Page 1

Operator's Manual

LAWN TRACTOR

19.5 HR* 42" Mower

Electric Start

6 Speed Transaxle

Mode! No.

917.28907

• Español, p. 33

This product has a low emission engine which operates

differently from previously built engines. Before you start the

engine, read and understand this Owner’s Manual.

IMPORTANT:

Read and follow all Safety

Rules and Instructions before

operating this equipment.

SEARS, ROEBUCK AND CO., HOFFMAN ESTATES, IL60179 U.S.A.

Visit our Craftsman website:www.sears.com/craftsman *As rated by the engine manufacturer

For answers to your questions

about this product, Caii:

1-800-659-5917

Sears Craftsman Help Line

5 am - 5 pm, Mon - Sat

425017 Rev. 3

Page 2

TABLE OF CONTENTS

Warranty

Safety Rules

Product Specifications

Assembiy/Pre-Operation..

Operation

Maintenance Schedule

...............................

.........................

.......

.............................

.......

......................

......................

......................

.........................

....................

....................

2

Maintenance

3

Service and Adjustments....

6

Storage

7

Troubleshooting

10

Sears Service

...................................

17

...........................

..................

..................

.................... ....................

.........................

....................

.... Back Cover

17

21

27

28

WARRANTY

CRAFTSMAN FULL WARRANTY

TWO YEARS ON RIDING EQUIPMENT

When operated and maintained according to all supplied instructions, if this riding equipment

fails due to a defect in material or workmanship within two years from the date or purchase,

call 1-800-4-MY-HOME® to arrange for free repair.

Also, when operated and maintained according to all supplied instructions. Warranty will

also cover defects in material and workmanship of the Frame and Front Axle for five years

from the date of purchase

This warranty covers ONLY defects In material and workmanship. Sears will NOT

pay for:

• Expendable items that become worn during normal use, including but not limited to

blades, spark plugs, air cleaners, belts, and oil filters.

• Standard maintenance servicing, oil changes, or tune-ups.

• Tire replacement or repair caused by punctures from outside objects, such as nails,

thorns, stumps, or glass.

• Tire or wheel replacement or repair resulting from normal wear, accident, or improper

operation or maintenance.

• Repairs necessary because of operator abuse, including but not limited to damage

caused by towing objects beyond the capability of the riding equipment, impacting

objects that bend the frame or crankshaft, or over-speeding the engine.

• Repairs necessary because of operator negligence, including but not limited to, electrical

and mechanical damage caused by improper storage, failure to use the proper grade

and amount of engine oil, failure to keep the deck clear of flammable debris, or failure to

maintain the riding equipment according to the instructions contained in the operator’s

manual.

• Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or

oxidized (stale). In general, fuel should be used within 30 days of its purchase date.

• Normal deterioration and wear of the exterior finishes, or product label replacement.

All riding equipment and battery warranty coverage is void if this product is ever used for

commercial or rental purposes.

This warranty applies only while this product is within the United States.

This warranty gives you specific legal rights, and you may also have other rights which

vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Page 3

SAFETY RULES

Ad ANGER: This cutting machine Is capable of amputating hands and feet and

throwing objects. Failure to observe the following safety Instructions could result

In serious Injury or death.

AwARNING: In order to prevent acciden

tal starting when setting up, transporting,

adjusting or making repairs, always discon

nect spark plug wire and place wire where

it cannot contact spark plug.

AwARNING: Do not coast down a hill in

neutral, you may lose control of the tractor.

AwARNING: Tow only the attachments

that are recommended by and comply with

specifications of the manufacturer of your

tractor. Use common sense when towing.

Operate only at the lowest possible speed

when on a slope. Too heavy of a load, while

on a slope, is dangerous. Tires can lose

traction with the ground and cause you to

lose control of your tractor.

AwARNING: Engine exhaust, some of

its constituents, and certain vehicle compo

nents contain or emit chemicals known to the

State of California to cause cancer and birth

defects or other reproductive harm.

AwARNING: Battery posts, terminals and

related accessories contain lead and lead

compounds, chemicals known to the State of

California to cause cancer and birth defects

or other reproductive harm. Wash hands

after handling.

I. GENERAL OPERATION

• Read, understand, and follow all instruc

tions on the machine and in the manual

before starting.

• Do not put hands or feet near rotating

parts or under the machine. Keep clear

of the discharge opening at all times.

• Only allow responsible adults, who are

familiar with the instructions, to operate

the machine.

• Clear the area of objects such as rocks,

toys, wire, etc., which could be picked

up and thrown by the blades.

• Be sure the area is clear of bystanders

before operating. Stop machine if anyone

enters the area.

• Never carry passengers.

• Do not mow in reverse unless absolutely

necessary. Always look down and behind

before and while backing.

Never direct discharged material toward

anyone. Avoid discharging material

against a wall or obstruction. Material

may ricochet back toward the operator.

Stop the blades when crossing gravel

surfaces.

Do not operate machine without the en

tire grass catcher, discharge chute, or

othersafetydevices in place and working.

Slow down before turning.

Never leave a running machine unat

tended. Always turn off blades, set

parking brake, stop engine, and remove

keys before dismounting.

Disengage blades when not mowing.

Shut off engine and wait for all parts to

come to a complete stop before cleaning

the machine, removingthe grass catcher,

or unclogging the discharge chute.

Operate machine only in daylightorgood

artificial light.

Do not operate the machine while under

the influence of alcohol or drugs.

Watch for traffic when operating near or

crossing roadways.

Use extra care when loading or unloading

the machine into a trailer or truck.

Always wear eye protection when operat

ing machine.

Data indicates that operators, age 60

years and above, are involved in a large

percentage of riding mower-related inju

ries. These operators should evaluate

their ability to operate the riding mower

safely enough to protect themselves and

others from serious injury.

Follow the manufacturer’s recommen

dation for wheel weights or counter

weights.

Keep machine free of grass , leaves or

otherdebris build-up which can touch hot

exhaust / engine parts and burn. Do not

allow the mower to plow leaves or other

debris which can cause build-up to oc

cur. Clean any oil or fuel spillage before

operating or storing the machine. Allow

machine to cool before storage.

Page 4

SAFETY RULES

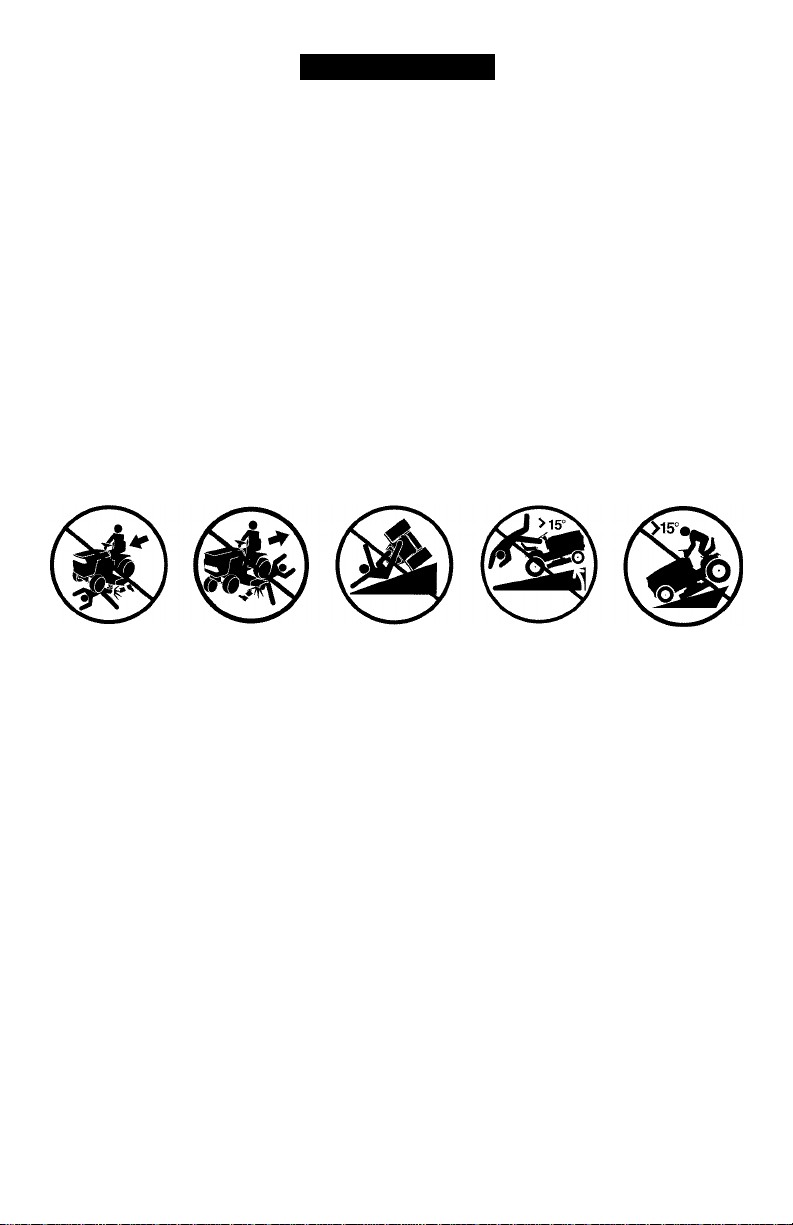

II. SLOPE OPERATION

Slopes are a major factor related to loss of

control and tip-over accidents, which can

result in severe injury or death. Operation

on all slopes requires extra caution. If you

cannot back up the slope or if you feel uneasy

on it, do not mow it.

• Mow up and down slopes, not across.

• Watch for holes, ruts, bumps, rocks, or

other hidden objects. Uneven terrain

could overturn the machine. Tall grass

can hide obstacles.

• Choose a low ground speed so that you

will not have to stop or shift while on the

slope.

• Do not mow on wet grass. Tires may lose

traction.

Always keep the machine in gear when

going down slopes. Do notshiftto neutral

and coast downhill.

• Avoid starting, stopping, or turning on a

slope. If the tires lose traction, disengage

the blades and proceed slowly straight

down the slope.

• Keep all movement on the slopes slow

and gradual. Do not make sudden

changes in speed or direction, which

could cause the machine to roll over.

• Use extra care while operating machine

with grass catchers or otherattachments;

they can affect the stability of the ma

chine. Do no use on steep slopes.

• Do not try to stabilize the machine by

putting your foot on the ground.

• Do not mow near drop-offs, ditches,

or embankments. The machine could

suddenly roll over if a wheel is over the

edge or if the edge caves in.

III. CHILDREN

Tragic accidents can occur if the operator

is not alert to the presence of children.

Children are often attracted to the machine

and the mowing activity. Never assume

that children will remain where you last

saw them.

• Keep children out of the mowing area

and in the watchful care of a responsible

adult other than the operator.

• Be alert and turn machine off if a child

enters the area.

• Before and while backing, look behind

and down for small children.

• Never carry children, even with the

blades shut off. They may fall off and

be seriously injured or interfere with safe

machine operation. Children who have

been given rides in the past may suddenly

appear in the mowing area for another

ride and be run over or backed over by

the machine.

• Never allow children to operate the ma

chine.

• Use extra care when approaching blind

corners, shrubs, trees, or other objects

that may block your view of a child.

IV. TOWING

• Tow only with a machine that has a hitch

designed fortowing. Do not attach towed

equipment except at the hitch point.

• Followthe manufacturer’s recommenda

tion for weight limits for towed equipment

and towing on slopes.

• Never allow children or others in or on

towed equipment.

• On slopes, the weight of the towed equip

ment may cause loss of traction and loss

of control.

• Travel slowly and allow extra distance to

stop.

V. SERVICE

SAFE HANDLING OF GASOLINE

To avoid personal injury or property dam

age, use extreme care in handling gasoline.

Gasoline is extremely flammable and the

vapors are explosive.

• Extinguish all cigarettes, cigars, pipes,

and other sources of ignition.

• Use only approved gasoline container.

• Never remove gas cap or add fuel with

the engine running. Allow engine to cool

before refueling.

• Never fuel the machine indoors.

• Neverstorethe machine orfuel container

where there is an open flame, spark, or

pilot light such as on a water heater or

other appliances.

• Never fill containers inside a vehicle or

on a truck or trailer bed with plastic liner.

Always place containers on the ground

away from your vehicle when filling.

• Remove gas-powered equipment from

the truck or trailer and refuel it on the

ground. If this is not possible, then refuel

such equipment with a portable container,

rather than from a gasoline dispenser

nozzle.

Page 5

SAFETY RULES

• Keep the nozzle in contact with the rim

of the fuel tank or container opening at

all times until fueling is complete. Do not

use a nozzle lock-open device.

• Iffuel is spilled on clothing, change cloth

ing immediately.

• Never overfill fuel tank. Replace gas cap

and tighten securely.

GENERAL SERVICE

• Never operate machine in a closed

area.

• Keep all nuts and bolts tightto be sure the

equipment is in safe working condition.

• Never tamper with safety devices. Check

their proper operation regularly.

• Keep machine free of grass, leaves, or

other debris build-up. Clean oil or fuel

spillage and remove anyfuel-soaked de

bris. Allow machineto cool before storing.

Do not mow in reverse unless absolutely

necessary. Always look down and behind

before and while backing.

Never carry children, even with the

blades shut off. They may fall off and

be seriously injured or interfere with safe

machine operation. Children who have

been given rides in the past may suddenly

appear in the mowing area for another

ride and be run over or backed over by

the machine.

Keep children out of the mowing area

and in the watchful care of a responsible

adult other than the operator.

Be alert and turn machine off if a child

enters the area.

If you strike a foreign object, stop and

inspect the machine. Repair, if necessary,

before restarting.

Never make any adjustments or repairs

with the engine running.

Check grass catcher components and the

discharge chute frequently and replace

with manufacturer’s recommended parts,

when necessary.

Mower blades are sharp. Wrap the blade

or wear gloves, and use extra caution

when servicing them.

Check brake operation frequently. Adjust

and service as required.

Maintain or replace safety and instruction

labels, as necessary.

Be sure the area is clear of bystanders

before operating. Stop machine if anyone

enters the area.

Never carry passengers.

Before and while backing, look behind

and down for small children.

Mow up and down slopes (15° Max), not

across.

Choose a low ground speed so that you

will not have to stop or shift while on the

slope.

Avoid starting, stopping, or turning on a

slope. Ifthetires losetraction, disengage

the blades and proceed slowly straight

down the slope.

If machine stops while going uphill,

disengage blades, shift into reverse and

back down slowly.

Do not turn on slopes unless necessary,

and then, turn slowly and gradually

downhill, if possible.

Page 6

PRODUCT SPECIFICATIONS

Gasoline Capacity

and Type:

Oil Type

(API-SG-SL):

Oil Capacity: W/ Filter: 56 oz.

Spark Plug: Champion RC12YC

Ground Speed Forward: 1st 1.0

Charging System: 3 Amps Battery

Battery: Amp/Hr: 28

Blade Bolt Torque: 45-55 Ft. Lbs.

CONGRATULATIONS on your purchase of

a new tractor. It has been designed, engi

neered and manufactured to give you the best

possible dependability and performance.

Should you experience any problem you

cannot easily remedy, please contact a Sears

or other qualified service center. We have

competent, well-trained representatives

and the proper tools to service or repair

this tractor.

Please read and retain this manual. The

instructions will enable you to assemble

and maintain your tractor properly. Always

observe the “SAFETY RULES”.

1.5 Gallons

Unleaded Regular

SAE 30 (above 32° F)

SAE5W30 (below 32°F)

W/0 Filter: 48 oz.

(Gap: .030")

2nd 1.4

3rd 2.1

4th 3.1

5th 4.0

6th 5.1

Reverse: 1.6

5 Amps Headlights

Min. CCA: 230

Case size: U1R

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining,

caring for and using your tractor.

• Follow the instructions under “Mainte

nance” and “Storage” sections of this

owner’s manual.

AwARNING: This tractor is equipped with

an internal combustion engine and should not

be used on or near any unimproved forestcovered, brush-covered or grass-covered

land unless the engine’s exhaust system is

equipped with a spark arrester meeting ap

plicable local or state laws (if any). If a spark

arrester is used, it should be maintained in

effective working order by the operator.

In the state of Californiatheabove is required

by law (Section 4442 of the California Public

Resources Code). Other states may have

similar laws. Federal laws apply on federal

lands. A spark arrester for the muffler is

available through your nearest Sears service

center (See REPAIR PARTS manual).

REPAIR PROTECTION

AGREEMENTS

Congratulations on making a smart purchase.

Your new Craftsman® product is designed

and manufactured for years of dependable

operation. But like all products, it may require

repair from time to time. That’s when having

a Repair Protection Agreement can save you

money and aggravation.

Purchase a Repair Protection Agreement

now and protect yourseif from unexpected

hassle and expense.

Here’s what’s included in the Agreement:

• Expert service by our 12,000 profesional

repair specialists.

• Unlimited service and no charge for parts

and labor on all covered repairs.

• Product replacement if your covered

product can’t be fixed.

• Discount of 10% from regular price of

service and service-related parts not

covered by the agreement; also, 10% off

regular price of preventive maintenance

check.

• Fast help by phone - phone support

from a Sears representative on products

requiring in-home repair, plus convenient

repair scheduling.

Once you purchase the Agreement, a

simple phone call is all that it takes for you

to schedule service. You can call anytime

day or night, or schedule a service appoint

ment online.

Sears has over 12,000 professional repair

specialists, who have access to over 4.5

million quality parts and accessories. That’s

the kind of professionalism you can count on

to help prolong the life of your new purchase

for years to come. Purchase your Repair

Protection Agreement today!

Some limitations and exclusions apply.

For prices and additional Information call

1-800-827-6655.

SEARS INSTALLATION SERVICE

For Sears professional installation of home

appliances, garage door openers, water

heaters, and other major home items, in the

U.S.A. call 1-800-4-MY-HOME®

Page 7

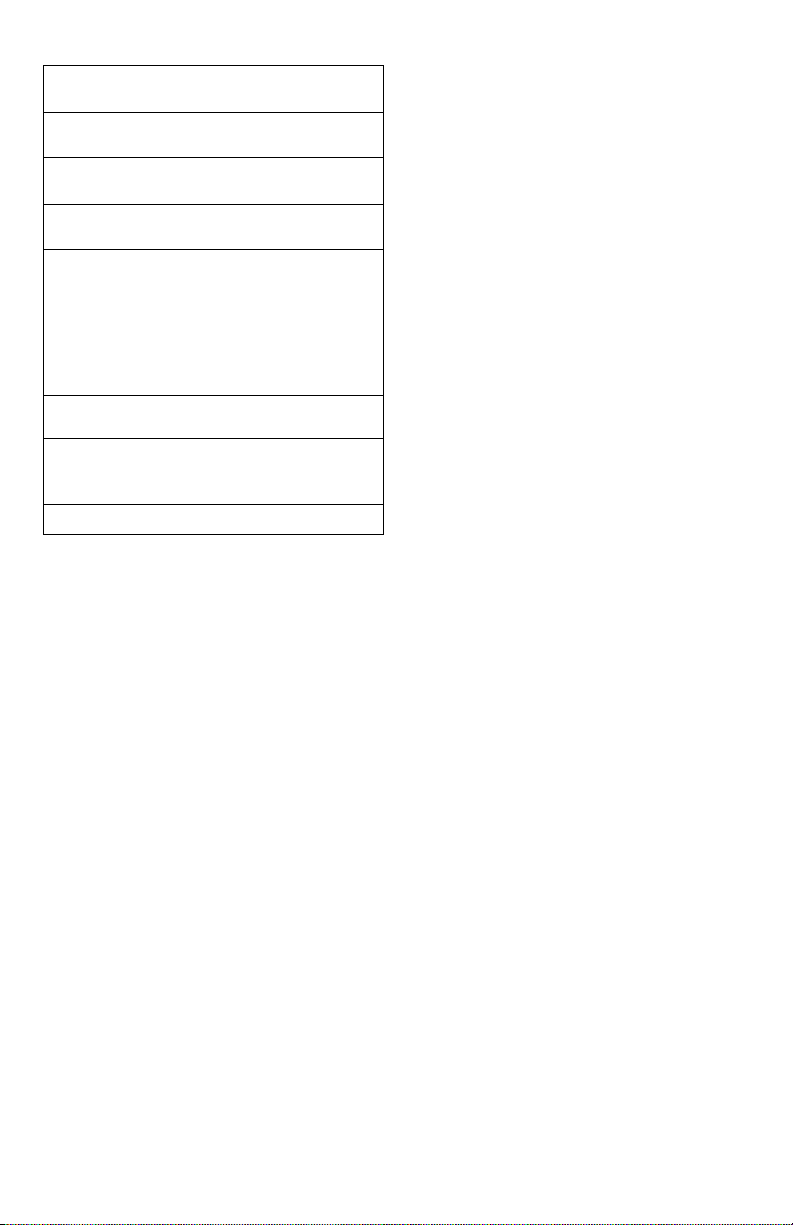

UNASSEMBLED PARTS

ASSEMBLY/PRE-OPERATION

Your new tractor has been assembled at the factory with the exception of those parts left

unassembled for shipping purposes. To ensure safe and proper operation of your tractor

all parts and hardware you assemble must be tightened securely. Use the correct tools as

necessary to insure proper tightness.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly

easier. Standard wrench sizes are listed.

(1) 5/16" wrench Utility knife

(2) 7/16" wrenches Tire pressure gauge

(2) 1/2" wrenches Pliers

(1) 9/16" wrench

When right or left hand is mentioned in this

manual, itmeanswhenyouarein the operating

position (seated behind the steering wheel).

TO REMOVE TRACTOR FROM

CARTON

UNPACK CARTON

1. Remove all accessible loose parts and

parts boxes from carton.

2. Cut along dashed lines on all four panels

of carton. Remove end panels and lay

side panels flat.

3. Check for any additional loose parts or

cartons and remove.

Page 8

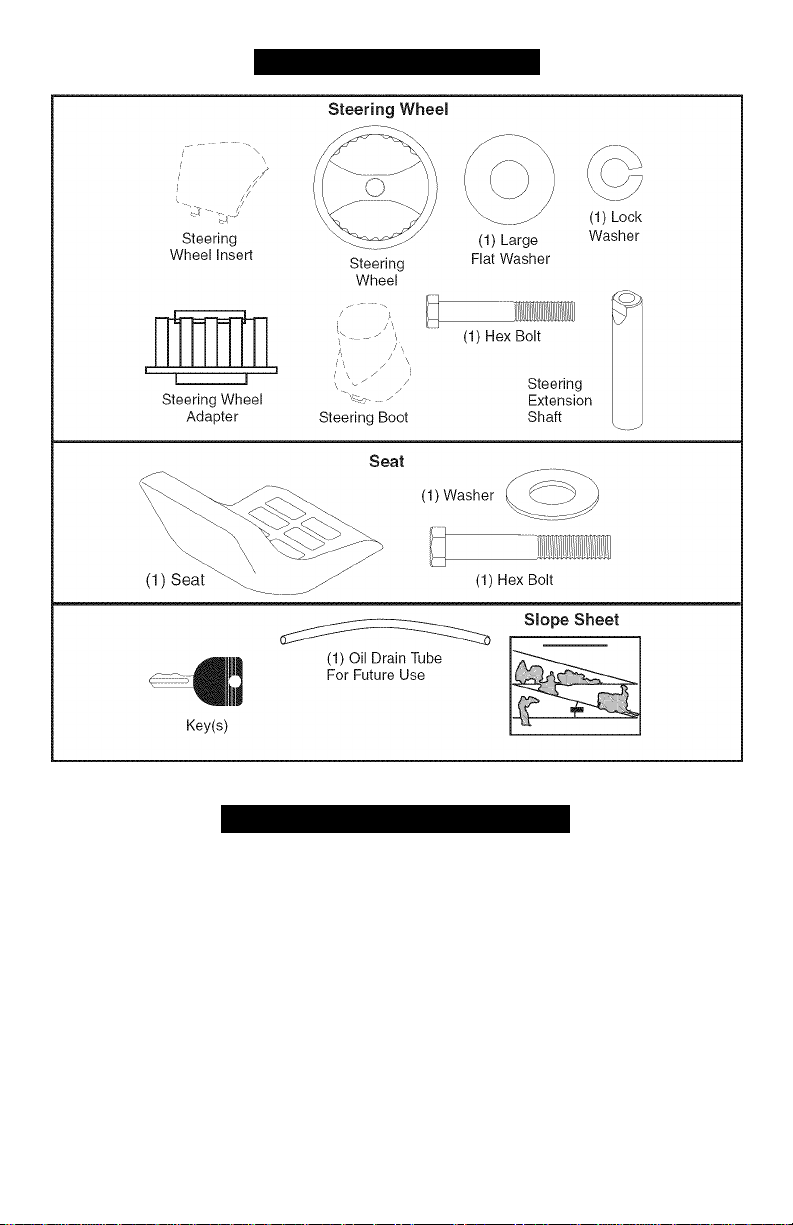

BEFORE REMOVING TRACTOR FROM SKID

TO CHECK BATTERY

1. Lift seat to raised position.

NOTE: If this battery is put into service after

month and year indicated on label (label is

located between terminals) charge battery

for minimum of one hour at 6-10 amps. (See

"BATTERY" in Maintenance section of this

manual for charging instructions).

• For battery and battery cable installation

see "REPLACING BATTERY" in the

"Service and Adjustments" section in

this manual.

ATTACH STEERING WHEEL

ASSEMBLE EXTENSION SHAFT AND

BOOT

1. Slide extension shaft onto lower steer

ing shaft.

2. Place tabs of steering boot over tab

slots in dash and push down to secure.

Label

INSTALL STEERING WHEEL

3. Position front wheels of the tractor so

they are pointing straight forward.

4. Remove steering wheel adapter from

steering wheel and slide adapter onto

steering shaft extension.

5. Position steering wheel so cross bars

are horizontal (left to right) and slide

inside boot and onto adapter.

6. Assemble large flat washer, 5/16 lock

washer, 5/16 hex bolt and tighten

securely.

7. Snap steering wheel insert into center

of steering wheel.

8. Remove protective materials from trac

tor hood and grill.

IMPORTANT: Check for and remove any

staples in skid that may puncture tires

where tractor is to roll off skid.

INSTALL SEAT

1. Remove bolt and flat washer securing

seat to cardboard packing and set aside

for assembly of seat to tractor. Remove

the cardboard packing and discard.

2. Connect switch to seat.

bottom pads are positioned over large

slotted holes in pan.

4. Push down on seat to engage pads in

slots and pull seat towards rear of tractor.

5. Raise seat and tighten bolt securely.

6. Remove tape and discard.

Page 9

7. Lower seat into operating position and

sit on seat. Press clutch/brake pedal all

the way down. If operating position is not

comfortable, adjust seat.

TO ADJUST SEAT

Grasp adjustment handle and pull up, slide

seat to desired position and release adjust

ment handle.

NOTE: You may now roll your tractor off

the skid. Follow the appropriate instruction

below to remove the tractor from the skid.

A WARNING: Before starting, read, un

derstand and follow all instructions in the

Operation section of this manual. Be sure

tractor is in a well-ventilated area. Be sure

the area in front of tractor is clear of other

people and objects.

TO ROLL TRACTOR OFF SKID

(See Operation section for location

and function of controls)

1. Raise attachment lift lever to its highest

position.

2. Release parking brake by depressing

clutch/brake pedal.

3. Place gearshift lever in neutral posi

tion.

4. Roll tractor forward off skid.

5. Remove banding holding the deflector

shield up against tractor.

Continue with the instructions that follow.

CHECK TIRE PRESSURE

The tires on your tractor were overinflated at

the factory for shipping purposes. Correct

tire pressure is important for best cutting

performance.

• Reduce tire pressure to PSI shown on

tires.

CHECK DECK LEVELNESS

For best cutting results, mower housing

should be properly leveled. See “TO LEVEL

MOWER” in the Service and Adjustments

section of this manual.

CHECK FOR PROPER POSITION OF ALL BELTS

See the figures that are shown for replacing

motion and mower blade drive belts in the

Service and Adjustments section of this man

ual. Verify that the belts are routed correctly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor,

check to see that the brake is operating

properly. See “TO CHECK BRAKE” in the

Service and Adjustments section of this

manual.

CHECKLIST

Before you operate your new tractor, we

wish to assure that you receive the best

performance and satisfaction from this

Quality Product.

Please review the following checklist:

y All assembly instructions have been

completed.

y No remaining loose parts in carton.

y Battery is properly prepared and

charged.

y Seat is adjusted comfortably and tight

ened securely.

y All tires are properly inflated. (For ship

ping purposes, the tires were overinflated

at the factory).

y Be sure mower deck is properly leveled

side-to-side/front-to-rear for best cutting

results. (Tires must be properly inflated

for leveling).

y Check mower and drive belts. Be sure

they are routed properly around pulleys

and inside all belt keepers.

y Check wiring. See that all connections

are still secure and wires are properly

clamped.

While learning howto use yourtractor, pay ex

tra attention to thefollowing important items:

y Engine oil is at proper level.

y Fuel tank is filled with fresh, clean, regular

unleaded gasoline.

y Become familiar with all controls, their

location and function. Operate them

before you start the engine.

y Be sure brake system is in safe operating

condition.

y Be sure Operator Presence System and

Reverse Operation System (ROS) are

working properly (See the Operation and

Maintenance sections in this manual).

Page 10

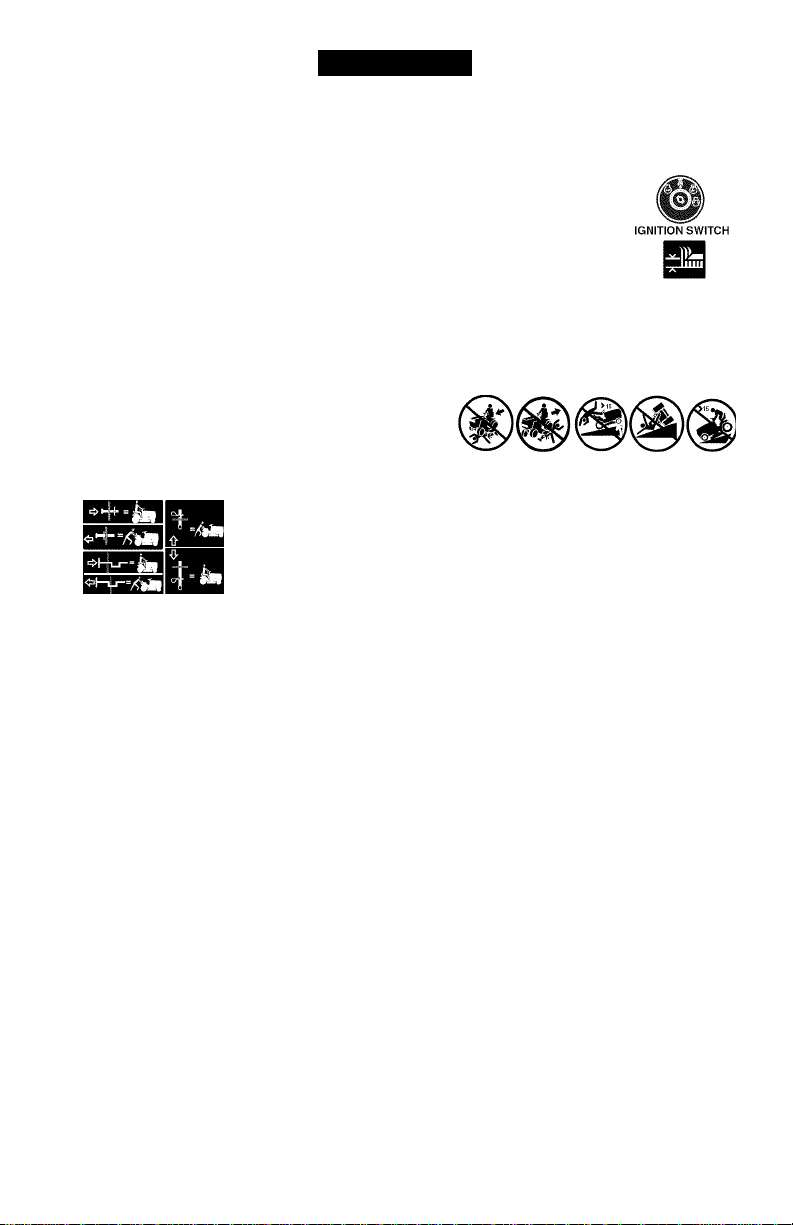

OPERATION

These symbols may appear on your tractor or in literature supplied with the product. Learn

and understand their meaning.

N

NEUTRAL HIGH

ENGINE OFF REVERSE ENGINE ON ENGINE START PARKING BRAKE MOWER HEIGHT MOWER LIFT

♦

EVERSI

ERATIC

OPERATION

SYSTEM (ROS)

H

© 0

ID i a Í

LIGHTS ON fuel BATTERY REVERSE

FERY

L \\\ ^ ^

♦

FORWARD

^ V ©irySi®

CRUISE CONTROL

/ml

CLUTCH/BRAKE

PEDAL

HlP

ATTACHMENT ATTACHMENT DANGER, KEEP HANDS

CLUTCH DISENGAGED CLUTCH ENGAGED AND FEET AWAY KEEP AREA CLEAR SLOPE HAZARDS

DANGER indicates a hazard which, if not avoided,

will result in death or serious injury.

A.

WARNING indicates a hazard which, if not avoided,

could result in death or serious injury.

FREEWHEEL

(Automatic Models only)

Failure to follow instructions

could result in serious injury or

death. The safety alert symbol

is used to identify safefy informafion abouf hazards which can

resulf in deafh, serious injury

and/or properfy damage.

A

CAUTION indicates a hazard which, if not avoided,

might result In minor or moderate Injury.

CAUTION when used without the alert symbol,

indicates a situation that could result in damage

to the tractor and/or engine.

I HOT SURFACES indicates a hazard which,

if not avoided, could result in death, serious injury

and/or property damage.

FIRE indicates a hazard which, if not avoided,

could result in death, serious Injury and/or

property damage.

(SEE SAFETY RULES SECTION)

10

Page 11

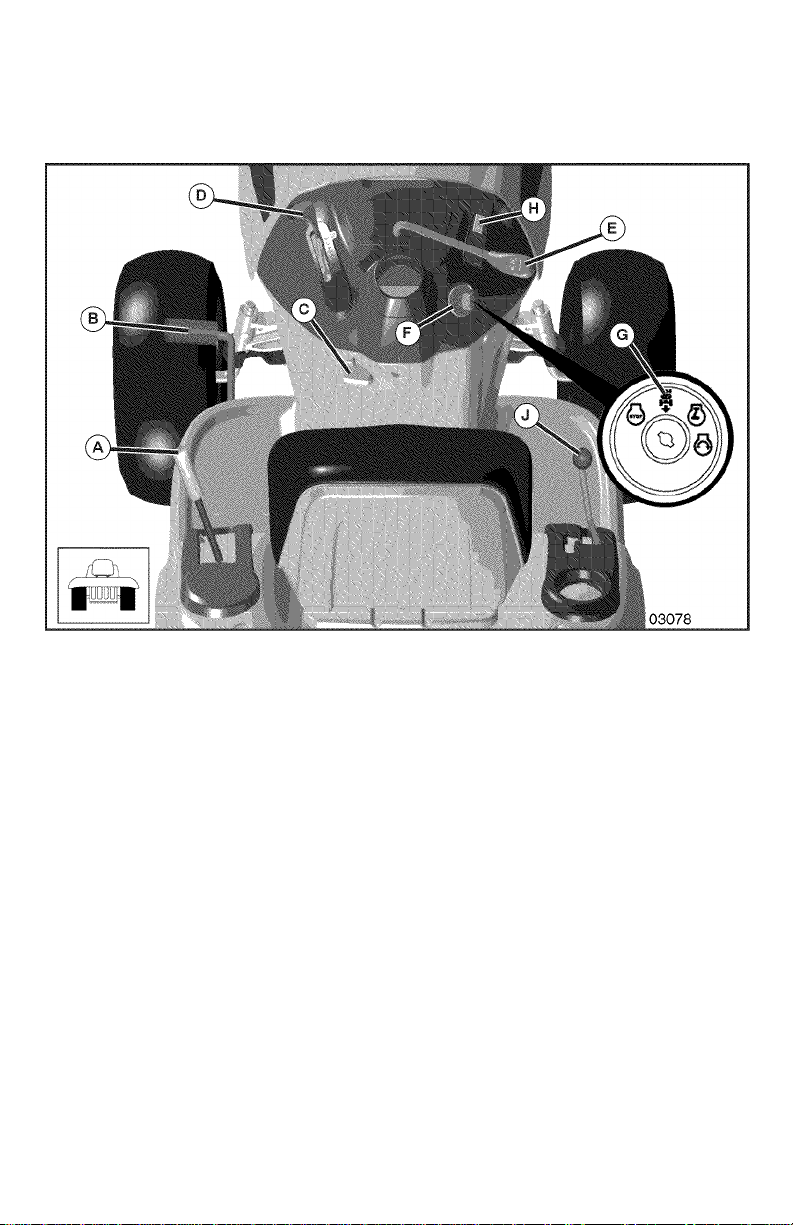

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

TRACTOR

Compare the illustrations with your tractor to familiarize yourself with the locations of

various controls and adjustments. Save this manual for future reference.

Our tractors conform to the applicable safety standards of the

American National Standards Institute.

(A) ATTACHMENT LIFT LEVER - Used to

raise and lower the mower or other attach

ments mounted to your tractor.

(B) CLUTCH/BRAKE PEDAL - Used for

declutching and braking the tractor and

starting the engine.

(C) PARKING BRAKE- Locks clutch/brake

pedal into the brake position.

(D) THROTTLE/CHOKECONTROL- Used

for starting and controlling engine speed.

(E) ATTACHMENTCLUTCHLEVER-Used

to engage the mower blades, or other attach

ments mounted to your tractor.

(F) IGNITION SWITCH - Used for starting

and stopping the engine.

(G) REVERSE OPERATION SYSTEM

(ROS) "ON" POSITION - Allows operation

of mower or other powered attachment while

in reverse.

(H) LIGHT SWITCH - Turns the headlights

on and off.

(J) GEARSHIFT LEVER - Selects the speed

and direction of tractor.

11

Page 12

The operation of any tractor can result In foreign objects thrown Into

the eyes, which can result In severe eye damage. Always wear safety

yy

glasses or eye shields while operating your tractor or performing any

adjustments or repairs. We recommend standard safety glasses or a

wide vision safety mask worn over spectacles.

HOW TO USE YOUR TRACTOR

TO SET PARKING BRAKE

Your tractor is equipped with an operator

presence sensing switch. When engine is

running, any attempt by the operatorto leave

the seat without first setting the parking brake

will shut off the engine.

1. Depress clutch/brake pedal (B) all the

way down and hold.

2. Pull parking brake lever (C) up and hold,

release pressurefrom clutch/brake pedal

(B), then release parking brake lever. Ped

al should remain in brake position. Make

sureparkingbrakewillholdtractorsecure.

ENGINE-

• Move throttle control (D) between half

and full speed (fast) position.

NOTE: Failure to move throttle control

between half and full speed (fast) position,

before stopping, may cause engine to

“backfire”.

STOPPING

MOWER BLADES -

• To stop mower blades, move attachment

clutch clutch lever to disengaged position

(fp).

GROUND DRIVE -

• To stop ground drive, depress clutch/

brake pedal all the way down.

• Move gear shift lever (J) to neutral posi

tion.

• Turn ignition key (F) to “STOP” position

and remove key. Always remove key

when leaving tractor to prevent unau

thorized use.

IMPORTANT: Leaving the ignition switch

in any position other than "STOP" will

cause the battery to discharge and go

dead.

NOTE: Under certain conditions when

tractor is standing idle with the engine

running, hot engine exhaust gases may

cause “browning” of grass. To eliminate

this possibility, always stop engine when

stopping tractor on grass areas.

^kcAUTION: Always stop tractor

completely, as described above, and set

parking brake before leaving the opera

tor's position.

TO USE THROTTLE CONTROL (D)

Always operate engine at full speed (fast).

• Operating engine at less than full speed

(fast) reduces engine's operating efficiency.

• Full speed (fast) offers the best mower

performance.

12

Page 13

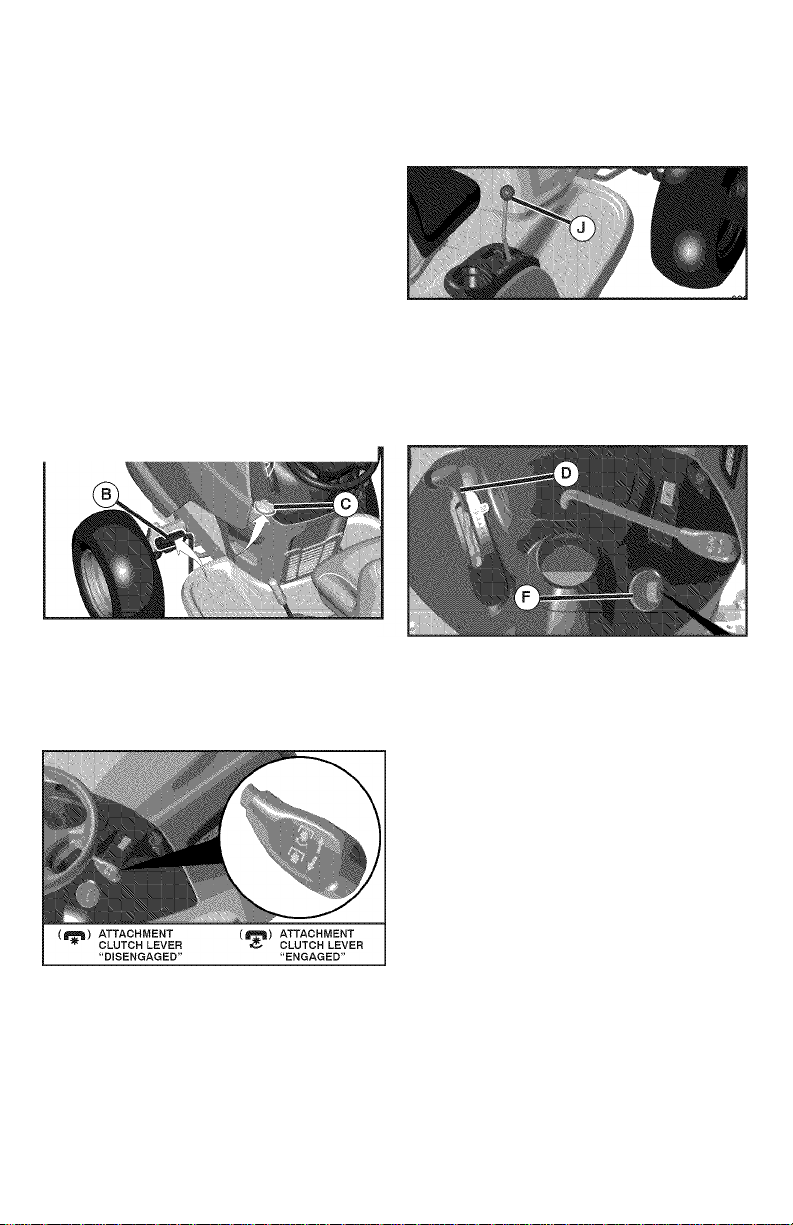

TO MOVE FORWARD AND

BACKWARD

The direction and speed of movement is

controlled by the gearshift lever (J).

1.

Start tractor with clutch/brake pedal de

pressed and gearshift lever in neutral

(N) position.

2.

Move gearshift lever to desired posi

tion.

3.

Slowly release clutch/brake pedal to

start movement.

IMPORTANT: Bring tractor to a complete

stop before shifting or changing gears.

Failure to do so will shorten the useful life

of your transaxle.

TO ADJUST MOWER CUTTING HEIGHT

The position of the attachment lift lever (A)

determines the cutting height.

• For best cutting performance, grass over

6" in heightshould be mowed twice. Make

the first cut relatively high; the second to

desired height.

TO ADJUST GAUGE WHEELS

Gauge wheels are properly adjusted when

they are slightly off the ground when mower

is at the desired cutting height in operating

position. Gauge wheels then keep the deck

in proper position to help prevent scalping

in most terrain conditions.

NOTE: Adjust gauge wheels with tractor on

a flat level surface.

1. Adjust mower to desired cutting height

(See “TO ADJUST MOWER CUTTING

HEIGHT” in this section of manual).

2. With mower in desired height of cut posi

tion, gauge wheels should be assembled

so they are slightly off the ground. Install

gauge wheel in appropriate hole. Tighten

securely.

3. Repeat for all, installing gauge wheel in

same adjustment hole.

• Put attachment lift lever in desired cutting

height slot.

The cutting height range is approximately

1" to 4". The heights are measured from

the ground to the blade tip with the engine

not running. These heights are approximate

and may vary depending upon soil condi

tions, height of grass and types of grass

being mowed.

• The average lawn should be cutto approxi

mately 2-1/2" during the cool season and

to over 3" during hot months. For healthier

and better looking lawns, mow often and

after moderate growth.

TO OPERATE MOWER

Your tractor is equipped with an operator

presence sensing switch. Any attempt by the

operator to leave the seat with the engine

running and the attachment clutch engaged

will shut off the engine. You must remain

fully and centrally positioned in the seat to

prevent the engine from hesitating or cutting

off when operating your equipment on rough,

rolling terrain or hills.

1. Select desired height of cut with attach

ment lift lever.

2. Start mower blades by engaging attach

ment clutch control.

TO STOP MOWER BLADES

Disengage attachment clutch control.

AcAUTION: Do not operate the mower

without either the entire grass catcher, on

mowers so equipped, or the deflector shield

(S) in place.

13

Page 14

REVERSE OPERATION SYSTEM (ROS)

Your tractor is equipped with a Reverse

Operation System (ROS). Any attempt by

the operator to travel in the reverse direc

tion with the attachment clutch engaged

will shut off the engine unless ignition key

is placed in the ROS "ON" position.

AwaRNING: Backing up with the at

tachment clutch engaged while mowing

is strongly discouraged. Turning the ROS

"ON", to allow reverse operation with the

attachment clutch engaged, should only

be done when the operator decides it is

necessary to reposition the machine with

the attachment engaged. Do not mow In

reverse unless absolutely necessary.

USING THE REVERSE OPERATION

SYSTEM Only use if you are certain no children or

other bystanders will enter the mowing

area.

1. Depress clutch/brake pedal all the way

down and hold.

2. With engine running, turn ignition key

counterclockwise to ROS "ON" posi

tion.

3. Look down and behind before and

while backing.

4. Move gear shift lever to reverse (R) po

sition and slowly release clutch/brake

pedal to start movement.

5. When use of the ROS is no longer

needed, turn the ignition key clockwise

to engine "ON" position.

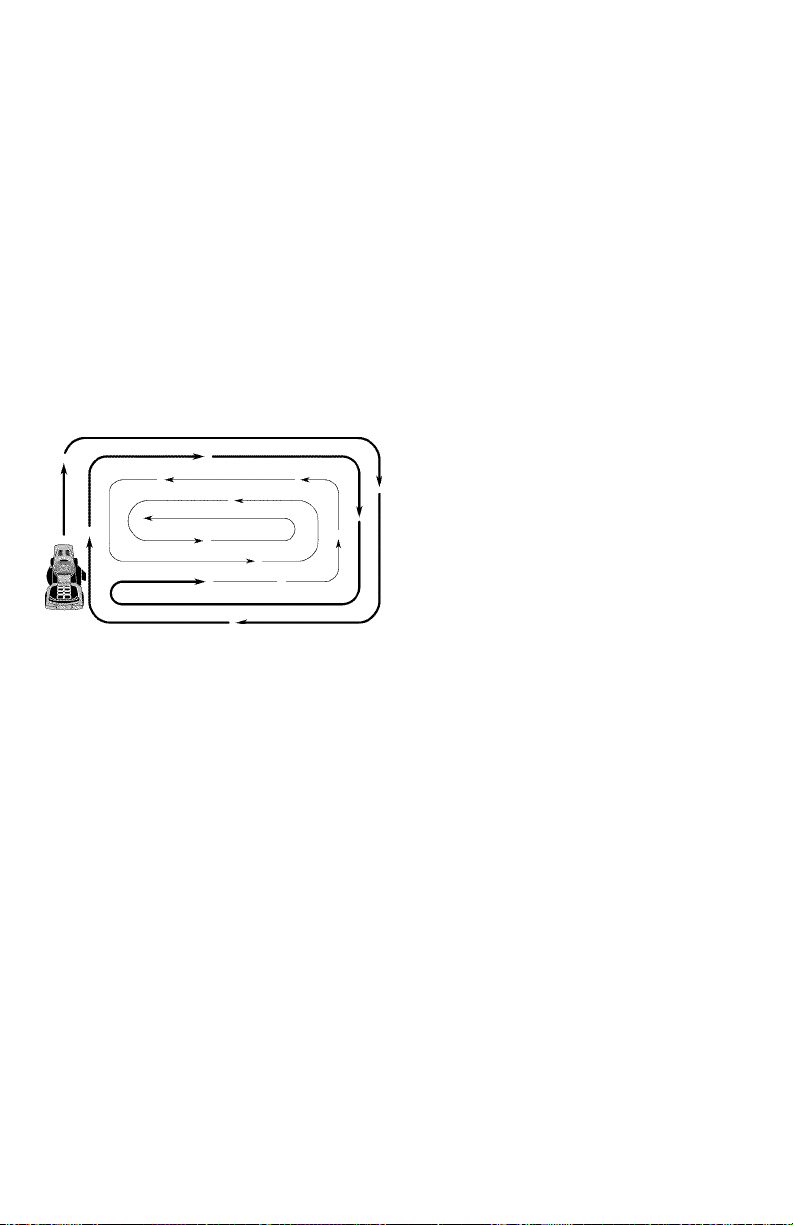

ROS "ON" Position Engine "ON" Position

(Normal Operating)

TO OPERATE ON HILLS

AwARNING: Do not drive up or down

hills with slopes greater than 15° and do

not drive across any slope. Use the slope

guide provided at the back of this manual.

• Choose the slowest speed before start

ing up or down hills.

• Avoid stopping or changing speed on

hills.

• If stopping is absolutely necessary, push

clutch/brake pedal quickly to brake posi

tion and engage parking brake.

• Move gearshift lever to 1 st gear. Be

sure you have allowed room for tractor

to roll slightly as you restart movement.

• To restart movement, slowly release

parking brake and clutch/brake pedal.

• Make all turns slowly.

TO TRANSPORT

• Raise attachment lift lever to its highest.

• When pushing or towing your tractor,

be sure gearshift lever is in neutral (N)

position.

• Do not push or tow tractor at more than

five (5) MPH.

NOTE: To protect hood from damage

when transporting your tractor on a truck

or a trailer, be sure hood is closed and

secured to tractor. Use an appropriate

means of tying hood to tractor (rope, cord,

etc.).

TOWING CARTS AND OTHER ATTACH

MENTS

Tow only the attachments that are recom

mended by and comply with specifications

of the manufacturer of your tractor. Use

common sense when towing. Too heavy of

a load, while on a slope, is dangerous. Tires

can lose traction with the ground and cause

you to lose control of your tractor.

14

Page 15

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL

The engine in yourtractor has been shipped,

from the factory, already filled with summer

weight oil.

1. Check engine oil with tractor on level

ground.

2. Remove oil fill cap/dipstick and wipe

clean, reinsertthe dipstick and screw cap

tight, wait for a few seconds, remove and

read oil level. If necessary, add oil until

“FULL mark on dipstick is reached. Do

not overfill.

• For cold weather operation you should

change oil for easier starting (See the oil

viscosity chart in the Maintenance section

of this manual).

• To change engine oil, see the Maintenance

section in this manual.

ADD GASOLINE

• Fill fuel tank to bottom of filler neck. Do not

overfill. Usefresh, clean, regular unleaded

gasoline with a minimum of 87 octane.

(Use of leaded gasoline will increase

carbon and lead oxide deposits and reduce

valve life). Do not mix oil with gasoline.

Purchase fuel in quantities that can be used

within 30 days to ensure fuel freshness.

AcAUTION: Wipe off any spilled oil or fuel.

Do not store, spill or use gasoline near an

open flame.

IMPORTANT: When operating in tempera

tures below 32°F(0°C), use fresh, clean

winter grade gasoline to help insure good

cold weather starting.

CAUTION: Alcohol blended fuels (called

gasohol or using ethanol or methanol) can

attract moisture which leads to separation

and formation of acids during storage. Acidic

gas can damage the fuel system of an engine

while in storage. To avoid engine problems,

the fuel system should be emptied before

storage of 30 days or longer. Drain the gas

tank, start the engine and let it run until the

fuel lines and carburetor are empty. Usefresh

fuel next season. See Storage Instructions

for additional information. Never use engine

or carburetor cleaner products inthefuel tank

or permanent damage may occur.

TO START ENGINE

When starting the engine for the first time

or if the engine has run out of fuel, it will

take extra cranking time to move fuel from

the tank to the engine.

1. Sit on seat in operating position,

depress clutch/brake pedal and set

parking brake.

2. Place gear shift lever in neutral (N)

position. i5

3. Move attachment clutch to disengaged

position.

4. Move throttle control to choke position.

NOTE: Before starting, read the warm

and cold starting procedures below.

5. Insert key into ignition and turn key

clockwise to start position and release

key as soon as engine starts. Do not

run starter continuously for more than

fifteen seconds per minute. If the

engine does not start after several

attempts, move throttle control to fast

position, wait a few minutes and try

again. If engine still does not start,

move the throttle control back to the

choke position and retry.

WARM WEATHER STARTING (50°F/10°C

and above)

6. When engine starts, move the throttle

control to the fast position.

• The attachments and ground drive can

now be used. If the engine does not

accept the load, restart the engine and

allow it to warm up for one minute using

the choke as described above.

COLD WEATHER STARTING (50°F/10°C

and below)

6. When engine starts, leave throttle

control in choke position until engine

warms up and begins to run roughly.

Once rough running begins, immedi

ately move the throttle control to the

fast position. Engine warm-up may

take from several seconds to several

minutes (the colder the temperature,

the longer the warm-up).

• The attachments can also be used dur

ing the engine warm-up period.

NOTE: If at a high altitude (above 3000

feet) or in cold temperatures (below 32°F)

the carburetor fuel mixture may need to

be adjusted for best engine performance

(see “TO ADJUST CARBURETOR” in the

Service and Adjustments section of this

manual).

Page 16

MOWING TIPS

• Tire chains cannot be used when the

mower housing is attached to tractor.

• Mower should be properly leveled for best

mowing performance. See “TO LEVEL

MOWER HOUSING” in the Service and

Adjustments section of this manual.

• The left hand side of mower should be

used for trimming.

• Drive so that clippings are discharged onto

the area that has already been cut. Have

the cut area to the right of the tractor. This

will result in a more even distribution of

clippings and more uniform cutting.

• When mowing large areas, start by turning

to the right so that clippings will discharge

away from shrubs, fences, driveways,

etc. After one or two rounds, mow in the

opposite direction making left hand turns

until finished .

If grass is extremely tall, it should be

mowed twice to reduce load and possible

fire hazard from dried clippings. Make

first cut relatively high; the second to the

desired height.

Do not mow grass when it is wet. Wet

grass will plug mower and leave undesir

able clumps. Allow grass to dry before

mowing.

Always operate engine at full throttle

when mowing to ensure better mow

ing performance and proper discharge

of material. Regulate ground speed by

selecting a low enough speed to give the

mower cutting performance as well as the

quality of cut desired.

When operating attachments, select a

ground speed that will suit the terrain and

give best performance of the attachment

being used.

16

Page 17

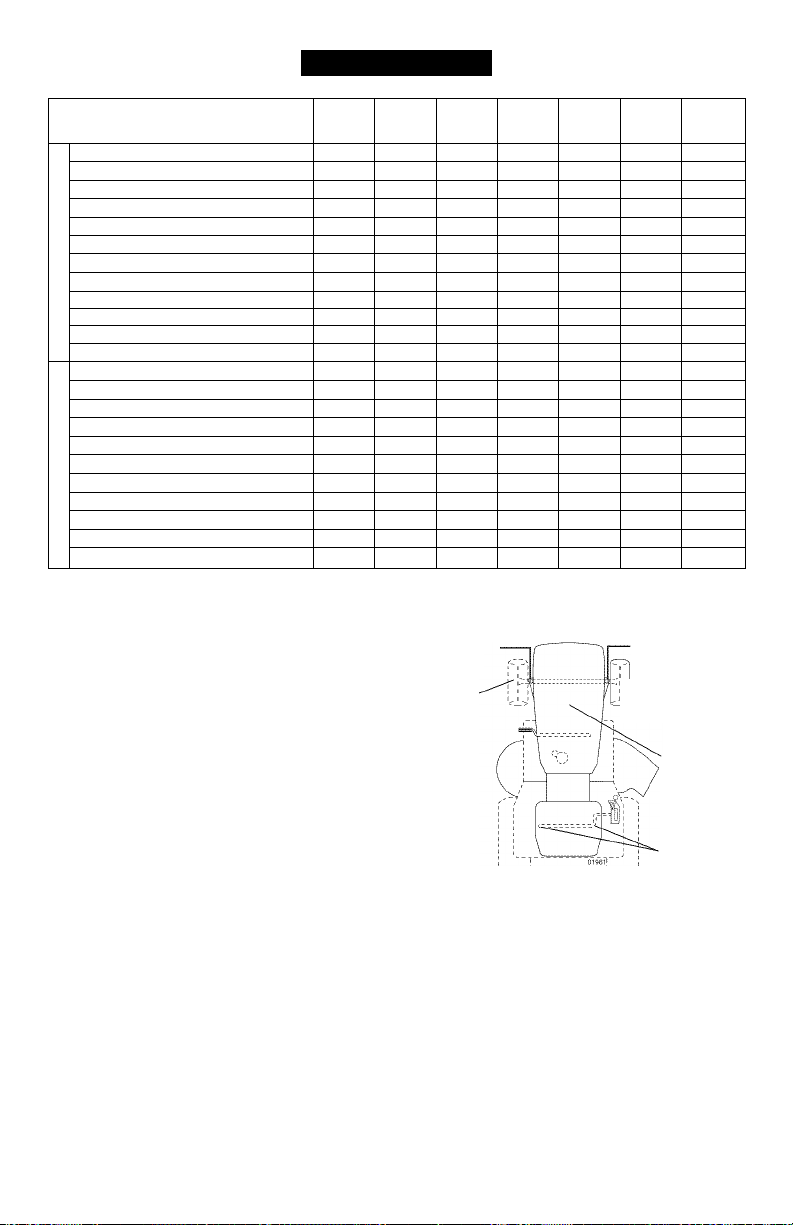

MAINTENANCE

MAINTENANCE

SCHEDULE

Che ck Brake Ooeration ✓

Che ck Tire Press ure

T

Che ck Operator Presence & ROS Systems

Che ck for Loo se Fas ten ers

A

Che ck/Replac e M ow er Blades

c

T

Lubrica tion Chart

0

Che ck Battery Le vel

R

Clean Battery and Terminals

Clean Deb ris Off Ste ering P late

Che ck Transa xle Cooling

Che ck Mower Leveln ess

Che ck V-B elts

Che ck Enaine Oil Level

Cha nae Enain e O il (with oil filter)

Cha nge Engin e O il (with out oil filter)

E

Clean Air Filte r

Clean Air Screen ✓ 2

Inspect Muffle r/Spark Arres ter

i

Rep lace O il Filter (If equ ipped)

N

E

Clean Engine Coolin q Fins

Rep lace Spark Plua

Rep lace Air Filter Pa per Ca rtridge

Rep lace Fuel Filter

sn operating under a heavy load or in high ambient temperatures.

>n operating in ditty or dusty conditions.

BEFORE

EACH

USE

✓

✓

✓

✓

- Replace blades more often wlien mowing in sandy soil.

- Not required it equipped with maintenance-free battery.

GENERAL RECOMMENDATIONS

The warranty on this tractor does not

cover items that have been subjected to

operator abuse or negligence. To receive

full value from the warranty, operator

must maintain tractor as instructed in this

manual.

Some adjustments will need to be made

periodically to properly maintain your

tractor.

At least once a season, check to see if

you should make any of the adjustments

described in the Service and Adjustments

section of this manual.

• At least once a year you should replace

the spark plug, clean or replace air filter,

and check blades and belts for wear.

A new spark plug and clean air filter

assure proper air-fuel mixture and help

your engine run better and last longer.

BEFORE EACH USE

1. Check engine oil level.

2. Check brake operation.

3. Check tire pressure.

4. Check operator presence and

ROS systems for proper operation.

5. Check for loose fasteners.

17

EVERY

HOURS

EVERY

8

HOURS

✓

EVERY

25

HOURS

✓ 3

✓

✓

EVERY

EVERY

50

100

SEASON

HOURS

✓

BEFORE

STORAGE

✓

✓

✓

✓

✓

K^1,2

✓ 2

1/1,2

✓

✓

✓

✓

✓

✓ 2

✓

✓ 2

✓

5 - See Cleaning in Maintenance Section.

LUBRICATION CHART

® Spindle

Zerk

® Front

Wheel

® Spindle

Zerk

\(D Front Wheel

Bearing zerk

Bearing

zerk

d) Engine

® Gearshift

_ _ Pivots

®SAE 30 or 10w30 Motor Oil

©General Purpose Grease

© Refer to Maintenance “ENGINE” Section

IMPORTANT: Do not oil or grease the pivot

points which have special nylon bearings.

Viscous lubricants will attract dust and dirt

that will shorten the life of the self-lubricating

bearings. If you feel they must be lubricated,

use only a dry, powdered graphite type

lubricant sparingly.

Page 18

TRACTOR

Always observe safety rules when performing

any maintenance.

BRAKE OPERATION

If tractor requires more than five (5) feet to

stop at highest speed in highest gear on a

level, dry concrete or paved surface, then

brake must be serviced. (See “TO CHECK

BRAKE” in the Service and Adjustments

section of this manual).

TIRES

• Maintain proper air pressure in all tires

(See the sides of tires for proper PSI).

• Keep tires free of gasoline, oil, or insect

control chemicals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp

objects and other hazards that may cause

tire damage.

NOTE: To seal tire punctures and prevent

flat tires due to slow leaks, tire sealant may

be purchased from your local parts dealer.

Tire sealant also prevents tire dry rot and

corrosion.

OPERATOR PRESENCE SYSTEM AND

REVERSE OPERATION SYSTEM (ROS)

Be sure operator presence and reverse

operation systems are working properly. If

your tractor does not function as described,

repair the problem immediately.

• The engine should not start unless the

brake pedal is fully depressed, and the

attachment clutch control is in the disen

gaged position.

CHECK CPERATCR PRESENCE

SYSTEM

• When the engine is running, any attempt

by the operator to leave the seat without

first setting the parking brake should shut

off the engine.

• When the engine is running and the at

tachment clutch is engaged, any attempt

by the operator to leave the seat should

shut off the engine.

• The attachment clutch should never oper

ate unless the operator is in the seat.

CHECK REVERSE CPERATICN (RCS)

SYSTEM

• When the engine is running with the ignition

switch in the engine "CN" position and the

attachment clutch engaged, any attempt

by the operator to drive in reverse should

shut off the engine.

• When the engine is running with the ignition

switch in the RCS "CN" position and the

attachment clutch engaged, any attempt

by the operator to drive in reverse should

NCT shut off the engine.

BLADE CARE

For best results mower blades must be sharp.

Replace worn, bent or damaged blades.

^ CAUTION: Use only a replacement

blade approved by the manufacturer of your

tractor. Using a blade not approved by the

manufacturer of your tractor is hazardous,

could damage your tractor and void your

warranty.

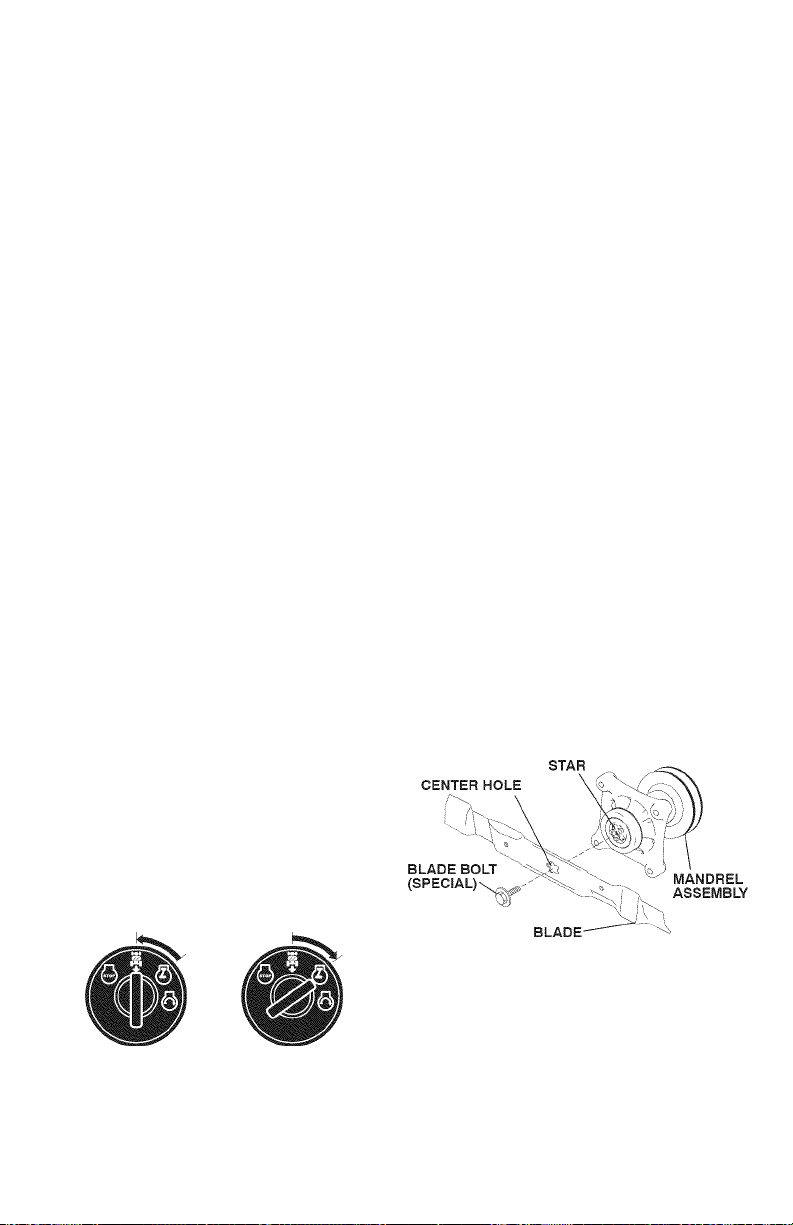

BLADE REMOVAL

1. Raise mower to highest position to allow

access to blades.

NOTE: Protect your hands with gloves and/

or wrap blade with heavy cloth.

2. Remove blade bolt by turning counter

clockwise.

3. Install new blade with stamped "GRASS

SIDE" facing the ground.

IMPORTANT: To ensure proper assembly,

center hole in blade must align with star on

mandrel assembly.

4. Install and tighten blade bolt securely

(45-55 Ft. Lbs. torque).

IMPORTANT: Special blade bolt is heat

treated.

ROS "ON" Position Engine "ON" Position

(Normal Operating)

18

Page 19

BATTERY

Your tractor has a battery charging system

which is sufficient for normal use. However,

periodic charging of the battery with an au

tomotive charger will extend its life.

• Keep battery and terminals clean.

• Keep battery bolts tight.

• Keep small vent holes open.

• Recharge at 6-10 amperes for 1 hour.

NOTE: The original equipment battery on

your tractor is maintenance free. Do not

attempt to open or remove caps or covers.

Adding or checking level of electrolyte is

not necessary.

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirton the battery and terminals

can cause the battery to “leak” power.

1. Disconnect BLACK battery cable first

then RED battery cable and remove

battery from tractor.

2. Rinse the battery with plain water and dry.

3. Clean terminals and battery cable ends

with wire brush until bright.

4. Coat terminals with grease or petroleum

jelly.

5. Reinstall battery (See “REPLACING

BATTERY" in the SERVICE AND AD

JUSTMENTS section of this manual).

TRANSAXLE MAINTENANCE

Keep transaxle free from build-up of dirt and

chaff which can restrict cooling.

Do not attempt to clean transaxle while

engine is running or while the transaxle is

hot. To prevent possible damage to seals,

do not use high pressure water or steam to

clean transaxle.

V-BELTS

CheckV-belts for deterioration and wear after

100 hours of operation and replace if neces

sary. The belts are not adjustable. Replace

belts if they begin to slip from wear.

ENGINE

LUBRICATION

Cnly use high quality detergent oil rated

with API service classification SG-SL.

Select the oil’s SAE viscosity grade

according to your expected operating

temperature.

SAE VISCOSITY GRADES

C -30

________

¡20______-10

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

_______0_______10_______20______

30 40

oil_viso_ohartl_6

19

NOTE: Although multi-viscosity oils (5W30,

10W30 etc.) improve starting in cold weather,

they will result in increased oil consumption

when used above 32°F. Check your engine

oil level more frequently to avoid possible

engine damage from running low on oil.

Change the oil after every 50 hours of op

eration or at least once a year if the tractor

is not used for 50 hours in one year.

Check the crankcase oil level before

starting the engine and after each eight

(8) hours of operation. Tighten oil fill cap/

dipstick securely each time you check the

oil level.

TO CHANGE ENGINE OIL

Determine temperature range expected

before oil change. All oil must meet API

service classification SG-SL.

• Be sure tractor is on level surface.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

1. Remove oil fill cap/dipstick. Be careful

not to allow dirt to enter the engine when

changing oil.

2. Remove yellow cap from end of drain valve

and install the drain tube onto the fitting.

Oil Drain Valve

slightly and turning counterclockwise.

4. To open, pull out on the drain valve.

5. After oil has drained completely, close and

lock the drain valve by pushing inward

and turning clockwise until the pin is in

the locked position as shown.

6. Remove the drain tube and replace the

cap onto the end of the drain valve.

7. Refill engine with oil through oil fill dipstick

tube. Pour slowly. Do not overfill. For

approximate capacity see “PRODUCT

SPECIFICATIONS”sectionofthis manual.

8. Use gauge on oil fill cap/dipstick for

checking level. For accurate reading,

insert dipstick into the tube and push

down firmly into place before removing.

Keep oil up to, but not over, the “FULL

line on dipstick. Push dipstick down firmly

into the tube when finished.

Page 20

ENGINE OIL FILTER

Replace the engine oil filter every season or

every other oil change if the tractor is used

more than 100 hours in one year.

AIR FILTER

Your engine will not run properly using

a dirty air filter. Service air cleaner more

often under dusty conditions. See Engine

Manual.

CLEAN AIR SCREEN

Air screen must be kept free of dirt and chaff

to prevent engine damage from overheating.

Clean with a wire brush or compressed air to

remove dirt and stubborn dried gum fibers.

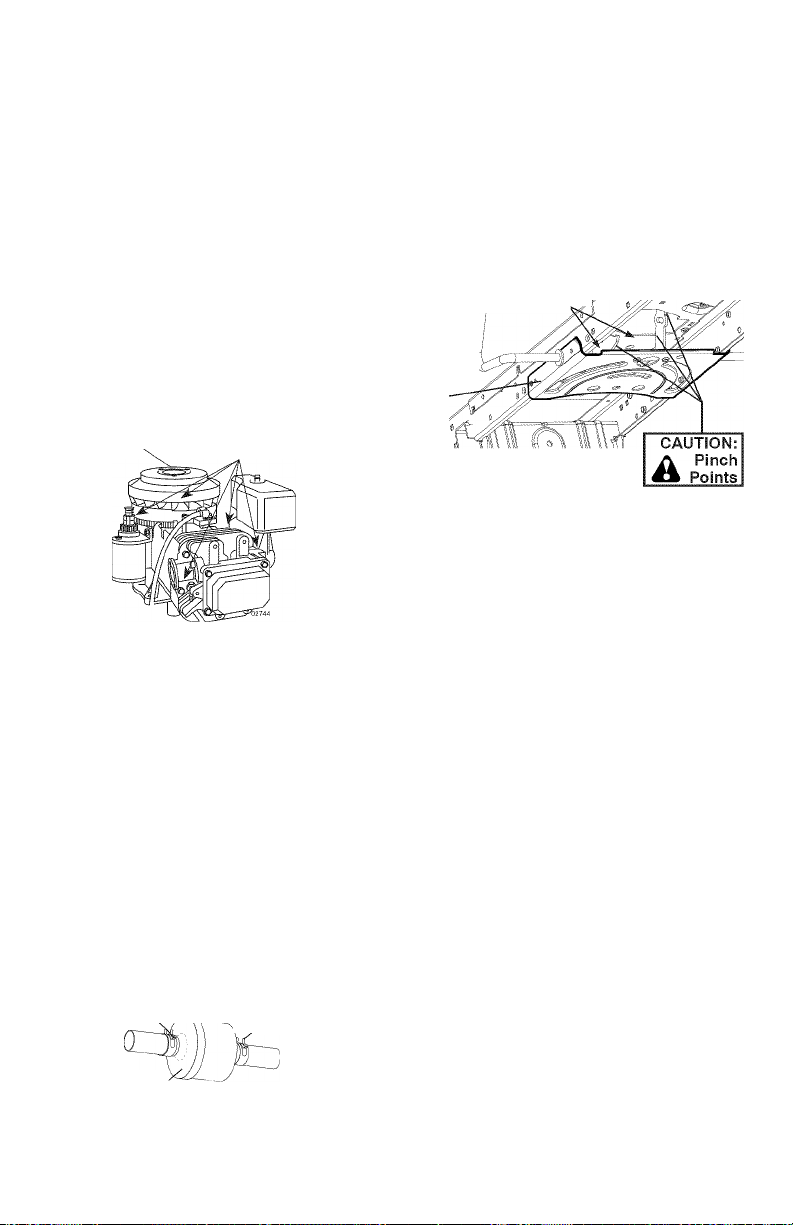

ENGINE COOLING SYSTEM

Debris may clog the engine’s air cooling

system. Remove blower housing and clean

area shown to prevent overheating and

engine damage.

Air Screen Clean out chaff

MUFFLER

Inspect and replace corroded muffler and

spark arrester (if equipped) as it could create

a fire hazard and/or damage.

SPARK PLUG(S)

Replace spark plug(s) at the beginning of each

mowing season or after every 100 hours of

operation, whichever occurs first. Sparkplug

type and gap setting are shown in “PRODUCT

SPECIFICATIONS” section of this manual.

IN-LINE FUEL FILTER

The fuel filter should be replaced once each

season. If fuel filter becomes clogged, ob

structing fuel flow to carburetor, replacement

is required.

1. With engine cool, remove filter and plug

fuel line sections.

2.

Place new fuel filter in position in fuel line

with arrow pointing towards carburetor.

' and debris

Clamp^_ Clamp

CLEANING

• Clean engine, battery, seat, finish, etc.

of ail foreign matter.

• Clean debris from steering plate.

Debris can restrict clutch/brake pedal

shaft movement, causing belt slip and

loss of drive.

A CAUTION: Avoid all pinch points and

movable parts

Clutch/brake pedal , '

Clean ,

I I top side^

Steering

Plate

Steering System, Dash,

Fender and Mower Not Shown

• Keep finished surfaces and wheels

free of all gasoline, oil, etc.

• Protect painted surfaces with automo

tive type wax.

We do not recommend using a garden hose

or pressure washer to clean your tractor

unless the engine and transmission are

covered to keep water out. Water in engine

or transmission will shorten the useful life of

your tractor. Use compressed air or a leaf

blower to remove grass, leaves and trash

from tractor and mower.

Fuel Filter

3. Be sure there are no fuel line leaks and

clamps are properly positioned.

4. Immediatelywipe up any spilled gasoline.

20

Page 21

SERVICE AND ADJUSTMENTS

WARNING: TO AVOID SERIOUS INJURY, BEFORE PERFORMING ANY

SERVICE OR ADJUSTMENTS:

A

Depress clutch/brake pedal fully and set parking brake.

Place gearshift lever in neutral (N) position.

Place attachment clutch in “DISENGAGED” position.

Turn ignition key to “STOP” and remove key.

Make sure the blades and all moving parts have completely stopped.

Disconnect spark plug wire from spark plug and place wire where it cannot

come in contact with plug.

TO REMOVE MOWER

1. Place attachment clutch in “DISEN

GAGED” position.

2. Lower attachment lift lever to its lowest

position.

3. Roll belt off engine pulley (M) and belt

keepers (G).

4. Remove retainer spring (K), slide collar

(L) off and push housing guide (P) out

of bracket.

5. Remove clutch cable spring (Q) from

idler arm (R).

6. Disconnect front link (E) from mower remove retainer spring and washer.

7. Go to either side of mower and discon

nect mower suspension arm (A) from

chassis pin (B) and rear lift link (C) from

rear mower bracket (D) - remove retainer

springs and washers.

A CAUTION: After rear lift links are discon

nected, the attachment lift lever will be spring

loaded. Have a tight grip on lift lever when

changing position of the lever.

8. Slide mower out from under right side of

tractor.

IMPORTANT: If an attachment other than

the mower is to be mounted on the tractor,

remove the front link (E) and rear lift links

(C) from tractor and hook the clutch spring

(Q) into the cable guide on front edge of

lower dash.

TO INSTALL MOWER

Be sure tractor is on level surface and engage

parking brake.

1. Lower attachment lift lever to its lowest

position.

A CAUTION: Lift lever is spring loaded.

Have a tight grip on lift lever, lower it slowly

and engage in lowest position.

NOTE: Be sure mower side suspension

arms (A) are pointing forward before sliding

mower under tractor.

2. Slide mower under tractor until it is cen

tered under tractor.

21

Page 22

ATTACH MOWER SIDE SUSPENSION

ARMS (A) TO CHASSIS - Position hole

in arm over pin (B) on outside of tractor

chassis and secure with retainer spring.

Repeat on opposite side of tractor.

'■ J

5. ATTACH REAR LIFT LINKS (C) - Lift

rear corner of mower and position slot

in link assembly over pin (D) on rear

mower bracket and secure with washer

and retainer spring.

7. Insert end of link (E) into hole in front

mower bracket (H) and secure with

8. Hook end of clutch cable spring (Q) into

hole in idler arm (R).

9. Push clutch cable housing guide (P) into

bracket, slide collar (L) onto guide and

secure with retainer spring (K).

10. Install belt onto engine pulley (M) and belt

keepers (G).

6. ATTACH FRONT LINK (E) - Work from

left side of tractor. Insert rod end of link

assembly through front hole in tractor

front suspension bracket (F).

IMPORTANT: Check belt for proper routing

in all mower pulley grooves.

11. Raise attachment lift lever to highest

position.

12. If necessary, adjust gauge wheels before

operating mower as shown in the Opera

tion section of this manual.

Page 23

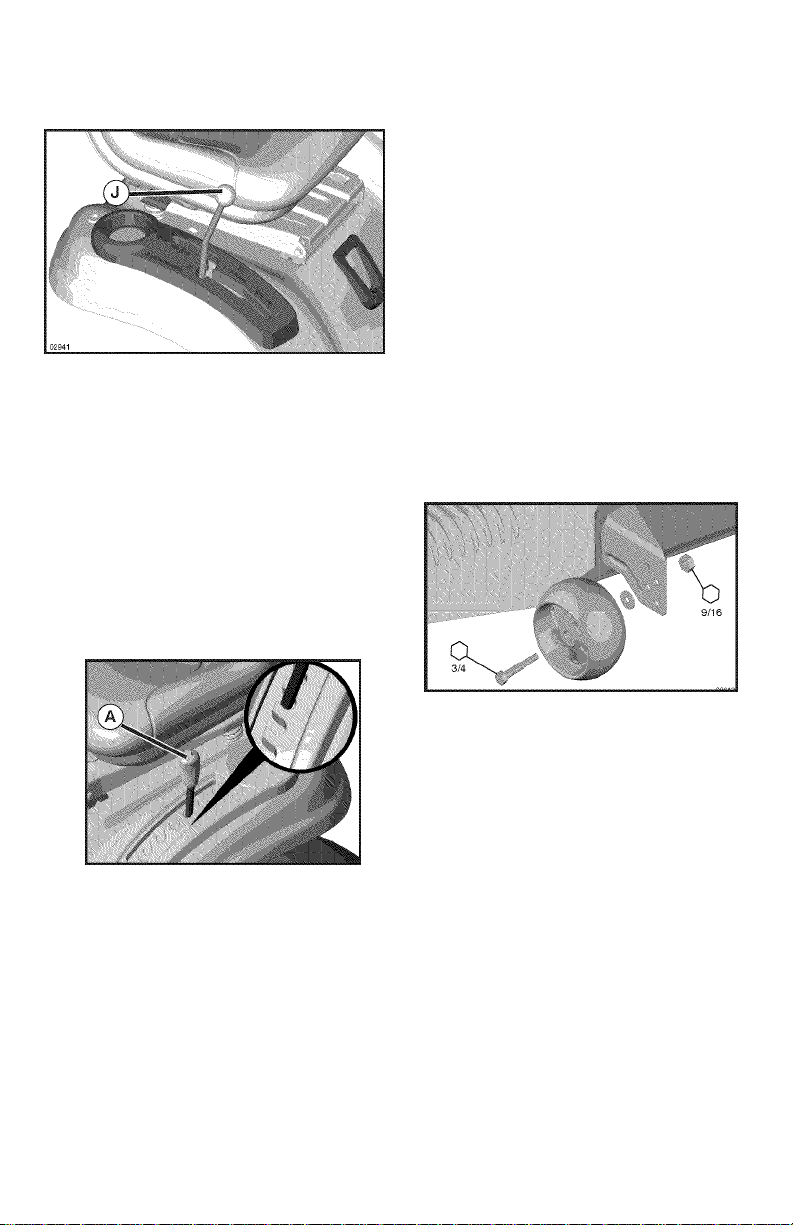

TO LEVEL MOWER

Make sure tires are properly inflated to the

PSI shown on tires. If tires are over or under

inflated, it may affect the appearance of your

lawn and lead you to think the mower is not

adjusted properly.

VISUAL SIDE-TO-SIDE ADJUSTMENT

1. With all tires properly inflated and if your

lawn appears unevenly cut, determine

which side of mower is cutting lower.

2. With a 3/4" or adjustable wrench, turn lift

link adjustment nut (A) to the left to lower

LH side of mower, or, to the right to raise

LH side of mower.

NOTE: Each full turn of adjustment nut will

change mower height about 3/16".

to raise mower

3. Test your adjustment by mowing some

uncut grass and visually checking the

appearance. Readjust, if necessary, until

you are satisfied with the results.

PRECISION SIDE-TO-SIDE ADJUSTMENT

1. With all tires properly inflated, parktractor

on level ground or driveway.

to lower mower

A CAUTION: Blades are sharp. Protect

your hands with gloves and/or wrap blade

with heavy cloth.

2. Raise mower to its highest position.

3. At both sides of mower, position blade at

side and measure the distance (A) from

bottom edge of blade to the ground. The

distance should be the same on both

sides.

4. If adjustment is necessary, see step 2 in

Visual Adjustment instructions above.

5. Recheck measurements, adjust if neces

sary until both sides are equal.

FRONT-TO-BACK ADJUSTMENT

IMPORTANT: Deck must be level side-

to-side.

To obtain the best cutting results, the mower

blades should be adjusted so the front tip is

1 /8" to 1 /2" lower than the rear tip when the

rnower is in its highest position.

A CAUTION: Blades are sharp. Protect

your hands with gloves and/or wrap blade

with heavy cloth.

• Raise mower to highest position.

• Position any blade so the tip is pointing

straight forward. Measure distance (B)

to the ground at front and rear tip of the

blade.

• If front tip of blade is not 1 /8" to 1 /2" lower

than the rear tip, go to the front of tractor.

• With an 11/16" or adjustable wrench,

loosen jam nut A several turns to clear

adjustment nut B.

With a 3/4" or adjustable wrench, turn

front link adjustment nut (B) clockwise

(tighten) to raise the front of mower, or,

counterclockwise (loosen) to lower the

front mower.

NOTE: Each full turn of the adjustment nut

will change mower height about 1/8".

• Recheck measurements, adjust if neces

sary until front tip of blade is 1/8" to 1/2"

lower than the rear tip.

• Hold adjustment nut in position with wrench

and tighten jam nut securely against ad

justment nut.

23

Page 24

TO REPLACE MOWER BLADE DRIVE BELT

The mower blade drive belt may be replaced

without tools. Park the tractor on level sur

face. Engage parking brake.

BELT REMOVAL -

1. Remove mower from tractor (See “TO RE

MOVE MOWER” inthissectionof manual).

Work belt off both mandrel pulleys and

2.

idler pulleys.

Pull belt away from mower.

3.

BELT INSTALLATION -

Work belt around both mandrel pulleys

1.

and Idler pulleys

Make sure belt is in all pulley grooves

2.

and inside all belt guides.

Install mower (See “To Install Mower” in

3.

this section of this manual).

Mandrel Idler

Pulley , Pulleys

Mandrel

■ ey

BELT INSTALLATION

1.

Install new belt from tractor rear to

front, over the steering plate (F) and

above clutch brake pedal shaft (G).

Pull belt toward front of tractor and roll

2.

belt onto engine pulley (E).

3.

Pull belt toward rear of tractor. Care

fully work belt down around transaxle

input pulley (D). Be sure belt is inside

the belt keeper.

4.

Install belt through stationary idler (A)

and clutching idler (B).

5.

Make sure belt is in all pulley grooves

and inside all belt guides and keepers.

6.

Install mower (See “TO INSTALL

MOWER” in this section of manual).

TO REPLACE MOTION DRIVE BELT

Park the tractor on level surface. Engage

parking brake. For assistance, there is

a belt installation guide decal on bottom

side of left footrest.

BELT REMOVAL -

1. Remove mower (See “TO REMOVE

MOWER” in this section of manual).

NOTE: Observe entire motion drive belt

and position of all belt guides and keepers.

2. Remove belt from stationary idler (A)

and clutching idler (B).

3. Pull belt slack toward rear of tractor.

Remove belt upwards from transaxle

input pulley (D).

4. Remove belt downward from engine

pulley (E).

5. Slide belt toward rear of tractor, off the

steering plate (F) and remove from tractor.

If tractor requires more than five (5) feet to

stop at highest speed in highest gear on a

level, dry concrete or paved surface, then

brake must be serviced.

You may also check brake by:

1. Park tractor on a level, dry concrete or

paved surface, depress clutch/brake

pedal all the way down and engage

parking brake.

2. Place gear shift lever in neutral position.

The rear wheels must lock and skid when

you try to manually push the tractor forward.

If the rear wheels rotate, then the brake

needs to be serviced. Contact a Sears or

other qualified service center.

24

Page 25

TO ADJUST STEERING WHEEL

ALIGNMENT

Ifsteering wheel crossbars are not horizontal

(left to right) when wheels are positioned

straight forward, remove steering wheel

and reassemble with crossbars horizontal.

Tighten securely.

FRONT WHEEL TOE-IN/CAMBER

Your new tractor front wheel toe-in and

camber is set at the factory and is normal.

The front wheel toe-in and camber are not

adjustable. If damage has occurred to

affect the factory set front wheel toe-in or

camber, contact a Sears or other qualified

service center.

TO REMOVE WHEEL FOR REPAIRS

1. Block up axle securely.

2. Remove axle cover, retaining ring and

washers to allow wheel removal (rear

wheels have a square key - Do not lose).

3. Repair tire and reassemble.

NOTE: On rearwheels only: align grooves in

rear wheel hub and axle. Insert square key.

4. Replace washers and snap retaining ring

securely in axle groove.

5. Replace axle cover.

NOTE: To seal tire punctures and prevent

flat tires due to slow leaks, purchase and

use tire sealant from Sears. Tire sealant also

prevents tire dry rot and corrosion.

Retaining

Axle ^'"9^

Cover,

Square

Key

(Rear Wheel Only)

Washers

Gearshift Lever

NOTE: If additional clearance is needed to

get to adjustment bolt, move mower deck

height to the lowest position.

TO START ENGINEWITHWEAKBATTERY

A WARNING: Lead-acid batteries gener

ate explosive gases. Keep sparks, flame

and smoking materials away from batteries.

Always wear eye protection when around

batteries.

Ifyour battery is too weak to start the engine, it

should be recharged. (See "BATTERY" in the

MAINTENANCE section of this manual).

If “jumper cables” are used for emergency

starting, follow this procedure:

IMPORTANT: Your tractor is equipped with

a 12 voltsystem. The othervehicle must also

be a 12 volt system. Do not use your tractor

battery to start other vehicles.

TO ATTACH JUMPER CABLES -

1. Connect one end of the RED cable to the

POSITIVE (•+) terminal of each battery(AB), taking care notto short against tractor

chassis.

2. Connect one end of the BLACK cable

to the NEGATIVE (-) terminal (C) of fully

charged battery.

TRANSAXLE GEAR SHIFT LEVER NEU

TRAL ADJUSTMENT

The transaxle should be in neutral when

the gear shift lever is in neutral (N) (lock

gate) position. The adjustment is preset

at the factory; however, if adjustment is

needed, proceed as follows:

1. Make sure transaxle is in neutral (N).

NOTE: When the tractor rear wheels

move freely, the transaxle is in neutral.

2. Loosen adjustment bolt in front of the

right rear wheel.

3. Position the gear shift lever in the neu

tral (N) position.

4. Tighten adjustment bolt securely.

Weak or

Dead

Battery

3. Connect the other end of the BLACK

cable (D) to good chassis ground, away

from fuel tank and battery.

TO REMOVE CABLES, REVERSE ORDER -

1. BLACK cable first from chassis and then

from the fully charged battery.

2. RED cable last from both batteries.

Charged

25

Fully

Battery

Page 26

REPLACING BATTERY

WARNING: Do not short battery ter

minals by allowing a wrench or any other

object to contact both terminals at the

same time. Before connecting battery, re

move metal bracelets, wristwatch bands,

rings, etc.

Positive terminal must be connected

first to prevent sparking from accidental

grounding.

Lift seat pan to raised position.

Disconnect BLACK battery cable first

then RED battery cable and carefully

remove battery from tractor.

3.

Install new battery with terminals in

same position as old battery.

4.

First connect RED battery cable to

positive (+) terminal with hex bolt and

keps nut as shown. Tighten securely.

Slide terminal cover over terminal

Connect BLACK grounding cable

5.

to negative (-) terminal with remain

ing hex bolt and keps nut. Tighten

securely. ___

Seat Pan ^

Terminal Cover

V

Positive (Red)

Cable

TO REPLACE HEADLIGHT BULB

1. Raise hood.

2. Remove bulb holder from the hole in

the backside of the grill.

3. Replace bulb in holder and install bulb

holder securely back into the hole in

the backside of the grill.

4. Close hood.

INTERLOCKS AND RELAYS

Loose or damaged wiring may cause

your tractor to run poorly, stop running, or

prevent it from starting.

• Check wiring. See electrical wiring

diagram in the Repair Parts manual.

Keps Nut

J

-lex Bolt

<4

Negative (Black)

Cable

TO REPLACE FUSE

Replace with 20 amp automotive-type

plug-in fuse. The fuse holder is located

behind the dash.

TO REMOVE HOOD & GRILL ASSEMBLY

Raise hood.

Unsnap headlight wire connector.

Stand in front of tractor. Grasp hood at

sides, tilt toward engine and lift off of

tractor.

4.

When replacing hood, be sure to re

connect the headlight wire connector.

TO ADJUST THROTTLE CONTROL

The throttle control has been preset at

the factory and adjustment should not be

necessary Check adjustment as described

below before loosening cable. If adjustment

is necessary, see engine manual.

TO ADJUST CHOKE CONTROL

The choke control has been preset at the

factory and adjustment should not be neces

sary. If adjustment is necessary, see engine

manual.

TO ADJUST CARBURETOR

Your carburetor has been preset atthe factory

and adjustment should not be necessary.

However, minoradjustment may be required

to compensate for differences in fuel, tem

perature, altitude or load . If the engine does

need adjustment, see engine manual.

26

Page 27

STORAGE

Immediately prepare yourtractorfor storage

at the end of the season or if the tractor will

not be used for 30 days or more.

^WARNING: Never store the tractor with

gasoline in the tank inside a building where

fumes may reach an open flame or spark.

Allow the engine to cool before storing in

any enclosure.

TRACTOR

When tractor is to be stored for a period

of time, clean it thoroughly, remove all dirt,

grease, leaves, etc. Store in a clean, dry area.

1. Clean entire tractor (See “CLEANING” in

the Maintenance section ofthis manual).

2. Inspectand replace belts, if necessary (See

beltreplacementinstructionsintheService

and Adjustments section ofthis manual).

3. Lubricate as shown in the Maintenance

section of this manual.

4. Be sure that all nuts, bolts and screws

are securely fastened. Inspect moving

parts for damage, breakage and wear.

Replace if necessary.

5. Touch up all rusted or chipped paint

surfaces; sand lightly before painting.

BATTERY

• Fully charge the battery for storage.

• After a period of time in storage, battery

may require recharging.

• To help prevent corrosion and power leak

age during long periods of storage, battery

cables should be disconnected and bat

tery cleaned thoroughly (see “TO CLEAN

BATTERY AND TERMINALS” in the

Maintenance section of this manual).

• After cleaning, leave cables disconnected

and place cables where they cannot come

in contact with battery terminals.

• If battery is removed from tractor for

storage, do not store battery directly on

concrete or damp surfaces.

ENGINE

FUEL SYSTEM

IMPORTANT: It is important to prevent

gum deposits from forming in essential fuel

system parts such as carburetor, fuel hose,

ortankduringstorage. Also, alcohol blended

fuels (called gasohol or using ethanol or

methanol) can attract moisture which leads

to separation and formation of acids during

storage. Acidic gas can damage the fuel

system of an engine while in storage.

• Empty the fuel tank by starting the engine

and letting it run until the fuel lines and

carburetor are empty.

• Never use engine or carburetor cleaner

products in the fuel tank or permanent

damage may occur.

• Use fresh fuel next season.

NOTE: Fuel stabilizer is an acceptable

alternative in minimizing the formation of

fuel gum deposits during storage. Add

stabilizer to gasoline in fuel tank or storage

container. Always follow the mix ratio found

on stabilizer container. Run engine at least

10 minutes after adding stabilizer to allow

the stabilizer to reach the carburetor. Do not

empty the gas tank and carburetor if using

fuel stabilizer.

ENGINE OIL

Drain oil (with engine warm) and replace

with clean engine oil. (See “ENGINE” in the

Maintenance section of this manual).

CYLINDER(S)

1. Remove spark plug(s).

2. Pour one ounce of oil through spark plug

hole(s) into cylinder(s).

3. Turn ignition key to start position for a

few seconds to distribute oil.

4. Replace with new spark plug(s).

OTHER

• Do not store gasoline from one season to

another.

• Replace your gasoline can ifyour can starts

to rust. Rust and/or dirt in your gasoline

will cause problems.

• If possible, store your tractor indoors and

cover it to give protection from dust and dirt.

• Cover your tractor with a suitable protec

tive cover that does not retain moisture.

Do not use plastic. Plastic cannot breathe

which allows condensation to form and will

cause your tractor to rust.

IMPORTANT: Never cover tractor while

engine and exhaust areas are still warm.

27

Page 28

TROUBLESHOOTING CHART:

See appropriate section in manuai unless directed to Sears service center

PROBLEM CAUSE CORRECTION

Will not start

Hard to start

Engine will not

turn over

1 Out of fuel. 1 Fill fuel tank.

2 Engine not “CHOKED” properly. 2 See “TC START ENGINE” in

3 Engine flooded. 3 Wait several minutes before

4 Bad spark plug. 4 Replace spark plug.

5 Dirty air filter. 5 Clean/replace air filter.

6 Dirty fuel filter. 6 Replace fuel fitter.

7 Water in fuel. 7 Empty fuel tank and carburetor,

8 Loose or damaged wiring. 8 Check all wiring.

9 Carburetor out of adjustment. 9 See “To Adjust Carburetor” in

10 Engine valves out of adjustment.10 Contact a Sears or other qualified

1 Dirty air filter. 1 Clean/replace air filter.

2 Bad spark plug. 2 Replace spark plug.

3 Weak or dead battery. 3 Recharge or replace battery.