Craftsman 917299230 Owner’s Manual

!sear

OWNERS

MANUAL

Caution:

Read Rules for

Safe Operation

and Instructions

Carefully

i lll

3o5H

REAR

WBTH

ROTA

Assembly

Operation

Maintenance

Repair Parts

Sears, Roebuck and Con, Chicago, 11t.60684 U.S.A.

oPoCRT 14 INCH

TINE TILLER

COUNTER

TIN G TONES

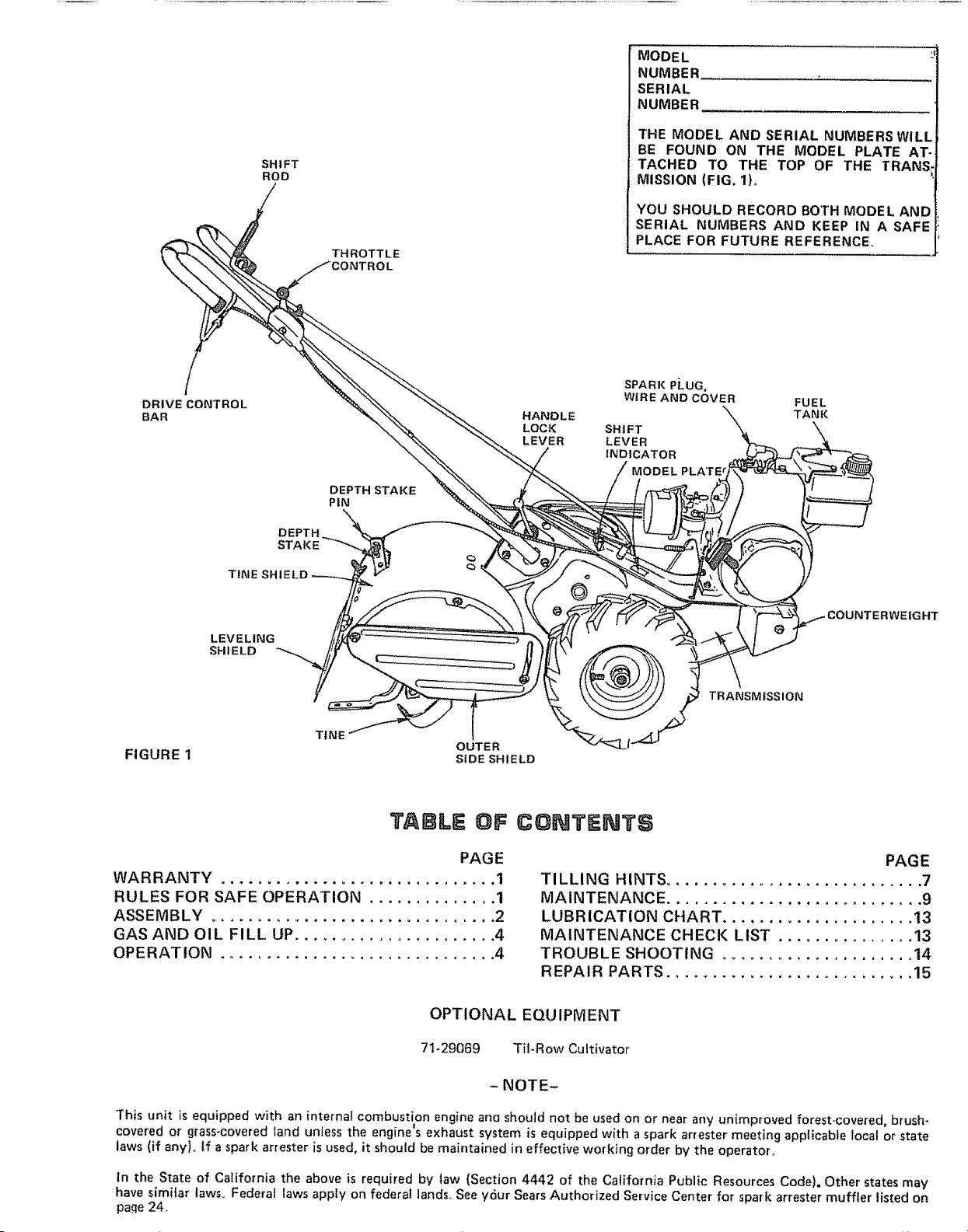

DRIVECONTROL

BAR

SHIFT

ROD

THROTTLE

DEPTH STAKE

PIN

HANDLE

LOCK

LEVER

MODEL

NUMBER

SERIAL

NUMBER

THE MODEL AND SERIAL NUMBERS WILL

BE FOUND ON THE MODEL PLATE AT-

TACHED TO THE TOP OF THE TRANS,

MISSION (FIG. 1L

YOU SHOULD RECORD BOTH MODEL AND

SERIAL NUMBERS AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

SPARK PLUG,

WIRE AND COVER

SHIFT

LEVER

INDICATOR

MODEL PLATE _

FUEL

TANK

OEPTH_

STAKE \

TINE SHIELD

LEVELING

SHIELD

TtNE

FIGURE 1 SIDE SHIELD

OUTER

TABLE OF

PAGE

WARRANTY .............................. 1

RULES FOR SAFE OPERATION .............. 1

ASSEMBLY ............................... 2

GAS AND OIL FILL UP ....................... 4

OPERATION .............................. 4

IGHT

TRANSMISSION

CONTENTS

PAGE

TILLING HINTS ............................ 7

MAINTENANCE ............................ 9

LUBRICATION CHART ..................... 13

MAINTENANCE CHECK LIST ............... 13

TROUBLE SHOOTING ..................... 14

REPAIR PARTS ........................... 15

OPTIONAL EQU IPMENT

71-29f369 Til-Row Cultivator

- NOTE-

This unit is equipped with an internal combustion engine ana should not be used on or near any unimproved forest_covered, brush-

covered or grass-covered land unless the engine s exhaust system is equipped with a spark arrester meeting applicable local or state

laws (if any). If a spark attester is used, it should be maintained in effective working order by the operator_

In the State of California the above is required by taw (Section 4442 of the California Public Resources Code), Other states may

have similar lawso Federal laws apply on federal lands See y6ur Sears Authorized Service Center for spark arrester muffler listed on

pa.qe 24

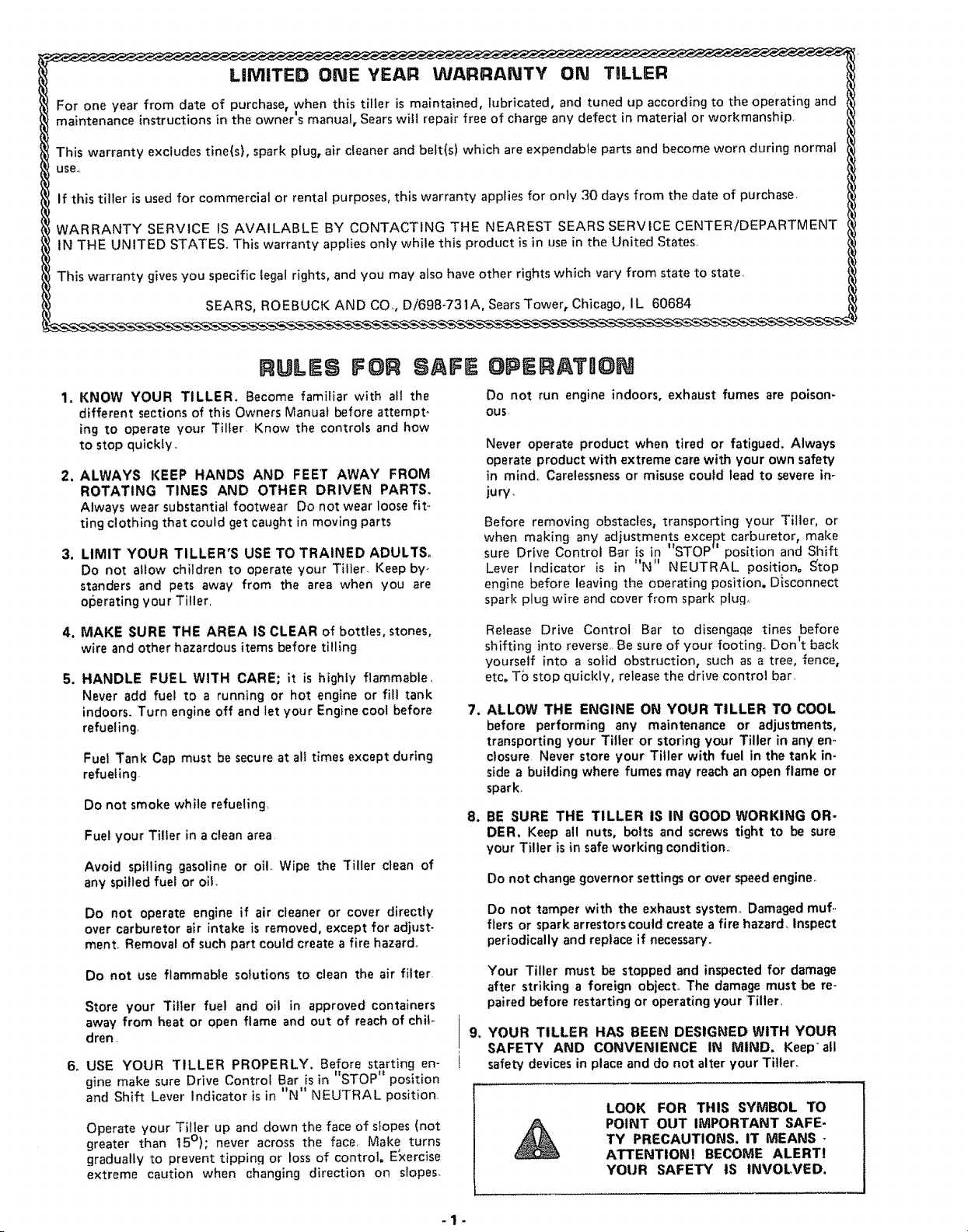

. I

LIMITED ONE YEAR _tVARRANTY ON TILLER

For one year from date of purchase, _Jhen this tiller is maintained, lubricated, and tuned up according to the operating and

maintenance instructions in the owner s manual, Sears will repair free of charge any defect in material or workmanship

This warranty excludes tine(s), spark plug, air cleaner and belt(s) which are expendable parts and become worn during norma_

use.

If this tiller is used for commercial or rental purposes,this warranty applies for only 30 days from the date of purchase.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER/DEPARTMENT

IN THE UNITED STATES. This warranty applies only while this product is in use in the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CQ, D/698o731A, SearsTower, Chicago, IL 60684

RULES FOR SAFE

1, KNOW YOUR TILLER. Become familiar with all the

different sections of this Owners Manual before attempt°

ing to operate your Tiller. Know the controls and how

to stop quickly.

2, ALWAYS KEEP HANDS AND FEET AWAY FROM

ROTATING TINES AND OTHER DRIVEN PARTS,

Always wear substantial footwear Do not wear loose fit ._

t|ng clothing that could get caught in moving parts

3, LIMIT YOUR TILLER'S USE TO TRAINED ADULTS,

Do not atfow children to operate your Tilter Keep by-

standers and pets away from the area when you are

o!Seratingyour Tiller

4, MAKE SURE THE AREA IS CLEAR of bottles, stones,

wire and other hazardous items before tilling

5, HANDLE FUEL WITH CARE; it is highly flammable,

Never add fuel to a running or hot engine or fill tank

indoors. Turn engine off and let your Engine coot before

refueling

Fuel Tank Cap must be secure at all times except during

refueling

Do not smoke while refueling

Fuel your Tiller in a clean area

Avoid spilling gasoline or oil. Wipe the Tiller clean of

any spilled fuel or o_t,

Do not operate engine if air cleaner or cover directly

over carburetor air intake is removed, except for adjust-

ment Removal of such part could create a fire hazard.

OPERATeON

Do not run engine indoors, exhaust fumes are poison-

ous

Never operate product when tired or fatigued. Always

operate product with extreme care with your own safety

in rain& Carelessness or misuse could lead to severe in-

jury,

Before removing obstacles, transporting your Tiller, or

when making any adjustments except carburetor, make

sure Drive Control Bar is in "STOP" position and Shift

Lever Indicator is in "N" NEUTRAL position° Stop

engine before leaving the operating position. D_sconnect

spark plug wire and cover from spark plug,

Release Drive Control Bar to disengaqe tines before

shifting into reverse,, Be sure of your footing,, DonTt back

yourself into a soiid obstruction, such as a tree, fence,

etco To stop quickly, release the drive control bar_

ALLOW THE ENGINE ON YOUR TILLER TO COOL

.

before performing any maintenance or adjustments,

transporting your Tiller or storing your Tiller in any en-

closure Never store your Tiller with fuel in the tank in-

side a building where fumes may reach anopen flame or

spark.

.

BE SURE THE TILLER IS IN GOOD WORKING OR-

DER, Keep all nuts, bolts and screws tight to be sure

your Tiller is in safe working condition°

Do not change governor settings or over speedengine°

Do not tamper with the exhaust system° Damaged muf-

tiers or spark arrestorscould create a fire hazard, Inspect

periodically and replace if necessary°

Do not use flammable solutions to clean the air filter

Store your Titler fuel and oil in approved containers

away from heat or open flame and out of reach of chil-

dren

6,, USE YOUR TILLER PROPERLY, Before starting en-

gine make sure Drive Control Bar is in _'STOP" position

and Shift Lever indicator is in "N" NEUTRAL position.

Operate your Tiller up and down the face of slopes (not

greater than 15°); never across the face. Make turns

gradually to prevent tipping or loss of control, EYercise

extreme caution when changing direction on slopes,

-1-

Your Tiller must be stopped and inspected for damage

after striking a foreign object_ The damage must be re_

paired before restarting or operating your Tiller

9_

YOUR TILLER HAS BEEN DESIGNED WITH YOUR

SAFETY AND CONVENIENCE IN MIND, Keep'all

safety devices in place and do not alter your Tiller.

LOOK FOR THIS SYMBOL TO

TY PRECAUTIONS, IT MEANS -

POINT OUT IMPORTANT SAFE-

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED.

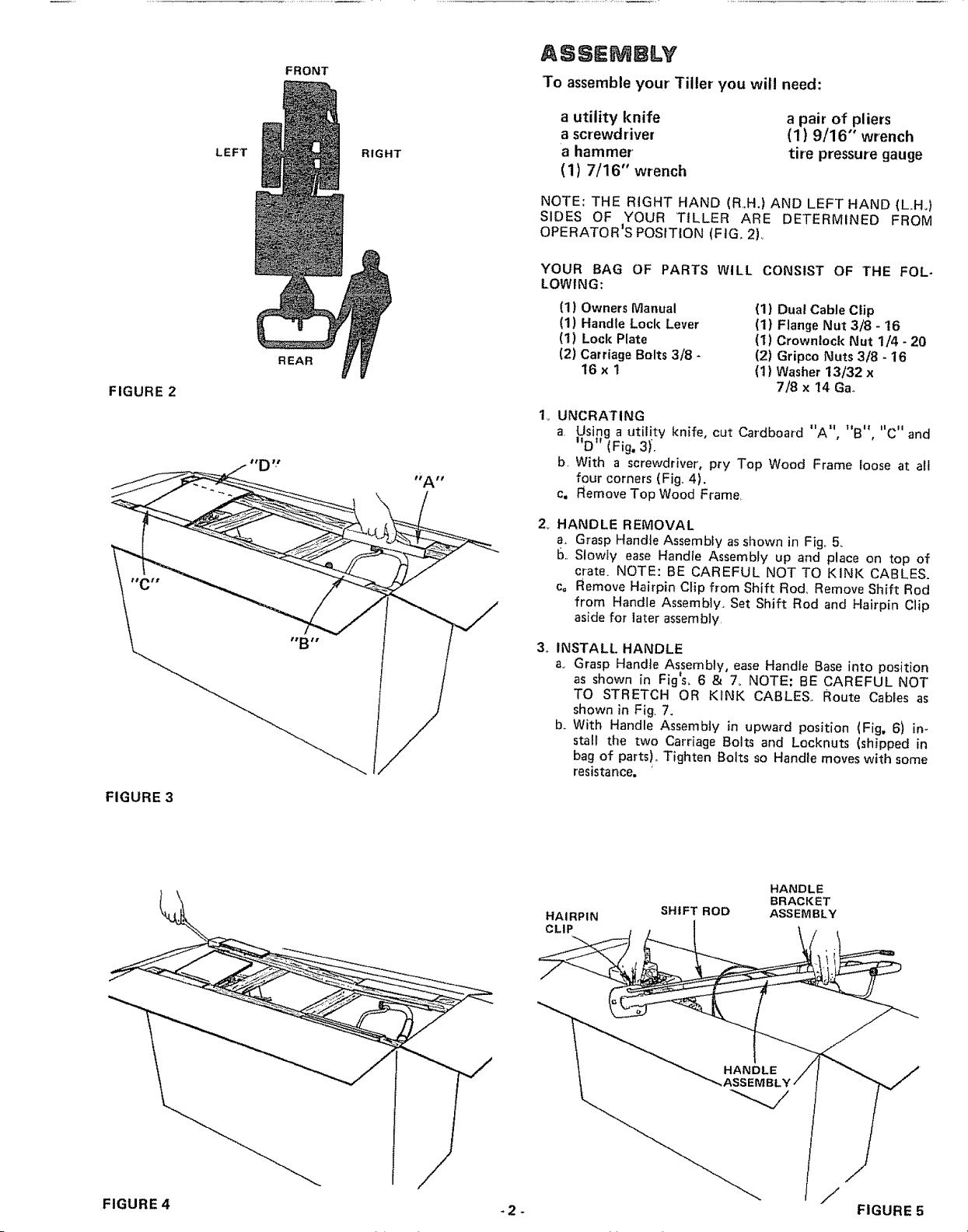

FRONT

ASSEMBLY

To assemble your' Tiller you will need:

FIGURE 2

LEFT

REAR

RIGHT

a utility knife

a screwdriver

a hammer'

a pair of pliers

(1) 9/16" wrench

tire pressure gauge

(1) 7/16" wrench

NOTE: THE RIGHT HAND (R,.H.) AND LEFT HAND (LH,)

SIDES OF YOUR TILLER ARE DETERMINED FROM

OPERATOR'S POSITION (FIG,, 2)°

YOUR BAG OF PARTS WILL CONSIST OF THE FOL-

LOWING:

(1) Owners Manual

(1) Handle Lock Lever

(1) Lock Plate

(2) Carriage Bolts 3/8 -

16xl

UNCRATING

a Using a utility knife, cut Cardboard A , and

tt tr , " w

D (Fig, 3),.

b, With a screwdriver, pry Top Wood Frame loose at atl

four corners (Fig,, 4).

c, Remove Top Wood Frame,

2_ HANDLE REMOVAL

a, Grasp Handle Assembly asshown in Fig,,5,

b,. Slowly ease Handle Assembly up and place on top of

crate, NOTE: BE CAREFUL NOT TO KINK CABLES,

co Remove Hairpin Clip from Shift Rod, Remove Shift Rod

from Handle Assembly, Set Shift Rod and Hairpin Clip

aside for later assembly,

(1) Dual Cable Clip

(1) Flange Nut 3/8 - 16

(i) Crowntock Nut 1/4 -20

(2) Gripco Nuts 3/8 - 16

(1) Washer 13/32 x

7/8 x 14 Ga.

" " _'B_ "C"

FIGURE 3

3. INSTALL HANDLE

ao Grasp Handle Assembly, ease Handle Base into position

as shown in Fig_s_6 & 7, NOTE; BE CAREFUL NOT

TO STRETCH OR KiNK CABLES,. Route Cables as

shown in Fig, 7,

b_ With Handle Assembly in upward position (Fig, 61 in-

stall the two Carriage Bolts and Locknuts (shipped in

bag of parts),,Tighten Bolts so Handle moves with some

resistance.

HANDLE

BRACKET

ASSEMBLY

HAIRPIN

SHIFT ROD

J

FIGURE 4 _2 - FIGURE 5

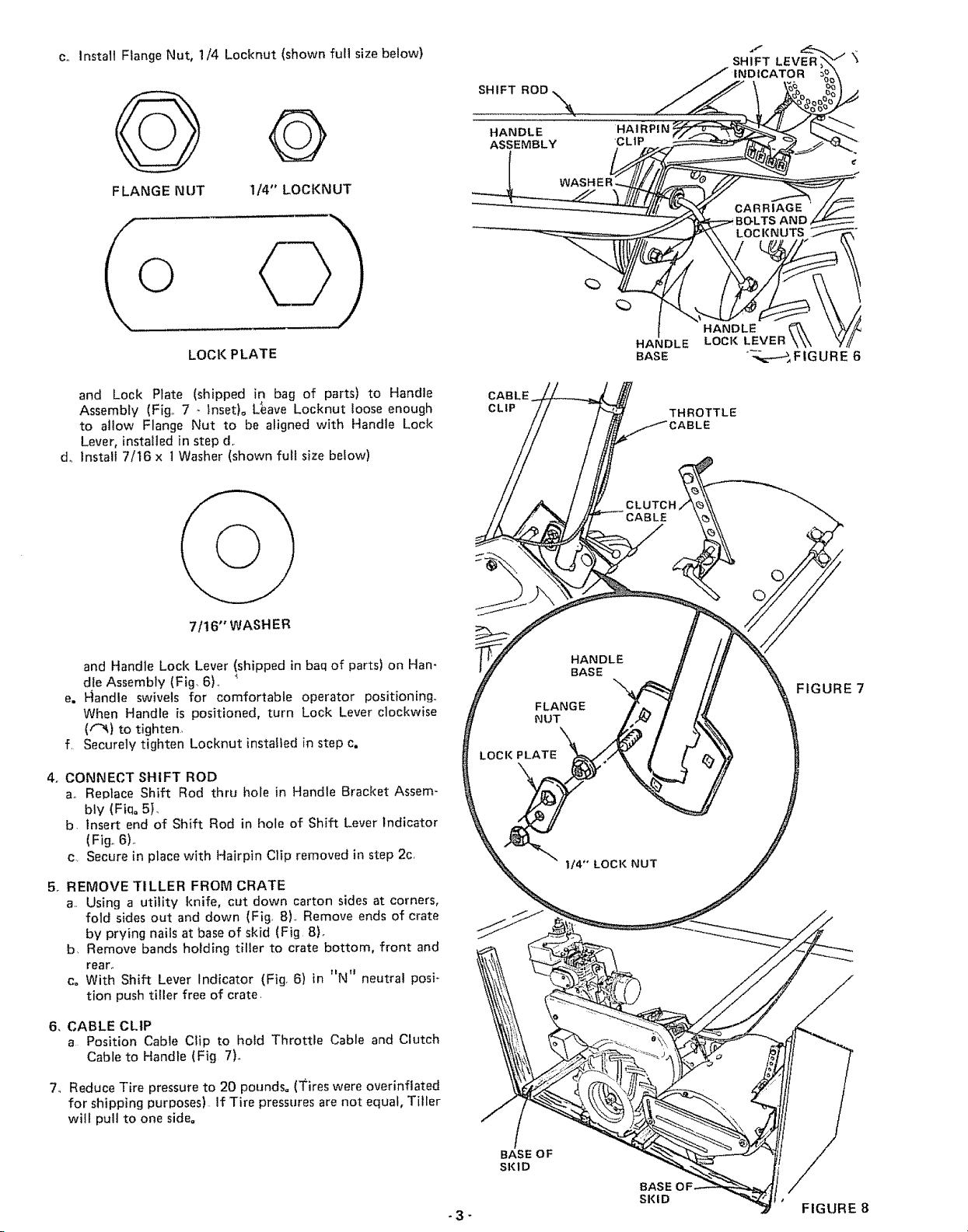

c., Install Flange Nut, 1/4 Locknut (shown full size below)

Q

FLANGE NUT 1/4" LOCKNUT

SHIFT ROD

HANDLE

ASSEMBLY

HAIRPIN

'CLIP

LOCK PLATE

and Lock Plate (shipped in bag of parts) to Handle

Assembly (Fig,. 7 - Inset)° L_ave Locknut loose enough

to allow Flange Nut to be aligned with Handle Loc!<

Lever, installed in step d.

d_

Install 7/16 x t Washer (shown full size below)

7/16" WASHER

and Handle Lock Lever (shipped in baq of parts) on Han-

dle Assembly (Fig 6)_, _

e. F1andle swivels for comfortable operator positioning..

When Handle is positioned, turn Lock Lever clockwise

(f"_) to tighten,

f, Securely tighten Locknut installed in step c.

4o CONNECT SHIFT ROD

a. Replace Shift Rod thru hole in Handle Bracket Assem-

bly (Fiq= 5},

b. Insert end of Shift Rod in hole of Shift Lever Indicator

(Fig. 6)..

c. Secure in place with Hairpin Clip removed in step 2c,

5. REMOVE TILLER FROM CRATE

a,, Using a utility knife, cut down carton sides at corners,

fold sides out and down (Fig, 8)., Remove ends of crate

by prying nails at base of skid (Fig 8)_

b. Remove bands holding tiller to crate bottom, front and

rear,,

c. With Shift Lever Indicator (Fig 6) in "N" neutral posi-

tion push tiller free of crate.

CABLE

CLIP

NUT

LOCI< PLATE

HANDLE

BASE

THROTTLE

:ABLE

CLUTCH

HANDLE

BASE

FIGURE 7

FLANGE

I14" LOCI( NUT

6, CABLE CLIP

a Position Cable Clip to hold Throttle Cable and Clutch

Cable to Handle (Fig 7).,

7., Reduce Tire pressure to 20 pounds° (3_ires were overinflated

for shipping purposes) If Tire pressures are not equal, TilLer

will pull to one side.

BASE OF

SKID

BASE

SKID

- 3 - FIGURE 8

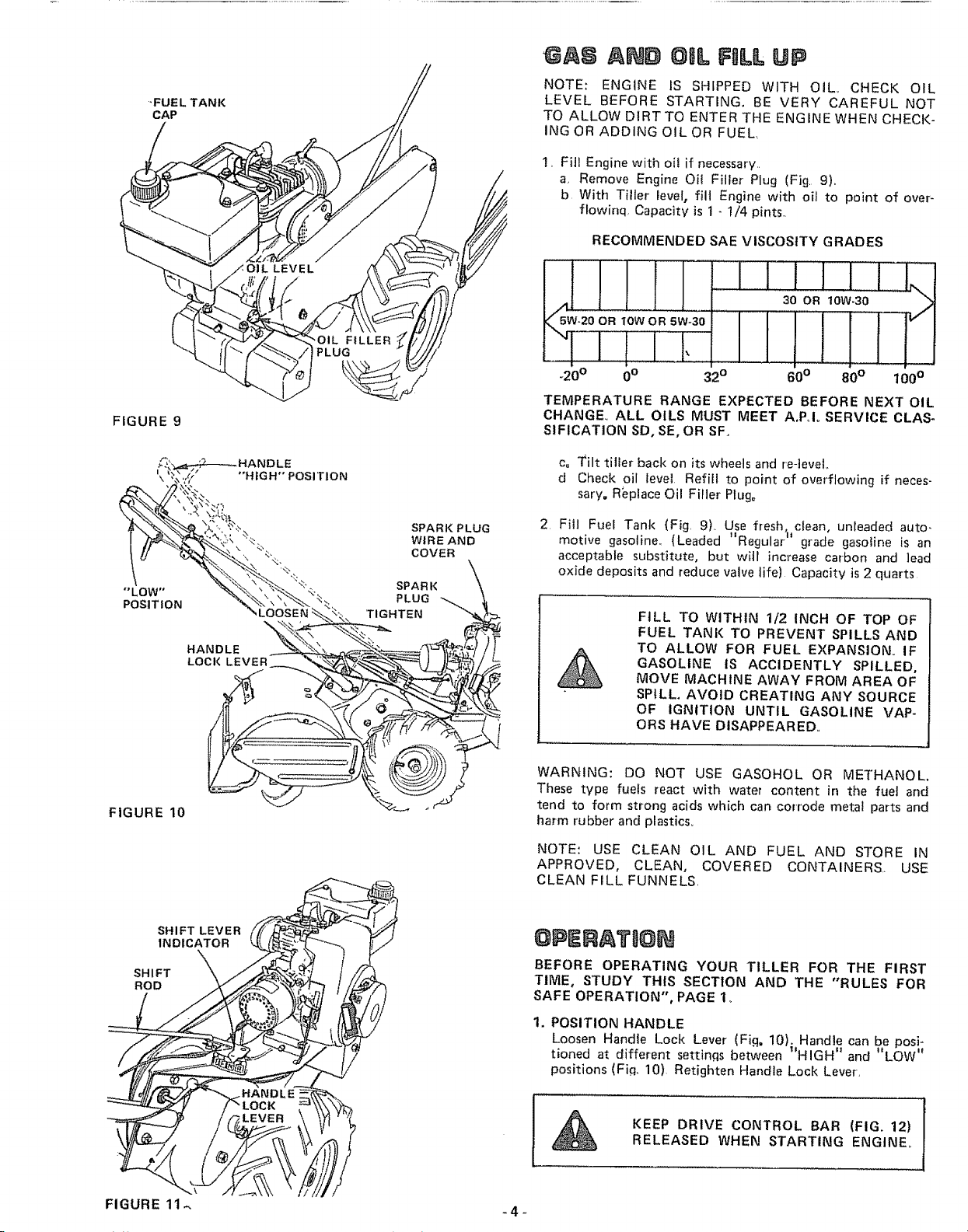

,FUEL TANK

CAP

AND OiL FILl UP

NOTE: ENGINE IS SHIPPED WITH OIL_ CHECK OIL

LEVEL BEFORE STARTING, BE VERY CAREFUL NOT

TO ALLOW DIRT TO ENTER THE ENGINE WHEN CHECK-

ING OR ADDING OIL OR FUEL,

1_ Fill Engine with oil if necessary_

a, Remove Engine Oil Filler Plug (Fig 9)

b With Tiller level, fill Engine with oil to point of over-

flowinq Capacity is 1 - 1/4 pints.

RECOMMENDED SAE VISCOSITY GRADES

FIGURE 9

_NDLE

"HIGH" POSITION

,LOOSEN

LOCI( LEVE

HANDLE __

"%_%'-

SPARK PLUG

WIRE AND

COVER

\

SPARK

PLUG _._ Li

TIGHTEN _ _

I I

II1 I1 .

ORlowOR5W30

I

_20o 0o

_2°

TEMPERATURE RANGE EXPECTED BEFORE NEXT OIL

CHANGE. ALL OILS MUST MEET A,PJ° SERVICE CLAS-

SIFICATION SO, SE, OR SF.

c= l'ilt tiller back on its wheels and re-level

d Check oil level Refill to point of overflowing if neces-

sary, Replace Oil Filler Plug=

2 Fill Fuel Tank {Fig 9) Use fresh, ciean, unleaded auto-

motive gasoline. (Leaded "Regular" grade gasoline is an

acceptable substitute, but witl increase carbon and lead

oxide deposits and reduce valve life) Capacity is 2 quarts

FILL TO WITHIN 1/2 INCH OF TOP OF

FUEL TANK TO PREVENT SPILLS AND

TO ALLOW FOR FUEL EXPANSION, IF

GASOLINE IS ACCIDENTLY SPILLED.

MOVE MACHINE AWAY FROM AREA OF

SP_LL. AVOID CREATING ANY SOURCE

OF IGNITION UNTIL GASOLINE VAP-

ORS HAVE DISAPPEARED,

60° 80 ° 100 °

FIGURE 10

SHIFT LEVER

INDICATOR

SHIFT X

ROD

FIGURE 11_. -4-

WARNING: DO NOT USE GASOHOL OR METHANOL.

These type fuels react with water content in the fueJ and

tend to form strong acids which can corrode metal parts and

harm rubber and plastics,

NOTE: USE CLEAN OIL AND FUEL AND STORE IN

APPROVED, CLEAN, COVERED CONTAINERS. USE

CLEAN FiLL FUNNELS

BEFORE OPERATING YOUR TILLER FOR THE FIRST

TIME, STUDY THIS SECTION AND THE "RULES FOR

SAFE OPERATION", PAGE 1_

1. POSITION HANDLE

Loosen Handte Lock Lever (Fig= 10). Handle can be posi-

tioned at different settings between _'HIGH" and "LOW"

positions (Fi.q_10) Retighten Handle Lock Lever,

KEEP DRIVE CONTROL BAR (FIG. 12)

RELEASED WHEN STARTING ENGINE_

2o STARTING THE ENGINE

NOTE: BE SURE SPARK PLUG, WIRE AND COVER

ARE ATTACHED TO SPARK PLUG,(FIG t0),

a., Move Shift Lever Indicator to N (neutral) position

(Fig.II).

bo Place Throttle Control (Figo 121in START position.

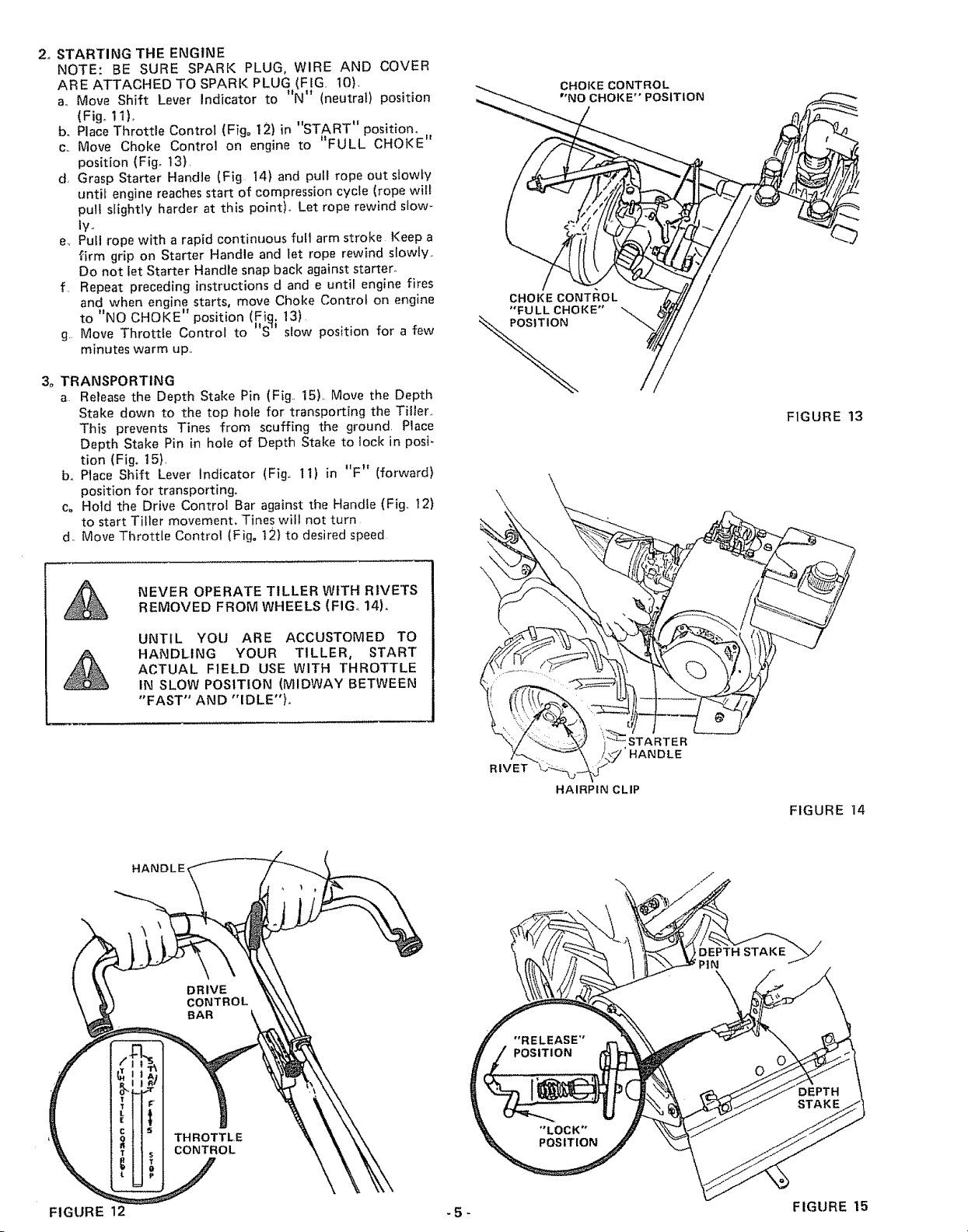

c.. Move Choke Control on engine to _'FULL CHOKE"

position (Fig. 13).

d, Grasp Starter HandJe (Fig. 14) and pull rope out slowty

untit engine reaches start of compression cycle (rope will

pull stightty harder at this point). Let rope rewind slow-

ty.

e, Pull rope with a rapid continuous full arm stroke Keep a

firm grip on Starter Handle and let rope rewind slowly.,

Do not let Starter Handle snap back against starter.

f, Repeat preceding instructions d and e until engine fires

and when engine starts, move Choke Control on engine

to t_NO CHOKE" position (Fiq, 13)

g. Move Throttte Control to S slow posttJon for a few

minutes warm up.,

3. TRANSPORTING

a Release the Depth Stake Pin (Fig., 15),. Move the Depth

Stake down to the top hole for transporting the Tiller',,

This prevents Tines from scuffing the ground. Place

Depth Stake Pin in hole of Depth Stake to loci{ in posi-

tion (Fig. 15),

bo Place Shift Lever Indicator (Fig. 11) in "F" (forward)

position for transporting,

c. Hold the Drive Control Bar against the Handle (Fig., t2)

to start Tiller movement, Tines 'will not turn

d° Move Throttle Control (Fig. 12) to desired speed

II II • •

II ,_II , ,

CHOKE CONTROL

/

J I

CHOK_ CO_JTROLZ,_/i,,FULLCHOKE,, _. _ y

FIGURE 13

\

NEVER OPERATE TILLER WITH RIVETS

REMOVED FROM WHEELS (FIG., 14)o

UNTIL YOU ARE ACCUSTOMED TO

HANDLING YOUR TILLER, START

ACTUAL FIELD USE WITH THROTTLE

tN SLOW POSITION (MIDWAY BETWEEN

"FAST" AND "IDLE").

HANDLE,

STARTER

HANDLE

RIVET

HAIRPIN CLIP

FIGURE 14

FIGURE 12 -5- FIGURE 15

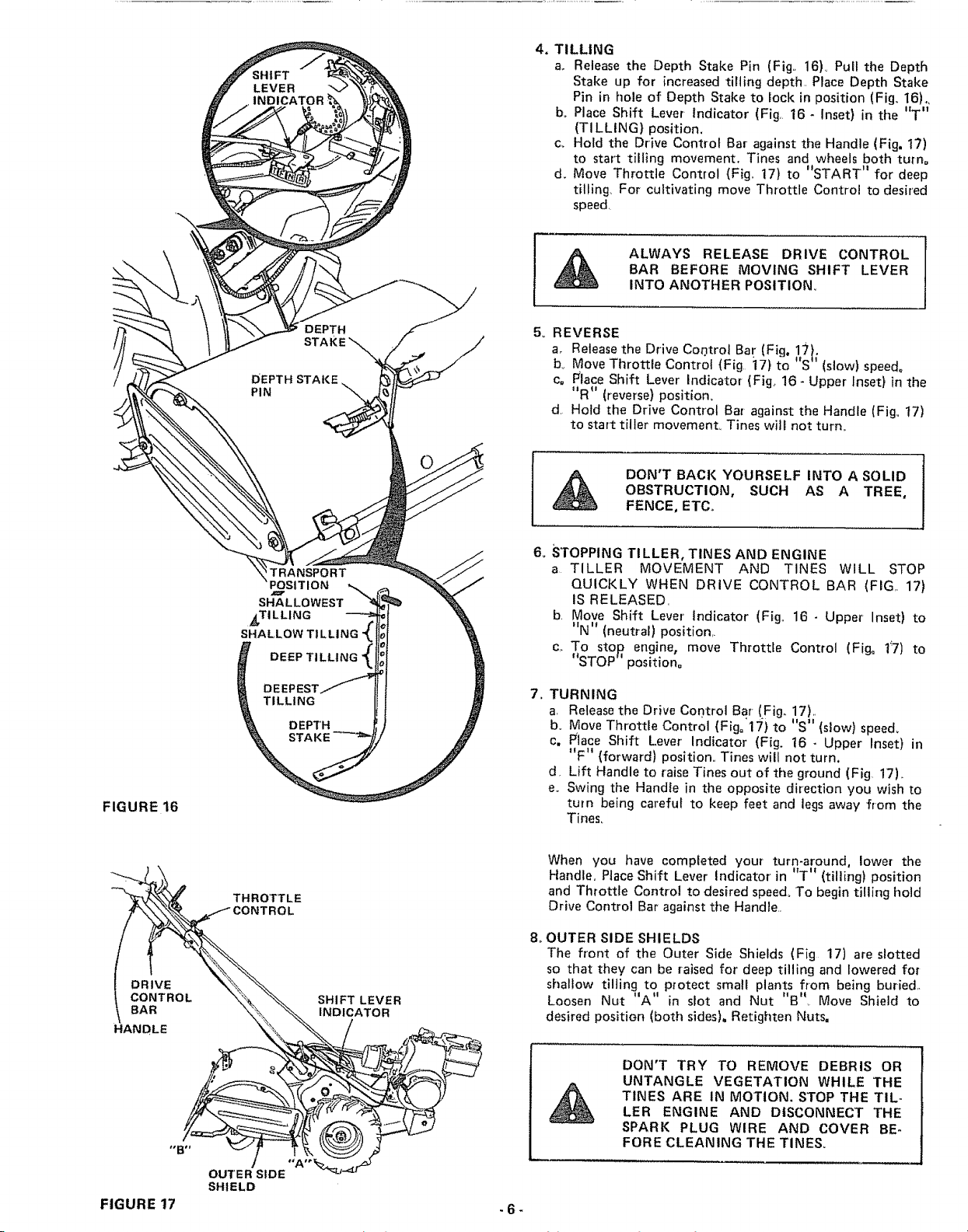

4, TILLING

SHIFT

LEVER

a_ Release the Depth Stake Pin (Fig. 16L Pull the Depth

Stake up for increased tilling depth, Place Depth Stake

Pin in hole of Depth Stake to lock in position (Fig, t6),,

bo Place Shift Lever Indicator (Fig, 16 - Inset) in the "T"

(TILLING) position.

c,. Hold the Drive Control Bar against the Handle (Fig. 17)

to start tilling movement. Tines and wheels both turn°

d, Move Throttle Control (Fig,, 17} to "START" for deep

tilling, For cultivating move Throttle Control to desired

speed,

ALWAYS RELEASE DRIVE CONTROL

\

BAR BEFORE MOVING SHIFT LEVER

INTO ANOTHER POSITION,

FIGURE 16

DEPTH

STAKE _

DEPTH STAKE

PIN

TRANSPORT

POSITION

SHALLOWEST

_TILLING

SHALLOW TILLING _

DEEP TILLING

TILLING

DEPTH

STAKE

5o REVERSE

a,_ Release the Drive Cor.ltrot Ba? (Fig. _7!.

bv Move Throttle Control (Fig 17} to S' (slow) speedo

c° Race Shift Lever indicator (Fig_ 16- Upper Inset) in the

"R" (reverse) position.

d, Hold the Drive Control Bar against the Handle (Fig_ t7)

to start tiller movement. Tines wiil not turn,

OBSTRUCTION, SUCH AS A TREE,

DON'T BACK YOURSELF INTO A SOLID

FENCE, ETC.

6,, STOPPING TILLER, TINES AND ENGINE

a TILLER MOVEMENT AND TINES WILL STOP

QUICKLY WHEN DRIVE CONTROL BAR (FIG 17)

IS RELEASED,

b. Move Shift Lever indicator (Fig,, 16- Upper Inset) to

"N" (neutral) position,,

c,. To stop engine, move Throttle Control (Fig° 17) to

"STOP" position=

7 ,,

TURNING

a Release the Drive Control Bar (Fig,, 17)1,

b. Move Throtde Control {Fig°'17) to "S" (slow) speed,

c, Place Shift Lever' Indicator (Fig, 16- Upper Inset) in

"F" (forward) position,. Tines will not turn.

d, Lift Handle to raise Tines out of the ground (Fig, 17),.

e,. Swing the Handie in the opposite direction you wish to

turn being careful to keep feet and legs away from the

Tines_

SHIFT LEVER

INDICATOR

OUTER SIDE

SHIELD

FIGURE 17 - 6 -

When you have compEeted your turn-around, lower the

Handle. Piace Shift Lever indicator in "T" (tilling) position

and Throttle Control to desired speed, To begin tilling hold

Drive Control Bar against the Handle.

8oOUTER SIDE SHIELDS

The front of the Outer Side Shields (Fig 17) are slotted

so that they can be raised for deep tilling and lowered for

shallow tilling to protect small plants from being buried.

Loosen Nut "A" in slot and Nut "B",, Move Shield to

desired position (both sides), Retighten Nuts.

DON'T TRY TO REMOVE DEBRIS OR

UNTANGLE VEGETATION WHILE THE

TINES ARE IN MOTION. STOP THE TIL-

LER ENGINE AND DISCONNECT THE

SPARK PLUG WIRE AND COVER BE-

FORE CLEANING THE TINES,

WUNTER OPERATION

(UNDER 32o[:.)

1. ENGINE LUBRICATION:

a, Drain the engine oil while engine is warm_

b_ Refill with new oito Use oil labeled 5W20 or 10W or

5W30 (See chart, page 4) Capacity is 1 - t/4 pints

2 FUEL:

ao Use fresh, clean, unleaded automotive gasoline Capacity

is 2 quarts,

3 COLD WEATHER STARTING HINTS:

a, Be sure to use the proper oil and gasoline

b Keep Drive Control Bar released when starting the

engine

c, Use full Choke for starting. Set Throttle Control at med-

ium to fast position. Slowly move Choke Control to

NO CHOKE pos tlon as engine warms up.

NOTE: BE SURE TO CHANGE ENGINE OIL BACK

TO S AoE 30 OR 10W30 (SD, SE OR SF} FOR SPRING

TILLING. (See chart, page 4)

TBLL0 G HB TS

Tilling is digging into, turning over, and breaking up packed

soil before planting Loose unpacked soil helps root growth

Best tilling depth is 4 to 6 A Tdter will also clear the

soil of unwanted vegetation. The decomposition of tf_is vegeta-

ble matter enriches rite soil, Cross-titling is the further breakup

of the soi!. Depending on the climate (rainfall and wind), it

may be advisable to till the soil at the end of the growing

season to further condition the soil

Soil conditions are important for proper tilling, Tines will not

readily penetrate dry, hard soil which may contribute to ex-

cessive bounce and difficult handling of your Tiller,, Hard soil

should be moistened before tilling_ In extremely wet condi-

tions, the soil will "ball up" or clump during tilling, Wait um

til the soil is less wet in order to achieve the best results,

When tilling in the fall, remove vines and long grass to prevent

them from wrapping around the tine shaft and slowing your

tilling operation.,

ii |I *

FIGURE 18

CULTIVATING

_

v

FIGURE t9

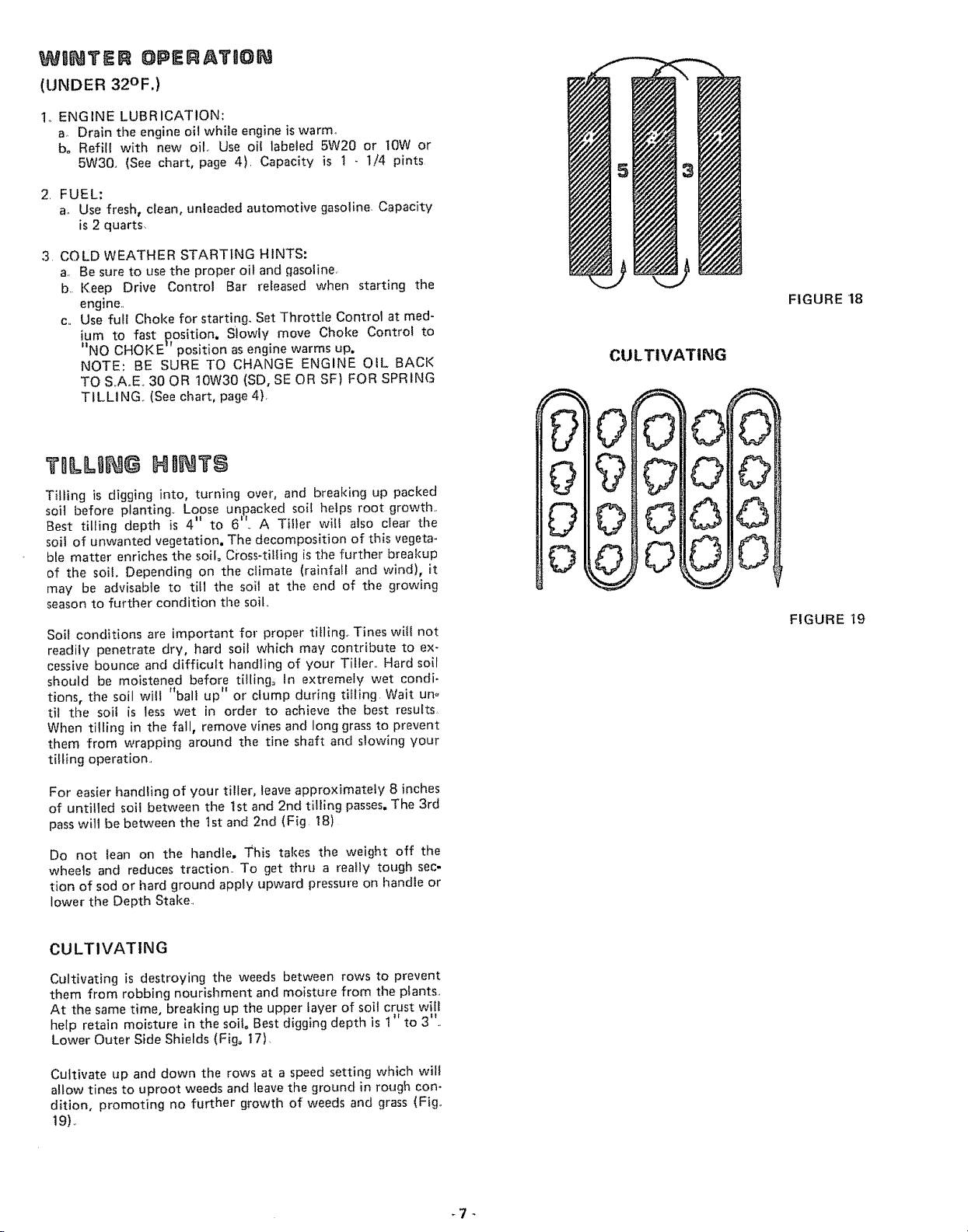

For easier handling of your tiller, leave approximately 8 inches

of untilled soil between the 1st and 2nd tilling passes, The 3rd

pass will be between the 1st and 2nd (Fig 18)

Do not lean on the handle, This takes the weight off the

wheels and reduces traction To get thru a really tough sec-

tion of sod or hard ground apply upward pressure on handle or

lower the Depth Stake

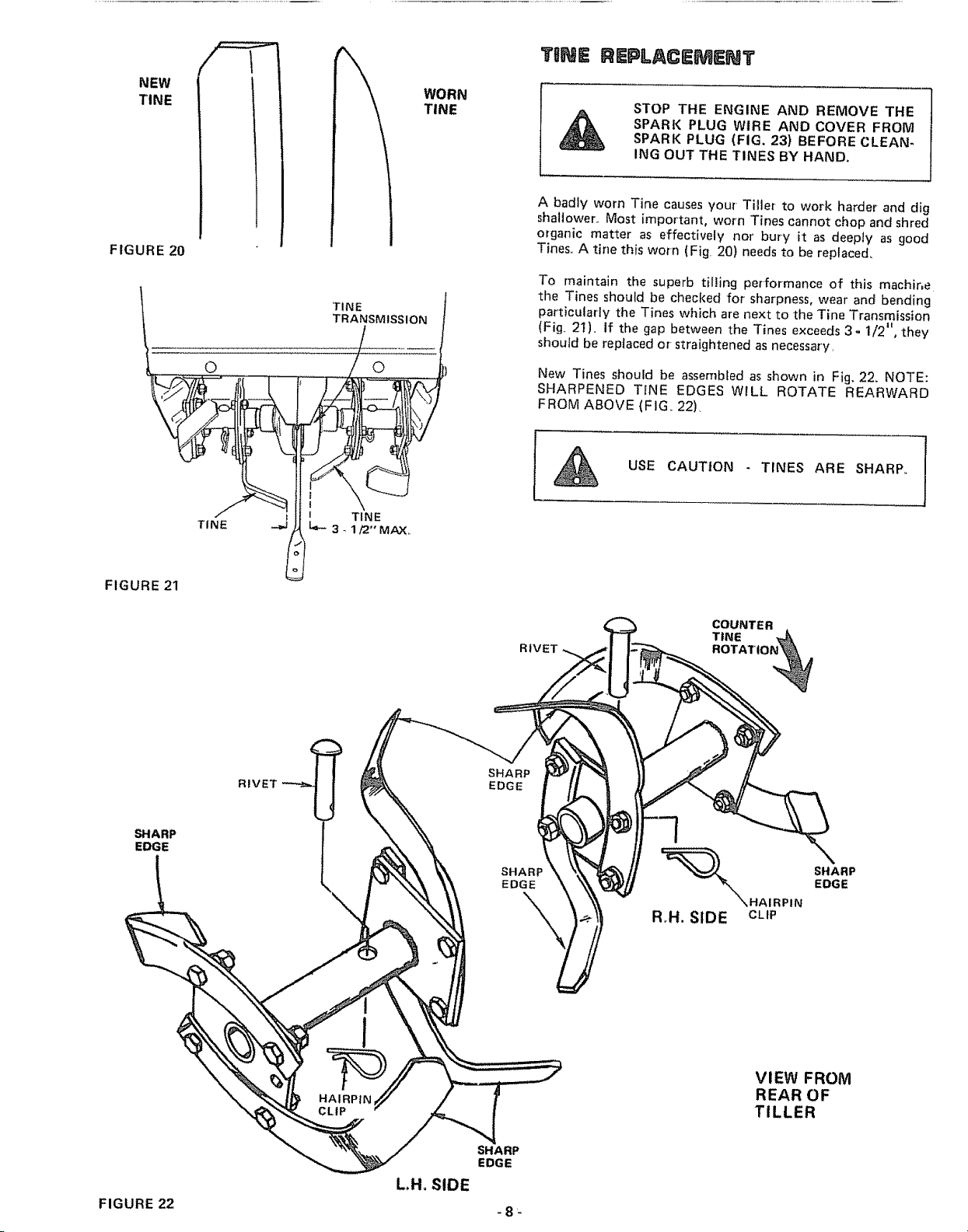

CULTIVATING

Cultivating is destroying the ,weeds between rows to prevent

them from robbing nourishment and moisture from the plants

At the same time, breaking up the upper layer of soil crust will

help retain moisture in the soilo Best digging depth is I" to 3"

Lower Outer Side Shields (Fig. 17)

Cultivate up and down the rows at a speed setting which will

allow tines to uproot weeds and leave the ground in rough con-

dition, promoting no further growth of weeds and grass (Fig,,

19).

TINE REPLACEMENT

NEW

TINE

FIGURE 20

TINE

WORN

TINE

TINE I

T|NE

3.1/2" MAX,.

STOP THE ENGINE AND REMOVE THE

SPARK PLUG WIRE AND COVER FROM

SPARK PLUG (FIG. 23) BEFORE CLEAN-

ING OUT THE TINES BY HAND.

A badly worn Tine causesyour Tiller to work harder and dig

shallower.. Most important, worn Tines cannot chop and shred

organic matter as effectively nor' bury it as deeply as good

Tines.. A tine this worn (Fig. 20) needs to be replaced,

To maintain the superb tilling performance of this machir, e

the Tines should be checked for sharpness, wear and bending

particularly the Tines which are next to the Tine Transmission

(Fig, 21), If the gap between the Tines exceeds 3- 1/2", they

should be repiaced or-straightened as necessary,

New Tines should be assembled as shown in Fig. 22. NOTE:

SHARPENED TINE EDGES WILL ROTATE REARWARD

FROM ABOVE (FIG.. 22).

USE CAUTION - TINES ARE SHARP°

FIGURE 21

SHARP

EDGE

RIVET

SHARP

EDGE

SHARP

EDGE

\

COUNTER

R,H. SIDE

SHARP

EDGE

CLIP

HAIRPIN

CLIP

SHARP

EDGE

L,H, SIDE

FIGURE 22 - 8-

VIEW FROM

REAR OF

TILLER

Loading...

Loading...