Page 1

Operator's Manual

(RRFT$1ViRN°

GAR TRACTO

26.0 HR* 54" Mower

Electric Start

6 Speed Transaxle

Model No.

917.28945

, Espaflol, p. 36

This product has a low emission engine which operates

differently from previously built engines. Before you start the

engine, read and understand this Owner's Manual.

IMPORTANT:

Read and follow all Safety

Rules and Instructions before

operating this equipment.

SEARS, ROEBUCK AND COo, HOFFMAN ESTATES, IL 60179 U.S.A.

Visit our Craftsman website:www_sears.com/craftsman *As rated by the engine manufacturer

For answers to your questions

about this product, Call:

1-800 =659-5917

Sears CraftsmanHelp Line

5 am - 5 pm, Mon - Sat

426114 Rev. 1

Page 2

Warranty .................................................. 2

Safety Rules ............................................ 3

Product Specifications ................................... 6

Assembly/Pre-Operation ......................... 8

Operation ............................................... 13

Maintenance Schedule .......................... 20

CRAFTSMAN FULL WARRANTY

TWO YEARS ON RIDING EQUIPMENT

When operated and maintained according to all supplied instructions, if this riding equipment

fails due to a defect in material or workmanship within two years from the date or purchase,

call 1-800-4-MY-HOME® to arrange for free repair.

Also, when operated and maintained according to all supplied instructions, Warranty will

also cover defects in material and workmanship of the Frame and Front Axle for five years

from the date of purchase

Maintenance .......................................... 20

Service and Adjustments ....................... 25

Storage .................................................. 30

Troubleshooting ..................................... 31

Sears Service ........................... Back Cover

This warranty covers ONLY defects in material and workmanship. Sears will NOT

pay for:

. Expendable items that become worn during normal use, including but not limited to

blades, spark plugs, air cleaners, belts, and oil filters.

° Standard maintenance servicing, oil changes, or tune-ups.

° Tire replacement or repair caused by punctures from outside objects, such as nails,

thorns, stumps, or glass.

- Tire or wheel replacement or repair resulting from normal wear, accident, or improper

operation or maintenance.

• Repairs necessary because of operator abuse, including but not limited to damage

caused by towing objects beyond the capability of the riding equipment, impacting

objects that bend the frame or crankshaft, or over-speeding the engine.

° Repairs necessary because of operator negligence, including but not limited to, electrical

and mechanical damage caused by improper storage, failure to use the proper grade

and amount of engine oil, failure to keep the deck clear of flammable debris, or failure to

maintain the riding equipment according to the instructions contained in the operator's

manual.

• Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or

oxidized (stale). In general, fuel should be used within 30 days of its purchase date.

- Normal deterioration and wear of the exterior finishes, or product label replacement.

All riding equipment and batter,.# warranty coverage is void if this product is ever used for

commercial or rental purposes.

This warranty applies only while this product is within the United States.

This warranty gives you specific legal rights, and you may also have other rights which

vary from state to state,

Sears, Roebuck and Co., Hoffman Estates, IL 60179

2

Page 3

_IbDANGER:This cutting machine is capable of amputating hands and feet and

throwing objects. Failure to observe the following safety instructions could result

in serious injury or death,

_WARNING" In order to prevent acciden-

tal starting when setting up, transporting,

adjusting or making repairs, always discon-

nect spark plug wire and place wire where

it cannot contact spark plug.

_WARNING: Do not coast down a hill in

neutral, you may lose control of the tractor.

,_WARNING: Tow only the attachments

that are recommended by and comply with

specifications of the manufacturer of your

tractor. Use common sense when towing.

Operate only at the lowest possible speed

when on a slope. Too heavy of a toad, while

on a slope, is dangerous. Tires can lose

traction with the ground and cause you to

lose control of your tractor.

,_WARNING: Engine exhaust, some of

its constituents, and certain vehicle compo-

nents contain or emit chemicals known to the

State of California to cause cancer and birth

defects or other reproductive harm.

_IbWARNING: Battery posts, terminals and

related accessories contain lead and lead

compounds, chemicals known to the State of

California to cause cancer and birth defects

or other reproductive harm, Wash hands

after handling.

I. GENERAL OPERATION

• Read, understand, and follow all instruc-

tions on the machine and in the manual

before starting.

• Do not put hands or feet near rotating

parts or under the machine. Keep clear

of the discharge opening at all times.

• Only allow responsible adults, who are

familiar with the instructions, to operate

the machine.

• Clear the area of objects such as rocks,

toys, wire, etc., which could be picked

up and thrown by the blades°

• Be sure the area is clear of bystanders

before operating. Stop machine ifanyone

enters the area.

• Never carry passengers_

• Do not mow in reverse unless absolutely

necessary_ Always look down and behind

before and while backing°

° Never direct discharged materialtoward

anyone. Avoid discharging material

against a wall or obstruction. Material

may ricochet back toward the operator.

Stop the blades when crossing gravel

surfaces.

• Do not operate machine without the en-

tire grass catcher, discharge chute, or

other safety devices in place and working.

• Slow down before turning.

• Never leave a running machine unat-

tended. Always turn off blades, set

parking brake, stop engine, and remove

keys before dismounting.

• Disengage blades when not mowing.

Shut off engine and wait for all parts to

come to a complete stop before cleaning

the machine, removing the grass catcher,

or unclogging the discharge chute.

• Operate machine onlyin daylightorgood

artificial light.

• Do not operatethe machine while under

the influence of alcohol or drugs.

, Watch for traffic when operating near or

crossing roadways_

• Use extracarewhen Ioadingor unloading

the machine into a trailer or truck.

. Always wear eye protectionwhen operat-

ing machine.

° Data indicates that operators, age 60

years and above, are involved in a large

percentage of riding mower-related inju=

ries. These operators should evaluate

their ability to operate the riding mower

safely enough to protect themselves and

others from serious injury.

• Follow the manufacturer's recommen-

dation for wheel weights or counter-

weights.

• Keep machine free of grass, leaves or

other debris build-up which can touch hot

exhaust / engine parts and burn. Do not

allow the mower to plow leaves or other

debris which can cause build-up to oc-

cur. Clean any oil or fuel spillage before

operating or storing the machine. Allow

machine to cool before storage.

3

Page 4

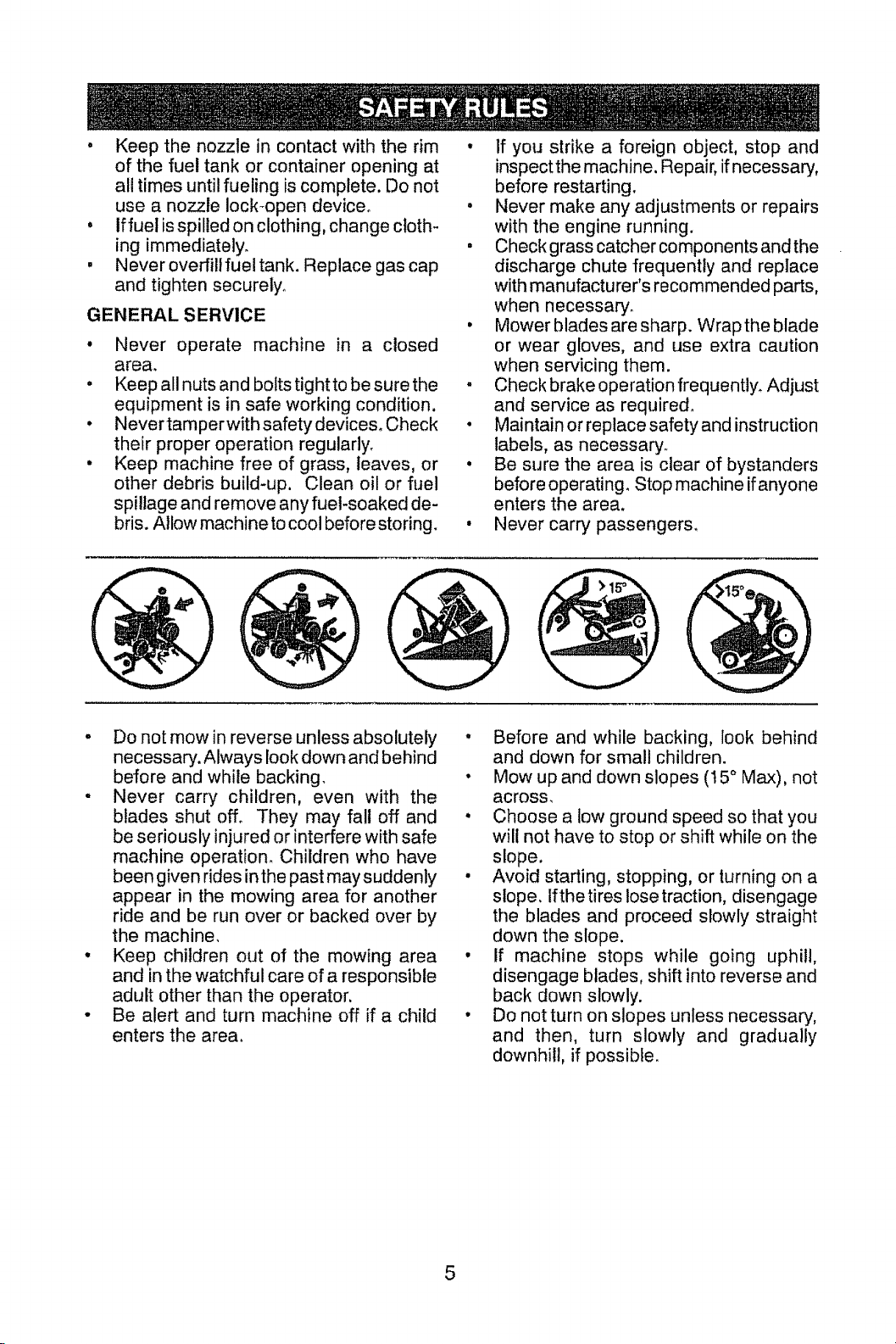

!1. SLOPE OPERATION

Slopes are a major factor related to loss of

control and tip-over accidents, which can

result in severe injury or death. Operation

on all slopes requires extra caution. If you

cannot back up the slope or ifyou feel uneasy

on it, do not mow it.

• Mow up and down slopes, not across.

• Watch for holes, ruts, bumps, rocks, or

other hidden objects. Uneven terrain

could overturn the machine. Tail grass

can hide obstacles.

° Choose a low ground speed so that you

will not have to stop or shift while on the

slope.

• Do not mow on wet grass, Tires may lose

traction.

Always keep the machine in gear when

going down slopes. Do not shift to neutral

and coast downhill.

, Avoid starting, stopping, or turning on a

slope, tfthe tires Iosetraction, disengage

the blades and proceed slowly straight

down the slope.

° Keep all movement on the slopes slow

and gradual. Do not make sudden

changes in speed or direction, which

could cause the machine to roll over.

° Use extra care while operating machine

with grass catchers or other attachments;

they can affect the stability of the ma-

chine. Do no use on steep slopes.

° Do not try to stabilize the machine by

putting your foot on the ground.

, Do not mow near drop-offs, ditches,

or embankments. The machine could

suddenly roll over if a wheel is over the

edge or if the edge caves in.

!11,CHILDREN

Tragic accidents can occur if the operator

is not alert to the presence of children.

Children are often attracted to the machine

and the mowing activity. Never assume

that children will remain where you last

saw them.

• Keep children out of the mowing area

and in the watchful care of a responsible

adult other than the operator.

• Be alert and turn machine off if a child

enters the area.

• Before and while backing, look behind

and down for small children.

• Never carry children, even with the

blades shut off° They may fall off and

be seriously injured or interfere with safe

machine operation, Children who have

been given rides in the past may suddenly

appear in the mowing area for another

ride and be run over or backed over by

the machine.

. Never allow children to operate the ma-

chine.

, Use extra care when approaching blind

corners, shrubs, trees, or other objects

that may block your view of a child.

IV, TOWING

° Tow only with a machine that has a hitch

designed for towing. Do not attach towed

equipment except at the hitch point.

° Followthemanufacturer'srecommenda-

tion for weight limits for towed equipment

and towing on slopes,

° Never allow children or others in or on

towed equipment.

. On slopes,the weight of the towed equip-

ment may cause loss of traction and loss

of control,

. Travel slowly and allow extra distance to

stop.

V. SERVICE

SAFE HANDLING OF GASOLINE

To avoid personal injury or property dam-

age, use extreme care in handling gasoline.

Gasoline is extremely flammable and the

vapors are explosive.

• Extinguish all cigarettes, cigars, pipes,

and other sources of ignition.

- Use only approved gasoline container.

• Never remove gas cap or add fuel with

the engine running. Allow engine to cool

before refueling.

, Never fuelthe machine indoors.

• Never store the machine or fuel container

where there is an open flame, spark, or

pilot light such as on a water heater or

other appliances°

• Never fill containers inside a vehicle or

on a truck or trailer bed with plastic liner.

Always place containers on the ground

away from your vehicle when filling_

• Remove gas-powered equipment from

the truck or trailer and refuel it on the

ground° If this is not possible, then refuel

such equipment with a portable container,

rather than from a gasoline dispenser

nozzle.

4

Page 5

• Keep the nozzle in contact with the rim

of the fuel tank or container opening at

all times until fueling is complete. Do not

use a nozzle lock-open device°

° iffuelisspilled on clothing, change cloth-

ing immediately.

, Never overfilt fuel tank. Replace gas cap

and tighten securety_

GENERAL SERVICE

, Never operate machine in a closed

area.

° Keep all nuts and bolts tightto be sure the

equipment is in safe working condition.

, NevertamperwithsafetydevicesoCheck

their proper operation regularly.

• Keep machine free of grass, leaves, or

other debris build-up, Clean oil or fuel

spillage and remove any fuel-soaked de-

bris. Allow machine to cool before storing.

• If you strike a foreign object, stop and

inspect the machine. Repair, if necessary,

before restarting.

• Never make any adjustments or repairs

with the engine running.

• Checkgrasscatchercomponentsandthe

discharge chute frequently and replace

with manufacturer's recommended parts,

when necessary.

• Mower blades are sharp. Wrapthe blade

or wear gloves, and use extra caution

when servicing them.

• Check brake operation frequently. Adjust

and service as required.

• Maintain or replace safetyand instruction

labels, as necessary.

, Be sure the area is clear of bystanders

before operating. Stop machine ifanyone

enters the area.

• Never carry passengers.

° Do not mowin reverse unless absolutely

necessary. Always look down and behind

before and while backing.

, Never carry children, even with the

blades shut off. They may fall off and

be seriously injured or interfere with safe

machine operation. Children who have

been given rides in the past may suddenly

appear in the mowing area for another

ride and be run over or backed over by

the machine,

• Keep children out of the mowing area

and in the watchful care of a responsible

adult other than the operator.

• Be alert and turn machine off if a child

enters the area.

° Before and while backing, look behind

and down for small children.

• Mow up and down slopes (15 ° Max), not

across_

• Choose a low ground speed so that you

will not have to stop or shift while on the

slope.

• Avoid starting, stopping, or turning on a

slope. Ifthetires lose traction, disengage

the blades and proceed slowly straight

down the slope.

• If machine stops while going uphill,

disengage blades, shift into reverse and

back down slowly.

• Do notturn on slopes unless necessary,

and then, turn slowly and gradually

downhill, if possible.

5

Page 6

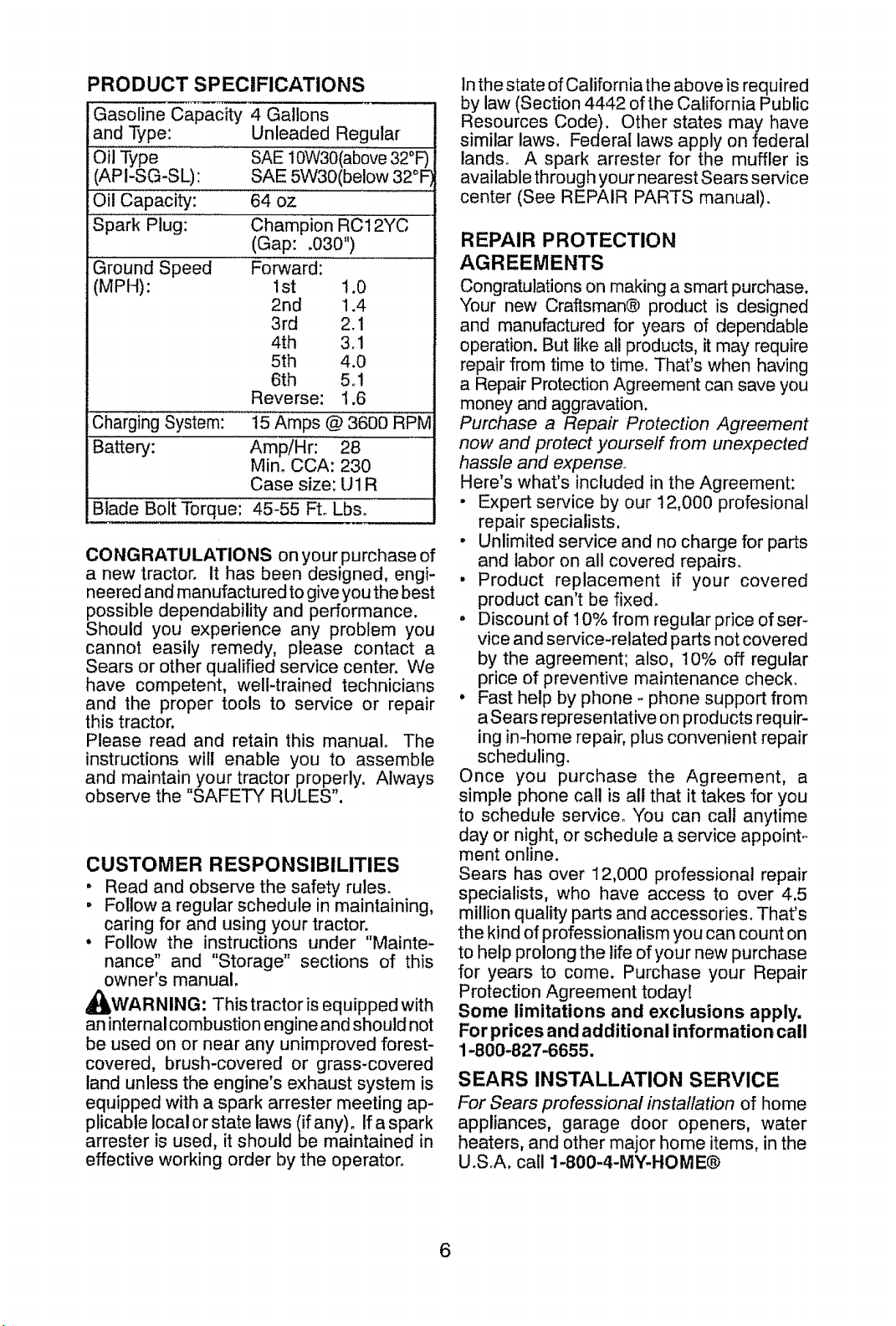

PRODUCT SPECIFICATIONS

Gasoline Capacity 4 Gallons

and Type: Unleaded Regular

Oil Type SAE 10W30(above 32°F)

(API-SG-SL): SAE 5W30(below 32°F

Oil Capacity: 64 oz

Spark Plug: Champion RC12YC

(Gap: .030")

Ground Speed For,_Jard:

(MPH):

Charging System: t5 Amps @ 3600 RPM

Battery: AmpiHr: 28

Blade Bolt Torque: 45-55 Ft. Lbso

CONGRATULATIONS on your purchase of

a new tractor, it has been designed, engi-

neered and manufactured to give you the best

possible dependability and performance.

Should you experience any problem you

cannot easily remedy, please contact a

Sears or other qualified service center. We

have competent, well-trained technicians

and the proper tools to service or repair

this tractor.

Please read and retain this manual. The

instructions will enable you to assemble

and maintain your tractor properly. Always

observe the "SAFETY RULES".

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining,

caring for and using your tractor.

• Follow the instructions under "Mainte-

nance" and "Storage" sections of this

owner's manual.

AI_WARNING: This tractor is equipped with

an internal combustion engine and should not

be used on or near any unimproved forest-

covered, brush-covered or grass-covered

land unless the engine's exhaust system is

equipped with a spark arrester meeting ap-

plicable local or state laws (if any) o if a spark

arrester is used, it should be maintained in

effective working order by the operator_

1st 1.0

2nd 1.4

3rd 2.1

4th 3.1

5th 4.0

6th 5,1

Reverse: 1.6

Mino CCA: 230

Case size: U1R

Inthe state of California the above is required

by law (Section 4442 of the California Public

Resources Code). Other states may have

similar laws. Federal laws apply on federal

lands. A spark arrester for the muffler is

available through your nearest Sears set€ice

center (See REPAIR PARTS manual).

REPAIR PROTECTION

AGREEMENTS

Congratulations on making a smart purchase.

Your new Craftsman@ product is designed

and manufactured for years of dependable

operation. But like all products, it may require

repair from time to time. That's when having

a Repair Protection Agreement can save you

money and aggravation.

Purchase a Repair Protection Agreement

now and protect yourself fiom unexpected

hassle and expense.

Here's what's included in the Agreement:

• Expert service by our 12,000 profesional

repair specialists.

• Unlimited service and no charge for parts

and labor on all covered repairs,

, Product replacement if your covered

product can't be fixed°

• Discount of 10% from regular price of ser-

vice and service-related parts not covered

by the agreement; also, 10% off regular

price of preventive maintenance check.

• Fast help by phone - phone support from

a Sears representative on products requir-

ing imhome repair, plus convenient repair

scheduling.

Once you purchase the Agreement, a

simple phone call is all that it takes for you

to schedule service_ You can call anytime

day or night, or schedule a service appoint-

ment online.

Sears has over 12,000 professiona! repair

specialists, who have access to over 4.5

million quality parts and accessories_ That's

the kind of professionalism you can count on

to help prolong the life of your new purchase

for years to come. Purchase your Repair

Protection Agreement todayE

Some limitations and exclusions apply.

For prices and additional information call

1-800-827-6655.

SEARS INSTALLATION SERVICE

For Sears professional installation of home

appliances, garage door openers, water

heaters, and other major home items, in the

U_S.A, call 1-800-4-MY-HOME®

6

Page 7

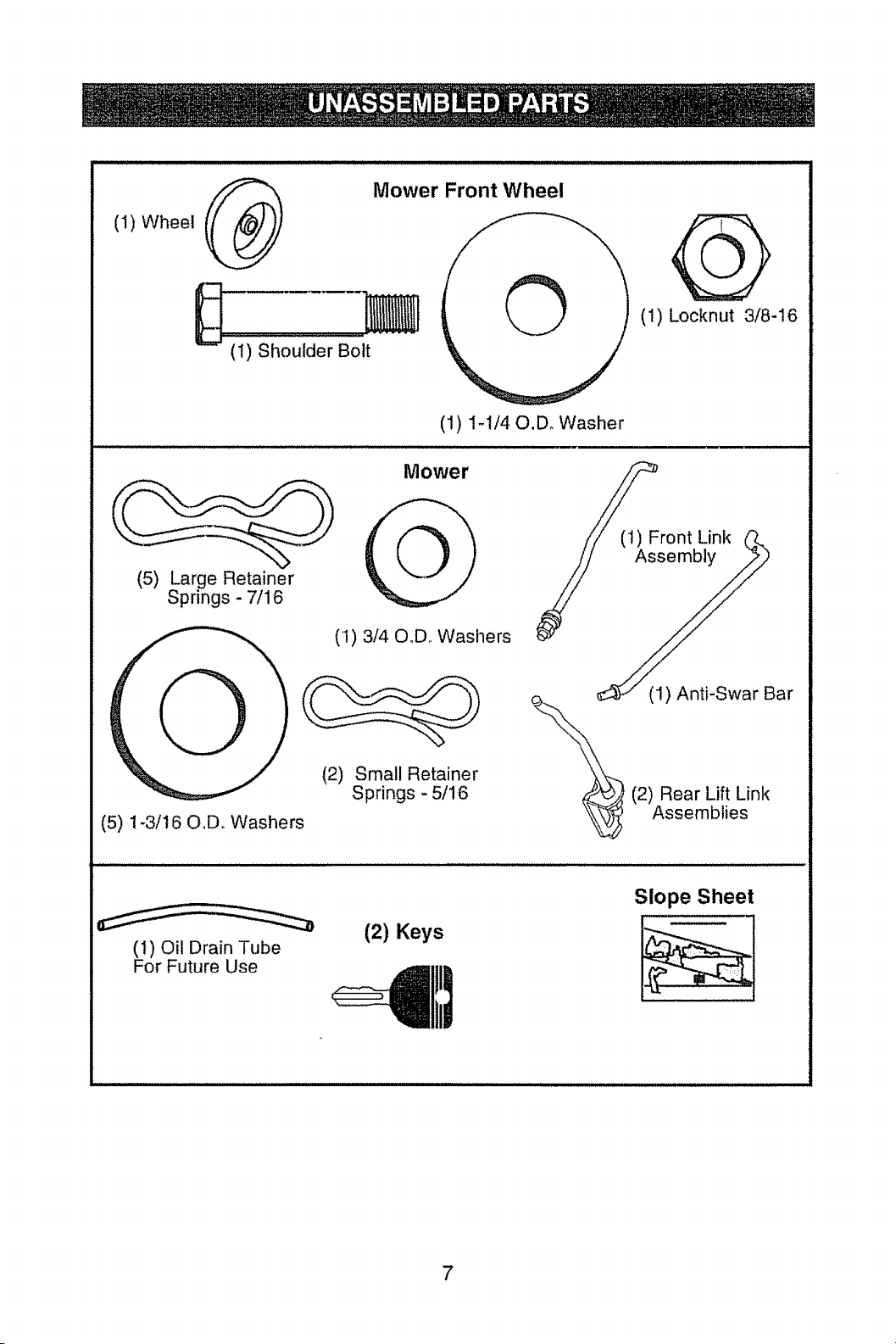

(I) Wheel _1_'_ Mower Front Wheel

(1) Shoulder Bolt

(1) 1-1/40,D. Washer

Mower

(5) Large Retainer

Springs - 7/1 6

(I) 314 O.Do Washers

(1) Locknut 3/8-16

_(t) Front Link (J_.

S __j. (1) Anti-Swar Bar

(5) 1-3/16 O,Do Washers

(i) Oil Drain Tube

For Future Use

(2) Small Retainer

Springs - 5/16

(2) Keys

(2) Rear Lift Link

Assemblies

Slope Sheet

7

Page 8

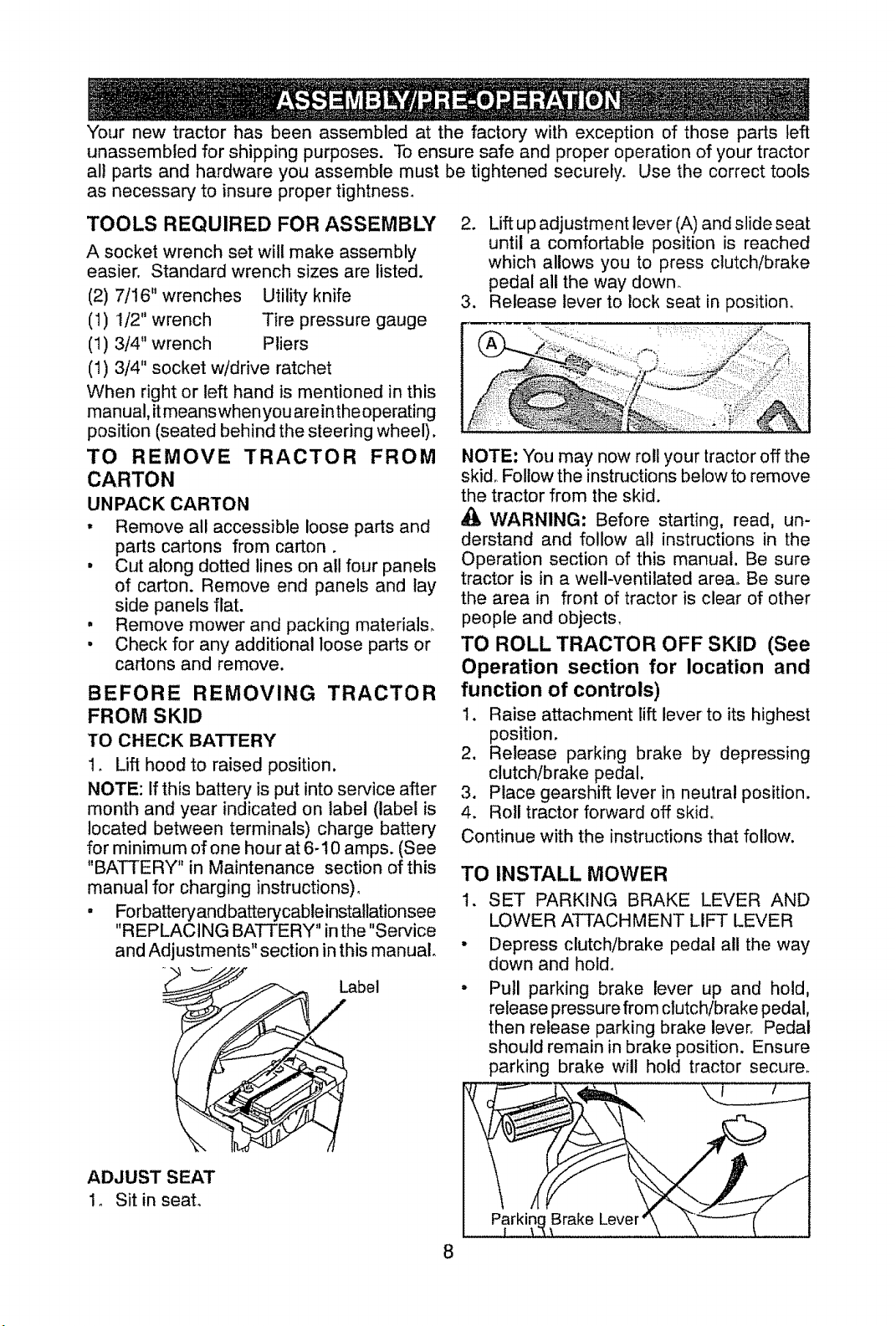

Your new tractor has been assembled at the factory with exception of those parts left

unassembled for shipping purposes. To ensure safe and proper operation of your tractor

all parts and hardware you assemble must be tightened securely. Use the correct tools

as necessary to insure proper tightness_

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly

easier. Standard wrench sizes are listed.

(2) 7/16" wrenches Utility knife

(1) 1/2" wrench Tire pressure gauge

(1) 3/4" wrench Pliers

(1) 3/4" socket w/drive ratchet

When right or left hand is mentioned in this

manual, itmeanswhenyou are inthe operating

position (seated behind the steering wheel).

TO REMOVE TRACTOR FROM

CARTON

UNPACK CARTON

. Remove all accessible loose parts and

parts cartons from carton.

o Cut along dotted lines on all four panels

of carton. Remove end panels and lay

side panels flat.

• Remove mower and packing materials.

• Check for any additional loose parts or

cartons and remove.

BEFORE REMOVING TRACTOR

FROM SKID

TO CHECK BATTERY

1, Uf_ hood to raised position.

NOTE: If this battery is put into service after

month and year indicated on label (label is

located between terminals) charge battery

for minimum of one hour at 6-10 amps, (See

"BATTERY" in Maintenance section of this

manual for charging instructions),

• Forbatteryand batterycableinstatlationsee

"R EPLACING BATTERY" inthe "Service

and Adjustments" section in this manual.

Label

2. Lift up adjustment lever (A) and slide seat

until a comfortable position is reached

which allows you to press clutch/brake

pedal all the way down.

3. Release lever to lock seat in position.

NOTE: You may now roll your tractor off the

skid° Follow the instructions below to remove

the tractor from the skid.

d_, WARNING: Before starting, read, un-

derstand and follow all instructions in the

Operation section of this manual. Be sure

tractor is in a well-ventilated area° Be sure

the area in front of tractor is clear of other

people and objects.

TO ROLL TRACTOR OFF SKID (See

Operation section for location and

function of controls)

I. Raise attachment lift lever to its highest

position,

2. Release parking brake by depressing

clutch/brake pedal,

3. Place gearshift lever in neutral position,

4. Roll tractor forward off skid.

Continue with the instructions that follow.

TO INSTALL MOWER

I. SET PARKING BRAKE LEVER AND

LOWER ATTACHMENT LIFT LEVER

Depress clutch/brake pedal all the way

down and holdo

Pull parking brake lever up and hold,

release pressure from clutch!brake pedal,

then release parking brake lever. Pedal

should remain in brake position. Ensure

parking brake wilt hold tractor secure.

1. Sit in seat.

Brake

Page 9

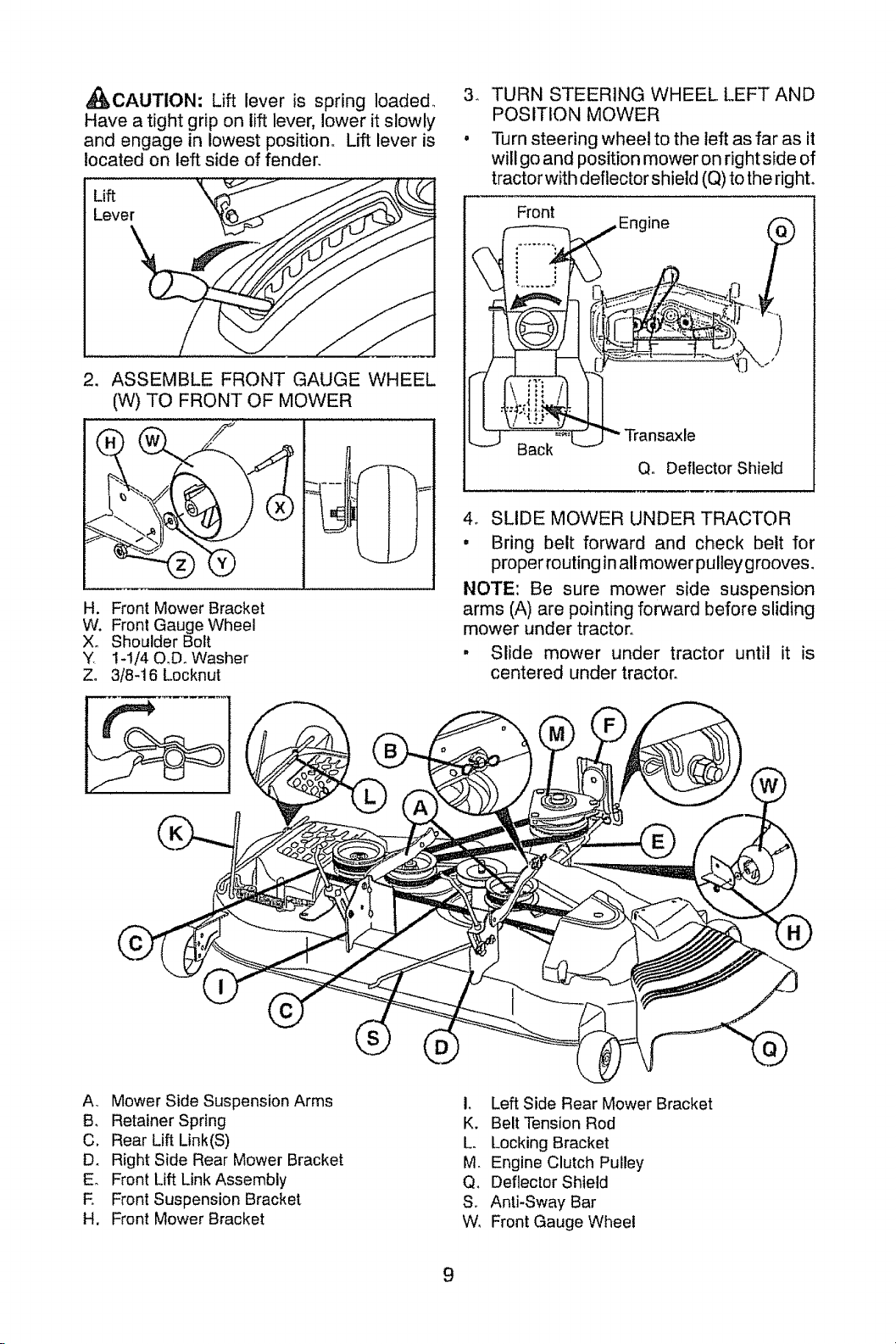

_CAUTION: Lift lever is spring loaded 3.

Have a tight grip on lift lever, lower it slowly

and engage in lowest position° Lift lever is •

located on left side of fender.

Lift

Lever

. ASSEMBLE FRONT GAUGE WHEEL

(W) TO FRONT OF MOWER

-®

H. Front Mower Bracket

W. Front Gauge Wheel

Xo Shoulder Bolt

¥ 1-I/40,D. Washer

Z. 3/8-16 Locknut

TURN STEERING WHEEL LEFT AND

POSITION MOWER

Turn steering wheel to the left as far as it

will go and position mower on right side of

tractor with deflector shield (Q) to the right.

Front

(

,)

Back

Q. Deflector Shield

4. SLIDE MOWER UNDER TRACTOR

• Bring belt forward and check belt for

proper routing in all mower pulley grooves _

NOTE: Be sure mower side suspension

arms (A) are pointing forward before sliding

mower under tractor.

° Slide mower under tractor until it is

centered under tractor.

A, Mower Side Suspension Arms

B, Retainer Spring

C. Rear Lift Link(S)

Dr Right Side Rear Mower Bracket

E. Front Lift Link Assembly

E Front Suspension Bracket

H. Front Mower Bracket

I, Left Side Rear Mower Bracket

K. Belt Tension Rod

L. Locking Bracket

M Engine Clutch Pulley

Q, Deflector Shield

S. Anti-Sway Bar

W, Front Gauge Wheel

9

Page 10

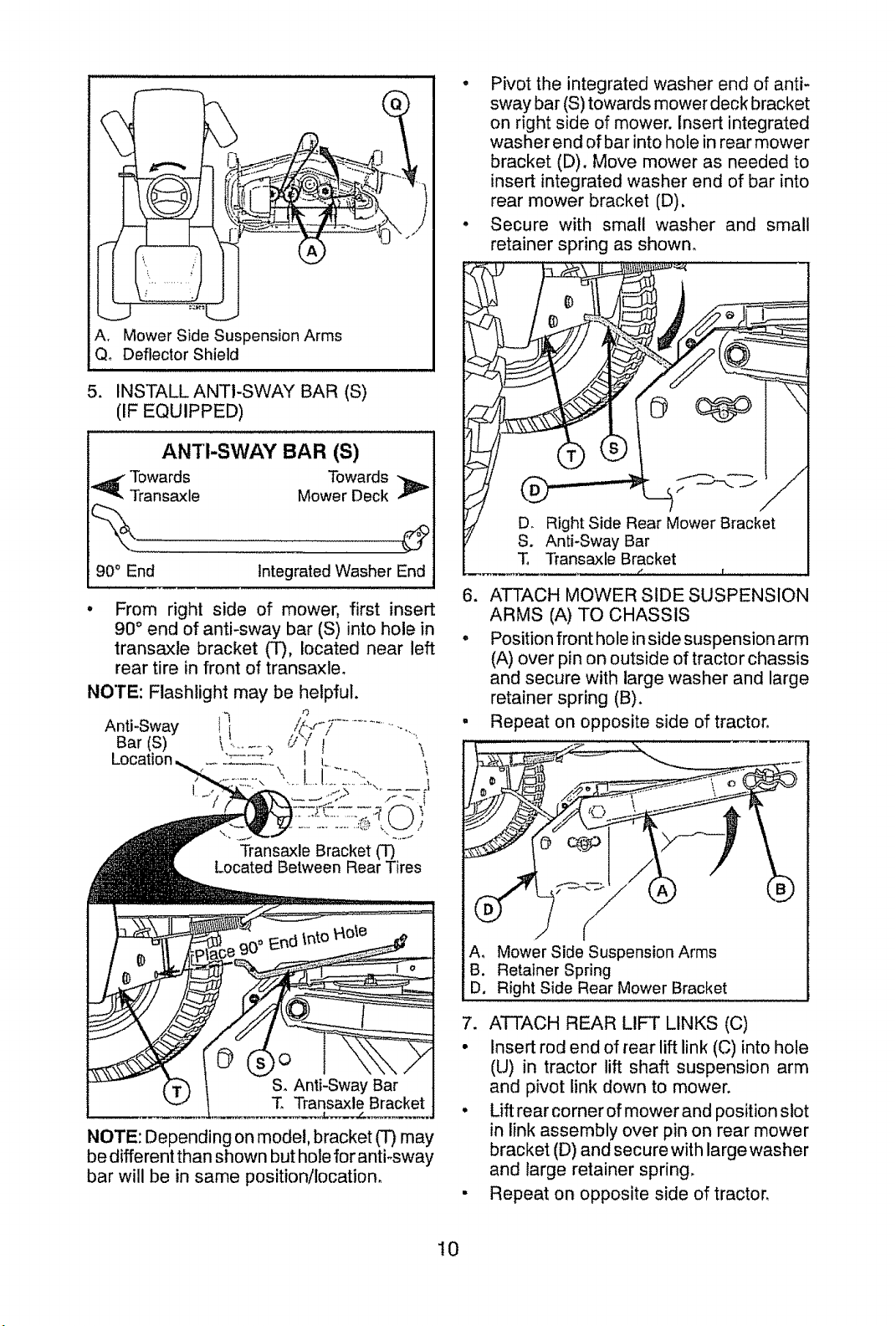

A. Mower Side Suspension Arms

Qo Deflector Shield

5. INSTALLANTI-SWAY BAR (S)

(IF EQUIPPED)

Towards Towards

i_ ANTI-SWAY BAR (S)

Transaxle Mower Deck

° Pivot the integrated washer end of anti-

sway bar (S) towards mower deck bracket

on right side of mower. Insert integrated

washer end of bar into hole in rear mower

bracket (D), Move mower as needed to

insert integrated washer end of bar into

rear mower bracket (D).

. Secure with small washer and small

retainer spring as shown,

90° End

From right side of mower, first insert

90 ° end of anti-sway bar (S) into hole in

transaxte bracket (T), located near left

rear tire in front of transaxle,

NOTE: Depending on model, bracket (T) may

be different than shown but hole for anti-sway

bar will be in same position/location,

Integrated Washer End

T. Transaxle Bracket

6. ATTACH MOWER SIDE SUSPENSION

ARMS (A) TO CHASSIS

• Position front hole inside suspension arm

(A) over pin on outside of tractor chassis

and secure with large washer and large

retainer spring (B).

, Repeat on opposite side of tractor.

A, Mower Side Suspension Arms

B, Retainer Spring

D. Right Side Rear Mower Bracket

7, ATTACH REAR LIFT LINKS (C)

• Insert rod end of rear lift link (C) into hole

(U) in tractor lift shaft suspension arm

and pivot link down to mower,

• Lift rear corner of mower and position slot

in link assembly over pin on rear mower

bracket (D) and secure with large washer

and large retainer spring,

• Repeat on opposite side of tractor,

I0

Page 11

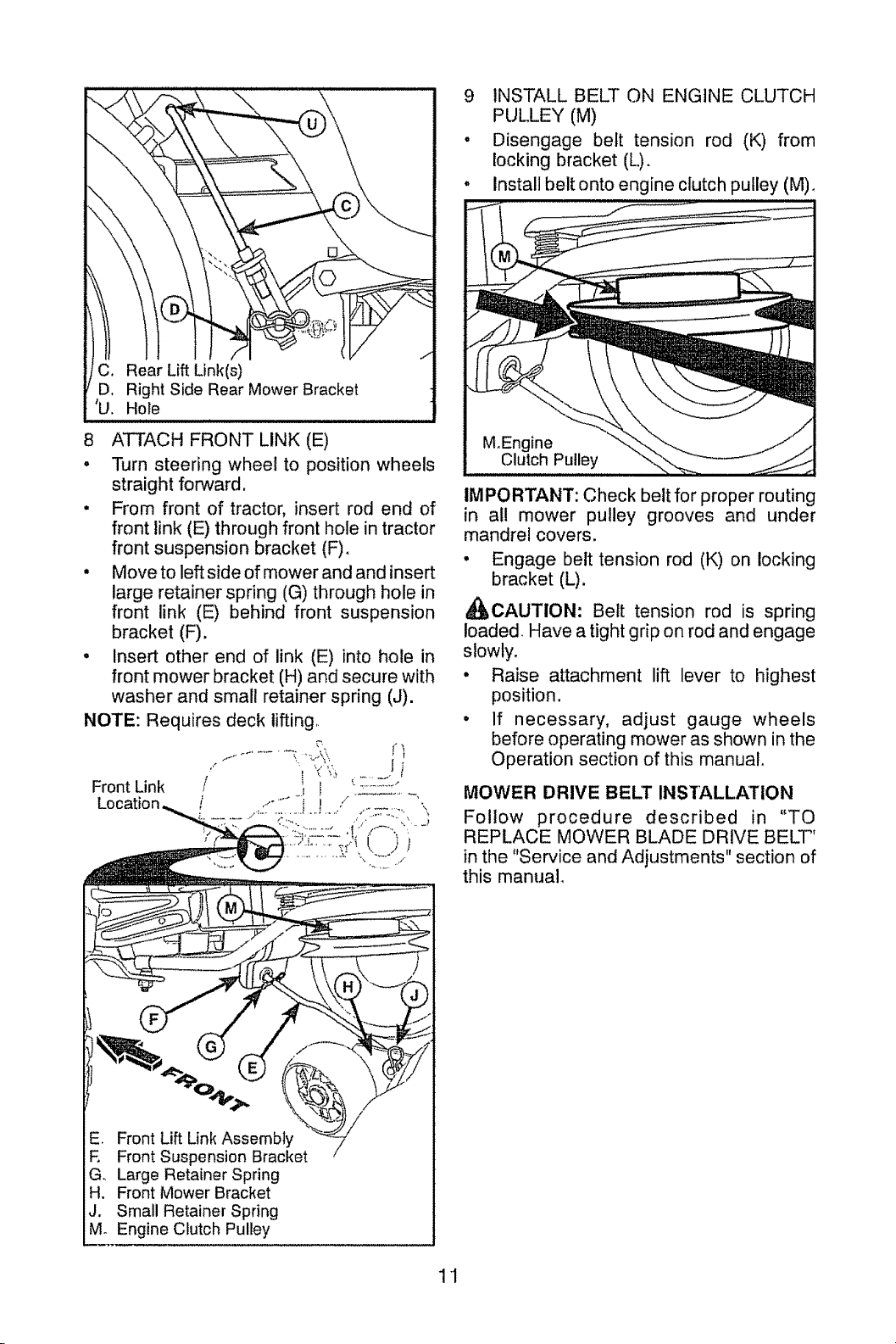

,./

ar Lift Link(s)

I/ D. Right Side Rear Mower Bracket

[ 'U. Hole

8 ATTACH FRONT LINK (E)

• Turn steering wheel to position wheels

straight forccard.

• From front of tractor, insert rod end of

front tink (E) through front hole in tractor

front suspension bracket (F),

• Moveto left side of mower and and insert

large retainer spring (G) through hole in

front link (E) behind front suspension

bracket (F).

. Insert other end of link (E) into hole in

front mower bracket (H) and secure with

washer and small retainer spring (J).

NOTE: Requires deck lifting

.... ! ,(,:_:_....... J;

Front Link / ' ' "

/ .,_°.....i I ./ ...........'\

.....;.......;:................... ..........(,,.;

9 INSTALL BELT ON ENGINE CLUTCH

PULLEY (M)

- Disengage belt tension rod (K) from

locking bracket (L),

- Install belt onto engine clutch pulley (M),

M°Engine

Clutch Pulley

IMPORTANT: Check belt for proper routing

in all mower pulley grooves and under

mandrel covers.

• Engage belt tension rod (K) on locking

bracket (L).

_CAUTION: Belt tension rod is spring

loaded. Have a tight grip on rod and engage

slowty.

• Raise attachment lift lever to highest

position.

° If necessary, adjust gauge wheels

before operating mower as shown in the

Operation section of this manual,

MOWER DRIVE BELT INSTALLATION

Follow procedure described in "TO

REPLACE MOWER BLADE DRIVE BELT"

in the "Service and Adjustments" section of

this manual_

"_'_O4_ _"- %

Front Lift Link Assembly

E Front Suspension Bracket--

G. Large Retainer Spring

H. Front Mower Bracket

t_ Small Retainer Spring

. Engine Clutch Pulley

11

Page 12

CHECK TIRE PRESSURE

The tires on your tractor were over-inflated

at the factory for shipping purposes. Correct

tire pressure is important for best cutting

performance.

• Reduce tire pressure to PSt shown on tires.

CHECK DECK LEVELNESS

For best cutting results, mower housing

should be properly leveled. See "TO LEVEL

MOWER" in the Service and Adjustments

section of this manual.

CHECK FOR PROPER POSITION OF

ALL BELTS

See the figures that are shown for replacing

motion and mower blade drive belts in the

Service and Adjustments section of this man-

ual. Verify that the belts are routed correctly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor,

check to see that the brake is operating prop-

erlyo See"TO CHECK B RAKE"in the Service

and Adjustments section of this manual.

_'CHECKLIST

Before you operate your new tractor, we

wish to assure that you receive the best

performance and satisfaction from this

Quality Product°

Please review the following checklist:

J" All assembly instructions have been

completed.

J" No remaining loose parts in carton.

_/" Battery is properly prepared and

charged.

_/' Seat is adjusted comfortably and tight-

ened securely.

All tires are properly inflated. (For ship-

ping purposes, the tires were overinflated

at the factory).

Vf Be sure mower deck is properly leveled

side-to-side/front-to-rear for best cutting

results. (Tires must be properly inflated

for leveling).

J" Check mower and drive belts. Be sure

they are routed properly around pulleys

and inside all belt keepers.

J" Check wiring, See that all connections

are still secure and wires are properly

clamped.

While learning how to use your tractor, pay ex-

tra attention to the following important items:

_/' Engine oil is at proper level°

J' Fueltank is filled with fresh, clean, regular

unleaded gasoline.

J" Become familiar with all controls, their

location and function. Operate them

before you start the engine.

v# Besure brake system is in safe operating

condition.

J" Be sure Operator Presence System and

Reverse Operation System (ROS) are

working properly (See the Operation and

Maintenance sections in this manual).

12

Page 13

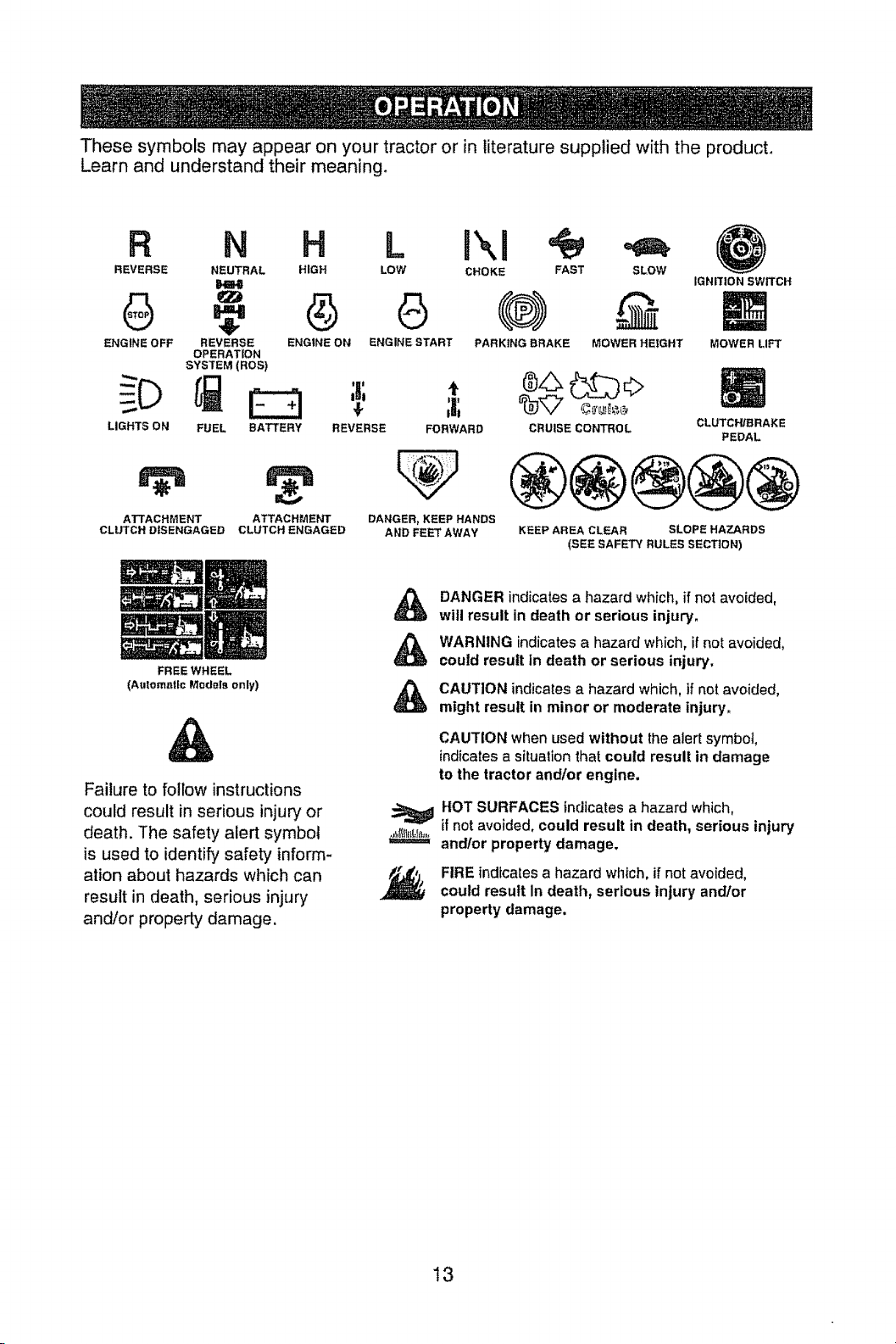

These symbols may appear on your tractor or in literature supplied with the product,

Learn and understand their meaning,

R N H L

REVERSE NEUTRAL HIGH LOW

CHOKE FAST SLOW

IGNITION SWITCH

ENGINE OFF REVERSE ENGINE ON ENGINE START

LIGHTS ON

ATTACHMENT ATTACHMENT DANGER_ KEEP HANDS

CLLrrCH DISENGAGED CLUTCH ENGAGED AND FEETAWAY

(Autom,_tlc Models only)

OPERATION

SYSTEM EROS)

FUEL

FREE WHEEL

BATTERY REVERSE FORWARD

A

Failure to follow instructions

could result in serious injury or

death. The safety alert symbol

is used to identify safety inform-

ation about hazards which can

result in death, serious injury

and/or property damage,

lm=_====l

PARKING BRAKE MOWER HEIGHT

;r

t

KEEP AREA CLEAR SLOPE HAZARDS

(SEE SAFETY RULES SECTION)

DANGER indicates a hazard wf_ich,if not avoided,

will result in death or serious injury.

WARNING indicates a hazard which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided,

might result in minor or moderate injury.

CAUTION when used without the alert symbot,

indicates a situation that could result in damage

to the tractor and/or engine.

HOT SURFACES indicates a hazard which,

if not avoided, could result in death, serious injury

and/or property damage,

FIRE indicates a hazard wllich, if ROtavoided,

could result In death, serious injury andlor

property damage.

MOWER LIFT

13

Page 14

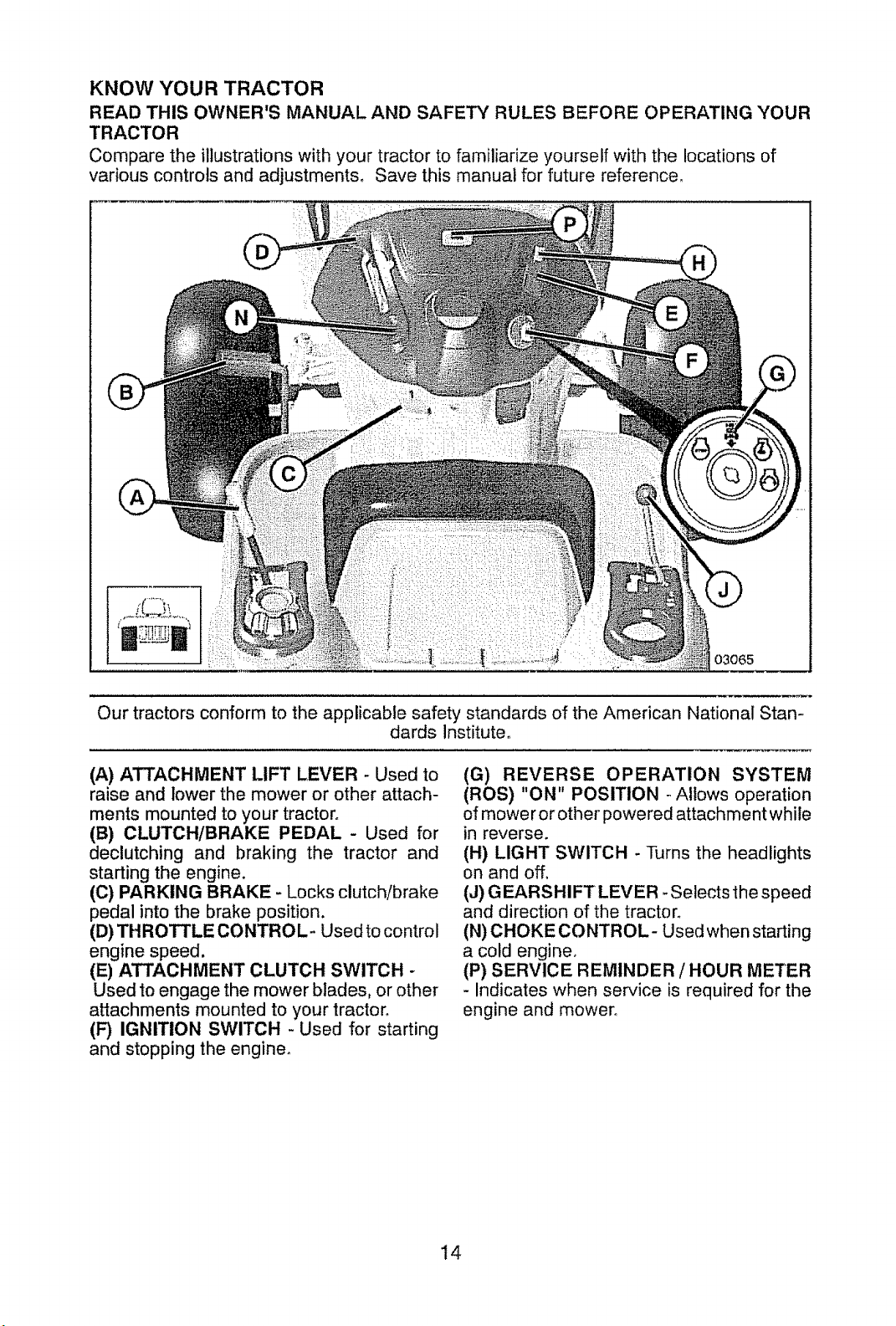

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

TRACTOR

Compare the illustrations with your tractor to familiarize yourself with the locations of

various controls and adjustments_ Save this manual for future reference_

::

O3O65

Our tractors conform to the applicable safety standards of the American National Stan-

dards Institute°

(A) ATTACHMENT LIFT LEVER - Used to

raise and lower the mower or other attach-

ments mounted to your tractor°

(B) CLUTCH/BRAKE PEDAL- Used for

declutching and braking the tractor and

starting the engine.

(C) PARKING BRAKE - Locks clutch/brake

pedal into the brake position.

(D) THROTTLE CONTROL- Used to control

engine speed.

(E) ATTACHMENT CLUTCH SWITCH -

Used to engage the mower blades, or other

attachments mounted to your tractor.

(G) REVERSE OPERATION SYSTEM

(ROS) "ON" POSITION - Allows operation

of mower or other powe red attachment while

in reverse.

(H) LIGHT SWITCH - Turns the headlights

on and off.

(J) GEARSHIFT LEVER *Selects the speed

and direction of the tractor.

(N) CHOKE CONTROL- Used when starting

a cold engine_

(P) SERVICE REMINDER / HOUR METER

- Indicates when service is required for the

engine and mower°

(F) IGNITION SWITCH - Used for starting

and stopping the engine.

14

Page 15

The operation of any tractor can result in foreign objects thrown into the

eyes, which can result in severe eye damage. Always wear safety glasses

or eye shields while operating your tractor or performing any adjustments

or repairs. We recommend standard safety glasses or a wide vision safety

mask worn over spectacles.

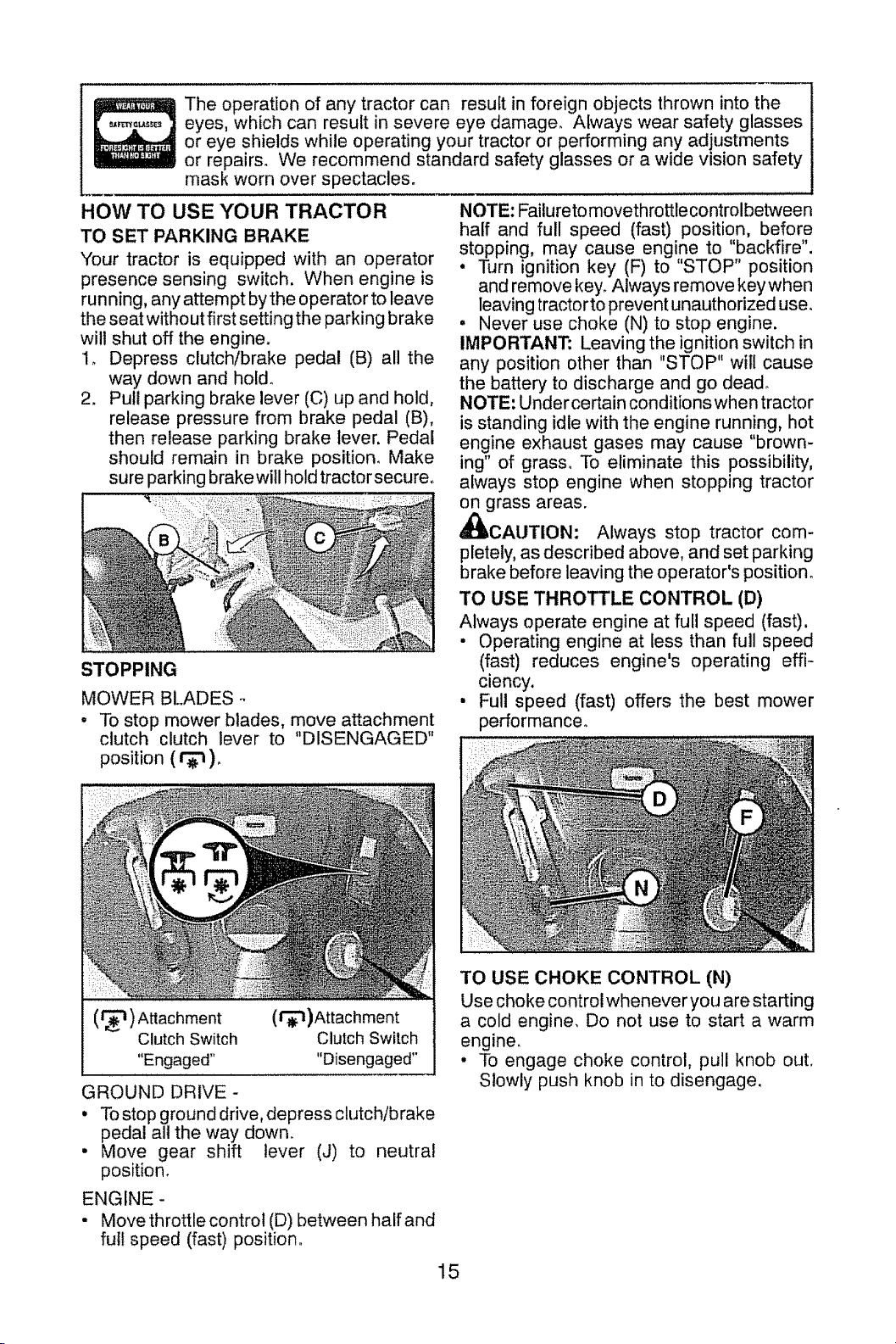

HOW TO USE YOUR TRACTOR

TO SET PARKING BRAKE

Your tractor is equipped with an operator

presence sensing switch, When engine is

run ning, any attempt by the operator to leave

the seat without first setting the parking b rake

will shut off the engine.

1. Depress clutch/brake pedal (B) all the

way down and hol&

2, Pull parking brake lever (C) up and hold,

release pressure from brake pedal (B),

then release parking brake lever. Pedal

should remain in brake position_ Make

sure parking brake will hold tractor secure.

STOPPING

MOWER BLADES o

- To stop mower blades, move attachment

clutch clutch lever to "DISENGAGED"

position ( r_ )_

NOTE: Failureto movethrottle control between

half and full speed (fast) position, before

stopping, may cause engine to "backfire".

• Turn ignition key (F) to "STOP" position

and remove key. Always remove key when

leaving tractor to prevent unauthorized use_

, Never use choke (N) to stop engine.

IMPORTANT: Leaving the ignition switch in

any position other than "STOP" will cause

the battery to discharge and go dead°

NOTE: Under certain conditions when tractor

is standing idle with the engine running, hot

engine exhaust gases may cause "brown-

ing" of grass° To eliminate this possibility,

always stop engine when stopping tractor

on grass areas.

_IbCAUTION: Always stop tractor com-

pletely, as described above, and set parking

brake before leaving the operator's position°

TO USE THROTTLE CONTROL (D)

Always operate engine at full speed (fast).

• Operating engine at less than full speed

(fast) reduces engine's operating effi-

ciency,

• Full speed (fast) offers the best mower

performance.

(_) Attachment

Clutch Switch

"Engaged"

GROUND DRIVE-

o To stop ground drive, depress clutch/brake

pedal all the way down.

• Move gear shift lever (J) to neutral

position,

ENGINE -

- Move throttle control (D) between half and

full speed (fast) position.

(l'_)Attachment

Clutch Switch

"Disengaged"

TO USE CHOKE CONTROL (N)

Use choke controtwhenever you are starting

a cold engine, Do not use to start a warm

engine.

• To engage choke control, pull knob out,

Slowly push knob in to disengage.

15

Page 16

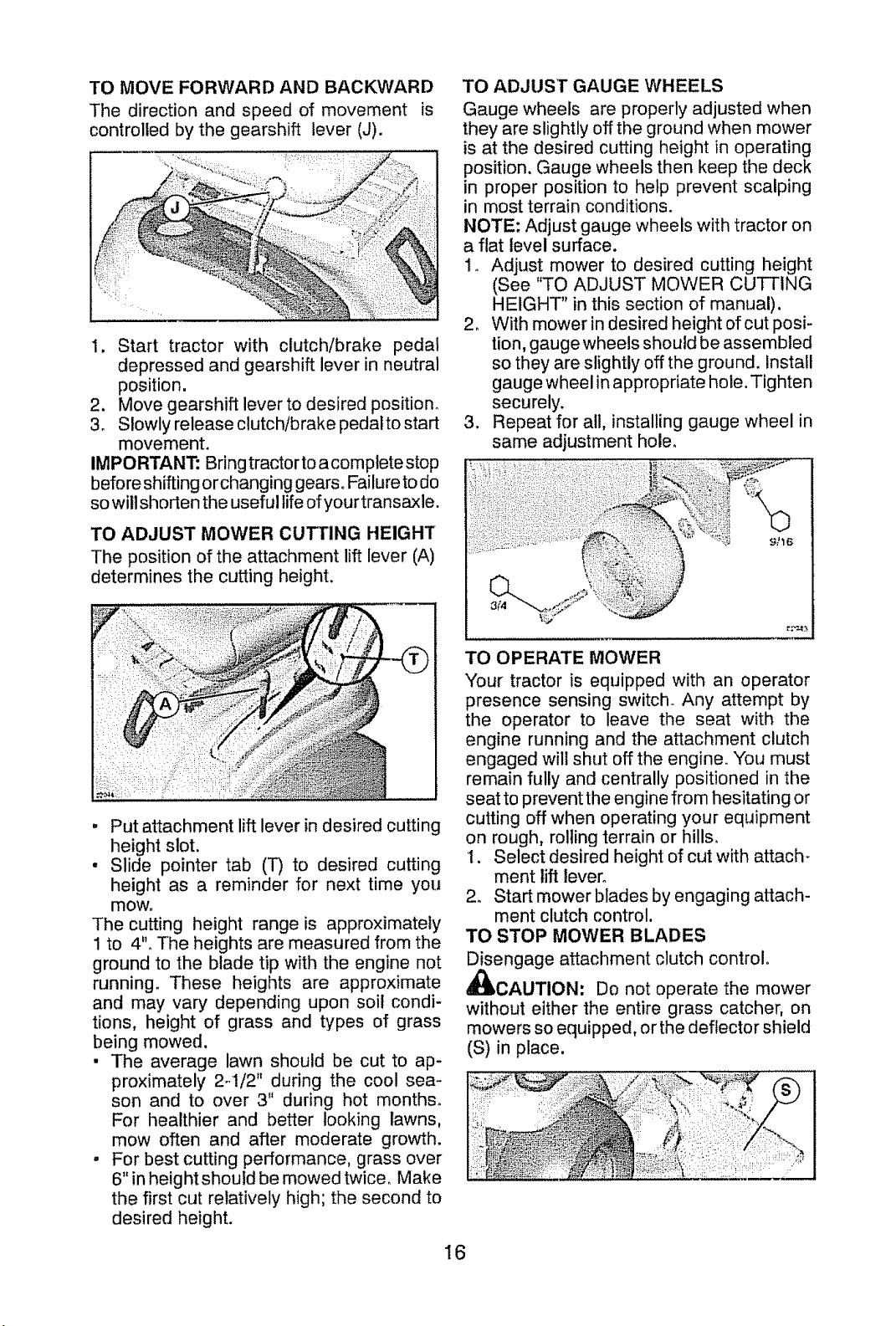

TO MOVE FORWARD AND BACKWARD

The direction and speed of movement is

controlled by the gearshift lever (J).

1, Start tractor with clutch/brake pedal

depressed and gearshift lever in neutral

position.

2. Move gearshift lever to desired position.

3. Slowly release clutch/brake pedal to start

movement.

IMPORTANT: Bringtractorto acompletestop

before shifting orchanging gears° Failure to do

so will shorten the useful fife of your transaxle.

TO ADJUST MOWER CUTTING HEIGHT

The position of the attachment lift lever (A)

determines the cutting height.

TO ADJUST GAUGE WHEELS

Gauge wheels are properly adjusted when

they are slightly off the ground when mower

is at the desired cutting height in operating

position, Gauge wheels then keep the deck

in proper position to help prevent scalping

in most terrain conditions.

NOTE: Adjust gauge wheels with tractor on

a flat level surface.

1o Adjust mower to desired cutting height

(See "TO ADJUST MOWER CUTTING

HEIGHT" in this section of manual),

2, With mower in desired height of cut posi-

tion, gauge wheels should be assembled

so they are slightly off the ground. Install

gauge wheel in appropriate hole. Tighten

securely.

3, Repeat for all, installing gauge wheel in

same adjustment hole,

, Put attachment lift lever in desired cutting

height slot.

• Slide pointer tab (T) to desired cutting

height as a reminder for next time you

mow.

The cutting height range is approximately

1 to 4"° The heights are measured from the

ground to the blade tip with the engine not

running. These heights are approximate

and may vary depending upon soil condi-

tions, height of grass and types of grass

being mowed.

• The average lawn should be cut to ap-

proximately 2q/2" during the cool sea-

son and to over 3" during hot months°

For healthier and better looking lawns,

mow often and after moderate growth.

, For best cutting performance, grass over

6" in height should be mowed twice, Make

the first cut relatively high; the second to

desired height,

TO OPERATE MOWER

Your tractor is equipped with an operator

presence sensing switch_ Any attempt by

the operator to leave the seat with the

engine running and the attachment clutch

engaged will shut off the engine You must

remain fully and centrally positioned in the

seat to prevent the engine from hesitating or

cutting off when operating your equipment

on rough, rolling terrain or hills.

1. Select desired height of cut with attach-

ment lift lever°

2o Start mower blades by engaging attach-

ment clutch control.

TO STOP MOWER BLADES

Disengage attachment clutch control.

A

_CAUTION: Do not operate the mower

without either the entire grass catcher, on

mowers so equipped, or the deflector shield

(S) in place.

16

Page 17

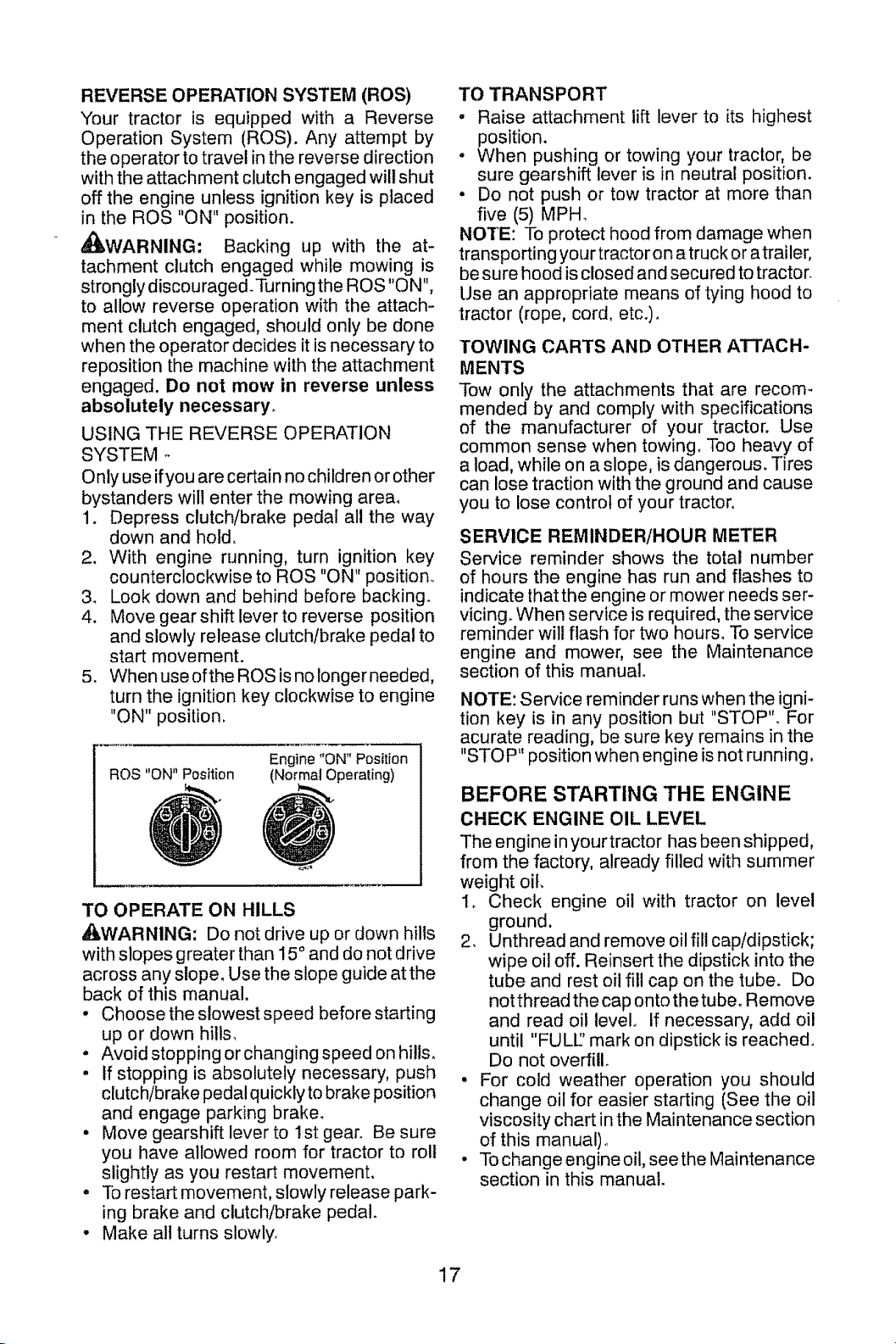

REVERSE OPERATION SYSTEM (ROS)

Your tractor is equipped with a Reverse

Operation System (ROS). Any attempt by

the operator to travel in the reverse direction

with the attachment clutch engaged will shut

off the engine unless ignition key is placed

in the ROS "ON" position.

•_WARNING: Backing up with the at-

tachment clutch engaged while mowing is

strongly discou raged, Turning the ROS "ON",

to allow reverse operation with the attach-

ment clutch engaged, should only be done

when the operator decides it is necessary to

reposition the machine with the attachment

engaged. Do not mow in reverse unless

absolutely necessary,

USING THE REVERSE OPERATION

SYSTEM o

Only use ifyou are certain no children or other

bystanders will enter the mowing area,

1, Depress clutch/brake pedal all the way

down and hold,

2. With engine running, turn ignition key

counterclockwise to ROS "ON" position,

3_ Look down and behind before backing,

4, Move gear shift lever to reverse position

and slowly release clutch/brake pedal to

start movement.

5, When use ofthe ROS isno longerneeded,

turn the ignition key clockwise to engine

"ON" position,

ROS "ON" Position

TO OPERATE ON HILLS

_WARNING: Do not drive up or down hills

with slopes greater than 15 0and do not drive

across any slope° Use the slope guide atthe

back of this manual.

• Choose the slowest speed before starting

up or down hills,

• Avoid stopping or changing speed on hills.

, if stopping is absolutely necessary, push

clutch/brake pedal quickly to brake position

and engage parking brake,

• Move gearshift lever to 1st gear. Be sure

you have allowed room for tractor to roll

slightly as you restart movement,

. ]b restart movement, slowly release park-

ing brake and clutch/brake pedal,

• Make all turns slowly,

Engine "ON" Position

(Norrnal Operating)

TO TRANSPORT

• Raise attachment lift lever to its highest

position.

. When pushing or towing your tractor, be

sure gearshift lever is in neutral position.

• Do not push or tow tractor at more than

five (5) MPH_

NOTE: To protect hood from damage when

transporting your tractor on a truck or atrailer,

be sure hood is closed and secured to tractor

Use an appropriate means of tying hood to

tractor (rope, cord, etc,),

TOWING CARTS AND OTHER ATTACH-

MENTS

Tow only the attachments that are recom_

mended by and comply with specifications

of the manufacturer of your tractor. Use

common sense when towing, Too heavy of

a load, while on a slope, is dangerous, Tires

can lose traction with the ground and cause

you to lose control of your tractor,

SERVICE REMINDER/HOUR METER

Service reminder shows the total number

of hours the engine has run and flashes to

indicate that the engine or mower needs ser-

vicing, When service is required, the service

reminder will flash for two hours° To service

engine and mower, see the Maintenance

section of this manual,

NOTE: Service reminder runs when the igni-

tion key is in any position but "STOP", For

acurate reading, be sure key remains in the

"STOP" position when engine is not running.

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL

The engine in yourtractor has been shipped,

from the factory, already filled with summer

weight oil,

1_ Check engine oil with tractor on level

ground.

2, Unthread and remove oil fill cap/dipstick;

wipe oil off. Reinsert the dipstick into the

tube and rest oil fill cap on the tube. Do

not thread the cap onto the tube. Remove

and read oil level, If necessary, add oil

until "FULL' mark on dipstick is reached,

Do not overfill,

• For cold weather operation you should

change oil for easier starting (See the oil

viscosity chart in the Maintenance section

of this manual)_

• To change engine oil, see the Maintenance

section in this manual.

17

Page 18

ADD GASOLINE

" Fill fuel tank to bottom of filler neck. Do

not overfill, Use fresh, clean, regular

unleaded gasoline with a minimum of

87 octane° (Use of leaded gasoline will

increase carbon and lead oxide deposits

and reduce valve life)_ Do not mix oil with

gasoline. Purchase fuel in quantities that

can be used within 30 days to assure fuel

freshness.

_CAUTION: Wipe off any spilled oil or fuel.

Do not store, spill or use gasoline near an

open flame.

IMPORTANT: When operating in tempera-

tures below32°F(0°C), use fresh, clean winter

grade gasoline to help ensure good cold

weather starting.

CAUTION: Alcohol blended fuels (called

gasohol or using ethanol or methanol) can

attract moisture which leads to separation

and formation of acids during storage. Acidic

gas can damage the fuel system of an engine

while in storage. To avoid engine problems,

the fuel system should be emptied before

storage of 30 days or longer. Drain the gas

tank, start the engine and let it run until the

fuel lines and carburetor are empty° Use fresh

fuel next season, See Storage Instructions

for additional information. Never use engine

or carburetor cleaner products in the fuettank

or permanent damage may occur.

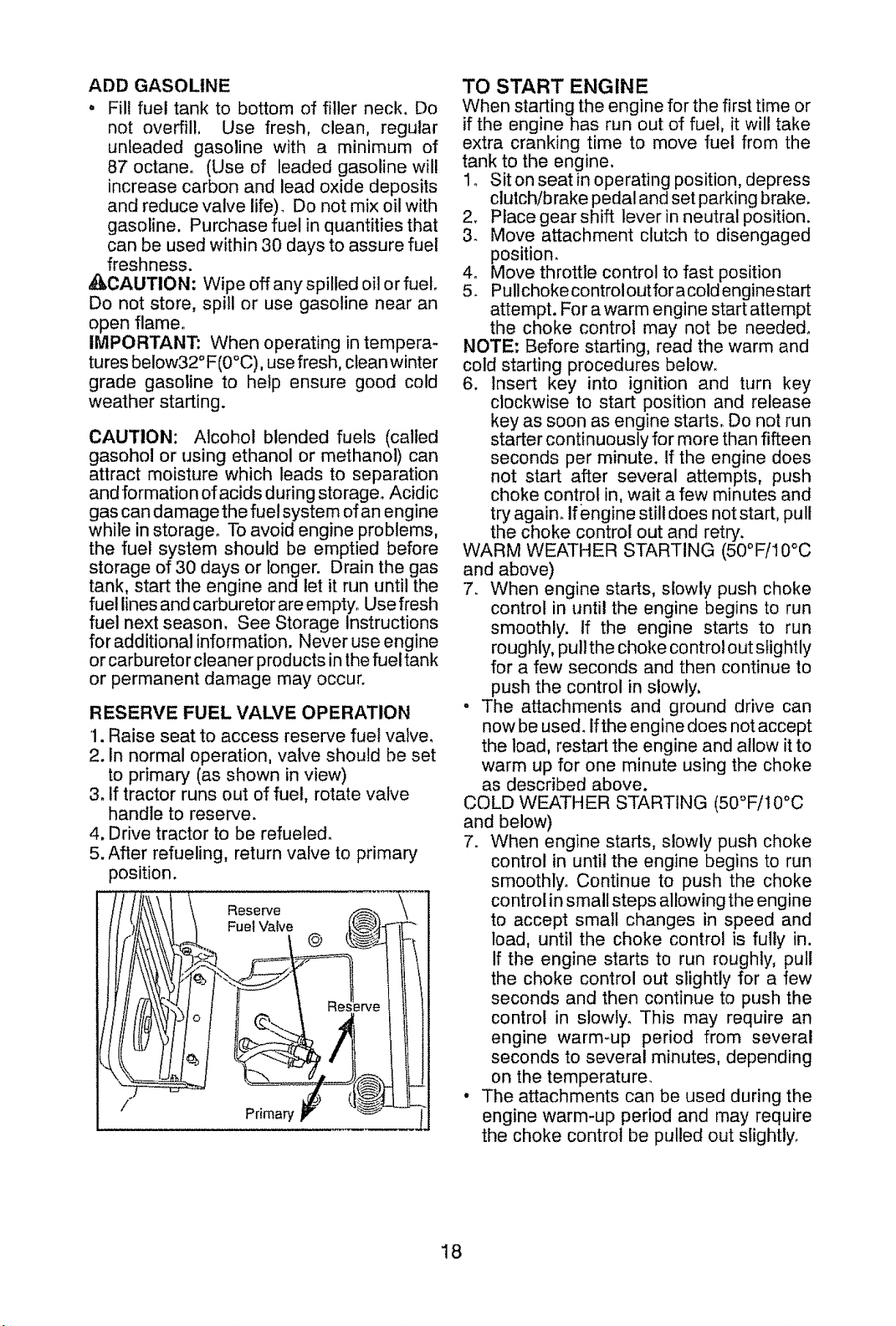

RESERVE FUEL VALVE OPERATION

1. Raise seat to access reserve fuel valve.

2. In normal operation, valve should be set

to primary (as shown in view)

3. If tractor runs out of fuel, rotate valve

handle to reserve.

4. Drive tractor to be refueled.

5. After refueling, return valve to primary

position.

Reserve

Fuel VaDe

@

Primary

TO START ENGINE

When starting the engine for the first time or

if the engine has run out of fuel, it will take

extra cranking time to move fuel from the

tank to the engine.

I. Siton seat in operating position, depress

clutch/b rake pedal and set parking brake.

2. Place gear shift lever in neutral position.

3. Move attachment clutch to disengaged

position.

4. Move throttle control to fast position

5. Pullchoke controloutfor a cold enginestart

attempt. For awarm engine start attempt

the choke control may not be needed.

NOTE: Before starting, read the warm and

cold starting procedures below.

6. insert key into ignition and turn key

clockwise to start position and release

key as soon as engine starts. Do not run

starter continuously for more than fifteen

seconds per minute. If the engine does

not start after several attempts, push

choke control in, wait a few minutes and

try again. If engine still does not start, pull

the choke control out and retry.

WARM WEATHER STARTING (50°F/10°C

and above)

7. When engine starts, slowly push choke

control in until the engine begins to run

smoothly. If the engine starts to run

roughly, pull the choke control out slightly

for a few seconds and then continue to

push the control in slowly,

° The attachments and ground drive can

now be used. if the engine does not accept

the load, restart the engine and allow it to

warm up for one minute using the choke

as described above.

COLD WEATHER STARTING (50°F/10°C

and below)

7. When engine starts, slowly push choke

control in until the engine begins to run

smoothly. Continue to push the choke

control in small steps allowing the engine

to accept small changes in speed and

load, until the choke control is fully in.

if the engine starts to run roughly, pull

the choke control out slightly for a few

seconds and then continue to push the

control in slowly. This may require an

engine warm-up period from several

seconds to several minutes, depending

on the temperature.

• The attachments can be used during the

engine warm-up period and may require

the choke control be pulled out slightly.

18

Page 19

NOTE; If at a high altitude (above 3000

feet) or in cold temperatures (below 32°F)

the carburetor fuel mixture may need to be

adjusted for best engine performance. See

"TO ADJUST CARBURETOR" in the Service

and Adjustments section of this manual.

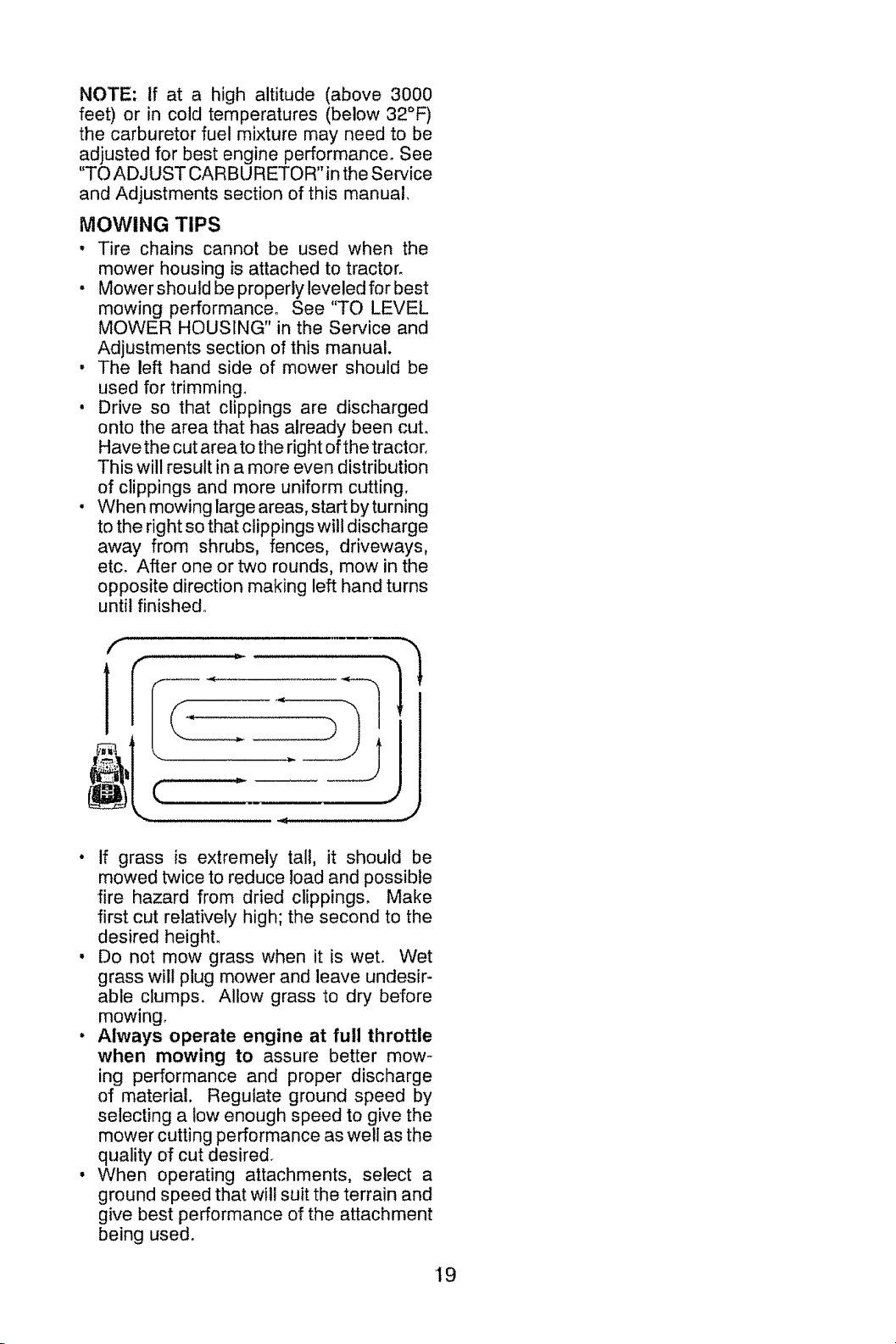

MOWING TIPS

, Tire chains cannot be used when the

mower housing is attached to tractor.

• Mowershould be properly leveled for best

mowing performance_ See "TO LEVEL

MOWER HOUSING" in the Service and

Adjustments section of this manual.

• The left hand side of mower should be

used for trimming.

• Drive so that clippings are discharged

onto the area that has already been cut.

Have the cut area to the right of the tractor,

This will result in a more even distribution

of clippings and more uniform cutting.

• When mowing large areas, start by turning

to the right so that clippings will discharge

away from shrubs, fences, driveways,

etc. After one or two rounds, mow in the

opposite direction making left hand turns

until finished.

f

• If grass is extremely tall, it should be

mowed twice to reduce load and possible

fire hazard from dried clippings. Make

first cut relatively high; the second to the

desired height.

• Do not mow grass when it is wet. Wet

grass will plug mower and leave undesir-

able clumps. Allow grass to dry before

mowing,

• Always operate engine at full throttle

when mowing to assure better mow-

ing performance and proper discharge

of material. Regulate ground speed by

selecting a low enough speed to give the

mower cutting performance as well as the

quality of cut desired_

• When operating attachments, select a

ground speed that will suit the terrain and

give best performance of the attachment

being used.

'19

Page 20

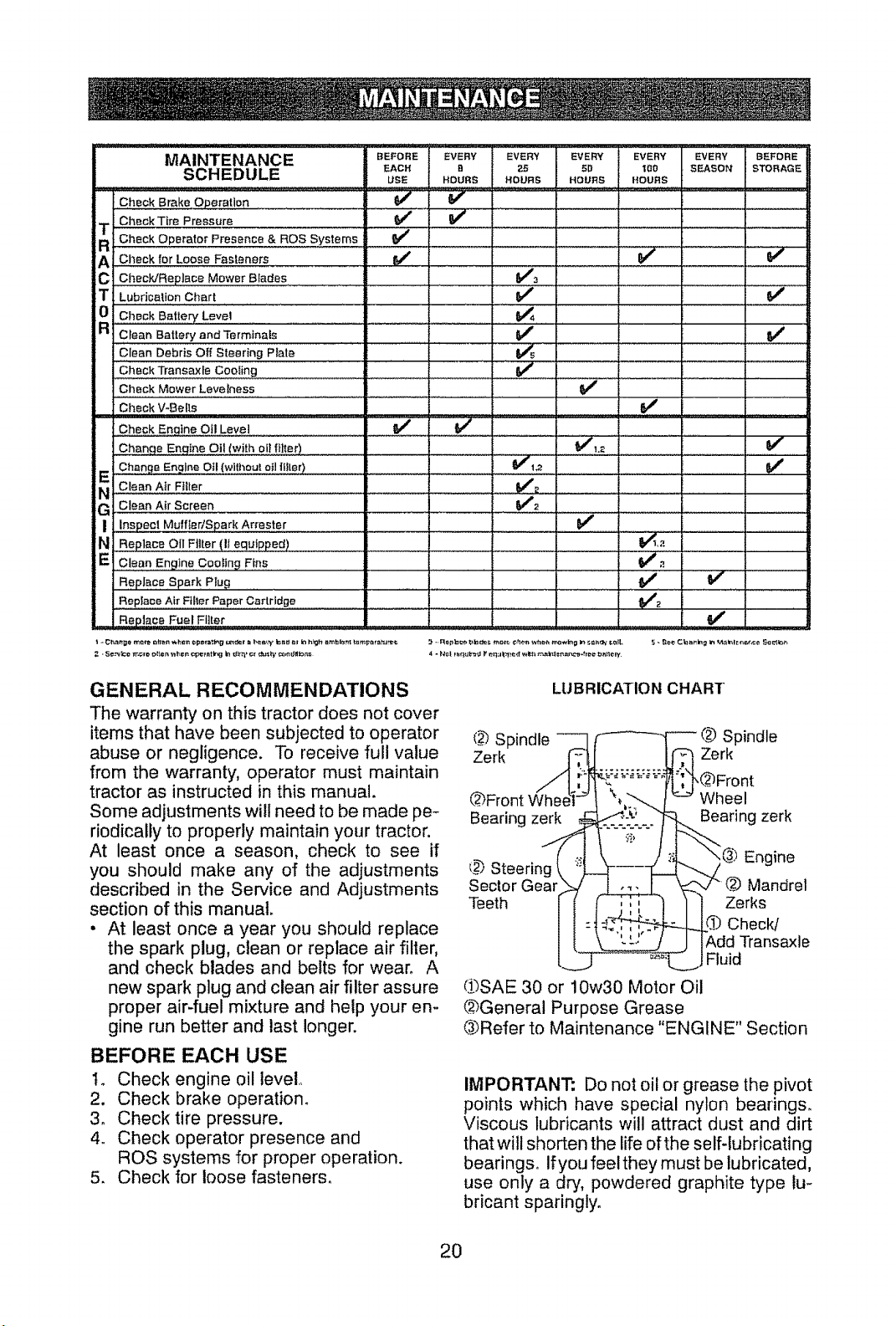

MAINTENANCE B'E_o'RE'" EVEn'l EVEm' EVERY EVERY EVERY BEFORE

SCHEDULE EACH _ 25 51:} t_0 SEASON STORAGE

Check Brake Operation 6_

U_;E HOURS HOURS HOURS HOURS

CheckT_roP,eosoro V" _ t _iiii] i iiiiiiiiiiii]iiiiiiiiiiiiiii/iiii

T CheekOperatorPresence&ROSsystems! _ i I I f I

R I , I I ilLi::iil:iliii "

A

C V'_

Check/Replace Mower Blades ..................

T Lubrication Chart 6/'

0 CheckB.fie,_.LeVe, V'.

R Clean Batlery andTermi,nals _' V I

Clean Debris Off Steering Plate

Check Transaxfe Cooling .............. _ ' ' '

Check Mower Levelness

Check V-Bells rvf

Check Eng!ne O!! Leve! _

Change Engine Oil (with oil [liter) .................... !_l,z ........... !_

E Change Engine Oil (wil!)ou! 0tl i!!!#r ) ...............................................

N C!ea# A

TRACTOR

Always observe safety rules when performing

any maintenance,

BRAKE OPERATION

if tractor requires more than five (5) feet to

stop at highest speed in highest gear on a

level, dry concrete or paved surface, then

brake must be serviced. (See "TO CHECK

BRAKE" in the Service and Adjustments

section of this manual).

TIRES

- Maintain proper air pressure in all tires

(See PSI on tires).

° Keep tires free of gasoline, oi!, or insect

control chemicals which can harm rub-

bero

° Avoid stumps, stones, deep ruts, sharp

objects and other hazards that may cause

tire damage.

NOTE: To sea! tire punctures and prevent

flat tires due to slow leaks, tire sealant may

be purchased from your local parts dealer,

Tire sealant also prevents tire dry rot and

corrosion.

OPERATOR PRESENCE SYSTEM AND

REVERSE OPERATION SYSTEM (ROS)

Be sure operator presence and reverse

operation systems are working properly. If

your tractor does not function as described,

repair the problem immediately_

• The engine should not start unless the

brake pedal is fully depressed, and the

attachment clutch control is in the disen-

gaged position.

CHECK OPERATOR PRESENCE

SYSTEM

, When the engine is running, any attempt

by the operator to leave the seat without

first setting the parking brake should shut

off the engine.

• When the engine is running and the at_

tachment clutch is engaged, any attempt

by the operator to leave the seat should

shut off the engine.

o The attachment clutch should never oper-

ate unless the operator is in the seat.

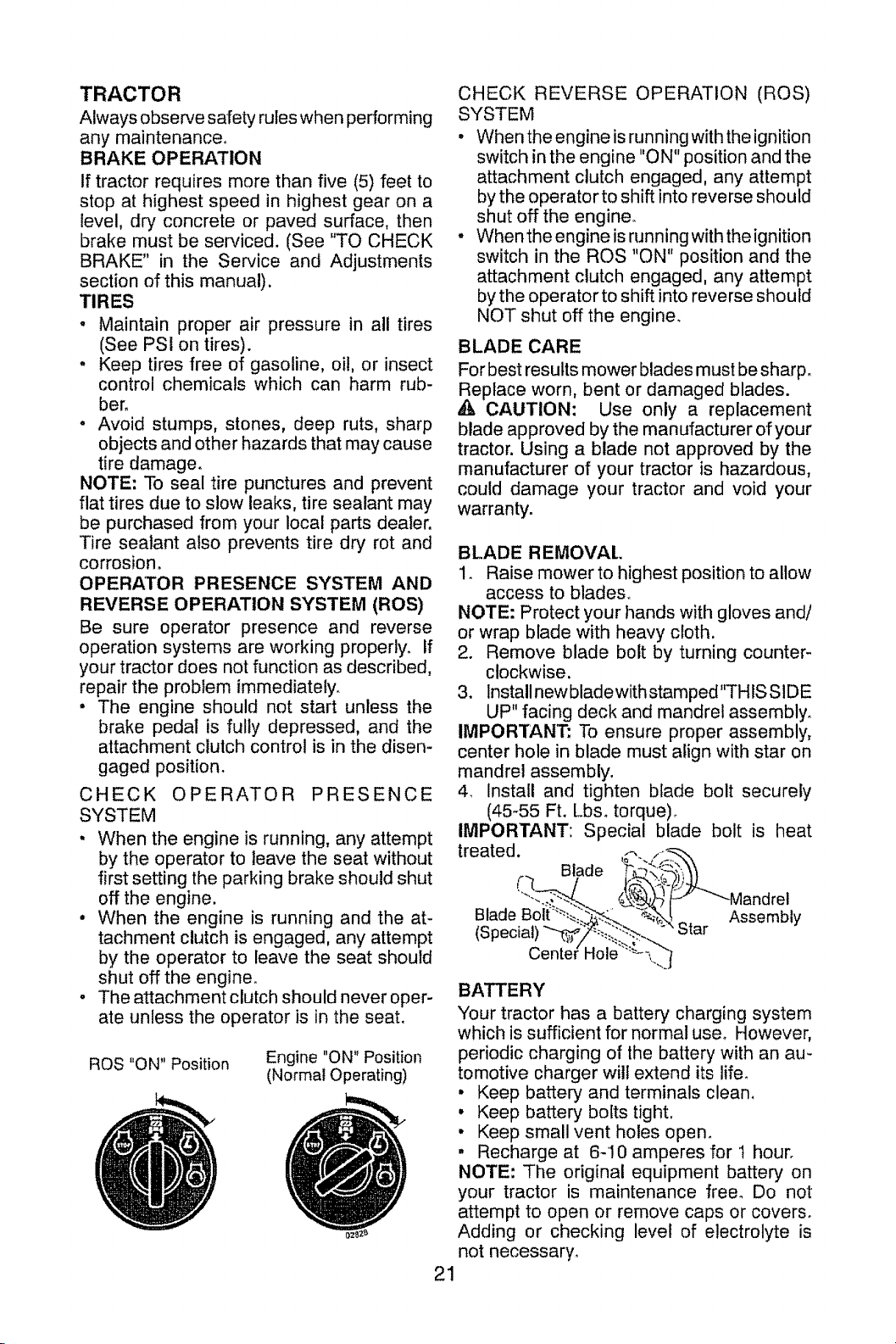

ROS "ON" Position

Engine "ON" Position

(Normal Operating)

CHECK REVERSE OPERATION (ROS)

SYSTEM

, When the engine is running with the ignition

switch in the engine "ON" position and the

attachment clutch engaged, any attempt

by the operator to shift into reverse should

shut off the engine.

• When the engine is running with the ignition

switch in the ROS "ON" position and the

attachment clutch engaged, any attempt

by the operator to shift into reverse should

NOT shut off the engine.

BLADE CARE

For best results mower blades must be sharp.

epface worn, bent or damaged blades.

CAUTION: Use only a replacement

blade approved by the manufacturer of your

tractor. Using a blade not approved by the

manufacturer of your tractor is hazardous,

could damage your tractor and void your

warranty.

BLADE REMOVAL

1o Raise mowerto highest position to allow

access to blades°

NOTE: Protect your hands with gloves and/

or wrap blade with heavy cloth.

2. Remove blade bolt by turning counter-

clockwise.

3. Install newbladewith stamped"THIS SIDE

UP" facing deck and mandrel assembly.

IMPORTANT: To ensure proper assembly,

center hole in blade must align with star on

mandrel assembly.

4. install and tighten blade bolt securely

(45-55 Ft. Lbs. torque).

IMPORTANT: Special blade bolt is heat

treated.

Blade

Blade Assembly

(St Star

BATTERY

Your tractor has a battery' charging system

which is sufficient for normal use° However,

periodic charging of the battery with an au-

tomotive charger will extend its life.

° Keep battery and terminals clean.

, Keep battery botts tight.

• Keep small vent holes open_

, Recharge at 6-10 amperes for t hour.

NOTE: The original equipment battery on

your tractor is maintenance free° Do not

attempt to open or remove caps or covers.

Adding or checking level of electrolyte is

not necessary_

21

Page 22

TOCLEANBATTERYANDTERMINALS

Corrosionanddirtonthe batteryandtermi-

nalscancausethe batteryto"leak"power.

1o Removeterminalguard.

2. DisconnectBLACKbattery cablefirst

then RED battery cable and remove

batteryfromtractor°

3. Rinsethebatterywithplainwateranddry.

4. Cleanterminalsandbatterycableends

withwire brushuntilbright.

5. Coatterminalswithgreaseorpetroleum

jelly.

6o Reinstall battery (See "REPLACING

BATTERY"in the SERVICEAND AD-

JUSTMENTSsectionofthis manual).

TRANSAXLE COOLING

Keep transaxle free from build-up of dirt and

chaff which can restrict cooling.

V-BELTS

Check V-belts for deterioration and wear after

! 00 hours of operation and replace if neces-

sary. The belts are not adjustable. Replace

belts if they begin to slip from wear.

ENGINE

LUBRICATION

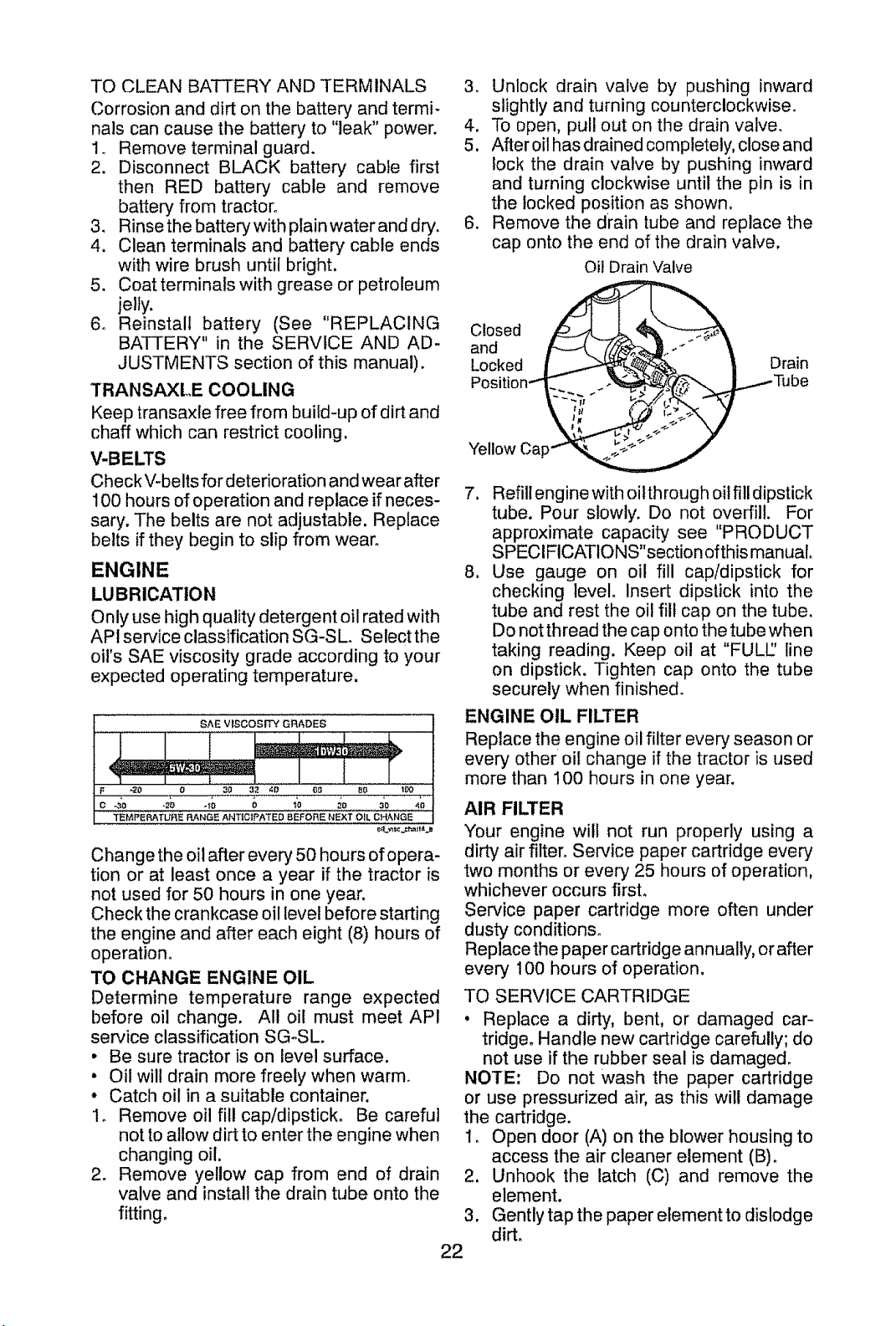

Only use high quality detergent oil rated with

AP1 service classification SG-SL. Selectthe

oil's SAE viscosity grade according to your

expected operating temperature.

BA£ VISCOSIT_GRADES

I

F '._0 0 30 32 _;0 60 _ ,DO

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

Change the oil after every 50 hours of opera-

tion or at least once a year if the tractor is

not used for 50 hours in one year.

Check the crankcase oil level before starting

the engine and after each eight (8) hours of

operation.

TO CHANGE ENGINE OIL

Determine temperature range expected

before oil change. All oil must meet API

service classification SG-SL.

• Be sure tractor is on level surface.

• Oil wil! drain more freely when warm°

• Catch oil in a suitable container.

1. Remove oil fill cap/dipstick. Be careful

not to allow dirt to enter the engine when

changing oil.

2. Remove yellow cap from end of drain

valve and install the drain tube onto the

fitting.

3o Unlock drain valve by pushing inward

slightly and turning counterclockwise.

4. To open, pull out on the drain valve.

5. Aftereil hasdrained completely, close and

lock the drain valve by pushing inward

and turning clockwise until the pin is in

the locked Position as shown.

6. Remove the drain tube and replace the

cap onto the end of the drain valve,

oil Drain Valve

Closed _ _

Locked I _._ _ _ Drain

Position."'_._ .% __ J......_Tube

7. Refill engine with oilthrough oilfill dipstick

tube. Pour slowly. Do not overfill. For

approximate capacity see "PRODUCT

SPECIFICATIONS"section ofthis manual

8. Use gauge on oil fill cap/dipstick for

checking level insert dipstick into the

tube and rest the oil fill cap on the tube.

Do not thread the cap onto the tube when

taking reading. Keep oil at "FULl/' line

on dipstick. Tighten cap onto the tube

securely when finished.

ENGINE OIL FILTER

Replace the engine oil filter every season or

every other oil change if the tractor is used

more than 100 hours in one year.

AIR FILTER

Your engine will not run properly using a

dirty air filter` Service paper cartridge every

two months or every 25 hours of operation,

whichever occurs first.

Service paper cartridge more often under

dusty conditions_

Replace the paper cartridge annually, or after

every 100 hours of operation.

TO SERVICE CARTRIDGE

, Replace a dirty, bent. or damaged car-

tridge. Handle new cartridge carefully; do

not use if the rubber seal is damage&

NOTE; Do not wash the paper cartridge

or use pressurized air. as this wilt damage

the cartridge.

1_ Open door (A) on the blower housing to

access the air cleaner element (B).

2. Unhook the latch (C) and remove the

element.

3. Gently tap the paper elementto dislodge

dirt_

22

Page 23

4. Cleanallaircleanercomponentsofany

accumulateddirt or foreign material,

Prevent any dirt from entering the throat

of carburetor.

5. Install cleaned or new element on the

base and secure with latch.

6. Close and latch the door,

CLEAN AIR SCREEN

Air screen must be kept free of dirt and chaff

to prevent engine damage from overheating,

Clean with a wire brush or compressed airto

remove dirt and stubborn dried gum fibers.

CLEAN AIR INTAKE/COOLING AREAS

To ensure proper cooling, make surethe grass

screen, cooling fins, and other external sur-

faces of the engine are kept clean at all times.

Every 100 hours of operation (more often

under extremely dusty, dirty conditions),

remove the blower housing and other cooling

shrouds. Clean the cooling fins and external

surfaces as necessary. Make sure the cooling

shrouds are reinstalled.

NOTE: Operating the engine with a blocked

grass screen, dirty or plugged cooling fins,

and/or cooling shrouds removed will cause

engine damage due to overheating.

MUFFLER

Inspect and replace corroded muffler and

spark arrester (if equipped) as it could create

a fire hazard and/or damage.

SPARK PLUG(S)

Replace spark plug(s) at the beginning of

each mowing season or after every 100

hours of operation, whichever occurs first.

Spark plug type and gap setting are shown

in "PRODUCT SPECIFICATIONS" section

of this manual.

IN-LINEFUEL FILTER

The fuel filter should be replaced once each

season, If fuel filter becomes clogged, ob-

structing fuel flow to carburetor, replacement

is required.

1o With engine cool, remove filter and plug

fuel line sections°

2, Place new fuel filter in position in fuel line

with arrow pointing towards carburetor.

3o Be sure there are no fuel line leaks and

clamps are properly positioned.

4. Immediately wipe up any spilled gasoline,

Clam___._ amp

Fuel Filter ------__/

CLEANING

, Clean engine, battery, seat, finish, etc.

of all foreign matter.

• Clean debris from steering plate.

Debris can restrict clutch/brake pedal

shaft movement, causing belt slip and

loss of drive.

_, CAUTION: Avoid all pinch points and

movable parts

_.____ Clutch/brake pedaI_o _,_

Clean j °_/_..__. ,,

Steering l

P

_: .... I A(_,_.ei?chI

F_ l_otShown IAr_ PointsI

, Keep finished surfaces and wheels

free of all gasoline, oil, etc_

• Protect painted surfaces with automo-

tive type wax.

We do not recommend using a garden hose

or pressure washer to clean your tractor

unless the engine and transmission are

covered to keep water out. Water in engine

or transmission will shorten the useful life of

your tracton Use compressed air or a leaf

blower to remove grass, leaves and trash

from tractor and mower°

23

Page 24

DECK WASHOUT PORT

'(our tractor's deck is equipped with a

washout port on its surface as part of its

deck wash system+ It should be utilized af-

ter each use.

1+ Drive the tractor to a level, clear spot

on your lawn, near enough to a water

spigot for your garden hose to reach.

IMPORTANT: Make certain the tractor's

discharge chute is directed AWAY from your

house, garage, parked cars, etc+ Remove

bagger chute or mulch cover if attached.

2+ Makesuretheattachmentclutch control

is in the "DISENGAGED" position, set

the parking brake, and stop the engine.

3. Thread the nozzle adapter (packaged

with your tractor's Operator's Manual)

onto the end of your garden hose.

4+ Pull back the lock collar of the nozzle

adapter and push the adapter onto the

deck washout port at the left end of the

mower deck. Release the lock collar to

lock the adapter on the nozzle.

9. Pull back the lock collar of the nozzle

adapter to disconnect the adapter from

the nozzle washout port+

I0+ Move the tractor to a dry area, prefer-

ably a concrete or paved are& Place

the attachment clutch control in the

"ENGAGED" position to remove excess

water and to help dn/before putting the

tractor away,

_WARHING: A broken or missing washout

fitting could expose you or others to thrown

objects from contact with the blade.

• Replace broken or missing washout fitting

immediately, prior to using mower again.

, Plug any holes in mower with bolts and

Iocknuts.

IMPORTANT: Tug hose ensuring connec-

tion is secure.

5+ Turn the water on+

6. While sitting in the operator's position

on the tractor, re+start the engine and

place the throttle lever in the Fast ",,_"

position.

IMPORTANT: Recheck the area making

certain the area is clear.

7. Move the tractor's attachment clutch

control to the "ENGAGED" position.

Remain in the operator's position

with the cutting deck engaged until the

deck is cleaned.

8+ Move the tractor's attachment clutch

control to the "DISENGAGED" posi-

tion. Turn the ignition key to the STOP

position to turn the tractor's engine off.

Turn the water off.

24

Page 25

WARNING: TO AVOID SERIOUS INJURY, BEFORE PERFORMING ANY

SERVICE OR ADJUSTMENTS:

1. Depress clutch/brake pedal fully and set parking brake.

2, Place gearshift lever in neutral position.

3, Place attachment clutch in "DISENGAGED" position,

4. Turn ignition key to "STOP" and remove key,.

5, Make sure the blades and all moving parts have completely stopped.

6o Disconnect spark plug wire from spark plug and place wire where it cannot

come in contact with plugo

TO REMOVE MOWER

1. Place attachment clutch

GAGED" position.

2.

Lower attachment lift lever to its lowest

position.

3,

Disengage belt tension rod (K) from lock

bracket (L).

CAUTION; Belt tension rod is spring

loaded. Have a tight grip on rod and release

slowly.

4. Remove mower belt from electric clutch

pulley (M),

5. Disconnect front link (E) from mower -

remove retainer spring and washer.,

6. Go to either side of mower and disconnect

mower suspension arm (A) from chas-

sis and rear lift link (C) from rear mower

bracket (D) -remove retainer springs and

washers_

7. Go to others!de ofmowerand disconnect

the suspension arm and rear lift link_

in "DISEN-

_h, CAUTION: After rear lift links are discon-

nected, the attachment lift lever will be spring

loaded. Have a tight grip on lift lever when

changing position of the lever.

8, From right side of mower, disconnect

anti-sway bar (S) from right rear mower

bracket (D) - remove retainer spring and

washer and pull mower toward you until

the bar falls from the hole in bracket.

9. Turn tractor steering wheel to the left as

far as it will go,

10oSlide mower out from under right side of

tracton

TO INSTALL MOWER

Follow procedure described in "INSTALL

MOWER AND DRIVE BELT" in the Assembly

section of this manual,

25

Page 26

TO LEVEL MOWER

Make sure tires are properly inflated to the

PSI shown on tires. If tires are over or under

inflated, it may affect the appearance of your

lawn and lead you to think the mower is not

adjusted properly.

VISUAL SIDE-TO-SIDE ADJUSTMENT

1. With al! tires properly inflated and if your

lawn appears unevenly cut, determine

which side of mower is cutting lower.

NOTE: As desired, you can raise the low

side of mower or lower the high side°

2. Go to side of mower you wish to adjust.

3_ With a 3/4" or adjustable wrench, turn

lift link adjustment nut (A) to the left to

lower the mower, or, to the right to raise

the mower_

4. if adjustment is necessary, see steps 2

and 3 in Visual Adjustment instructions

above.

5o Recheck measurements, adjust if neces-

sary until both sides are equal.

FRONT-TO-BACK ADJUSTMENT

IMPORTANT: Deck must be level side-

to-sideo

To obtain the best cutting results, the mower

blades should be adjusted so the front tip is

1/6" to 1/2" lower than the rear tip when the

mower is in its highest position.

,_ CAUTION: Blades are sharF Protect

your hands with gloves and/or wrap blade

with heavy cloth.

• Raise mower to highest position.

• Position any blade so the tip is pointing

straight forward° Measure distance (B) to

the ground at front and rear tip of the blade.

Turn nut rig

to raise mower

NOTE: Each full turn of adjustment nut will

change mower height about 3/16".

4. Test your adjustment by mowing some

uncut grass and visually checking the

appearance. Readjust, if necessary, until

you are satisfied with the results.

PRECISION SIDE-TO-SIDE ADJUSTMENT

1. With alltires properly inflated, park tractor

on level ground or driveway.

•(_ CAUTION: Blades are sharp. Protect

your hands with gloves and/or wrap blade

with heavy cloth.

2. Raise mower to its highest position.

3. At both sides of mower, position blade at

side and measure the distance (A) from

bottom edge of blade to the ground. The

distance should be the same on both sides.

Turn nut left

to Dowermower

• If front t!p of blade is not 1/8" to 1/2" lower

than the rear tip, go to the front of tractor.

• With an 11/16" or adjustable wrench,

loosen jam nut A several turns to clear

adjustment nut B.

• With a 3/4" or adjustable wrench, turn

front link adjustment nut (B) clockwise

(Itighten) to raise the front of mower, or,

counterclockwise (loosen) to lower the

front mower.

Tighten adjust nut

B to raise mower

Loosen jam nut A first

NOTE: Each full turn of the adjustment nut

will change mower height about 1/8".

° Recheck measurements, adjust if neces-

sary until front tip of blade is 1/8" to t/2"

lower than the rear tip.

° Hold adjustment nut in position with wrench

and tighten jam nut securely against ad-

justment nut.

Loosen adjust

nut B to lower

26

mower

Page 27

TO REPLACE MOWER DRIVE BELT

MOWER DRIVE BELT REMOVAL

I, Park tractor on a level surface, Engage

parking brake,

2, Lower attachment lift lever to its lowest

position.

3, Disengage belt tension rod (K) from lock

bCracket (L),

AUTION: Belt tension rod is spring load-

ed, Have afirm grip on rod and release slowly,

4, Remove screws (P) from Roll, and L.H.

mandrel covers and remove covers (Q) o

5. Remove any dirt or grass clippings which

may have accumulated around mandrels

and entire upper deck surface°

6. Remove belt from electric clutch pulley

(M), both mandrel pulleys (R) and all idler

pulleys (S).

MOWER DRIVE BELT INSTALLATION

1_ Install belt around both mandrel pulleys

(R) and around idler pulleys (S) as shown.

2. Install belt onto electric clutch pulley (M).

IMPORTANT: Check belt for proper routing

in all mower pulley grooves_

3. Reassemble R.H. and L.H. mandrel cov-

ers (Q). Securely tighten all screws.

4. Engage belt tension rod (K) on locking

bracket (L).

CAUTION: Belt tension rod is spring load-

ed, Have atight grip on rod and engage slowly,

5. Raise attachment lift lever to highest

position,

BELT REMOVAL-

t. Remove mower (See "TO REMOVE

MOWER" in this section of manual).

NOTE: Observe entire motion drive belt

and position of all belt guides and keepers°

2. Disconnect clutch wire harness (A).

3_ Remove anti-rotation link (B) on right

side of tractor.

4. Remove belt from stationary idler (C)

and clutching idler (D).

5. Remove belt from centerspan idler (E).

6. Pull belt slack toward rear of tractor.

Remove belt upwards from transaxle

input pulley (F)_

7. Remove belt downward from engine

pulley and around electric clutch (G).

8. Slide belt toward rear of tractor, off the

steering plate (H) and remove from tractor.

BELT INSTALLATION -

1. Install new belt from tractor rear to

front, over the steering plate (H) and

above clutch brake pedal shaft (J).

2. Pull belt toward front of tractor and roll

belt around electric clutch and onto

engine pulley (G)o

3. Pull belt toward rear of tractor° Care-

fully work belt down around transaxle

input pulley (F)o Be sure belt is inside

the belt keeper.

4. Install belt on centerspan idler (E)o

5. Install belt through stationary idler (C)

and clutching idler (D).

6_ Reinstall anti-rotation link (B) on right

side of tractor. Tighten securely.

7o Reconnect clutch harness (A)_

8. Make sure belt is in all pulley grooves

and inside all belt guides and keepers.

9. Install mower (See "TO INSTALL

MOWER" in this section of manual).

I

TO REPLACE MOTION DRIVE BELT

Park the tractor on level surface. Engage

parking brake. For assistance, there is a

belt installation guide decal on bottom side

of left footrest.

27

Page 28

TRANSAXLE GEAR SHIFT LEVER NEU-

TRAL ADJUSTMENT

The transaxle should be in neutral when the

gear shift lever is in neutral (N) (lock gate)

position, The adjustment is preset at the

factory; however, if adjustment is needed,

proceed as follows:

1, Make sure transaxle is in neutral (N),

NOTE: When the tractor rear wheels move

freely, the transaxle is in neutral

2, Loosen adjustment bolt in front of the

right rear wheel.

3, Position the gear shift lever in the neutral

(N) position,

4. Tighten adjustment bolt securely.

NOTE: If additional clearance is needed to

get to adjustment bolt, move mower deck

height to the lowest position.

Gearshift Adjustment Bolt

Lever

,,.,_ :ral

/ _,__ '! Lock Gate

TO REMOVE WHEEL FOR REPAIRS

i. Block up axle securely_

2. Remove axle cover, retaining ring and

washers to allow wheel removal (rear

wheels have a square key - Do not Iose)_

3. Repair tire and reassemble.

NOTE: On rear wheels only: align grooves in

rear wheel hub and axle. Insert square key.

4. Reptacewashers and snap retaining ring

securely in axle groove,

5. Replace axle cover.

NOTE: To seal tire punctures and prevent

flat tires due to slow leaks, purchase and

use tire sealant from Sears. Tire sealant also

prevents tire dry rot and corrosion,

Washers

Retaining

Axle

Cover

TO CHECK BRAKE

tf tractor requires more than five (5) feet to

stop at highest speed in highest gear on a

level, dry concrete or paved surface, then

brake must be serviced.

You may also check brake by:

!. Parktractoron alevel, dryconcreteor paved

surface, depress clutch/brake pedal all

the way down and engage parking brake.

2. Place gear shift lever in neutral position.

The rear wheels must lock and skid when

you try to manually push the tractor forward.

If the rear wheels rotate, then the brake

needs to be serviced. Contact a Sears or

other qualified service center.

TO START ENGINE WITH A WEAK BAT-

TERY

_IbWARNING: Lead-acid batteries gener-

ate explosive gases_ Keep sparks, flame

and smoking materials away from batteries.

Always wear eye protection when around

batteries,

Ifyour battery is too weak to start the engine, it

should be recharged. (See "BATTERY" in the

MAINTENANCE section of this manual).

if "jumper cables" are used for emergency

starting, follow this procedure:

IMPORTANT: Your tractor is equipped with

a 12 volt system, The other vehicle must also

be a i 2 volt system_ Do not use your tractor

battery to start other vehicles°

TO ATTACH JUMPER CABLES

I. Connect one end ofthe RED cable to the

POSITIVE (+) terminal of each battery(A-

B), taking care notto short against tractor

chassis.

2. Connect one end of the BLACK cable

to the NEGATIVE (_) terminal (C) of fully

charged battery.

3. Connect the other end of the BLACK

cable (D) to good chassis ground, away

from fuel tank and battery.

TO REMOVE CABLES, REVERSE

ORDER

I. BLACK cable first from chassis and then

from the fully charged battery.

2. RED cable last from both batteries.

Square

Key ly.

(Rear Wheel Only) -='_-

Weak or Dead Fully Charged

Battery Battery

28

Page 29

REPLACING BATTERY

,_WARNING: Do notshort battery terminals

by allowing a wrench or any other object to

contact both terminals at the same time.

Before connecting battery, remove metal

bracelets, wristwatch bands, rings, etc,

Positive terminal must be connected first to

prevent sparking from accidental grounding.

1. Lift hood to raised position.

2o Disconnect BLACK battery cable (A)then

RED battery cable and carefully remove

battery from tractor.

3. Install new battery with terminals in same

position as old battery.

4. First connect RED battery cable (B) to

positive (+) battery terminal with hex bolt

and keps nut as shown. Tighten secu rely.

Slide terminal cover (C) over terminal

5. ConnectBLACKgrounding cableto neg-

ative (-) battery terminal with remaining

hex bolt and keps nut. Tighten securely.

6. Close hood.

_ Negative

(Black)

Cable

TO REPLACE HEADLIGHT BULB

I. Raise hood.

2. Remove bulb holder from the hole in the

backside of the grill.

3. Replace bulb in holder and install bulb

holder securely back into the hole in the

backside of the grill.

4. Close hood.

TO REMOVE HOOD & GRILL ASSEMBLY

1. Raise hood.

2. Unsnap headlight wire connector.

3o Stand in front of tractor. Grasp hood at

sides, tilt toward engine and lift off of

tractor.

4. When replacing hood, be sure to recon-

nect the headlight wire connector.

Hood

Headlight Wire

Connector

Positive

(Red)

Cable

FRONT WHEEL TOE-IN/CAMBER