic top; clear plastic windshield offers 360 degree visibility

Hinged metal doors with catch. Keeps operator warm and dry.

Remove vinyl sides and windshields for use as sun protector in

summer. Optional accessories include: tintedltempered solid

safety glass windshield with hand operated wiper;, 12-volt amber

caution light for mounting on cab top,

VACS for powerful collection of heavy grass clippings and leaves

Optional wand attachment to pick up debris in hard-to-reach places,

VAC/CHIPPER includes a chipper-shredder,

WEIGHT BRACKET for drawbar for snow removal applications,, Can

be mounted on front of tractor for plowing applications, Uses (1) 55

Ib weight

WHEEL WEIGHTS for rear wheels provide needed traction for snow

removal or dozing heavy materials,

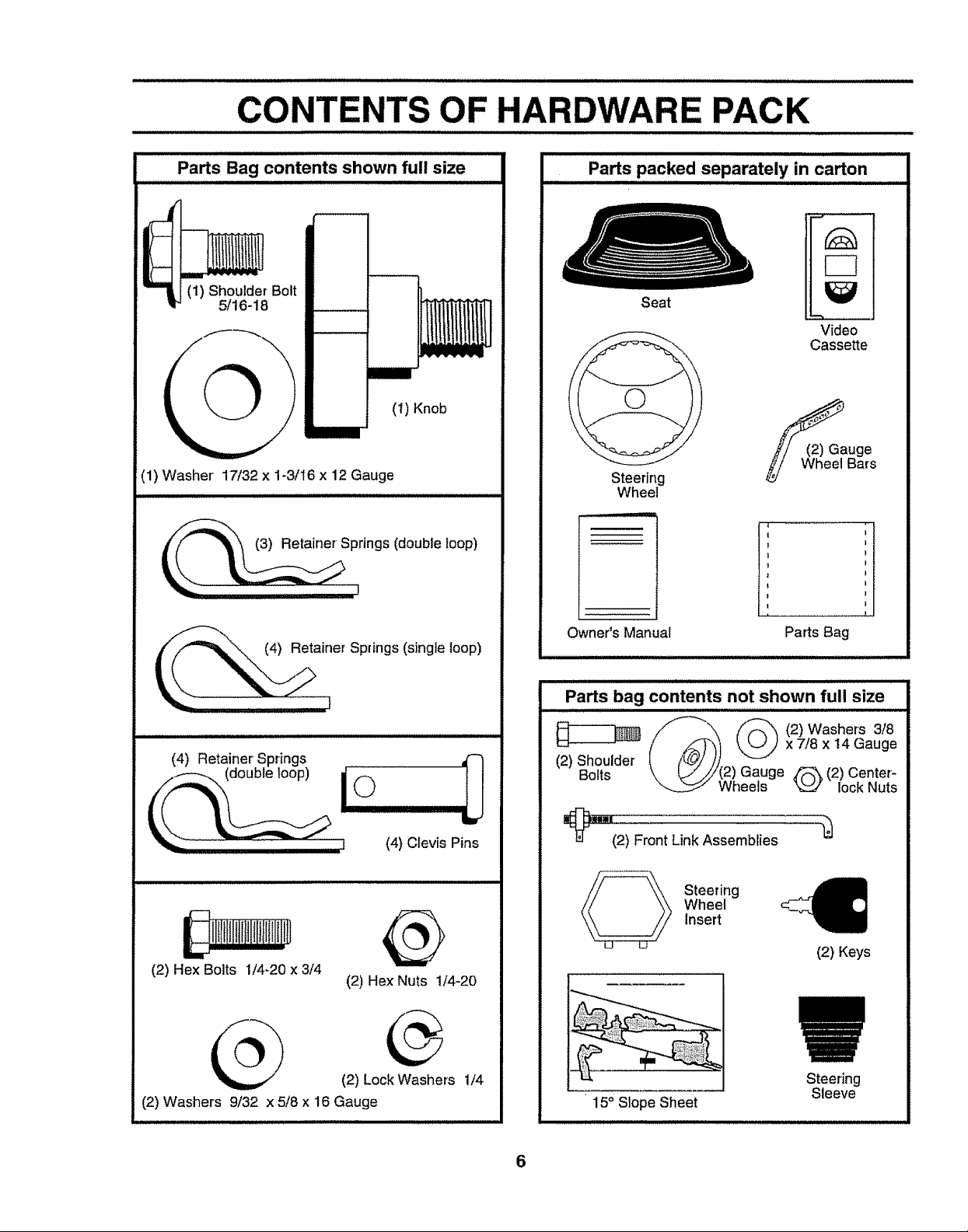

CONTENTS OF HARDWARE PACK

,,,,,, ,,, ,,,,,,,,,,,,,llllllllll i ill

Parts Bag contents shown full size

(1) Shoulder Bolt

5/16-18

__ 1

(1) Washer 17/32 x 1-3/16 x 12 Gauge

SPlrings (double loop)

_,. (4) Retainer Springs (single loop)

(t) Knob

: llllllll

Parts packed separately in carton

Seat

Steering

Wheel

H

Owner's Manual

Parts Bag

Video

Cassette

auge

Bars

l

(2) Hex Bolts 1/4-20 x 3/4

__ (2) Lock Washers 1/4

(2) Washers 9/32 x 5/8 x 16 Gauge

(2) Hex Nuts 1/4-20

(4) Clevis Pins

@

Parts bag contents not shown full size

/_, _ (2)Washers 3/8

(2) Shoulder (/_) k___x7/Sx14Gauge

Bolts \ I_J//(2) Gauge _ (2) Center-

_"="(2) Fr0nl

15° Slope Sheet

Wheels _ lock Nuts

Link Assemblies

Steering

Wheel

Insert

(2) Keys

Steering

Sleeve

6

ASSEMBLY

i,llll illJl ui N,I i

Your newtractorhasbeenassembtedatthefactorywith the exceptionofthosepartsleftunassembledforshippingpurposes°

To ensure safeand proper operationofyourtractorall partsand hardwareyouassemble must be tightened securely. Use

thecorrect toolsas necessary to insurepropertightness_

TOOLS REQUIRED FOR ASSEMBLY

A socket wrenchset willmakeassembly easier° Standard

wrench sizes are listed.

(2) 7/16" wrenches Tire pressure gauge

(1) I/2" wrench Utility knife

(1) 9/16" wrench

(1) 3/4" socket with drive ratchet

When right or left hand is mentioned in this manual, it

means when you are in the operating position (seated

behind the steering wheel).

TO REMOVE TRACTOR FROM CARTON

UNPACKCARTON

° Remove all accessible loose parts and parts cartons

from carton (See page 6).

• Cut, from top to bottom, along lines on all four corners

of carton, and lay panels flat.

BEFORE ROLLING TRACTOR OFFSKID

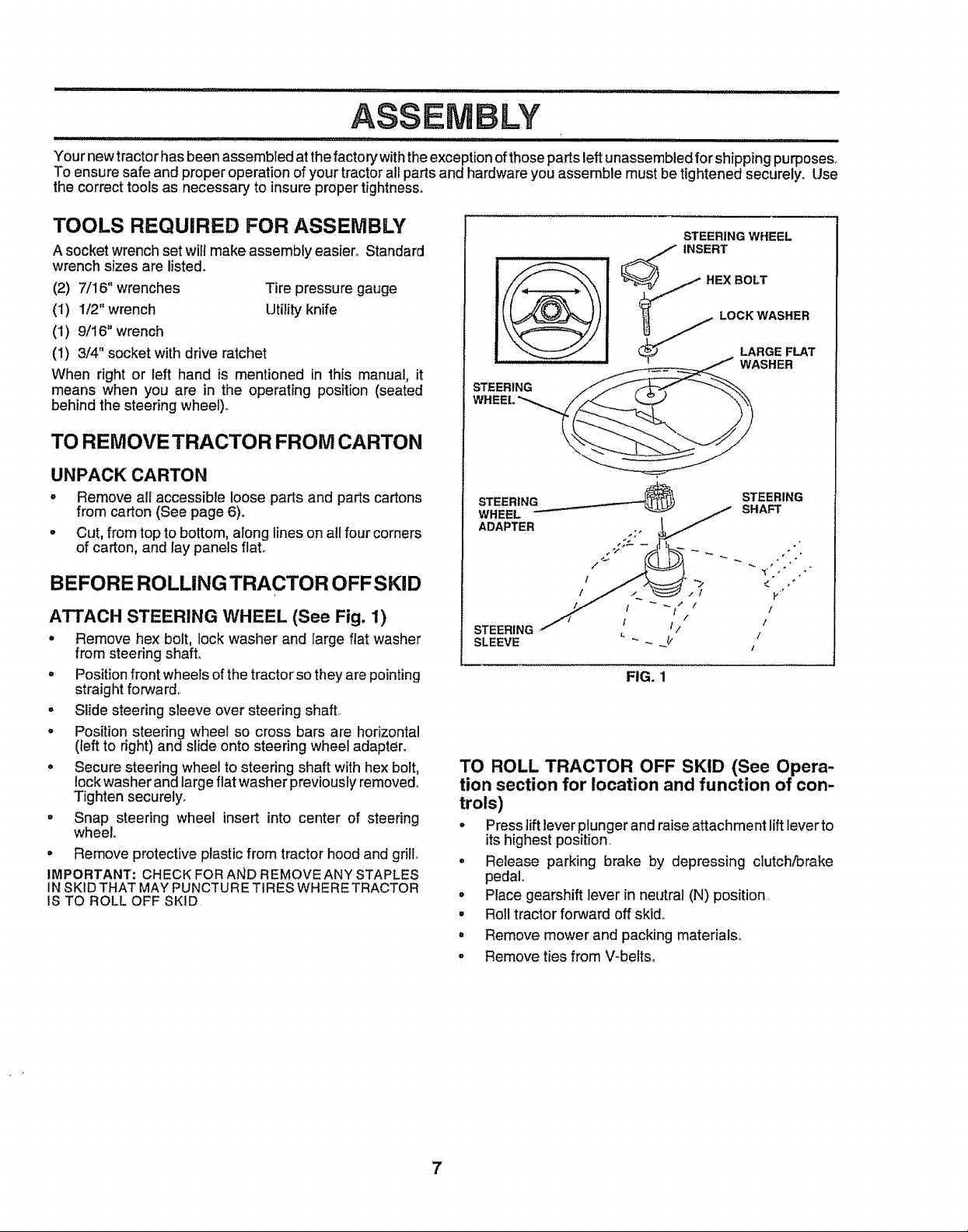

ATTACH STEERING WHEEL (See Fig. 1)

• Remove hex bolt, lock washer and large flat washer

from steering shaft.

° Position front wheels of the tractor so they are pointing

straight forward..

, Slide steering sleeve over steering shaft..

° Position steering wheel so cross bars are horizontal

(left to right) and slide onto steering wheel adapter°

° Secure steering wheel to steering shaft with hex bolt,

lock washer and large flat washer previously removed°

Tighten securely_

° Snap steering wheel insert into center of steering

wheel.

° Remove protective plastic from tractor hood and grill

IMPORTANT: CHECK FORAND REMOVE ANYSTAPLES

IN SKIDTHAT MAYPUNCTURETIRES WHERETRACTOR

IS TO ROLL OFF SKID

STEERING WHEEL

SLEEVE

FIG. 1

TO ROLL TRACTOR OFF SKID (See Opera-

tion section for location and function of con-

trols)

° Press lift lever plunger andraise attachment lift lever to

itshighest position.

, Release parking brake by depressing clutch/brake

pedal_

° Place gearshift lever in neutral (N) position.

° Roll tractor forward off skid..

° Remove mower and packing materials_

, Remove ties from V-belts.

7

ii i iillll

ASSEMBLY

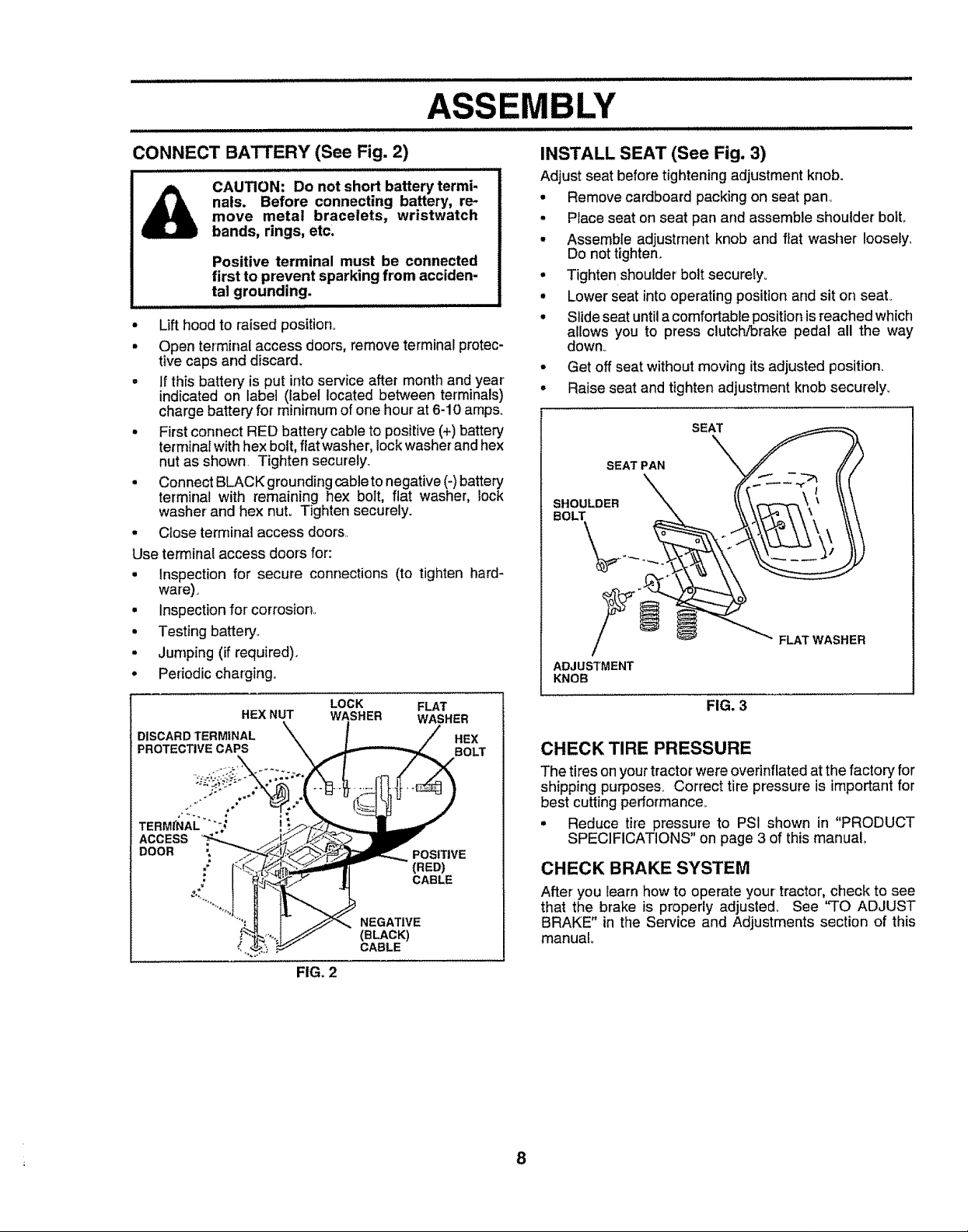

CONNECT BATTERY (See Fig. 2)

i ,,,,uJnuJt

nals. Before connecting battery, re-

move metal bracelets, wristwatch

CAUTION: Do not short battery termi-

bands, rings, etc.

Positive terminal must be connected

first to prevent sparking from acciden-

tal grounding.

• Lifthood to raised position°

• Open termina! access doors, remove terminal protec-

tive caps and discard.

. If this battery is put into service after month and year

indicated on label (label located between terminals)

charge battery for minimum of one hour at 6-10 amps.

• First connect RED battery cable to positive (+)battery

terminal with hex bolt, fiat washer, lockwasherand hex

nut as shown Tighten securely.

• Connect BLACK grounding cable tonegative (-)battery

terminal with remaining hex bolt, flat washer, lock

washer and hex nut. Tighten securely.

• Close terminal access doors..

Use terminal access doors for:

• Inspection for secure connections (to tighten hard-

ware),

• inspectionfor corrosion_

• Testing battery_

• Jumping(if required).

• Periodic charging.

HEX NUT WASHER

LOCK

DISCARDTERMINAL X

PROTECTIVE CAPS "\

FLAT

WASHER

ACCESS

INSTALL SEAT (See Fig. 3)

Adjust seat before tighteningadjustment knob.

• Remove cardboardpacking on seat pan

• Place seat on seat pan and assemble shoulder bolt,

• Assemble adjustrnentknob and fiat washer loosely,

Do nottighten.

• Tightenshoulder bolt securelyo

• Lower seat intooperating positionand siton seat°

° Slide seat untilacomfortableposition isreached which

allows you to press clutch/brake pedal all the way

down_

• Get off seat without moving its adjusted position_

• Raise seat and tighten adjustment knob securety_

SEAT

SEAT PAN

SHOULDER

BOLT

FLAT WASHER

ADJUSTMENT

KNOB

FIG. 3

CHECK TIRE PRESSURE

The tires on yourtractor were overinflated at the factory for

shipping purpose& Correct tire pressure is important for

best cutting performance..

• Reduce tire pressure to PSI shown in "PRODUCT

SPECIFICATIONS" on page 3 of this manual.

: I _.,'_ " J

FIGo2

NEGATIVE

(BLAC_

CABLE

CABLE

CHECK BRAKE SYSTEM

After you learn how to operate your tractor,check to see

that the brake is properly adjusle& See "TO ADJUST

BRAKE" in the Service and Adjustments section of this

manual

8

ASSEMBLY

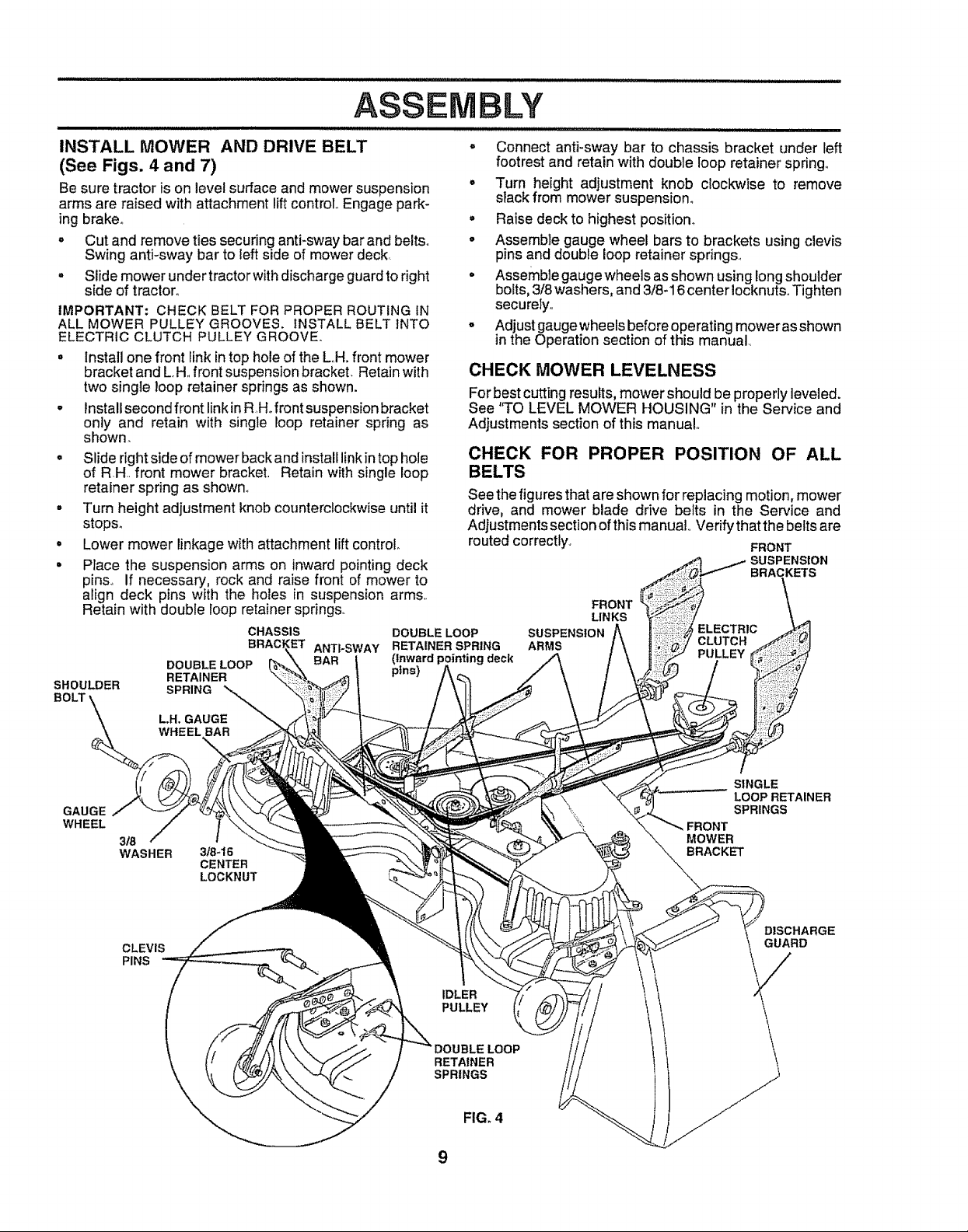

INSTALL MOWER AND DRIVE BELT

(See Figs. 4 and 7)

Be sure tractor is on love! surface and mower suspension

arms are raised with attachment lift control,,Engage park-

ingbrake°

o Cut and remove ties securing anti-sway bar and belts.

Swing anti-sway bar to left side of mower deck,

= Slide mower under tractorwith discharge guardto right

side of tractor.

IMPORTANT: CHECK BELT FOR PROPER ROUTING IN

ALL MOWER PULLEY GROOVES. INSTALL BELT INTO

ELECTRIC CLUTCH PULLEY GROOVE.,

• Install one front link intop hole of the LH, front mower

bracket and L,H,,front suspension bracket. Retain with

two single loop retainer springs as shown.

° Install second front linkin R,Hofrontsuspension bracket

onty and retain with single loop retainer spring as

shown.

• Slide right side of mower back and install linkintop hole

of RH.. front mower bracket. Retain with single loop

retainer spring as shown°

• Turn height adjustment knob counterclockwise until it

stops°

• Lower mower linkagewithattachment lift control

° Place the suspension arms on inward pointing deck

pins., If necessary', rock and raise front of mower to

align deck pins with the holes in suspension arms,.

Retain with double roop retainer springs.

SHOULDER

BOLT'

DOUBLELOOP

RETAINER

SPRING

L.H, GAUGE

WHEEL BAR

CHASSIS

BRACI

ANTI-SWAY

DOUBLE LOOP

RETAINER SPRING

(Inward p, deck

pins)

= Connect anti-sway bar to chassis bracket under left

footrest and retain with double loop retainer spring.,

° Turn height adjustment knob clockwise to remove

slack from mower suspensiom

° Raise deck to highest position°

° Assemble gauge wheel bars to brackets using clevis

pins and doubie loop retainer springs.,

• Assemble gaugewheels asshown using long shoulder

bolts, 3/8washers, and 3/8-16 center Iocknuts.Tighten

securely,,

= Adjustgaugewheels before operating mowerasshown

in the Operation section of this manual,,

CHECK MOWER LEVELNESS

For best cutting results, mower should be properly leveled.

See 'q'O LEVEL MOWER HOUSING" in the Service and

Adjustments section of this manual°

CHECK FOR PROPER POSITION OF ALL

BELTS

See the figures that are shown for replacing motion, mower

drive, and mower blade drive belts in the Service and

Adjustmentssectionofthis manual Verifythatthe beltsare

routed correctly., FRONT

FRONT

LINKS

SUSPENSION ELECTRIC

ARMS CLUTCH

PULLEY

SUSPENSION

BRACKETS

GAUGE

WHEEL

3_

WASHER

CLEVIS

PINS

3/8-16

CENTER

LOCKNUT

SINGLE

LOOP RETAINER

SPRINGS

FRONT

MOWER

BRACKET

DISCHARGE

GUARD

IDLER

PULLEY

LOOP

RETAINER

SPRINGS

FIG. 4

9

ASSEMBLY

v"CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRACTOR, WE WISH TO ASSURE THAT YOURECEIVE

THEBEST PERFORMANCEAND SATISFACTION FROM

THIS QUALITY PRODUCT.

PLEASE REVIEW THE FOLLOWING CHECKLIST:

,/ All assembly instructions have been completed.

,/ No remaining loose parts incarton_

,/ Battery isproperly prepared and charged. (Minimum

1 hour at 6 amps)..

,f Seat is adjusted comfortably and tightened securely.

#' All tires are propedy inflated. (For shipping purposes,

the tires were overinflated at the factory)..

J Be sure mower deck is properly leveled side-to-side/

front-to-rear for best cutting results. (Tires must be

properly inflated for leveling).

J Check mower and drive belts. Be sure they are routed

properly around pulleys and inside all belt keepers_

J Check wiring.. See that all connections are still secure

and wires are properly clamped.

WHILE LEARNING HOW TO USE YOUR TRACTOR,

PAYEXTRA ATTENTION TO THE FOLLOWING IMPOR-

TANT ITEMS:

,/ Engine oil is at proper level.

v" Fuel tank is filled with fresh, clean, regular unleaded

gasoline._

#" Become familiar' with all controls - their location and

function. Operate them before you start the engine..

v" Be sure brake system is in safe operating condition°

10

OPERATION

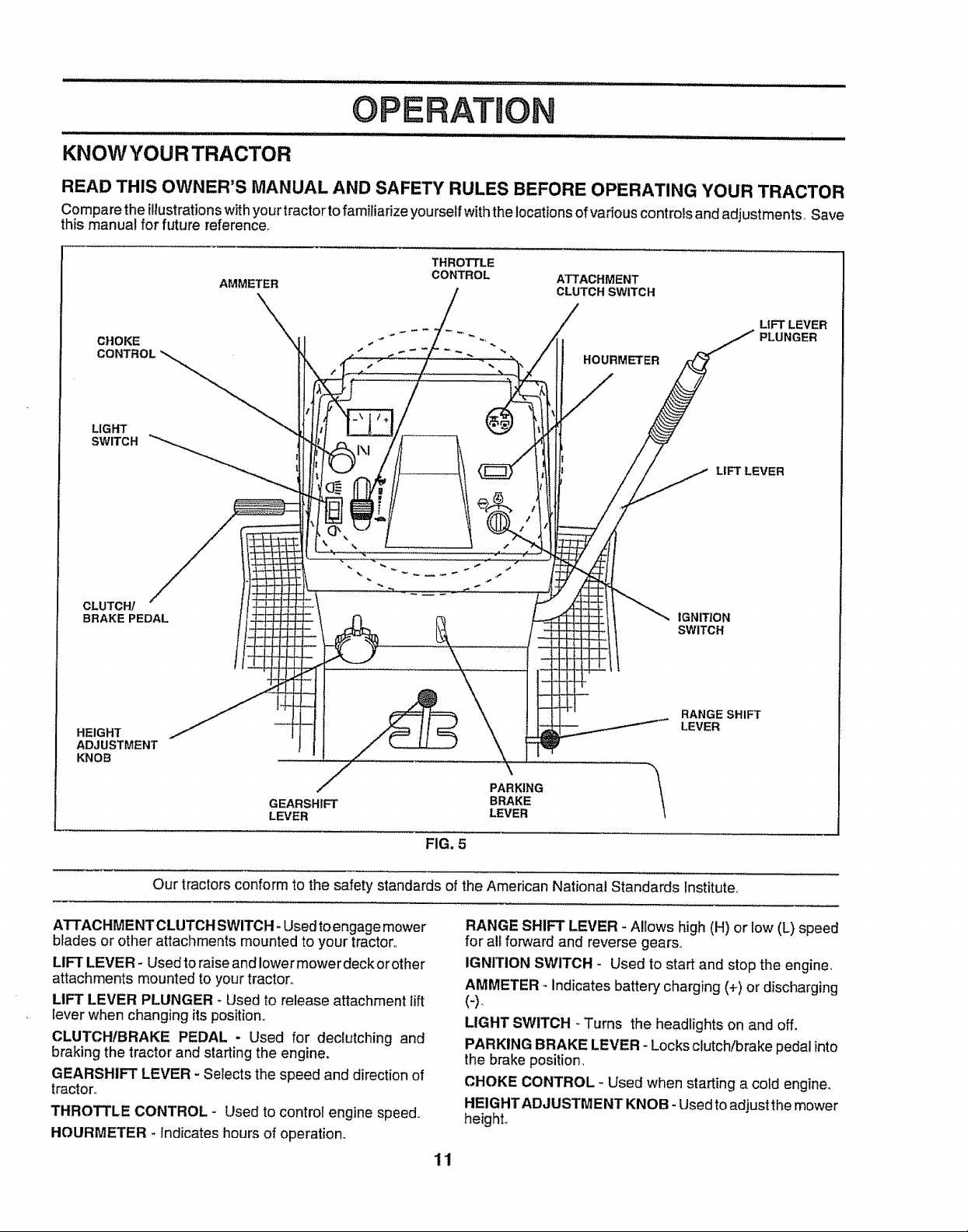

KNOWYOURTRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Compare the illustrationswithyour tractortofamiliarize yourself withthe locationsofvariouscontrolsandadjustments, Save

this manual for future reference.

THROTTLE

AMMETER CONTROL ATTACHMENT

CLUTCH SWITCH

CHOKE

CONTROL

LIGHT

SWITCH

CLUTCH/

BRAKE PEDAL

HEIGHT

ADJUSTMENT

KNOB

"\_'\. \ LIFT LEVER

HOURMETER

IGNITION

SWITCH

RANGE SHIFT

LEVER

PLUNGER

LIFT LEVER

LEVER LEVER

Our tractorsconform to the safety standards of the American National Standards Institute.

ATTACHMENTCLUTCH SWITCH +Usedto engage mower

blades or other attachments mounted to your tractor,,

LIFT LEVER- Used toraise and lower mower deck or other

attachments mounted to your tractor.,

LIFT LEVER PLUNGER - Used to release attachment lift

lever when changing itsposition,,

CLUTCHtBRAKE PEDAL - Used for dectutching and

braking the tractor and starting the engine.

GEARSHIFT LEVER +Selects the speed and direction of

tractor.

THROTTLE CONTROL + Used to controi engine speed+

HOURMETER +Indicates hours of operation°

PARKING _'_\lGEARSHIFT BRAKE

FIG. 5

RANGE SHIFT LEVER - Allows high (H) or low (L) speed

for all forward and reverse gears,,

IGNITION SWITCH - Used to start and stop the engine,

AMMETER - Indicates battery charging (+) or discharging

LIGHT SWITCH - Turns the headlights on and off.

PARKING BRAKE LEVER - Locks clutch!brake pedal into

the brake position_

CHOKE CONTROL - Used when starting a cold engine_

HEIGHTADJUSTMENT KNOB- Used toadjust the mower

height+

11

OPERATION

, ,, , ,,,, ,, ,,,, ,,, ,,,,,,,,,,,,,,, ,liliiH

The operation of any tractor can result inforeign objects thrown into the eyes, which can result

in severe eye damage. Always wear safety glasses or eyeshields while operating your tractor

or performing any adjustments or repairs. We recommend a wide vision safety mask over the

spectacles or standard safety glasses.

iiiiii ..............................................

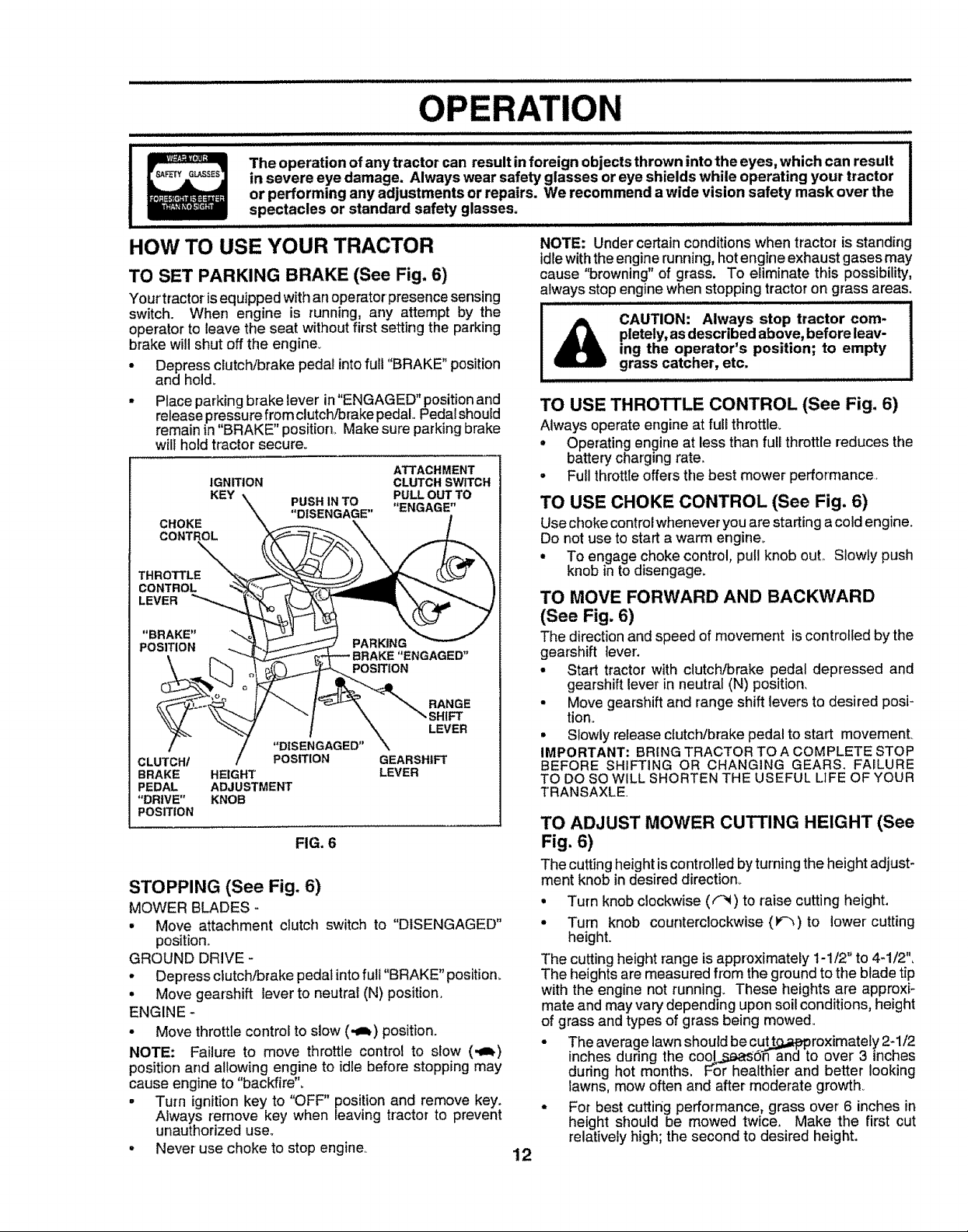

HOW TO USE YOUR TRACTOR

TO SET PARKING BRAKE (See Fig. 6)

Your'tractor isequipped withan operator presence sensing

switch. When engine is running, any attempt by the

operator to leavethe seat without first setting the parking

brake will shut off the engine.

• Depress clutch/brake pedal into full "BRAKE" position

and hold_

• Place parking brake lever in"ENGAGED" position and

release pressure from clutch/brake pedal,, Pedalshould

remain in"BRAKE" position,, Makesure parking brake

will hold tractor secure_

IGNITION CLUTCH SWITCH

KEY -- USH IN TO PULL OUT TO

CHOKE "\ _._-,-,,--_ ",,, /

CONTROL ._ .'_V_-_f-.._"-_ \ _..L

P_ .......... "ENGAGE"

"BRAKE" :-V "-J

POSITION -.... _ _-----'-'_ _

\ _ _,_ BRAKE "ENGAGED"

\ l_ J F_L')J_T-_--_PosrnoN

"_\/ '.".. _ -J/ "" I \ _, SHIFT

,.% / ......!........ \ LEVER

/ "DISENGAGED" \

CLUTCH/ / POSITION GEARSHIFT

BRAKE HEIGHT LEVER

PEDAL ADJUSTMENT

"DRIVE" KNOB

POSITION

FIG. 6

STOPPING (See Fig. 6)

MOWER BLADES -

• Move attachment clutch switch to "DISENGAGED"

position,,

GROUND DRIVE -

• Depress clutch/brake pedat into full "BRAKE" position.

° Move gearshift lever to neutral iN) position.

ENGINE -

• Move throttle control to slow (,,J_) position.

NOTE: Failure to move throttle control to slow (.,m_)

position arid allowing engine to idle before stopping may

cause engine to "backfire".

• Turn ignition key to "OFF" position and remove key.

Always remove key when leaving tractor to prevent

unauthorized use,.

° Never use choke to stop engine,.

ATTACHMENT

PARKING

.................................. iiiii iiii iii1,11 i,,i,

NOTE: Under certain conditions when tractoris standing

idlewiththe engine_nning, hotengine exhaustgasesmay

cause "browning" of grass. To eliminate this possibility,

alwaysstop enginewhen stopping tractor on grassareas.

pletely,asdescribed above, before leav-

CAUTION: Always stop tractor com-

ing the operator's position; to empty

grass catcher, etc.

TO USE THROTTLE CONTROL (See Fig. 6)

Always operate engine at full throttle_

° Operating engineat lessthan full throttle reduces the

battery chargingrate°

• Full throttleoffersthe best mower performance_

TO USE CHOKE CONTROL (See Fig. 6)

Use chokecontrolwheneveryouarestartingacoldengine.

Do not useto start a warm engine_

° To engagechoke control,pull knob ouL Slowlypush

knob in todisengage.

TO MOVE FORWARD AND BACKWARD

(See Fig. 6)

The directionand speed of movement iscontrolledby the

geat'shift lever.

° Start tractor' with clutch/brake pedal depressed and

gearshift lever in neutral iN) position.

- Move gearshift and range shift levers to desired posi-

tion.

• Slowly release clutch/brake pedal to start movement.

IMPORTANT: BRINGTRACTOR TO A COMPLETE STOP

BEFORE SHIFTING OR CHANGING GEARS. FAILURE

TO DO SO WILL SHORTEN THE USEFUL LIFE OF YOUR

TRANSAXLE.

TO ADJUST MOWER CUTTING HEIGHT (See

Fig. 6)

The cutting height iscontrolled byturning the height adjust-

ment knob in desired direction.

• Turn knob clockwise (("_) to raise cutting height.

- Turn knob counterclockwise (1_'_)to lower cutting

height.

The cutting height range isapproximately 1-1/2" to 4-1/2",

The heights are measured from the ground to tile blade tip

with the engine not running. These heights are approxi-

mate and may vary depending upon soil conditions, height

of grass and types of grass being mowed,.

• The average lawnshould be cutt=t.J.g.approximately2-1/2

inches during the cool_d'_ and to over 3 inches

during hot months, For healthier and better looking

lawns, mow often and after moderate growth_

• For best cutting performance, grass over 6 inches in

height should be mowed twice. Make the first cut

relativelyhigh; the second to desired height.

12

OPERATION

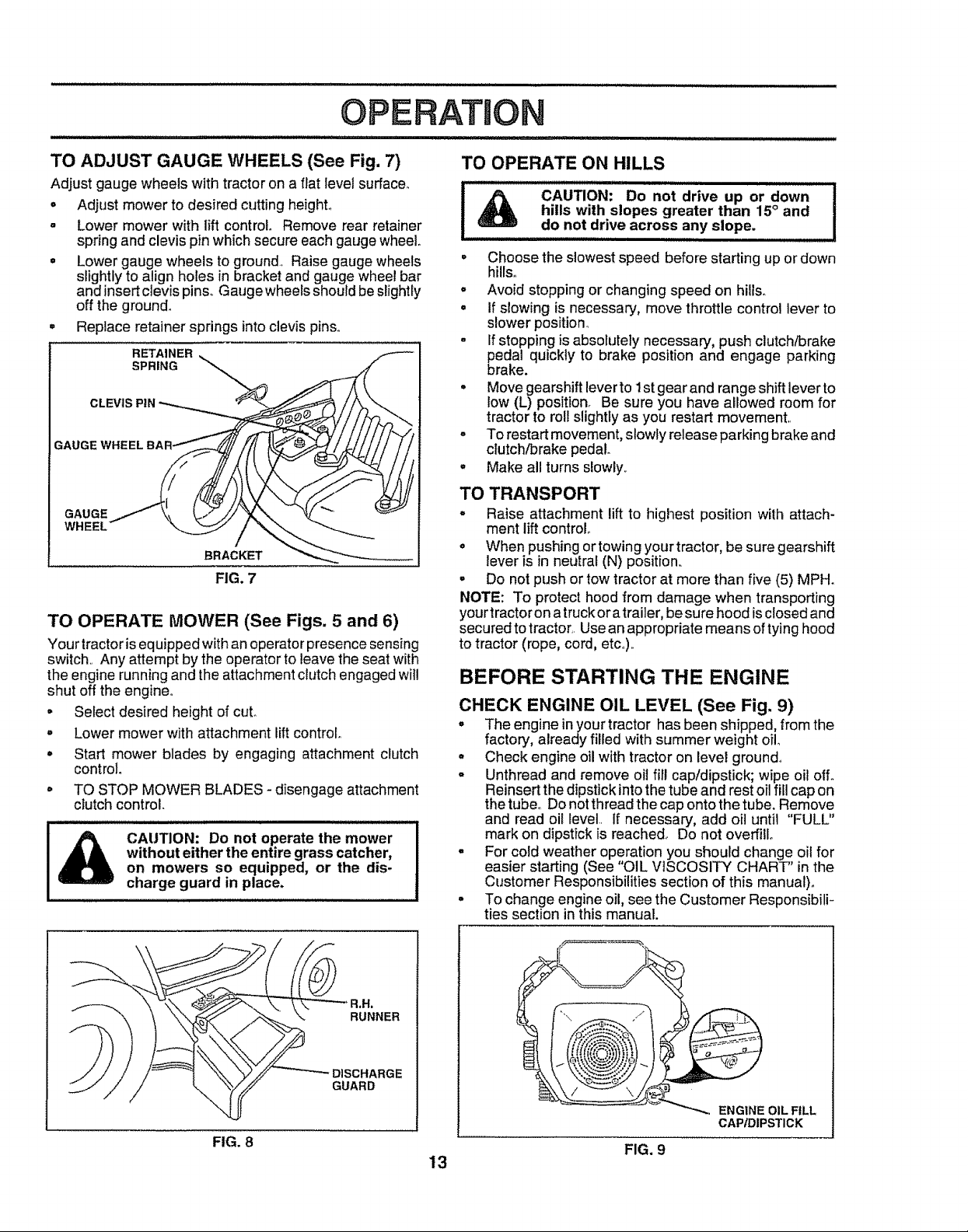

TO ADJUST GAUGE WHEELS (See Fig. 7)

Adjust gauge wheels with tractor on a flat level surface°

o Adjust mower to desired cutting height°

- Lower mower with lift control. Remove rear retainer

spring and clevis pin which secure each gauge wheel.

o Lower gauge wheels to ground. Raise gauge wheels

slightly to align holes in bracket and gauge wheel bar

and insert clevis pins° Gaugewheels should be slightly

off the ground°

° Replace retainer springs into clevis pins.

RETAINER

SPRING

CLEVIS PiN

GAUGE WHEEL BA

GAUGE

WHEEL

BRACKET

FIG. 7

TO OPERATE MOWER (See Figs. 5 and 6)

Your tractor is equipped with an operator presence sensing

switch Any attempt by the operator to leave the seat with

the engine running and the attachment clutch engaged will

shut off the engine°

- Select desired height of cut°

- Lower mower with attachment lift control.

° Start mower blades by engaging attachment clutch

control°

° TO STOP MOWER BLADES- disengage attachment

clutch control.

without either the entire grass catcher,

CAUTION: Do not operate the mower

on mowers so equipped, or the dis-

charge guard in place.

TO OPERATE ON HILLS

I _ CAu_oN" Do notdriveup ordown .........J

• Choose the slowest speed before starting up or down

hills.

° Avoid stopping or changing speed on hills.

° If slowing is necessary, move throttle control lever to

slower position_

- If stopping is absolutely necessary, push clutch/brake

pedal quickly to brake position and engage parking

brake.

• Move gearshift lever to 1st gearand range shift lever to

low (L) position. Be sure you have allowed room for

tractor to roll slightly as you restart movement

° To restart movement, slowly release parking brake and

clutch/brake pedal.

• Make all turns slowly

TO TRANSPORT

° Raise attachment lift to highest position with attach-

ment lift control

o When pushing or towing your tractor, be sure gearshift

lever is in neutral (N) position.

• Do not push or tow tractor at more than five (5) MPH.

NOTE: To protect hood from damage when transporting

yourtractor on a truck oratrailer, besure hood isclosed and

secured totractor. Usean appropriate means oftying hood

to tractor (rope, cord, etc)

hills with slopes greater than 15° and

do not drive across...a,nyslope.

BEFORE STARTING THE ENGINE

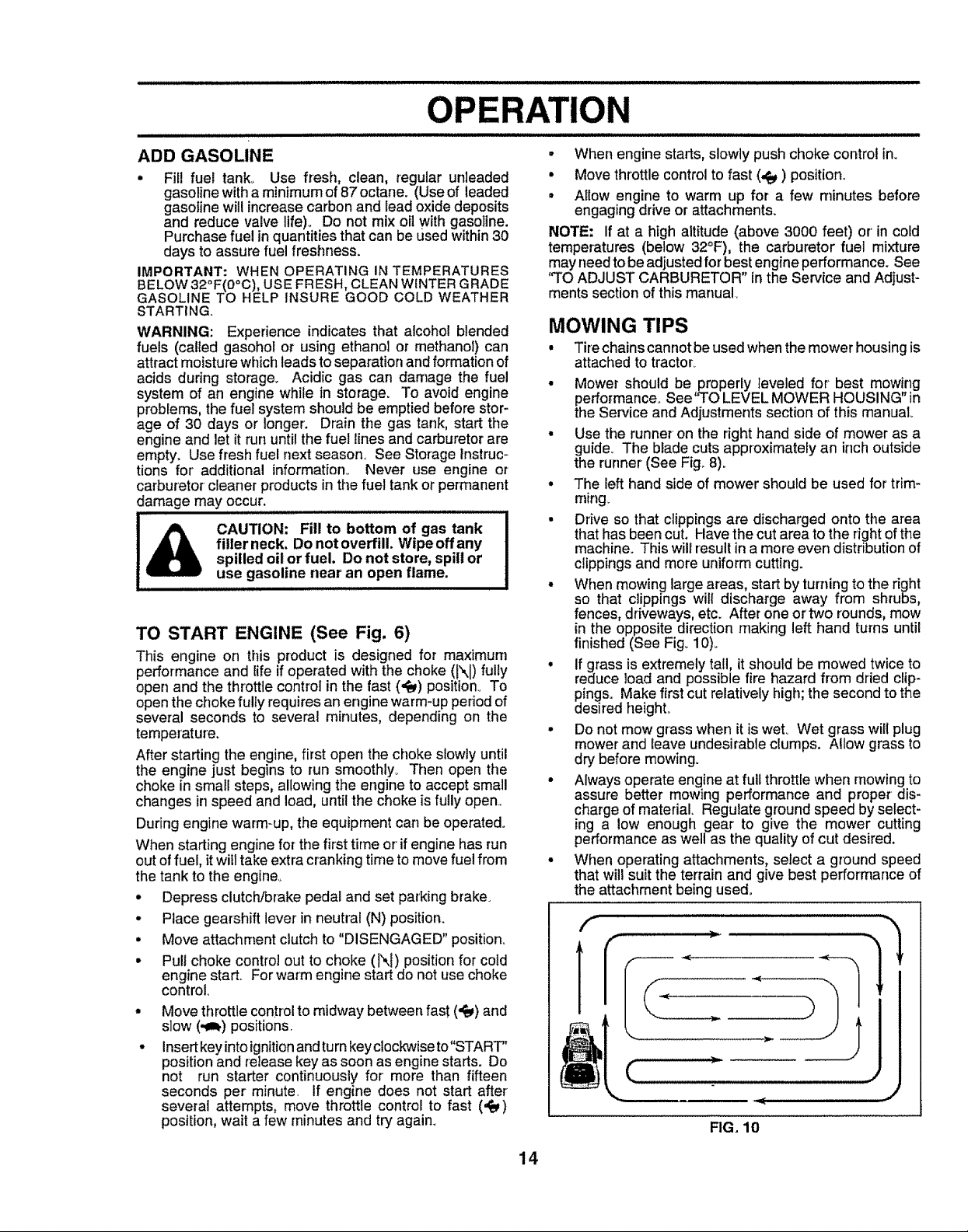

CHECK ENGINE OIL LEVEL (See Fig. 9)

° The engine inyour tractor has been shipped, from the

factory, already filled with summer weight oil

, Check engine oil with tractor on level ground_

° Unthread and remove oiJfill cap/dipstick; wipe oil off°

Reinsert the dipstick into the tube and rest oil fill cap on

thetube. Donotthread thecap ontothe tube. Remove

and read oil level if necessary, add oil until "FULL"

mark on dipstfck is reached° Do not overfill

- For cold weather operation you should change oil for

easier starting (See "OIL VISCOSITY CHART" in the

Customer Responsibilities section of this manual)°

• To change engine oil, see the Customer Responsibili-

ties section in this manual.

FIG. 8

RUNNER

DISCHARGE

GUARD

E.G,.EO,'F,LL

CAP/DIPSTICK

FIG. 9

13

OPERATION

ADD GASOLINE

• Fill fuel tank, Use fresh, clean, regular unleaded

gasoline with a minimum of87 octane. (Use of leaded

gasoline wil! increasecarbon and lead oxide deposits

and reduce valve life). Do not mix oil with gasoline.

Purchase fuel in quantities that can be used within 30

days to assure fuel freshness.

IMPORTANT: WHEN OPERATING IN TEMPERATURES

BELOW 32°F(0°C), USE FRESH, CLEAN WINTER GRADE

GASOLINE TO HELP INSURE GOOD COLD WEATHER

STARTING.

WARNING: Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or methanol) can

attract moisture which leads to separation and formation of

acids during storage. Acidic gas car] damage the fuel

system of an engine while in storage. To avoid engine

problems, the fuel system should be emptied before stor-

age of 30 days or longer. Drain the gas tank, start the

engine and let it run until the fuel lines and carburetor are

empty. Use fresh fuel next season. See Storage Instruc-

tions for' additional information. Never use engine or

carburetor cleaner products in the fuel tank or permanent

damage may occur.

fiilerneck. Do notoveffill. Wipeoffany

'"& CAUTION; Fill to bottom of gas tank

spilled oil or fuel. Do not store, spill or

use gasoline near an open flame.

TO START ENGINE (See Fig. 6)

This engine on this product is designed for maximum

performance and Fifeif operated with the choke (!\l) fully

open and the throttle control in the fast (,_) position_To

open the choke fully requires an engine warm-up pedod of

several seconds to several minutes, depending on the

temperature°

After starting the engine, first open the choke slowly until

the engine just begins to run smoothly. Then open the

choke in small steps, allowing the engine to accept small

changes in speed and load, until the choke is fully open..

During engine warm-up, the equipment can be operated.

When starting engine for the first time or if engine has run

out offuel, itwill take extra cranking time to move fuel from

the tank to the engine.

• Depress clutch/brake pedal and set parking brake.

• Place gearshift leverin neutral (N) position.

• Move attachment clutch to "DISENGAGED" position°

• Pull choke control out to choke (N) position for cold

engine start. For warm engine start do not use choke

control.

• Move throttle control to midway between fast ('_) and

slow (._) positions.

- Insert key intoignitionandturn keyclockwise to"START"

position and release key as soon as engine starts. Do

not run starter continuously for more than fifteen

seconds per minute. If engine does not start after

several attempts, move throttle control to fast (,_)

position, wait a few minutes and try again.

• When engine starts, slowly push choke control in.

• Move throttle control to fast (._) position.

• Allow engine to warm up for a few minutes before

engaging drive or attachments.

NOTE= If at a high altitude (above 3000 feet) or in cold

temperatures (below 32°F), the carburetor fuel mixture

may needto be adjusted for best engine performance. See

,,TOADJUST CARBURETOR" in the Service and Adjust-

ments section of this manual.

MOWING TIPS

• Tirechainscannot be used when the mower housing is

attached to tractor.

• Mower should be properly leveled for' best mowing

performance_ See'q"O LEVEL MOWER HOUSING" in

the Service and Adjustments section of this manual

• Use the runner on the right hand side of mower as a

guide_ The blade cuts approximately an inch outside

the runner (See Fig° 8).

= The left hand side of mower should be used for trim-

ming_

• Drive so that clippings are discharged onto the area

that has been cut. Have the cut area to the fight of the

machine. This will resultin a more even distribution of

clippings and more uniformcutting.

• When mowing large areas, start byturning to the right

so that clippings will discharge away from shrubs,

fences, driveways, etc. After one or two rounds, mow

in the opposite direction making left hand turns until

finished (See Fig_10)_

• if grass is extremely tall, it should be mowed twice to

reduce load and possible fire hazard from dried clip-

pings. Make first cut relatively high; the second to the

desired heighL

= Do not mow grass when it is wet_ Wet grass will plug

mower and leave undesirable clumps. Allow grass to

dry before mowing.

• Always operate engine at full throttle when mowing to

assure better mowing performance and proper dis-

charge of material Regulate ground speed by select-

ing a low enough gear to give the mower cutting

performance as well as the quality of cut desired.

• When operating attachments, select a ground speed

that will suit the terrain and give best performance of

the attachment being used.

FIG. 10

14

CUSTOMER RESPONSmBIUTIES

AS YOU COMPLETE

F,LL,NDATES

REGULAR SERV1CE _'___'SERVICE DATES

CheckBrakeOpe,atfon .......................i_

Check Tire Pressure

T Check for Loose Fasteners

Sharpen/Replace Mower Blades

Lubrication Chart

c

T Check Battery kevel/Rech,ar,g_......

0 Clean Battery and Terminals

R Check Transaxle Cooling

Adjust Blade Bait(s) Tension

Adjust Motion Drive Belt(s) Tension

Check Engine Oil Level ............

Change Engine Oil

!= Clean Air Filter

N Clean Air Screen .....

!G Inspect Mufffer/SparkArrester

I Replace Oil Filter (If equipped)

v"

,/ V'

v'

v"2

v', e,'

................... n.,-

_,"e

Ks

'" v,,,,,,

I

NO,eanEn0,oe 9'o,,ogF,ns........ii...............,"i,,ii"",,. ..... .............

Replace Spark Plug _#' 6#4

Replace Air Filter Paper Cartridge _2

Replace Fuel Filter

I - Change mere o|ten when operaling under a heavy toad or in hlgh ambient temperatures 5 - f_ equipped with adjustable system..

2 ,,Servicemoreoftenwhenoperatinginditty ordustyconditions

3 - Ifequippedwith oilfiller, changeoil every50 hours

4 -RepIace bladesmoreoftenwhenmowinginsandysoil

GENERAL RECOMMENDATIONS

The warranty on this tractor does not cover items that have

been subjected to operator abuse or negligence., To

receive full value from the warranty, operator must maintain

tractor as instructed in this manual

Some adjustments will need to be made periodically to

properly maintain your tractor,,

All adjustments in the Service and Adjustments section of

this manual should be checked at least once each season,,

Once a year you should replace the spark plug, clean

or replace air filter, and check blades and belts for

wear. A new spark plug and clean air filter assure

proper air4uel mixture and help your engine run better

and last longer.

BEFORE EACH USE

• Check engine oi! level,

• Check brake operation.

- Check tire pressure,,

• Check for loose fasteners.

IMPORTANT: DO NOT OIL OR GREASE THE PIVOT

POINTS WHICH HAVE SPECIAL NYLON BEARINGS.

VISCOUS LUBRICANTS WtLL ATTRACT DUST AND DIRT

THAT WILL SHORTEN THE LIFE OF THE SELF-

LUBRICATING BEARINGS. IF YOU FEEL THEY MUST

BE LUBRICATED, USE ONLY A DRY, POWDERED

GRAPHITE TYPE LUBRICANT SPARINGLY.

S - Not required if equipped with matr_lenance4ree ba_ler,j

7 _Tighten front axle pivot boil to 35 It -lbs maximum

Do not ovettighlen

LUBRICATION CHART

(_)']'IE ROD BALL JOINTS

(_) SPINDLE ZERK __ t_ SPINDLE ZERK (_)

(_) STEERIr

SECTOR GEAR ENGINE (_

TEETH

O

TRANSAXLE

FLUID

(_)SAE 30 MOTOR OIL AP! - SFISG

(_)GENERAL PURPOSE GREASE

(_)REFER TO CUSTOMER RESPONSIBILITIES "ENGINE" SECTION

(_)SPRAY SILICONE LUBRICANT (MOVE BOOTS TO LUBRICATE)

'15

C RESPONSIBI

TRACTOR

Always observe safety rules when performing any mainte-

nance.

BRAKE OPERATION

If tractor requires more than six (6) feet stopping distance

athigh speed in highest gear, then brake mustbeadjusted.

(See 'q'O ADJUST BRAKE" in the Service and Adjust-

ments section of this manual).

TIRES

• Maintain proper air pressure in all tires (See "PROD-

UCT SPECIFICATIONS" on page 3 ofthismanual).

• Keeptiresfree ofgasoline, oil,or insectcontrol chemi-

cals which can harm rubber:

• Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage.

BLADE CARE

For best results mower blades must be kept sharp,. Re-

place bent or damaged blades.

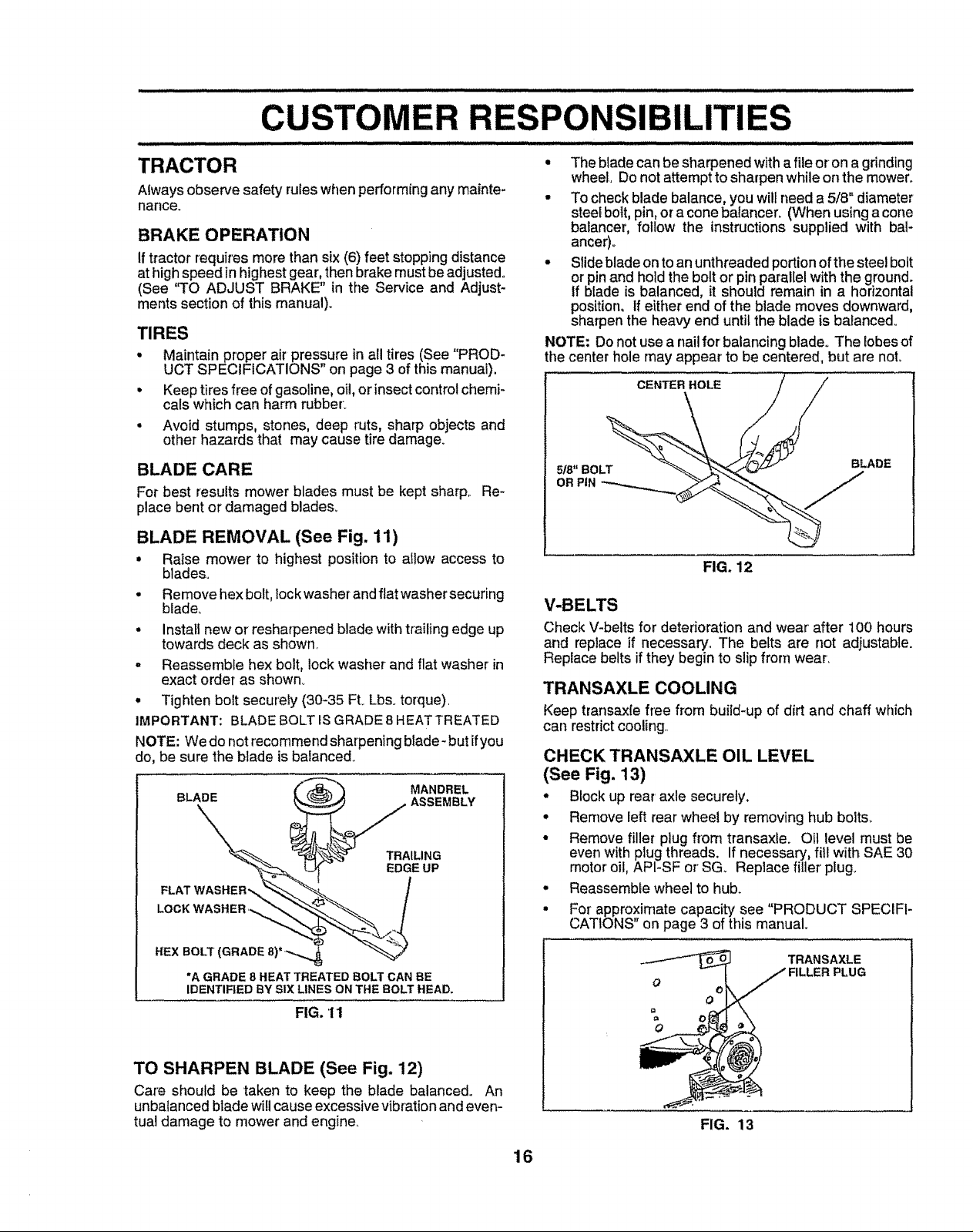

BLADE REMOVAL (See Fig. 11)

• Raise mower to highest position to allow access to

blades.

o

Remove hex bolt, lock washerand fiat washer securing

blade,

e

Install new or resharpened blade with trailing edge up

towards deck as shown.

o

Reassemble hex bolt, lock washer and flat washer in

exact order as shown.

• Tighten bolt securely (30-35 FtoLbs. torque),

IMPORTANT: BLADEBOLTISGRADE8HEATTREATED

NOTE: We do not recommend sharpening btade- butifyou

do, be sure the blade is balanced.

"_ MANDREL

BLADE _ ASSEMBLY

_" __TRAILING

EDGE UP

FLAT WASHER',, _ /

• The blade can be sharpened with a fileor on a grinding

wheel, Do not attempt to sharpen while on the mower.

• To check blade balance, you wilt need a 5/8" diameter

steel bolt, pin, or a cone balancer. (When using a cone

balancer, follow the instructionssupplied with bal-

ancer)_

• Slide blade on toanunthreaded portion ofthe steel bolt

or pin and hold the bolt or pin parallel with the ground.

If blade is balanced, it should remain in a horizontal

position, if either end of the blade moves downward,

sharpen the heavy end until the blade is balance&

NOTE: Do not use a nail for' balancing blade° The lobes of

the center hole may appear to be centered, but are not.

CENTER HOLE

5/8" BOLT

OR PIN

BLADE

FIG. 12

V-BELTS

Check V-belts for deterioration and wear' after 100 hours

and replace if necessary., The belts are not adjustable.

Replace belts if they begin to slip from wear.

TRANSAXLE COOLING

Keep transaxle free from buiid-up of dirt and chaff which

can restrictcooling.

CHECK TRANSAXLE OIL LEVEL

(See Fig, 13)

° Block up rear'axle securely.

• Remove left rear wheel by removing hub bolts_

• Remove filler plug from transaxle. Oil level must be

even with plug threads, if necessary, fill with SAE 30

motor oil, API-SF or SG. Replace filler plug_

• Reassemble wheel to hub.

• For approximate capacity see "PRODUCT SPECIFI-

CATIONS" on page 3 of this manual°

.ExBoLT(G.ADE

"A GRADE 8 HEAT TREATED BOLT CAN BE

,DEN.nEDBYs,xUNESO.THEBOLT.EAO.

FIG. 11

TO SHARPEN BLADE (See Fig. 12)

Care should be taken to keep the blade balanced° An

unbalanced bladewill cause excessive vibration and even-

tual damage to mower and engine.

TRANSAXLE

O (3

o

I

FIG. 13

16

,1111i ............

CUSTOMER

i ..................

RESPONSmBmLJTmE$

BATTERY

Your tractor has a battery charging system which is suffi-

cient for norma_use However, periodic charging of the

battery with an automotive charger will extend its life.

= Keep battery and terminals Clean

= Keep battery bolts tight

° Keep small vent holes open

• Recharge at 6-10 amperes for 1 hour

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and terminals can cause

the battery to "leal¢' power°

° Remove terminal guard°

- Disconnect BLACK battery cable first then RED bat-

ter] cable and remove battery from tractor.

° Rinse the battery with plain water and dry°

° Clean terminals and battery cable ends with wire brush

until bright

• Coat terminals with grease or petroleum jelly

° Reinstall battery (See "CONNECT BATTERY" in the

Assembly section of this manual)

HIll i iiii iiii i ii

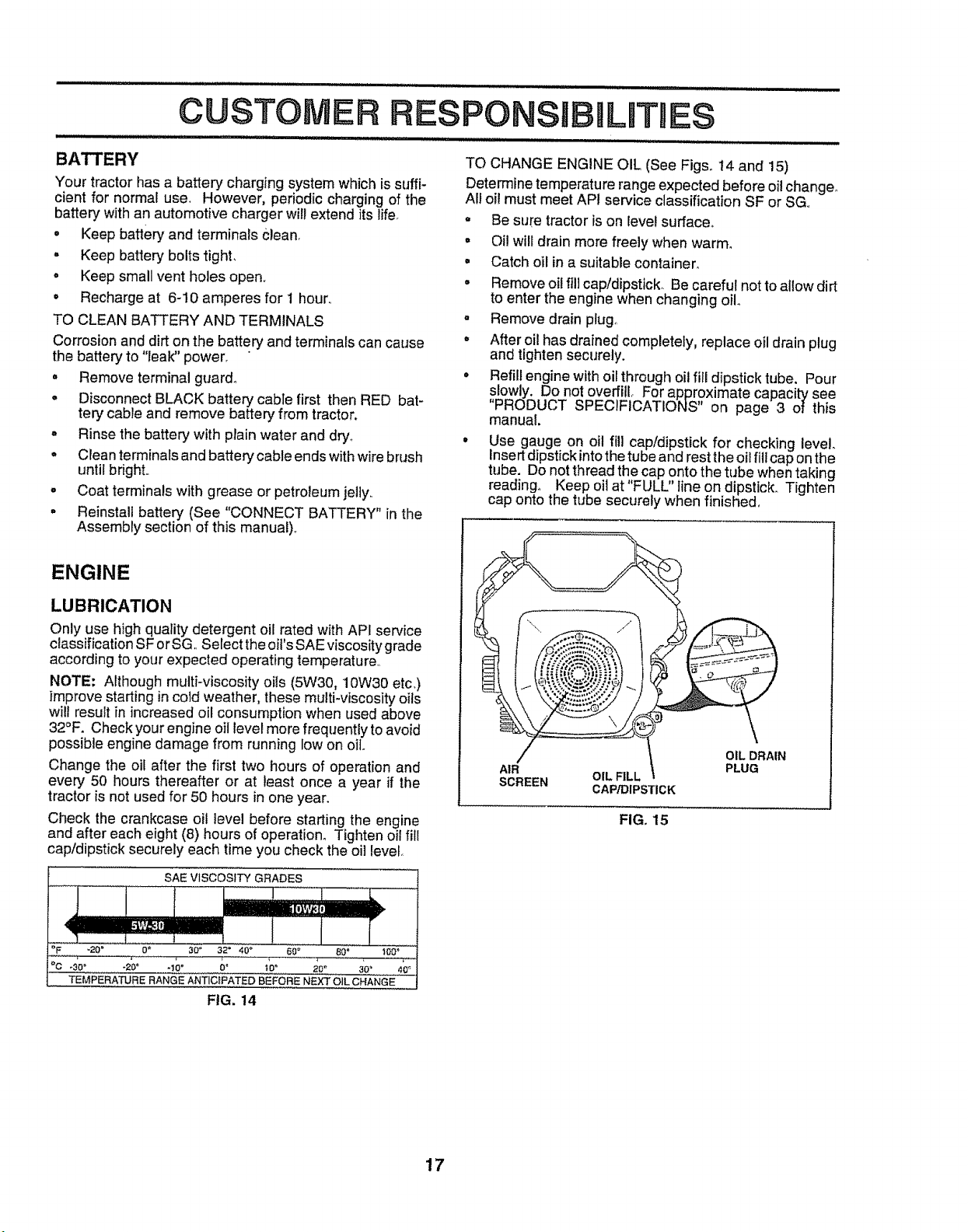

TO CHANGE ENGINE OIL (See Figs° 14 and 15)

Determine temperature range expected before oil change°

All oil must meet API service classification SF or SG

° Be sure tractor ison Ievel surface°

° Oi! will drain more freely when warm°

= Catch oil inasuitable container

° Remove oil fill cap/dipstick Be careful not to allow dirt

to enter the engine when changing oil

= Remove drain plug

° After oil has drained completely, replace oil drain plug

and tighten securely

o Refill engine with oil through oil fill dipstick tube Pour

slowly Do not overfill For approximate capac ty see

"PRODUCT SPECIFICATIONS" on page 3 of this

manual

Use gauge on oil fill cap/dipstick for checking level

insertdipstick intothe tube and rest the oil fillcap on the

tube Do not thread the cap onto the tube when taking

reading° Keep oil at 'FULL' line on dipstick. Tighten

cap onto the tube securely when finished

ENGINE

LUBRICATION

Only use high quality detergent oil rated withAPI service

classification SForSG Select the oil's SAE viscosity grade

according to your expected operating temperature

NOTE: Although multi-viscosity oils (5W30, 10W30 etc)

improvestarting incold weather, these multi viscosity oils

will result in increased oil consumption when used above

32°F Check your engine oil levelmore frequently toavoid

possible engine damage from running low on oil

Change the oil after the first two hours of operation and

every 50 hours thereafter or at least once a year if the

tractor isnot used for 50 hours in one yearn

Check the crankcase oil level before starting the engine

and after each eight (8) hours of operation Tighten oil fill

cap/dipstick securely each time you check the oil level

SAEVlSCOSfTYGRADES......

I

-20° O" 30" 32= 40 _ 60 _ 80' I00 _.......

.......TEMPERATURE RANGE ANTICIPATEDBEFORE NEXTOILCHANGE

FIG. !4

AIR

SCREEN

OIL FILL i

CAP/DIPSTICK

FIG. 15

OIL DRAIN

PLUG

17

CUSTOMER

................................ , ,, ,, ,, ,,,

CLEAN AIR SCREEN (See Fig. 15)

Air screen must be kept free of dirt and chaff to prevent

engine damage from overheating_ Clean with a wire brush

or'compressed air to remove dirt and stubborn dried gum

fibers..

CLEAN AIR INTAKE/COOLING AREAS

To insure proper cooling, make sure the grass screen,

cooling fins, and other external surfaces of the engine are

kept clean at all times.

Every 100 hours of operation (more often underextremely

dusty, dirty conditions), remove the blower housing and

other cooling shrouds_Clean the cooling fins and external

surfaces as necessary. Make sure the cooling shrouds are

reinstalled,.

NOTE: Operating the engine withablocked grass screen,

dirty or plugged cooling fins, and!or cooling shrouds re-

moved will cause engine damage due to overheating_

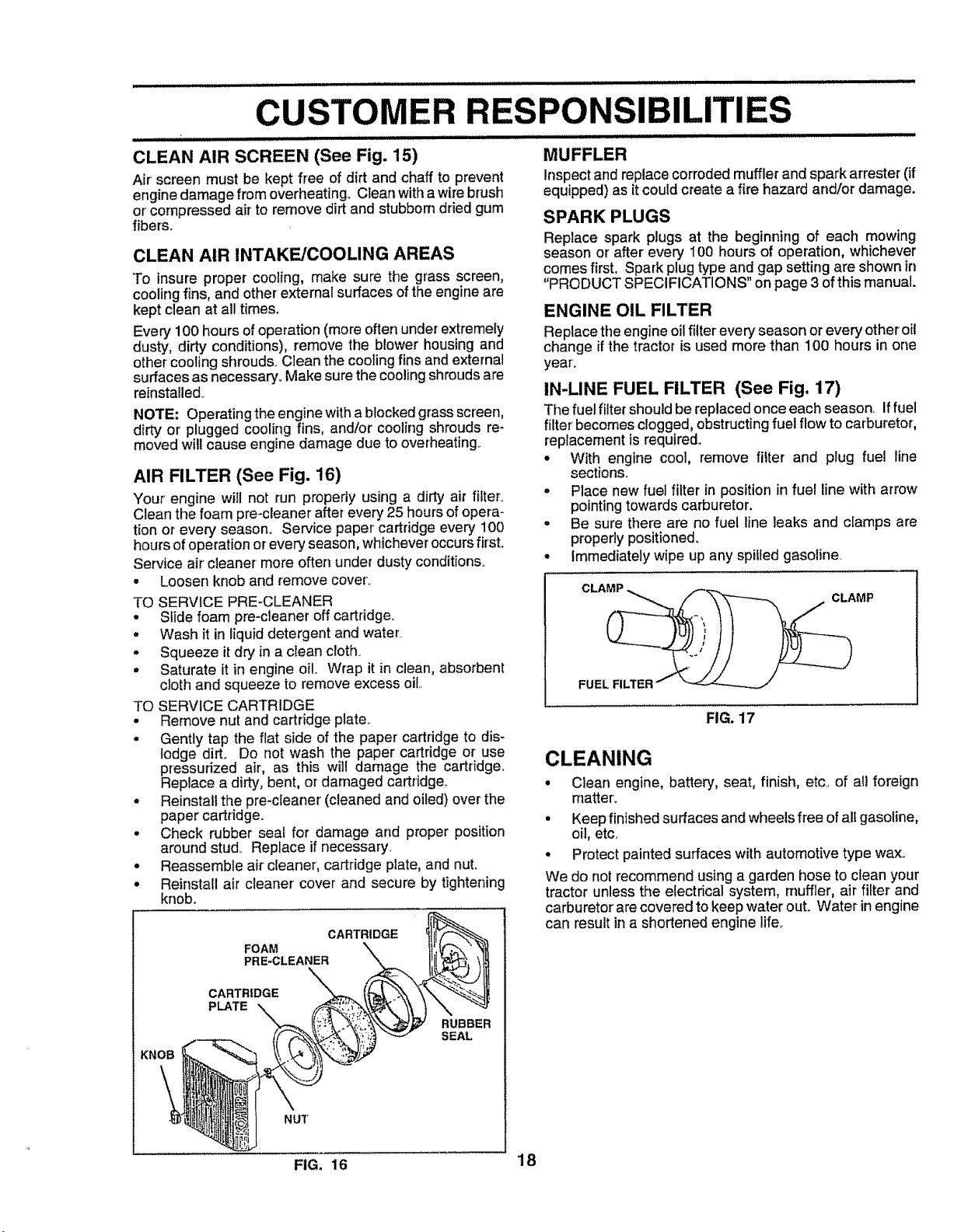

AIR FILTER (See Fig. 16)

Your engine will not run properly using a dirty air filter°

Clean the foam pre-cleaner after every 25 hours of opera-

tion or every season° Service paper cartridge every 100

hours of operation or'every season, whichever occurs first.

Service air cleaner more often under dusty conditions.

• Loosen knob and remove coverL

TO SERVICE PRE-CLEANER

• Slide foam pre-cleaner off cartridge.

• Wash it in liquid detergent and water

• Squeeze itdry in a clean cloth.

• Saturate it in engine oil. Wrap it in clean, absorbent

cloth and squeeze to remove excess oil.

TO SERVICE CARTRIDGE

• Remove nut and cartridge plate..

• Gently tap the flat side of the paper cartridge to dis-

lodge dirL Do not wash the paper cartridge or' use

pressurized air, as this wil! damage the cartridge,,

Replace a dirty, bent, or damaged cartridge_

• Reinstall the pre-cleaner (cleaned and oiled) over the

paper cartridge.

• Check rubber seat for damage and proper position

around stud_ Replace if necessary.

• Reassemble air cleaner, cartridge plate, and nuL

• Reinstall air cleaner cover and secure by tightening

knob.

CARTRIDGE

FOAM

PRE*CLEANER

MUFFLER

Inspect and replace corroded muffler'and spark arrester (if

equipped) as itcould create a fire hazard and/or damage.

SPARK PLUGS

Replace spark plugs at the beginning of each mowing

season or after every i00 hoursof operation, whichever

comes first. Spark plug type and gap setting are shown in

"PRODUCT SPECIFICATIONS" on page 3 of this manual.

ENGINE OIL FILTER

Replace tile engine oil filter ever,.#season or every otheroil

change ifthe tractor is used more than 100 hours in one

yearL

IN-LINE FUEL FILTER (See Fig. 17)

The fuel filter should be replacedonce each season. Iffuel

filter becomesclogged,obstructingfuel flow tocarburetor,

replacement is required.

• With engine cool, remove filter and plug fuel line

sections_

° Place new fuel filter in position in fuel line with arrow

pointing towards carburetor.

• Be sure there are no fuel line leaks and clamps are

properly positioned_

• Immediately wipe up any spiffed gasoline.

FIG. 17

CLEANING

* Clean engine, battery, seat, finish, etc_of all foreign

matter.

• Keep finished surfaces andwheels free ofall gasoline,

oil, etc.

• Protect painted surfaces with automotive type wax_

We do not recommend using a garden hose to clean your

tractor unless the electrical system, muffler, air filter and

carburetor are covered to keep water out. Water in engine

can result in a shortened engine lifeo

CARTRIDGE

PLATE "X,

RUBBER

SEAL

NUT

FIG. 16 18

Loading...

Loading...