Craftsman 917298231 Owner’s Manual

_/A/,_

OWNER'S

MANUAL

MODEL NO.

917.298231

• / t_J f ___

Place Photo Here

Caution:

Read and follow

all Safety Rules

and Instructions

Before Operating

This Equipment

3,0 HORSEPOWER

17 RNCH Tt E WIDTH

FRONT TNNE TALLER

Assembly

Operation

Maintenance

Service and Adjustment

Repair Parts

Sears, Roebuck and Co,, Chicago, IL 60684 UoS.A,

SAFETY RULES

_2-'_} Safe Operation Practices for Walk-Behind Powered Rotaiy Tillel s _._,_l_._i},'_

]'RAINING

Read the operating and service instruction manual

carefully Be thoroughly familiar wilh the controls end

the proper use of the equipment Know how to slop the

unit and disengage the controls quickly

Never allow children to operate Ihe equipment Never

allow adults to operale the equipment without proper

instruction.

Keep the area of operation clear of all persons, particu-

larly small children, and pets

PREPARATION

• Thoroughly inspect the area where the equipment_isto

be used and remove all foreign objects.

Disengage all clutches and shill into neutral before

starting the engine (motor)

Do not operate the equipment without wearing ade-

quate outer garmenls. Wear footwear that will improve

footing on slippery s_daces.

• Handle fuel with:care; it is highly flammable

• Lisa an ap.prbved fue .con alner

Never add fuel to a running engine or hot engine.

Fill fuel tank outdoors with extreme care Never fill

fuel tank indoors

Replace gasoline cap securely and clean up spilled

fuel before restading.

• Use extension cords and receptacles as specified bythe

manufacturer for all units with electric drive motors or

electric starting motors.

• Never attempt to make any adjustments while the engine

(motor) is running (except where specifically recom-

mended by manutacturer).

OPERATION

• Do not put hands or feet near or under rotating parts

• Exercise extreme caution when operating on or crossing

gravel drives, walks, or roads Stay alert for hidden

hazards or traffic. Do not carry passengers.

• After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, thoroughly inspect

the tiller for any damage, and repair the damage before

restariing and operating the tiller.

• Exercise caution to avoid slipping or failing

• !l the unit should stad to vibrate abnomlally, stop the

engine (motor) and check immediately for the cause Vi-

bration is generally a warning of trouble.

• Slop the engine (motor) when leaving the operating

position, before unclogging the tines, and when making

any repair, adjuslments, and inspections

• "Fakeall possible precautions when leaving the machine

unattended Disengage Ihe power take-off, lower the

attachment, shift into neutral, stop the engine, and

remove the key

• Before cleaning, repairing, or inspecting, shut off [he

engine and make certain all moving parts have stoppe&

Disconnect the spark plug wire, and keep thewire away

from the plug lo prevent accidental starting. Disconnec!

the cord on electric molors.

• Do not run the engine indoors; exhaust fumes are dan-

gerous.

• Never operate the tiller wilhout proper guards, plates, or

other safety protective devices in place

• Keep children and pets away

• Donot overload the machine capacity by attempting totill

too deep at too fast a rate

• Never allow bystanders near the unit

• Use only attachments and accessories approved by the

manufacturer ofthetiller (such aswheelweighls, co_ "-

weights, cabs, and the like).

• Never operate the tiller without good visibilily or light

, Be careful when tilling in hard ground. Tile tines may

catch in the ground and propel the tiller forward. If this

occurs, let go of the hand!ebars and do not restrain the

machine.

MAINTENANCE ANDSTORAGE

• Keep machine, attachments, and accessories in safe

working condition_

• Check shear bolts, engine mounting bolts, and other

bolts at frequenl intervals lor proper tightness to be sure

the equipment is in safe working condition.

• Never store the machine with fuel in the fuel lank inside

abuilding where ignition sources are present, such as hol

waler and space heaters, clothes dryers, and the like

Allow the engine to cool before storing in any enclosure

• Always refer to the operalor's guide instructions for

important details ifthe tiller is tobe stored for an extended

period

-IMPORTANT

Warnings, Cautions, and Notes are a means of attracting altention to important or critical information in this manual

LOOK FOR THIS SYMBOL TO POINT

OUT IMPOR'rANT SAFETY PRE-

CAUTIONS. IT MEANS -- ATTENTION!

BECOME ALERT! YOUR SAFETY IS

INVOLVED.

CAUTION: USED TO ALERT' YOU THAT ]'HERE IS

NOTE: Gives essential information that will aid you to

better understand, incorporate, or execute a particular

set of instructions

2

A POSSIBILITY OF DAMAGING ':

EQUIPMENT

CONGRAI_ULATIONS on your purchase of a Sears

Craftsman "Filler. il has been designed, engineered and

manufactured to give you the best possible dependabilily

and pedormance

Should you experience any problems you cannot easily

remedy, please contact your nearest Sears Service Cen-

ter/Depadment We have compelenl, well trained techni-

cians and the proper tools to service or repair this unit

Please read and retain this manual. The instructions will

enable you to assemble and maintain your Tiller prop-

erly Always observe the "SAFETY" RULES"

MODEL

NUMBER 917 298231

SERIAL

NUMBER

DATE OF

PLtRCHASE

THE MODEL AND SERIAL NUMBEFiS WILL BE

FOUND ON THE MODEL PLATE ATTACHED TO

THE RIGHT HAND ENGINE BRACKET_

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP tN A SAFE

PLACE FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product. Contact your nearest Sears store for delails

CUSTOMER RESPONSIBILITIES

. Read and observe the safety rules.

• Fellow a regutar schedule in maintaining, caring for and using your Tiller,

• Follow the instructions under "Maintenance" and "Storage" sections of this Owner's Manuat,

PRODUCT SPECIFICATIONS

HORSEPOWER: 30 HP

DISPLACEMENT: 7 75 CU IN

GASOLINE CAPACITY: 2 QUART

OIL (20 OZ CAPACITY): SAE 30W

SPARK PLUG (GAP 030 IN): CHAMPION

(UNLEADED)

(SAE 10W 30)

RCJ8

LIMITED ONE YEAR WARRANTY ON CRAFTSMAN TILLER

For one year from date o purchase when this Craftsman Tiller is maintained lubricated, and tuned up ac-

cording to the instructions in the owner s manual, Sears will repair, free of charge, any defect in material and

workmanship.

If this Craftsman Tiller is used for commerc[a! or rental purposes, this Warranty applfes for only 30 days from

the date of purchase

This Warranty does not cover:

• expendable items which became worn during normal use, such as tines, spark plug, air cleaners and belts.

- Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure to

maintain the equipment according to the instructions contained in the owner's manual

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN TILLER TO THE NEAREST

SEARS SERVICE CENTER/DEPARTMENT IN THE UNITED STATES THIS WARRANTY APPLIES ONLY

WHILE THIS PRODUCT IS IN USE IN THE UNITED STATES.

This Warranty gives you specific legal rights, and you may atso have other rights which vary from state to

state

Sears, Roebuck and Co, D/731CR-W, Sears Tower, Chicago, IL 60684

-NOTE-

Th sun t s equipped w th an in erna con busl on engine and should not be used on or near any unimproved forest-

covered brush-covered or grass covered and unless he eng ]es exhaust system is equipped with a spark arrester

meeting applicable local or state aws (any) t a spark arrester is used, it should be maintained in effect ve working order

by the operator

In the state of California the above is required by law (Section 4442 of the California Public Resources Code) Other

s ares may have similar laws. Federal laws apply on federal lands See your Sears Aulhodzed Service Cenler for spark

attester Refer 1opage 31 of Repair Pads section of lhis manual for part number

3

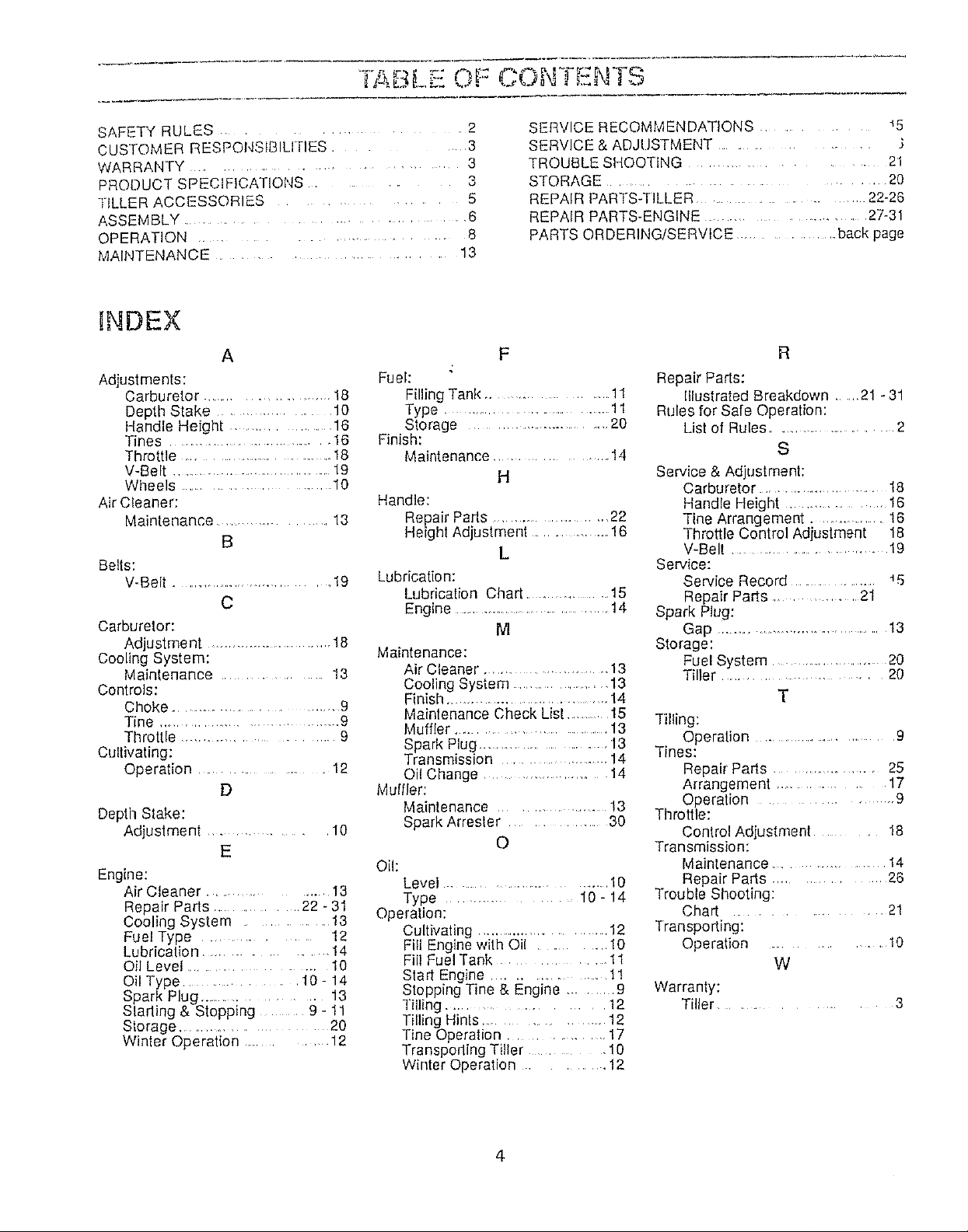

ABL . OF C(aN I=NTS

SAFETY RULES ............ 2

cuSTOMER RESPONStBILI RES ............ 3

WARRANTY .............................

PRODUCT SPECIFICATIONS .................. 3

TILLER ACCESSORIES ........... 5

ASSEMBLY .............................................. 6

OPERATION ............................. 8

MAINTENANCE ......................... 13

HNDEX

A

Adjustments:

Carburetor .......................... 18

Depth Stake ................ 10

Handle Height .................... 16

Tines .................................. 16

Throttle ...................................... 18

V-Belt .................................. 19

Wheels ...................................... 10

Air Cleaner:

Maintenance ................ 13

B

Belts:

V-Belt .............................. 19

C

Carburetor:

Adjustment ............................... 18

Cooling System:

Maintenance ............ 13

Controls:

Choke .............................. 9

Tine ................................... 9

Throttle ................................... 9

Cultivating:

Operation .................. 12

D

Depth Stake:

Adjustment ............. 10

E

Engine:

Air Cleaner ............... I3

Repair Parts .......... 22 - 31

Cooling System .............. 13

Fuel Type ....................... 12

Lubrication .............. !4

Oil Level ............................. 10

Oil Type ................. 10- 14

Spark Plug ................. 13

Stading & Stopping .... 9 - 11

Storage .................... 20

Winler Operation ............ 12

Fuel:

Filling Tank ................. 11

Type ................................................! 1

Storage ................................... 20

Finish:

Maintenance .................. 14

Handle:

Repair Parts ......................... 22

Heigh! Adjuslment ............. 16

Lubrication:

Lubrication Chart ........................15

Engine ..................................... 14

Maintenance:

Air Cleaner ....................... 13

Cooling System .................... 13

Finish ...................................... 14

Maintenance Check List ...........15

Muffler ............................ 13

Spark Plug ...................... 13

Transmission ..................... 14

Oil Change ...................... 14

Muffler:

Maintenance ................... 13

Spark Arrester .............. 30

Oil:

Level .............................. 10

Type ................. 10 - 14

Operation:

Cultivating ............................ 12

Fill Engine with Oil .......... t0

Fill Fuel Tank ........... 11

Start Engine .............. 1!

Stopping Tine & Engine ...... 9

Tilling .................... 12

Tilling Hinls .............. 12

Tine Operation. 17

Transporting Tiller .................. 10

Winter Operation ............. 12

SERVICE RECOMMENDATIONS .................. 45

SERVICE & ADJUSTMENT ............................ .}

3

TROUBLE SHOOTING ........................... 21

STORAGE ....................................... 20

REPAIR PARTS-TILLER ..................... 22-26

REPAIR PARTS-ENGINE ......................... 27-31

PARTS ORDERING/SERVICE ................. back page

R

Repair Parts:

Illustrated Breakdown ..... 21 - 31

Rules for Safe Operation:

List of Rules ........................ 2

S

H

L

M

Service & Adjustment:

Carburetor .......................... 18

Handle Height ................. 16

Tine Arrangement .............. 16

Throttle Control Adjustment 18

V-Belt ........................... 19

Service:

Service Record ..................... _5

Repair Parts ................ 21

Spark Plug:

Gap ...................................... 13

Storage:

Fuel System ..................... 20

Tiller ......................... 20

T

Tilling:

Operation ....................... 9

Tines:

Repair Parts ..................... 25

Arrangement .................... 17

Operation .......................... 9

Throttle:

O

Control Adjustment ............ 18

Transmission:

Maintenance ................... t 4

Repair Parts ............. 26

Trouble Shooting:

Chart .............. 21

Transporting:

Operation ............... 10

W

Warranty:

Tiller ....................... 3

4

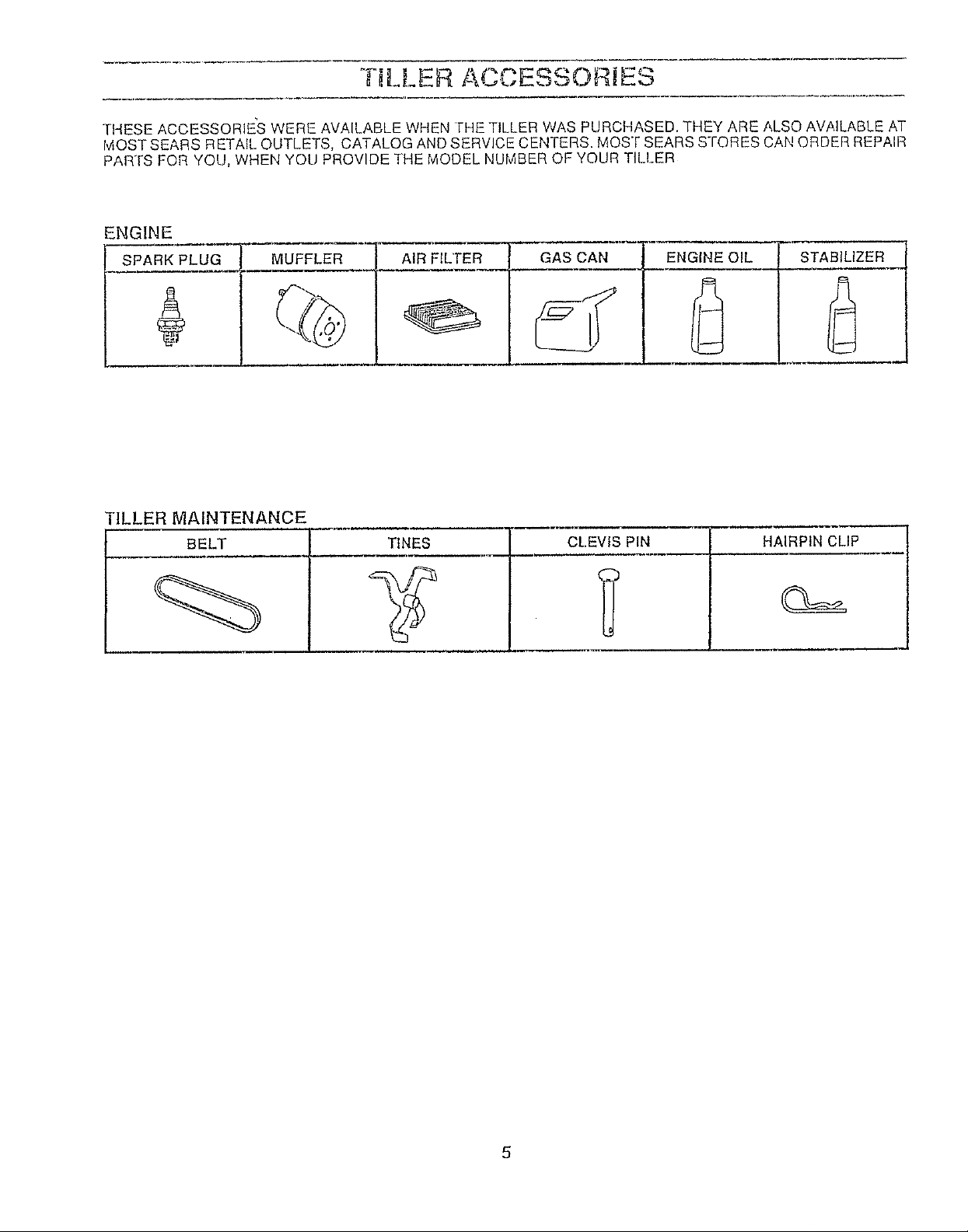

TILLER AOt, ESSOR]Eo

THESE ACCESSORIE_S WERE AVAILABLE WHEN FHE TILLER WAS PURCHASED. THEY ARE ALSO AVAILABLE AT

IviOST SEARS RETAfL OUTLETS, CATALOG AND SERVICE CENTERS. MOST SEARS STORES CANORDER REPAIR

PARTS FOR YOU, WHEN YOU PROVIDE THE MODEL NUMBER OF YOUR TILLER

ENGINE

SPARK PLUG MUFFLER

AIR FILTER GAS CAN ENGINE OIL STABILIZER

L

"ILLER MAINTENANCE

BELT TINES

CLEVIS PIN HAIRPIN CLIP

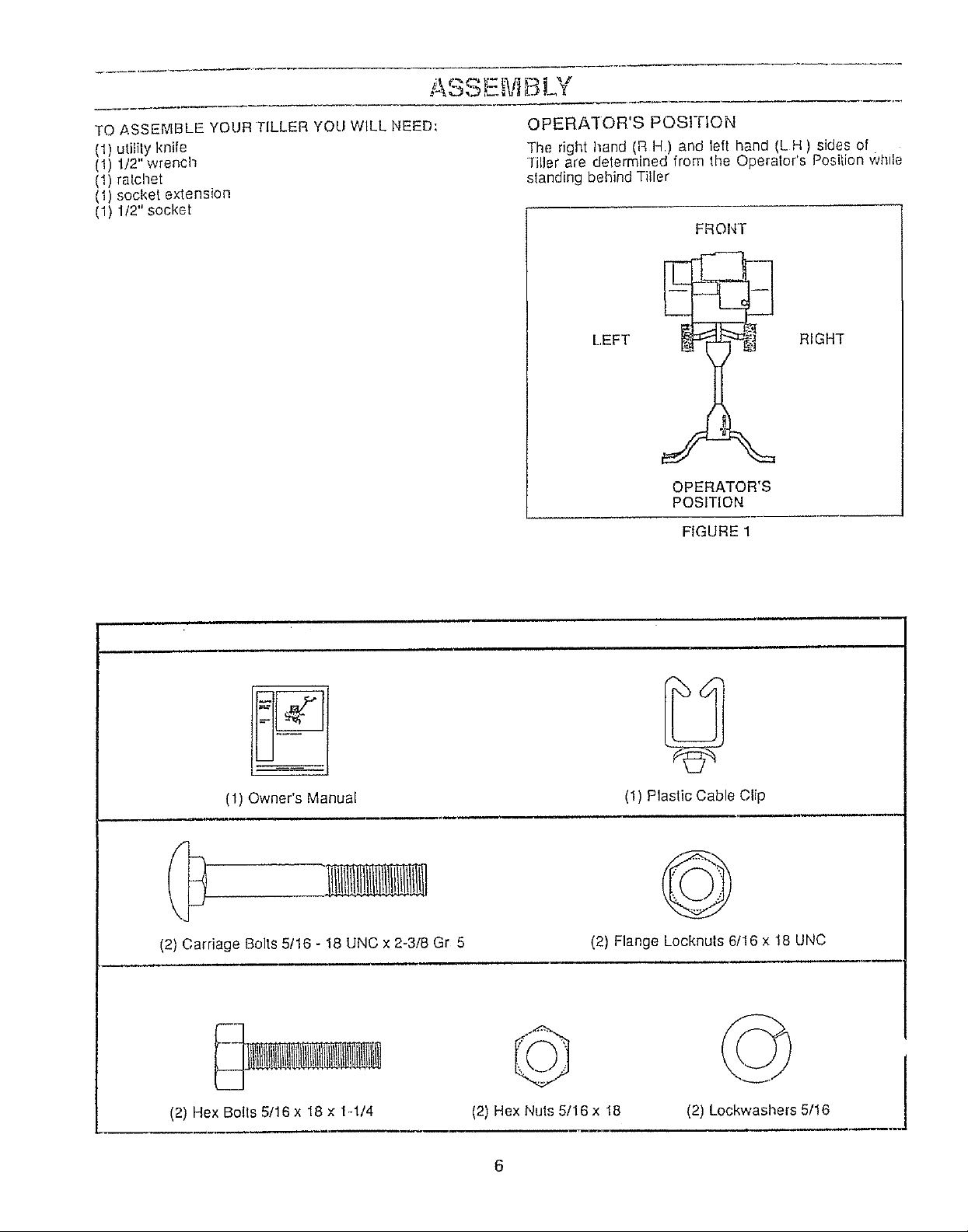

TO ASSEMBLE YOUR TILLER YOU WILL NEED:

(1) utility knife

(1) 1/2" wrench

(1) ratchet

(1) socket extension

(1) 1/2" socket

OPERATOR'S POSITION

]'he right hand (R H.) and left hand (L H ) sides of

*filler are determined from the Operelor's Position while

standing behind Tiller

FROI,,IT

LEFT RIGHT

OPERATOR'S

POSITION

FIGURE 1

(1) Owner's Manual

(2) Carriage Bolts 5!16 - 18 UNC x 2-3/8 Gr 5

(2) Hex Bolts 5/16 x 18 x 1-1/4

(2) Flange Locknuts 6/16 x 18 UNC

(2) Hex Nuts 5/16x 18

6

(1) Plastic Cable Clip

©

(2) Lockwashers 5/16

!

E,.ViBLV

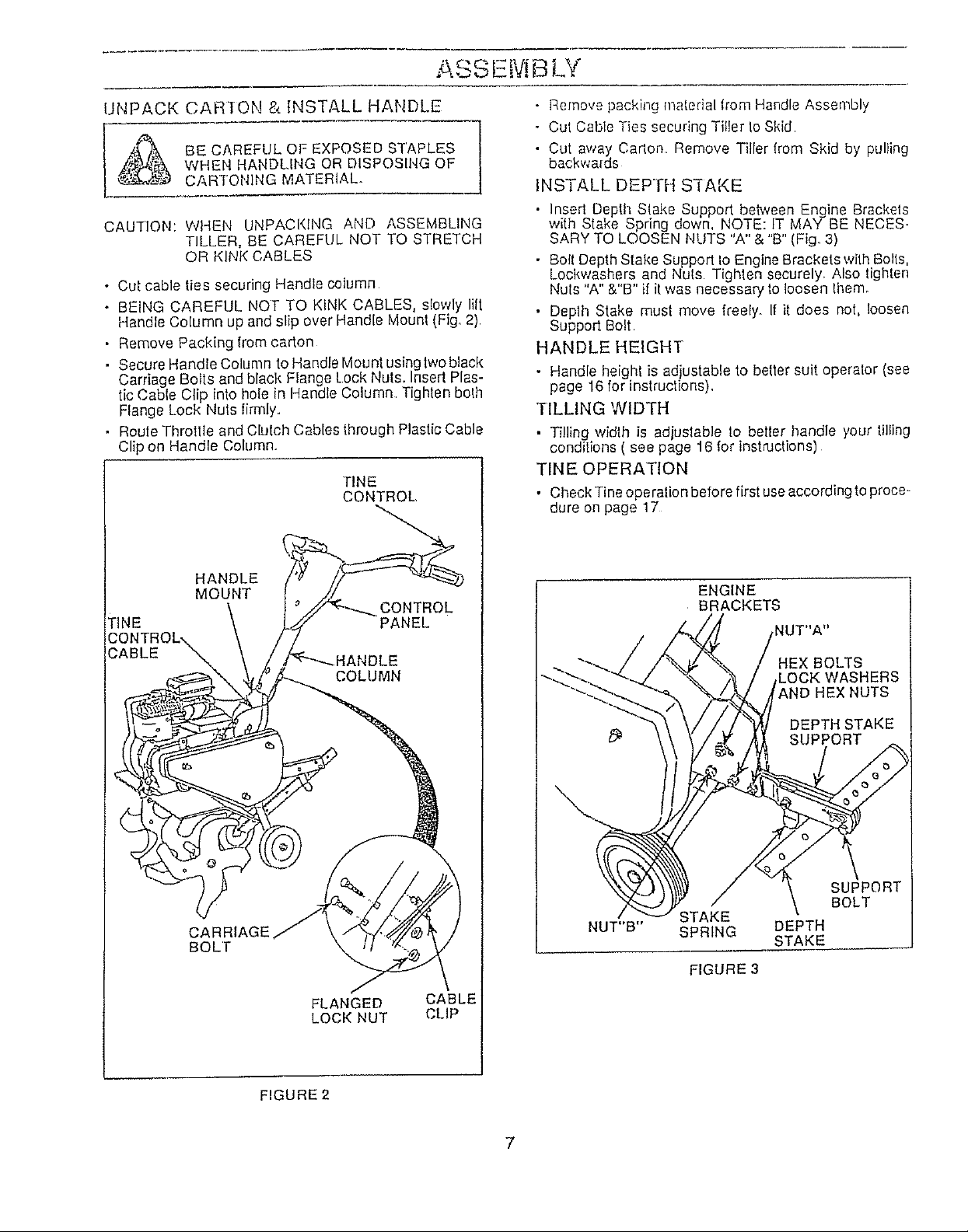

UNPACK CARTON & INSTALL HANDLE

_ BE CAREFUL OF EXPOSED STAPLES

WHEN HANDLING OR DISPOSING OF

CAR'i'ONING MATERIAL°

CAUTION: Wt4EN UNPACKING AND ASSEMBLING

TILLER, BE CAREFUL NOT TO STRETCH

OR KINK CABLES

• Cut cable ties securing Handle column

• BEING CAREFUL NOT TO KINK CABLES, slowly lift

Handle Column up and slip over Handle Mounl (Fig, 2)

• Remove Packing from carton

• Secure HandleColumn to Handle Mounlusinglwoblack

Carriage Bolts and black Flange Lock Nuts, Insert Plas-

tic Cable Clip into hole in Handle Column Tighten bolh

Flange Lock Nuls limlly.

• Roule Throttle and Clulch Cables through Plastic Cable

Clip on Handle Column.

TINE

CONTROL,

• Remove packing matedal from Handle Assembly

o Cut Cable Ties securing Tiller to Skid

• Cut away Carlon Remove Tiller lrom Skid by pulling

backwards

INSTALL DEPTH S'I-AKE

• Insed Depth Slake Support beh*zeenEngine Brackets

with Stake Spring down, NOTE: IT MAY BE NECES_

SARY TO LOOSEN NUTS "A" & "B" (Fig. 3)

• Boll Depth Stake Support Io Engine Brackets with Bolls,

Lockwashers and Nuls Tighten securely. Also lighten

Nuts "A" &"B" if it was necessary fo loosen Ihem_

• Deplh Stake must move freely, If it does not, loosen

Support Bolt

HANDLE HEIGHT

• Handle height is adjustable to better suit operator (see

page 16 for instructions),

TILLING WIDTH

• Tilling width is adjuslable to beller handle your tilling

conditions ( see page 16 for instructions)

TINE OPERATION

• Check Tine operation before first useaccording to proce-

dure on page 17

HANDLE

MOUNT

CONTROL

TINE PANEL

COLUMN

CARRIAGE

BOLl"

FLANGED CABLE

LOCK NUT CLiP

ENGINE

BRACKETS

STAKE

NUT"B" SPRING

FIGURE 3

: BOLTS

SUPPORT

BOLT

DEPTH

STAKE

FIGURE 2

7

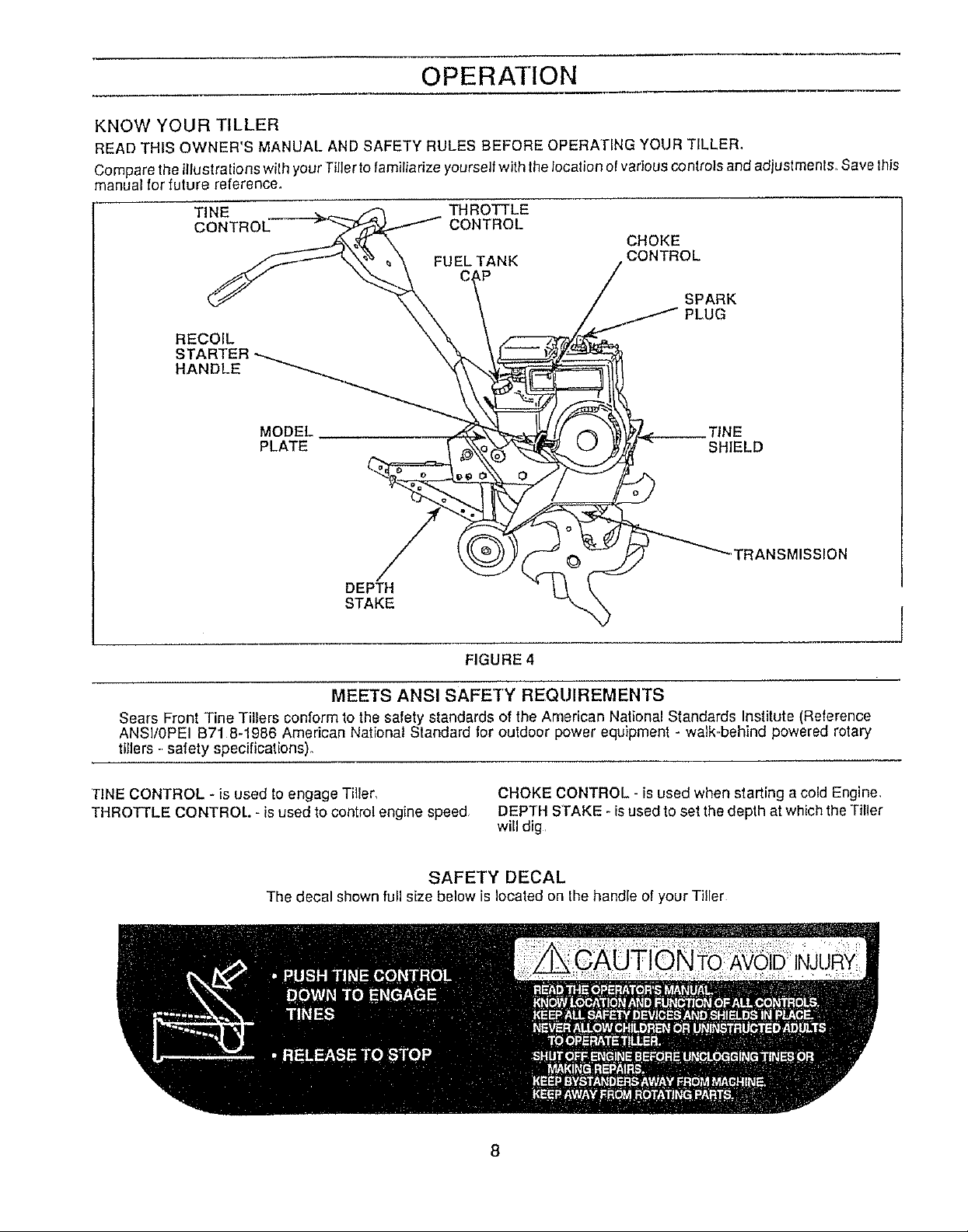

OPERATION

KNOW YOUR TILLER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TILLER,

Compare the illustrations with your Tiller to familiarize yourself with the location el various controls and adjustment& Save this

manual for future reference.

TINE THROTTLE

CONTROL CONTROL

FUEL TANK

RECOIL

HANDLE

MODEl. __TINE

PLATE SHIELD

CHOKE

CONTROL

SPARK

JG

""TRANSMISSION

DEPTH

STAKE I

FIGURE 4

MEETS ANSI SAFETY REQUIREMENTS

Sears Front Tine Tillers conform to lhe safety standards of the American Nalional Standards Institute (Reference

ANSI/0PEI B71 8-1986 American National Standard for outdoor power equipment - walk..behind powered rotary

tillers -safety specifications).

TINE CONTROL - is used to engage Tiller,

THROTTLE CONTROL. - is used to control engine speed

SAFETY DECAL

The decal shown full size below is Iocaled on the handle of your Tiller

CHOKE CONTROL - is used when starting a cold Engine,

DEPTH STAKE - isused to set the depth at which the Tiller

will dig

8

OPERATION

....... Fheoperalion of any Tiller can result inforeign objects thrown intotile eyes, which can result in severe

recommend Wide Vision Safely Mask for over Ihe speclacles or standard safely glasses, available at

eye damage, Always wear safety glasses or eyeshields before starting you rTiller and while lilling We

Sears Retail or Catalog Stores

HOW TO USE YOUR TILLER

Know how Io operate all controls before adding fuel and

oil or attempting to start Engine (To stop Engine pIace

Throttle Control in "STOP" position )

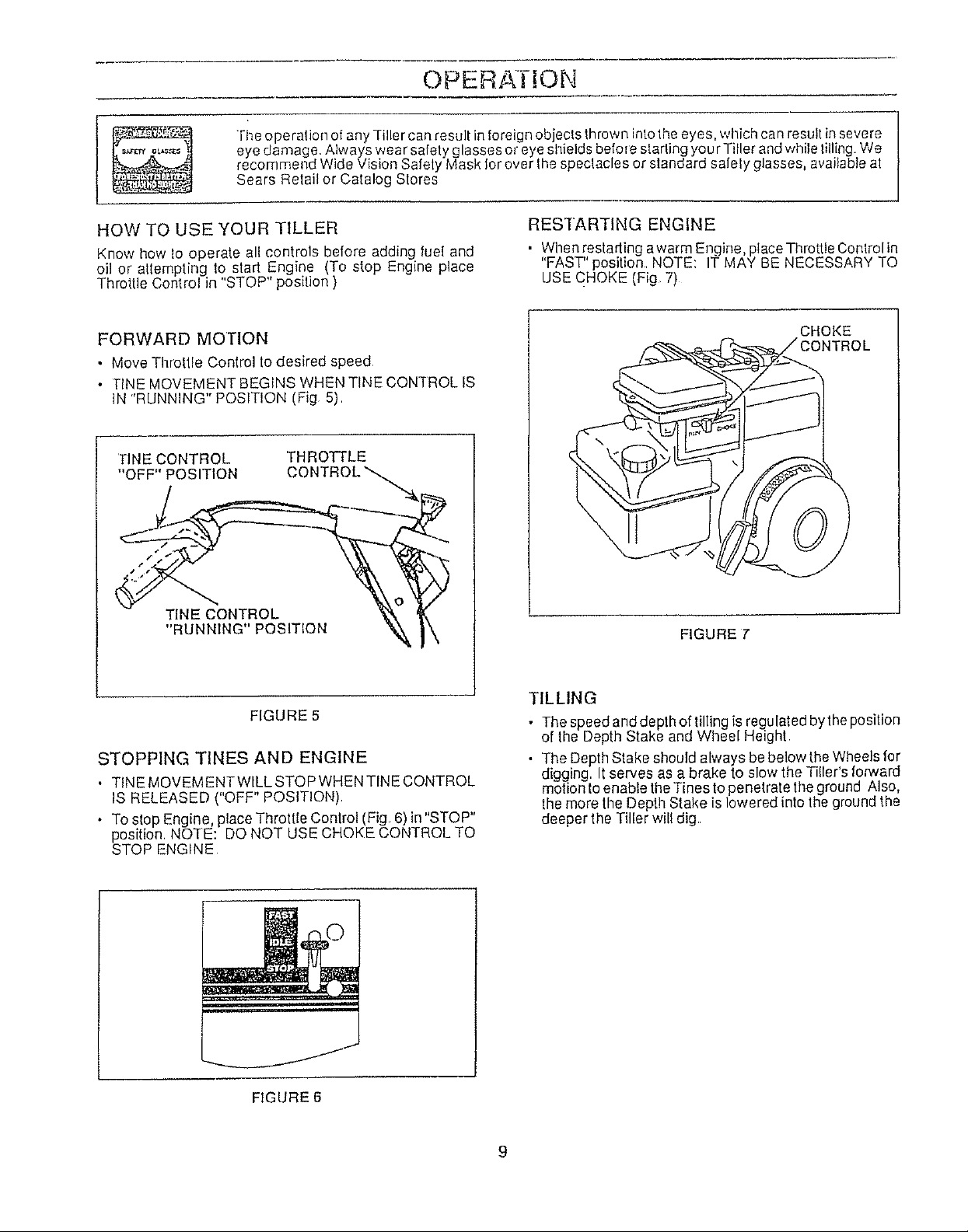

FORWARD MOTION

• Move Throtlle Control to desired speed

• TINE MOVEMENT BEGINS WHEN TINE CONq-ROL IS

tN "RUNNING" POSITION (Fig 5)

TINE CONTROL

"OFF" POSITION

TINE CONTROL

"RtJNNING" POSITION

THROTTLE

CONTROL'_.4_

RESTARTING ENGINE

• When restading awarm Engine, ptace Throttle Conlrol in

"FAST" position NOTE: IT MAY BE NECESSARY TO

USE CHOKE (Fig 7)

CHOKE

ONTROL

FIGURE 7'

FIGURE 5

STOPPING TINES AND ENGINE

• TINE MOVEMENTWILL STOP WHEN TINE CONTROL

IS RELEASED ( OFF POSIT ON),

• To stop Engine, place Throttle Control (Fig, 6) in"STOP"

position, NOTE: DO NOT USE CHOKE CONTROL TO

STOP ENGINE

FIGURE 6

TILLING

• The speed and depth of tillingis regulated bythe position

of the Depth Stake and Wheel Height

• The Depth Stake should always be below theWheels for

digging, It serves as a brake to slow the Tiller's fonNard

motion toenable the Tines to penetrate theground Also,

the more the Depth Stake is lowered into the ground the

deeper the Tiller will dig

OPERATION

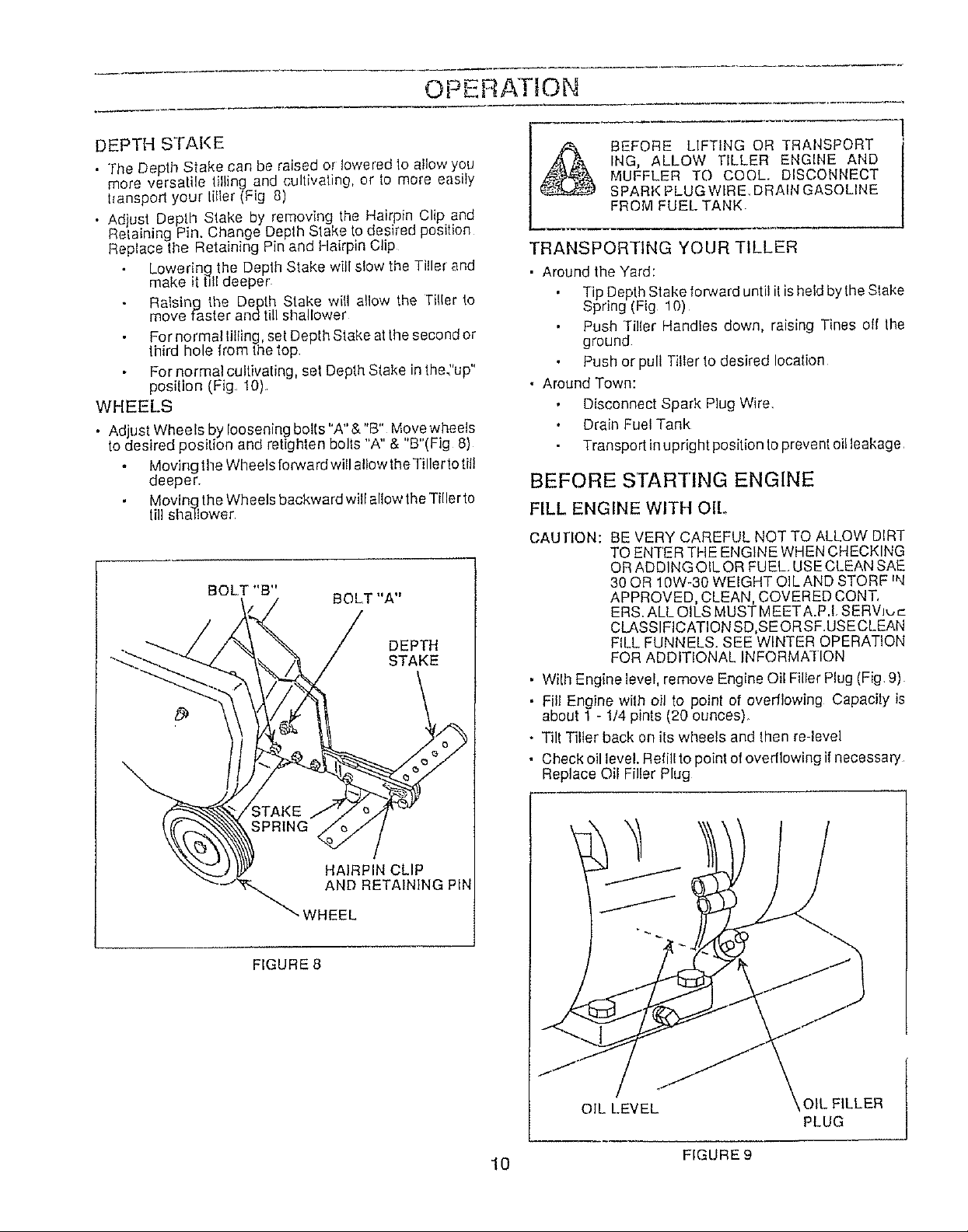

DEPTH STAKE

• "[he Dep "_Sake can be raised or lowered to allow you

more versatile lifting and cultivating, or _omore easily

hanspod your titier (Fig 8)

• Ad ust Depth Stake by removing the Hairpin Clip and

Retan ng Pin. Change Depth Stake to desired position

Replace the Retaining Pin and Hairpin Clip

Lowering the Depth Stake will slow the Tiller and

make it till deeper

Raising the Depth Stake will allow the Tiller to

move faster andtill shallower

For normal lilting, set Depth Stake at the second or

third hole from the top

For normal cultivating, set Depth Stake in the"up"

post{ion (Fig 10)

WHEELS

. Adjust Wheels by loosening bolts "A" & "B" Move wheels

to desired position and retighten bolts "A" & "B"(Fig 8)

Moving the Wheels forward will allow the Tiller'iotil!

deeper

Moving the Wheels backward will allow the Tiller to

till shallower

BOLT "B"

BOLT "A"

DEPTH

STAKE

BEFORE LIFTING OR TRANSPORT

ING, ALLOW TILLER ENGINE AND

MUFFLER TO COOL. DISCONNECT

SPAR}( PLUG WIRE, DRAIN GASOLINE

FROM FUEL TANK.

TRANSPORTING YOUR TILLER

• Around the Yard:

Tip Depth Stake forward until it ishefdby the Stake

Spring (Fig 10)

Push Ti]{er Handles down, raising Tines oil the

ground

Push or pull Tiller to desired location

• Around Town:

Disconnect Spark Plug Wire

Drain Fuel Tank

Transport in upright position to prevent of!leakage

BEFORE STARTING ENGINE

FILL ENGINE WITH OIL

CAUTION: BE VERY CAREFUL NOT TO ALLOW DIRT

TO ENTER THE ENGINE WHEN CHECKING

ORADDING OIL OR FUEL USE CLEAN SAE

30 OR 10W-30 WEIGHT OIL AND STORF rN

APPROVED, CLEAN, COVERED CONT,

ERS. ALL OILS MUST MEET A.P.! SERVJ,-,c

CLASSIFICATION SD,SE OR SF.USECLEAN

FILL FUNNELS. SEE WINTER OPERATION

FOR ADDITIONAL INFORMATION

• With Engine level, remove Engine Oil Filler Plug (Fig 9)

• Fill Engine with oil to point of ovedlowing Capacity is

about 1 - 1/4 pints (20 ounces)_

• Tilt Tiller back on its wheels and then re-level

• Check oil level. Refill to point of ovedlowing if necessary

Replace Oil Filler Plug

"WHEEL

FIGURE 8

HAIRPIN CLIP

AND RETAINING PIN

10

OIL LEVEL OIL FILLER

PLUG

FIGURE 9

J

Loading...

Loading...