Craftsman 917986960 Owner’s Manual

Owner's Manual

CRRFTSMRII°

TI

COU T

900 Series

14"

Model No.

917,986960

Tine Width

T LL

ROTATI

Briggs & Stratton

ITH

G TI

Engine

E

\

. Espahol, p. 21

This product has a low emission engine which operates

differently from previously built engines. Before you start

the engine, read and understand this Owner's Manual.

Gasoline containing up to 10% ethanol (EIO) is acceptable for use in this machine.

The use of any gasoline exceeding 10% ethanol (EIO) will void the product warranty.

Esta m_quina puede utilizar gasolina con un contenido de hasta el 10% de etanol (EIO).

El uso de una gasolina que supere el 10% de etanol (El0) anular_ la garantia del producto.

IMPORTANT:

Read and follow all Safety Rules and Instructions

before operating this equipment.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website:www.sears.com/craftsman

Safety Rules ........................................ 2-3

Warranty ................................................. 2

Product Specifications ......................... 4

Assembly/Pre-Operation ..................... 6-7

Operation .......................................... 8-12

Maintenance Schedule ........................ 13

Maintenance .................................... 13-15

Service and Adjustments ................ 15-18

Storage ................................................. 18

Troubleshooting .............................. 19-20

Illustrated Parts List ......................... 40-48

Sears Service ........................ Back Cover

LIMITED ONE YEAR WARRANTY ON CRAFTSMAN TILLER

For one (1) year from date of purchase, when this Craftsman Tiller is maintained, lubricated,

and tuned up according to the operating and maintenance instructions in the owner's

manual, Sears will repair free of charge any defect in material or workmanship.

This Warranty does not cover:

• Expendable items which become worn during normal use, such as tines, spark plugs,

air cleaners and belts.

• Repairs necessary because of operator abuse or negligence, including bent crankshafts

and the failure to maintain the equipment according to the instructions contained in the

owner's manual.

• If this Craftsman Tiller is used for commercial or rental purposes, this Warranty applies

for only thirty (30) days from the date of purchase.

Warranty service is available by returning the craftsman power mower to the nearest sears

service center/department in the united states. This warranty applies only while this product

is in use in the united states.

This Warranty gives you specific legal rights, and you may also have other rights which

vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

iMPORTANT: This cutting machine is capable of amputating hands and feet and throwing

objects. Failure to observe the following safety instructions could result in serious injury

or death.

TRAINING

• Read the Owner's Manual carefully. Be

thoroughly familiar with the controls and

the proper use of the equipment. Know

how to stop the unit and disengage the

controls quickly.

• Never allow children to operate the

equipment. Never allow adults to operate

the equipment without proper instruction.

• Keep the area of operation clear of all

persons, particularly small children, and

pets.

PREPARATION

• Thoroughly inspect the area where the

equipment is to be used and remove all

foreign objects.

• Disengage all clutches and shift into

neutral before starting the engine (motor).

• Do not operate the equipment without

wearing adequate outer garments. Wear

footwear that will improve footing on

slippery surfaces.

• Handle fuel with care; it is highly

flammable.

2

• Use an approved fuel container.

• Never add fuel toa running engine or hot

engine.

• Fill fuel tank outdoors with extreme care.

Never fill fuel tank indoors.

• Replace gasoline cap securely and clean

up spilled fuel before restarting.

• Use extension cords and receptacles

as specified by the manufacturer for all

units with electric drive motors or electric

starting motors.

• Never attempt to make any adjustments

whilethe engine (motor) is running (except

where specifically recommended by

manufacturer).

OPERATION

• Do not put hands or feet near or under

rotating parts.

• Exercise extreme caution when operating

on or crossing gravel drives, walks, or

roads. Stay alert for hidden hazards or

traffic. Do not carry passengers.

• After striking a foreign object, stop the

engine (motor), remove the wire from the

spark plug, thoroughly inspect the tiller

for any damage, and repair the damage

before restarting and operating the tiller.

• Exercise caution to avoid slipping or

falling.

• If the unit should start to vibrate abnor-

mally, stop the engine (motor) and check

immediately for the cause. Vibration is

generally a warning of trouble.

• Stop the engine (motor) when leaving the

operating position.

• Take all possible precautions when leav-

ing the machine unattended. Disengage

the tines, shift into neutral, and stop the

engine.

• Before cleaning, repairing, or inspecting,

shut off the engine and make certain all

moving parts have stopped. Disconnect

the spark plug wire, and keep the wire

away from the plug to prevent accidental

starting. Disconnect the cord on electric

motors.

• Do not run the engine indoors; exhaust

fumes are dangerous.

• Never operate the tiller without proper

guards, plates, or other safety protective

devices in place.

• Keep children and pets away.

• Do not overload the machine capacity

by attempting to till too deep at too fast

a rate.

• Never operate the machine at high speeds

on slippery surfaces. Look behind and use

care when backing.

• Never allow bystanders near the unit.

• Use only attachments and accessories

approved bythe manufacturer of the tiller.

• Never operate the tiller without good

visibility or light.

• Be careful when tilling in hard ground. The

tines may catch in the ground and propel

the tiller forward. If this occurs, let go of

the handlebars and do not restrain the

machine.

MAINTENANCE AND STORAGE

• Keep machine, attachments, and

accessories in safe working condition.

• Check shear pins, engine mounting bolts,

and other bolts at frequent intervals for

proper tightness to be sure the equipment

is in safe working condition.

• Never store the machine with fue! in the

fuel tank inside a building where ignition

sources are present, such as hot water

and space heaters, clothes dryers, and

the like. Allow the engine to cool before

storing in any enclosure.

• Always refer to the operator's guide

instructions for important details ifthetiller

is to be stored for an extended period.

_l_Look for this symbol to point out important

safety precautions. It means CAUTION!!!

BECOME ALERT!!! YOUR SAFETY IS

INVOLVED.

_,CAUTION: Always disconnect spark plug

wire and place wire where it cannot contact

spark plug in order to prevent acciden-

tal starting when setting up, transporting,

adjusting or making repairs.

,4_WARNING: Engine exhaust, some

of its constituents, and certain vehicle

components contain or emit chemicals

known to the State of California to cause

cancer and birth defects or other repro-

ductive harm.

3

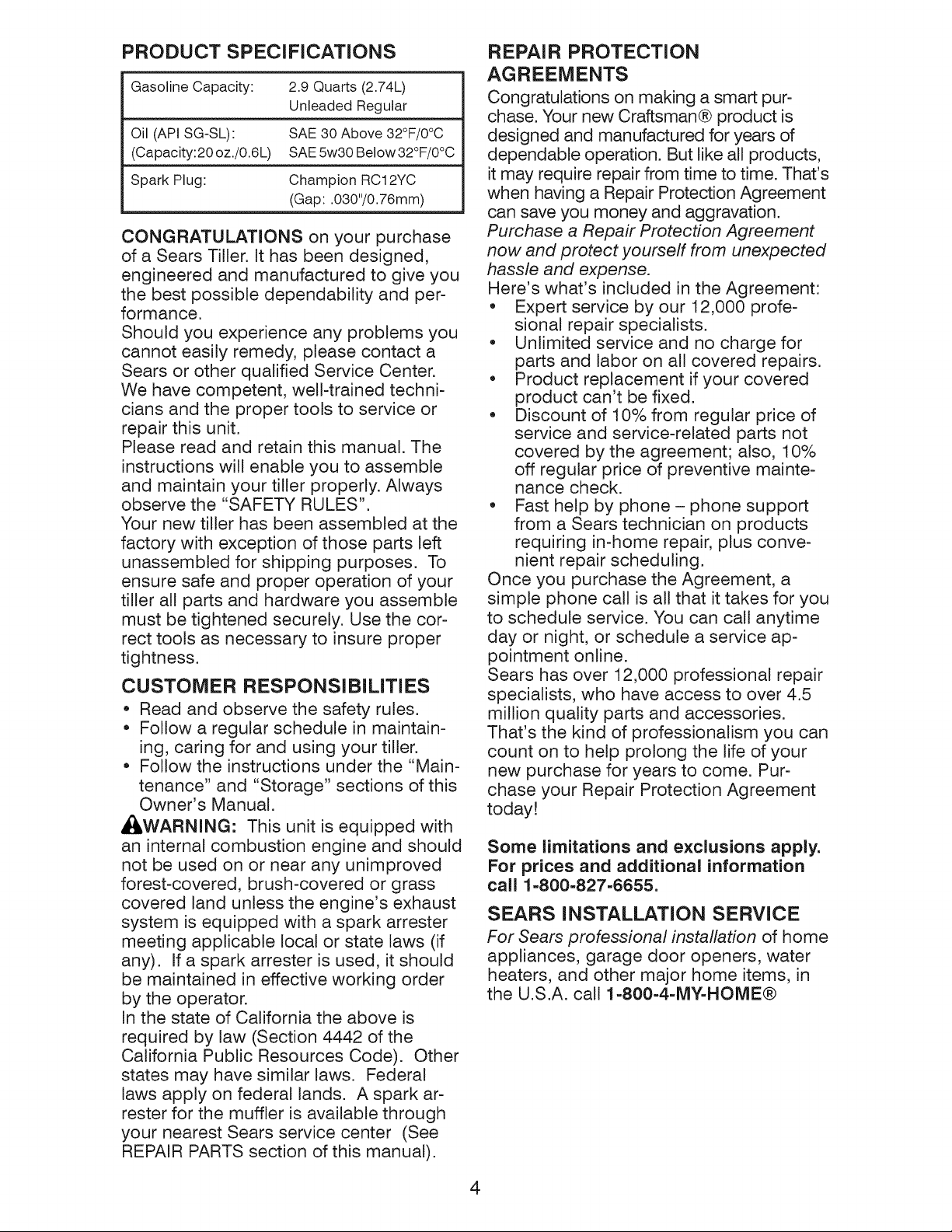

PRODUCT SPECIFICATIONS

Gasoline Capacity: 2.9 Quarts (2.74L)

Unleaded Regular

Oil (API SG-SL): SAE 30 Above 32°F/0°C

(Capacity:20oz./0.6L) SAE5w30 Below32°F/0°C

Spark Plug: Champion RC12YC

(Gap: .030"/0.76mm)

CONGRATULATIONS on your purchase

of a Sears Tiller. It has been designed,

engineered and manufactured to give you

the best possible dependability and per-

formance.

Should you experience any problems you

cannot easily remedy, please contact a

Sears or other qualified Service Center.

We have competent, well-trained techni-

cians and the proper tools to service or

repair this unit.

Please read and retain this manual. The

instructions will enable you to assemble

and maintain your tiller properly. Always

observe the "SAFETY RULES".

Your new tiller has been assembled at the

factory with exception of those parts left

unassembled for shipping purposes. To

ensure safe and proper operation of your

tiller all parts and hardware you assemble

must be tightened securely. Use the cor-

rect tools as necessary to insure proper

tightness.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintain-

ing, caring for and using your tiller.

• Follow the instructions under the "Main-

tenance" and "Storage" sections of this

Owner's Manual.

_I_WARNING: This unit is equipped with

an internal combustion engine and should

not be used on or near any unimproved

forest-covered, brush-covered or grass

covered land unless the engine's exhaust

system is equipped with a spark arrester

meeting applicable local or state laws (if

any). If a spark arrester is used, it should

be maintained in effective working order

by the operator.

In the state of California the above is

required by law (Section 4442 of the

California Public Resources Code). Other

states may have similar laws. Federal

laws apply on federal lands. A spark ar-

rester for the muffler is available through

your nearest Sears service center (See

REPAIR PARTS section of this manual).

REPAIR PROTECTION

AGREEMENTS

Congratulations on making a smart pur-

chase. Your new Craftsman® product is

designed and manufactured for years of

dependable operation. But like all products,

it may require repair from time to time. That's

when having a Repair Protection Agreement

can save you money and aggravation.

Purchase a Repair Protection Agreement

now and protect yourself from unexpected

hassle and expense.

Here's what's included in the Agreement:

• Expert service by our 12,000 profe-

sional repair specialists.

• Unlimited service and no charge for

parts and labor on all covered repairs.

• Product replacement if your covered

product can't be fixed.

• Discount of 10% from regular price of

service and service-related parts not

covered by the agreement; also, 10%

off regular price of preventive mainte-

nance check.

• Fast help by phone- phone support

from a Sears technician on products

requiring in-home repair, plus conve-

nient repair scheduling.

Once you purchase the Agreement, a

simple phone call is all that it takes for you

to schedule service. You can call anytime

day or night, or schedule a service ap-

pointment online.

Sears has over 12,000 professional repair

specialists, who have access to over 4.5

million quality parts and accessories.

That's the kind of professionalism you can

count on to help prolong the life of your

new purchase for years to come. Pur-

chase your Repair Protection Agreement

today!

Some limitations and exclusions apply.

For prices and additional information

call 1-800-827-6655.

SEARS INSTALLATION SERVICE

For Sears professional installation of home

appliances, garage door openers, water

heaters, and other major home items, in

the U.S.A. call 1-800-4-MY=HOME®

4

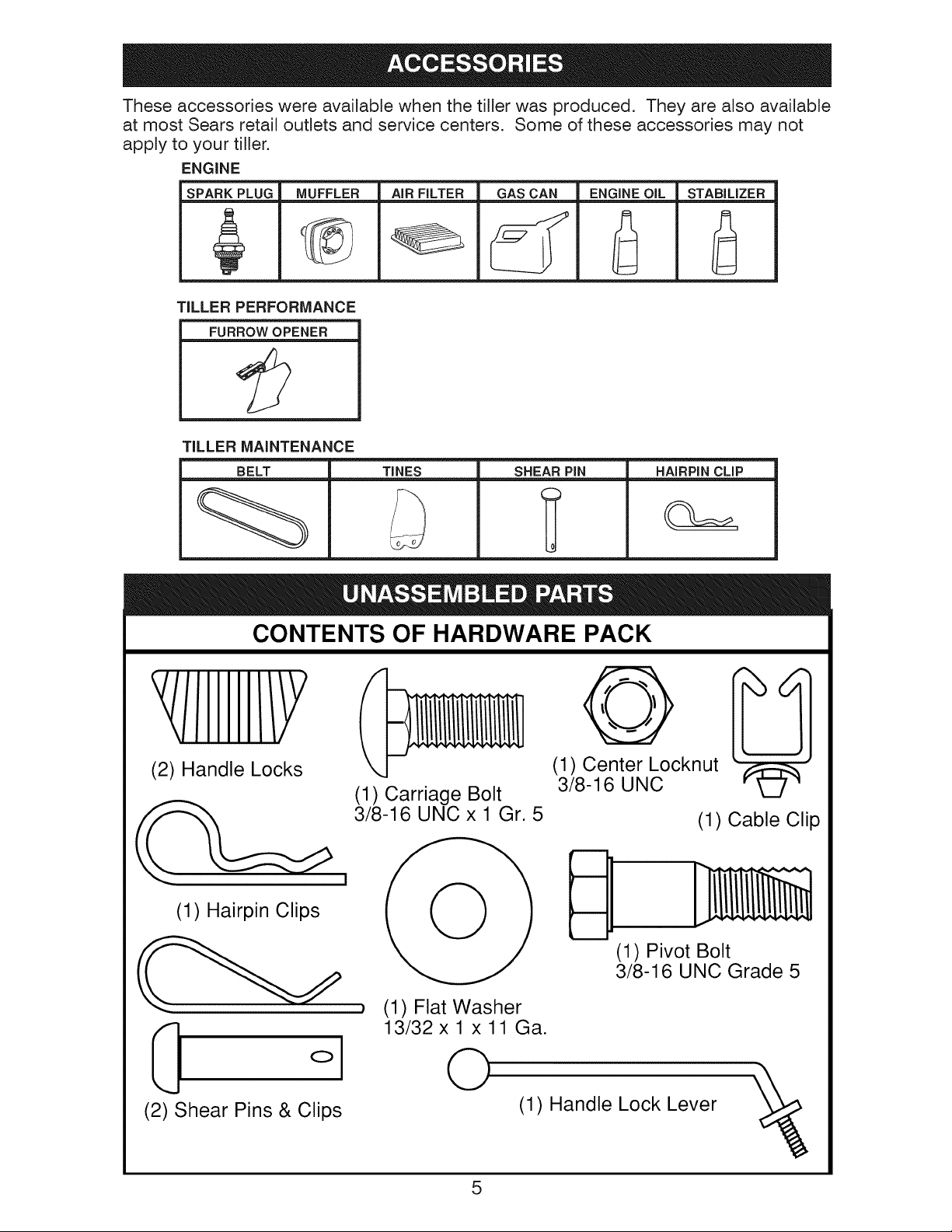

These accessories were available when the tiller was produced. They are also available

at most Sears retail outlets and service centers. Some of these accessories may not

apply to your tiller.

ENGINE

SPARK PLUG MUFFLER AIR FILTER GAS CAN ENGINE OIL STABILIZER

TILLER PERFORMANCE

FURROWOPENER

TILLER MAINTENANCE

BELT TINES SHEAR PiN

HAiRPiN CLiP

o

,I

CONTENTS OF HARDWARE PACK

(2) Handle Locks

(1) Hairpin Clips

(1) Carriage Bolt

3/8-16 UNC x 1 Gr. 5

(1) Flat Washer

13/32xlx11Ga.

o

@

(1) Center Locknut

3/8-16 UNC

(1) Cable Clip

(1) Pivot Bolt

3/8-16 UNC Grade 5

©

(2) Shear Pins & Clips

(1) Handle Lock Lever

5

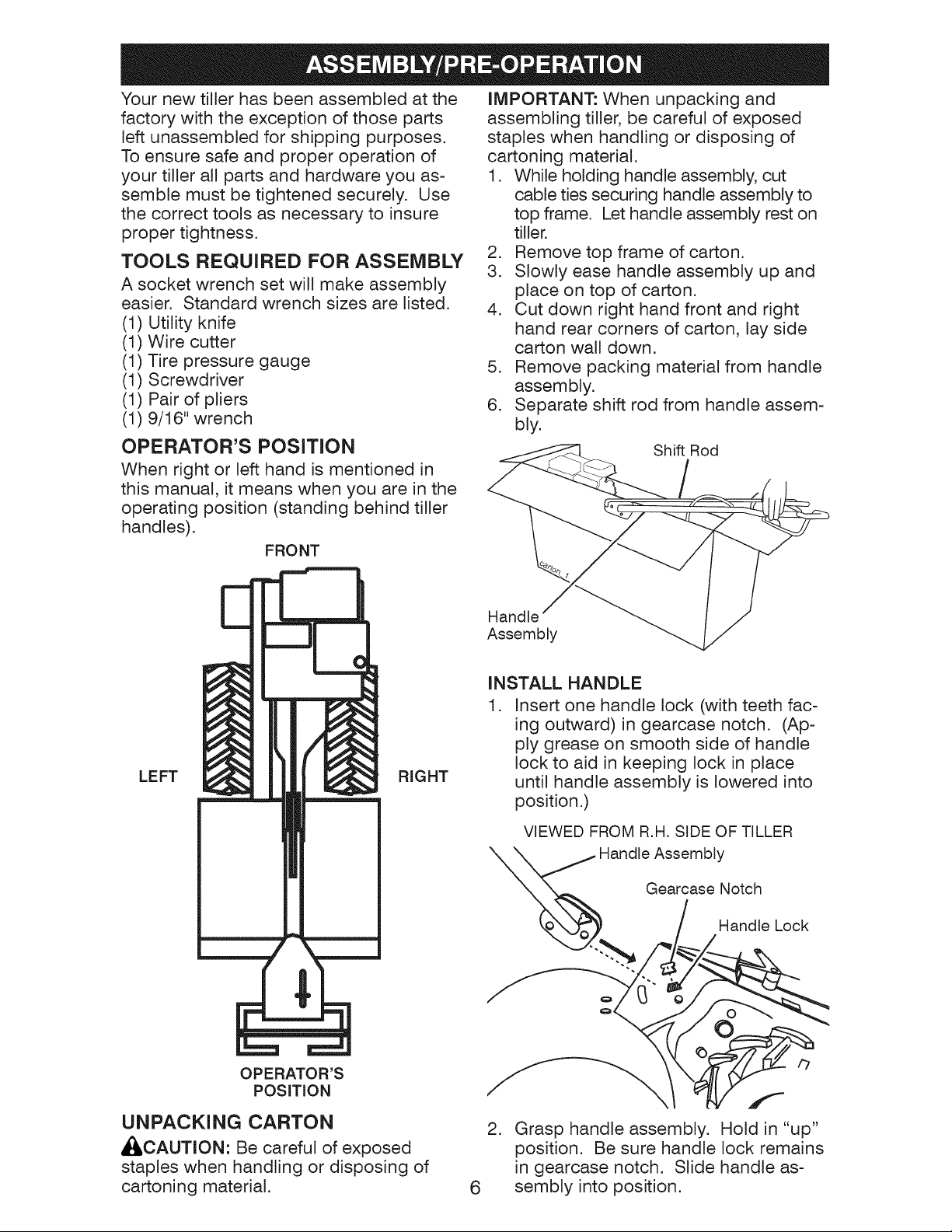

Your new tiller has been assembled at the

factory with the exception of those parts

left unassembled for shipping purposes.

To ensure safe and proper operation of

your tiller all parts and hardware you as-

semble must be tightened securely. Use

the correct tools as necessary to insure

proper tightness.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly

easier. Standard wrench sizes are listed.

(1) Utility knife

(1) Wire cutter

(1) Tire pressure gauge

(1) Screwdriver

(1) Pair of pliers

(1) 9/16" wrench

OPERATOR'S POSITION

When right or left hand is mentioned in

this manual, it means when you are in the

operating position (standing behind tiller

handles).

FRONT

IMPORTANT: When unpacking and

assembling tiller, be careful of exposed

staples when handling or disposing of

cartoning material.

1. While holding handle assembly, cut

cable ties securing handle assembly to

top frame. Let handle assembly rest on

tiller.

2. Remove top frame of carton.

3. Slowly ease handle assembly up and

place on top of carton.

4. Cut down right hand front and right

hand rear corners of carton, lay side

carton wall down.

5. Remove packing material from handle

assembly.

6. Separate shift rod from handle assem-

bly.

Shift Rod

LEFT RIGHT

Handle

Assembly

INSTALL HANDLE

.

Insert one handle lock (with teeth fac-

ing outward) in gearcase notch. (Ap-

ply grease on smooth side of handle

lock to aid in keeping lock in place

until handle assembly is lowered into

position.)

VIEWED FROM R.H. SIDE OF TILLER

Handle Assembly

Gearcase Notch

Handle Lock

OPERATOR'S

POSITION

UNPACKING CARTON

,_CAUTION: Be careful of exposed

staples when handling or disposing of

cartoning material.

.

Grasp handle assembly. Hold in "up"

position. Be sure handle lock remains

in gearcase notch. Slide handle as-

6

sembly into position.

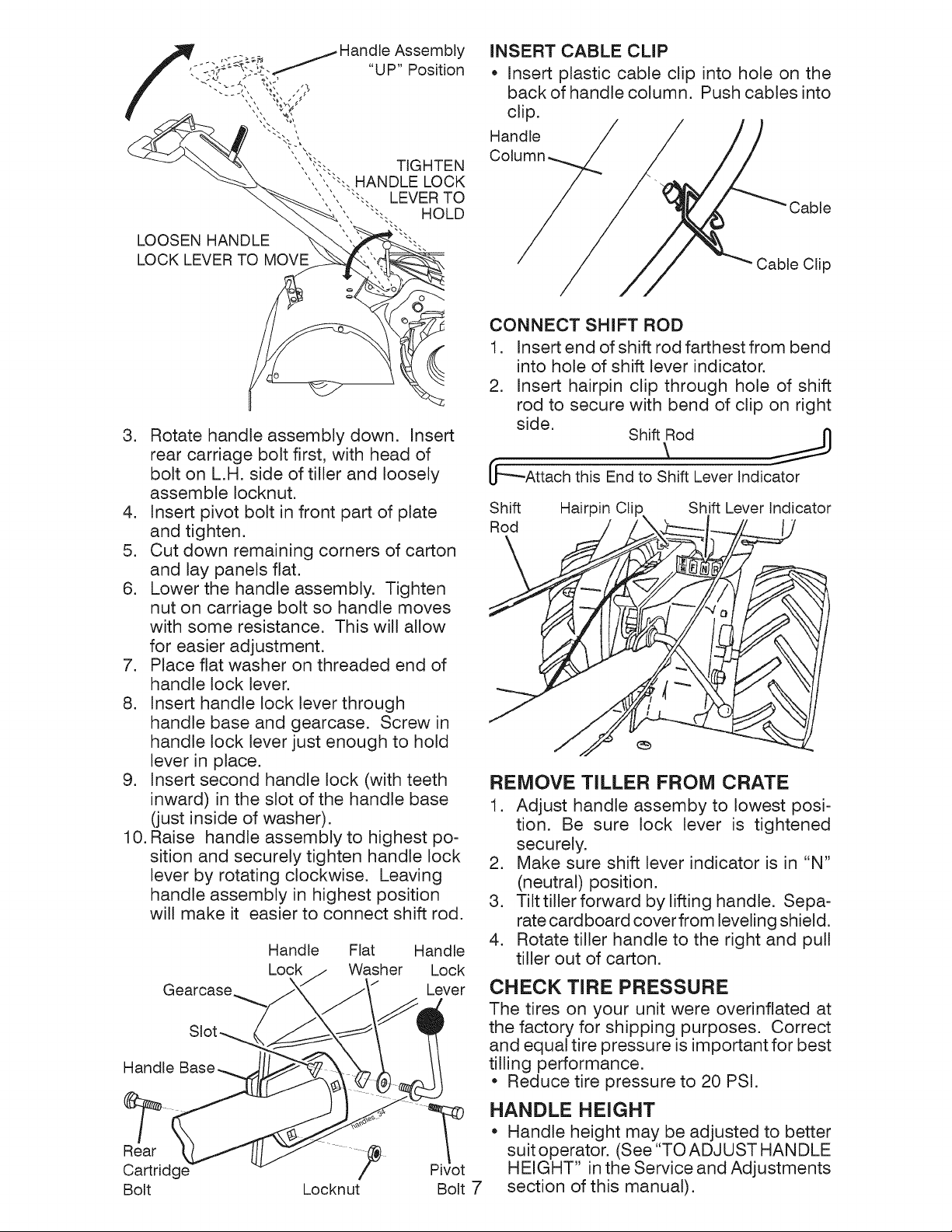

3. Rotate handle assembly down. Insert

rear carriage bolt first, with head of

bolt on L.H. side of tiller and loosely

assemble Iocknut.

4. Insert pivot bolt in front part of plate

and tighten.

5. Cut down remaining corners of carton

and lay panels flat.

6. Lower the handle assembly. Tighten

nut on carriage bolt so handle moves

with some resistance. This will allow

for easier adjustment.

7. Place flat washer on threaded end of

handle lock lever.

8. Insert handle lock lever through

handle base and gearcase. Screw in

handle lock lever just enough to hold

lever in place.

9. Insert second handle lock (with teeth

inward) in the slot of the handle base

(just inside of washer).

10. Raise handle assembly to highest po-

sition and securely tighten handle lock

lever by rotating clockwise. Leaving

handle assembly in highest position

will make it easier to connect shift rod.

Handle Flat Handle

Lock Washer Lock

Gearcase

Lever

Handle

Rear

Cartridge

Bolt

" '_ Pivot

Locknut Bolt 7

INSERT CABLE CLIP

o

Insert plastic cable clip into hole on the

back of handle column. Push cables into

clip,

Sable

Hoalu__ndle /

Cable Clip

CONNECT SHIFT ROD

1. Insert end of shift rod farthest from bend

into hole of shift lever indicator.

2. Insert hairpin clip through hole of shift

rod to secure with bend of clip on right

side.

Shift Rod

0--_Attach this End to Shift Lever Indicator

Shift Hairpin

Shift Lever Indicator

Rod

REMOVE TILLER FROM CRATE

1. Adjust handle assemby to lowest posi-

tion. Be sure lock lever is tightened

securely.

2. Make sure shift lever indicator is in "N"

(neutral) position.

3. Tilt tiller forward by lifting handle. Sepa-

rate cardboard cover from leveling shield.

4. Rotate tiller handle to the right and pull

tiller out of carton.

CHECK TIRE PRESSURE

The tires on your unit were overinflated at

the factory for shipping purposes. Correct

and equal tire pressure is important for best

tilling performance.

• Reduce tire pressure to 20 PSI.

HANDLE HEIGHT

• Handle height may be adjusted to better

suit operator. (See "TO ADJUST HANDLE

HEIGHT" in the Service and Adjustments

section of this manual).

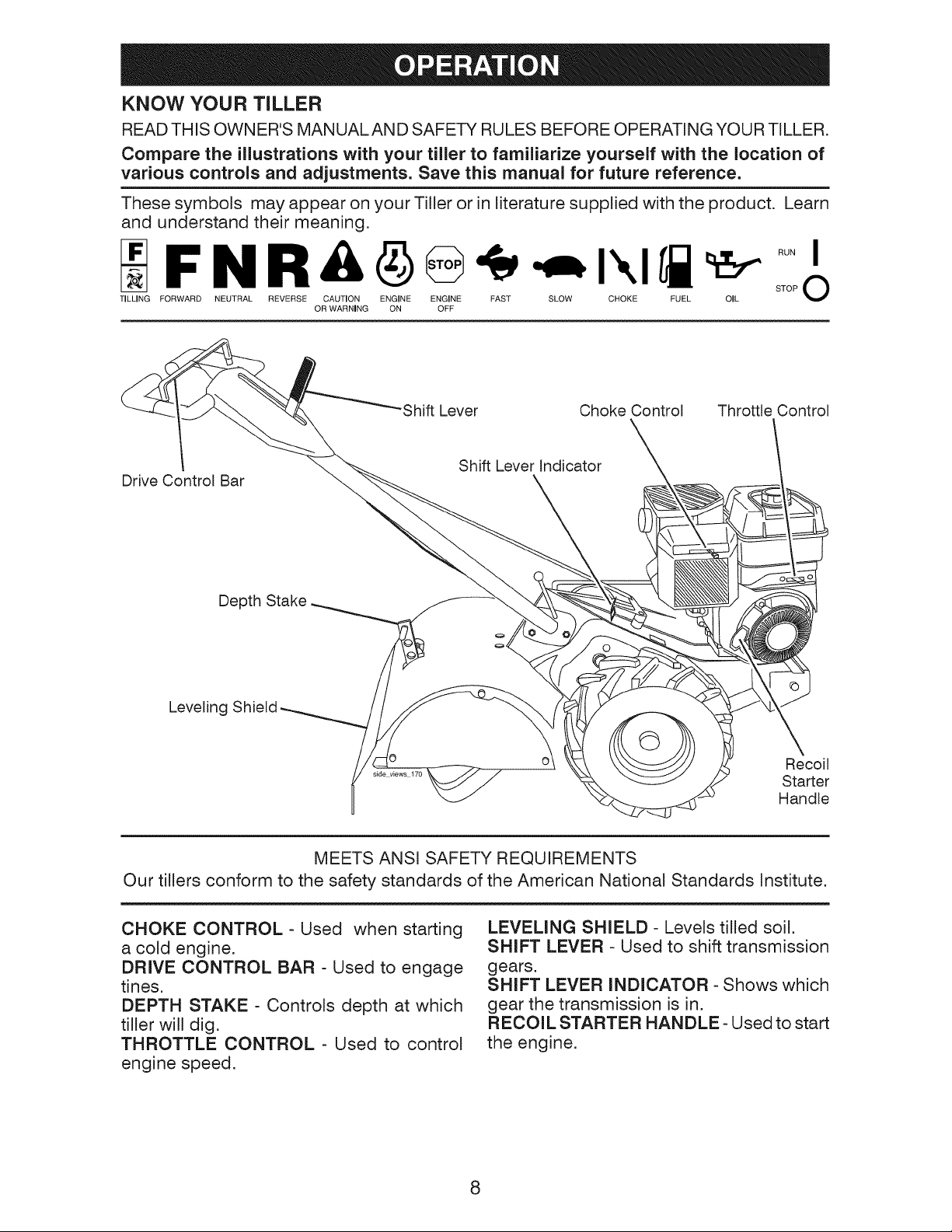

KNOW YOUR TILLER

READ THIS OWNER'S MANUALAND SAFETY RULES BEFORE OPERATING YOUR TILLER.

Compare the illustrations with your tiller to familiarize yourself with the location of

various controls and adjustments. Save this manual for future reference.

These symbols may appear on your Tiller or in literature supplied with the product. Learn

and understand their meaning,

F N

TILLING FORWARD NEUTRAL REVERSE CAUTION ENGINE ENGINE FAST SLOW CHOKE FUEL OIL STOP

Drive Control Bar

OR WARNING ON OFF

'Shift Lever Choke Control Throttle Control

Shift Lever Indicator

Depth Stake

Leveling

Recoil

Starter

Handle

MEETS ANSI SAFETY REQUIREMENTS

Our tillers conform to the safety standards of the American National Standards Institute.

CHOKE CONTROL - Used when starting

a cold engine.

DRIVE CONTROL BAR - Used to engage

tines,

DEPTH STAKE - Controls depth at which

tiller will dig.

THROTTLE CONTROL - Used to control

engine speed.

LEVELING SHIELD - Levels tilled soil.

SHIFT LEVER - Used to shift transmission

gears.

SHIFT LEVER INDICATOR - Shows which

gear the transmission is in.

RECOIL STARTER HANDLE- Used to start

the engine.

8

The operation of any tiller can result in foreign objects thrown into the eyes,

which can result in severe eye damage. Always wear safety glasses or eye

shields before starting your tiller and while tilling. We recommend a wide vision

safety mask over spectacles or standard safety glasses.

HOW TO USE YOUR TILLER

Know how to operate all controls before

adding fuel and oil or attempting to start

engine.

STOPPING

TINES AND DRIVE

1. Release drive control bar to stop

movement.

2. Move shift lever to "N" (neutral) posi-

tion.

ENGINE

• Move throttle control to "STOP" posi-

tion. If equipped with stop switch, move

switch to "STOP" position.

NOTE: Never use choke to stop engine.

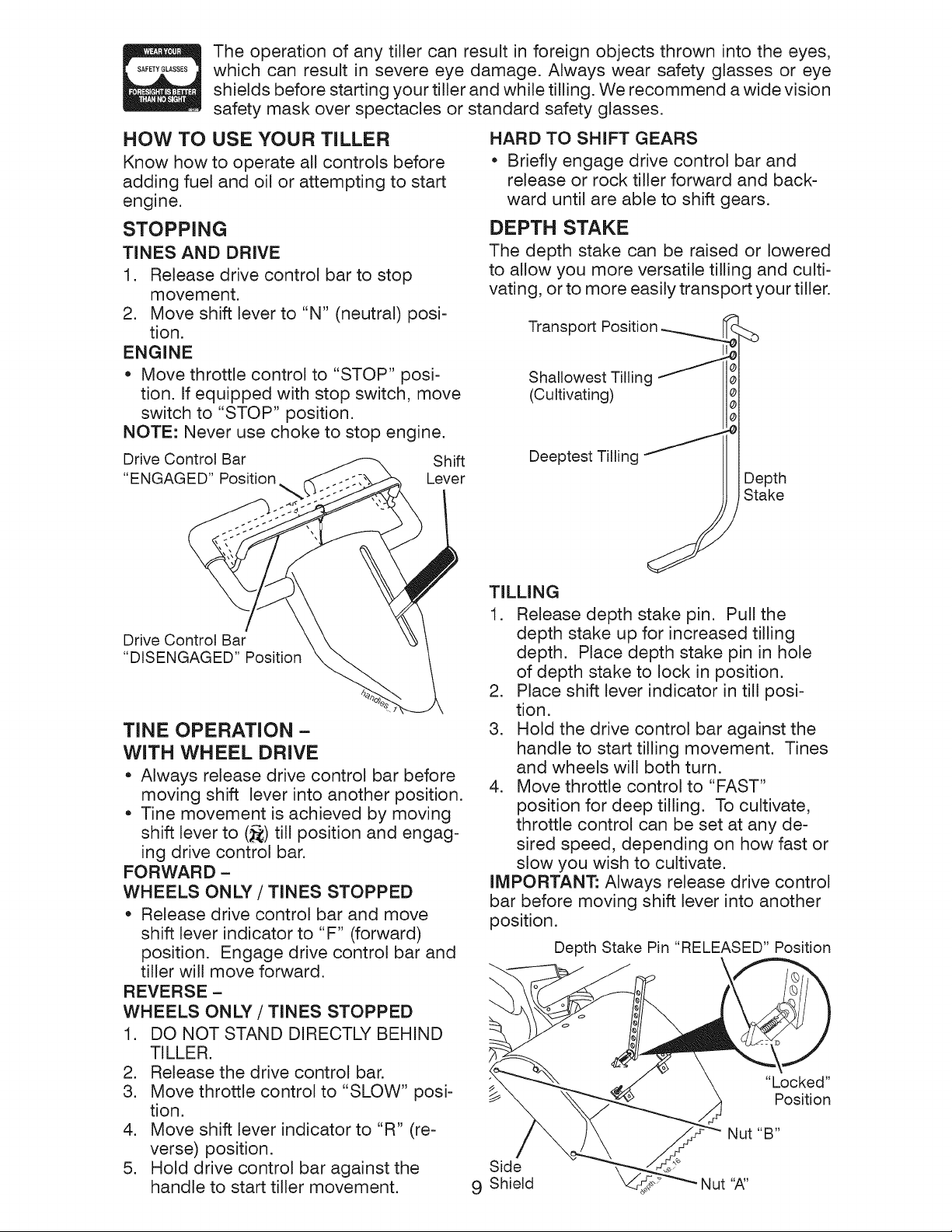

Drive Control Bar Shift

"ENGAGED" Position ,_ Lever

HARD TO SHIFT GEARS

• Briefly engage drive control bar and

release or rock tiller forward and back-

ward until are able to shift gears.

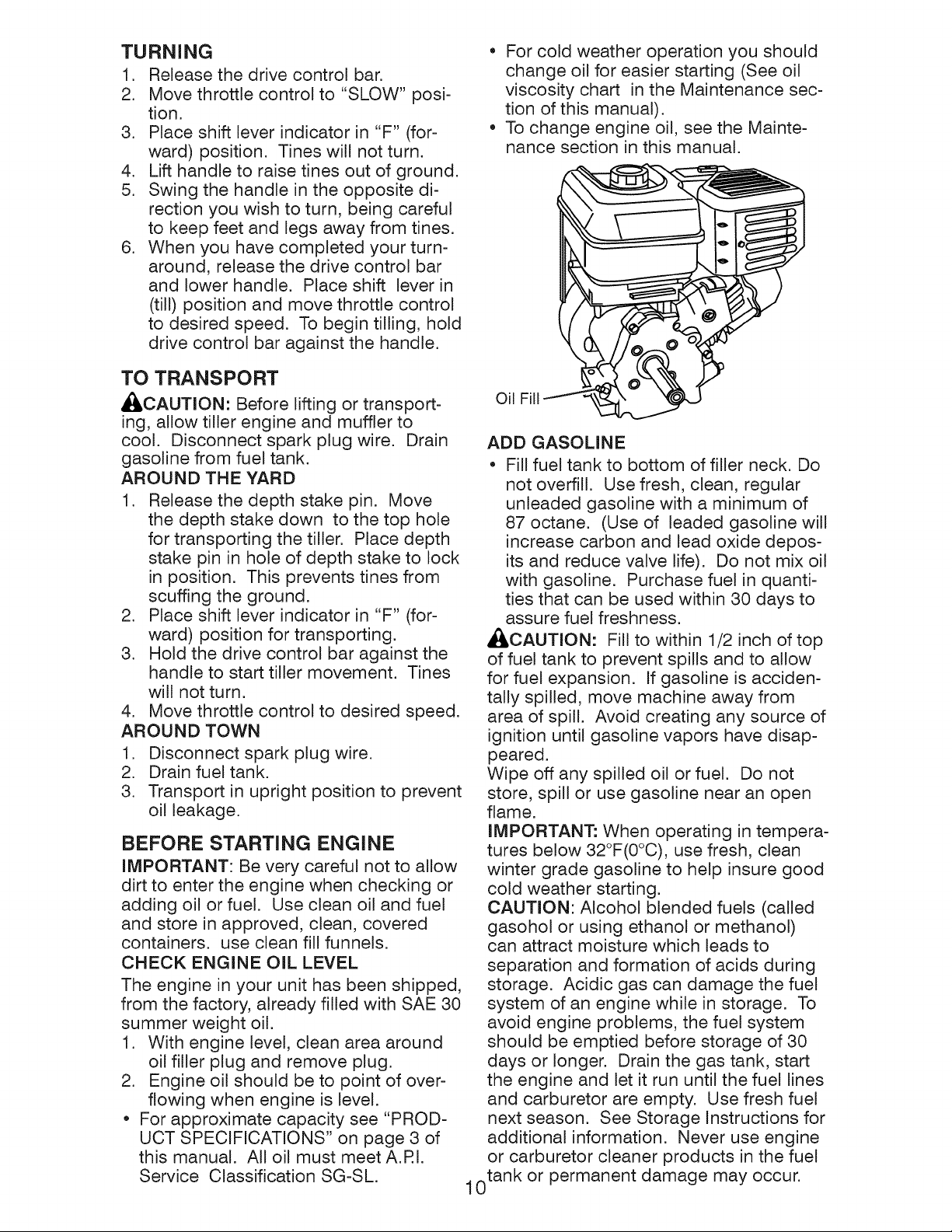

DEPTH STAKE

The depth stake can be raised or lowered

to allow you more versatile tilling and culti-

vating, or to more easily transport your tiller.

Transport Position _._

Shallowest Tilling ._

(Cultivating)

Deeptest Tilling

Depth

Stake

Drive Control Bar

"DISENGAGED" Position

TINE OPERATION -

WiTH WHEEL DRIVE

• Always release drive control bar before

moving shift lever into another position.

• Tine movement is achieved by moving

shift lever to (_) till position and engag-

ing drive control bar.

FORWARD -

WHEELS ONLY / TINES STOPPED

• Release drive control bar and move

shift lever indicator to "F" (forward)

position. Engage drive control bar and

tiller will move forward.

REVERSE -

WHEELS ONLY / TINES STOPPED

1. DO NOT STAND DIRECTLY BEHIND

TILLER.

2. Release the drive control bar,

3. Move throttle control to "SLOW" posi-

tion.

4. Move shift lever indicator to "R" (re-

verse) position.

5. Hold drive control bar against the

handle to start tiller movement.

TILLING

1. Release depth stake pin. Pull the

depth stake up for increased tilling

depth. Place depth stake pin in hole

of depth stake to lock in position.

2. Place shift lever indicator in till posi-

tion.

3. Hold the drive control bar against the

handle to start tilling movement. Tines

and wheels will both turn.

4. Move throttle control to "FAST"

position for deep tilling. To cultivate,

throttle control can be set at any de-

sired speed, depending on how fast or

slow you wish to cultivate.

IMPORTANT: Always release drive control

bar before moving shift lever into another

position.

Depth Stake Pin "RELEASED" Position

\

"Locked"

Position

Nut "B"

Side \

9 Shield "A"

TURNING

1. Release the drive control bar.

2. Move throttle control to "SLOW" posi-

tion.

3. Place shift lever indicator in "F" (for-

ward) position. Tines will not turn.

4. Lift handle to raise tines out of ground.

5. Swing the handle in the opposite di-

rection you wish to turn, being careful

to keep feet and legs away from tines.

6. When you have completed your turn-

around, release the drive control bar

and lower handle. Place shift lever in

(till) position and move throttle control

to desired speed. To begin tilling, hold

drive control bar against the handle.

TO TRANSPORT

,ACAUTION: Before lifting or transport-

ing, allow tiller engine and muffler to

cool. Disconnect spark plug wire. Drain

gasoline from fuel tank.

AROUND THE YARD

1. Release the depth stake pin. Move

the depth stake down to the top hole

for transporting the tiller. Place depth

stake pin in hole of depth stake to lock

in position. This prevents tines from

scuffing the ground.

2. Place shift lever indicator in "F" (for-

ward) position for transporting.

3. Hold the drive control bar against the

handle to start tiller movement. Tines

will not turn.

4. Move throttle control to desired speed.

AROUND TOWN

1. Disconnect spark plug wire.

2. Drain fuel tank.

3. Transport in upright position to prevent

oil leakage.

BEFORE STARTING ENGINE

IMPORTANT: Be very careful not to allow

dirt to enter the engine when checking or

adding oil or fue!. Use clean oil and fuel

and store in approved, clean, covered

containers, use clean fill funnels.

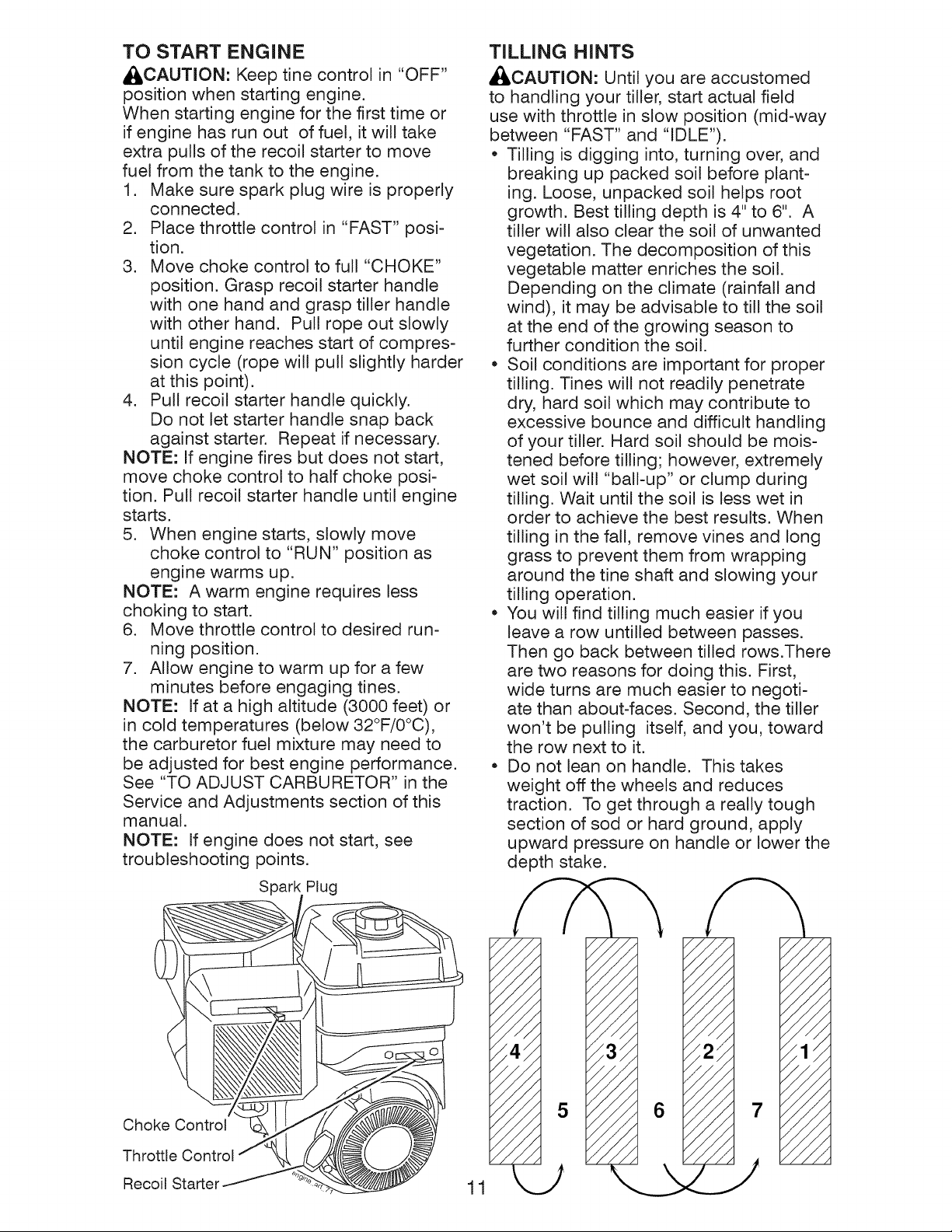

CHECK ENGINE OIL LEVEL

The engine in your unit has been shipped,

from the factory, already filled with SAE 30

summer weight oil.

1. With engine level, clean area around

oil filler plug and remove plug.

2. Engine oil should be to point of over-

flowing when engine is level.

For approximate capacity see "PROD-

UCT SPECIFICATIONS" on page 3 of

this manual. Atl oil must meetA.RI.

Service Classification SG-SL

For cold weather operation you should

change oil for easier starting (See oil

viscosity chart in the Maintenance sec-

tion of this manual).

To change engine oil, see the Mainte-

nance section in this manual.

Oil

ADD GASOLINE

Fill fuel tank to bottom of filler neck. Do

not overfill. Use fresh, clean, regular

unleaded gasoline with a minimum of

87 octane. (Use of leaded gasoline will

increase carbon and lead oxide depos-

its and reduce valve life). Do not mix oil

with gasoline. Purchase fuel in quanti-

ties that can be used within 30 days to

assure fuel freshness.

_:_CAUTION: Fill to within 1/2 inch of top

of fuel tank to prevent spills and to allow

for fuel expansion. If gasoline is acciden-

tally spilled, move machine away from

area of spill. Avoid creating any source of

ignition until gasoline vapors have disap-

peared.

Wipe off any spilled oil or fuel. Do not

store, spill or use gasoline near an open

flame.

IMPORTANT: When operating in tempera-

tures below 32°F(0°C), use fresh, clean

winter grade gasoline to help insure good

cold weather starting.

CAUTION: Alcohol blended fuels (called

gasohol or using ethanol or methanol)

can attract moisture which leads to

separation and formation of acids during

storage. Acidic gas can damage the fuel

system of an engine while in storage. To

avoid engine problems, the fuel system

should be emptied before storage of 30

days or longer. Drain the gas tank, start

the engine and let it run until the fuel lines

and carburetor are empty. Use fresh fuel

next season. See Storage Instructions for

additional information. Never use engine

or carburetor cleaner products in the fuel

0tank or permanent damage may occur.

1

TO START ENGINE

_CAUTION: Keep tine control in "OFF"

position when starting engine.

When starting engine for the first time or

if engine has run out of fuel, it will take

extra pulls of the recoil starter to move

fuel from the tank to the engine.

1. Make sure spark plug wire is properly

connected.

2. Place throttle control in "FAST" posi-

tion.

3. Move choke control to full "CHOKE"

position. Grasp recoil starter handle

with one hand and grasp tiller handle

with other hand. Pull rope out slowly

until engine reaches start of compres-

sion cycle (rope will pull slightly harder

at this point).

4. Pull recoil starter handle quickly.

Do not let starter handle snap back

against starter. Repeat if necessary.

NOTE: If engine fires but does not start,

move choke control to half choke posi-

tion. Pull recoil starter handle until engine

starts.

5. When engine starts, slowly move

choke control to "RUN" position as

engine warms up.

NOTE: A warm engine requires less

choking to start.

6. Move throttle control to desired run-

ning position.

7. Allow engine to warm up for a few

minutes before engaging tines.

NOTE: If at a high altitude (3000 feet) or

in cold temperatures (below 32°F/0°C),

the carburetor fuel mixture may need to

be adjusted for best engine performance.

See "TO ADJUST CARBURETOR" in the

Service and Adjustments section of this

manual.

NOTE: If engine does not start, see

troubleshooting points.

Spark Plug

TILLING HINTS

_CAUTION: Until you are accustomed

to handling your tiller, start actual field

use with throttle in slow position (mid-way

between "FAST" and "IDLE").

• Tilling is digging into, turning over, and

breaking up packed soil before plant-

ing. Loose, unpacked soil helps root

growth. Best tilling depth is 4" to 6". A

tiller will also clear the soil of unwanted

vegetation. The decomposition of this

vegetable matter enriches the soil.

Depending on the climate (rainfall and

wind), it may be advisable to till the soil

at the end of the growing season to

further condition the soil.

• Soil conditions are important for proper

tilling. Tines will not readily penetrate

dry, hard soil which may contribute to

excessive bounce and difficult handling

of your tiller. Hard soil should be mois-

tened before tilling; however, extremely

wet soil will "ball-up" or clump during

tilling. Wait until the soil is less wet in

order to achieve the best results. When

tilling in the fall, remove vines and long

grass to prevent them from wrapping

around the tine shaft and slowing your

tilling operation.

• You will find tilling much easier if you

leave a row untilled between passes.

Then go back between tilled rows.There

are two reasons for doing this. First,

wide turns are much easier to negoti-

ate than about-faces. Second, the tiller

won't be pulling itself, and you, toward

the row next to it.

• Do not lean on handle. This takes

weight off the wheels and reduces

traction. To get through a really tough

section of sod or hard ground, apply

upward pressure on handle or lower the

depth stake.

Choke Control

Throttle

Recoil

// i/t

J/' //_

11

CU LTIVATI NG

Cultivating is destroying the weeds

between rows to prevent them from rob-

bing nourishment and moisture from the

plants. At the same time, breaking up the

upper layer of soil crust will help retain

moisture in the soil. Best digging depth is

1" to 3" (2.5-7.5 cm).

• Cultivate up and down the rows at a

speed which will allow tines to uproot

weeds and leave the ground in rough

condition, promoting no further growth

of weeds and grass.

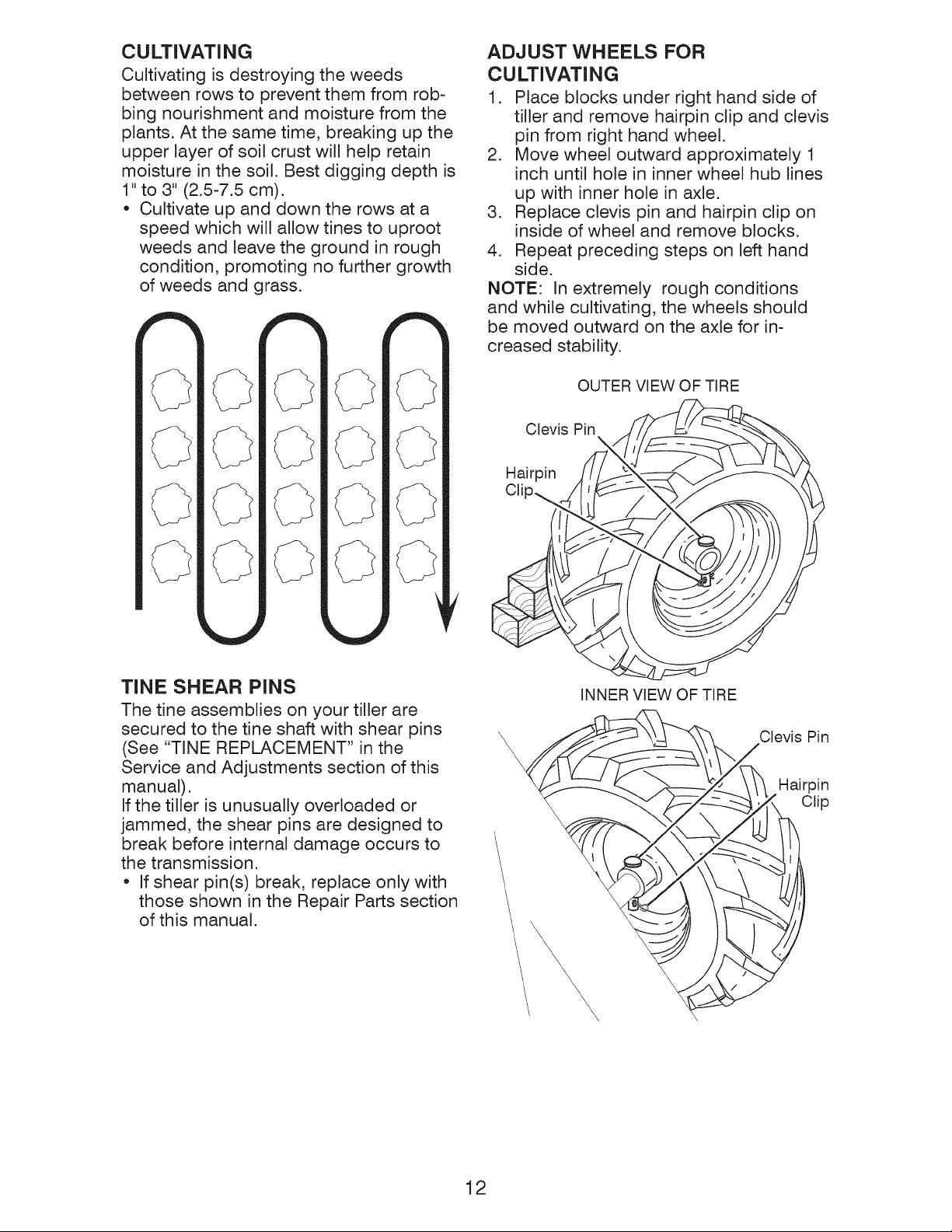

ADJUST WHEELS FOR

CU LTIVATI NG

1. Place blocks under right hand side of

tiller and remove hairpin clip and clevis

pin from right hand wheel.

2. Move wheel outward approximately 1

inch until hole in inner wheel hub lines

up with inner hole in axle.

3. Replace clevis pin and hairpin clip on

inside of wheel and remove blocks.

4. Repeat preceding steps on left hand

side.

NOTE: In extremely rough conditions

and while cultivating, the wheels should

be moved outward on the axle for in-

creased stability.

OUTER VIEW OF TIRE

Clevis Pin

Hairpin

Clip._

TINE SHEAR PINS

The tine assemblies on your tiller are

secured to the tine shaft with shear pins

(See "TINE REPLACEMENT" in the

Service and Adjustments section of this

manual).

If the tiller is unusually overloaded or

jammed, the shear pins are designed to

break before internal damage occurs to

the transmission.

• If shear pin(s) break, replace only with

those shown in the Repair Parts section

of this manual.

/

INNER VIEW OF TIRE

Clevis Pin

\

Hairpin

Clip

\

\

\

12

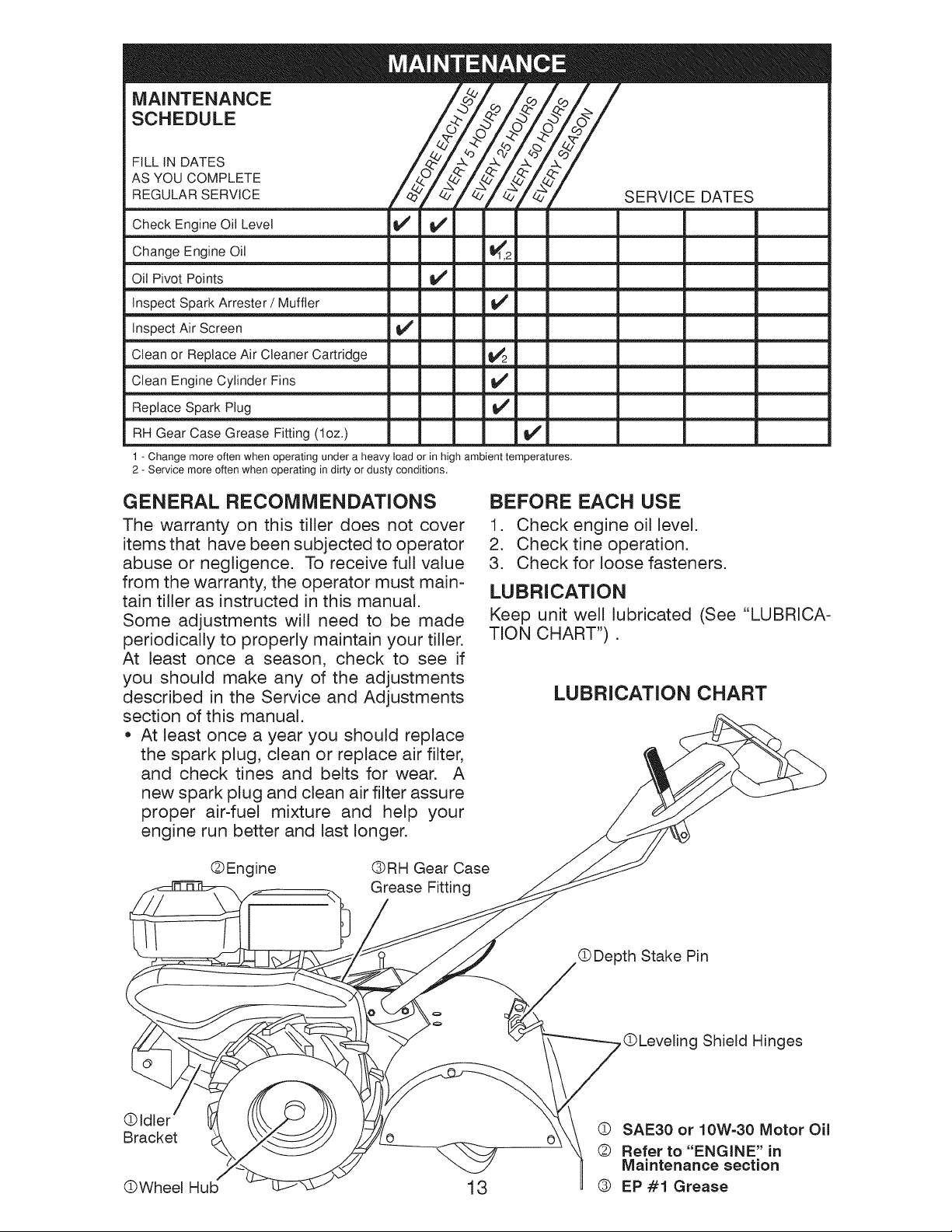

MAINTENANCE /_/,_ _/ /

F,LL,.OATES

REGULAR SERVICE _4/ z4/ z4/ z4/ z,_

Check Engine Oil Level

Change Engine Oil

Oil Pivot Points

Inspect Spark Arrester / Muffler

Inspect Air Screen

Clean or Replace Air Cleaner Cartridge

Clean Engine Cylinder Fins

Replace Spark Plug

RH Gear Case Grease Fitting (1oz.)

1 - Change more often when operating under a heavy load or in high ambient temperatures.

2 - Service more often when operating in dirty or dusty conditions.

GENERAL RECOMMENDATIONS

The warranty on this tiller does not cover

items that have been subjected to operator

abuse or negligence. To receive full value

from the warranty, the operator must main-

tain tiller as instructed in this manual.

Some adjustments will need to be made

periodically to properly maintain your tiller.

At least once a season, check to see if

you should make any of the adjustments

described in the Service and Adjustments

section of this manual.

• At least once a year you should replace

the spark plug, clean or replace air filter,

and check tines and belts for wear. A

new spark plug and clean air filter assure

proper air-fue! mixture and help your

engine run better and last longer.

v'

v'

v'

v"

v'

v'

BEFORE EACH USE

1. Check engine oil level.

2. Check tine operation.

3. Check for loose fasteners.

LUBRiCATiON

Keep unit well lubricated (See "LUBRICA-

TION CHART") .

SERVICE DATES

LUBRiCATiON CHART

Oldler

Bracket

OWheel Hub

QEngine ®RH Gear Case

Grease Fitting

\

13

ODepth Stake Pin

OLeveling Shield Hinges

O SAE30 or 10W=30 Motor Oil

Q Refer to "ENGINE" in

Maintenance section

Q EP #1 Grease

_CAUTION: Disconnect spark plug

wire before performing any maintenance

(except carburetor adjustment) to prevent

accidental starting of engine.

Prevent fires! Keep the engine free of

grass, leaves, spilled oil, or fuel. Remove

fuel from tank before tipping unit for main-

tenance. Clean muffler area of all grass,

dirt, and debris.

Do not touch hot muffler or cylinder fins

as contact may cause burns.

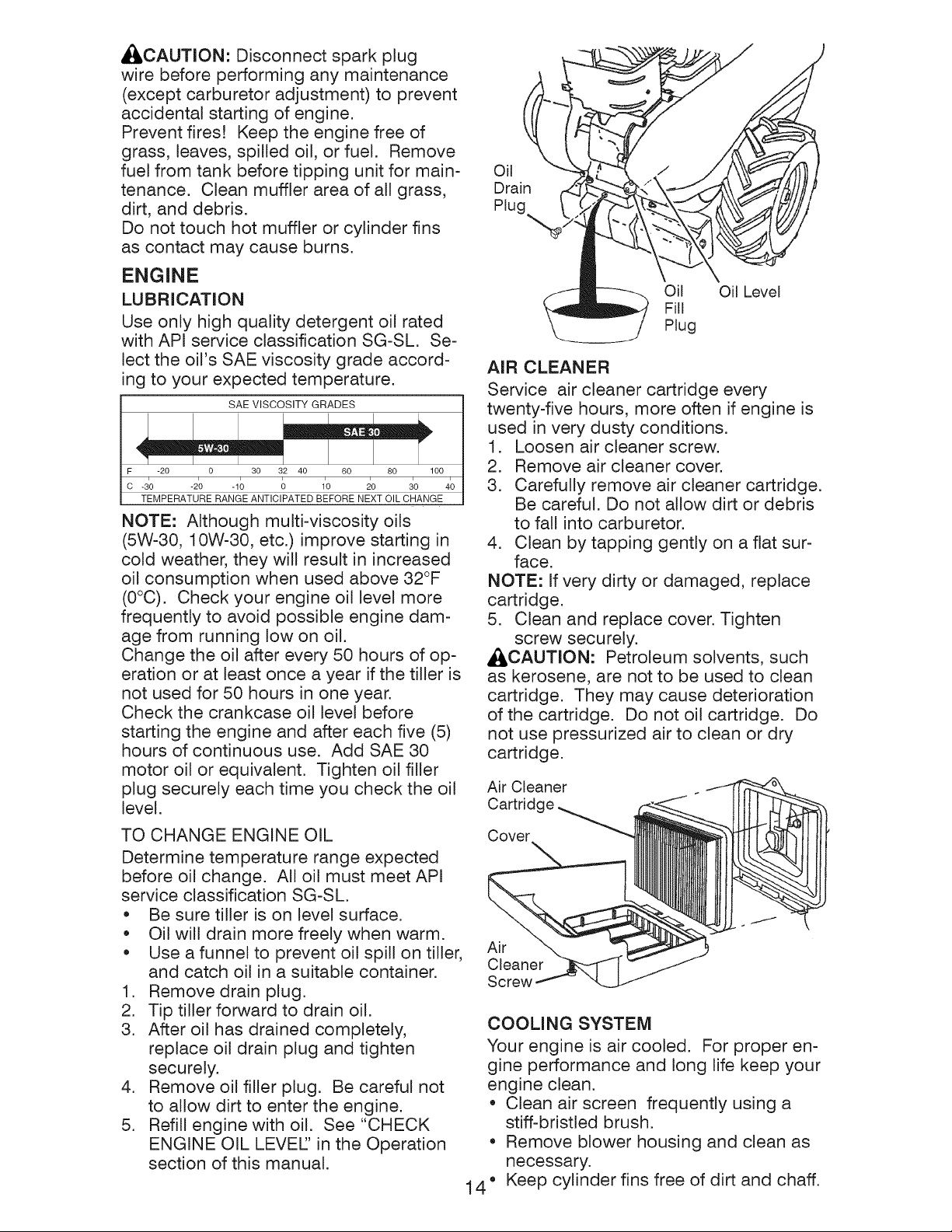

ENGINE

LUBRiCATiON

Use only high quality detergent oil rated

with API service classification SG-SL Se-

lect the oil's SAE viscosity grade accord-

ing to your expected temperature.

SAE VISCOSITY GRADES

F -20 0 30 32 40 60 80 100

c -do -_ -1_ o ;o do do 4o

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

NOTE: Although multi-viscosity oils

(5W-30, 10W-30, etc.) improve starting in

cold weather, they will result in increased

oil consumption when used above 32°F

(0°C). Check your engine oil level more

frequently to avoid possible engine dam-

age from running low on oil.

Change the oil after every 50 hours of op-

eration or at least once a year if the tiller is

not used for 50 hours in one year.

Check the crankcase oil level before

starting the engine and after each five (5)

hours of continuous use. Add SAE 30

motor oil or equivalent. Tighten oil filler

plug securely each time you check the oil

level.

TO CHANGE ENGINE OIL

Determine temperature range expected

before oil change. All oil must meet API

service classification SG-SL

• Be sure tiller is on level surface.

• Oil will drain more freely when warm.

• Use a funnel to prevent oil spill on tiller,

and catch oil in a suitable container.

1. Remove drain plug.

2. Tip tiller forward to drain oil.

3. After oil has drained completely,

replace oil drain plug and tighten

securely.

4. Remove oil filler plug. Be careful not

to allow dirt to enter the engine.

5. Refill engine with oil. See "CHECK

ENGINE OIL LEVEL' in the Operation

section of this manual.

Oil

Drain

Plug

Oil Oil Level

Fill

Plug

AiR CLEANER

Service air cleaner cartridge every

twenty-five hours, more often if engine is

used in very dusty conditions.

1. Loosen air cleaner screw.

2. Remove air cleaner cover.

3. Carefully remove air cleaner cartridge.

Be careful. Do not allow dirt or debris

to fall into carburetor.

4. Clean by tapping gently on a flat sur-

face.

NOTE: If very dirty or damaged, replace

cartridge.

5. Clean and replace cover. Tighten

screw securely.

_ILCAUTION: Petroleum solvents, such

as kerosene, are not to be used to clean

cartridge. They may cause deterioration

of the cartridge. Do not oil cartridge. Do

not use pressurized air to clean or dry

cartridge.

Air Cleaner

Cartrid(

Cover

Air

Cleaner

Screw

COOLING SYSTEM

Your engine is air cooled. For proper en-

gine performance and long life keep your

engine clean.

• Clean air screen frequently using a

stiff-bristled brush.

• Remove blower housing and clean as

necessary,

• Keep cylinder fins free of dirt and chaff.

14

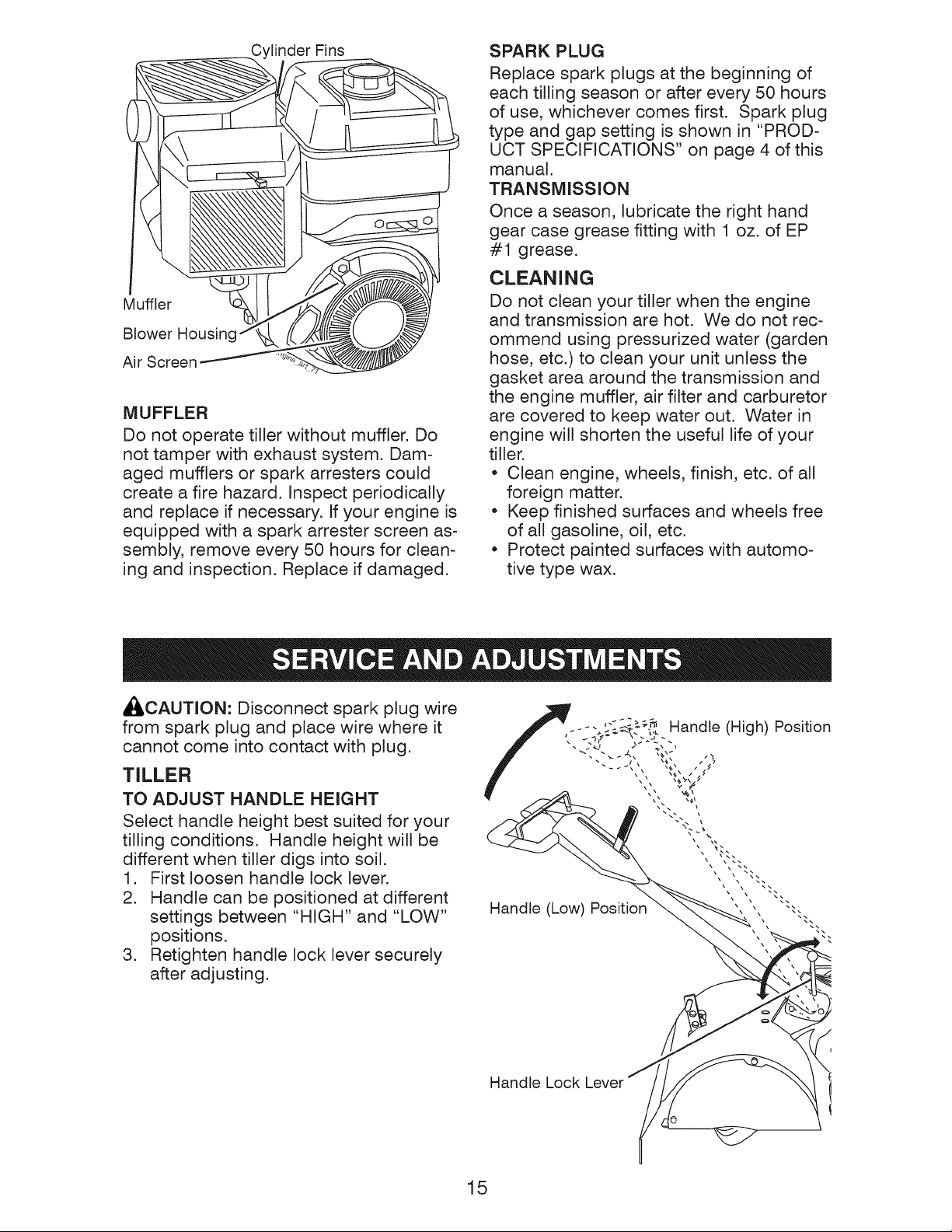

'linder Fins

Muffler

Blower Housing

Air Screen

MUFFLER

Do not operate tiller without muffler. Do

not tamper with exhaust system. Dam-

aged mufflers or spark arresters could

create a fire hazard. Inspect periodically

and replace if necessary. If your engine is

equipped with a spark arrester screen as-

sembly, remove every 50 hours for clean-

ing and inspection. Replace if damaged.

SPARK PLUG

Replace spark plugs at the beginning of

each tilling season or after every 50 hours

of use, whichever comes first. Spark plug

type and gap setting is shown in "PROD-

UCT SPECIFICATIONS" on page 4 of this

manual.

TRANSMISSION

Once a season, lubricate the right hand

gear case grease fitting with 1 oz. of EP

#1 grease.

CLEANING

Do not clean your tiller when the engine

and transmission are hot. We do not rec-

ommend using pressurized water (garden

hose, etc.) to clean your unit unless the

gasket area around the transmission and

the engine muffler, air filter and carburetor

are covered to keep water out. Water in

engine will shorten the useful life of your

tiller.

* Clean engine, wheels, finish, etc. of all

foreign matter.

* Keep finished surfaces and wheels free

of all gasoline, oil, etc.

* Protect painted surfaces with automo-

tive type wax.

_CAUTION: Disconnect spark plug wire

from spark plug and place wire where it

cannot come into contact with plug.

TILLER

TO ADJUST HANDLE HEIGHT

Select handle height best suited for your

tilling conditions. Handle height will be

different when tiller digs into soil.

1. First loosen handle lock lever.

2. Handle can be positioned at different

settings between "HIGH" and "LOW"

positions.

3. Retighten handle lock lever securely

after adjusting.

Handle (Low) Position

Handle Lock Lever

15

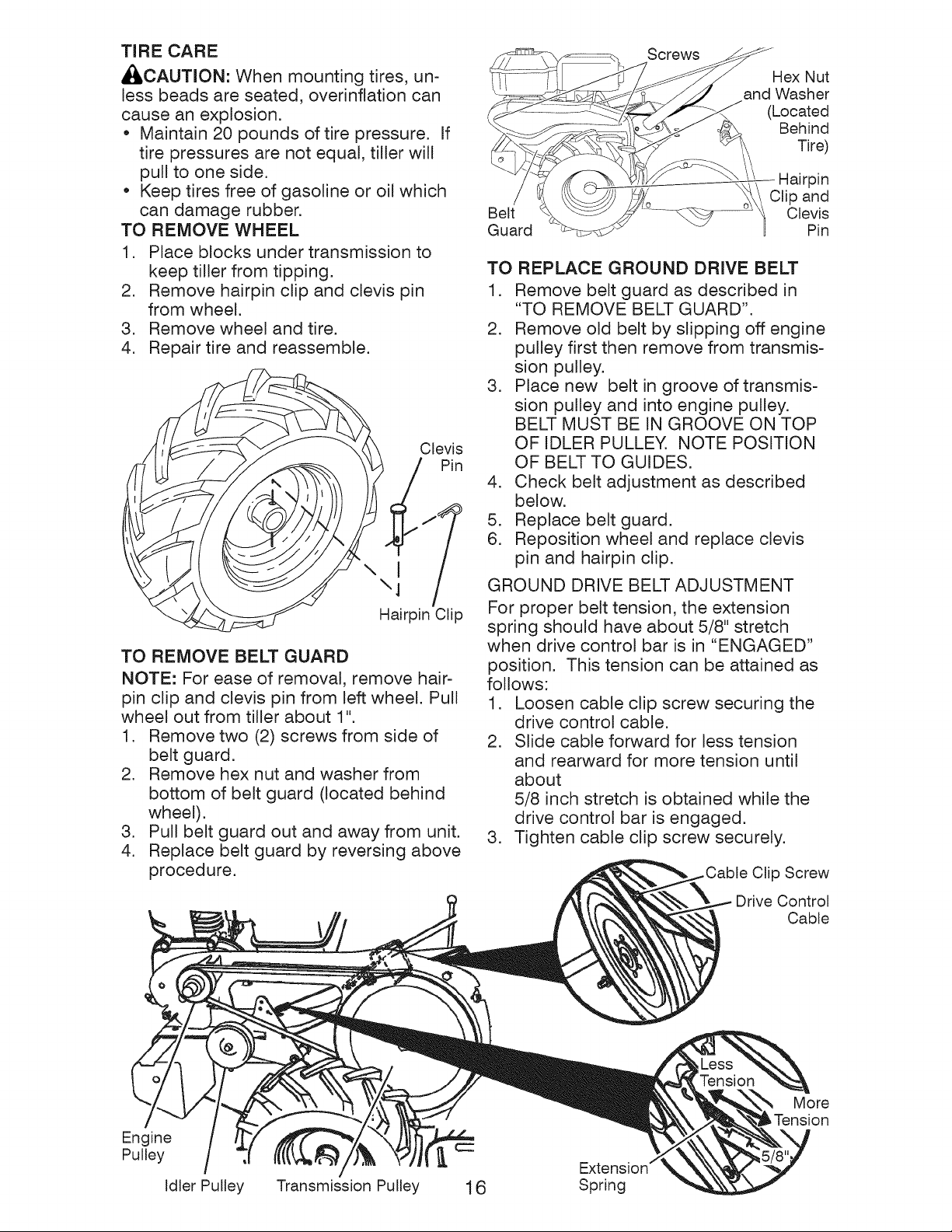

TiRE CARE

_,CAUTION: When mounting tires, un-

less beads are seated,overinfiationcan

causean explosion.

• Maintain 20 pounds of tire pressure. If

tire pressures are not equal, tiller will

pull to one side.

• Keep tires free of gasoline or oil which

can damage rubber.

TO REMOVE WHEEL

1. Place blocks under transmission to

keep tiller from tipping.

2. Remove hairpin clip and clevis pin

from wheel.

3. Remove wheel and tire.

4. Repair tire and reassemble.

Clevis

Hairpin Clip

TO REMOVE BELT GUARD

NOTE: For ease of removal, remove hair-

pin clip and clevis pin from left wheel. Pull

wheel out from tiller about 1"

1. Remove two (2) screws from side of

belt guard.

2. Remove hex nut and washer from

bottom of belt guard (located behind

wheel).

3. Pull belt guard out and away from unit.

4. Replace belt guard by reversing above

procedure.

Pin

Screws

Hex Nut

and Washer

(Located

Behind

Tire)

Clip and

Belt Clevis

Guard Pin

TO REPLACE GROUND DRIVE BELT

1. Remove belt guard as described in

"TO REMOVE BELT GUARD".

2. Remove old belt by slipping off engine

pulley first then remove from transmis-

sion pulley.

3. Place new belt in groove of transmis-

sion pulley and into engine pulley.

BELT MUST BE IN GROOVE ON TOP

OF IDLER PULLEY, NOTE POSITION

OF BELT TO GUIDES.

4. Check belt adjustment as described

below.

5. Replace belt guard.

6. Reposition wheel and replace clevis

pin and hairpin clip.

GROUND DRIVE BELT ADJUSTMENT

For proper belt tension, the extension

spring should have about 5/8" stretch

when drive control bar is in "ENGAGED"

position. This tension can be attained as

follows:

1. Loosen cable clip screw securing the

drive control cable,

2. Slide cable forward for less tension

and rearward for more tension until

about

5/8 inch stretch is obtained while the

drive control bar is engaged,

3. Tighten cable clip screw securely.

Clip Screw

Drive Control

Cable

Engine

Pulley

Idler Pulley Transmission Pulley

More

Extension

Spring

Loading...

Loading...