Craftsman 917299642 Owner’s Manual

SWAURS

OWNER'S

MANUAL

MODEL NO,

917.299642

Caution:

Read and follow

all Safety Rules

and Instructions

Before Operating

This Equipment

£RI:IFTSMI:IN

4.0 HORSEPOWER

14 INCH TINE WIDTH

COUNTER ROTATING TINES

REAR TINE TILLER

Assembly

Operation

Maintenance

Service and Adjustment

Repair Parts

Sears, Roebuck and Co., Chicago, IL 60684 U.S.A.

Safe Operation Practices for Walk-Behind Powered Rotary Tillers

SAFETY RULES

&

TRAINING

- Read the operating and service instructionmanual

carefully. Be thoroughlyfamiliar with the controls and

the proper use of the equipmentv Know howto stopthe

unit and disengage the controls quickly_

• Never allow children to operate the equipment° Never

allow adults to operate the equipment without proper

instruction

. Keep the area of operation clear of allpersons, particu-

larly small children, and pets_

PREPARATION

° Thoroughly inspectthe area where the equipment isto

be used and remove all foreign objects°

. Disengage all clutches and shift into neutral before

starting the engine (motor)..

= Do not operate the equipment without wearing ade-

quate outer garments.. Wear footwear that will improve

footing on slippery"surfaces.

. Handle fuel with care; it is highly flammable..

• Use an approved fuel container.,

• Never add fuel to a running engine or hot engine.

• Fillfuel tank outdoors with extreme care. Never fill

fuel tank indoors_

• Replace gasoline cap securely and clean upspilled

fuel before restarting

• Use extension cords andreceptaclesasspecified bythe

manufacturer for all units with electric drive motors or

electric starting motors.

• Never attempt to make any adjustments while the engine

(motor) is running (except where specifically recom-

mended by manufacturer),

OPERATION

. Do not put hands or feet near or under rotating parts.,

° Exercise extreme caution when operating on orcrossing

gravel drives, walks, or roads_ Stay alert for hidden

hazards or traffic, Do not carry passengers,

• After' striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, thoroughly inspect

the tiller for any damage, and repair the damage before

restarting and operating the tillers.

• Exercise caution to avoid slipping or falling.

. If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately forthe cause°Vi-

bration is generally awarning of trouble.,

. Stop the engine (motor) when leaving the operating

position, before unclogging the tines, and when making

any repair, adjustments, and inspections,

° Take all possible precaufionswhen leaving the machine

unattended., Disengage the power take-off, lower the

attachment, shift into neutral, stop the engine, and

remove the key.

• Before cleaning, repairing, or' inspecting, shut off the

engine and make certain all moving parts have stopped_

Disconnect the spark plug wire, and keep the wire away

from the plug to prevent accidental starting Disconnect

the cord on electric motors.

° Do not run the engine indoors;exhaust fumesare dan-

gerous.

• Never operate the tillerwithout properguards, plates, or

other safety protective devices in place.

• Keep children and pets away.

• Donotoverload the machine capacity by attempting totill

too deep at too fast a rate.

• Never allow bystanders near the unit.,

• Use only attachments and accessories approved by the

manufacturer ofthetirler(such aswheelweights, counter_

weights, cabs, and the like).

• Never operate the tillerwithout good visibility or light,

• Be careful when tilling in hard ground. The tines may

catch in the ground and propel the tiller forward. Ifthis

occurs, let go of the handlebars and do not restrainthe

machine.

MAINTENANCE AND STORAGE

• Keep machine, attachments, and accessories in safe

workingcondition..

. Check shear bolts, engine mounting bolts, and other

bolts at frequent intervalsfor propertightnessto be sure

the equipmentisin safe workingcondition_

. Never storethe machine withfuel inthe fuel tankinside

abuildingwhere ignitionsourcesare present,suchas hot

water and space heaters, clothesdryers, and the like.

Allowthe enginetocoolbeforestoringinany enclosure.,

. Always refer to the Owner's Manual instructionsfor im-

portantdetails ifthe tiller isto be storedfor an extend-

ed period.

-IMPORTANT -

Warnings, Cautions, and Notes are a means of attracting attentionto importantor criticalinformationinthis manual.,

illll i ill i i illl illlllllllllllllll illlll

LOOK FOR THIS SYMBOL TO POINT

OUT IMPORTANT SAFETY PRE-

CAUTIONS. IT MEANS -- ATTENTION!

BECOME ALERT! YOUR SAFETY IS

INVOLVED.

CAUTION: USED TO ALERT YOU THAT THERE IS

A POSSIBILITY OF DAMAGING THIS

EQUIPMENT_

NOTE: Gives essential informationthat will aid you to

better understand, incorporate, or execute a particular

set of instructions.

2

CONGRATULATIONS on your purchase of a Sears

PRODUCT SPECIFICATIONS

Craftsman Tiller° it has been des=gned,engineered and

manufacturedto give you the bestpossibledependability

and performance.

Should you experience any problems you cannoteasily

remedy, please contactyournearest Sears Service Cen-

HORSEPOWER: 4_0

DISPLACEMENT: 11,39 CUoIN,,

teriDepartmentoWe have competent,well trainedtechni-

cians and the propertools to service or repairthisunit

GASOLINE CAPACITY: 2 QUART

Please read and retain this manual. The instructionswill

enable you to assembleand maintainyour Tiller prop-

erty, Always observe the SAFETY RULES

OIL (20 OZ. CAPACITY): SAE 30W

MODEL

NUMBER 917.299642

SPARK PLUG (GAP ,030 IN,): CHAMPION

SERIAL

NUMBER

DATE OF

PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON THE MODEL PLATE ATTACHED TO

THE TOP OF THE TRANSMISSION,

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE,,

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product. Contact your nearest Sears store'for details,

CUSTOMER RESPONSIBILITIES

. Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring for and using your Tiller_

. Fo_towthe instructionsunder Maintenance" and "Storage" sections of thisOwner's Manual,,

(UNLEADED)

(SAE 10W 30)

RCJ8

LIMITED ONE YEAR LIMITED WARRANTY ON CRAFTSMAN TILLER

For one year from date of purchase, when this Craftsman Tiller is maintained, lubricated, and tuned up ac-

cording to the instructions in the owner s manual, Sears wilt repair, free of charge, any detect in material and

workmanship,,

If this Craftsman Tiller is used for commercial or rental purposes, this Warranty applies for only 30 days from

the date of purchase.

This Warranty does not cover:

• expendable itemswhich become worn during normal use, such as tines, spark plug, air cleaners and bells,

• Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure to

maintain the equipment according to the instructions contained in the owner's manual

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN TILLER TO THE NEAREST

SEARS SERVICE CENTER/DEPARTMENT IN THE UNITED STATES. THIS WARRANTY APPLIES ONLY

WHILE THIS PRODUCT iS IN USE IN THE UNITED STATES

This Warranty gives you specific legal rights, and you may also have other rights which vary from state to

state.,

Sears, Roebuck and Co., D/731CR-W, Sears Tower, Chicago, IL 60684

-NOTE-

This unit is equipped with an internalcombustion engine and should not be used on or near any unimprovedforest-

covered, brush-covered or grass covered land unless the engine's exhaust system is equipped with a spark arrester

meetingapplicablelocal or statelaws(if any). Ifa sparkarrester is used, it should be maintained in effectiveworkingorder

by the operator.

in the state of California the above is required by law (Section 4442 of the California Public Resources Code) Other

states may have similar laws. Federal laws apply on federal lands, See your Sears Authorized Service Center for spark

arrester. Refer to page 33 of Repair Partssection of this manualfor part number.

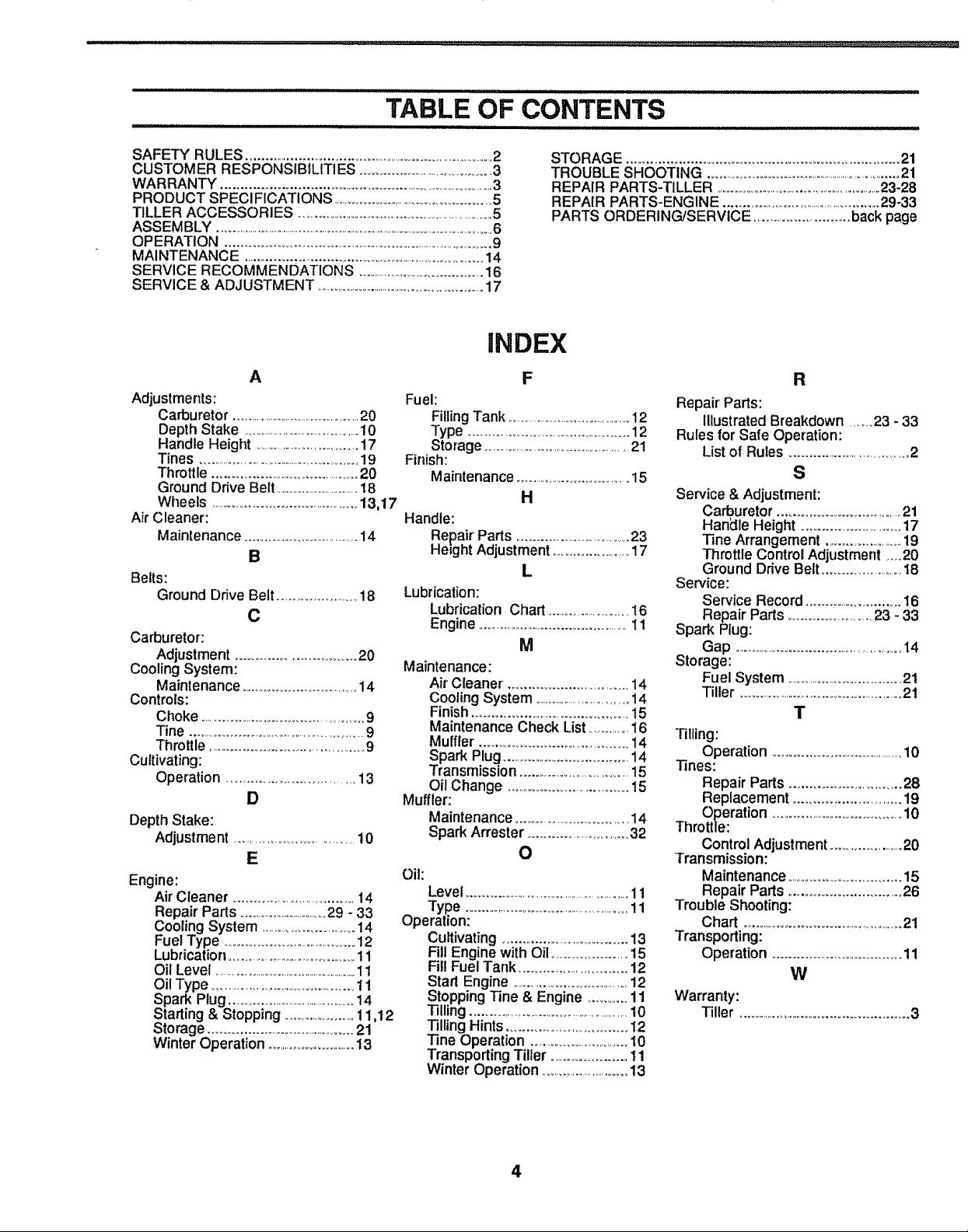

TABLE OF CONTENTS

, iii1,,Jl,Jll,,,Jlll,,Ji J, i, ,,ulJl, i,ii,llll,ll,,ii,u,lll iin iii i i ii i i i

SAFETY RULES ............................................................................ 2

CUSTOMER RESPONSIBILITIES ...............................................3

WARRANTY ...............................................................................3

PRODUCT SPECI FICATtONS ..................................................5

TILLER ACCESSORIES ........................................................................5

ASSEMBLY ...................................................................................................................6

OPERATION ............................................................................................9

MAINTENANCE .............................................................................14

SERVICE RECOMMENDATIONS ...........................................16

SERVICE & ADJUSTMENT ..............................................................17

A

Adjustments:

Carburetor ......................................................20

Depth Stake ...............................................10

Handle Height .....................................17

Tines .........................................................19

Throttle ...............................................20

Ground Drive Belt ................................18

Wheels ....................................................13,17

Air Cleaner:

Maintenance ......................................14

B

Belts:

Ground Drive Belt .................................18

C

Carburetor':

Adjustment ......................................20

Cooling System:

Maintenance.........................................14

Controls:

Choke ..................................................9

Tine .................................................................9

Throttle ..............................................9

Cultivating:

Operation ....................................13

D

Depth Stake:

Adjustme nt ..........................................10

Fuel:

Filling Tank ..................................................12

Type ................................................12

Storage ...........................................................21

Finish:

Maintenance ...........................................15

Handle:

Repair Parts .....................................23

Height Adjustment ........................17

Lubrication:

Lubrication Chart ..............................16

Engine .................................................11

Maintenance:

Air Cleaner. ...............................14

Cooling System ......................................14

Finish ................................................15

Maintenance Check List...............i6

Muffler ...................................................14

Spark Plug..........................................14

Transmission .................................15

Oil Change ..........................................15

Muffler:

Maintenance.....................................14

Spark Arrester ...............................32

E

Engine:

Air'Cleaner .....................................14

Repair Parts ..................................29 - 33

Cooling System .....................................14

Fuel Type ...........................................12

Lubrication.........................................11

Oil Level .........................................................11

Oil Type ..................................................11

Spark Plug ...............................................14

Starting & Stopping ..........................11,t2

Storage .................................................21

Winter Operation ................................13

Oil:

Level .........................................................11

Type .....................................................11

Operation:

Cultivating.....................................13

Fill Engine with Oil ......................15

Fill Fuel Tank ..............................12

Start Engine ....................................12

Stopping Tine & Engine ..............11

Tilling .....................................................10

Tilling Hints ..................................t2

Tine Operation ...................................10

Transporting Tiller ......................11

Winter Operation ..............................13

INDEX

F

H

L

M

O

STORAGE .................................................................... 21

TROUBLE SHOOTING .......................................................................21

REPAIR PARTS-TILLER ...........................................................23-28

REPAIR PARTS-ENGINE .......................................................29-33

PARTS ORDERING/SERViCE ................................back page

R

Repair Parts:

Illustrated Breakdown ........23 - 33

Rules for Safe Operation:

List of Rules .....................................2

S

Service & Adjustment:

Carburetor .......................................21

Han_lle Height ................................17

Tine Arrangement ..........................19

Throttle Control Adjustment ....20

Ground Drive Belt ............................I8

Service:

Service Record ...................................16

Repair Parts...........................23 - 33

Spark Plug:

Gap ........................................................t4

Storage:

Fuel System ...................................21

Tiller ........................................................21

T

Tilling:

Operation ....................................................10

Tines:

Repair Parts .................................28

Replacement ..................................19

Operation ...............................................10

Throttle:

Control Adjustment .....................20

Transmission:

Maintenance ..................................15

Repair Parts .................................26

Trouble Shooting:

Chart ..................................................21

Transporting:

Operation .........................................11

W

Warranty:

Tiller .......................................................3

4

TILLER ACCESSORIES

THESE ACCESSORIES WERE AVAILABLE WHEN THE TILLER WAS PURCHASED. THEY ARE ALSO AVAILABLE AT

MOST SEARS RETAIL OUTLETS, CATALOG AND SERVICE CENTERS. MOST SEARS STORES CAN ORDER REPAIR

PARTS FOR YOU, WHEN YOU PROVIDE THE MODEL NUMBER OF YOUR TILLER,

ENGINE

SPARK PLUG

MUFFLER

AIR FILTER GAS CAN

ENGINE OIL

STABILIZER

ill, lll,ii

TILLER PERFORMANCE

FURROW OPENER

TILLER MAINTENANCE

BELT TINES RETAINING PIN HAIRPIN CLIP

...................... , i............ ,i ....

%

,2

................. iii iljlllll I I II IIIIII1[

5

ASSEMBLY

TO ASSEMBLE YOUR TILLER YOU WILL NEED:

(1) utility knife

(1) wire cutter

(1) tire pressure gauge

(1) pair of pliers

(1) screwdriver

(1) 9/16" wrench

(1) ratchet

(1) socket extension

(1) 9/16" socket

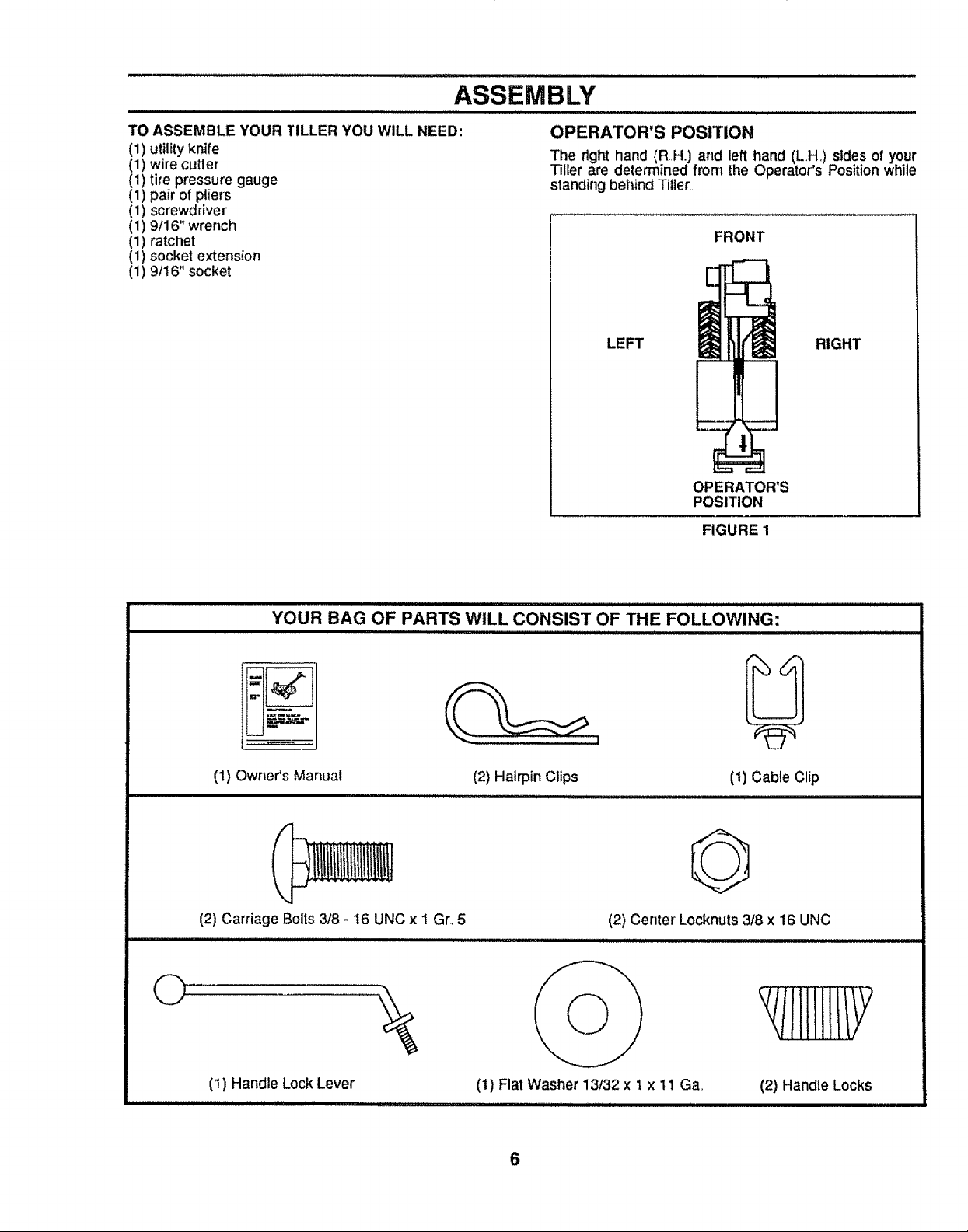

OPERATOR'S POSITION

The right hand (RH.) and left hand (LH,) sides of your

Tiller are determined from the Operator's Position while

standing beilind Tiller

FRONT

LEFT RIGHT

OPERATOR'S

POSITION

FIGURE 1

O

YOUR BAG OF PARTS WILL CONSIST OF THE FOLLOWING:

(1) Owner's Manual

IIIIIIIIIIIlUlIIIIIIIIIIIIIlUlUlIII I I III1'11'11'111111 I I I .....

(2) Carriage Bolts 3/8 - 16 UNC x 1 Gr..5

(2) Hairpin Clips (1) Cable Clip

O

(2) Center Locknuts 3/8 x 16 UNC

(1) Handle Lock Lever

iiiiiiii ilUl,ll,ll_UUll,i-iiiuiiii iiiii

(1) Fiat Washer 13/32 x 1 x 11 Ga.

iiiiiiiiiiiiii ii I iiiii I i i

6

(2) Handle Locks

ASSEMBLY

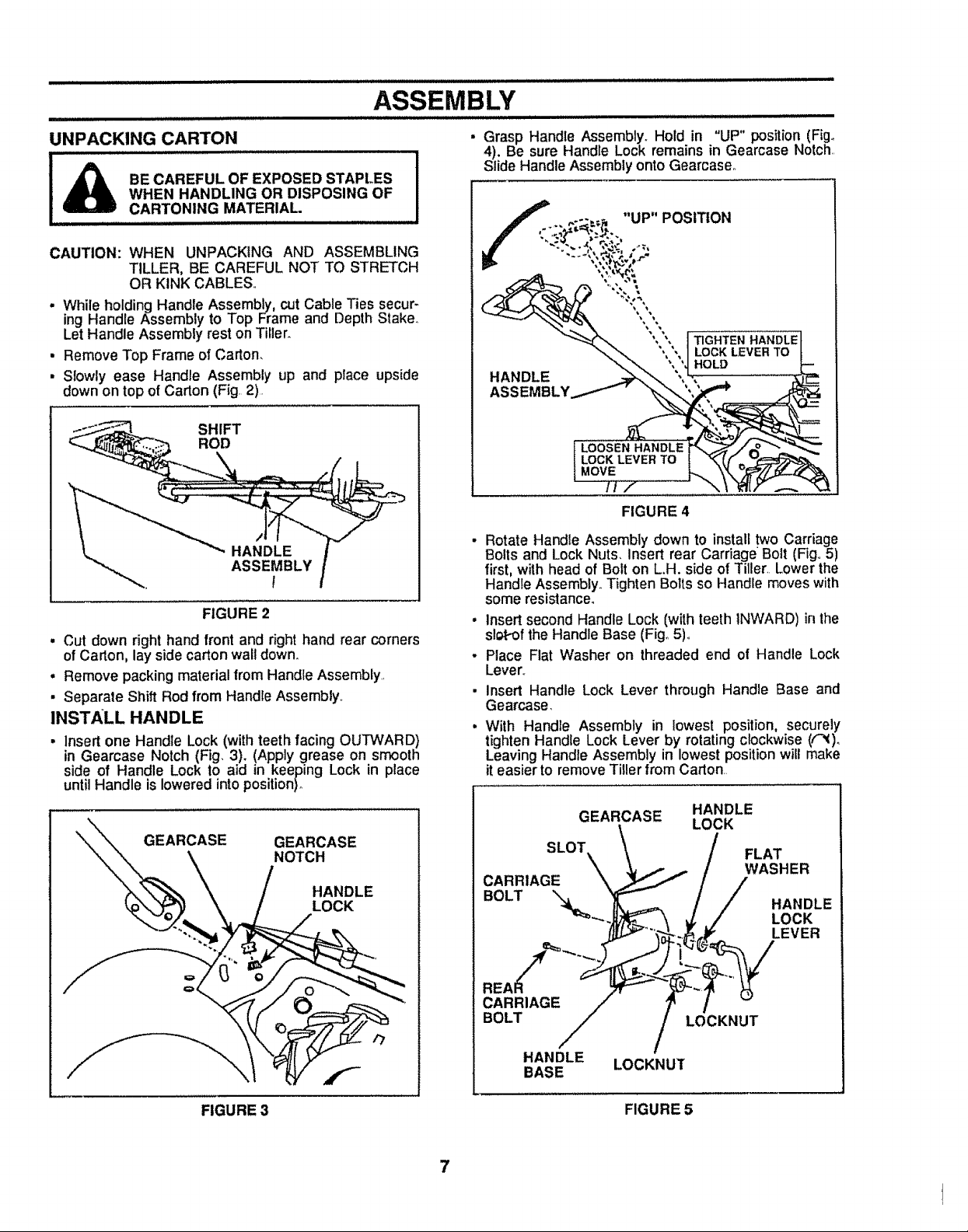

UNPACKING CARTON

WHEN HANDLING OR DISPOSING OF

BE CAREFUL OF EXPOSED STAPLES

CARTONING MATERIAL.

.... H,H,

CAUTION: WHEN UNPACKING AND ASSEMBLING

TILLER, BE CAREFUL NOT TO STRETCH

OR KINK CABLES,,

. While holding Handle Assembly, cut Cable Ties secur-

ing Handle Assembly to Top Frame and Depth Slake°

Let Handle Assembly rest on Tiller.

• Remove Top Frame of Carton.

• Slowly ease Handle Assembly up and place upside

down on top ofCarton (Fig. 2).

FIGURE 2

• Cut down right hand front and right hand rear corners

of Carton, lay side carton wall down.,

• Remove packing material from Handle Assembly,,

• Separate Shift Rod from Handle Assembly,

INSTALL HANDLE

• Insertone Handle Lock (with teeth facing OUTWARD)

in Gearcase Notch (Fig. 3). (Apply grease on smooth

side of Handle Lock to aid in keeping Lock in place

until Handle is lowered into position)°

Grasp Handle Assembly. Hold in "UP" position (Fig.

4), Be sure Handle Lock remains in Gearcase Notch,,

Slide Handle Assembly onto Gearcaseo

f ,...-..= "UP" POSITION

"": "" ', ', _GF'_'_EN HANDLE

"_._ "',", I LOCK LEVER TO

HANDLE ==,_'_. ', -, ....

• Rotate Handle Assembly down to install two Carriage

Bolts and Lock Nuts, Insert rear Carriage Bolt (Fig,,5)

first, with head of Bolt on L.H. side of Tiller, Lower the

Handle Assembly,,Tighten Bolts so Handle moves with

some resistance.

• Insert second Handle Lock (with teeth INWARD) inthe

slot-of the Handle Base (Fig,,5)°

- Place Flat Washer on threaded end of Handle Lock

Lever.,

• Insert Handle Lock Lever through Handle Base and

Gearcase.

• With Handle Assembly in lowest position, securely

tighten Handle Lock Lever by rotating clockwise ((_)o

Leaving Handle Assembly in lowest position wilt make

it easier to remove Tiller from Carton,

_?'_ " "t HOLD

z

FIGURE 4

GEARCASE GEARCASE

NOTCH

HANDLE

LOCK

FIGURE 3

GEARCASE HANDLE

\

SLOT \ / FLAT

LOCK

c,

BOLT / / .ANDLE

"_'_-.JJ_- _ _,./ LOCK

CARRIAGE / ? /

BOLT LOCKNUT

HANDLE LOCKNUT

BASE

FIGURE 5

7

ASSEMBLY

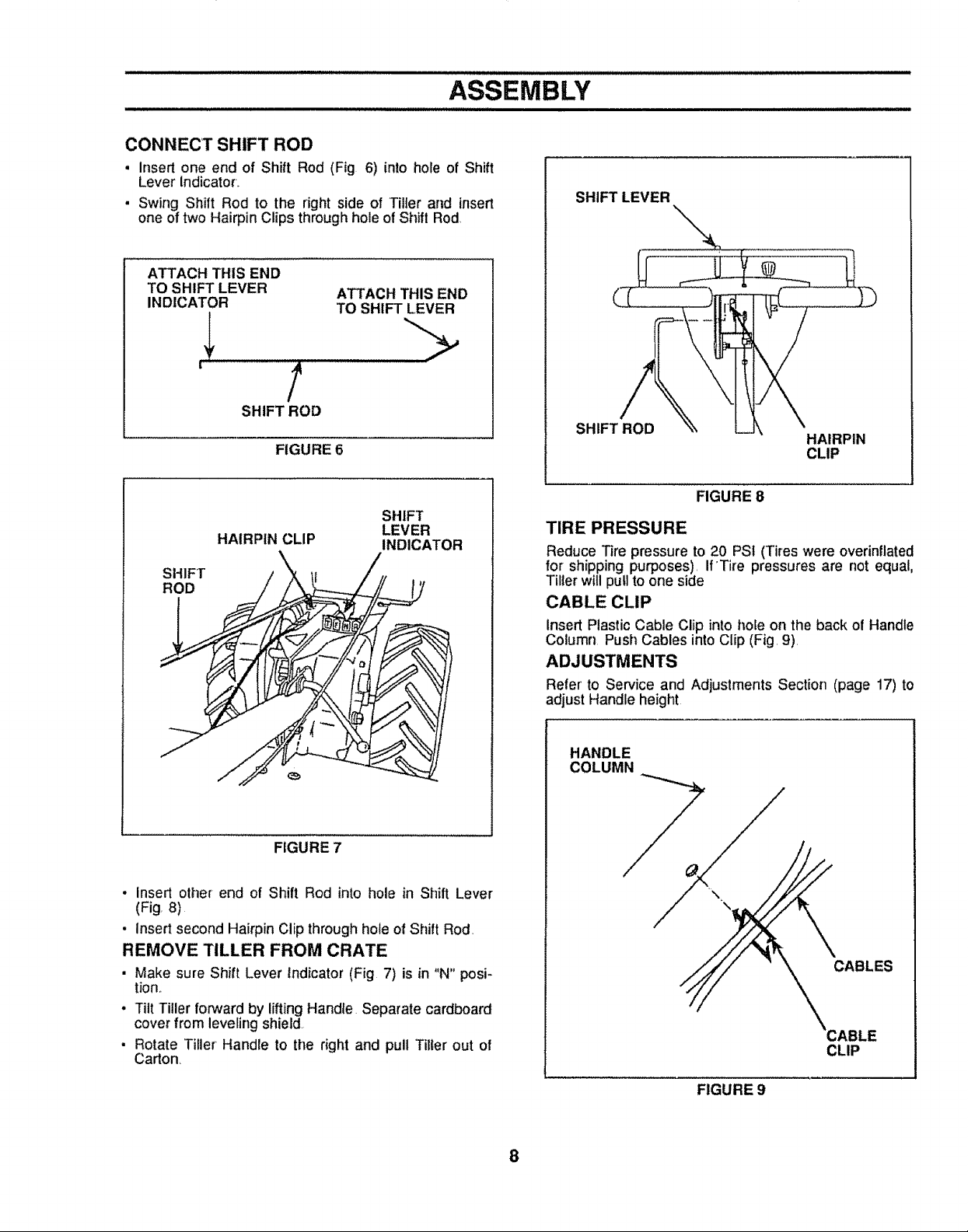

CONNECT SHIFT ROD

, Insert one end of Shift Rod (Fig 6) into hole of Shift

Lever Indicator..

• Swing Shift Rod to the right side of Tiller and insert

one of two Hairpin Clips through hole of Shift Rod.

ATTACH THIS END

TO SHIFT LEVER ATTACH THIS END

INDICATOR TO SHIFT LEVER

' /

SHIFT ROD

FIGURE 6

SHIFT

HAIRPIN CLIP

SHIFT

ROD

LEVER

INDICATOR

SHIFT LEVER

SHIFT ROD

FIGURE 8

TIRE PRESSURE

Reduce Tire pressure to 20 PSI (Tires were overinflated

for shipping purposes). If'Tire pressures are not equal,

Tillerwill pull to one side

CABLE CLIP

Insert Plastic Cable Clip into hoEeon the back of Handle

Column. Push Cables into Clip (Fig. 9)

ADJUSTMENTS

Refer' to Service and Adjustments Section (page 17) to

adjust Handle height

HAIRPIN

CLIP

FIGURE 7

. insert other end of Shift Rod into hole in Shift Lever

(Fig. 8)

• insert second Hairpin Clip throughhole of Shift Rod.

REMOVE TILLER FROM CRATE

• Make sure Shift Lever Indicator (Fig 7) is in "N" posi-

tion._

• Tilt Tiller forward by lifting Handle Separate cardboard

cover from leveling shield.

• Rotate Tiller Handle to the right and pull Tiller out of

Carton

HANDLE

COLUMN

CABLES

CLIP

FIGURE 9

8

- illl i lllU ill LLUIJLIIILILLII,,, " ........... II JlLILll i ,,.,... Illl ILLJLJLJ I,

OPERATION

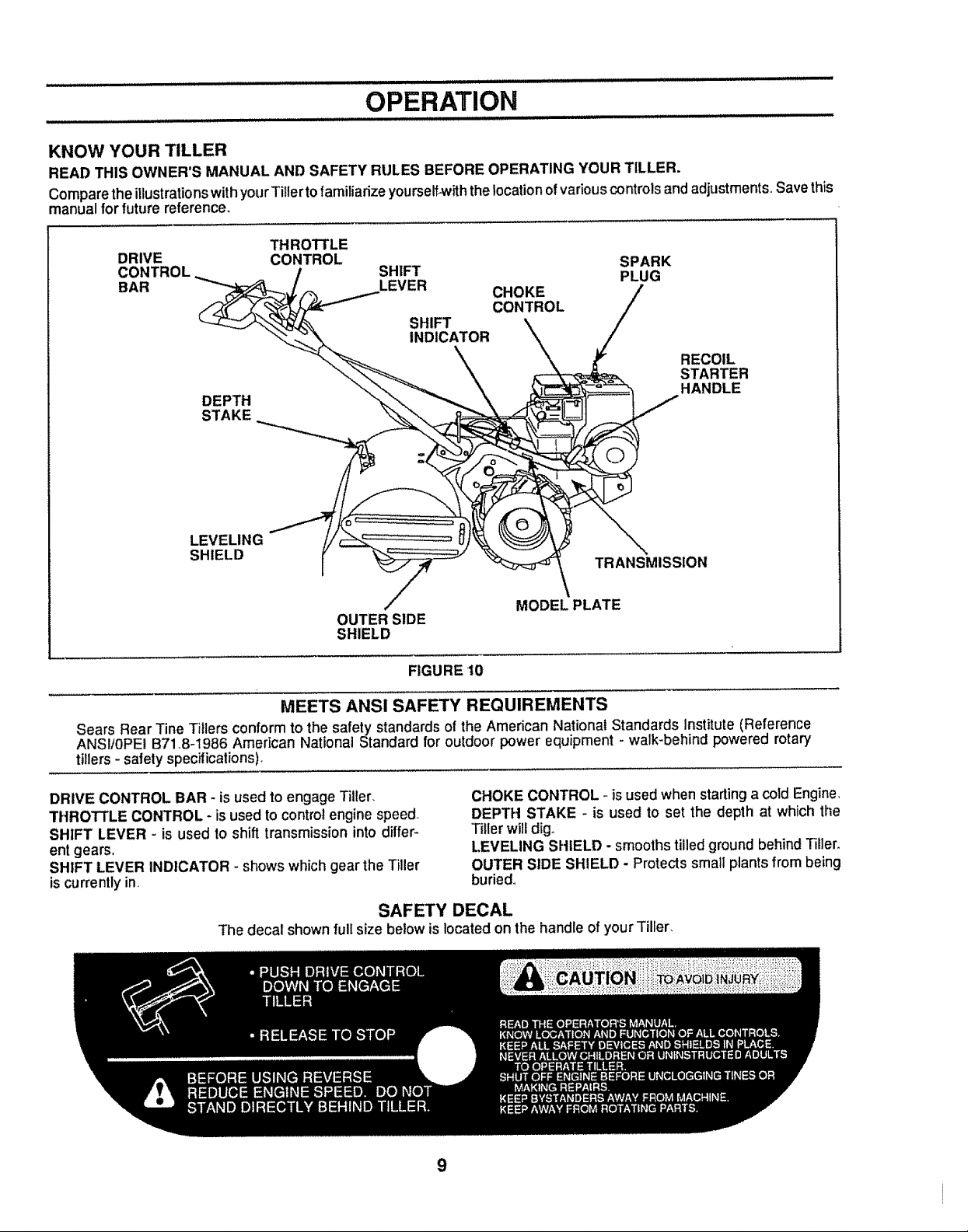

KNOW YOUR TILLER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TILLER.

ComparetheillustrationswithyourTitierto familiadze yourself-withthelocationofvariouscontrolsandadjustments Save this

manual forfuture reference°

DRIVE CONTROL

THROTTLE

DEPTH

STAKE

LEVELING

SHIELD

SHIFT PLUG

SPARK

LEVER CHOKE

CONTROL

SHIFT

INDICATOR

RECOIL

STARTER

HANDLE

TRANSMISSION

MODEL PLATE

OUTER SIDE

SHIELD

FIGURE 10

MEETS ANS! SAFETY REQUIREMENTS

Sears Rear Tine Tillers conform to the safety standards of the American National Standards Institute (Reference

ANSI/0PE! B71.8-1986 American National Standard for outdoor power equipment - walk-behind powered rotary

tillers- safety specifications),

DRIVE CONTROL BAR - isused to engage Tiller,

THROTTLE CONTROL- is used to control engine speed

SHIFT LEVER - is used to shift transmissioninto differ-

ent gears,

SHIFT LEVER INDICATOR - shows which gear the Tiller

is currently in.

CHOKE CONTROL - isused when starting a cold Engine_

DEPTH STAKE - is used to set the depth at which the

Tiller will dig.

LEVELING SHIELD - smooths tilled ground behind Tiller.

OUTER SIDE SHIELD - Protects small plants from being

buried..

SAFETY DECAL

The decal shown full size below is located on the handle of your Tiller.

9

OPERATION

The operationofany Tiller can resultinforeign objectsthrownintotheeyes, whichcanresultinsevere

eye damage. Always wear safety glasses oreye shields before starting your Tiller andwhile tilling. We

recommend Wide Vision Safety Mask for over the spectacles or standard safety glasses, available at

Sears Retail or Catalog Stores°

HOW TO USE YOUR TILLER

Know how to operate all controlsbeforeadding fuel and

oil or attempting to start Engine. (To stop Engine place

ThrottleControl in STOP position,)

TINE OPERATION - WiTH WHEEL DRIVE

• Always release Drive Control Bar before movingShift

Lever intoanother position,

- Tine movement is achieved by moving Shirt Lever to

"T" positionand engaging Drive ControlBar.,

FORWARD - WHEELS ONLY ! TINES STOPPED

• Release Drive Control Barand move Shift Lever Indi-

cator to "F" position, Engage Drive Control Bar and

Tiller will move forward

REVERSE - WHEELS ONLY / TINES STOPPED

. DO NOT STAND DIRECTLY BEHIND TILLER

• Release the Drive Control Bar

• Move Throttle Control to "SLOW" position..

• Move Shift Lever Indicator to "R" position,

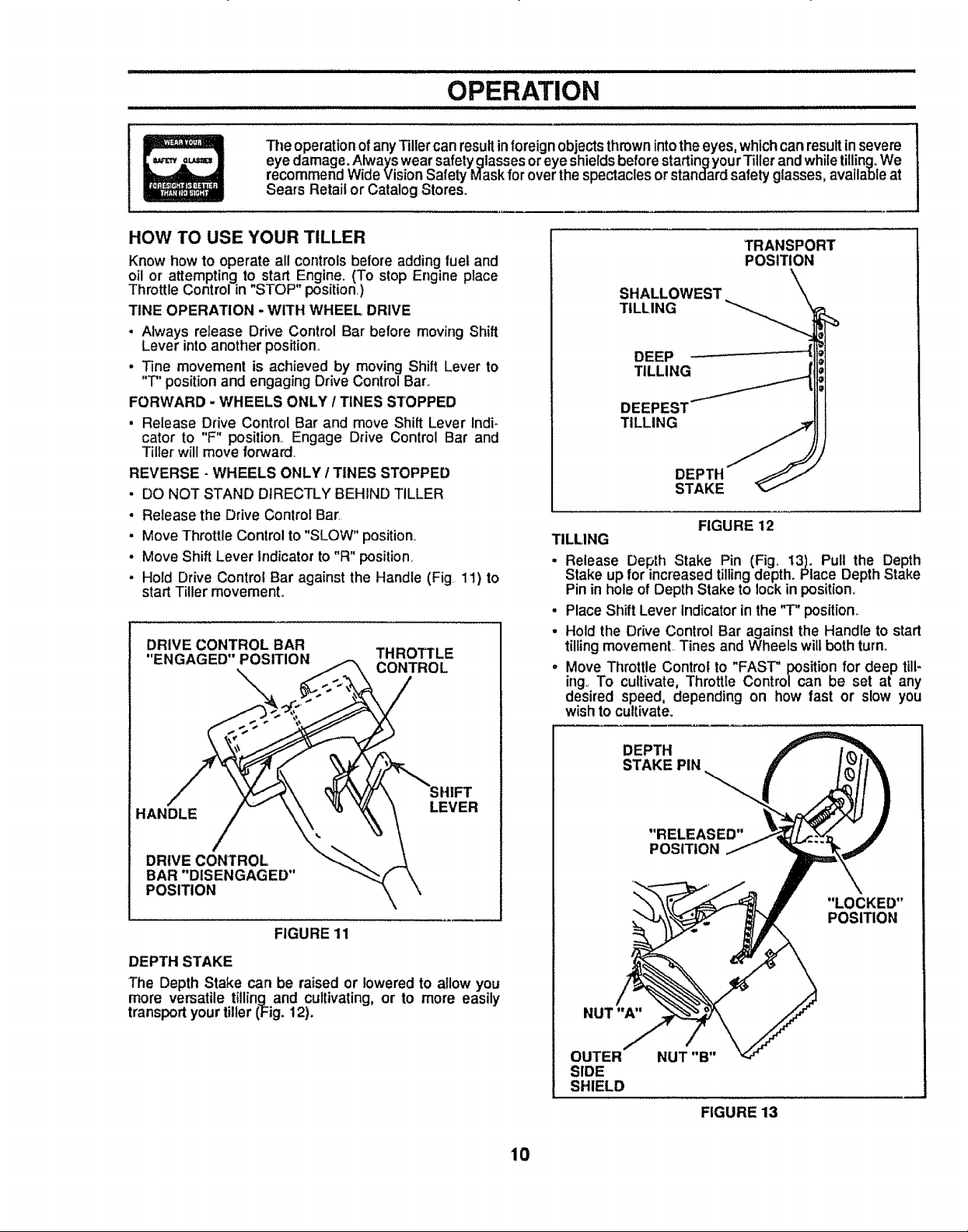

. Hold Drive Control Bar against the Handle (Fig. 11) to

start Tiller movement.,

DRIVE CONTROL BAR

TRANSPORT

POSITION

SHALLOWEST

TILLING

DEEP

TILLING

TILLING

DEPTH

STAKE

FIGURE 12

TILLING

. Release Depth Stake Pin (Fig. 13). Pull the Depth

Stake up for increased tilling depth. Place Depth Stake

Pin in hole of Depth Stake to lockin position.

• Place Shift Lever Indicator inthe "T" position..

• Hold the Drive Control Bar against the Handle to start

tilling movement. Tines and Wheels will both turn.,

. Move Throttle Control to "FAST" position for deep till-

ing. To cultivate, Throttle Control can be set at any

desired speed, depending on how fast or slow you

wish to cultivate.

Z

BAR DISENGAGED _ \

POSITION _ \

FIGURE 11

DEPTH STAKE

The Depth Stake can be raised or lowered to allow you

more versatile tilling and cultivating, or to more easily

transportyour tiller (Fig. 12)°

10

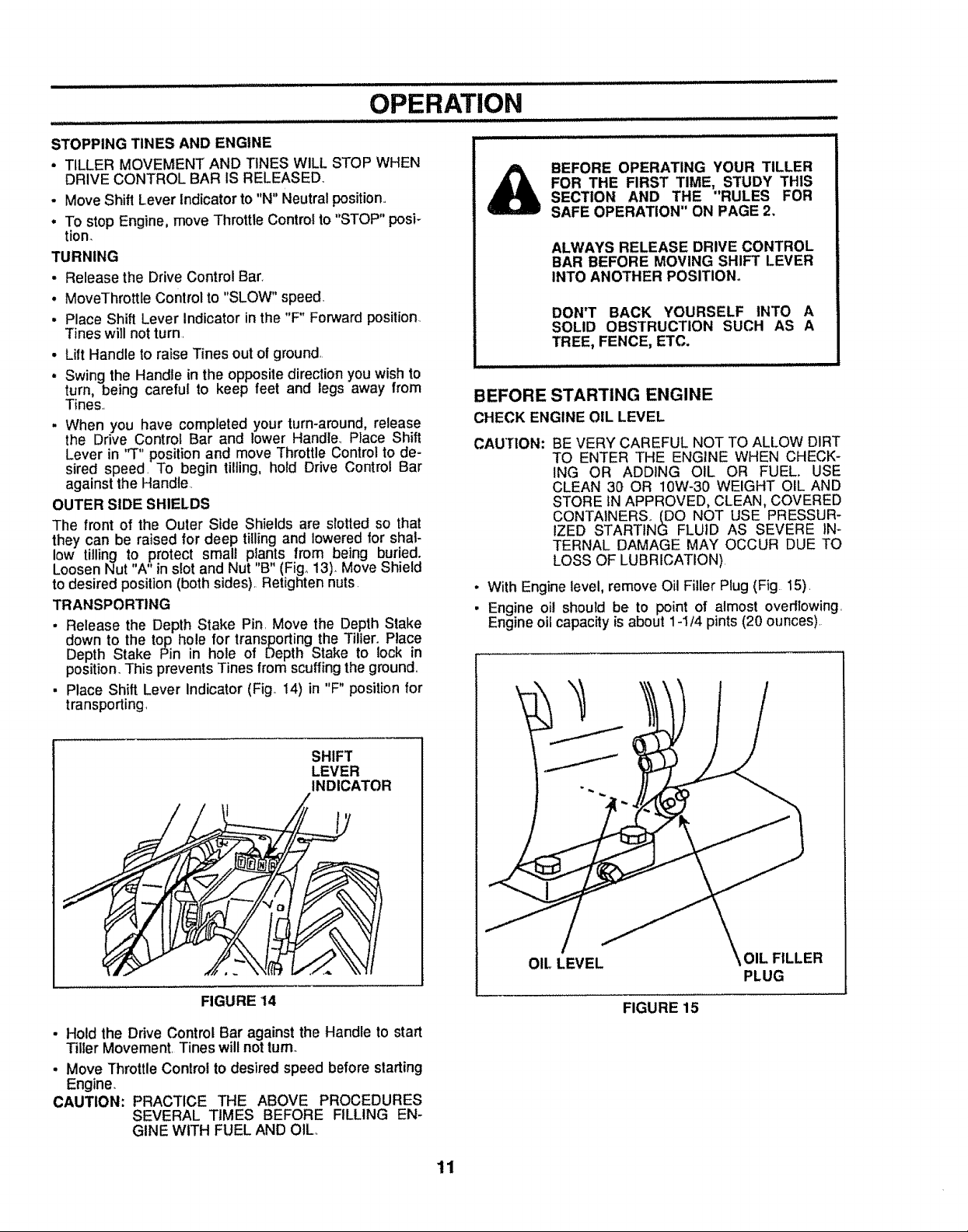

NUT "A"

OUTER

SIDE

SHIELD

DEPTH

STAKE PIN

"RELEASED"

POSITION

"LOCKED"

POSITION

NUT "B"

FIGURE 13

OPERATION

STOPPING TINES AND ENGINE

. TILLER MOVEMENT AND TINES WILL STOP WHEN

DRIVE CONTROL BAR iS RELEASED.

• Move Shift Lever Indicator to "N" Neutral position.,

• To stop Engine, move Throttle Control to "STOP" posi-

tion.

TURNING

• Release the Drive Contro! Bar.

• MoveThrottle Control to "SLOW" speed,

. Place Shift Lever Indicator in the "F" Forward position.

Tines will not turn,

• Lift Handle to raise Tines out of ground,.

• Swing the Handle in the opposite direction you wish to

turn, being careful to keep feet and legs away from

Tines,,

• When you have completed your turn-around, release

the Drive Control Bar and lower Handle., Place Shift

Lever in "T" positionand move Throttle Control to de-

sired speed, To begin tilling, hold Drive Control Bar

against the Handle.,

OUTER SIDE SHIELDS

The front of the Outer Side Shields are slotted so that

they can be raised for deep tilling and lowered for shal-

low tilling to protect small plants from being buried.

Loosen Nut "A" in slot and Nut "B" (Fig. 13). Move Shield

to desired position (both sides).,Retighten nuts.

TRANSPORTING

. Release the Depth Stake Pin, Move the Depth Stake

down to the top hole for transporting the Tiller. Place

Depth Stake Pin in hole of Depth Stake to lock in

position. This prevents Tines from scuffing the ground,,

• Place Shift Lever Indicator (Fig° 14) in "F" position for

transporting,

BEFORE OPERATING YOUR TILLER

FOR THE FIRST TIME, STUDY THIS

SECTION AND THE "RULES FOR

SAFE OPERATION" ON PAGE 2,

ALWAYS RELEASE DRIVE CONTROL

BAR BEFORE MOVING SHIFT LEVER

INTO ANOTHER POSITION°

DON'T BACK YOURSELF INTO A

SOLID OBSTRUCTION SUCH AS A

TREE, FENCE, ETC.

BEFORE STARTING ENGINE

CHECK ENGINE OIL LEVEL

CAUTION: BE VERY CAREFUL NOT TO ALLOW DIRT

TO ENTER THE ENGINE WHEN CHECK-

ING OR ADDING OIL OR FUEL. USE

CLEAN 30 OR 10W-30 WEIGHT OIL AND

STORE IN APPROVED, CLEAN, COVERED

CONTAINERS,, (DO NOT USE PRESSUR-

IZED STARTING FLUID AS SEVERE IN-

TERNAL DAMAGE MAY OCCUR DUE TO

LOSS OF LUBRICATION)

• With Engine level, remove Oil Filler Plug (Fig 15),

• Engine oil should be to point of almost overttowing,

Engine oil capacity is about 1-1/4 pints (20 ounces),

SHIFT

LEVER

INDICATOR

FIGURE 14

• Hold the Drive Control Bar against the Handle to start

Tiller Movement, Tines will not turn

• Move Throttle Control to desired speed before slarting

Engine.

CAUTION: PRACTICE THE ABOVE PROCEDURES

SEVERAL TIMES BEFORE FILLING EN-

GINE WITH FUEL AND OIL,,

OIL LEVEL OIL FILLER

PLUG

FIGURE 15

11

Loading...

Loading...