Craftsman 917299691 Owner’s Manual

OWNER'S

MANUAL

MODEL NO.

917.299691

Cauti6n;

Read and follow

all Safety Rules

and Instructions

Before Operating

This Equipment

5.0 HP

17 INC TINE WIDTH

COUNTER ROTATING

EAR TI TILLER

• Assembly

, Operation

• Maintenance

• Service and Adjustment

• Repair Parts

TINES

Sears, Roebuck and Co., Chicago, IL 60684 U.S.A.

SAFETY RULES

Safe Operation Practices for Walk-Behind Powered Rotary Tillers

TRAINING

, Read the operating and service instruction manual care-

fuIly. Be thoroughly familiar with the controls and the

proper use of the equipment. Know how to stop the unit

and disengage the controls quickly.

• Never allow children to operate the equipment. Never

allow adults to operate the equipment without proper

instruction.

, Keep the area of operation clear of all persons, particu-

larly small children, and pets.

PREPARATIO N

• Thoroughly inspectthe area where the equipment isto be

used and remove all foreign objects.

, Disengage all clutches and shift into neutral before

starting the engine (motor),

° Do not operate the equipment without wearing adequate

Outer garments. Wear footwear that wilt improve footing

on slippery surfaces.

• Handle fuel with care; it is highly flammable.

Use an approved fuel container,

, Never add fuel to a running engine or hot engine.

, Fill fuel tank outdoors with extreme care. Never fill

fuel tank indoors.

• Replace gasoline cap securely and clean up spilled

fuel before restarting.

• Use extension cords and receptacles as specified bythe

manufacturer for all units with electric drive motors or

electric starting motors.

• Never attempt to make any adjustments while the engine

(motor) is running (except where specifically recom+

mended by manufacturer)+

OPERATION

" Do not put hands or feet near or under rotating parts.

• Exercise extreme caution when operating on or crossing

gravel drives, walks, or roads. Stay alert for hidden

hazards or traffic. Do not carry passengers.

• After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, thoroughly inspect

the tiller for any damage, and repair the damage before

restarting and operating the tiller.

• Exercise caution to avoid slipping or falling.

• If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

• Stop the engine (motor) when leaving the operating

position, before unclogging the tines, and when making

any repair, adjustments, and inspections.

• Take all possible precautions when leaving the machine

unattended. Disengage the power take-off, lower the

attachment, shift into neutral, stop the engine, and

remove the key.

• Before cleaning, repairing, or inspecting, shut off the

engine and make certain al! moving parts have stopped.

Disconnect the spark plug wire, and keep the wire away

from the plug to prevent accidental starting. Disconnect

the cord on electric motors.

, Do not run the engine indoors; exhaust fumes are dan-

gerous.

• Never operate the tiller without proper guards, plates, or

other safety protective devices in place.

+ Keep children and pets away.

• Do not overload the machine capaci_ by attempting totill

too deep at too fast a rate.

, Never operate the machine at high speeds on slippery

surfaces. Look behind and use care when backing.

, Never allow bystanders near the unit.

• Use only attachments and accessories approved by the

manufacturer of the tiller (such as wheel weights,

counterweights, cabs, and the like).

• Never operate the tiller without good visibility or light.

+ Be careful when tilling in hard ground. The tines may

catch in the ground and propel the tiller forward. If this

occurs, let go of the handlebars and do not restrain the

machine.

MAINTENANCE AND STORAGE

• Keep machine, attachments, and accessories in safe

working condition,

° Check shear bolts, engine mounting bolts, and other

bolts at frequent intervals for proper tightness to be sure

the equipment is in safe working condition,

, Never store the machine with fuel in the fuel tank inside

a buitding where ignition sources are present, such as hot

water and space heaters, clothes dryers, and the like.

Allow the engine to cool before storing in any enclosure.

• Always refer to the operator's guide instructions for

importantdetails if the tiller isto be stored for an extended

period.

-IMPORTANT -

Cautions, [mportants, and Notes are a means of attracting attention to important or critical information in this manual,

_for this symbol to_

IMPORTANT," USED TO ALERT YOU THAT THERE

IS A POSSIBILITY OF DAMAGING THIS EQUIPMENT.

NOTE: Gives essential information that will aid you to

better understand, incorporate, or execute a particular

set of instructions.

NGRATULATIONSonyourpurchaseofaSearsTiller.

_sbeendesigned,engineeredandmanufacturedto

youthebestpossibledependabilityandperform-

;e.

_uid you experience any probiems you cannot easily

ledy, please contact your nearest authorized Service

qteriDepartment. They have competent, well-trained

hnicians and the proper tools to serwce or repair this

t.

ase read and retain this manual. The instructions will

_ble you to assemble and maintain your tiller properly.

/ays observe the "SAFETY RULES".

MODEL

NUMBER 917.299691

SERIAL

NUMBER

DATE OF

PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON THE MODEL PLATE ATTACHED TO

THE TOP OF THE TRANSMISSION.

YOU SHOULD RECORD BOTH SERIALNUMBER

AND DATE OF PURCHASE AND KEEPIN A SAFE

PLACE FOR FUTURE REFERENCE.

PRODUCT SPECIFICATIONS

HORSEPOWER: 5.0 H.P.

DISPLACEMENT: 12.57 cu. in.

GASOLINE CAPACITY: 3 QUART

(UNLEADED)

OIL (20 OZ. CAPACITY): SAE 30W

(SAE 10W 30)

SPARK PLUG (GAP .030 IN.): Champion

RJ19LM

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product. Contact your nearest Sears store for details.

CUSTOMER RESPONSIBiLITiES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring for

and using your tiller.

• Follow the instructions under "Maintenance" and "Stor-

age" sections of this OwneCs Manual.

MMtTED ONE YEAR WARRANTY ON CRAFTSMAN TILLER

For one year from date of purchase, when this Craftsman Tiller is maintained, lubricated, and tuned up according to

the operating and maintenance instructions in the owner's manuaf, Sears will repair free of charge any defect in

material or workmanship.

This Warranty does not cover:

• Expendable items which become worn during normal use, such as tines, spark plugs, air cleaners and belts.

• Repairs r_ecessary because of operator abuse or negligence, including bent crankshafts and the failure to

maintain the equipment according to the instructions contained in the owner's manual.

o if this Craftsman Tiller is used for commercial or rental purposes, this Warranty applies for only 30 days from the

date of purchase.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN TILLER TO THE NEAREST SEARS

SERVICE CENTER/DEPARTMENT tN THE UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE THIS

PRODUCT IS tN USE tN THE UNITED STATES.

This Warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO., D/731CR-W SEARS TOWER, CHICAGO, IL 60684

-NOTE-

qis unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered,

"ush_covered orgrass covered tand unless the engine's exhaust system is equipped with a spark arrester meeting applicable

ca1or state taws (if any). ff a spark attester is used, it should be maintained in effective working order by the operator.

the state of California the above is required by faw (Section 4442 of the California Public Resources Code). Other states

,ay have similar laws. Federal laws apply on federal lands. See your Sears Authorized Service Center for spark arrester.

efer to page 33 of Repair Parts section of this manual for part number.

3

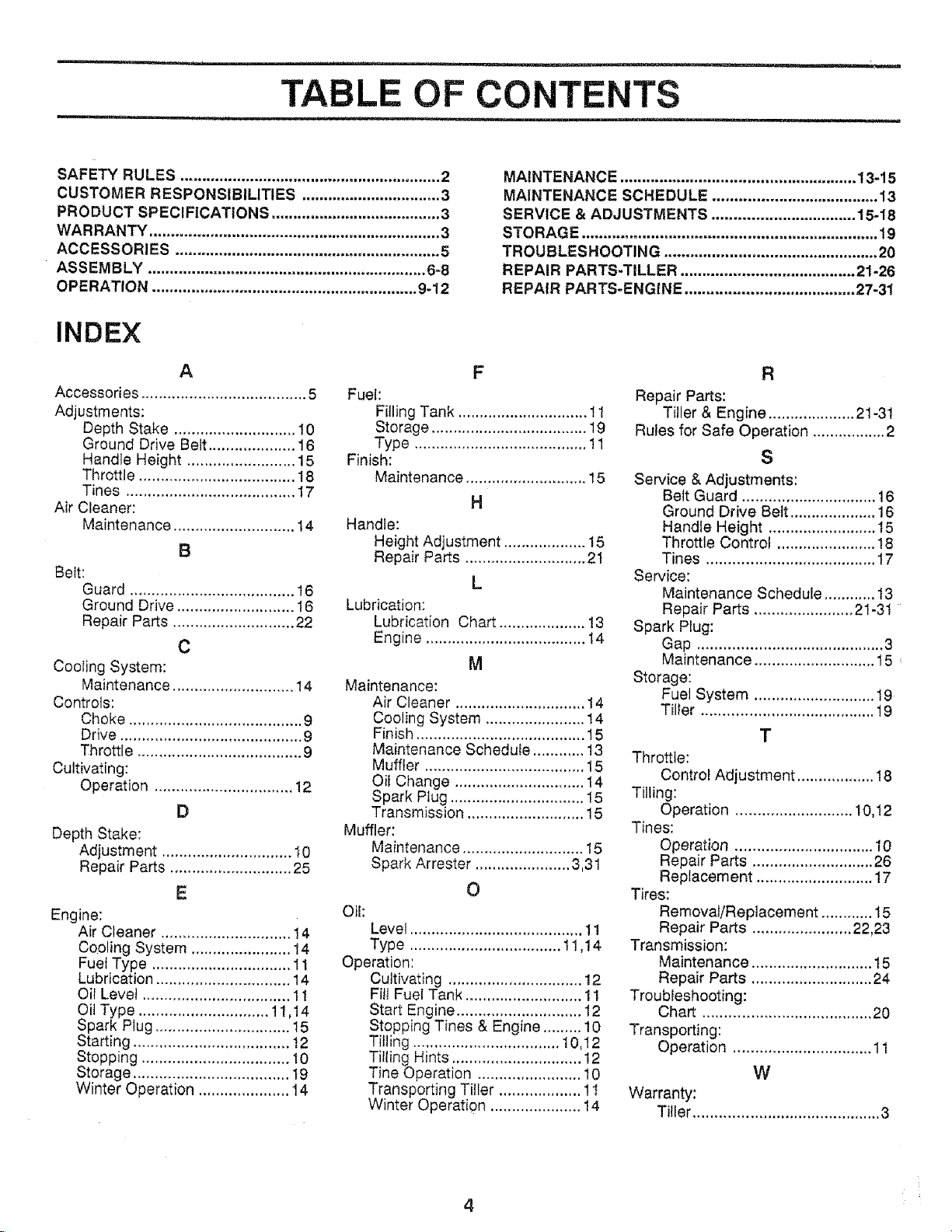

INDEX

OF CONTENTS

A

Accessories ...................................... 5

Adjustments:

Depth Stake ............................ 10

Ground Drive Belt .................... 16

Handle Height ......................... 15

Throttle .................................... 18

Tines ....................................... 17

Air Cleaner:

Maintenance ............................ 14

B

Belt:

Guard ...................................... 16

Ground Drive ........................... 16

Repair Parts ............................ 22

C

Cooling System:

Maintenance ............................ 14

Controls:

Choke ........................................ 9

Drive .......................................... 9

Throttle ...................................... 9

Cultivating:

Operation ................................ 12

D

Depth Stake:

Adjustment .............................. i 0

Repair Parts ............................ 25

E

Engine:

Air Cleaner .............................. 14

Cooling System ....................... 14

Fuel Type ................................ 11

Lubrication ............................... 14

Oil Level .................................. 11

Oil Type .............................. 11,14

Spark Plug ............................... 15

Starting .................................... 12

Stopping .................................. 10

Storage .................................... 19

Winter Operation ..................... t 4

F

Fuel:

Filling Tank .............................. 11

Storage .................................... 19

Type ........................................ 11

Finish:

Maintenance ............................ 15

H

Handle:

Height Adjustment ................... 15

Repair Parts ............................ 21

L

Lubrication:

Lubrication Chart .................... 13

Engine ..................................... t4

M

Maintenance:

Air Cleaner .............................. 14

Cooling System ....................... 14

Finish ....................................... 15

Maintenance Schedule ............ 13

Muffler ..................................... 15

Oil Change .............................. 14

Spark Plug ............................... 15

Transmission ........................... 15

Muffler:

Maintenance ............................ 15

Spark Arrester ...................... 3,31

O

Oil:

Level ........................................ 11

Type ................................... 11,14

Operation:

Cultivating ............................... 12

Fit! Fuel Tank ........................... 11

Start Engine ............................. 12

Stopping Tines & Engine ......... 10

Tilling .................................. 10,12

Tilling Hints .............................. 12

Tine Operation ........................ 10

Transporting Tiller ................... 11

Winter Operation ..................... 14

R

Repair Parts:

Tiller & Engine .................... 21-31

Rules for Safe Operation ................. 2

S

Service & Adjustments:

Bett Guard ............................... 16

Ground Drive Belt .................... 16

Handle Height ......................... 15

Throttle Control ....................... 18

Tines ....................................... 17

Service:

Maintenance Schedule ............ 13

Repair Parts ....................... 21-3t

Spark Plug:

Gap ........................................... 3

Maintenance ............................ 15

Storage:

Fuel System ............................ 19

Tilter ........................................ 19

T

Throttle:

Control Adjustment .................. 18

Tilling:

Operation ........................... 10,12

Tines:

Operation ................................ 10

Repair Parts ............................ 26

Replacement ........................... 17

Tires:

Removal/Replacement ............ I5

Repair Parts ....................... 22,23

Transmission:

Maintenance ............................ t5

Repair Parts ............................ 24

Troubleshooting:

Chart ....................................... 20

Transporting:

Operation ................................ 11

W

Warranty:

Tiller ........................................... 3

4

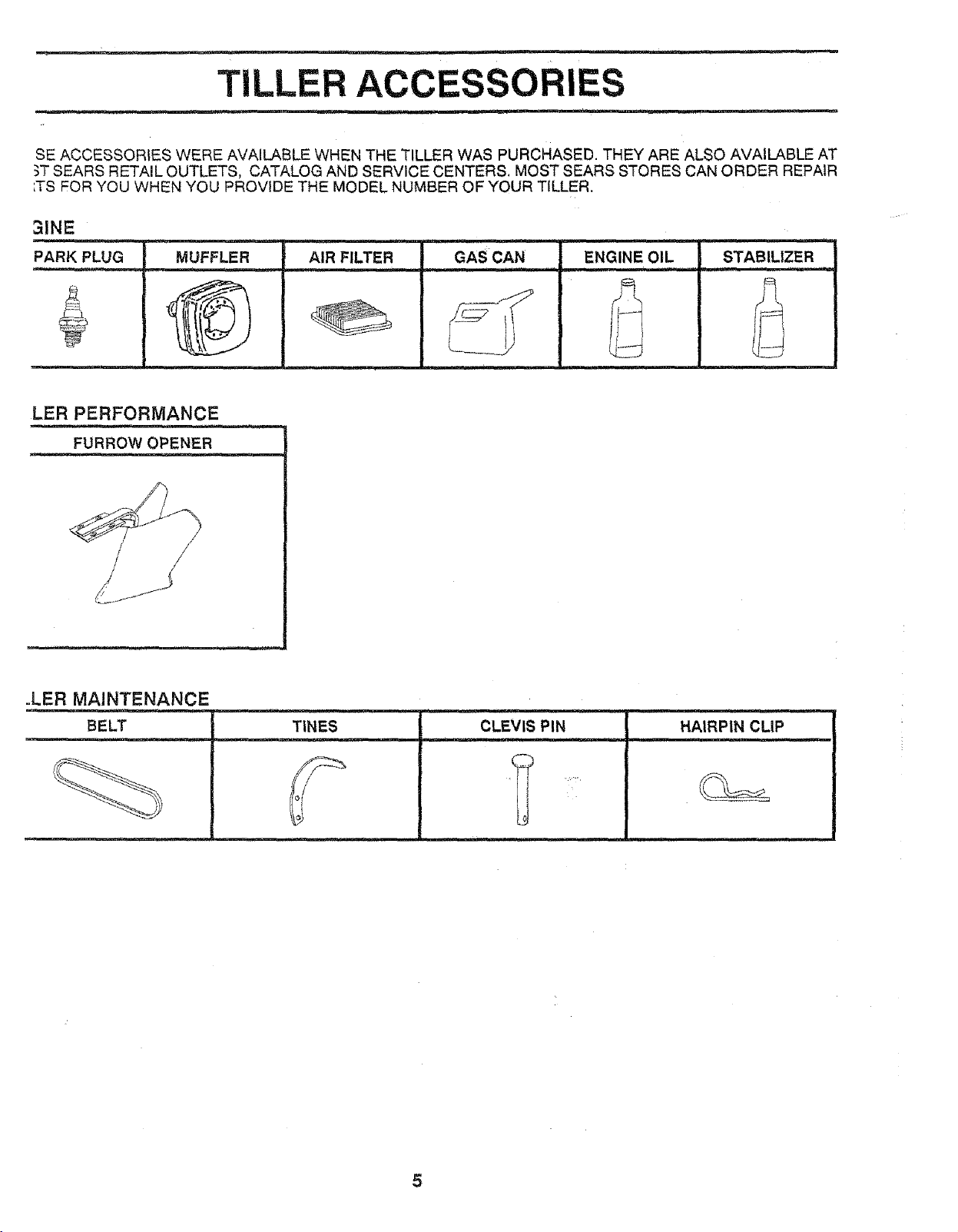

TILLER ACCESSORIES

SE ACCESSORIES WERE AVAILABLE WHEN THE TILLER WAS PURCHASED. THEY ARE ALSO AVAILABLE AT

_TSEARS RETAIL OUTLETS, CATALOG AND SERVICE CENTERS, MOST SEARS STORES CAN ORDER REPAIR

;TS FOR YOU WHEN YOU PROVIDE THE MODEL NUMBER OF YOUR TILLER.

31NE

PARK PLUG

m,,,,i

MUFFLER AIR FILTER ENGINE OIL

LER PERFORMANCE

FURROW OPENER

...... ., i =1

STABILIZER

.LER MAINTENANCE

BELT TINES CLEVIS PIN HAIRPIN CLIP

m

5

,u ,i i

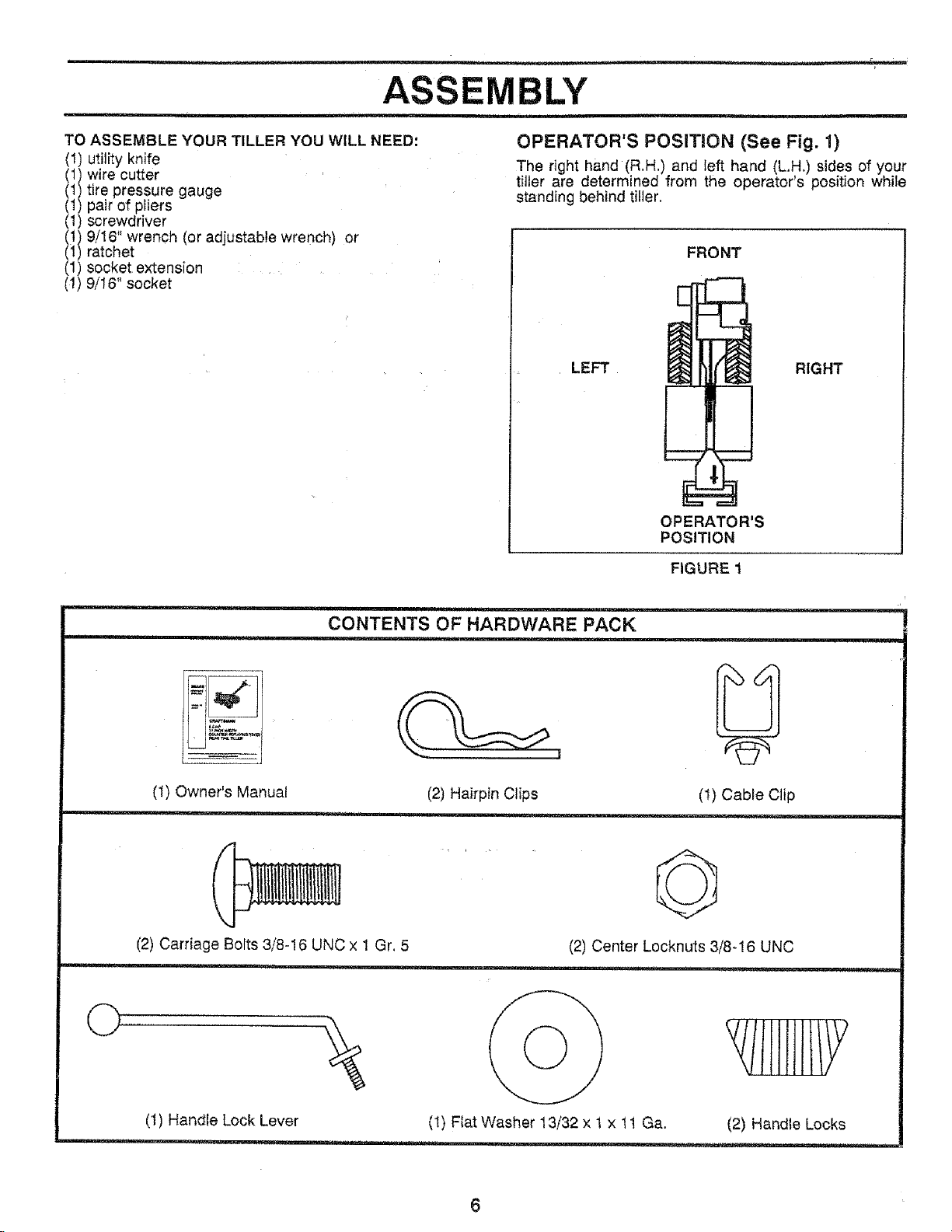

ASS LY

TO ASSEMBLE YOUR TILLER YOU WILL NEED:

(1) utility knife

(1) wire cutter

tli tire pressure gauge

pair of pliers

(1) screwdriver

Ill ratchet9/16"wrench (or adjustable wrench) or

(1) socket extension :

(I) 9/t6" socket

OPERATOR'S POSITION (See Fig. 1)

The right hand (R.H.) and left hand (LH.) sides of your

titler are determined from the operator's position while

standing behind tiNer,

FRONT

LEFT

OPERATOR'S

POSITION

FIGURE 1

RIGHT

• • .... lill ii i ii !

CONTENTS OF HARDWARE PACK

(t) Owner's Manual (2) Hairpin Clips (1) Cabte Clip

©

(2) Carriage Bolts 3/8-16 UNC x 1 Gr, 5

(2) Center Locknuts 3/8-16 UNC

(1) Handle Lock Lever (1) Flat Washer 13/32 x 1x t 1 Ga. (2) Handle Locks

......................... u

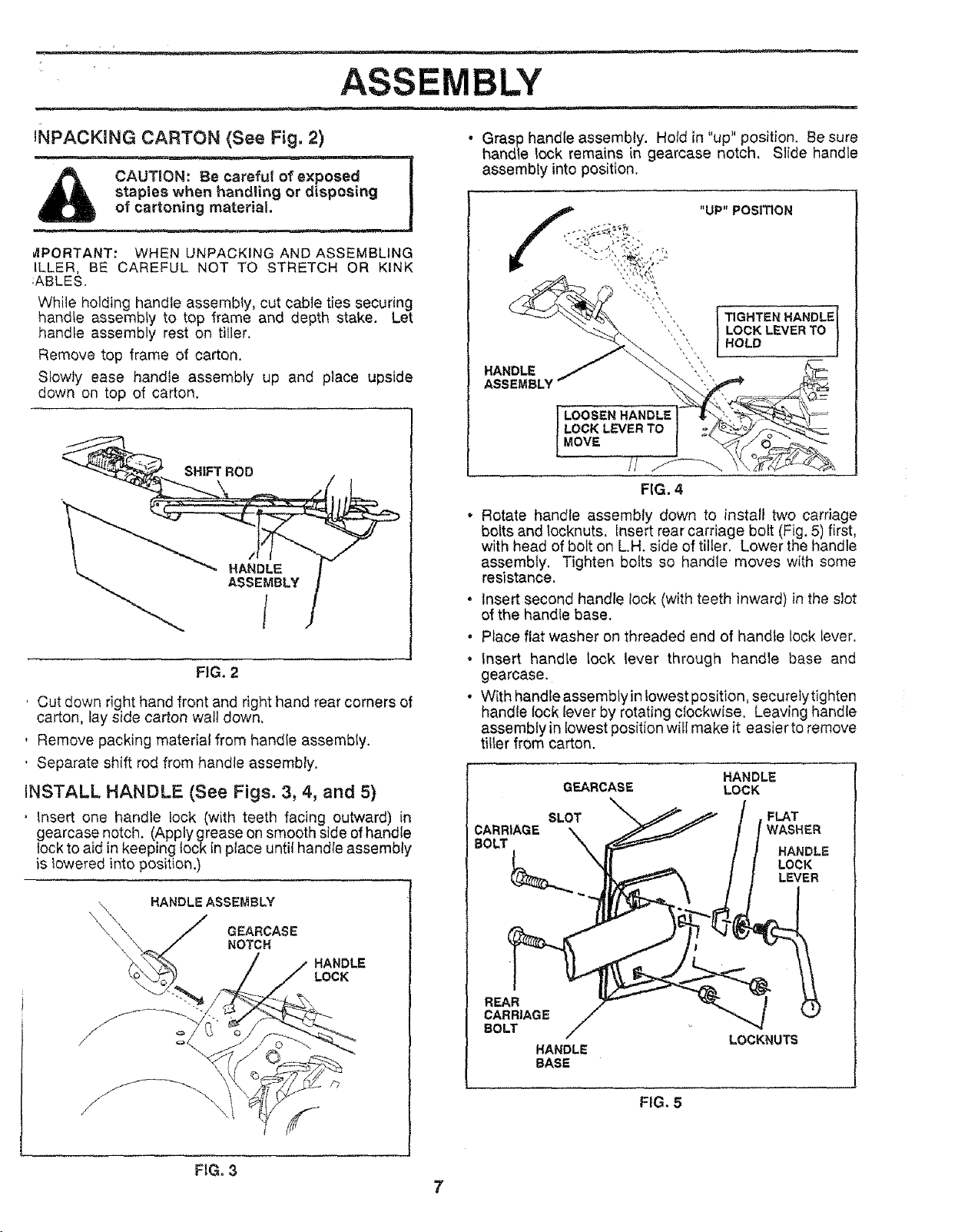

ASSEMBLY

INPACKiNG CARTON (See Fig. 2)

of ¢attoning material.CAUTION:Be careful of expose -----1

staples when handling or disposing i

_PORTANT: WHEN UNPACKING AND ASSEMBLING

ILLER, BE CAREFUL NOT TO STRETCH OR KINK

;ABLES.

While holding handle assembly, cut cable ties securing

handle assembly to top frame and depth stake. Let

handle assembly rest on tiller.

Remove top frame of carton.

Slowly ease handle assembly up and place upside

down on top of carton.

SHIFT ROD

HANDLE

ASSEMBLY

/

FIG. 2

Cut down right hand front and right hand rear corners of

carton, lay side carton wall down,

Remove packing material from handle assembly.

Separate shift rod from handle assembly.

INSTALL HANDLE (See Figs. 3, 4, and 5)

Insert one handle lock (with teeth facing outward) in

gearcase notch. (Apply grease on smooth side of handle

lock to aid in keeping lock in place until handle assembly

is lowered into position,)

• Grasp handle assembly. Hold in "up" position. Be sure

handle lock remains in gearcase notch, Slide handle

assembly into position.

"UP" POSITION

TIGHTEN HANDLE

LOCK LEVER TO

HOLD

HANDLE

ASSEMBLY

LOOSEN

LOCK LEVER TO

MOVE

FIG, 4

• Rotate handle assembly down to install two carriage

bolts and tocknuts. Insert rear carriage bolt (Fig. 5) first,

with head of bolt on L.H. side of tiller. Lower the handle

assembly, Tighten bolts so handle moves with some

resistance,

, Insert second handle lock (with teeth inward) in the slot

of the handle base.

• Place flat washer on threaded end of handle lock lever,

• insert handle lock lever through handle base and

gearcase.

• With handle assemblyin !owest position, secureiytighten

handle lock lever by rotating clockwise. Leaving handle

assembly in lowest position will make it easier to remove

tilter from carton.

GEARCASE

SLOT

CARRIAGE

BOLT

HANDLE

LOCK

FLAT

WASHER

HANDLE

LOCK

LEVER

\ _,, HANDLEASSEMBLY

NOTCH

FiG. 3

HANDLE

LOCK

REAR

CARRIAGE

BOLT

HANDLE

BASE

FIG. 5

LOCKNUTS

7

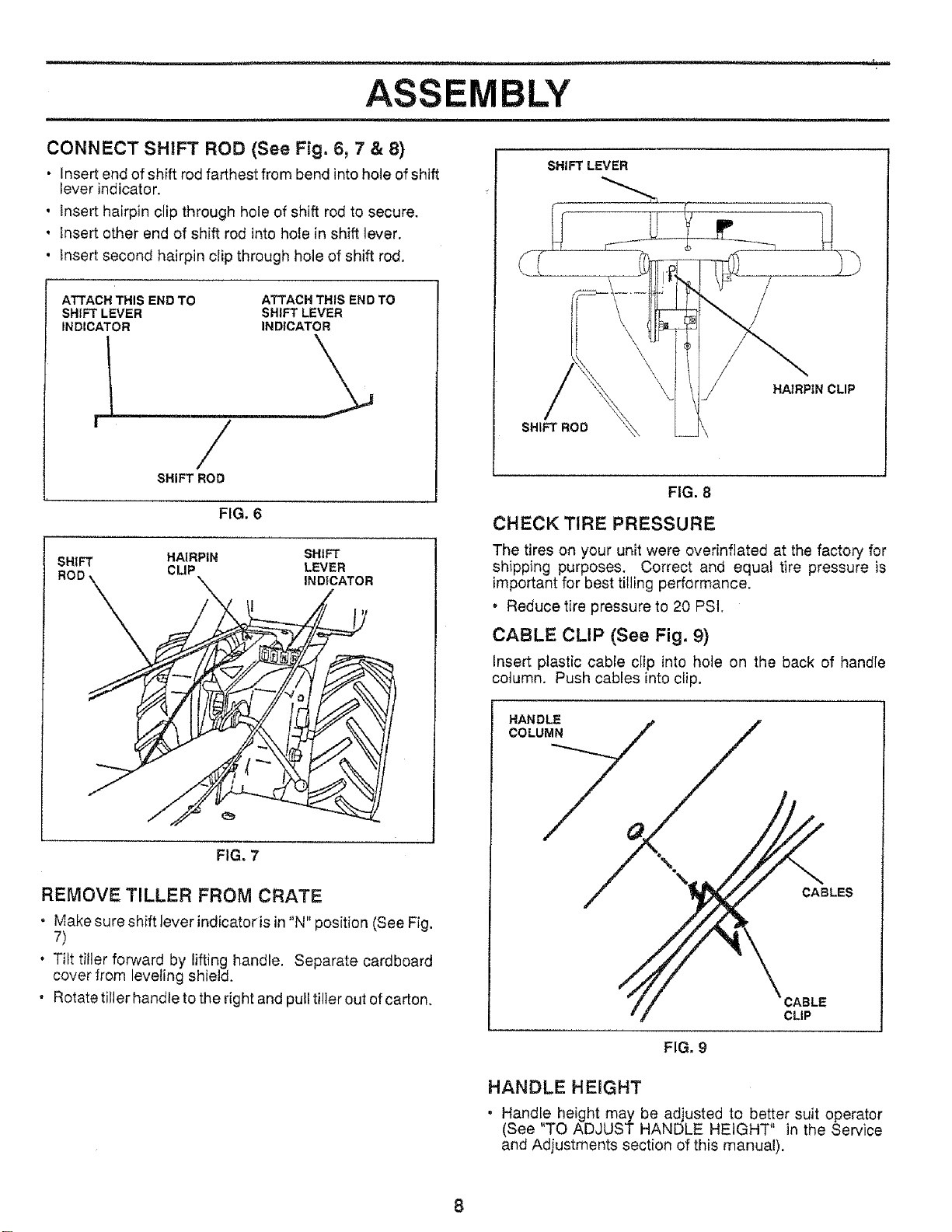

ASSE BLY

CONNECT SHIFT ROD (See Fig. 6, 7 & 8)

• Insert end of shift rod farthest from bend into hote of shift

lever indicator.

, Insert hairpin clip through hole of shift rod to secure.

• Insert other end of shift rod into hoie in shift lever.

• Insert second hairpin clip through hole of shift rod.

ATTACH THIS END TO

SHIFT LEVER

INDICATOR

ATTACH THIS END TO

SHIFT LEVER

INDICATOR

' /

SHIFT ROD

FIG. 6

SHIFT HAIRPIN

CLIP

SHIFT

LEVER

INDICATOR

SHIFT LEVER

HAIRPIN CLIP

SHIFT ROD

FIG. 8

CHECK TIRE PRESSURE

The tires on your unit were overinflated at the factory for

shipping purposes. Correct and equal tire pressure is

important for best tilling performance.

• Reduce tire pressure to 20 PSI.

FIG. 7

REMOVE TILLER FROM CRATE

, Make sure shift lever indicator is in "N" position (See Fig.

7)

• Tilt filler forward by lifting handle. Separate cardboard

cover from leveling shield.

, Rotate tiller handle to the right and putl tiller out of carton.

CABLE CLIP (See Fig. 9)

Insert plastic cable clip into hole on the back of handle

column. Push cables into clip.

CABLES

CABLE

CLIP

FIG, 9

HANDLE HEIGHT

, Handle height may be adjusted to better suit operator

(See "TO ADJUST HANDLE HEIGHT" in the Service

and Adjustments section of this manual).

8

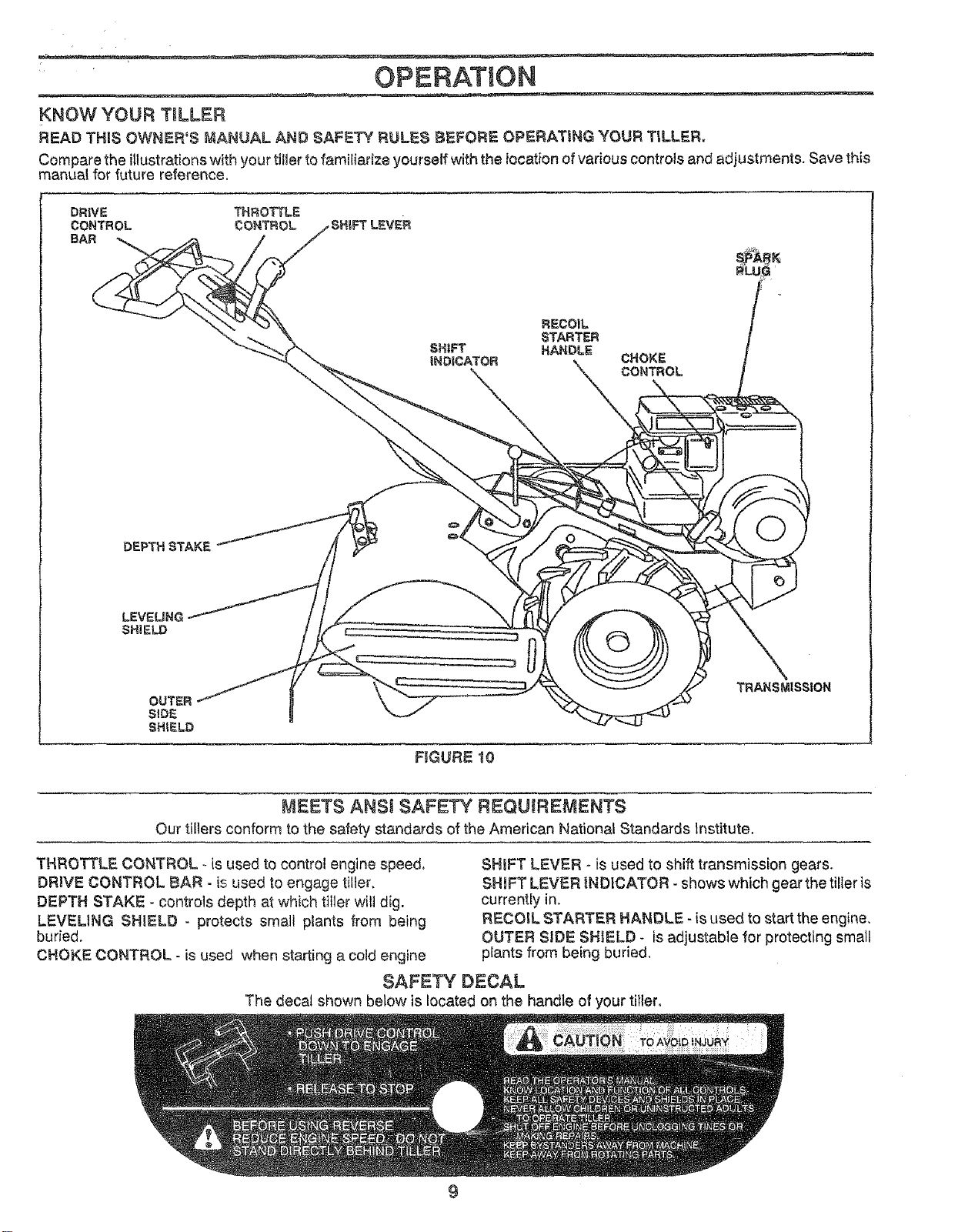

OPERATION

KNOW YOUR TILLER

READ THiS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR T_LLER.

Compare the illustrations with your tiller to familiarize yourself with the location of various controls and adjustments. Save this

manual for future reference.

RECOIL

STARTER

HANDLE

LEVELING

SHIELD

MEETS ANSl SAFETY REQUUREMENTS

Our tillers conform to the safety standards of the American National Standards institute,

THROTTLE CONTROL - is used to control engine speed,

DRIVE CONTROL BAR - is used to engage tiller,

DEPTH STAKE - controls depth at which tiller witi dig.

LEVELING SHIELD - protects small plants from being

buried.

CHOKE CONTROL - is used when starting a cold engine

SAFETY DECAL

The decat shown below is located on the handle of your tiller.

©

FIGURE to

SHIFT LEVER - is used to shift transmission gears.

SNDFTLEVER iNDICATOR- shows which gear the tiller is

currently in.

RECOIL STARTER HANDLE - is used to start the engine.

OUTER SIDE SHIELD - is adjustable for protecting small

plants from being buried,

9

OPERATION

The operation of any tiller can result In foreign objects thrown into the eyes, which can

result in severe eye damage. Always wear safety glasses or eye shields before starting

your tiller and while til|ing. We recommend wide vision safety mask for over the spectacles

or standard safety glasses.

HOW TO USE YOUR TILLER

Know how to operate ali controls before adding fuel and

oil or attempting to start engine,

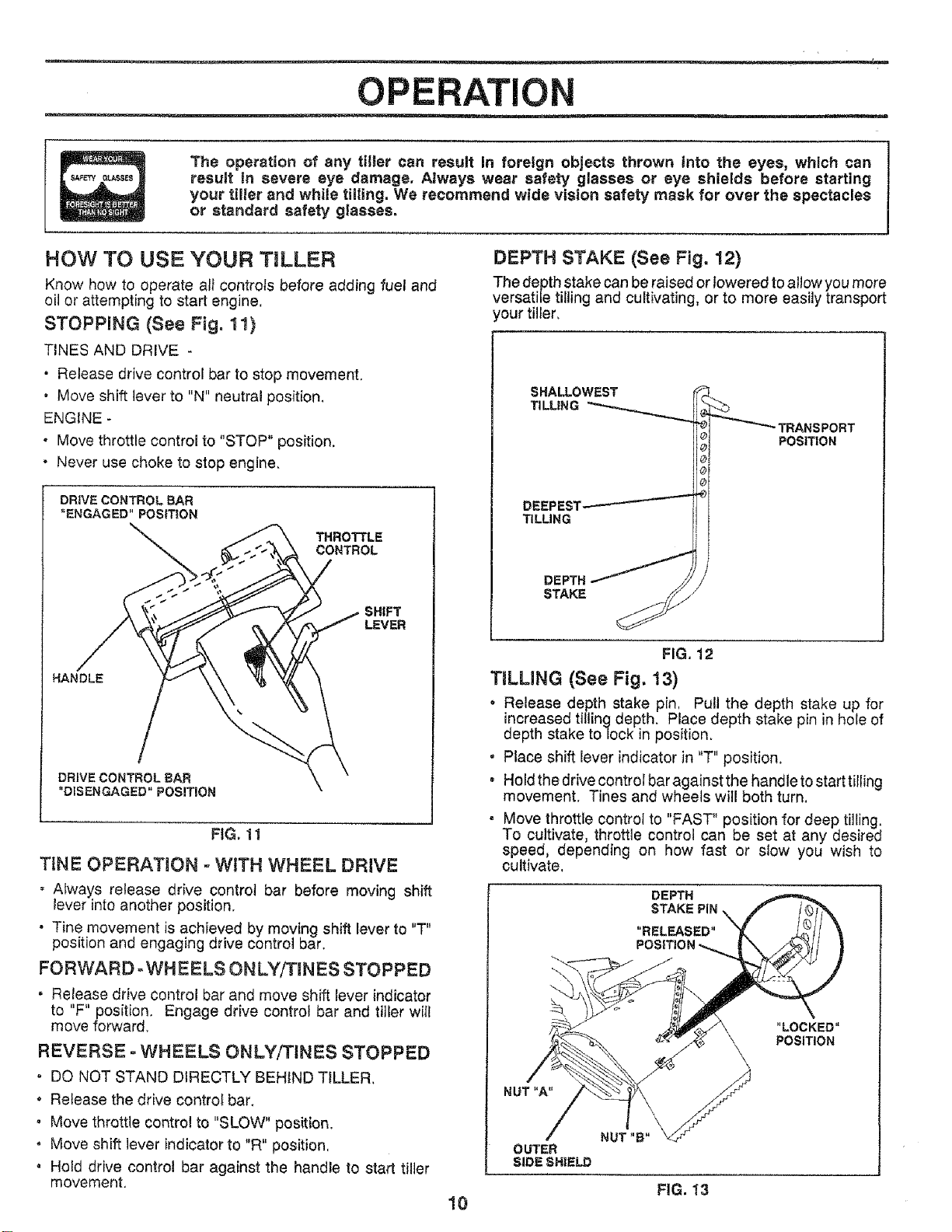

STOPPING (See Fig. 11)

TINES AND DRIVE -

. Release drive control bar to stop movement.

, Move shift lever to "N" neutral position,

ENGINE -

• Move throttle control to "STOP" position.

o Never use choke to stop engine,

DRIVE CONTROL BAR

"ENGAGED" POSiTiON

THROTTLE

CONTROL

LEVER

HANDLE

DRIVECONTROLBAR

"DISENGAGED"POSMON

FiG. 11

TfNE OPERATION - WiTH WHEEL DRIVE

DEPTH STAKE (See Fig. 12)

The depth stake can be raised or iowered to allow you more

versatile tilling and cultivating, or to more easily transport

,our tiller+

SHALLOWEST

TILLING "_+-=_

DEEPEST,..--- "="

TILLING

DEPTH_

STAKE

I

c_

"__'_'-_""_ TRANSPORT

¢ POSITION

®

®

FIG. 12

TILLING (See Fig. 13)

• Release depth stake pin, Pull the depth stake up for

increased tilling depth. Place depth stake pin in hole of

depth stake to lock in position.

. Place shift lever indicator in "T" position.

• Hold the drive control bar against the handle to start tiliing

movement. Tines and wheels wi]l both turn.

• Move throttle controf to "FAST" position for deep tilling.

To cultivate, throttle control can be set at any desired

speed, depending on how fast or slow you wish to

cultivate,

• Always release drive control bar before moving shift

lever into another position.

- Tine movement is achieved by moving shift lever to "T"

position and engaging drive control bar.

FORWARD +WHEELS ONLY/TINES STOPPED

" Release drive control bar and move shift lever indicator

to "F" position. Engage drive control bar and tiller wiit

move forward,

REVERSE-WHEELS ONLY/TINES STOPPED

• DO NOT STAND DIRECTLY BEHIND TELLER.

o Release the drive control bar.

• Move throttle control to "SLOW" position.

° Move shift lever indicator to "R" position.

° Hold drive control bar against the handle to start tiller

movement,

DEPTH

"LOCKED"

POSITION

OUTER

SIDE SHIELD

FIG. 13

10

Loading...

Loading...