Page 1

Operator's Manual

LAWN TRACTOR

21.0 HP,* 46" Mower

Electric Start

Automatic Transmission

Model No.

917.28852

° Espa_ol, p. 33

ThiSdifferentlyprOducthaSpreviouslyalow emission engines,enginewhich operates I '

engine, read and understand this Operator's Manual.

IMPORTANT: For answers to your questions

Read and follow all Safety about this product, Call:

Rules and Instructions before 1-800-659-5917

operating this equipment, 5 am - 5 pm, Mon - Sat

Gasoline containing up to 10% ethanol (EIO) is acceptable for use in this machine.

The use of any gasoline exceeding 10% ethanol (EIO) will void the product warranty,

Esta mdquina puede utilizar gaso]ina con un contenido de hasta el 10% de etanol (El0),

El uso de una gasolina que supere el 10% de etanol (EIO) anulard la garantia del producto.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S,A,

Visit our Craftsman website:www, sears.comicraftsman *Astat_ bytheengineraanufactu_'er

from built Before start the

SEARS Craftsman Help Line

you

l

581884740

Page 2

Warranty .................................................. 2

Safety Rules ............................................ 3

Product Specifications ............................. 6

Assembly/Pre-Operation ......................... 7

Operation ................................................. 9

Maintenance Schedule .......................... 16

Maintenance .......................................... 16

Service and Adjustments ....................... 2t

Storage .................................................. 27

Troubleshooting ..................................... 28

Sears Service ......................... Back Cover

Craftsman Riding Equipment Warranty

CRAFTSMAN FULL WARRANTY

FOR TWO YEARS fromthe date of purchase, all non-expendable parts of this riding equipment are

warranted against any defects in material or workmanship. A defective non-expendable part will

receive free in-home repair or replacement if repair is impossible.

FOR FiVE YEARS from the date of purchase, the frame and front axle of this riding equipment are

warranted against any defects in material or workmanship. A defective frame or front axle will receive

free in-home repair orreplacement if repair is impossible,

FOR 90 DAYS from the date of purchase, the battery (an expendable part) of this riding equipment

is warranted against any defects in material or workmanship (our testing proves that it wilt not hold a

charge). A defective battery will receive free in-home replacement.

ADDITIONAL LIFETIME LIMITED WARRANTY on CAST IRON FRONT AXLE (if equipped)

FOR AS LONG AS tT iS USED by the original owner after the fifth year from the date of purchase, the

cast ironfront axle (if equipped) of this riding equipment iswarranted against any defects in matedal or

workmanship. With proof of purchase, adefective cast front axtewill receive free in-home replacement,

WARRANTY SERVICE

For warranty coverage details to obtain free repair or replacement, call 1-800-659-5917 or visitthe

web site: www.craftsman.com

In all cases above, if part repair or replacement isimpossible, the riding equipment will be replaced

free of charge with the same or an equivalent model.

All of the above warranty coverage is void if this riding equipment is ever used while providing

commercial services or if rented to another person.

This warranty covers ONLY defects in material and workmanship. Warranty coverage does NOT

include:

• Expendable parts (except battery) that can wear out from normal use within the warranty period,

includingbut not limited to blades, spark plugs, air cleaners, belts, and oil filters.

• Standard maintenance servicing, oit changes, or tune-ups,

° Tire replacement or repair caused by punctures from outside objects, such as nails, thorns,

.....st=umps_or g!ass_........................................................................................

• Tire or wheel replacement or repair resulting from normal wear, accident, or improper operation or

maintenance.

• Repairs necessary because of operator abuse, including but not limited to damage caused by

towing objects beyond the capability of the dding equipment, impacting objects that bend the

frame, axle assembly or crankshaft, or over-speeding the engine.

• Repairs necessary because of operator negligence, includingbut not limited to, electrical and

mechanical damage caused by improper storage, failure to use the proper grade and amount

of engine oiJ,failure to keep the deck clear of flammable debris, orfailure to maintain the riding

equipment according to the instructions contained in the operator's manual.

• Engine (fuel system) cleaning or repairs caused byfuel determined to be contaminated oroxidized

(stale). in general, fuel should be used within 30 days of its purchase date.

• Normal deterioration and wear of the exterior finishes, or product label replacement,

This warranty gives you specific legal rights, and you may also have other rights which.vary from

state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

2

Page 3

_DANGER: This cutting machine is capable of amputating hands and feet and

throwing objects. Failure to observe the following safety instructions could result

in serious injury or death.

_WARNING: in order to prevent acciden-

tal starting when setting up, transporting,

adjusting or making repairs, a[ways discon-

nect spark plug wire and place wire where

it cannot contact spark plug.

_.WARNING: Do not coast down a hill in

neutral, you may lose control of the tractor.

_WARNING: Tow only the attachments

that are recommended by and comply with

specifications of the manufacturer of your

tractor. Use common sense when towing.

Operate only at the lowest possible speed

when ona slope. Too heavy of a load, while

on a slope, is dangerous. Tires can lose

traction with the ground and cause you to

lose control of your tractor.

_:_.WARNING: Engine exhaust, some of

its constituents, andcertain vehicle compo-

nents contain or emit chemicals known to

the State of California to cause cancer and

birth defects or other reproductive harm.

,_I_WARNING: Battery posts, terminals and

related accessories contain lead and lead

compounds, chemicals knowntotheState of

California to cause cancer and birth defects

or other reproductive harm. Wash hands

after handling.

I, GENERAL OPERATION

• Read, understand, and follow all instruc-

tions on the machine and in the manual

before starting.

• Do not put hands or feet near rotating . .

_arts or under the machine Keen clear " Followthe manuTacturer's recommenda-

.............of the discharge opening at'all times. .......,.................................. i......... T

• Only allow responsible adults, who are

familiar with the instructions,to operate

the machine.

Clear thearea of objects such as rocks,

toys, wire, etc., which could be picked

up and thrown by the blades.

• Be sure the area is clear of bystanders

before operating. Stop machineifanyone

enters the area.

• Never carry passengers.

• Do notmow in reverse unless absolutely

necessary. Always lookdown and behind

before and while backing.

_ B0nforwheelweights orco unterwelghts

• Never direct discharged material toward

anyone. Avoid discharging material

against a wall or obstruction. Material

may ricochet back toward the operator.

Stop the blades when crossing gravel

surfaces.

• Do not operate machine without the en-

tire grass catcher, discharge chute, or

other safetydevices in placeand working.

• Slow down before turning.

• Never leave a running machine unat-

tended. Always turn off blades, set

• parkingbrake, stop engine, and remove

keys before dismounting.

, Disengage blades when not mowing.

Shut off engine and wait for all parts to

come to a complete stop before cleaning

the machine,removing the grass catcher,

or unclogging the discharge chute.

• Operate machine only indaylight or good

artificial light.

• Do not operate the machine while under

the influence of alcohol or drugs.

• Watch for traffic when operating near or

crossing roadways.

• Use extracare when loadingorunloading

the machine intoa trailer or truck.

• Always wear eyeprotection when operat-

ing machine.

• Data indicates that operators, age 60

years and above, are involved in a large

percentage of riding mower-related inju-

ries. These operators should evaluate

their ability to operate the riding mower

safely enough to protect themselves and

others from serious injury.

Keep machine free of grass, leaves or

other debris build-up which cantouch hot

exhaust/engine parts and burn. Do not

allow the mower to plow leaves or other

debris which can cause build-up to oc-

cur.Clean any oil or fuel spillage before

operating or storing the machine. Allow

machine to cool before storage.

Page 4

!i.SLOPE OPERATION

Slopes are a major factor related to loss of

control and tip-over accidents, which can

result in severe injury or death. Operation

on all slopes requires extra caution. If you

cannot back upthe slope or ifyou feel uneasy

on it, do not mow it.

• Mow up and down slopes, not across.

• Watch for holes, ruts, bumps, rocks, or

other hidden objects. Uneven terrain

could overturn the machine, Tall grass

can hide obstacles.

• Choose a low ground speed so that you

will not have to stop or shift while on the

slope.

° Do not mow onwet grass. Tires may lose

traction.

Always keep the machine in gear when

going down slopes, Do notshiftto neutral

and coast downhill.

° Avoid starting, stopping, or turning on a

slope. Ifthetireslosetraction, disengage

the blades and proceed slowly straight

down the slope.

• Keep alt movement on the slopes slow

and gradual, Do not make sudden

changes in speed or direction, which

could cause the machine to roll over.

• Use extra care while operating machine

with grass catchers orother attachments;

they can affect the stability of the ma-

chine, Do no use on steep slopes.

• Do not try to stabilize the machine by

putting your foot on the ground.

• Do not mow near drop-offs, ditches,

or embankments. The machine could

suddenly roll over if a wheel is over the

edge or if the edge caves in.

I!1. CHILDREN

-_.WARNING: CHILDRENCANBEINJURED...............Extinguish all cigarettes; cigars_.pipes,.......

BYTHIS EQUIPMENT.The American Acade- and other sources of ignition.

my of Pediatrics recommends that children

be a minimum of 12 year of age before op-

erating a pedestrian controlled lawn mower

and a minimum of 16 years of age before

operating a riding lawn mower.

Tragic accidents can occur if the operator

is not alert to the presence of children.

Children are often attracted to the machine

and the mowing activity. Never assume

that children will remain where you last

saw them,

° Keep children out of the mowing area

and inthe watchful care of a responsible

adult other than the operator.

• Be alert and turn machine off if a child

enters the area.

• Before and while backing, look behind

and down for small children,

• Never carry children, even withthe blades

shutoff. They mayfall offand beseriously

injured or interfere with safe machine

operation. Children who have been given

rides inthe past may suddenly appear in

the mowing area for another rideand be

runover or backed over by the machine.

• Never allow children to operate the ma-

chine.

• Use extra care when approaching blind

corners, shrubs, trees, or other objects

that may block your view of a child,

IV. TOWING

t Tow only with a machine that has a hitch

designed for towing, Do notattach towed

equipment except at the hitch point.

• Followthe manufacturer's recommenda-

tion for weight limitsfortowed equipment

and towing on slopes.

• Never allow children or others in or on

towed equipment,

• On slopes, the weightofthe towedequip-

ment may cause loss oftraction and loss

of control.

• Travel slowly and allow extra distance to

stop.

V. SERVICE

SAFE HANDLING OF GASOLINE

To avoid personal injury or property dam-

age, use extreme care in handling gasoline.

Gasoline is extremely flammable and the

vapors are explosive.

• Use only approved gasoline container.

• Never remove gas cap or add fuel with

the engine running. Allow engine to cool

before refueling.

• Never fuel the machine indoors.

• Never store the machine orfuel container

where there is an open flame, spark, or

pilot lightsuch as on a water heater or

other appliances.

• Never fill containers insidea vehicle or

on atruck or trailer bed with plastic liner,

Always place containers on the ground

away from your Vehiclewhen filling.

Page 5

• Removegas-poweredequipmentfrom

thetruckortrailerandrefuelitonthe

ground.Ifthisisnotpossible,thenrefuel

suchequipmentwifhaportablecontainer,

ratherthanfromagasolinedispenser

nozzle.

• Keepthenozzleincontactwiththerim

ofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donot

useanozzlelock-opendevice.

- Iffuelisspilledonclothing,changecloth-

ingimmediately.

• Neveroverfillfueltank.Replacegascap

andtightensecurely.

GENERAL SERVICE

• Never operate machine in aclosed area,

• Keep allnuts and boltstightto besurethe

equipment is in safe working condition.

• Nevertamperwith safetydevices. Check

their proper operation regularly.

• Keep machine free of grass, leaves, or

other debris build-up, Clean oil or fuel

spillageand remove anyfuel-soaked de-

bris. Allow machineto cool beforestoring.

• If you strike a foreign object, stop and

inspectthe machine. Repair,ifnecessary,

before restarting.

• Never make any adjustments or repairs

with the engine running.

• Checkgrass catcher components andthe

discharge chute frequently and replace

with manufacturer's recommended parts,

when necessary.

- Mower blades aresharp, Wrap the blade

or wear gloves, and use extra caution

when servicing them,

• Check brake operation frequently. Adjust

and service as required.

• Maintain or replace safety and instruction

labels, as necessary.

• Be sure the area is clear of bystanders

beforeoperating. Stopmachine ifanyone

enters the area.

• Never carry passengers.

• Do not mow in reverse unlessabsolutely

necessary.Always lookdown and behind

before and while backing.

• Never carry children, even with the

blades shut off. They may fall off and

......beseriously injured or interfereWithsafe......................the blades and proceed slowly straight ....

machine operation. Children who have down the slope.

beengiven ridesinthe past maysuddenly

appear in the mowing area for another

ride and be run over or backed over by

the machine.

Keep children out of the mowing area

and in the watchful care of a responsible

adult other than the operator.

• Be alert and turn machine off if a child

enters the area,

° Before and while backing, look behind

and down for small children.

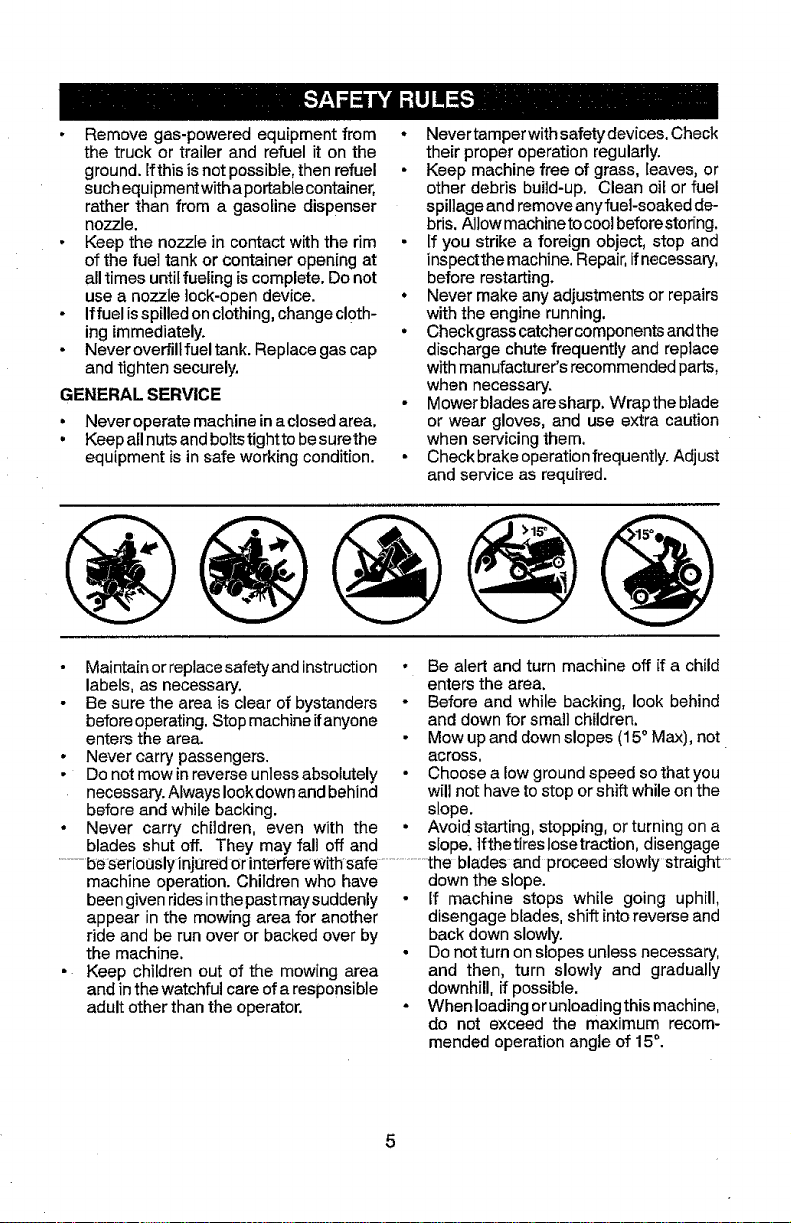

• Mow up and downslopes (15° Max), not

across.

• Choose a low ground speed so that you

will not have to stop or shift while on the

slope.

• Avoid starting, stopping, or turning on a

slope. ]fthetireslosetraction, disengage

• If machine stops while going uphill,

disengage blades, shift into reverse and

back down slowly.

• Do notturn on slopes unless necessary,

and then, turn slowly and gradually

downhill, if possible.

• When loading or unloading this machine,

do not exceed the maximum recom-

mended operation angle of 15°.

Page 6

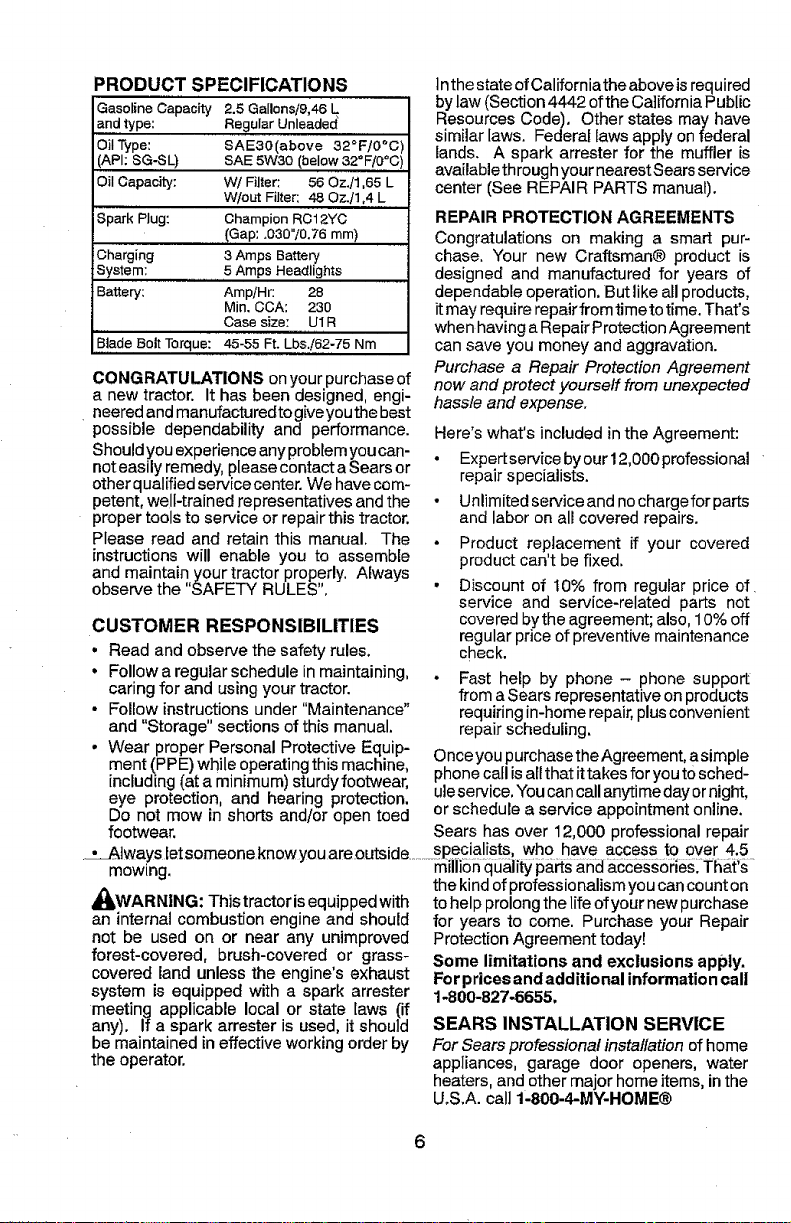

PRODUCT SPECIFICATIONS

Gasoline Capacity 2.5 Gallons/9,46 L

and type: Regular Unleaded

Oil Type: SAE-30(above 32°F/0°C

(API: SG-SL) BAE 5W30 (below 32°F/0_C

Oil Capacity: W/Filter: 56 Oz./1,65 L

Spark Plug: Champion RC12YC

Charging 3 Amps Battery

System: 5 Amps Headlights

Battery: Amp/Hr: 28

Blade Bolt Torque: 45-55 Ft. LbsJ62-75 Nm

W/out Filter: 48 Oz./1,4 L

(Gap: .030"/0.76 mm)

Min. CCA: 230

Case size: UIR

CONGRATULATIONS onyour purchase of

a new tractor. It has been designed, engi-

neeredand manufacturedto giveyou the best

possible dependability and performance.

Shouldyou experience any problemyoucan-

not easily remedy, pleasecontact a Sears or

other qualified service center. We havecom-

petent, well-trained representatives and the

proper tools to service or repair this tractor.

Please read and retain this manual. The

instructions will enable you to assemble

and maintain your tractor properly, A_ways

observe the "SAFETY RULES",

Inthe state of California the aboveis required

bylaw (Section4442 ofthe California Public

Resources Code), Other states may have

similar laws. Federal taws apply on federal

lands. A spark arrester for the muffler is

availablethrough your nearestSearsservice

center (See REPAIR PARTS manual).

REPAIR PROTECTION AGREEMENTS

Congratulations on making a smart pur-

chase. Your new Craftsman® product is

designed and manufactured for years of

dependable operation. But like all products,

itmay require repair from timeto time. That's

when having a RepairProtection Agreement

can save you money and aggravation.

Purchase a Repair Protection Agreement

now and protect yourseff from unexpected

hassle and expense.

Here's what's included in the Agreement:

. Expert service byour 12,000professional

repair specialists.

• Unlimited service and nochargeforparts

and labor on all covered repairs.

• Product replacement if your covered

product can't be fixed.

• Discount of t0% from regular price of

service and service-related parts not

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules,

• Follow a regular schedule in maintaining,

caring for and using your tractor.

• Follow instructionsunder "Maintenance"

and "Storage" sections of this manual.

• Wear proper Personal Protective Equip-

ment (PPE) while operating this machine,

including (at a minimum) sturdy footwear,

eye protection, and hearing protection.

Do not mow in shorts and/or open toed

footwear.

,._--Aiwaysietsomeoneknowyouareoutside ...........speci.a!!sts, wing.have acces§ to g_e_ _5..

mowing.

Ai_WARNING: This tractor is equipped with

an internalcombustion engine and should

not be used on or near any unimproved

forest-covered, brush-covered or grass-

covered land unless the engine's exhaust

system is equipped with a spark arrestor

meeting applicable local or state laws (if

any). if a spark arrester is used, it should

be maintained ineffective working order by

the operator.

covered by the agreement; also, 10% off

regular price of preventive maintenance

check.

• Fast help by phone - phone support

from aSears representative on products

requiring in-home repair,plusconvenient

repair scheduling.

Once you purchase the Agreement, asimple

phone call isall that ittakes for youtOsched-

uleservice. Youcan callanytime dayor night,

or schedule a service appointment online.

Sears has over 12,000 professional repair

million quality parts andaccessones. That's

the kind of professionalism you cancount on

tohelp prolong the life of your new purchase

for years to come. Purchase your Repair

Protection Agreement today!

Some limitations and exclusions apply.

For prices and additional information call

1-800-827-6655,

SEARS INSTALLATION SERVICE

For Sears professional installation of home

appliances, garage door openers, water

heaters, and other major home items, inthe

U,S,A. call 1-800-4-MY-HOME®

Page 7

Keys

SlopeSheet

Your new tractor has been assemb]ed at the factory with the exception of those parts left

unassembled for shipping purposes,

TOOLS REQUIRED FOR ASSEMBLY

A socketwrench set will make assembly

easier. Standard wrench sizes are listed.

(1) 1/2" wrench Tire pressure gauge

(2) 7/16" wrenches Utility knife

Pliers

When right or left hand is mentioned inthis

manual,itmeanswhenyouareintheoperating

position (seated behind the steering wheel).

TO CHECK BATTERY

1. Lift seat to raised position.

NOTE: Ifthis battery is put into service after

month and year indicated on label (label is

located between terminals) charge battery

for minimum ofone hour at 6-10 amps. (See

"BATTERY" in Maintenance section of this

manual for charging instructions).

• For battery and battery cable installation

see "REPLACING BATTERY" in the

"Service and Adjustments" section in

this manual.

ADJUST SEAT

1, Sit in seat,

2. Lift upadjustment lever (A)and slide seat

until a comfortable position is reached

which allows you to press clutch/brake

pedal all the way down.

3. Release lever to lock seat in position,

NOTE: You may now roll your tractor off

the skid. Follow the instructions below to

remove the tractor from the skid.

_, WARNING: Before starting, read, un-

derstand and follow all instructions in the

Operation section of this manual. Be sure

tractor is in a well-ventilated area. Be sure

the area in front of tractor is clear of other

people and objects.

Operation section for location and

function of controls)

1. Raise attachment lift lever to its highest

position.

2. Release parking brake by depressing

clutchtbrake pedal.

3. Place gearshift leverin neutral position.

4. Roll tractor forward off skid.

5. Remove banding holding the deflector

, shield up against tractor.

Continue with the instructions that foltow.

Page 8

CHECK TIRE PRESSURE

Thetires onyour tractor were overinflated at

the factory for shipping purposes. Correct

tire pressure is important for best cutting

performance.

• Reduce tire pressure to PSI shown on

tires.

CHECK DECK LEVELNESS

For best cutting results, mower housing

should be properly leveled. See "TO LEVEL

MOWER" in the Service and Adjustments

section of this manual.

CHECK FOR PROPER POSITION OF

ALL BELTS

See the figures that are shown for replacing

motion and mower blade drive belts in the

ServiceandAdjustments section ofthis man-

ual. Verify thatthe belts are routed correctly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor,

check to see that the brake is operating

properly. See "TO CHECK BRAKE" in the

Service and Adjustments section of this

manual.

t/_CHECKLIST

Before you operate your new tractor, we

wish to assure that you receive the best

performance and satisfaction from this

Quality Product.

Please review the following checklist:

J" All assembly instructions have been

completed.

No remaining loose parts in carton.

_" Batteryis properlypreparedandcharged.

!/" Seat is adjusted comfortably and tight-

ened securely.

_/' All tires are properly inflated. (For ship-

ping purposes, thetires wereoverinflated

at the factory).

J' Be sure mower deck is properly leveled

side-to-side/front-to-rear for best cutting

results. (Tires must be properly inflated

for leveling).

!/Check mower and drive belts. Be sure

they are routed properly around pulleys

and inside all belt keepers.

1/" Check wiring. See that all connections

are still secure and wires are properly

clamped,

_/" Before driving tractor, be sure freewheel

control is in "transmission engaged"

position (see "TO TRANSPORT" in the

Operation section of this manual).

While learning howto useyour tractor,payex-

traattention to the following important items:

J" Engine oil is at proper level.

J" Fuel tank isfilledwith fresh, clean, regular

unleaded gasoline.

J" Become familiar with all controls, their

location and function. Operate them

before you start the engine.

!,/ Be sure brake system isinsafe operating

condition.

_--BesureOperator PresenceSystemand .........

Reverse Operation System (ROS) are

working properly (Seethe Operation and

Maintenance sections in this manual).

1/,. It is important to purge the transmission

before operating your tractor for the

first time. Follow proper starting and

transmission purging instructions (See

"TO START ENGINE" and "PURGE

TRANSMISSION" in the Operation sec-

tion of this manual).

.

Page 9

These symbols may appear on your tractor or in literature supplied with the product. Learn

and understand their meaning,

R N

REVERSE NEUTRAL

H L I' ,1

HIGH LOW CHOKE FAST SLOW

6

I_NGINE OFF REVERSE

UGHTS ON FUEL

ATTACHMENT ATTACHMENT DANGER, KEEP HANDS

CLUTCH DISFJ',IGAGED CLUTCH ENGAGED AND F-_ETAWAY

Failure to follow instructions

Could result in serious injury or

death. The safety aiert symbol

is used to identify safety inform-

ation about hazards which can

result in death, serious injury

and/or property damage,

OPERATION

SYSTEM (ROS t

FREE WHEEL

(Automatic Models only)

ENGINE ON ENGINE START PARKING BRAKE MOWER HEIGHT

BA31"ERY REVERSE FORWARD

IGNITION SWITCH

MOWER LIFT

C.0,SECONTROLCLUTC_SRAKE

PEDAL

®@@@@

KEEP AREA CLEAR SLOPE HAZARDS

(SEE SAFERY RULES SECTION)

DANGER indicates a hazard which, if not avoided,

will result in death or serious injury,

WARNING indicates a hazard which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided,

might result in minor or moderate injury.

CAUTION when used without the ale_ symbol,

indicates a situation that could result in damage

to the tractor and/or engine.

HOT SURFACES indicates a hazard which,

if not avoided, could result in death, serious injury

and/or property damage.

FIRE indicates a hazard which, if not avoided,

could result in death, serious injury and/or

property damage.

Page 10

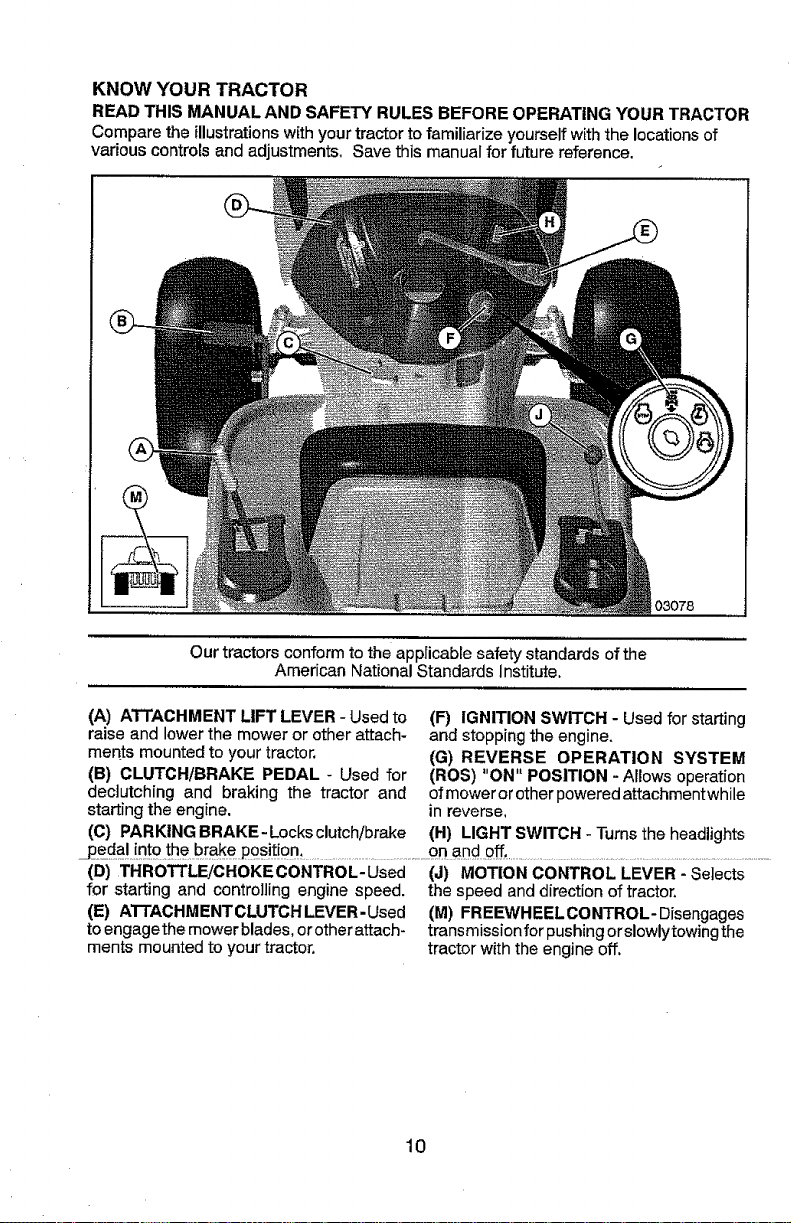

KNOW YOUR TRACTOR

READ THIS MANUAL AND SAFE'rY RULES BEFORE OPERATING YOUR TRACTOR

Compare the illustrationswith your tractorto familiarize yourself withthe locations of

various controls and adjustments. Save this manual for future reference.

03078

Our tractors conformto the applicable safety standards of the

American National Standards Institute.

(A) ATTACHMENT LIFT LEVER - Used to

raise and lower the mower or other attach-

ments mounted to your tractor.

(B) CLUTCH/BRAKE PEDAL - Used for

deciutching and braking the tractor and

starting the engine.

(C) PARKING BRAKE- Locks clutch/brake

(F) IGNITION SWITCH - Used for starting

and stopping the engine.

(G) REVERSE OPERATION SYSTEM

(ROS) "ON" POSITION - Allows operation

ofmower orother powered attachment while

in reverse,

(H) LIGHT SWITCH - Turnsthe headlights

_pedal !r_to.th.e.brake p0sit!0n...............................................on arid .off.................................................................................

(D) THROTTLE/OHOKECONTROL-Used (J) MOTION CONTROL LEVER - Selects

for starting and controlling engine speed, the speed and direction of tractor,

(E) ATTACHMENTCLUTCHLEVER.Used (M) FREEWHEELOONTROL-Disengages

to engagethe mower blades, or other attach- transmission for pushing or slowlytowing the

ments mounted to your tractor, tractor with the engine off,

10

Page 11

The operation of any tractor can result in foreign objects thrown into

the eyes, which can result in severe eye damage. Always wear safety

glasses or eye shields while operating your tractor or performing any

adjustments or repairs. We recommend standard safety glasses or a

wide vision safety mask worn over spectacles.

HOW TO USE YOUR TRACTOR

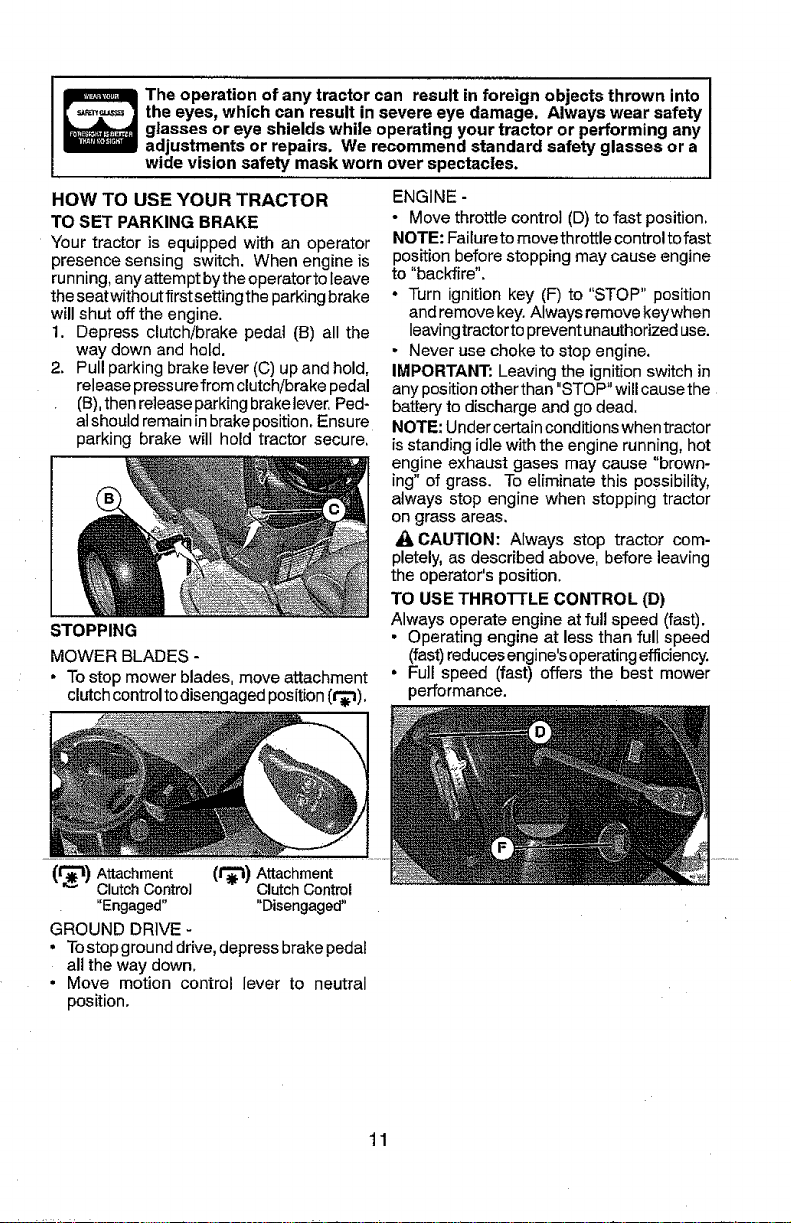

TO SET PARKING BRAKE

Your tractor is equipped with an operator

presence sensing switch. When engine is

running, any attempt bythe operator to leave

the seatwithoutfirst settingthe parkingbrake

will shut off the engine.

1. Depress clutch/brake pedal (B) all the

way down and hold.

2. Pull parking brake lever (C) up and hold,

release pressure from clutch/brake pedal

(B),then release parking brakelever.Ped-

alshould remain in brakeposition, Ensure

parking brake will hold tractor secure,

STOPPING

MOWER BLADES -

• To stop mower blades, move attachment

clutch control to disengaged position(t_).

ENGINE -

• Move throttle control (D) to fast position.

NOTE: Failure to move throttlecontrol to fast

position before stopping may cause engine

to "backfire".

• Turn ignitionkey (F) to "STOP" position

andremove key.Always remove keywhen

leavingtractor to prevent unauthorized use.

• Never use choke to stop engine.

IMPORTANT: Leaving the ignition switch in

anyposition otherthan "STOP" will causethe

batteryto discharge and go dead,

NOTE:Under certain conditions when tractor

isstanding idlewith the engine running, hot

engine exhaust gases may cause "brown-

ing" of grass. To eliminate this possibility,

always stop engine when stopping tractor

on grass areas.

_, CAUTION: Always stop tractor com-

pletely, as described above, before leaving

the operator's position.

TO USE THROTTLE CONTROL (D)

Always operate engine at full speed (fast).

• Operating engine at less than full speed

(fast)reducesengine'soperatingefficiency,

• Full speed (fast) offers the best mower

performance.

"_ Clutch Control -' Clutch Control

"Engaged.... Disengaged"

GROUND DRIVE -

• Tostop ground drive,depress brakepedal

all the way down.

• Move motion control lever to neutral

position.

11

Page 12

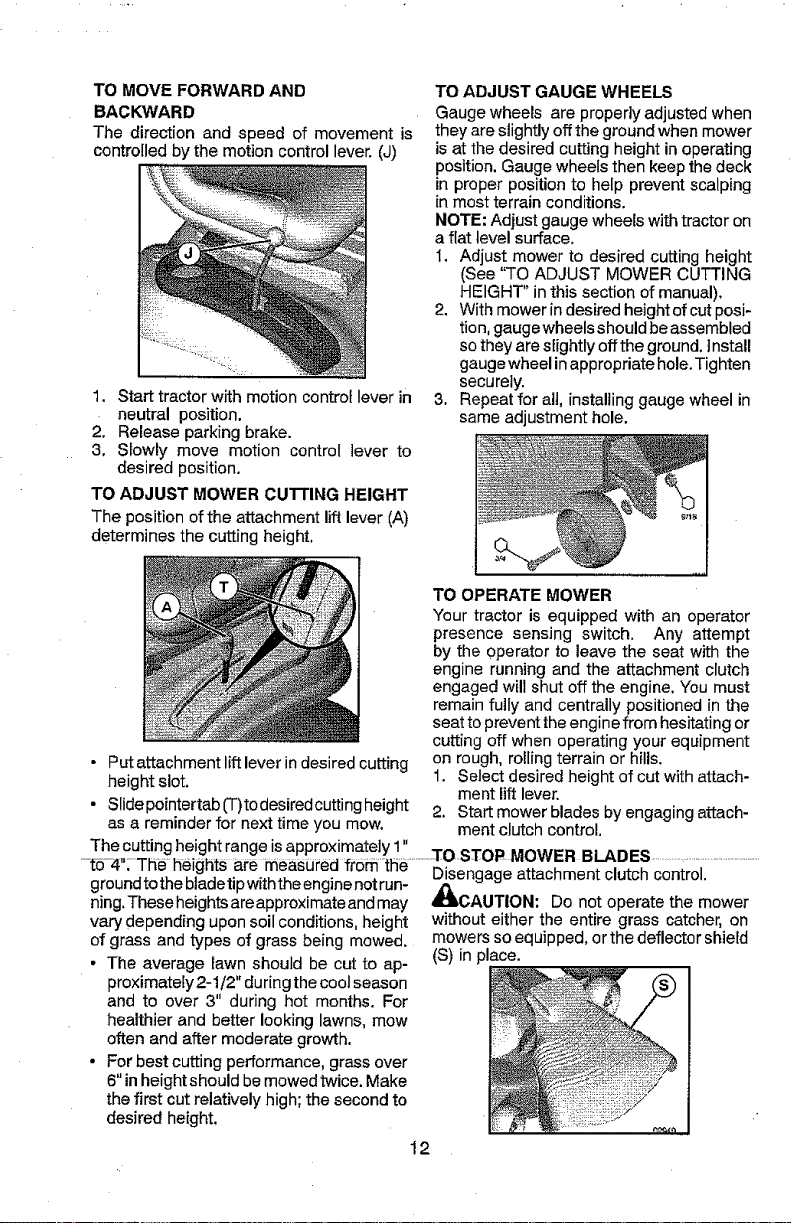

TO MOVE FORWARD AND

BACKWARD

The direction and speed of movement is

controlled by the motion control lever. (J)

1. Start tractor with motion control lever in

neutral position.

2. Release parking brake.

3. Slowly move motion control lever to

desired position.

TO ADJUST MOWER CUTTING HEIGHT

The position of the attachment lift lever (A)

determines the cutting height,

• Put attachment lift lever in desired cutting on rough, rolling terrain or hills,

height slot. 1. Select desired height of cut with attach-

• Slidepointertab(T)todesiredcuttingheight 2. Start mower blades by engaging attach-

as a reminder for next time you mow. merit clutch control.

The cutting height range isapproximately I" Tn -_Tt_D Mnw_ .....

-t-64":TheheightS are measured ftomtfi6 ........E)?isen_a'uea'_ac"" DL_U,,-_ ...........T-;........................

groundto the bladetip withthe engine notrun- Zk

ning,Theseheightsareapproximateandmay _OAUTION" Do not operate the mower

vary depending upon soil conditions, height

of grass and types of grass being mowed.

• The average lawn should be cut to ap-

proximately 2-1/2" duringthe cool season

and to over 3" during hot months. For

healthier and better looking lawns, mow

often and after moderate growth.

• For best cutting performance, grass over

6" in height should be mowedtwice. Make

the first cut relatively high; the second to

desired height.

TO ADJUST GAUGE WHEELS

Gauge wheels are properly adjusted when

they are slightly off the ground when mower

is at the desired cutting height in operating

position. Gauge wheels then keep the deck

m proper position to help prevent scalping

in most terrain conditions.

NOTE: Adjust gauge wheels with tractor on

aflat level surface.

I. Adjust mower to desired cutting height

(See "TO ADJUST MOWER CUTTING

HEIGHT" in this section of manual).

2. With mower indesired height of cut posi-

tion, gauge wheels should be assembled

so they are slightly offthe ground. Install

gauge wheel inappropriate hole. Tighten

securely.

3. Repeat for all, installing gauge wheel in

same adjustment hole.

TO OPERATE MOWER

Your tractor is equipped with an operator

presence sensing switch. Any attempt

by the operator to leave the seat with the

engine running and the attachment clutch

engaged will shut off the engine. You must

remain fully and centrally positioned in the

seat to prevent theengine from hesitating or

cutting off when operating your equipment

ment liftlever.

g g _ nmentclu[cn control

without either the entire grass catcher, on

mowers so equipped, or the deflector shield

(S) in place.

12

Page 13

REVERSE OPERATION SYSTEM (ROS)

Your tractor is equipped with a Reverse

Operation System (ROS). Any attempt by

the operator to travel inthe reverse direction

with the attachment clutch engaged will shut

off the engine unless ignition key is placed

in the ROS "ON" position,

_WARNING: Backing up with the at-

tachment clutch engaged while mowing is

strongly discouraged. _Jrningthe ROS"ON",

to allow reverse operation with the attach-

ment clutch engaged, should only be done

when the operator decides itis necessary to

reposition the machine with the attachment

engaged. Do not mow in reverse unless

absolutely necessary.

USING THE REVERSE OPERATION

SYSTEM -

Only useifyou arecertain nochildren orother

bystanders will enter the mowing area.

1. Move motion control lever to neutral

position.

2. With engine running, turn ignition key

counterclockwise to ROS "ON" posi-

tion.

3. Look down and behind before and while

backing.

4. Slowly move motion control lever to

reverse (R) position to start movement,

5. When useofthe ROS isnolonger needed,

turnthe ignition key clockwise to engine

"ON" position.

ROS "ON" Position

Engine "ON" Position

{Normal Operating)

IMPORTANT: The motion control lever does

not returnto neutral positionwhenthe clutch/

brake pedal is depressed.

• To restart movement, slowly release park-

ing brake and clutch/brake pedal.

• Slowly move motion control lever to slow-

est setting.

• Make all turns slowly.

TO TRANSPORT

When pushing or towing your tractor, En-

sure to disengage transmission by placing

freewheel control in freewheel!rig position.

Freewheel control is located at the rear

drawbar of tractor.

1. Raise attachment lift lever to its highest

position.

2. Pullfreewheel control outand intothe slot

and release soit isheld inthe disengaged

position.

• Do not push or tow tractor at more than

two (2) MPH.

• Tore-engage transmission, reverseabove

procedure.

TRANSMISSION ENGAGED

TRANSMISSION DISENGAGED

NOTE: To protect hood from damage when

transporting your tractor onatruck or atrailer,

Ensurehood isclosed and secured totractor.

Use an appropriate means of tying hood to

tractor (rope, cord, etc.).

-=TO-OPERATEONHILLS .................................................................................._TQ'_tlNG.CARTSAND OTHER.A37rAC.H.....

_:_IkWARNING: Do not drive up or clown MENTS

hillswith slopes greater than 15° and do not mended by and comply with specifications

drive across any slope. Use the slope guide

provided at the back of this manual,

• Choose the slowest speed before starting

up or down hills.

° Avoid stopping or changing speed on

hills.

Tow only the attachments that are recom-

of the manufacturer of your tractor. Use

common sense when towing. Too heavy of

aload, while on aslope, is dangerous. Tires

can lose traction with the ground and cause

you to lose control of your tractor.

• If stopping is absolutely necessary, push

clutch/brake pedatquicklyto brakeposition

and engage parking brake.

• Move motion control lever to neutral posi- "

tion.

13

Page 14

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL

The enginein your tractor hasbeen shipped,

from the factory, already filled with summer

weight oil,

1. Check engine oil with tractor on level

ground.

2. Remove oil fill cap/dipstick and wipe

clean, reinsert the dipstick and screw cap

tight, wait for afew seconds, remove and

read oil level. If necessary, add oil until

"FUL_ mark on dipstick is reached. Do

not overfill.

• For cold weather operation you should

change oil for easier starting (See the oil

viscosity chart inthe Maintenance section

of this manual).

• Tochangeengine oil,seethe Maintenance

section in this manual,

ADD GASOLINE

o Fill fuel tank to bottom offifter neck. Do not

overfill. Usefresh, clean, regular unleaded

gasoline with a minimum of 87 octane.

(Use of leaded gasoline will increase

carbonand lead oxide depositsand reduce

valve life). Do not mix oil with gasoline.

Purchasefuel inquantities thatcan beused

within 30 days to ensure fuel freshness.

_CAUTION: Wipe offany spilled oil orfuel.

Do not store, spill or use gasoline near an

open flame.

IMPORTANT: When operating in tem-

peratures below 32°F(0°C), use fresh, clean

winter grade gasoline to help ensure good

cold weather starting.

CAUTION: Alcohol blended fuels (called

gasohol or using ethanol or methanol) can

attract moisture which leads to separation

andformation ofacids during storage, Acidic

gascan damage the fuel system of anengine

while in storage. Toavoid engine problems,

the fuel system should be emptied before 1. Ensure the tractor is on level ground.

storage of 30 days or Ionqer, Drain the gas 2. Place the motion control leverin neutral.

fuellinesandcarburetorareempty. Usefresh clutch/brake slowly return to operating

fuel next season. See Storage Instructions position.

foradditional information. Never useengine

or carburetor cleaner products inthefueltank

or permanent damage may occur.

TO START ENGINE

When starting the engine for the first time or

if the engine has run out of fuel, it will take

extra cranking time to move fuel from the

tank to the engine.

I, Ensure freewheel control is in the trans-

mission engaged position.

2. Siton seat in operating position, depress

clutch/brake pedaland set parkingbrake.

3. Place motion control lever in neutral

position.

4. Move attachment clutch to disengaged

position.

5. Move throttle control to choke position.

NOTE: Before starting, read the warm and

cold starting procedures below.

6. Insert key into ignition and turn key

clockwise to start positionand release

key as soon as engine starts, Do not run

starter continuously for more than fifteen

seconds per minute. If the engine does

not start after several attempts, move

throttle control to fast position, wait a

few minutes and try again. Ifengine still

does not start, move the throttle control

back to the choke position and retry.

WARM WEATHER STARTING

(50°F/10°C and above)

7. When engine starts, move the throttle

control to the fast position.

• The attachments and ground drive can

nowbe used, tftheengine does notaccept

the load, restart the engine and allow itto

warm up for one minute using the choke

as described above.

COLD WEATHER STARTING

(50°F/10°C and below)

7. When engine starts, leavethrottle control

in choke position until engine warms up

and begins to run roughly, Once rough

running begins, immediately move the

throttle controlto the fast position. Engine

warm-up maytake from several seconds

to several minutes (the colder the tem-

perature, the longer the warm-up).

AUTOMATIC TRANSMISSION WARM UP

Before driving the unit in cold weather, the

transmissionshould bewarmedupasfollows:

3. AUowoneminutefor transmissiontowarm

up. This can be done during the engine

warm up period.

• The attachments can also be used dur-

ing the engine warm-up period after the

transmission has been warmed up.

NOTE: Ifat ahigh altitude (above 3000feet)

or in cold temperatures (below 32°F/0°C)

the carburetor fuel mixture may needto be

adjusted for best engine performance (see

"TOADJUST CARBURETOR" inthe Service

and Adjustments section of this manual).

14

Page 15

PURGE TRANSMISSION

_CAUTION: Never engageordisengage

freewheel lever while the engine is running.

Toensure proper operation and performance,

it is recommended that the transmission be

purged before operating tractor for the first

time.This procedure will removeanytrapped

air inside the transmission which may have

developed during shipping of yourtractor.

IMPORTANT: Should your transmission

require removal for service or replacement,

itshould bepurged after reinstallation before

operating the tractor.

1, Place tractor safely on a level surface -

that is clear of objects and open - with

engine off and parking brake set.

2. Disengage transmission by placing

freewheel control indisengaged position

(See "TO TRANSPORT" inthis section

of manual).

3. Sitting in the tractor seat, start engine.

After the engine isrunning, move throttle

control to slow position. With motion

control lever in neutral position, slowly

disengage clutch!brake pedal.

A_JLCAUTION:At any time, during step 4,

there may be movement ofthe drive wheels,

4, Move motion control leverto full forward

position and hold for five (5) seconds,

Move lever to full reverse position and

hold for five (5) seconds, Repeat this

procedurethree (3) times,

5. Move motion control lever to neutral

position. Shutoff engine and set parking

brake.

6. Engage transmission by placing free-

wheel control in engaged position (See

"TO TRANSPORT" in this section of

manual),

7. Sitting in the tractor seat, start engine.

After the engine isrunning, movethrottle nn np.rfnrmance and nroner discharae

controlto half (t/2) speed With motion .-_ r-,.----, r r o

.............. '...................... of-material: Regulategrour_d speedby .........

control lever in neutral position, slowly

disengage clutch!brake pedal.

8. Slowlymove motion controlleverforward,

after the tractor moves approximately

five (5)feet, slowly move motion control

leverto reverse position. After thetractor

moves approximately five (5) feet return

the motion control lever to the neutral

position. Repeat this procedure with the

motion control lever three (3)times.

Your transmission is now purged and now

ready for normal operation.

MOWING TIPS

* Tire chains cannot be used when the

mower housing is attached to tractor.

. Mowershould beproperlyleveled for best

mowing performance, See "TO LEVEL

MOWER HOUSING" in the Service and

Adjustments section of this manual.

* The left hand side of mower should be

used for trimming.

* Drivesothat clippings are discharged onto

the area that has already been cut. Have

the cutarea to the rightof thetractor. This

will result in a more even distribution of

clippings and more uniform cutting.

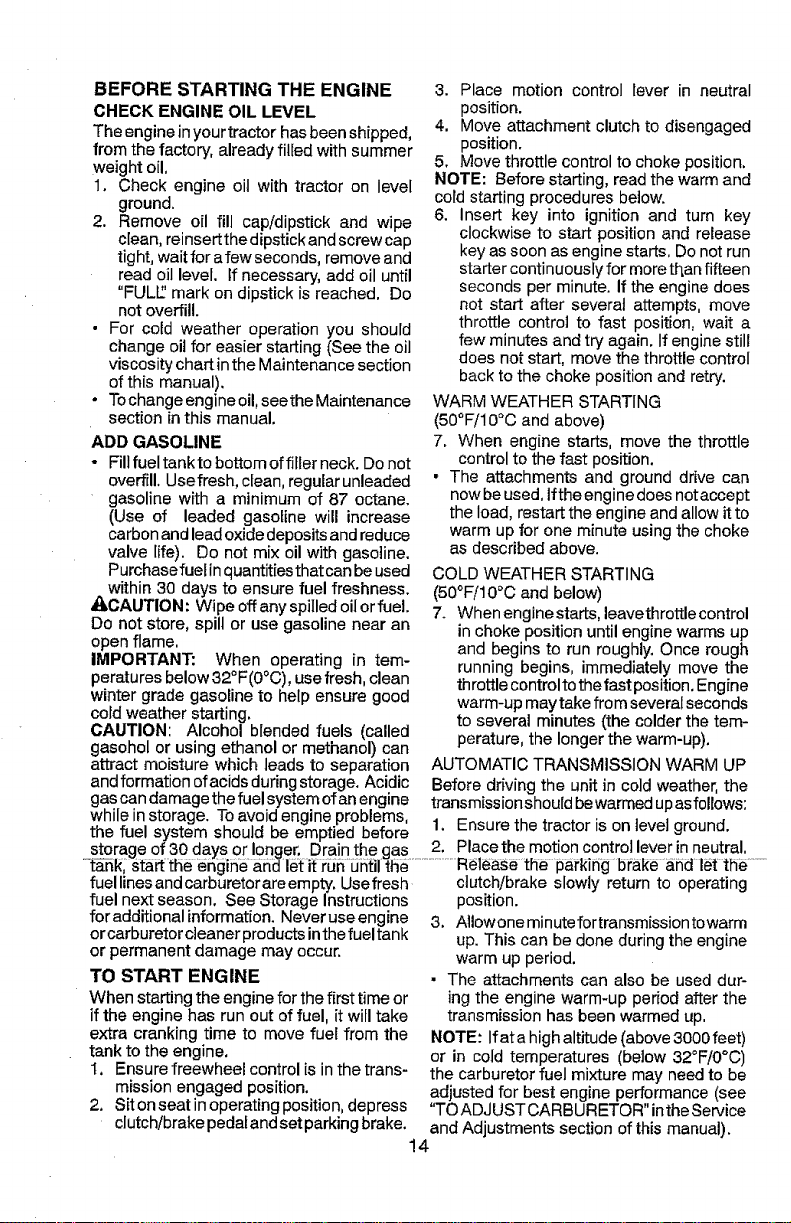

° When mowinglarge areas, startbyturning

tothe right so that clippings will discharge

away from shrubs, fences, driveways,

etc. After one or two rounds, mow in the

opposite direction making left hand turns

until finished.

• If grass is extremely tall, it should be

mowed twice to reduce load and possible

fire hazard from dried clippings. Make

first cut relatively high; the second to the

desired height.

• Do not mow grass when it is wet. Wet

grass will plug mower and leave undesir-

able clumps. Allow grass to dry before

mowing.

• Always operate engine at full throttle

when mowing to ensure better mow-

selecting a tow enough speed to give the

mower cutting performance as well as the

quality of cut desired.

* When operating attachments, select a

ground speed that will suit the terrain and

give best performance of the attachment

being used.

15

Page 16

MAINTENANCE SEWOR_

SCHEDULE SAC.

Cheek Brake O_er'a_fon V F

Chee,k Tire Pressure

aT Check Operator Presence & P,OS Systems

A Cheek for Loose Fasteners V f

C Chec_Replaee Mower Blades

T LubriBation Chart

0 Cheek Batt_t_ Leve!

R clean Battetv and Terminals

Clean Debris Off Steering Plate

Cheek Tra_saxle Coo,l!t_g

Cheek Mower Levelness

Check V-Be_ts

C,heek Engine Oii Level V*

Chat_qe Enqine Oil (w!th oil filter)

Ch_ng_ Engine Oil (withQul _iI !!!t_r)

E Clean Air Filter

G Clean Air Semen

I Inspect Muffler,/Spark Arrester

U RepIsce 0il tilter (If equipped)

E Clean Engine Cooling Fins

Replace Spark PZu9

Repines Ai_ Filt e_" Paper Car t_'idge

Rept_,tce Fuel Filter

EVERY EVERY EVERY EVERY EVEW¢ BEFORE

USE

B 2,5 50 100 SEASON BTORAGE

HOURB HOURS HOURS HOURS

v"

v'

V= ........................

V

=/ v'

V_5 .........................

v"

v'

V_,,

ii ii ii iiiiiiiiiiiiiiiii iiiiiiiv'

v',,= v'

v'.

v',

_L_, _.....

i/ ,v"..........

v',

iii iii iiii

v"

GENERAL RECO MMENDATIONS LUBRICATIONCHART

The warranty onthis tractordoes not cover

items that have been subjected to operator _\ " "

_)SteenngPivotBolts

abuse or negligence. To receive full value • Spindle_f_/L_'_r_ Spindle

from the warranty, operator must maintain Zerk I_1! / \ _1_ Zerk -

tractor as instructed in this manual, _J__IP_,--I_

Some adjustments wiBneedto bemade pe- d)Fr°ntJl- LZ=I!_o \\" II2"J_"_'_ Front

riodically toproperly maintain your tractor, - • ,_;__.__.'_ _/heeI

Wheel

At least once a season, check to see if _Te_knng _ ..... _'_-_\ Bearing

you should make any of the adjustments ._/I _ IX,,"7 Zerk

described in the Service and Adjustments (D Steerin.qj _ ,.-__'_'_

section of this manual. Sector [ ( t_-_' 'I 1 \x_.

_';-At le_t once a year youshould replace.................................Ge ngine..........

the spark plug, clean or replace air filter, Teeth I i ,\ '-_. J, ] I

and check blades and belts for wear, A _-_ <--_

new spark plugandclean air filter assure

proper air-fuel mixture and help your en-

gine run better and last longer,

(DGeneral Purpose Grease

@Refer to Maintenance "ENGINE" Section

BEFORE EACH USE

1. Check engine oillevel.

2. Check brake operation.

3, Check tire pressure,

4. Check operator presence and

ROS systems for proper operation,

5. Check for loose fasteners.

IMPORTANT: Do not oilor grease the pivot

points which have special nylon bearings.

Viscous lubricants wilt attract dust and dirt

thatwill shorten the lifeof the self-lubricating

bearings, Ifyou feelthey must belubricated,

use only a dry, powdered graphite type lu-

bricant sparingly.

16

Page 17

TRACTOR

Alwaysobservesafetyruleswhenperforming

anymaintenance.

BRAKE OPERATION

tf tractor requires more than five (5) feet to

stop at highest speed in highest gear on a

level, dr:/concrete or paved surface, then

brake must be serviced. (See "TO CHECK

BRAKE" in the Service and Adjustments

section of this manual).

TIRES

• Maintain proper air pressure in all tires

(See the sides of tires for proper PSI).

• Keep tires free of gasoline, oil, or insect

control chemicals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp

objects and other hazards that may cause

tire damage.

NOTE: To seal tire punctures and prevent

flat tires due to slow leaks, tire sealant may

be purchased from your local parts dealer.

Tire sealant also prevents tire dry rot and

corrosion.

OPERATOR PRESENCE SYSTEM AND

REVERSE OPERATION SYSTEM (ROS)

Ensure operator presence and reverse

operation systems are working properly. If

your tractor does not 1unction as described,

repair the problem immediately.

°

The engine should not start unless the

brake pedal is fully depressed, and the

attachment clutch control is in the disen-

gaged position.

CHECK OPERATOR PRESENCE

SYSTEM

• When the engine is running, any attempt

bythe Operatorto leave the seat without

first setting the parking brake should shut

off the engine.

• When the engine is running and the at-

tachment clutch is engaged, any attempt

by the operator to leave the seat should

• The attachment clutch should never oper-

ate unless the operator is in the seat.

CHECK REVERSE OPERATION (ROS)

SYSTEM

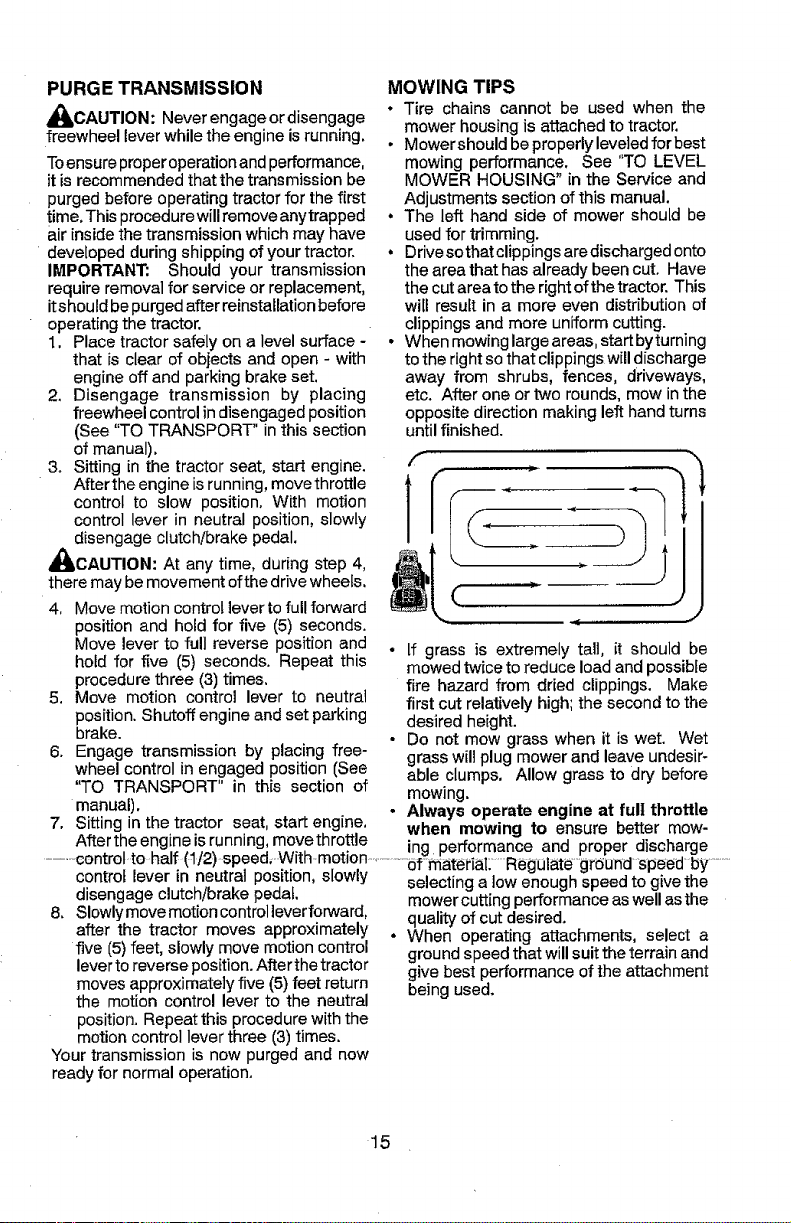

° Whenthe engine is runningwith the ignition

switch in the engine "ON" position andthe

attachmentclutch engaged, any attempt

bythe operator to drive in reverse should

shut off the engine.

° Whenthe engine isr,unn!ngwiththe ignition

switch in the ROS ON position and the

attachment clutch engaged, any attempt

by the operator to drive in reverse should

NOT shut off the engine.

BLADE CARE

Forbestresults mower blades must besharp.

Replace worn, bent or damaged blades.

&CAUTION: Useonlya replacement blade

approved bythe manufacturer ofyour tractor.

Using a blade not approved by the manu-

facturer of your tractor Is hazardous, could

damage your tractor andvoid your warranty.

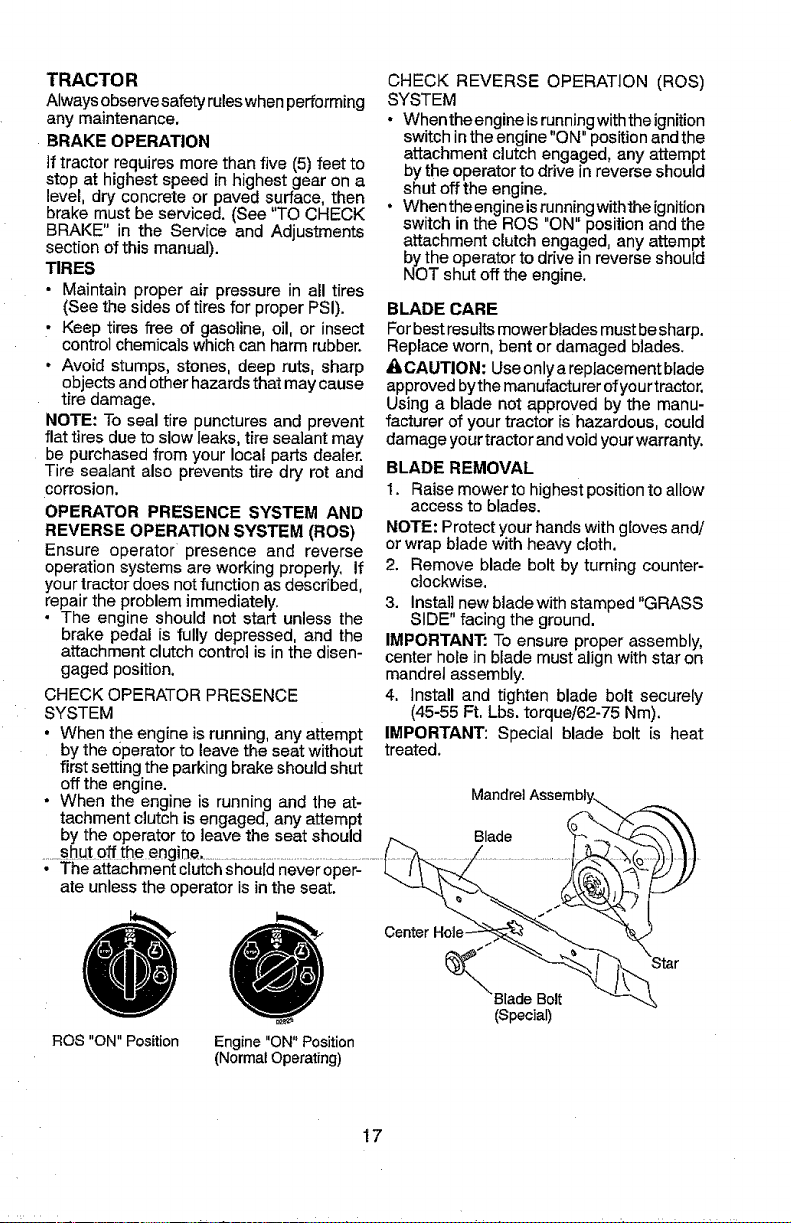

BLADE REMOVAL

1. Raise mower to highest position to allow

access to blades.

NOTE; Protect your hands with gloves and/

or wrap blade with heavy cloth.

2. Remove blade bolt by turning counter-

clockwise.

3. Install new blade with stamped "GRASS

SIDE" facing the ground.

IMPORTANT: To ensure proper assembly,

center hole in blade must align with star on

mandrel assembly.

4. Install and tighten blade bolt securely

(45-55 Ft. Lbs. torque/62-75 Nm).

IMPORTANT: Special blade bolt is heat

treated.

ROS "ON" Position Engine "ON" Position

(Normal Operating)

Center Hole-

(_i'Blade Bolt

(Special)

17

Page 18

BATTERY

Your tractor has a batter_jcharging system

which is sufficient for normal use, However,

periodic charging of the battery with .an au-

tomotive charger willextend its life.

Keep battery and terminals clean.

Keep battery bolts tight,

• Keep small vent holes open.

• Recharge at 6-10 amperes for 1 hour.

ENGINE

LUBRICATION

Only use high quality detergent oil rated with

APt service classification SG-SL. Selectthe

oil's SAE viscosity grade according to your

expected operating temperature.

$AE V_SCOS£_Y GRAD:ES

NOTE: The original equipment battery on

your tractor is maintenance free, Do not

attempt to open or remove caps or covers.

Adding or checking level of electrolyte is

not necessary.

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and termi-

nals can cause the battery to "leak" power.

1. Disconnect BLACK battery cable first

then RED battery cable and remove

battery from tractor,

2. Rinse the battery with plainwater anddry,

3. Clean terminals and battery cable ends

with wire brush until bright.

4. Coat terminals with grease or petroleum

i_lly.

5. Reinstafi battery (See "REPLACING

BATTERY" in the SERVICE AND AD-

JUSTMENTS section of this manual).

V-BELTS

CheckV-belts for deterioration andwear after

t00 hours ofoperation and replace ifneces-

sary. The belts are not adjustable. Replace

belts if they begin to slip from wear.

TRANSAXLE COOLING

The transmission fan andcooling finsshould

be kept dean to ensure proper cooling_

Do not attempt to clean fan or transmission

while engine is running or while the trans-

mission is hot, To prevent possible damage

to seals, do not use high pressure water or

steam to clean transaxle.

• Inspect cooling fan to Ensure fan blades

are intactand clean.

C -_ -s0 -to _ 1o 2g _o 40

_"EMp ERATU'RERANGE ANTIC _'PATED_"OR E N_T OIL C_*NG_

NOTE: Although multi-viscosity oils(5W30,

10W30etc.) improve starting in cold weather,

they will result in increased oil consumption

when used above 32°F/0°C. Check your

engine oil level more frequentlyto avoid pos-

sible engine damage from running low onoil.

Change the oil after every 50 hoursof opera-

tion or at least once a year ifthe tractor is

not used for 50 hours in one year.

Check the crankcase oil level before starting

the engine and after each eight (8) hours

of operation. Tighten oil fill cap/dipstick

securely each time you check the oil level.

TO CHANGE ENGINE OIL

Determine temperature range expected

before oil change. Ail oil must meet AP1

service classification SG-SL,

• Be sure tractor ison level surface.

• Oil will drain more freely when warm.

• Catch oil in a suitable container,

1. Remove oil fill cap/dipstick. Be careful

notto allow dirt to enter the engine when

changing oil.

2. Slide oil drainextension fromthe docking

position on the engine blower housing

and extend outward from engine.

-T-lnspectcooling finsfordirt; grass clippings ........D°cki_g ..........................Oil=Drain...............

andother materials, Toprevent damageto .....

seals, do not use compressed air or high

pressure sprayer to clean cooling fins.

TRANSAXLE PUMP FLUID

The transaxle was sealed atthe factory and

fluidmaintenance is not required for the life

nsion

ofthe transaxle. Should the transaxle ever

leak or require servicing, contact your near-

est Sears or other qualified service center.

3. To open, twist cap counter-clockwise

4. After oil is drained completely,replace

cap and twist clockwise until it stops.

5. Re-attach oil drain extension to engine

blower housing.

18

Page 19

6. Refill engine with oilthrough oilfill dipstick

tube. Pour slowly. Do not overfill. For ap-

proximate capacity see "PRODUCT SP-

ECIFICATIONS" section of this manual.

7. Use gauge on oil fill cap/dipstick for

checking level. For accurate reading,

tighten dipstick cap securely onto the

tube before removing dipstick. Keep oil

at "FULE' line on dipstick. Tighten cap

onto the tube securely when finished.

ENGINE OIL FILTER

Replace the engine oil filter every season or

every other oil change if the tractor is used

more than 100 hours in one year.

AIR FILTER

Your engine will not run properly using a

dirty air filter. Service paper cartridge every

100 hours of operation or every season,

whichever occurs first.

Service air cleaner more often under dusty

conditions.

1. Remove coven

2. Carefully remove air filter cartridge and

pre-cleaner from base.

3. Clean base carefully to prevent debris

from falling into carburetor.

Knobs Cartridge

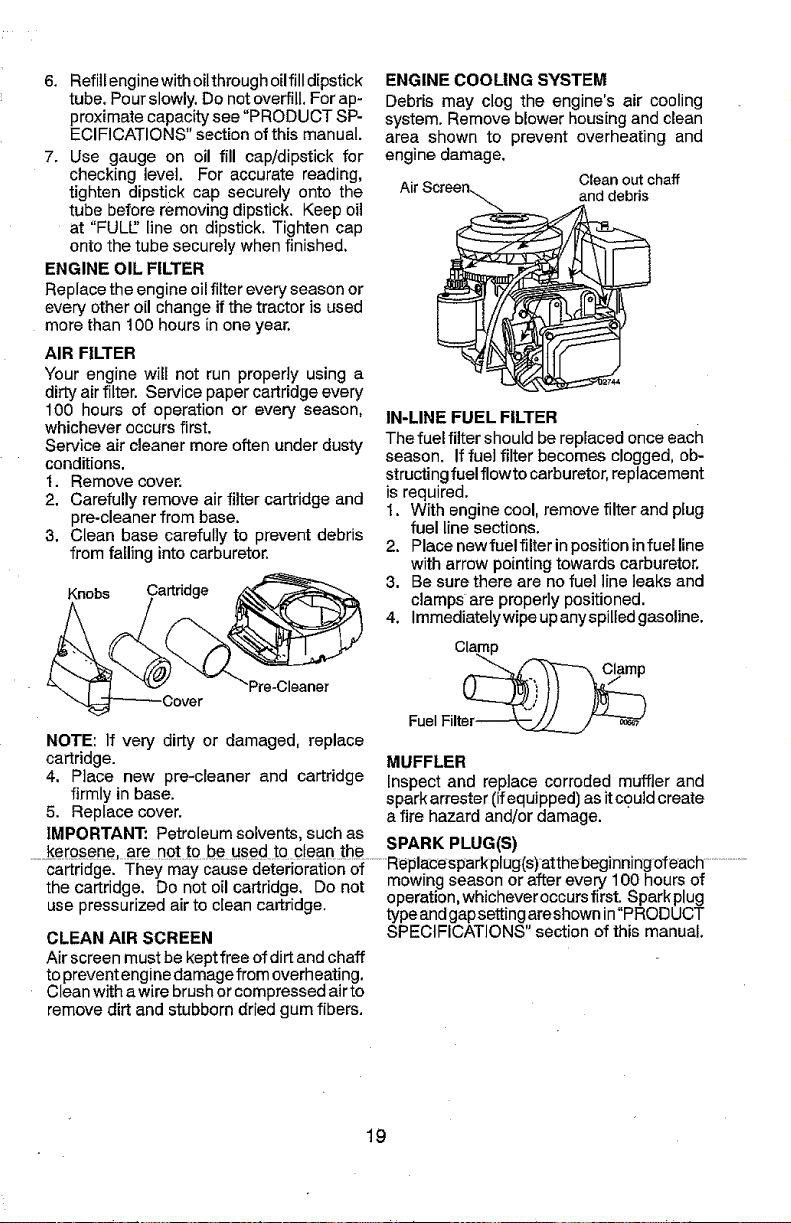

ENGINE COOLING SYSTEM

Debris may clog the engine's air cooling

system. Remove blower housing and clean

area shown to prevent overheating and

engine damage.

Air Scree Clean out chaff

n"-.. and debris

IN-LINE FUEL FILTER

The fuel filter should be replaced once each

season. If fuel filter becomes clogged, ob-

structing fuel flowto carburetor, replacement

is required,

t. With engine cool, remove filter and plug

fuel line sections.

2. Place newfuelfilter in position infuel line

with arrow pointing towards carburetor.

3. Be sure there are no fuel line leaks and

clamps are properly positioned.

4. immediatelywipeup anyspilled gasoline.

Clamp

'Pre-Oleaner

Fuel Filter-_-_--__../---_

NOTE: If very dirty or damaged, replace

cartridge.

4. Place new pre-cleaner and cartridge

firmly in base.

5. Replace cover.

MUFFLER

Inspect and replace corroded muffler and

spark arrester (if equipped) as it could create

afire hazard and/or damage.

IMPORTANT: Petroleumsolvents, such as

a i Replacesparkplag(s) atthebeg_nnlngoteacn

c rtr'dge_ They may cause deteriora{ion of

the cartridge. Do not oil cartridge, Do not

use pressurized air to clean cartridge.

CLEAN AIR SCREEN

mowing season or after every 100 hours of

operation, whichever occursfirst. Spark plug

type and gapsetting areshown in"PRODUCT

SPECIFICATIONS" section of this manual.

Air screen must be keptfree of dirt andchaff

toprevent enginedamage from overheating.

Clean with a wire brush or compressed airto

remove dirt and stubborn dried gum fibers.

19

Page 20

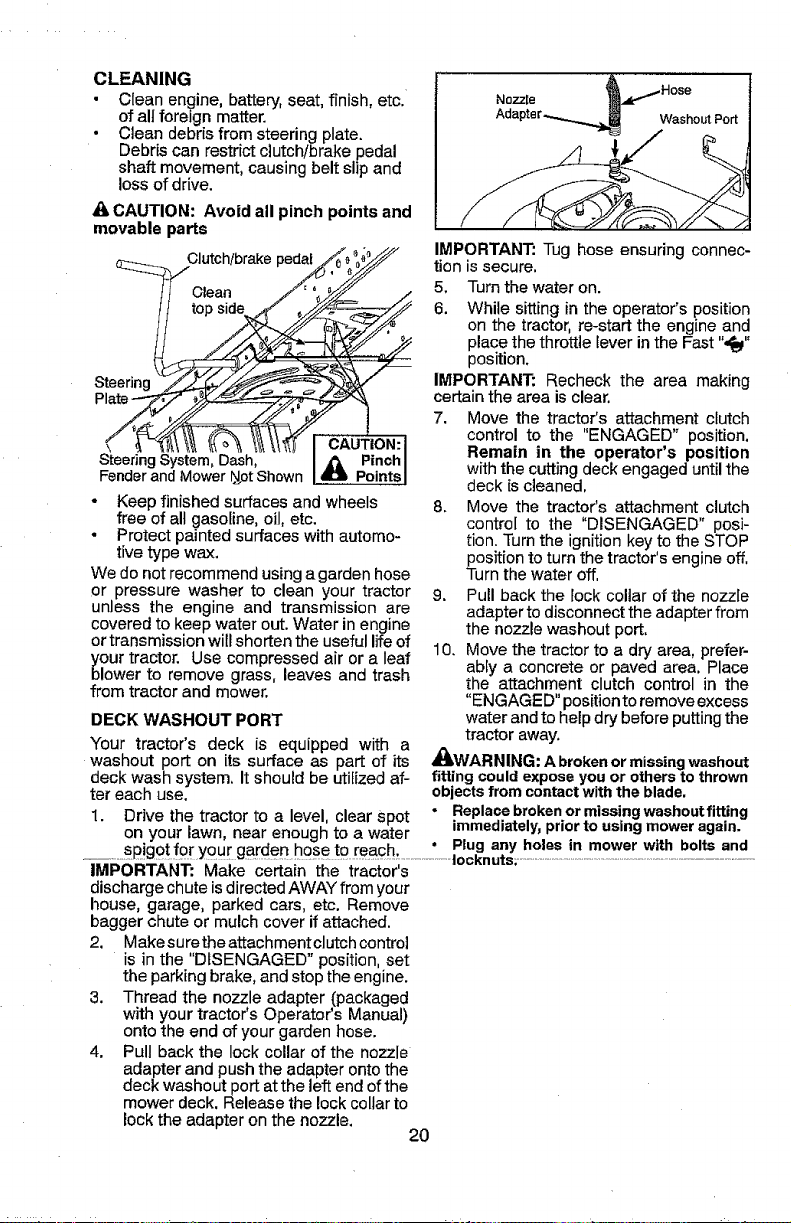

CLEANING

• Clean engine, battery, seat, finish, etc.

of all foreign matter.

• Clean debris from steering plate.

Debris can restrict clutch/brake pedal

shait movement, causing belt slip and

loss of drive.

& CAUTION: Avoid all pinch points and

movable parts

_ CclUtch!brakepedal_y

topside f _z_J

SteeneJi_ngaSdYStJomw'erDaS_h'shown_1_ Pinch

- Keep finished surfaces and wheels

free of all gasoline, oil, etc.

. Protect painted surfaces with automo-

tive type wax.

We do not recommend using a garden hose

or pressure washer to clean your tractor

unless the engine and transmission are

covered to keep water out. Water in engine

or transmission will shorten the useful life of

_our tractor. Use compressed air or a leaf

lower to remove grass, leaves and trash

from tractor and mower.

DECK WASHOUT PORT

Your tractor's deck is equipped with a

washout port on its surface as part of its

deck wash system, It should be utilized af-

ter each use,

1. Drive the tractor to a level, clear Spot

on your lawn, near enough to a water

Nozzle

Washout Port

IMPORTANT: Tug hose ensuring connec-

tion is secure.

5. Turn the water on.

6. While sitting in the operator's position

on the tractor, re-start the engine and

place the throttle lever in the Fast "_"

position.

IMPORTANT: Recheck the area making

certain the area is clear.

7. Move the tractor's attachment clutch

control to the "ENGAGED" position.

Remain in the operator's position

withthe cutting deck engaged untilthe

deck is cleaned.

8. Move the tractor's attachment clutch

control to the "DISENGAGED" posi-

tion. Turnthe ignition key to the STOP

position to turn the tractor's engineoff,

Turn the water off.

9. Pull back the lock coltar of the nozzle

adapter to disconnect the adapter from

the nozzle washout port,

10. Move the tractor to a dry area, prefer-

ably a concrete or paved area. Place

the attachment clutch control in the

"ENGAGED" position to remove excess

water andto help dry before putting the

tractor away.

_WARNING: A brokenormissing washout

fitting couldexposeyouor othersto thrown

objectsfromcontactwiththe blade,

• Replacebrokenormissingwashoutfltting

immediately_priortousingmoweragain.

IMPORTANT: Make certain the tractor's

discharge chute is directed AWAYfrom your

house, garage, parked cars, etc. Remove

bagger chute or mulch cover if attached.

2. Makesure the attachment clutch control

is in the "DISENGAGED" position, set

the parking brake, and stop the engine.

3. Thread the nozzle adapter (packaged

with your tractor's Operator's Manual)

onto the end of your garden hose.

4. Pull back the lock collar of the nozzle

adapter and push the adapter onto the

deck washout port at the leftend of the

mower deck, Release the lockcollar to

lock the adapter on the nozzle.

20

Page 21

I_WARNING: TO AVOID SERIOUS INJURY, BEFORE PERFORMING ANY

SERVICE OR ADJUSTMENTS:

1. Depress clutch/brake pedal fully and set parking brake.

2. Place motion control lever in neutral position.

3. Place attachment clutch in "DISENGAGED" position.

4. Turn ignition key to "STOP" and remove key.

5. Ensure the bIades and all moving parts have completely stopped.

6. Disconnect spark plug wire from spark plug and place wire where it cannot

come in contact with plug.

TO REMOVE MOWER

1. Place attachment clutch in "DISEN-

GAGED" position,

2. Lower attachment lift tever to its lowest

position.

3. Roll belt off engine pulley (M) and belt

keepers (G).

4. Remove retainer spring (K), slide collar

(L) off and push housing guide (P) out

of bracket.

5. Remove clutch cable spring (Q) from

idler arm (R).

6. Disconnect front link (E) from mower -

remove retainer spring and washer.

7. Go to either side of mower and discon-

nect mower suspension arm (A) from

chassis pin (B) and rear lift link (C) from

rear mower bracket (D)- remove retainer

springs and washers.

CAUTION: After rear liftlinks arediscon-

nected, the attachment liftleverwili bespring

toaded.Have a tight grip on liftlever when

changingposition of the lever.

8. Slide mower out fromunder right side of

tractor.

IMPORTANT: If an attachment other than

the mower is to be mounted on the tractor,

remove the front link (E) and rear lift links

(C) from tractor and hook the clutch spring

(Q) into the cable guide on front edge of

lower dash.

TO INSTALL MOWER

Ensuretractor isonlevel surface andengage

parking brake,

t. Lower attachment rift lever to its lowest

position.

_1_CAUTION: Lift lever is spring loaded.

Have a tight grip on lift lever, lower it slowly

and engage in lowest position.

NOTE: Ensure mower sidesuspension arms

(A)are pointing forward beforesliding mower

undertractor.

2. Slide mower under tractor until it is cen-

tered under tractor.

21

Page 22

3. ATTACH MOWER SIDE SUSPENSION

ARMS (A) TO CHASSIS - Position hole

in arm over pin (B) on outside of tractor

chassis and secure with retainer spring.

4. Repeat on opposite side of tractor.

7. Insert end of link (E) into hole in front

mower bracket (H) and secure with

washer and retainer spring (J).

5. ATTACH REAR LIFT LINKS (C) - Lift

rear corner of mower and position slot

in link assembly over pin (D) on rear

mower bracket and secure with washer

and retainer spring.

6. ATTACH FRONT LINK (E) - Work from

left side of tractor. Insert rod end of link

assembly through front hole in tractor

front suspension bracket (F).

8, Hook end of clutch cable spring (Q) into

hole in idler arm (R).

9, Push clutch cable housing guide (P) into

bracket, slide collar (L) onto guide and

secure with retainer spring (K),

10, Install belt onto engine pulley (M) and belt

keepers (G).

IMPORTANT: Check belt for proper routing

in all mower pulley grooves.

11.Raise attachment lift lever to highest

position,

12. Ifnecessary, adjust gauge wheels before

operating mower as shown in the O pera-

tion section of this manual.

22

03042rex

Page 23

TO LEVEL MOWER

Make sure tires are properly inflated to the

PSI shown ontires, lftires areover or under

inflated, it may affectthe appearance of your

lawn and lead you to think the mower isnot

adjusted properly.

VISUAL SIDE-TO-SIDE ADJUSTMENT

1. With alltires properlyinflatedand if your

lawn appears unevenly cut, determine

which side of mower is cutting lower.

2. With a3/4" or adjustable wrench, turn lift

link adjustment nut (A) to the leftto lower

LH side of mower, or, to the right to raise

LH side of mower.

NOTE: Each full turn of adjustment nut will

change mower height about 3/16".

FRONT-TO-BACK ADJUSTMENT

IMPORTANT: Deck must be level side-

to-side.

Toobtainthe best cutting results, the mower

blades should be adjusted so the front tip is

1/8" to !/2" lower than the rear tip when the

_ower is in its highest position.

CAUTION: Blades are sharp. Protect

your hands with gloves and/or wrap blade

with heavy cloth.

• Raise mower to highest position.

• Position any blade so the tip is pointing

straight forward, Measure distance (B)

to the ground at front and rear tip of the

blade.

• If fronttip of blade is not 1/8" to 1/2" lower

than the rear tip, go to the front of tractor,

• With an 11/18" or adjustable wrench,

loosen jam nut A several turns to clear

adjustment nut B.

Turn nut right Turn nut left

to raise mower \ to lower mower

3. Test your adjustment by mowing some

• With a 3/4" or adjustable wrench, turn

front link adjustment nut (B) clockwise

(tighten) to raise the front of mower, or,

counterclockwise (loosen) to lower the

front mower.

uncut grass and visually checking the

appearance, Readjust, ifnecessary, until

you are satisfied with the results,

PRECISION SIDE-TO-SIDE ADJUSTMENT

I. With alltires properly inflated,parktractor

on level ground or driveway.

_1=CAUTION: Blades are sharp, Protect

your hands with gloves and/or wrap blade

with heaW cloth.

....__._Ba!semowertQ its highest position .........'............................!_!_

3. At both sides of mower, position blade at Tightenadjustnut

side and measure the distance (A) from Bto raisemower

bottom edge of blade tothe ground. The

distance should be the same on both

sides.

4. If adjustment is necessary, see step 2 in

Visual Adjustment instructions above.

5. Recheck measurements, adjust ifneces-

sary untilboth sides are equal.

NOTE: Each full turn ofthe adjustment nut

will change mower height about 1/8".

- Recheck measurements, adjust if neces-

sary until front tip of blade is 1/8" to 1/2"

lower than the rear tip.

• Hold adjustment nut inpositionwithwrench

and tighten jam nut securely against ad-

justment nut.

23

nut Bto lower

mower

Loosen jam nut A first

Page 24

TO REPLACE MOWER BLADE DRIVE

BELT

The mower blade drive belt may bereplaced

without tools. Park the tractor on level sur-

face. Engage parking brake.

BELT REMOVAL -

1. Remove mowerfromtractor (See"TO RE-

MOVEMOWER"inthissectionofmanual).

2. Work belt off both mandrel pulleys and

idfer pulleys.

3. Pull belt away from mower.

BELT INSTALLATION -

1. Work belt around both mandrel puUeys

and idler pulleys

2. Ensure belt is in all pulley grooves and

inside all belt guides.

3, Install mower (See "To Install Mower" in

this section of this manual).

Mandrel Idler

Mandrel

BELT INSTALLATION -

1. Install new beltfrom tractor rearto front.

over the steering plate (F) and above

clutch brake pedal shaft (G).

2. Pull belt toward front of tractor and roll

belt onto engine pulley (E).

3. Pull belttoward rear of tractor, Carefully

work belt down around transmission

cooling fan and onto the input pulley (D).

Ensure belt is inside the belt keeper.

4. Install belt on centerspan idler (C).

5. Install belt through stationary idler (A)

and clutching idler (B).

6. Ensure belt is in all pulley grooves and

inside all belt guides and keepers,

7. Install mower (See "TO INSTALL MOW-

ER" inthis section of manual).

TO REPLACE MOTION DRIVE BELT

Park the tractor on level surface, Engage

parking brake. For assistance, there is a

belt installation guide decal on bottom side

of left footrest.

BELT REMOVAL-

1. Remove mower (See "TO REMOVE

TO CHECK BRAKE

If tractor requires more than five (5) feet to

stop at highest speed in highest gear on a

level, dry concrete or paved surface, then

brake must be serviced.

......... MOWER!! in this section of manual)...................You may-also check brake+by;......................................

NOTE: Observe entire motion drive belt

and position of all belt guides and keepers,

2, Remove belt from stationary idler (A)and

clutching idler (8).

3. Remove belt from centerspan idler (C).

6, Pull belt slack toward rear of tractor.

Carefully remove belt upwards from

transmission input pulley and over cool-

ing fan blades (D),

4. Remove belt downward from engine

pulley (E).

5. Slide belt toward rear of tractor, off the

1, Park tractor on a level, dry concrete or

paved surface, depress brake pedal all

the way down and engage parking brake.

2. Disengage transmission by placing

freewheel control in "transmission dis-

engaged" position, Pullfreewheel control

out and into the slot and release so it is

held in the disengaged position.

The rear wheels must lock and skid when

you tryto manually push the tractor forward.

If the rear wheels rotate, then the brake

needs to be serviced. Contact a Sears or

other qualified service center.

steering plate (F)and removefrom tractor.

24

Page 25

TO REMOVE WHEEL FOR REPAIRS

1. Block up axle securely,

2. Remove axle cover, retaining ring and

washers to allow wheel removal (rear

wheels have a square key- Do not lose).

3. Repair tire and reassemble.

NOTE: On rearwheels only: align grooves in

rear wheel hub and axle. Insert square key.

4. Replacewashers and snapretaining ring

securely in axle groove.

5. Replace axle cover.

NOTE: To seal tire punctures and prevent

flat tires due to slow leaks, purchase and

usetire sealant from Sears. Tire sealant also

prevents tire dry rot and corrosion,

Washers

Retaining

Axle

NOTE: If additional clearance is needed to

get to adjustment bolt, move mower =deck

height to the lowest position.

After above adjustment is made, ifthe trac-

tor still creeps forward or backward while

motion control lever is in neutral position,

follow these steps:

1. Loosen the adjustment bolt.

2. Movethe motion control lever 1/4 to 1/2

inch in the direction it is trying to creep.

3. Tighten adjustment bolt securely.

4. Start engine and test.

5/ Iftractor still creeps, repeat above steps

until satisfied.

TO START ENGINEwrrH WEAK BATTERY

_ILWARNING: Lead-acid batteries gener-

ate explosive gases. Keep sparks, flame

andsmoking materials away from batteries.

Always wear eye protection when around

batteries.

lfyourbattery istooweakto startthe engine, it

Square

(Rear Wheel Only)

FRONT WHEEL TOE-IN/CAMBER

Your new tractor front wheel toe-in and

camber is set at the factory and is normal.

The front wheel toe-in and camber are not

adjustable. If damage has occurred to

affect the factory set front wheel toe-in or

camber, contact a Sears or other qualified

service center.

TRANSAXLE MOTION CONTROL LEVER

NEUTRAL ADJUSTMENT

Themotioncontrol leverhasbeenpresetatthe

factory; adjustment should notbe necessary.

1. Loosen adjustment bolt in front of the

right rear wheel, and lightly tighten.

2. Start engine and move motion control

leveruntil tractor does not moveforward

or backward.

should berecharged, (See"BATI-ERY" inthe

MAINTENANCE section of this manual).

If "jumper cab[es" are used for emergency

starting, follow this procedure:

IMPORTANT: Yourtractor is equipped with

a12volt system. The othervehicle must also

be a 12 volt system. Do not use your tractor

battery to start other vehicles.

TO A-I-FACHJUMPER CABLES -

1. Connectone end ofthe RED cabletothe

POSITIVE (+)terminal of each battery(A-

B),taking care notto short againsttractor

chassis.

2. Connect one end of the BLACK cable

to the NEGATIVE (-)terminal (C) offully

charged battery.

3. Connect the other end of the BLACK

cable (D)to good chassis ground, away

from fuel tank and battery.

TO REMOVE CABLES, REVERSE ORDER-

=-3.-Hold motioncontrollever inthatposition__1 ._BLACK cablefirst from chassis andthen .........

and turn engine off. from the fully charged battery,

4. While holding motion control lever in 2. RED cable lastfrom both batteries.

place, loosen the adjustment bolt.

5. Move motion control lever to the neutral

(lock gate) position.

6, Tighten adjustment bolt securely. Weak or

Neutral Dead

Lever Lock Battery

Gate

Adjustment Bolt

25

Page 26

REPLACING BATTERY

n_asWARNING: Do not short battery termi-

byallowing a wren chorany other object

to contact both terminals at the same time.

Before connecting battery, remove metal

bracelets, wristwatch bands, rings, etc.

Positive terminal must be connected first to

prevent sparking from accidental grounding.

1. Lift seat pan to raised position.

2. Remove terminal cover.

3, Disconnect BLACK battery cable then

RED battery cable and carefully remove

battery from tractor.

4. Install new batterywith terminals insame

position as old battery.

5. Reinstall terminal cover.

6. First connect RED battery cable to posi-

tive (+) battery terminal with be_tand nut

as shown. Tighten securely.

7. ConnectBLACKgrounding cableto nega-

tive (-) battery termina] with remaining

bolt and nut. Tighten securely

8. Lower seat pan.

TO REPLACE FUSE

Replace with20amp automotive-type plug-

in fuse. The fuse holder is located behind

the dash.