Page 1

Owner's ManuaJ

20.0 HP

ELECTRIC START

46" MOWER

6 SPEED

TRACTOR

Model No.

917.273010

* Safety

,, Assembly

,, Operation

- Maintenance

, Repair Parts

®

CAUTmON:

Read and follow all

Safety Rules and nnstructions

before operating this equip-

ment,

Sears, Roebuck and Co., Hoffman Estates, BL 60179

For answers to your questions

about this product, Call:

1-800-659-5917

Sears Craftsman Help Line

5 am - 5 pro, Mon- Sat

Page 2

Warranty ................................................. 2

Safety Hu_s ...........................................

_ 2

Product Specifications ........................... 5

Assembly ................................................ 8

Operation .............................................. 12

Maintenance Schedule ......................... !9

Maintenance ................................... 19

Service and Adiustments ................ 23

Storage ................................................ 3!

Troubleshooting .................................. 32

Repair Parts ....................................... 35

Parts Ordering ....................... Back Cover

LIMITED TWO YEAR WARRANTY ON CRAFTSMAN RID!NG EQUIPMENT

For two (2) years from the date of purchase, if this Craftsman Riding Equipment is main-

tained, lubricated and tuned up according to the instructions in the owneCs manual,

Sears will repair or replace, free of charge, any parts found to be defective in material or

workmanship.

This Warranty does not cover:

,, Expendable items which become worn during normal use, such as blades, spark

plugs, air cleaners, belts, etc.

Tire re_nlacement or repair caused by punctures from outside objects, such as nails,

thorns, stumps, or glass.

Repairs necessary because of operator abuse, negligence, improper storage or acci-

dent or the failure to maintain the equipment according to the instructions contained in

the owner's manual.

,, Riding equipment used for commercial or rental purposes.

LIMITED 90 DAY WARRANTY ON BATTERY

For ninety (90) days from date of purchase, if any battery, included with this riding equip-

ment proves defective in materiat or workmanship and our testing determines the bat-

tery will not hold a charge, Sears will replace the battery at no charge. In*home warranty

service on your Craftsman riding equipment is available at no charge for 30 days from

the date of purchase. Please contact your nearest service center. After 30 days from the

date of purchase, warranty service is available by taking your Craftsman riding equip-

ment to your nearest Sears Service Center. (In-home warranty service will still be avail-

able after 30 days from the date of purchase but a standard trip charge will apply). This

warranty appties only while this product is in the United States. This Warranty gives you

specific !egal rights, and you may a!so have other rights which may vary from state to

state.

Sears, Roebuck and Co., D/817 WA, Hoffman Estates, IL 60179

GENERAL OPERATION

o Read, understand, and follow all instruc-

tions in the manual and on the machine

before starting.

o Only allow responsible adults, who are

familiar with the instructions, to operate

the machine.

• Clear the area of objects such as rocks,

toys, wire, etc., which could be picked

up and thrown by the blade.

o Be sure the area is clear of other people

before mowing. Stop machine if anyone

enters the area.

Never carry passengers.

Do not mow in reverse unless absolute-

ly necessary. Always look down and

behind before and while backing.

o Be aware of the mower discharge direc-

tion and do not point it at anyone. Do

not operate the mower without either

the entire grass catcher or the guard in

place.

o Slow down before turning.

o Never leave a running machine unat-

tended. Always turn off blades, set park-

ing brake, stop engine, and remove

keys before dismounting.

Page 3

Turnoffbladeswhennotmowing

_Stopenginebeforeremovinggrass

catcheroruncloggingchute.

Mowonlyindaylightorgoodartificial

light.

Donotoperatethemachinewhileunder

theinfluenceofalcoholordrugs.

Watchfortrafficwhenoperatingnearor

crossingroadways.

_Useextra care when loading or unload-

ing the machine into a trailer or truck.

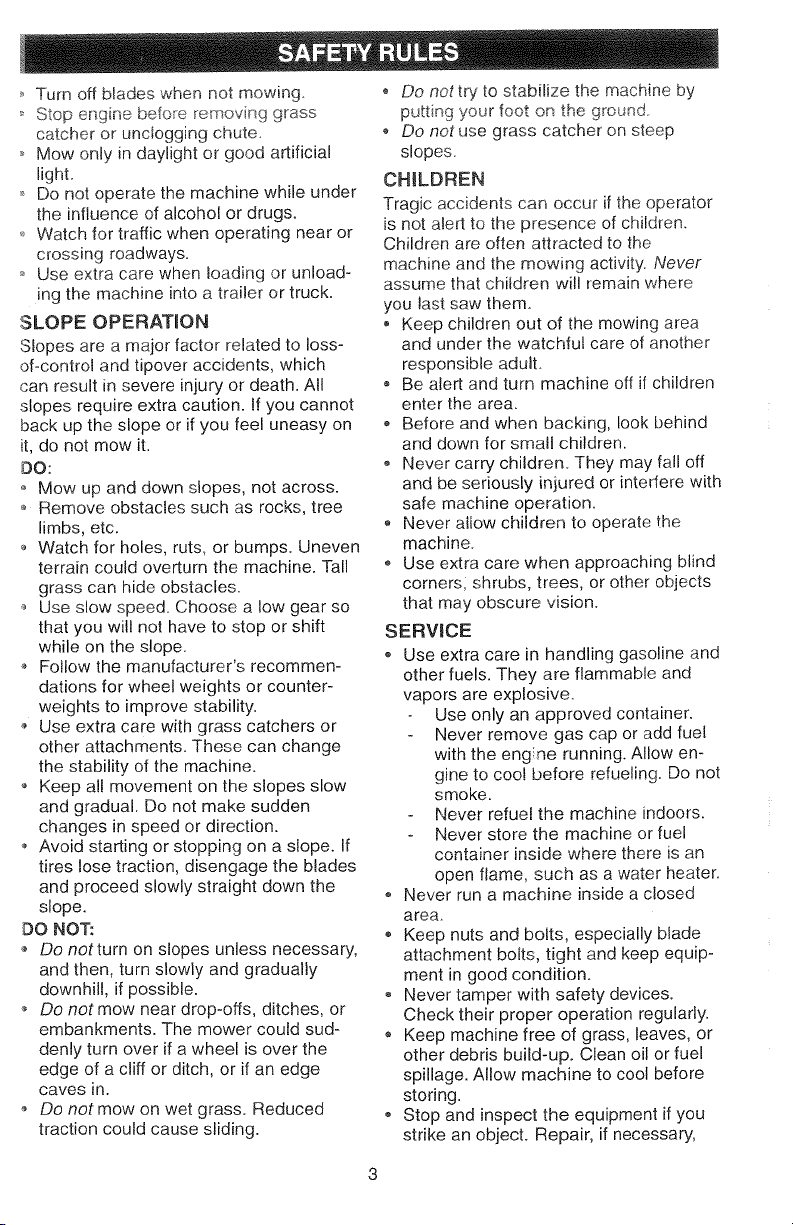

SLOPE OPERATnON

Slopes are a major factor related to loss-

of-control and tipover accidents, which

can result in severe injury or death. All

slopes require extra caution. If you cannot

back up the slope or if you feel uneasy on

it, do not mow it.

DO:

o Mow up and down slopes, not across.

,o Remove obstacles such as rocks, tree

limbs, etc.

o Watch for holes, ruts, or bumps. Uneven

terrain could overturn the machine. Tall

grass can hide obstacles.

o Use slow speed. Choose a low gear so

that you will not have to stop or shift

while on the slope.

o Follow the manufacturer's recommen-

dations for wheel weights or counter-

weights to improve stability.

,_ Use extra care with grass catchers or

other attachments. These can change

the stability of the machine.

o Keep a!! movement on the slopes slow

and gradual. Do not make sudden

changes in speed or direction.

• Avoid starting or stopping on a slope. If

tires lose traction, disengage the blades

and proceed slowly straight down the

slope.

DO NOT:

Do notturn on slopes unless necessary,

and then, turn slowly and gradually

downhill, if possible.

', Do not mow near drop-offs, ditches, or

embankments. The mower could sud-

denly turn over if a wheel is over the

edge of a cliff or ditch, or if an edge

caves in.

o Do net mow on wet grass. Reduced

traction could cause sliding.

Do not try to stabilize the machine by

putting your foot on the %ound

o Do not use grass catcher on steep

slopes.

CHILDREN

Tragic accidents can occur if the operator

is not alert to the presence of children.

Children are often attracted to the

machine and the mowing activity. Never

assume that children will remain where

you last saw them.

Keep children out of the mowing area

and under the watchful care of another

responsible adult.

Be alert and turn machine off if children

enter the area_

• Before and when backing, look behind

and down for small children.

,, Never carry children_ They may fall off

and be seriously injured or interfere with

safe machine operation.

o Never aiiow children to operate the

machine.

o Use extra care when approaching blind

corners, shrubs, trees, or other objects

that may obscure vision.

SERWCE

,, Use extra care in handling gasoline and

other fuels. They are flammable and

vapors are explosive.

Use only an approved container.

Never remove gas cap or add fuel

with the engne running. Allow en-

gine to coo! before refueling. Do not

smoke.

Never refuel the machine indoors.

Never store the machine or fuel

container inside where there is an

open flame, such as a water heater.

o Never run a machine inside a closed

area

Keep nuts and bolts, especially blade

attachment bolts, tight and keep equip-

ment in good condition.

o Never tamper with safety devices.

Check their proper operation regularly.

Keep machine free of grass, leaves, or

other debris build-up. Clean oil or fuel

spillage. Allow machine to cool before

storing.

Stop and inspect the equipment if you

strike an object. Repair, if necessary,

Page 4

beforerestarting.

Nevermakeadjustmentsorrepairswith

theenginerunning.

Grasscatchercomponentsaresubject

towear,damage,anddeterioration,

whichcouldexposemovingpartsor

allowobjectstobethrown.Frequently

checkcomponentsandreplacewith

manufacturersrecommendedparts

MowerbladesaresharpandcancuL

Wrapthebtade(s)orweargloves,and

useextra caution when servicing them.

o Check brake operation frequently.

Adjust and service as required.

J

o Be sure the area is clear of other people

before mowing. Stop machine if anyone

enters the area.

Never carry passengers.

Do not mow in reverse unless absolute-

ly necessary. AJways took down and

behind before and while backing.

Never carry children. They may fall off

and be seriously injured or interfere with

safe machine operation.

Keep children out of the mowing area

and under the watchful care of another

responsible adult.

o Be alert and turn machine off if children

enter the area.

• Before and when backing, look behind

and down for small children.

,_Look for this symbol to point out impor-

tant safety precautions, it means CAUo

TION!!! BECOME AWARE!!! YOUR SAFE-

TY IS INVOLVED.

_CAUTION: In order to prevent acciden-

tal starting when setting up, transporting,

adjusting or making repairs always discon-

nect spark plug wire and place wire where

it cannot contact spark plug.

Mow up and down slopes (15° Max), not

across.

Remove ,obstacles such as rocks, tree

limbs, etc.

® Watch for holes, ruts, or bumps Uneven

terrain could overturn the machine. Taft

grass can hide obstacles.

• Use slow speed. Choose a low gear so

that you will not have to stop or shift

while on the slope.

Avoid starting or stopping on a slope. If

tires lose traction, disengage the blades

and proceed slowly straight down the

slope.

Do not turn on slopes unless necessary,

and then, turn slowly and gradually

downhill, if possible.

_WARNJNG: The engine exhaust from

this product contains chemicals known to

the State of California to cause cancer,

birth defects, or other reproductive harm.

Page 5

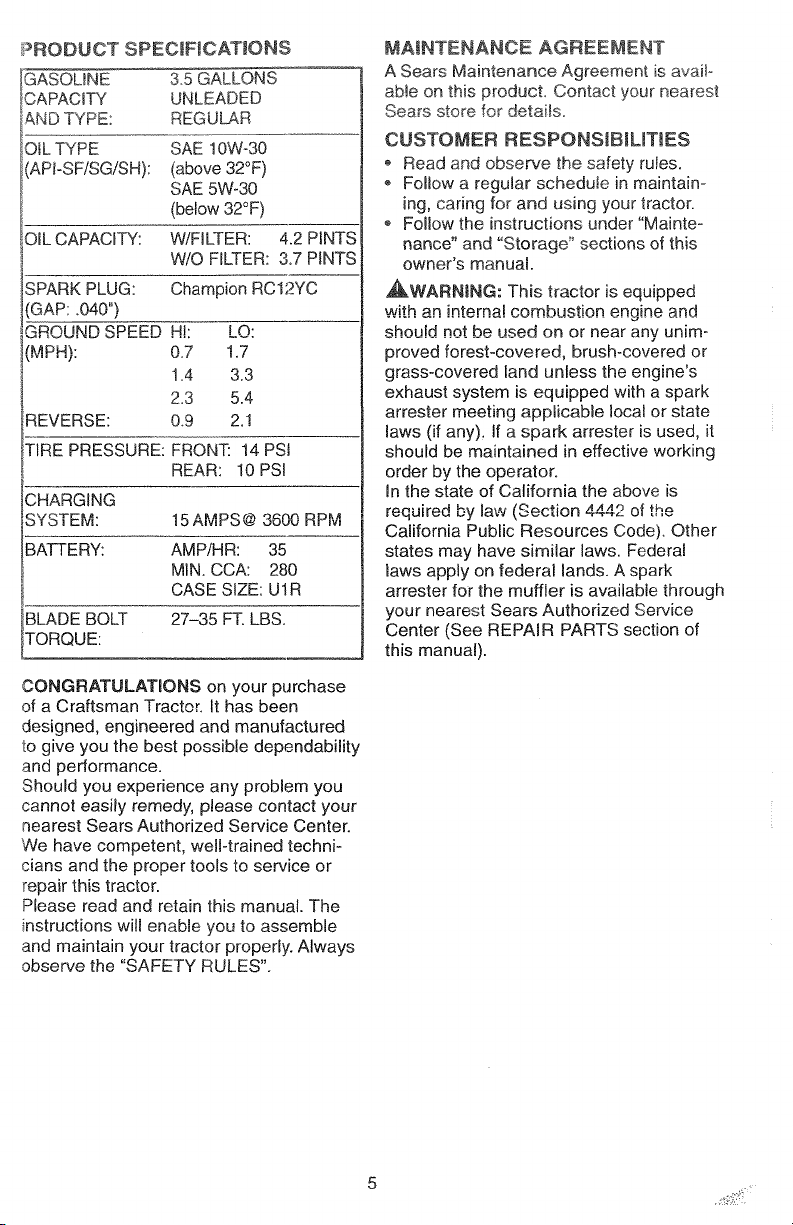

I_RODUCTSPECmFJCATJONS

GAS©UNE 35GALLONS

CAPACITY UNLEADED

ANDTYPE: REGULAR

OiLTYPE SAE10W-30

(API°SFiSG/SH):(above32°F)

SAE5W-30

_ (below32°F)

OILCAPACITY:W/FILTER:4.2PINTS

W!OFILTER:3.7PINTS

._PARKPLUG: Champion RC12YC

GAP: _040")

GROUND SPEED H!: LO:

(MPH): 0.7 1.7

1.4 3.3

2.3 5.4

REVERSE: 0.9 2.1

TIRE PRESSURE: FRONT: 14 PSI

REAR: 10 PSI

CHARGING

SYSTEM: 15 AMPS@ 3600 RPM

BATTERY: AMP/HR: 35

MIN. CCA: 280

CASE SIZE: U1R

BLADE BOLT 27-35 FT. LBS.

TORQUE:

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is avaiF

able on this product Contact your nearest

Sears store for details.

CUSTOMER RESPONSIBILmES

Read and observe the safety ruJes.

Follow a regular schedule in maintain-

ing, caring for and using your tractor.

* Follow the instructions under"Mainte-

nance" and "Storage" sections of this

owner's manual

_WARNJNG: This tractor is equipped

with an interna! comb_st.on engine and

shouid not be used on or near any unim-

proved forest-covered, brush-covered or

grass-covered land unless the engine's

exhaust system is equipped with a spark

arrester meeting appJicaMe local or state

laws (if any), If a spark attester is used, it

should be maintained in effective working

order by the operator.

In the state of California the above is

required by law (Section 4442 of the

California Public Resources Code). Other

states may have similar laws. Federal

laws apply on federal lands. A spark

arrester for the muffler is available through

your nearest Sears Authorized Service

Center (See REPAIR PARTS section of

this manual).

CONGRATULATIONS on your purchase

of a Craftsman Tractor. It has been

designed, engineered and manufactured

to give you the best possible dependability

and performance.

Should you experience any problem you

cannot easily remedy, please contact your

nearest Sears Authorized Service Center.

We have competent, weIFtrained techni-

cians and the proper tools to service or

repair this tractor.

Please read and retain this manual. The

instructions will enable you to assemble

and maintain your tractor properly. Always

observe the "SAFETY RULES".

5

Page 6

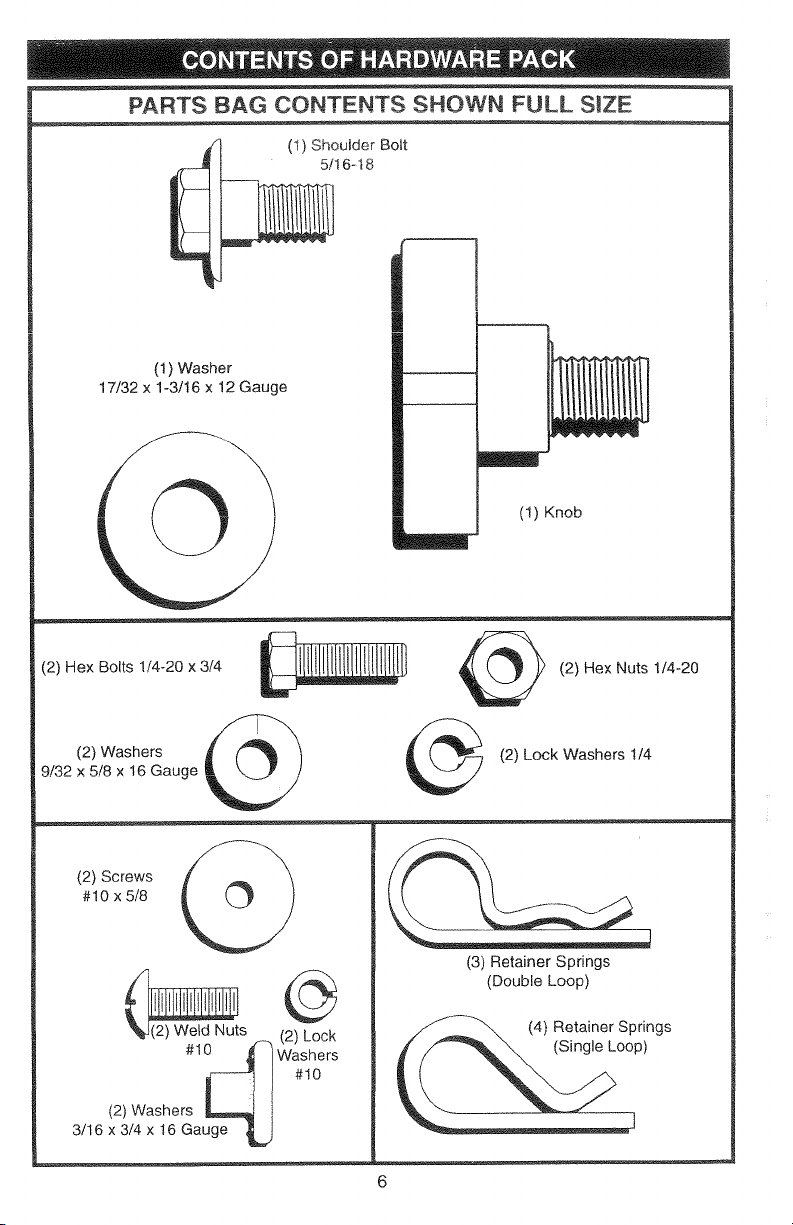

PARTS BAG CONTENTS SHOWN FULL SIZE

(1) ShouJder Bolt

5/16-18

(1) Washer

17/32 x 1-3/16 x 12 Gauge

(!) Knob

(2) Hex Bolts 1/4-20 x 3/4

9/32 x B/8 x 16 Gauge

(2) Washers

(2) Screws

#10 x 5/8

_s (2) Locq

#1_ Washers#10

(2) Washers _ I

3/16 x 3/4 x16 Gauge _ j

(2) Hex Nuts 1/4-20

(2) Lock Washers 1/4

(3) Retainer Springs

(Double Loop)

Page 7

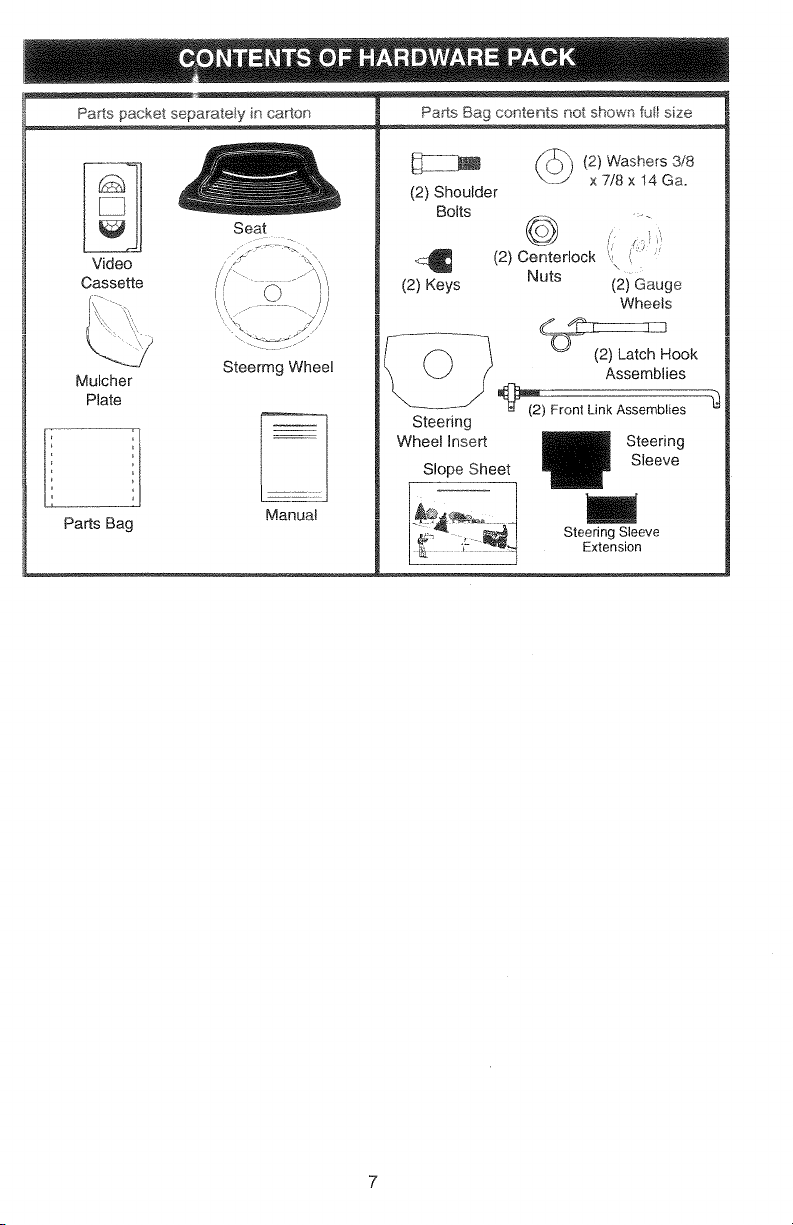

PartspacketseparateIyncarton

Seat

Video

Cassette

i

Parts Bag contents not shown fut! size

(2} Washers 3/8

(2) Shoulder

Bolts

x 7/8 x 14 Ga.

/21coo,er,ock

(2) Keys (2) Gauge

Nuts

Wheels

Mulcher

Plate

PartsBag

SteermgWheel

Manual

L? /(_ _ (2) Latch Hook

_,_nt LinkAssemblies

Steering

Wheel Insert

Slope Sheet

Assemblies

Steering

Sleeve

m

Steering Sleeve

Extension

7

Page 8

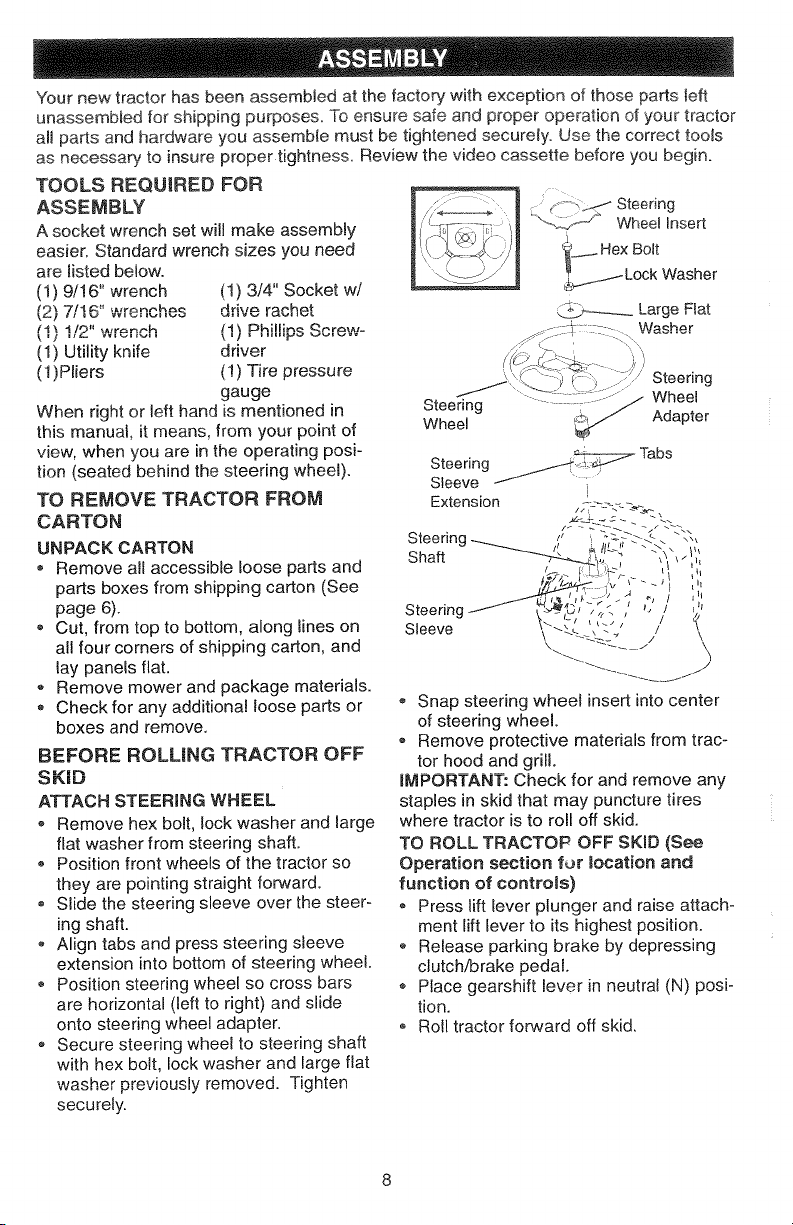

Yournewtractorhasbeenassembledatthefactorywithexception of those parts left

unassembled for shipping purposes. To ensure safe and proper operation of your tractor

all parts and hardware you assemMe must be tightened securely. Use the correct tools

as necessary to insure proper tightness Review the video cassette before you begin.

TOOLS REQUIRED FOR

ASSEMBLY

A socketwrench set will make assembly

easier, Standardwrench sizes you need

are listed below.

(1) 9/16" wrench (1) 3/4" Socket wi

(2) 7/16" wrenches drive rachet

(!) !/2" wrench (!) Phillips Screw °

(1) Utility knife driver

(t)Pliers (1) Tire pressure

gauge

When right or left hand is mentioned in

this manual, it means, from your point of

view, when you are in the operating posi-

tion (seated behind the steering wheel).

TO REMOVE TRACTOR FROM

CARTON

UNPACK CARTON

Remove all accessible loose parts and

parts boxes from shipping carton (See

page 6).

Cut, from top to bottom, along lines on

all four corners of shipping carton, and

lay panels flat.

Remove mower and package materials.

Check for any additiona! loose parts or

boxes and remove.

BEFORE ROLLING TRACTOR OFF

SKiD

ATTACH STEERING WHEEL

® Remove hex bolt, lock washer and large

flat washer from steering shaft.

o Position front wheels of the tractor so

they are pointing straight forward.

o Slide the steering sleeve over the steer-

ing shaft.

- Align tabs and press steering sleeve

extension into bottom of steering wheel.

Position steering wheel so cross bars

are horizontal (left to right) and slide

onto steering wheel adapter.

o Secure steering wheel to steering shaft

with hex bolt, lock washer and large fiat

washer previously removed. Tighten

securely.

Steerinc

Sleeve

• Snap steering wheel insert into center

of steering wheel.

Remove protective materials from trac-

tor hood and grill.

iMPORTANT: Check for and remove any

staples in skid that may puncture tires

where tractor is to roll off skid.

TO ROLL TRACTOP OFF SKID (See

Operation section for _ocation and

function of controls)

® Press lift lever plunger and raise attach°

ment lift lever to its highest position.

Release parking brake by depressing

clutch/brake pedal.

o Place gearshift lever in neutral (N) posi-

tion.

o Roll tractor forward off skid.

Page 9

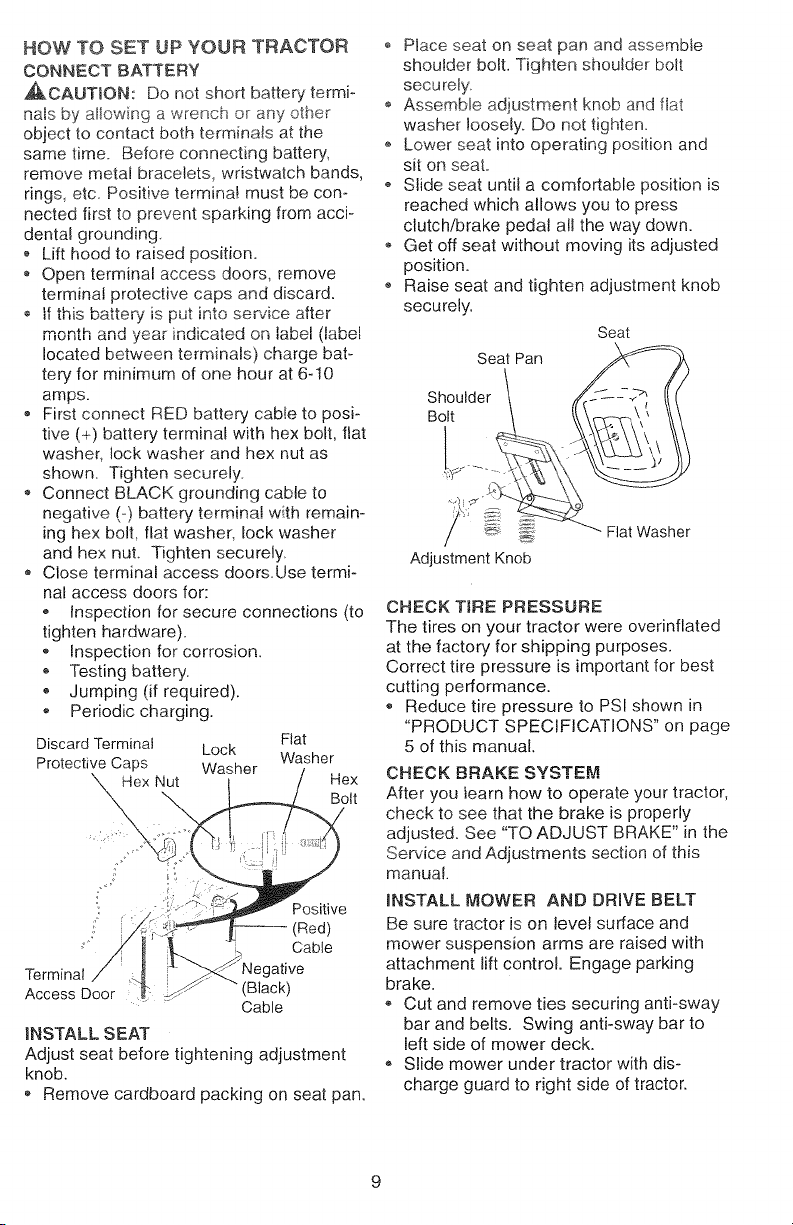

HOWTOSETUPYOURTRACTOR

CONNECTBAKERY

,_CAUTION: Do not short battery termi-

nais by aliowing a wrench or any other

object to contact both terminals at the

same time. Before connecting battery,

remove metal bracelets, wristwatch bands,

rings_ etc. Positive terminal must be con-

nected first to prevent sparking from accio

dental grounding.

,, Lift hood to raised position.

o Open terminal access doors, remove

terminal protective caps and discard.

ti¢ _, ,

,, ,h_s battery' is put into service after

month _,,_'4,uyear _<,4_ _ .4 _h_/_,_

located between terminals) charge _'-'

tery for minimum of one hour at 6-10

amps.

o First connect RED battery cabte to posi-

tive (+) battery terminal with hex bolt, flat

washer, lock washer and hex nut as

shown. Tighten securely.

,, Connect BLACK grounding cable to

negative (-) battery termina! with remain-

ing hex bolt, flat washer, lock washer

and hex nut. Tighten securely.

,, Close terminal access doors.Use termi-

nal access doors for:

, Inspection for secure connections (to

tighten hardware).

® Inspection for corrosion.

,, Testing battery.

o Jumping (if required).

Periodic charging.

DiscardTerminal

ProtectiveCaps

Lock

Washer / Hex

x Nut

,i' I i,

-- (Red)

Terminal _tive

Access Door / ...... (Black)

Cable

INSTALL SEAT

Adjust seat before tightening adjustment

knob.

Remove cardboard packing on seat pan.

LJ*:_L"

Flat

Washer

Bolt

Positive

Cable

• Place seat on seat pan and assemb!e

shoutder bolt. Tighten shoutder bolt

securely.

o Assemble adiustment knob and f!at

washer loosely. Do not tighten.

o Lower seat into operating position and

sit on seat.

o Slide seat until a comfortable position is

reached which allows you to press

clutch/brake pedal all the way down.

o Get off seat without moving its adjusted

position.

o Raise seat and tighten adjustment knob

securely.

Seat

Shoulder \

FlatWasher

Adjustment Knob

CHECK TIRE PRESSURE

The tires on your tractor were overinflated

at the factory for shipping purposes.

Correct tire pressure is important for best

cutting performance.

® Reduce tire pressure to PSI shown in

"PRODUCT SPECIFICATIONS" on page

5 of this manual.

CHECK BRAKE SYSTEM

After you team how to operate your tractor,

check to see that the brake is properly

adjusted. See "TO ADJUST BRAKE" in the

Service and Adjustments section of this

manual.

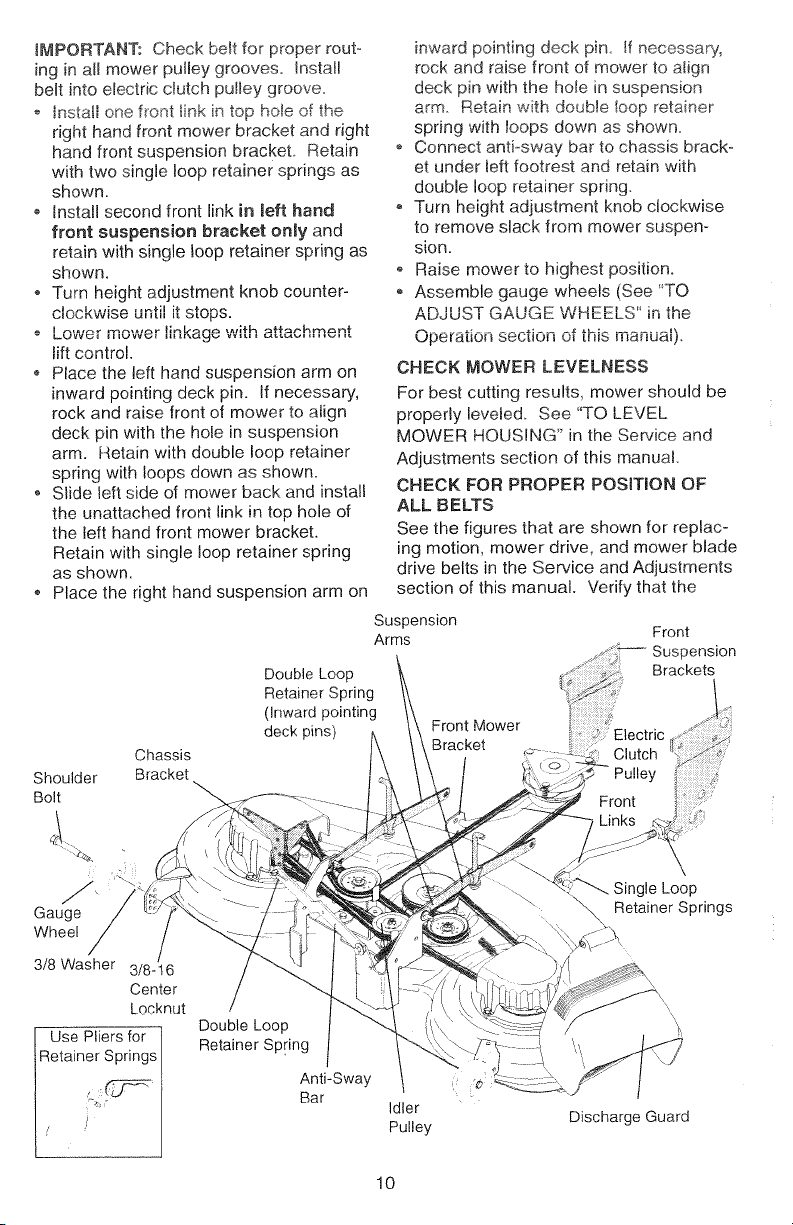

mNSTALL MOWER AND DRIVE BELT

Be sure tractor is on level surface and

mower suspension arms are raised with

attachment lift control. Engage parking

brake.

o Cut and remove ties securing anti-sway

bar and belts. Swing anti-sway bar to

left side of mower deck.

, Slide mower under tractor with dis-

charge guard to right side of tractor.

Page 10

iMPORTANT:Checkbeltforproperrout°

inginallmowerpulleygrooves.Install

beltintoelectricclutchpuileygroove.

oinstallonefrontlinkintopholeofthe

righthandfrontmowerbracketandright

handfrontsuspensionbracketRetain

withtwosingleloopretainerspringsas

shown.

installsecondfrontlinkin left hand

front suspension bracket only and

retain with single loop retainer spring as

shown.

o Turn height adjustment knob counter-

t,_,Jcr_vwo_ it

o _.......... we, linkage with attachment

lift control.

o Place the left hand suspension arm on

inward pointing deck pin. if necessary,

rock and raise front of mower to align

deck pin with the hole in suspension

arm. Retain with double loop retainer

spring with loops down as shown.

o Slide left side of mower back and install

the unattached front link in top hole of

the left hand front mower bracket.

Retain with single loop retainer spring

as shown.

,, Place the right hand suspension arm on

Shoulder

Bolt

ul iLii .:__v[M o.

Double Loop

Retainer Spring

(Inward pointing

deck pins)

Chassis

Bracket

inward pointing deck pin. If necessary,

rock and raise front of mower to atign

deck pin with the hole in suspension

arm. Retain with double Ioop retainer

spring with toops down as shown.

Connect anti-sway bar to chassis brack-

et under left footrest and retain with

double loop retainer spring.

Turn height adjustment knob clockwise

to remove slack from mower suspen-

sion.

Raise mower to highest position.

Assemble gauge wheels (See "TO

ADJUST GAUGE WHEELS" in the

Operation section of this manual).

CHECK MOWER LEVELNESS

For best cutting results, mower should be

properly leveled. See "TO LEVEL

MOWER HOUSING" in the Sen,ice and

Adjustments section of this manual

CHECK FOR PROPER POSITnON OF

ALL BELTS

See the figures that are shown for replac-

ing motion, mower drive, and mower blade

drive belts in the Service and Adjustments

section of this manual. Verify that the

Suspension

Arms Front

Brackets

Front Mower

Bracket

/

Clutch_'_

_

Gauge

Wheel

3/8 Washer 3/8-16

Center

Locknut

Use Pliers for

Retainer Springs

/ /

Double Loop

Retainer Spring

Anti-Sway

Bar

10

Idler

Pulley

\

igle Loop

_\ Retainer Springs

\\

\\

,i_ _,1 I

Discharge Guard

Page 11

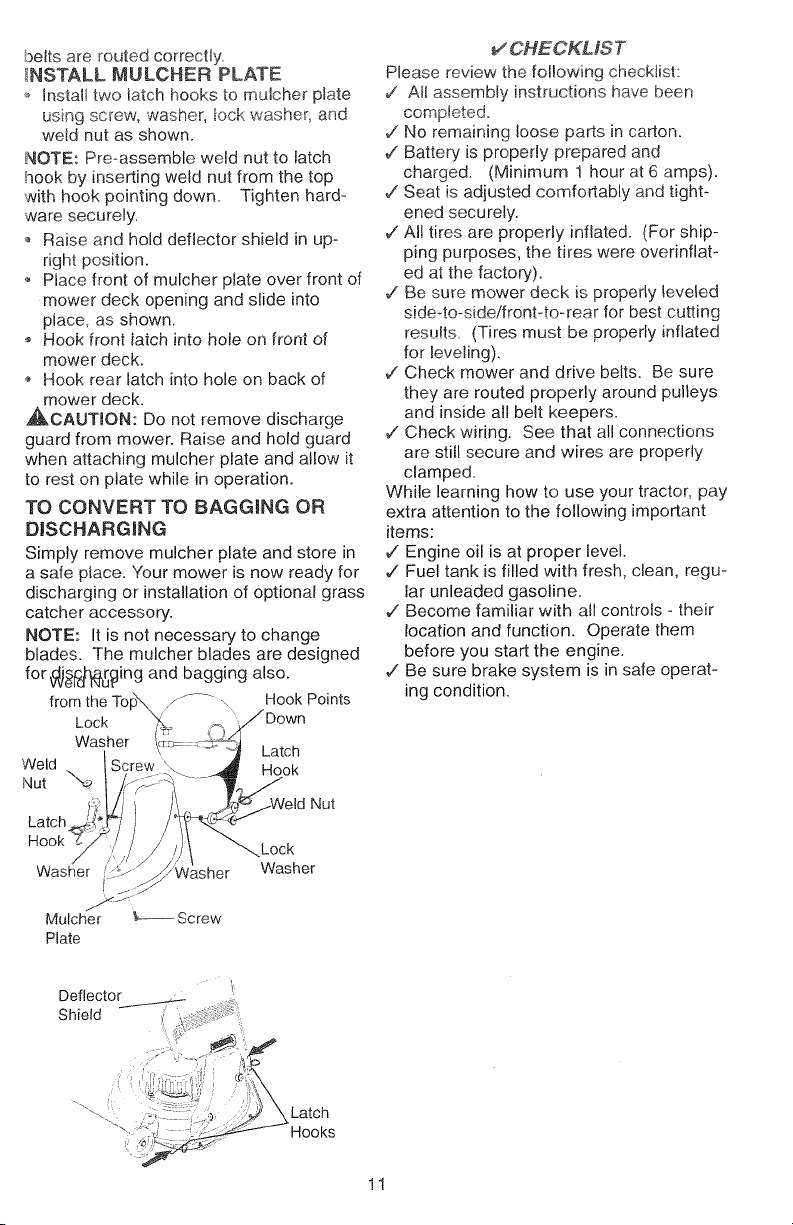

beltsareroutedcorrectly.

_NSTALLMULCHERPLATE

_,installtwolatchhookstomulcherplate

usingscrew,washer,_ockwasher,and

weldnutasshown.

NOTE:Pre-assembleweldnuttolatch

hookbyinsertingweldnutfromthetop

withhookpointingdown Tightenhard-

waresecurely.

oRaiseandholddeflectorshieldinup-

rightposition.

• Placefrontofmulcherplateoverfrontof

mowerdeckopeningandslideinto

place,asshown.

Hookfrontiatchintoholeonfrontof

mowerdeck.

Hookrearlatchintoholeonbackof

mowerdeck.

,_CAUTRON: Do not remove discharge

guard from mower. Raise and hold guard

when attaching mulcher plate and allow it

to rest on plate while in operation.

TO CONVERT TO BAGGING OR

DiSCHARGiNG

Simply remove mulcher plate and store in

a safe place. Your mower is now ready for

discharging or installation of optional grass

catcher accessory.

NOTE: It is not necessary to change

blades. The mulcher blades are designed

for_r_ing and bagging also.

from the Topx.. _--" \ Hook Points

Lock "_ _'. JDown

Washer ;........ _ Latch

Weld -.. ! Hook

Nut _ / _"

Latchji :)

IScrew\

" _..jWeld Nut

_CHECKMST

Please review the following checklist:

,/ All assembly instructions have been

completed.

7" No remaining loose parts in carton.

¢" Battery is properly prepared and

charged. (Minimum 1 hour at 6 amps).

,/Seat is adjusted comfortably and tight-

ened securely.

,/All tires are properly inflated. (For ship-

ping purposes, the tires were overinflat-

ed at the factory,).

,/Be sure mower deck is property leveled

side4o-side!front4o-rear for best cutting

results (Tires must be properly inflated

for leveling).

V Check mower and drive belts. Be sure

they are routed properly around pulleys

and inside all belt keepers.

,/Check wiring. See that all connections

are still secure and wires are properly

clamped.

While learning how to use your tractor, pay

extra attention to the following important

items:

,/Engine oil is at proper level.

,/Fuel tank is filled with fresh, clean, regu-

lar unleaded gasoline

,/Become familiar with all controls - their

location and function. Operate them

before you start the engine.

¢ Be sure brake system is in safe operat-

ing condition.

Hook_:/// /!Jt_/_asher_LOck

Washer i(':t; Washer

.....¢S

Mulcher _---Screw

Plate

Latch

Hooks

11

Page 12

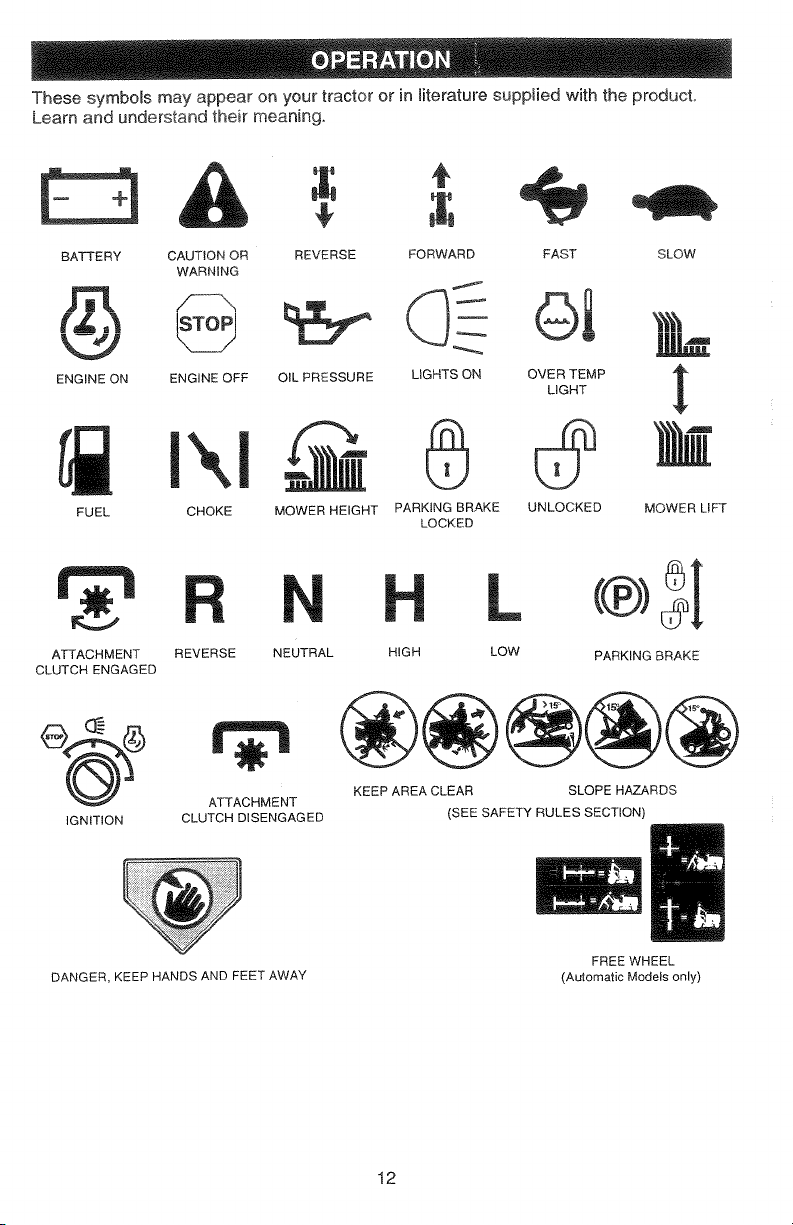

Thesesymbolsmayappearonyourtractororinliteraturesuppliedwiththeproduct

Learnandunderstandtheirmeaning.

BATTERY

ENGINE ON

FUEL

ATTACHMENT

CLUTCH ENGAGED

IGNITION

CAUTION OR REVERSE FORWARD

WARNING

ENGINE OFF OIL PRESSURE LIGHTS ON

l\l 0

CHOKE MOWER HEIGHT PARKING BRAKE

REVERSE NEUTRAL HIGH

ATTACHMENT

CLUTCH DISENGAGED

KEEP AREA CLEAR SLOPE HAZARDS

LOCKED

(SEE SAFETY RULES SECTION)

FAST

SLOW

&a

OVER TEMP

LIGHT

UNLOCKED

MOWER LIFT

L (®)_i

LOW PARKING BRAKE

DANGER, KEEP HANDS AND FEET AWAY

FREE WHEEL

(Automatic Models only)

12

Page 13

KNOWYOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

TRACTOR

Compare the iHustratior_s with your tractor to familiarize yourself with the locations of

various controls and adjustments. Save this manual for future reference.

Light Switch

Ignition

Switch

Ammeter

Throttle Control

J i_"_Lift Lever

Position

Attachment

CRutch Switch

Clutch/Brake

Pedal

Choke

Height

Adjustment

Knob

Our tractors co:qform to the safety standards of the American

National Standards Institute,

ATTACHMENT CLUTCH SWITCH: Used

to engage the mower blades, or other at-

tachments mounted to your tractor.

LIGHT SWITCH: Turns the headlights on

and off,

THROTTLE CONTROL: Used to control

engine speed.

CLUTCH/BRAKE PEDAL: Used for

declutching and braking the tractor and

starting the engine.

CHOKE CONTROL: Used when starting a

cold engine,

HEIGHT ADJUSTMENT KNOB: Used to

adjust the mower cutting height.

_ Ptunger

/ / Attachment

_/ Lift Lever

Parking Brake

GEARSHIFT LEVER: Selects the speed

and direction of the tractor.

RANGESHIFT LEVER: Allows high (H)

and low (L) speed for all forward and

reverse gears.

ATTACHMENT LIFT LEVER: Used to

raise and lower the mower deck or other

attachments mounted to your tractor.

LIFT LEVER PLUNGER: Used to release

attachment lift lever when changing its

position.

IGNITION SWITCH: Used for starting and

stopping the engine.

AMMETER: Indicates battery charging (+)

or discharging (-).

PARKING BRAKE: Locks clutch/brake

13

Page 14

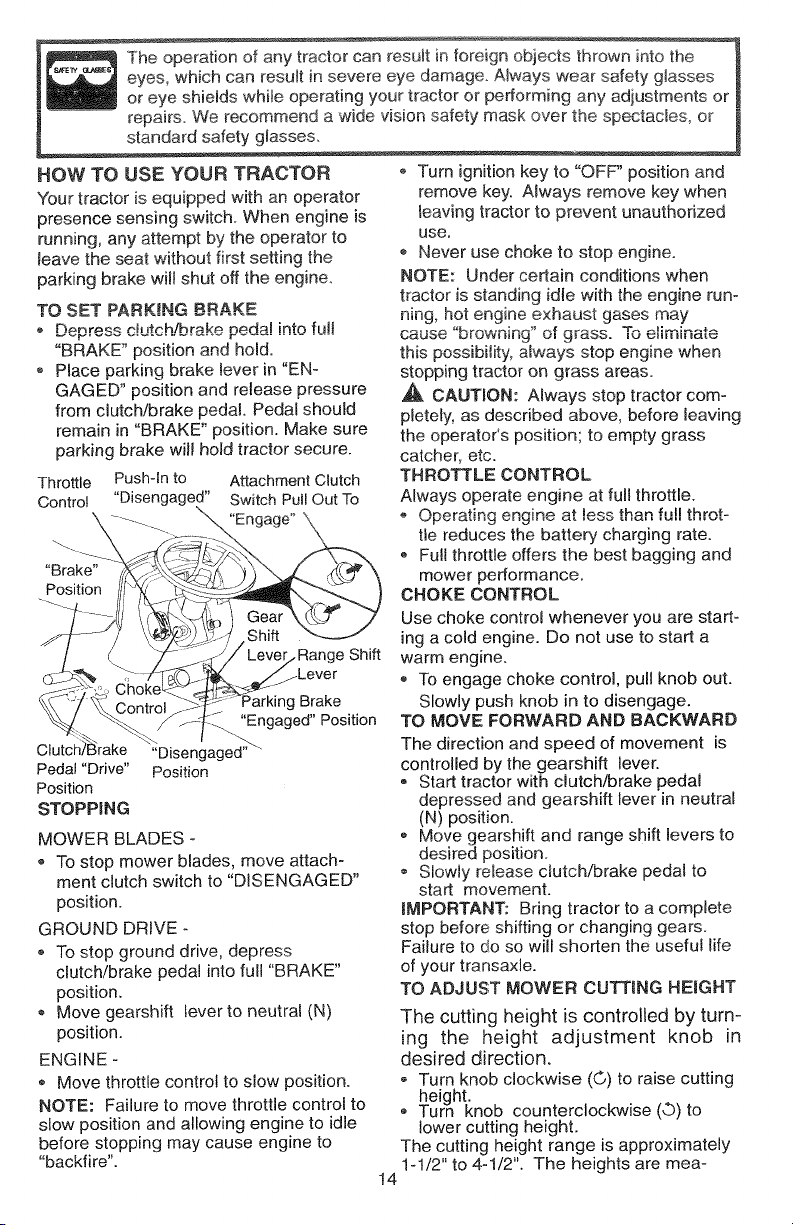

HOWTOUSEYOURTRACTOR

Yourtractorisequippedwithanoperator

presencesensingswitch_Whenengineis

running,anyattemptbytheoperatorto

_eavetheseatwithoutfirstsettingthe

parkingbrakewinshutofftheengine°

TOSETPARKINGBRAKE

,,Depressdutch!brakepeda!intofun

"BRAKE"positionandhold.

o Placeparkingbrakeleverin"EN-

GAGED"positionandreleasepressure

fromclutch/brakepedal.Pedalshould

remainin"BRAKE"position.Makesure

parkingbrakewil!holdtractorsecure.

Throttle Push-in to Attachment Clutch

Control "Disengaged" Switch Pull Out To

"Engage"

"Brake"

Position

.Lever

_gBrake

"Engaged"Position

C

Pedal "Drive"

Position

STOPPING

MOWER BLADES -

To stop mower blades, move attach-

ment clutch switch to "DISENGAGED"

position.

GROUND DRIVE -

To stop ground drive, depress

clutch/brake pedal into full "BRAKE"

position.

Move gearshift lever to neutral (N)

position.

ENGINE -

® Move throttle control to slow position.

NOTE: Failure to move throttle control to

slow position and allowing engine to idle

before stopping may cause engine to

"backfire".

"Disengaged'""

Position

Turn ignition key to "OFF" position and

remove key. Always remove key when

leaving tractor to prevent unauthorized

use.

Never use choke to stop engineo

NOTE: Under certain conditions when

tractor is standing idle with the engine run-

ning, hot engine exhaust gases may

cause "browning" of grass. "Toeliminate

this possibility, always stop engine when

stopping tractor on grass areas.

CAUTION: Always stop tractor com-

pletely, as described above, before leaving

the operator's position; to empty grass

catcher, etc.

THROTTLE CONTROL

Always operate engine at full throttle.

- Operating engine at !ess than full throt-

tle reduces the battery charging rate.

Full throttle offers the best bagging and

mower performance.

CHOKE CONTROL

Use choke control whenever you are start-

ing a cold engine. Do not use to start a

warm engine.

,, To engage choke control, pull knob out.

Slowly push knob in to disengage.

TO MOVE FORWARD AND BACKWARD

The direction and speed of movement is

controlled by the gearshift lever.

® Start tractor with clutch/brake pedal

depressed and gearshift lever in neutral

(N) position.

o Move gearshift and range shift levers to

desired position.

Slowly re_ease clutch/brake pedal to

start movement.

mMPORTANT: Bring tractor to a complete

stop before shifting or changing gears.

Failure to do so will shorten the useful life

of your transaxle.

TO ADJUST MOWER CUTTING HEIGHT

The cutting height is controlled by turn-

ing the height adjustment knob in

desired direction.

Turn knob clockwise (©) to raise cutting

height.

® Turn knob counterclockwise (O) to

lower cutting height.

The cutting height range is approximately

1-1/2" to 4ol/2 ". The heights are mea-

l4

Page 15

suredfromthegroundtothebtadetipwith

theenginenotrunning.Theseheightsare

approximateandmavarydepending

uponsoitconditions,_eightofgrassand

typesofgrassbeingmowed.

Theaveragelawnshouldbecutto

approxmate_y2-1/2inchesduringthe

coolseasonandtoover3inchesduring

hotmonths.Forhealthierandbetter

lookinglawns,mowoftenandafter

moderategrowth.

Forbestcuttingperformance,grass

over6inchesinheightshouldbe

mowedtwice°Makethefirstcutrela-

tive!yhigh;thesecondtodeskedheighL

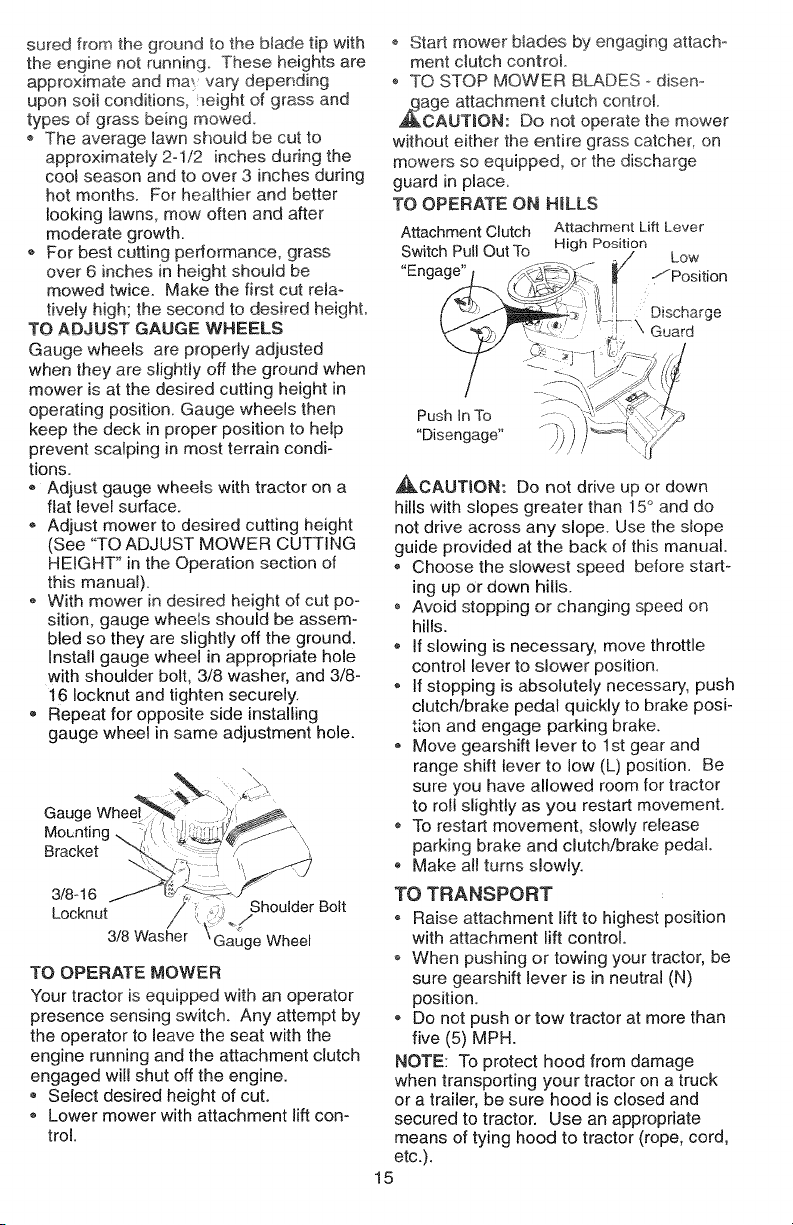

TO ADJUST GAUGE WHEELS

Gauge wheels are properly adjusted

when they are slightly off the ground when

mower is at the desired cutting height in

operating position. Gauge wheels then

keep the deck in proper position to help

prevent scalping in most terrain condi-

tions.

Adjust gauge wheels with tractor on a

ftat tevel surface.

Adjust mower to desired cutting height

(See "TO ADJUST MOWER CUTTING

HEIGHT" in the Operation section of

this manual).

• With mower in desired height of cut poo

sition, gauge wheels should be assem-

bled so they are slightly off the ground.

Install gauge wheel in appropriate hole

with shoulder bolt, 3/8 washer, and 3/8-

16 Iocknut and tighten securely.

® Repeat for opposite side installing

gauge wheel in same adjustment hole.

Gauge

Mounting

Bracket \

3/8- 16

Locknut ,,, ,_j

3/8 Washer \Gauge Wheel

TO OPERATE MOWER

Your tractor is equipped with an operator

presence sensing switch. Any attempt by

the operator to leave the seat with the

engine running and the attachment clutch

engaged will shut off the engine.

• Select desired height of cut.

o Lower mower with attachment lift con-

trol.

Shou der Bolt

Start mower blades by engaging attach°

ment clutch control.

o TO STOP MOWER BLADES disen.-

ge attachment ctutch contro_

AUTmON: Do not operate the mower

without either the entire grass catcher, on

mowers so equipped, or the discharge

guard in place.

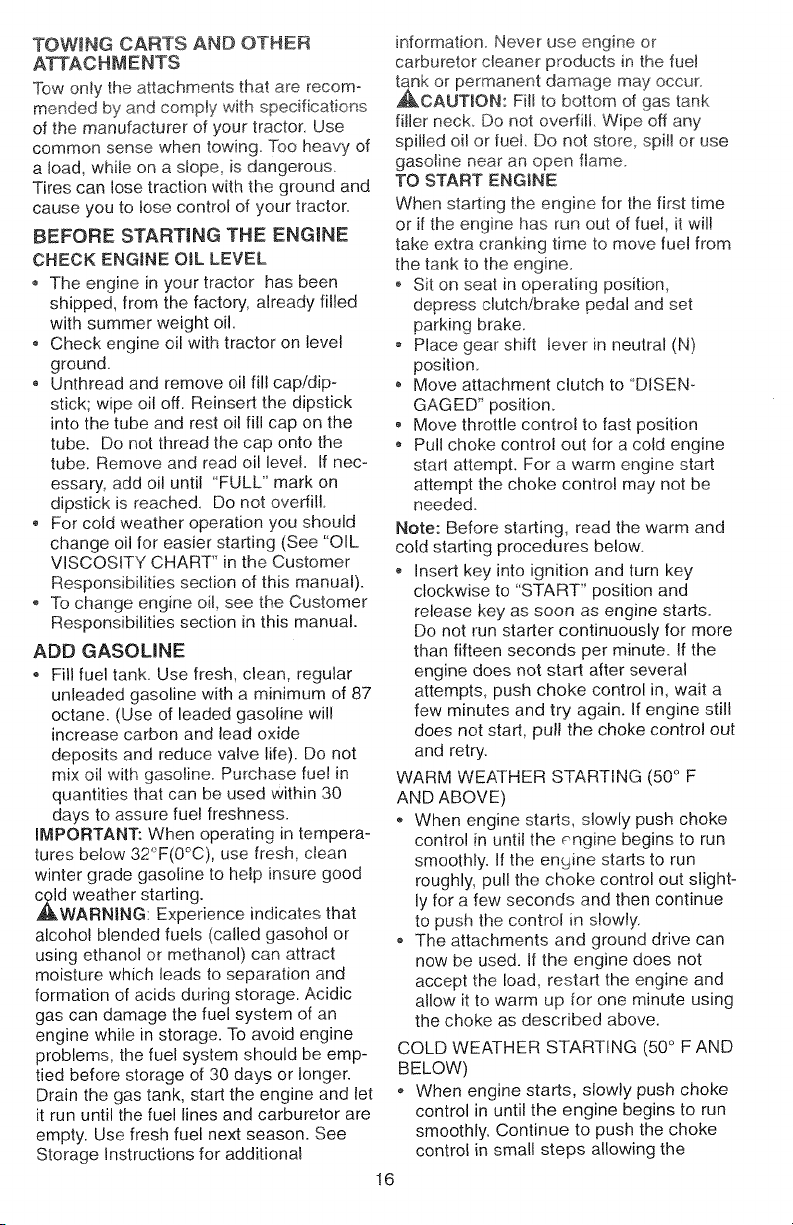

TO OPERATE ON H_LLS

Attachment Clutch Attachment Lift Lever

Switch Pull Out To High Position

"Engage" -/Position

Push InTo _/:

"Disengage" _)'))

,_CAUTION: Do not drive up or down

hills with slopes greater than 15° and do

not drive across any slope. Use the slope

guide provided at the back of this manual.

Choose the slowest speed before start-

ing up Ordown hills.

o Avoid stopping or changing speed on

hills.

If slowing is necessary, move throttle

control lever to slower position.

If stopping is absolutely necessary, push

clutch!brake pedal quickly to brake posi-

tion and engage parking brake.

* Move gearshift lever to 1st gear and

range shift lever to low (L) position. Be

sure you have allowed room for tractor

to roll slightly as you restart movement.

To restart movement, slowly release

parking brake and clutch/brake pedal.

* Make al! turns slowly.

TO TRANSPORT

- Raise attachment lift to highest position

with attachment lift control.

o When pushing or towing your tractor, be

sure gearshift lever is in neutral (N)

position.

° Do not push or tow tractor at more than

five (5) MPH.

NOTE: To protect hood from damage

when transporting your tractor on a truck

or a trailer, be sure hood is closed and

secured to tractor. Use an appropriate

means of tying hood to tractor (rope, cord,

etc.).

15

Low

Discharge

Guard

Page 16

TOWINGCARTSANDOTHER

A_ACHMENTS

Towonlytheattachmentsthatarerecom-

mendedbyandcomplywithspecifications

ofthemanufacturerofyourtractor.Use

commonsensewhentowingTooheavyof

aload,whileonastope,isdangerous

Tirescanlosetractionwiththegroundand

causeyoutolosecontrolofyourtractor

BEFORESTARTINGTHEENGINE

CHECKENGINEOILLEVEL

Theengineinyourtractorhasbeen

shipped,fromthefactory,alreadyfilled

withsummerweightoil.

Checkengineoilwithtractoronlevel

ground.

Unthreadandremoveoilfillcap/dip-

stick;wipeoiloff.Reinsertthedipstick

intothetubeandrestoilfillcaponthe

tube.Donotthreadthecapontothe

tube.Removeandreadoillevel.Ifnec-

essary,addoiluntil'FULL"markon

dipstickisreached.Donotovedi!l

Forcoldweatheroperationyoushould

changeoilforeasierstarting(See"OIL

VISCOSITYCHART"intheCustomer

Responsibilitiessectionofthismanua!).

oTochangeengineoil,seetheCustomer

Responsibilitiessectioninthismanual.

ADDGASOLINE

, Fillfueltank.Usefresh,clean,regular

unleadedgasolinewithaminimumof87

octane.(Useofleadedgasolinewill

increasecarbonandleadoxide

depositsandreducevalvelife).Donot

mixoilwithgasolinePurchasefue!in

quantitiesthatcanbeusedwithin30

daystoassurefuelfreshness.

IMPORTANT:Whenoperatingintempera-

turesbelow32'_F(0°C),usefresh,dean

wintergradegaso!inetohelpinsuregood

,_d weather starting.

WARNING: Experience indicates that

alcohol blended fuels (called gasohol or

using ethanol or methanol) can attract

moisture which leads to separation and

formation of acids during storage. Acidic

gas can damage the fuel system of an

engine while in storage. To avoid engine

problems, the fuel system should be emp-

tied before storage of 30 days or longer.

Drain the gas tank, start the engine and let

it run until the fuel lines and carburetor are

empty. Use fresh fuel next season. See

Storage Instructions for additional

16

information Never use engine or

carburetor cleaner products in the fuel

tank or permanent damage may occur.

,_CAUTRON: Fill to bottom of gas tank

filler neck. Do not overfill. Wipe off any

spilled oil or fuel. Do not store, spitl or use

gasoline near an open flame

TO START ENGINE

When start ng the engine for the first time

or if the engine has run out of fuel, it wil!

take extra cranking time to move fuel from

the tank to the engine.

o Sit on seat in operating position,

depress clutch/brake pedal and set

parking brake.

,, Place gear shift lever in neutral (N)

position.

o Move attachment clutch to "DISEN-

GAGED" position.

Move throttle control to fast position

,, Pull choke control out for a cold engine

start attempt. For a warm engine start

attempt the choke control may not be

needed.

Note: Before starting, read the warm and

cold starting procedures below.

Insert key into ignition and turn key

clockwise to "START" position and

release key as soon as engine starts.

Do not run starter continuously for more

than fifteen seconds per minute. If the

engine does not start after several

attempts, push choke control in, wait a

few minutes and try again. If engine still

does not start, pull the choke control out

and retry.

WARM WEATHER STARTING (500 F

AND ABOVE)

When engine starts, slowly push choke

control in until the engine begins to run

smoothly. If the enyine starts to run

roughly pull the choke control out slight-

ly for a few seconds and then continue

to push the control in slowly.

o The attachments and ground drive can

now be used. If the engine does not

accept the load, restart the engine and

allow it to warm up _orone minute using

the choke as described above.

COLD WEATHER STARTING (50° F AND

BELOW)

When engine starts, slowly push choke

control in until the engine begins to run

smoothly. Continue to push the choke

control in small steps allowing the

Page 17

enginetoacceptsmallchangesin

speedandload,unt_thechokecontrol

isfullyin.tftheengi_estartstorun

rougHy_pullthechokecontro!outslighto

lyforafewsecondsandthencontinue

topushthecontrolinslowly.Thismay

requireanenginewarmoupperiodfrom

severalsecondstoseveralminutes,

dependingonthetemperature.

Theattachmentscanbeuseddudng

theenginewarm-upperiodandmay

requirethechokecontrolbeputtedout

slightly.

NOTE:Ahighaltitude(above3000feet)

orincoldtemperatures(below32F)the

carburetorfuelmixturemayneedtobe

adjustedforbestengineperformance.

See"TO ADJUST CARBURETOR _ in the

Service and Adjustments section of this

manual

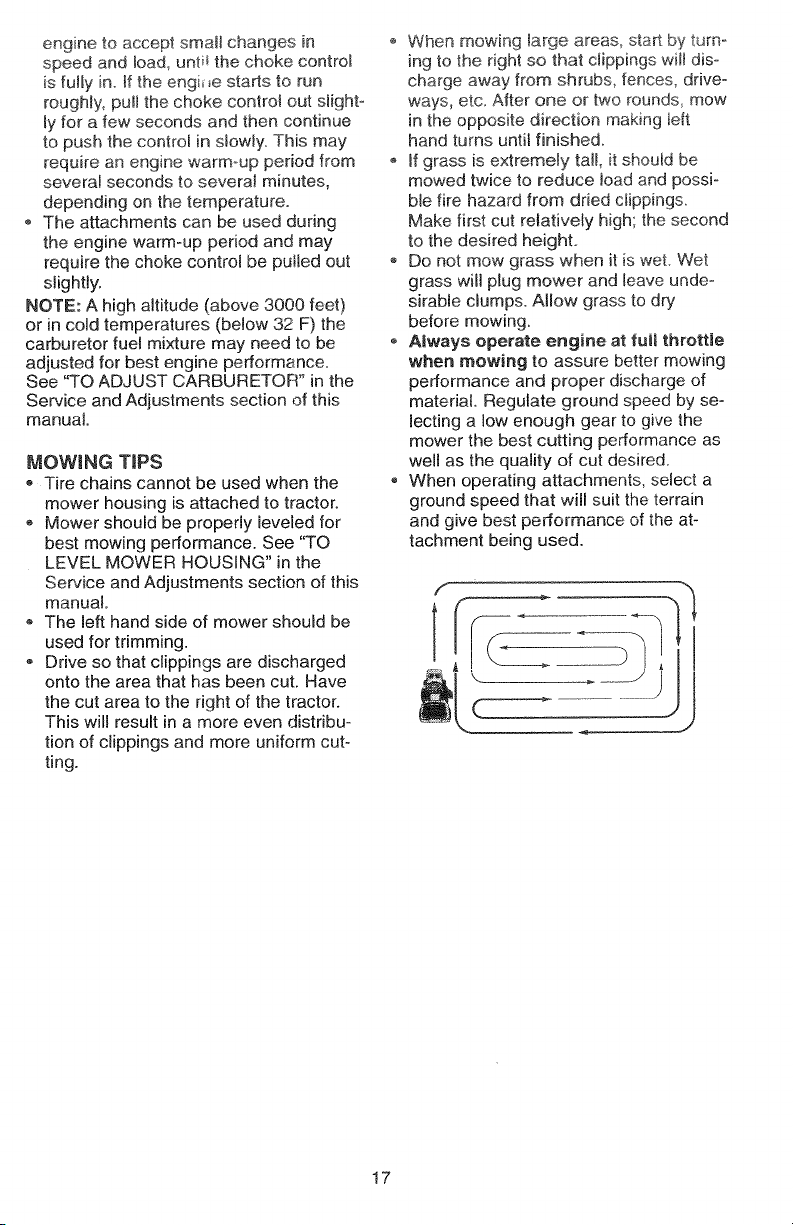

MOWING TiPS

o Tire chains cannot be used when the

mower housing is attached to tractor.

® Mower should be properly leveled for

best mowing performance. See "TO

LEVEL MOWER HOUSING" in the

Service and Adjustments section of this

manual.

The left hand side of mower should be

used for trimming.

- Drive so that clippings are discharged

onto the area that has been cut. Have

the cut area to the right of the tractor.

This will result in a more even distribu-

tion of clippings and more uniform cut-

ting.

o When mowing large areas_ sta_ by turn°

ing to the right so that clippings wilt dis-

charge away from shrubs, fences, drive-

ways, etc. After one or two rounds, mow

in the opposite direction making left

hand turns until finished.

o If grass is extremely tall, it should be

mowed twice to reduce load and possi-

ble fire hazard from dried clippings.

Make first cut relatively high; the second

to the desired height.

Do not mow grass when it is wet. Wet

grass will plug mower and leave unde-

sirable clumps. Allow grass to dry

before mowing.

® Always operate engine at _uii throttie

when mowing to assure better mowing

performance and proper discharge of

material. Regulate ground speed by se-

lecting a low enough gear to give the

mower the best cutting performance as

well as the quality of cut desired.

, When operating attachments, select a

ground speed that will suit the terrain

and give best performance of the at-

tachment being used.

f

7

lj

17

Page 18

MULCHINGMOWINGT_PS

8MPORTANT_Forbestperformance,keep

mowerhousingfreeofbuilt-upgrassand

trashC!eanaftereachuse_

Thespecialmulchingbladewil!recut

thegrassclippingsmanytimesand

reducetheminsizesothatastheyfall

ontothelawntheywilldisperseintothe

grassandnotbenoticed°Also,the

mulchedgrasswillbiodegradequickly

toprovidenutrientsforthelawn.Always

mulchwithyourhighestengine(blade)

speedasthiswillprovidethebestrecut-

tingactionoftheblades.

oAvoidcuttingyourlawnwhenitiswet.

Wetgrasstendstoformc_umpsand

interfereswiththemulchingaction.The

besttimetomowyourlawnistheearly

afternoon.Atthistimethegrasshas

driedandthenewlycutareawillnotbe

exposedtothedirectsun.

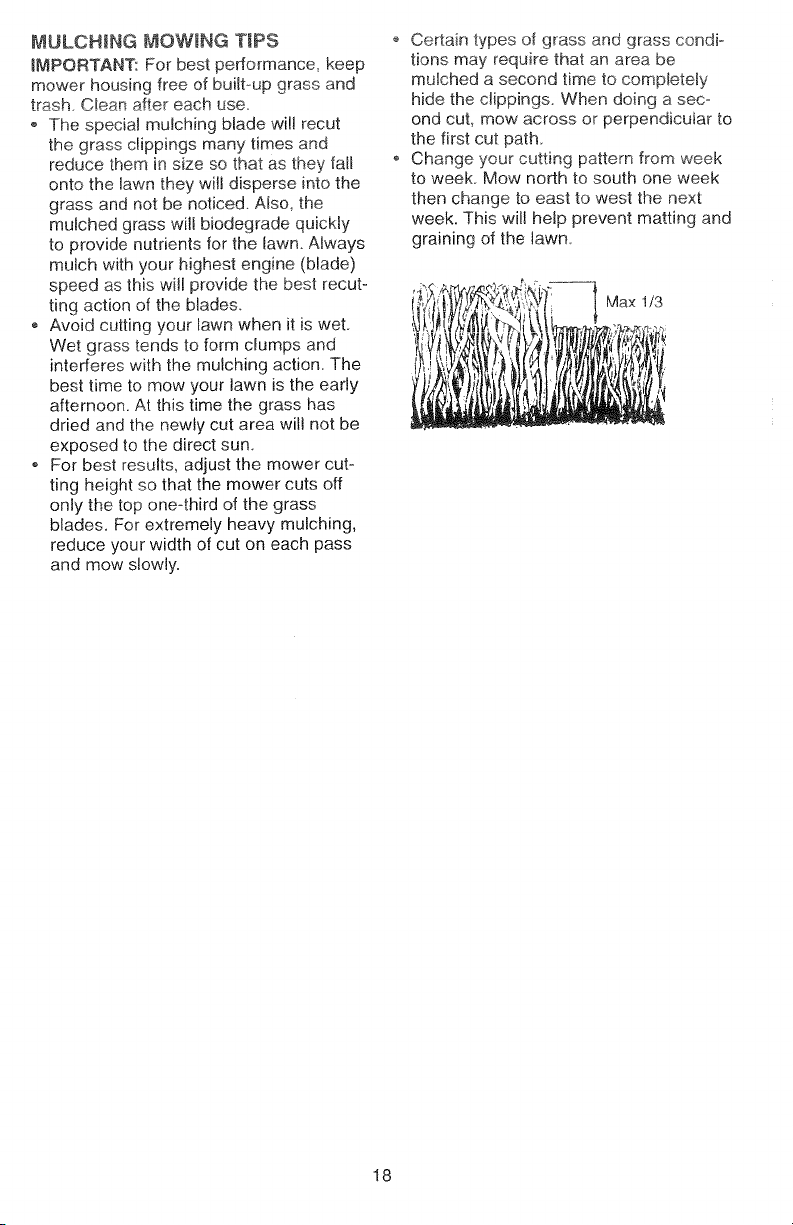

oForbestresults,adjustthemowercut-

tingheightsothatthemowercutsoff

onlythetoponeothirdofthegrass

blades.Forextremelyheavymulching,

reduceyourwidthofcutoneachpass

andmowslowly.

oCertaintypesofgrassandgrasscondi_

tionsmayrequirethatanareabe

mulchedasecondtimetocompletely

hidetheclippings.Whendoingaseco

ondcut,mowacrossorperpendicularto

thefirstcutpath.

oChangeyourcuttingpatternfromweek

toweek.Mownorthtosouthoneweek

thenchangetoeasttowestthenext

week.Thiswillhelppreventmattingand

grainingofthelawn.

" 1 Max 1/3

18

Page 19

CUSTOMERRESPONSiBiLITiES

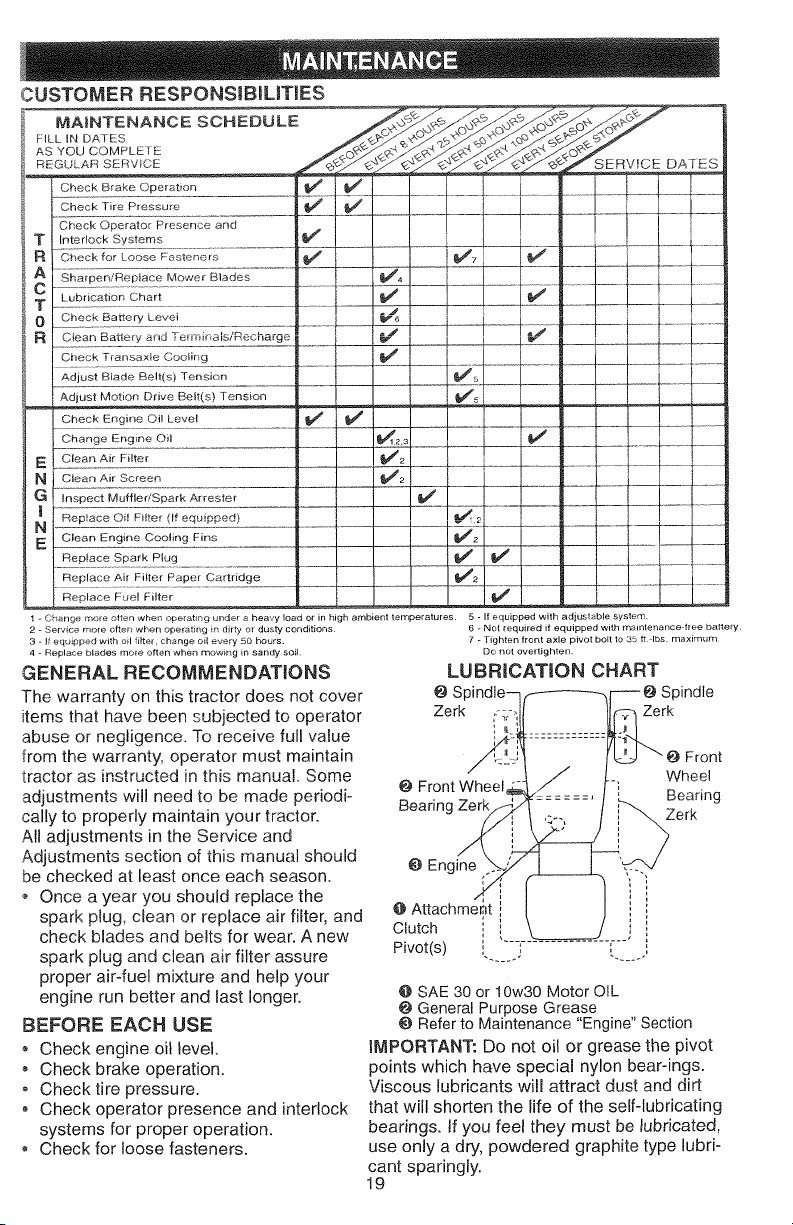

MAINTENANCE SCHEDULE

F_LL IN DATES

AS YOU COMPLETE

REGULARSERV/C__ E ....

Check Brake Operation

CheekOper,to+P_e............d ..,, , , ,,o., I I I ! I

Sh+pe , R+t°ceM.....Bides l

Check Battery Levei

M Ciean Ba_.ery and Te_ rdnals/Recharge

Check Trarlsax_2 Co?tin2 ...........

Adjust Blade Belt(s) Tension

Adjust Motion Drive Belt(s) Tension

Check Engine Oil Level

Change Engine Oil

NE Clean Air Filter

Clean Air Screen

G Enspect Muffler/Spark Arrester

Reptace Oi! Fitter (If equipped)

N

E Clean Engine Cooling Fins

R.eplace spar _ Plug ............................

.......F-- ++ __ __

-2-7

_,,/a

______v_!

+q+--i--P.........!........

..... e

Replace Fuel Filter

+Change t'r_o+eotlen when _%_erat nO under a heavy load or in high ambient temperatures 5 - If equipped with adjustable system

+ Service mo+e often when operat ng in drty or dusty conditions.

+ if eq_+_pped with e_l filter, change o_1 every 50 hours.

+ Repl_*ce blades mo_e often when rrvow ng in sandy soil

GENERAL RECOMMENDATIONS

The warranty on this tractor does not cover

items that have been subjected to operator

6 + Not required if equipped with maintenance ftee battery

7 - Tighten front axle pivot bolt to 35 II +lbs maximum

Do not overtighten.

LUBRICATION CHART

@ S Spindle

Zerk r-:__ Zerk

abuse or negligence. To receive full value

from the warranty, operator must maintain

tractor as instructed in this manual. Some

adjustments will need to be made periodi-

cally to properly maintain your tractor.

@ Front Wheel

Bearing Zerk

All adjustments in the Service and

Adjustments section of this manual should

be checked at least once each season.

+ Once a year you should replace the

spark plug, clean or replace air filter, and

check blades and belts for wear. A new

spark plug and clean air filter assure

proper air-fuel mixture and help your

engine run better and last longer.

BEFORE EACH USE

, Check engine oil level.

, Check brake operation.

Check tire pressure.

, Check operator presence and interlock

systems for proper operation.

, Check for loose fasteners.

O Engine

@Attachment

Clutch

Pivot(s) ',

@SAE 30 or 10w30 Motor OIL

General Purpose Grease

Referto Maintenance "Engine"Section

IMPORTANT: Do not oil or grease the pivot

points which have special nylon bear-ings.

Viscous lubricants will attract dust and dirt

that will shorten the life of the self-lubricating

bearings. If you feel they must be lubricated,

use only a dry, powdered graphite type lubri-

cant sparingly.

19

Front

Wheel

Bearing

Page 20

TRACTOR

Alwaysobservesafetyruleswhenper-

forminganymaintenance.

BRAKEOPERATION

Iftractorrequiresmorethansix(6)feet

stoppingdistanceathighspeedinhighest

gear,thenbrakemustbeadjusted.(See

'%0ADJUSTBRAKFintheServiceand

Adjustmentssectionofthismanual).

TIRES

Maintainproperairpressureinalltires

(See"PRODUCTSPECIFICATIONS"

onpage5ofthismanual).

o,.,_p_,es,,_ of or insect::jaSO_h _, u_h

control chemicals which can harm rub-

ber

,, Avoid stumps, stones, deep ruts, sharp

objects and other hazards that may

cause tire damage.

NOTE: To seal tire punctures and prevent

flat tires due to slow leaks, tire sealant

may be purchased from your local parts

dealer Tire sealant a!so prevents tire dry

rot and corrosion.

BLADE CARE

For best results mower blades must be

kept sharp. Replace bent or damaged

blades.

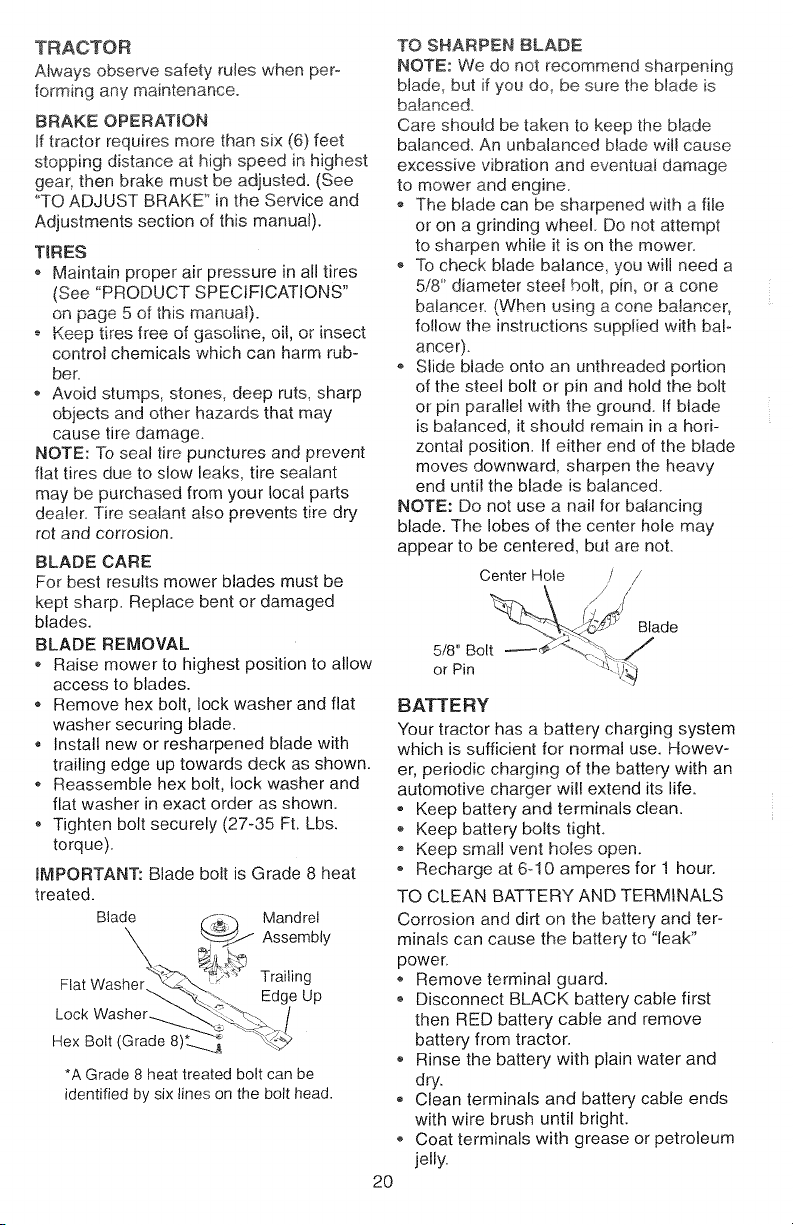

BLADE REMOVAL

Raise mower to highest position to allow

access to blades.

Remove hex bolt, lock washer and flat

washer securing blade.

, Instait new or resharpened blade with

trailing edge up towards deck as shown.

o Reassemble hex bolt, lock washer and

flat washer in exact order as shown.

,, Tighten bolt securely (27-35 Ft. Lbs.

torque).

IMPORTANT: Blade bolt is Grade 8 heat

treated.

Blade _ Mandrel

FlatWasher

Lock

Hex Bolt (Grade 8)t._&

*AGrade 8heat treated boltcan be

identified by six lines on the bolt head.

_;_ Trailing

Assembly

Edge Up

TO SHARPEN BLADE

NOTE: We do not recommend sharpening

blade, but if you do, be sure the blade is

batanced

Care should be taken to keep the blade

balanced. An unbalanced blade will cause

excessive vibration and eventual damage

to mower and engine.

_, The blade can be sharpened with a rite

or on a grinding wheel Do not attempt

to sharpen while it is on the mower.

o TOcheck blade balance, you will need a

5/8 _'diameter steel holt, pin, or a cone

ba!ancer_ (When using a cone ba!ancer,

follow the instructions supp!ied with ba!-

ancer)_

_, Slide blade onto an unthreaded portion

of the steel bolt or pin and hold the bolt

or pin parallel with the ground. If blade

is balanced, it should remain in a hori-

zontal position. If either end of the blade

moves downward, sharpen the heavy

end until the blade is balanced.

NOTE: Do not use a nail for balancing

blade. The lobes of the center hole may

appear to be centered, but are not.

Center Hole j

Blade

5/8" Bolt

or Pin

BATTERY

Your tractor has a battery charging system

which is sufficient for normal use. Howev-

er, periodic charging of the battery, with an

automotive charger will extend its life.

® Keep batter/and terminals clean.

,, Keep battery bolts tight°

o Keep small vent holes open.

, Recharge at 6-10 amperes for 1 hour.

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and tero

minds can cause the battery to "leak"

power.

o Remove terminal guard.

o Disconnect BLACK battery cable first

then RED battery cable and remove

battery from tractor.

o Rinse the battery with plain water and

dry.

o Clean terminals and battery cable ends

with wire brush until bright.

Coat terminals with grease or petroleum

jelly.

2O

Page 21

,_Reinstallbattery(See"CONNECTBAT°

TERY" in the Assembly section of this

manual).

_foBELTS

Check V-heRs for deterioration and wear

after 100 hours of operation and reptace if

necessary. The belts are not adjustable.

Replace belts if they begin to slip from

wear.

TRANSA×LE COOLING

Keep transaxie free from build-up of dirt

and chaff which can restrict cooling.

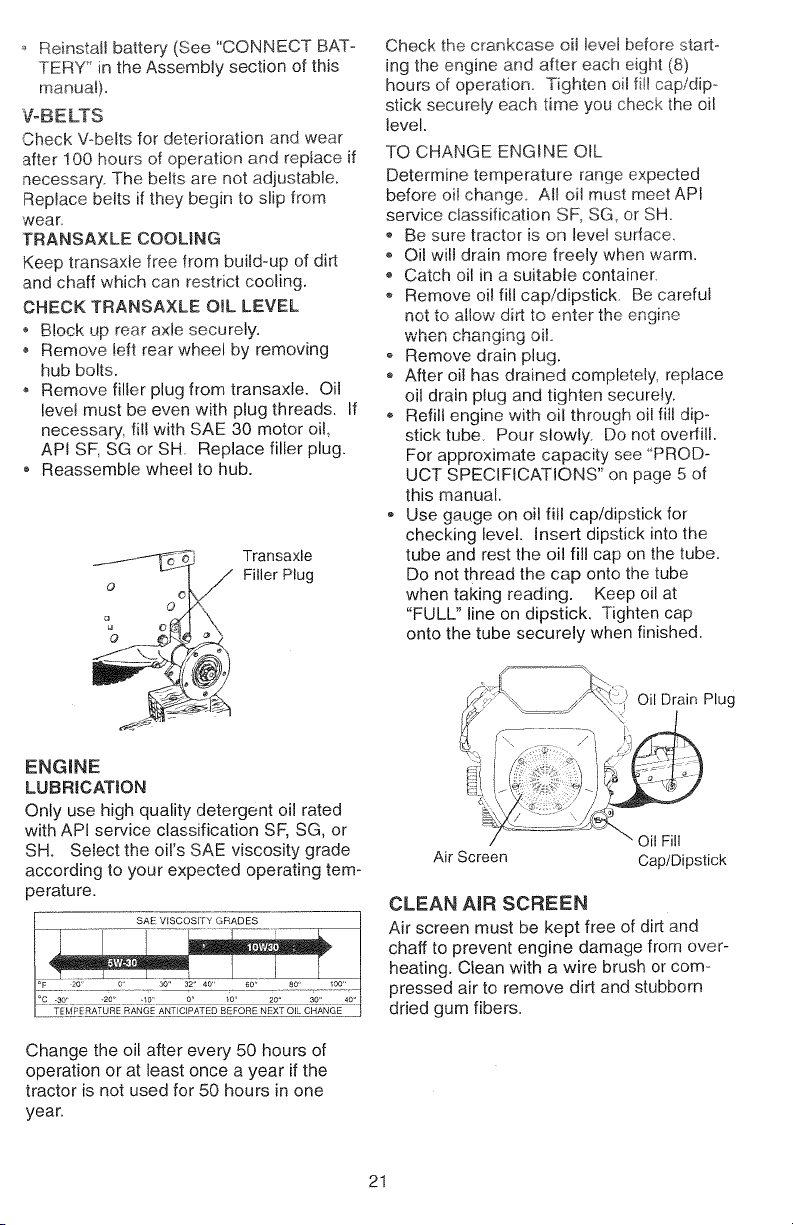

CHECK TRANSAXLE OIL LEVEL

Block up rear axle securely.

', Remove left rear wheel by removing

hub bolts.

o Remove filler plug from transaxle. Oil

level must be even with plug threads. If

necessary, fill with SAE 30 motor oil,

API SF, SG or SH. Replace filler plug.

o Reassemble wheel to hub.

Transaxle

O

O

Check the crankcase oil level before start-

ing the engine and after each eight (8)

hours of operation.. Tighten oil fi!l cap/dip-

stick securely each time you check the oil

level.

TO CHANGE ENGINE OIL

Determine temperature range expected

before oi! change All oil must meet API

service classification SE SG, or SH

o Be sure tractor is on level surface

o Oil will drain more freely when warm.

,, Catch oil in a suitable container.

® Remove oil fill cap/dipstick Be careful

_ut to a,,uv-,dirt to enter the engine

when _'_'_

o Remove drain plug.

o After oil has drained completely, replace

oil drain plug and tighten securely.

,, Refill engine with oil through oil fill dip-

stick tube. Pour slowly. Do not ovedill.

For approximate capacity see 'PROD-

UCT SPECIFICATIONS" on page 5 of

this manual.

Use gauge on oil fill cap/dipstick for

checking level. Insert dipstick into the

tube and rest the oil fill cap on the tube.

Do not thread the cap onto the tube

when taking reading. Keep oil at

"FULL" line on dipstick. Tighten cap

onto the tube securely when finished.

i Filler Plug

ENGINE

LUBRICATION

Only use high quality detergent oi! rated

with API service classification SF, SG, or

SH. Select the oi!'s SAE viscosity grade

according to your expected operating tem-

perature.

SAE ViSCOSiTY GRADES

Change the oil after every 50 hours of

operation or at least once a year if the

tractor is not used for 50 hours in one

year.

Air Screen Cap/Dipstick

CLEAN AiR SCREEN

Air screen must be kept free of dirt and

chaff to prevent engine damage from over-

heating. Clean with a wire brush or com-

pressed air to remove dirt and stubborn

dried gum fibers.

21

Page 22

CLEANAiRINTAK_COOLINGAREAS

q_binsurepropercooling,makesurethe

grassscreen,coolingfins,andother

externalsurfacesoftheenginearekept

cleanatalltimes.

Every100hoursofoperation(moreoften

underextremelydusty,dirtycOnditions),

removetheblowerhousingandother

coolingshrouds.Cleanthecoolingfins

andexternalsurfacesasnecessary.Make

surethecoolingshroudsarereinstalled.

NOTE:Operatingtheenginewitha

blockedgrassscreen,dirtyorplugged

coolingfins,andorcoolingshroudsre-

movedwiltcauseenginedamagedueto

overheating.

AIRFILTER

Yourenginewillnotrunpropedyusinga

dirtyairfilter.Cleanthefoampre-cleaner

aftereven/25hoursofoperationorevery

season.Servicepapercartridgeevery

!00 hours of operation or ever':/season,

whichever occurs firsL

Service air cleaner more often under dusty

conditions.

,, Loosen knob and remove cover.

TO SERVICE PRE-CLEANER

Slide foam pre-cleaner off cartridge.

,, Wash it in liquid detergent and water.

,_ Squeeze it dry in a clean cloth. Allow it

to dry.

,, Saturate it in engine oil. Wrap it in

clean, absorbent cloth and squeeze to

remove excess oil.

TO SERVICE CARTRIDGE

Replace a dirty, bent, or damaged car-

tridge.

Cartridge

Foam

Pre-cleaner

Cartridge

Plate

Rubber

Seal

NOTE: Do not wash the paper cartridge

or use pressurized air, as this will damage

the cartridge..

o Remove nut and cartridge plate.

,, Reinstall the pre-cleaner (cleaned and

oiled) over the paper cartridge.

o Check rubber seat for damage and

proper position around stud. Replace if

necessary.

Reassemble air cleaner, cartridge ptate,

and nut.

o Reinstall air cleaner cover and secure

by tightening knob.

ENGLNE OIL F!LTER

Replace the engine oi! filter every season

or with ever,! second oi! change if the trac-

tor is used more than 100 hours in one

year

MUFFLER

Inspect and replace corroded muffler and

spark arrester (if equipped) as it could cre-

ate a fire hazard and/or damage.

SPARK PLUGS

Replace spark plugs at the beginning of

each mowing season or after every 100

hours of operation, whichever occurs first.

Spark plug type and gap setting are

shown in "PRODUCT SPECIFICATIONS"

on page 5 of this manual.

IN-LINE FUEL FILTER

The fue! filter should be replaced once

each season. If fuel filter becomes

clogged, obstructing fuel flow to carbure-

tor, replacement is required.

® With engine cool, remove filter and plug

fuel line sections.

,, Place new fuel filter in position in fuel

line with arrow pointing towards carbu-

retor.

o Be sure there are no fuel line leaks and

clamps are properly positioned.

22

Page 23

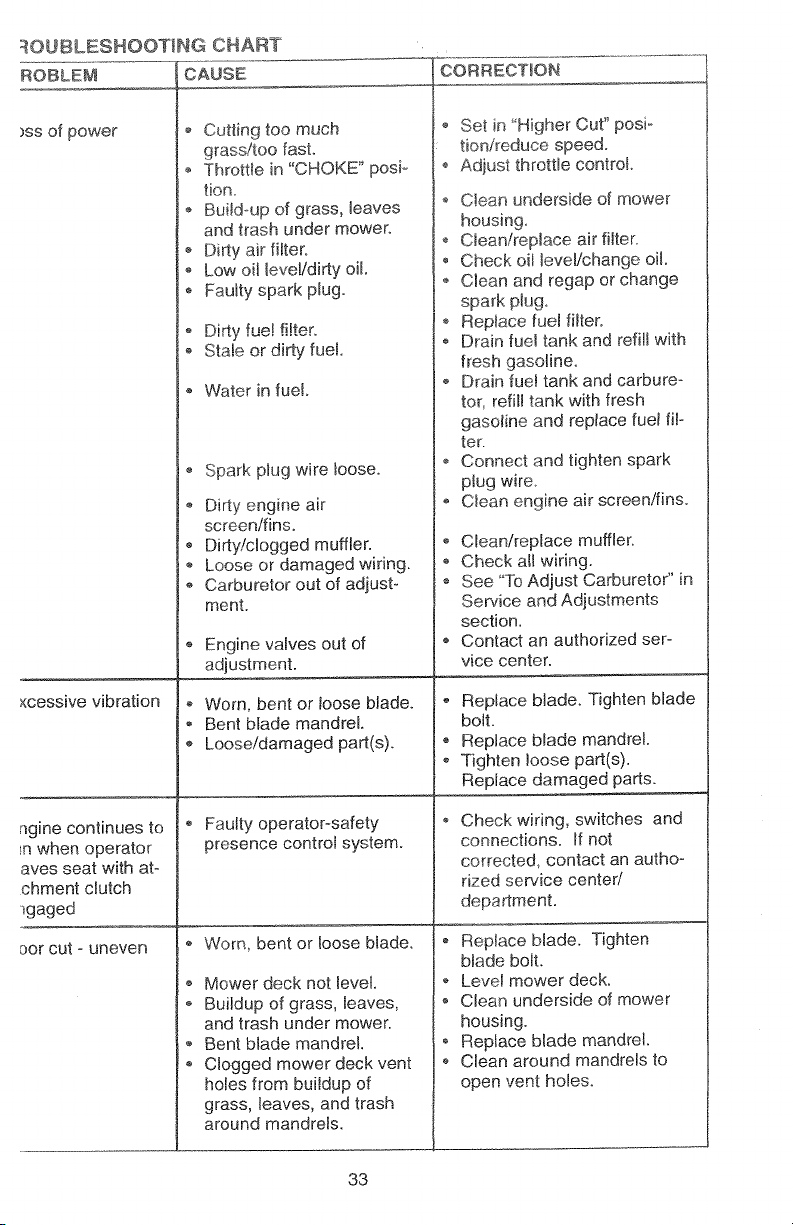

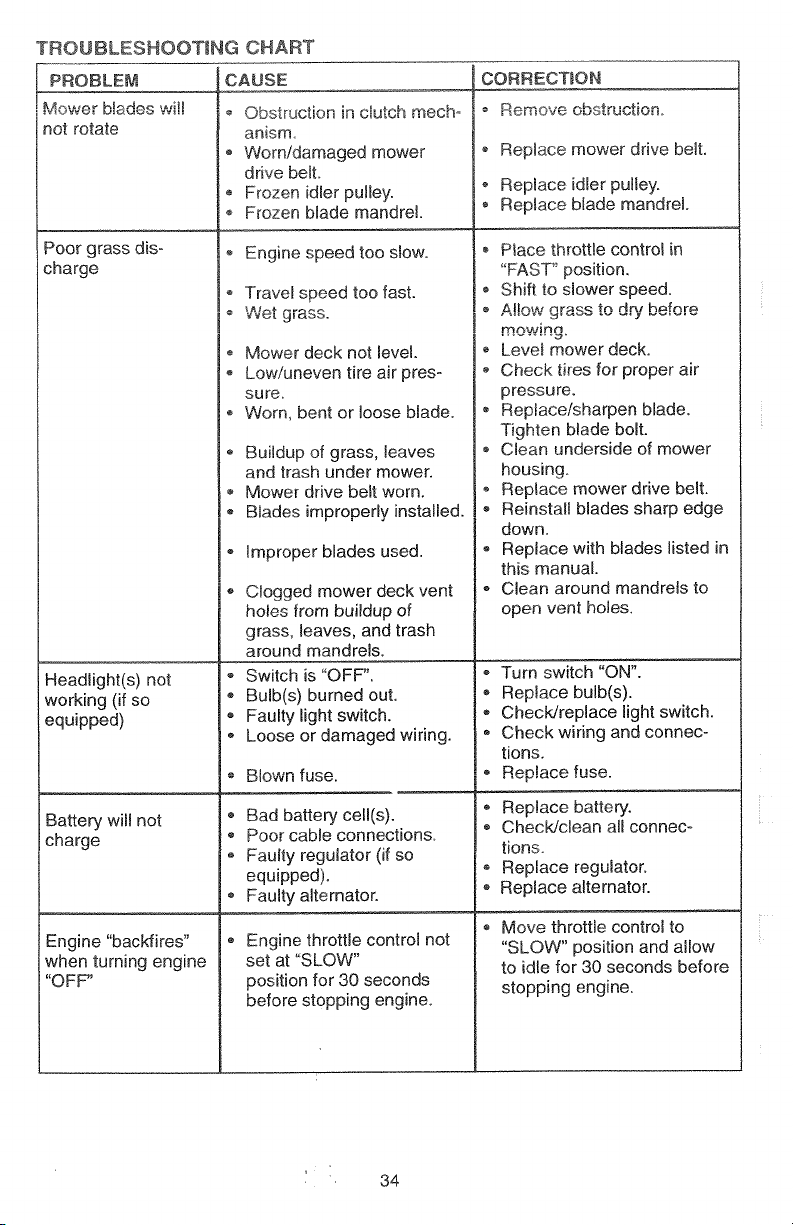

_,LEAN_N

Cleanengine,batteryseat,finish,etc.

ofallforeignmatter

Keepfinishedsu#acesandwheelsfree

ofallgasoline,oil,etc.

* Protectpaintedsurfaceswithautomo_

We do not recommend using a garden

hose to c_ean your tractor unless the elec-,

tricat system, muffler, air filter and carbure-

tor are covered to keep water ouL Water

in engine can resuit in a shortened engine

life.

tivetypewax.

A_,,CAUTION: Before performing any service or adjustments:

, Depress clutch/brake peda! fully and set parking brake.

- Place gearshift lever in neutral (N) position.

o Place attachment clutch in 'DISENGAGED" position.

-r_,,,_ignition key "OFF' and remove key.

,, Make sure the blades and a!! moving parts have completely stopped.

• Disconnect spark plug wire from spark plug and place wire where it cannot come

in contact with plug.

I

l

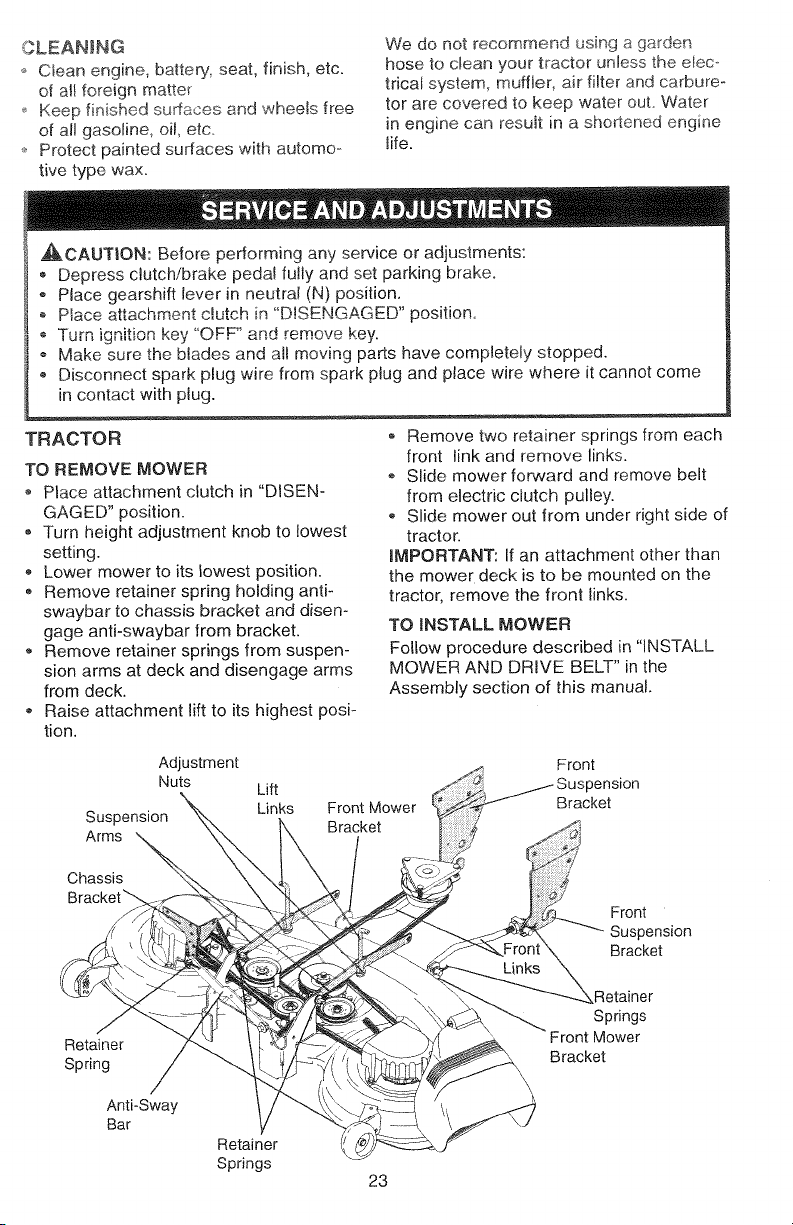

TRACTOR

TO REMOVE MOWER

Place attachment clutch in "DISEN-

GAGED" position.

, Turn height adjustment knob to lowest

setting.

,, Lower mower to its lowest position.

, Remove retainer spring holding anti-

swaybar to chassis bracket and disen-

gage anti-swaybar from bracket.

- Remove retainer springs from suspen-

sion arms at deck and disengage arms

from deck.

® Raise attachment lift to its highest posi-

tion.

Adjustment

Nuts

Suspension

Arms

Chassis

Bracket_

Retainer

Spring

/

Anti-Sway

Bar

Retainer

Springs

Lift

Links

Front Mower

Bracket

, Remove two retainer springs from each

front link and remove links.

,, Slide mower forward and remove belt

from electric clutch pulley.

,, Slide mower out from under right side of

tractor.

mMPORTANT: If an attachment other than

the mower deck is to be mounted on the

tractor, remove the front links.

TO iNSTALL MOWER

Follow procedure described in "INSTALL

MOWER AND DRIVE BELT" in the

Assembly section of this manual.

Front

)ension

Bracket

Front

Suspension

Bracket

_Retainer

Springs

Front Mower

Bracket

23

Page 24

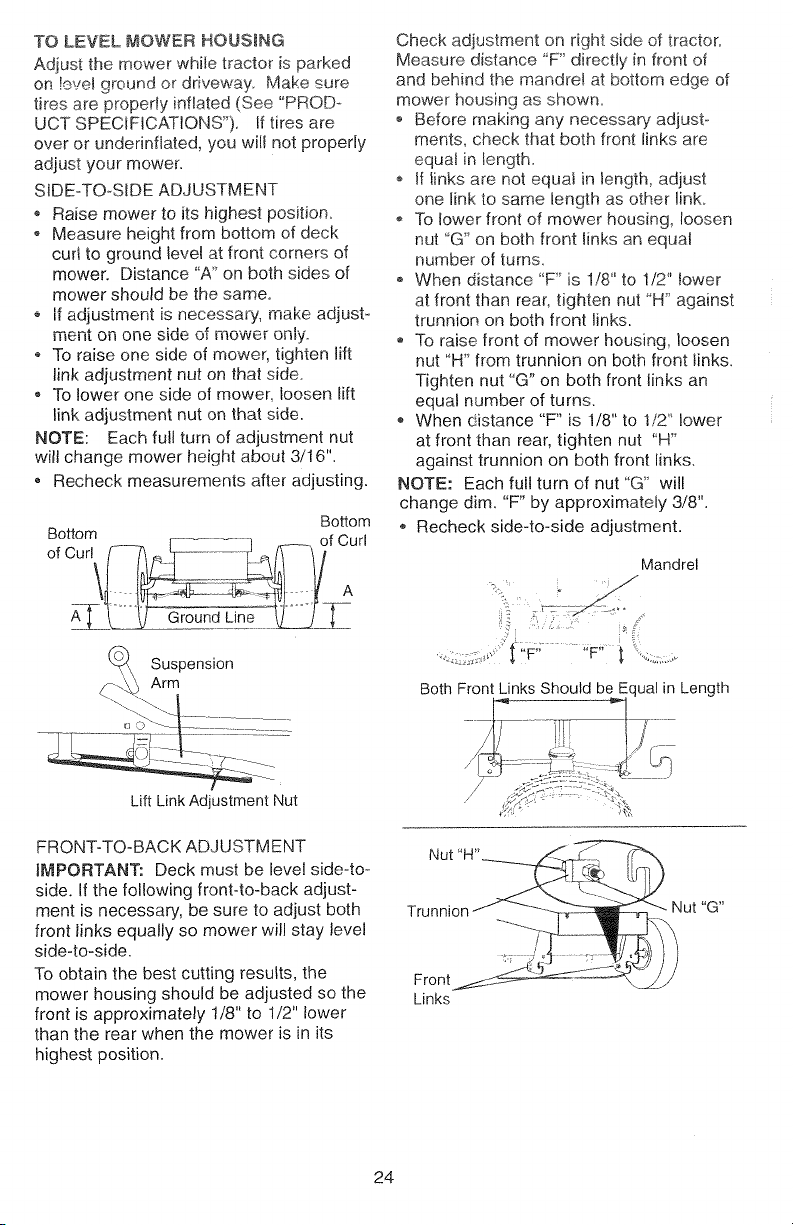

TO LEVEL MOWER HOUSING

Adjust the mower while tractor is parked

ors!e!e_ ground or driveway Make sure

tires are propedy inflated (See '*PROD_*

UCT SPECIFICATIONS'). If tires are

over or undennfiated, you will not properly

adjust your mower.

SIDE-TO-SIDE ADJUSTMENT

Raise mower to its highest position.

Measure height from bottom of dock

cud to ground level at front corners of

mower. Distance "A'_on both sides of

mower should be the same.

If adjustment is necessary, make adjust-

Itl_11L Ull OI1_ _lu_ u_ mower on .

.............. ly

To raise one side of mower, tighten lift

link adjustment nut on that side.

,, To lower one side of mower, loosen lift

link adjustment nut on that side.

NOTE: Each full turn of adjustment nut

will change mower height about 3/16".

o Recheck measurements after adjusting.

Bottom

oB°c°rT _-_ E_---._ n--- °fcurl

Check adjustment on right side of tractor.

Measure distance 'F' directty in front of

and behind the mandret at bottom edge of

mower housing as shown.

Before making any necessary adjust

merits, check that both front links are

equal in length_

o If links are not equal in length, adjust

one link to same length as other rink.

To lower front of mower housing, loosen

nut _G" on both front links an equal

number of turns.

When distance "F' is 1/8" to 1/2" tower

at front than rear, tighten nut *'H*'against

trunnion on both front links.

To raise front of mower housing, loosen

nut "H'* from trunnion on both front links.

Tighten nut "G" on both fronl links an

equal number of turns.

• When distance "F" is 1/8" to 1/2_lower

at front than rear, tighten nut 'H'

against trunnion on both front links.

NOTE: Each full turn of nut "G" will

change dim. "F" by approximately 3/8".

o Recheck side-to-side adjustment.

Mandrel

Suspension

Arm

Lift Link Adjustment Nut

FRONT-TO-BACK ADJUSTMENT

iMPORTANT: Deck must be level side-to-

side. If the following front-to-back adjust-

ment is necessary, be sure to adjust both

front links equally so mower will stay level

side-to-side.

To obtain the best cutting results, the

mower housing should be adjusted so the

front is approximately t/8" to 1/2" lower

than the rear when the mower is in its

highest position.

BothFront Links Should be Equal in Length

Front

Links

24

Page 25

TOREPLACEMOWERDRmVEBELT

MOWERDR_VEBELq-REMOVAL

ParktractoronalevelsudaceEngage

parkingbrake.

Removefourscrewsfromlefthand

mandrelcoverandremovecover..

o Rollbeltoverthetopoflefthandman°

dre_pulley.

o RemovebeltfromeJectdcclutchpulley.

o Removebeltfromidlerpulleys.

o RemoveanydirtorgrasscJippings

whichmayhaveaccumulatedaround

mandrelsandentireupperdecksur-

face.

oCheckprimaryidlerarmandtwoidlers

toseethattheyrotatefreely.

o Besurespringissecurelyhookedtopri-

maryidlerarmandboltinmowerhous-

ing.

MOWERDRWEBELTINSSALLAttO

oInstallbeltinbothidlers.Makesurebelt

isinbothbeltkeepersattheidlersas

shown.

,_ Install new belt onto electric clutch pul-

ley.

,, Roll belt into upper groove of left hand

mandre_ pulley.

o Carefully check belt routing making sure

belt is in the grooves correctly and

inside belt keepers.

o Reassemble _....t hand ,---'_'^'__, ,u,_, cover.

Left Hand Screws

Mandrel

Cover X_

,7

Left Hand

Mandrel

Primaqt

Idler Arm

Belt

Keepers

Idler

Pulleys

j-i_i Electric

Clutch

25

Page 26

TO REPLACE MOWER BLADE DRIVE

BELT

Park the tractor on leve_sufaceo Engage

parking brake.

Remove mower drive be_t (See "TO

REPLACE MOWER DR_VE BELT" in

this section of this manual).

Remove mower (See "TO REMOVE

MOWER" in this section of this manual}.

* Remove screws from right hand man-

drel cover and remove cover. Unhook

spring from bolt on mower housing.

Carefully roll beit off right hand mandrel

pulley_

Remove belt from center mandrel puF

Icy, idler pulley, and left hand mandrel

puiiey.

Remove any dirt or grass which may

have accumulated around mandrels and

entire upper deck surface.

LeftHand

Mandrel

Secondar

Idler Arm

Spring

Anti-Sway-Bar

Bracket

Mower Blade

Drive Belt

o Check secondary idler arm and idler to

see that they rotate freely.

Be sure spring is hooked in secondary

idler arm and sway-bar bracket.

install new belt in lower groove of left

hand mandrel pulte_; idler pulley, and

center mandrel pultey as shown.

Roll belt over right hand mandret pulley.

Make sure belt is in aH grooves properlyo

Reconnect spring to bolt in mower

housing and reinstall right hand mandrem

cover.

Reinstall mower to tractor (See

"INSTALL MOWER AND DRIVE BELT"

in the Assembly section of this manua 0.

Reassemble mower drive belt (See "TO

[3 [3 A_E R _! F_ I_/E" tZm

,,E, LA,J_. M,.,WER __,R,_,-B,-,-, in

this section of this manual).

Center

Mandrel

_dler

Pulley

Right Hand

Cover

TO ADJUST ATTACHMENT CLUTCH

The electric clutch should provide years of

service. The clutch has a built-in brake

that stops the pulley within 5 seconds.

Eventually, the intema! brake wil! wear

which may cause the mower blades to not

engage, or, to not stop as required.

Adjustments should be made by your

nearest authorized service center/depart-

ment.

o Make sure attachment clutch and igni-

tion switches are in "OFF" position.

o Adjust the three nylon Iocknuts until

space between clutch plate and rotor

measures .0!2" at all three slot loca-

tions cut in the side of brake plate.

Rotor Clutch Plate

\

Slot (3)

Nylon Locknut (3)

.0!2"

Brake Plate

NOTE: After installing a new electric

clutch, run tractor at full throttle and

engage and disengage electric clutch t0

cycles to wear in clutch plate.

TO ADJUST BRAKE

Your tractor is equipped with an adjustable

brake system which is mounted on the left

side of the transaxie.

fftractor requires more than six (6) feet

stopping distance at high speed in high-

est gear, then brake must be adjusted.

Depress clutch/brake pedal and engage

parking brake°

® Measure distance between brake oper-

ating arm and nut "A" on brake rod.

If distance is other than 1-3/4", loosen

jam nut and turn nut "A" until distance

becomes 1-3/4". Retighten jam nut

against nut "A".

o Road test tractor for proper stopping

distance as stated above. Readjust if

necessary. If stopping distance is still

greater than six (6) feet in highest gear,

further maintenance is necessary.

Contact your nearest authorized ser-

vice center/department.

26

Page 27

TOREPLACEMOTIONDRIVEBELT

ParkthetractoronlevelsurfaceEngage

parkingbrake.Foreaseofservicethere

isabe_tinstallationguidedecalonbottom

ofleftfootrest.Itisnotnecessaryto

removemower

BELTREMOVAL-

Engage parking brake (creates slack in

belt).

o Remove mower drive belt from electric

clutch pulley only (See "TO REPLACE

MOWER DRIVE BELT" in this section of

this manual).

o Roll motion drive belt off transaxle pul-

ley.

Roll _" t_we,, off, ,-,h ,_,-.Mr_,_ 1,4!_r pu!lc_y_, fh_qn

off engine pulley and front 'v-idler pulley.

o Pull belt out of all belt keepers.

BELT INSTALLATION -

o Place V part of belt into grooves on

engine pulley and front V-idler; making

sure to route belt inside of belt keepers.

, Put belt coming from V-idler above

midspan belt keeper, then onto clutch-

ing idler pulleys as shown.

o Make sure V part of belt engages '4-

idler:

Place belt around transaxle pulley_

beginning at top.

V part of belt should engage transaxle

pulley.

Place long lower section of belt through

loop in midspan belt keeper.

o Check to be sure belt is on proper side

of all belt keepers.

• Reinstall mower drive belt onto electric

clutch pulley,

IMPORTANT: Check brake adjustment,

Clutching

Idler

Clutching \ Belt

_<,_in,_ Flat Idler \ / Keeper

Pul_'e'y Above Belt \

TO ADJUST STEERING WHEEL ALiGN-

MENT

If steering wheel crossbars are not hod-

zontal (left to right) when whee!s are posi-

tioned straight forward, remove steering

wheel and reassemble per instructions in

the Assembty section of this manual.

FRONT WHEEL TOE-IN ADJUSTMENT

Front wheel toeqn is required for proper

steering operation. Toe-in was set at the

factory and adjustment should not be neco

essary. If parts in the front axle or steering

mechanism have been replaced or dam_

aged, check toe-in and adjust if necessary'.

TO CHECK TOE-IN

o Position front wheels straight ahead.

® Measure distance between wheels at

front and rear of tires (dimensions "A"

and "B").

Front dimension "A" should be 1/8" to

1/4" tess than rear dimension "B".

TO ADJUST TOE-IN

-- Loosen jam nuts at adjustment sleeves

on tie rod.

Adjust tie rod until dimension "A" is 1/8"

to 1/4" less than dimension "B".

o Tighten jam nuts securely.

FRONT WHEEL CAMBER

The front wheel camber is not adjustable

on your tractor. If damage has occurred to

affect the front wheel camber, contact your

nearest authorized service center/depart-

ment.

/

_En-gin_Twists Belt /

_, 1- _ Pullev I Keeper /

_ " t Transaxle

_ V-Idler Pulley

As Viewed from Bottom

• / AdjustmentSleeves

: XieRod

........ / ....

Jam Nuts

27

Page 28

TOREMOVEWHEELFORREPAmRS

FRONTWHEEL

oBlockupaxiesecurety.

o Removeaxlecover,retainingringand

washerstoallowwheelremoval.

,,Repairtireandreassembfe

®Replacewashersandsnapretaining

ringsecurelyinaxlegroove

,, Replaceaxlecover.

REARWHEEL

Blockrearaxlesecurely.

Removefive(5)hubboltstoallow

wheelremoval

Repairtireandreassemble.Replace

andtightenhubboltssecurely.

NOTE:Tosealtirepuncturesandprevent

flattiresduetoslowleaks,tiresealant

maybepurchasedfromyourlocalparts

dealer.Tiresealantalsopreventstiredry

rotandcorrosion.

Washers

Retaining

Ring

Axle Cover

TO START ENGINE THAT HAS A WEAK

BATTERY

,_CAUTION: Lead-acid batteries gener-

ate explosive gases. Keep sparks, flame

and smoking materials away from batter-

ies. Always wear eye protection when

around batteries.

If your battery is too weak to start the

engine, it should be recharged. If "jumper

cables" are used for emergency starting,

follow this procedure:

IMPORTANT: Your tractor is equipped

with a !2 volt negative grounded system.

The other vehicle must also be a 12 volt

negative grounded system. Do not use

your tractor battery to start other vehicles.

TO ATTACH JUMPER CABLES -

Connect each end of the RED cable to

the POSITIVE (+) terminal of each bat-

tery, taking care not to short against

chassis.

o Connect one end of the BLACK cable to

the NEGATIVE (-) terminal of fully

charged battery.

o Connect the other end of the BLACK

cable to good CHASSIS GROUND

away from fuel tank and battery.

TO REMOVE CABLES REVERSE

ORDER -

o Remove BLACK cable first from chassis

and then from the fully charged battery.

o Remove RED cable last from both bat-

teries.

"Positive" (+) "Negative"(-)

L.H. Panel [ _il

Bolt "_-'--.._

¢ " /

<_...... /

TO REPLACE HEADLIGHT BULB

" Raise hood.

,, Pull bulb holder out of the hole in the

backside of the gril!.

,, Replace bulb in holder and push bulb

holder securely back into the hole in the

backside of the grill

o Close hood.

INTERLOCKS AND RELAYS

Loose or damaged wiring may cause your

tractor to run poorly, stop running, or pre-

vent it from starting.

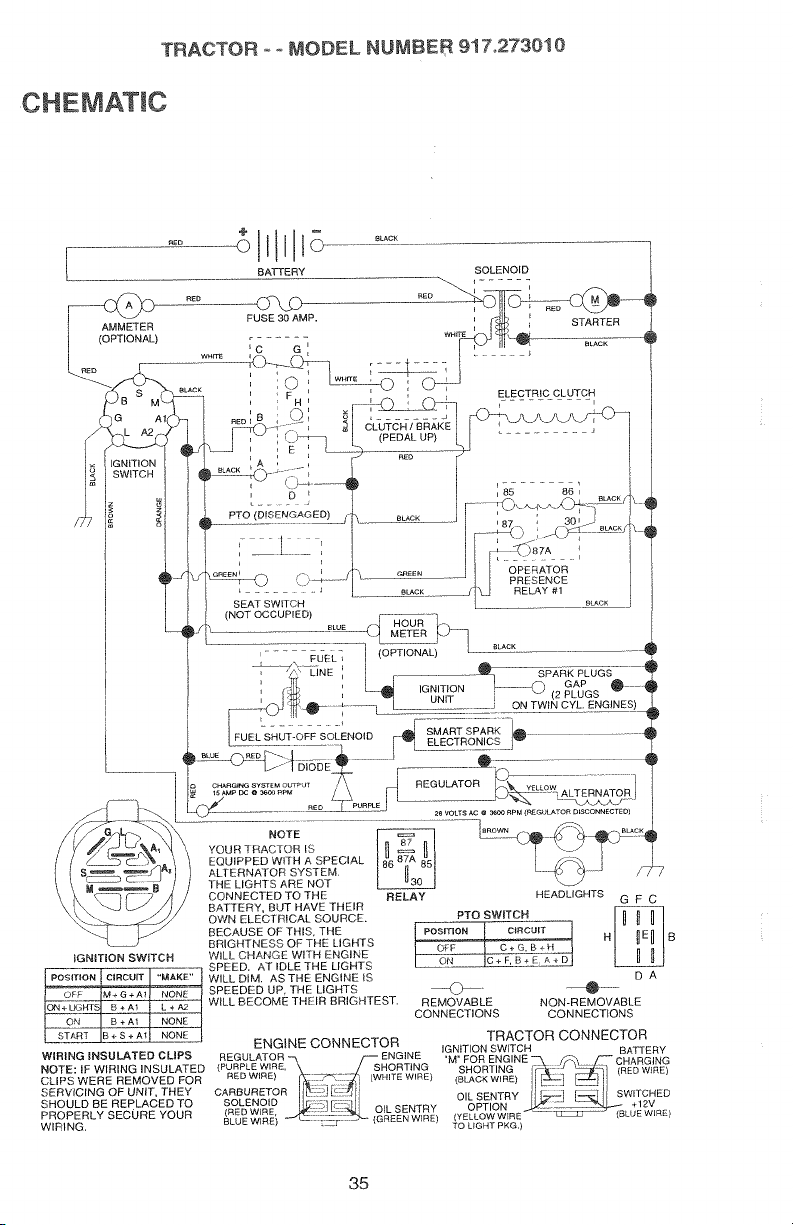

,, Check wiring. See electrical wiring dia-

gram in the Repair Parts section of this

manual.

TO REPLACE FUSE

Replace with 30 amp automotive-type

plug-in fuse. The fuse holder is located

behind the dash.

formed by an authorized engine manufac-

turer's service outleL

TO REMOVE HOOD AND GRILL

ASSEMBLY

o Raise hood.

,, Unsnap headlight wire connector.

* Stand in front of tractor. Grasp hood at

sides, tilt toward engine and lift off of

tractor.

To replace, reverse above procedure.

Hood

@ Headlight

Wire

Connector

28

Page 29

ENGINE

Maintenance,repair,orreplacementofthe

emissioncontrotdevicesandsystems,

whicharebeingdoneatthecustomers

expense,maybeperformedbyanynon-

roadenginerepairestablishmentorindi-

vidual.Warrantyrepairsmustbeper-

formedbyanauthorizedenginemanufac-

turer'sserviceoutlet.

TOADJUSTTHROTTLECONTROL

CABLE

Thethrottlecontrolhasbeenpresetatthe

factoryandadjustmentshouldnotbenec-

essary.Checkadjustmentasdescribed

u_,,J,,vbe,orelooseningcab,e.!fadjust-

mentisnecessary,proceedasfollows:

,,Withenginenotrunning,movethrottle

controllevertofastposition.

oCheckthatspeedcontrolleveris

againststopscrew.Ifitisnot,loosen

casingclampscrewandpullthrottle

cableuntilleverisagainstscrew.

Tightenclampscrewsecurely.

Idle Fuel

Adjusting Idle Speed

Needle Adjusting Screw

Control

Cable

i]_i i _¸¸_ '

..... _,I I_iliilil,ii!, i_lii_ill _ .........

• __ ! , ,,,! ,_ ¢

, I , jq

I, i _ _iII _i /

]Li/,,,!,I!,! ,,,,(I

I_-/_ LuU|IU{J[IJLI[JUii[]! l!illjUg; L_ [

Stop Screw-" _ /

TO ADJUST CHOKE CONTROL

The choke control has been preset at the

factory and adjustment should not be nec-

essary, check adjustment as described

below before loosening cable. If adjust-

ment is necessary, proceed as follows:

o With engine not running, move choke

control (located on dash panel) to full

choke position.

Clamp Screw Choke Control Cable

o Remove air cleaner cover fitter and car-

tridge plate to expose carburetor choke

(See "AIR F_LTER" in the Customer Reo

sponsibitities section of this manual).

o Choke shouid be dosed. If it is not,

loosen casing clamp screw and move

choke cable untiJ choke is completely

closed. Tighten casing clamp screw se-

curely.

o Reassemble air cleaner.

Closed for Full

Choke , q,

TO ADJUST CARBURETOR

The carburetor has been present at the

factory and adjustment should not be neco

essary. However, minor adjustment may

be required to compensate for differences

in fuel, temperature, altitude or load. If the

carburetor does need adjustment, proceed

as follows:

In general, turning the adjusting needles

in (clockwise) decreases the supply of fuel

to the engine giving a leaner fuel/air mix-

ture. Turning the adjusting needles out

(counterclockwise) increases the supply of

fuel to the engine giving a richer fuel/air

mixture.

RMPORTANT: Damage to the needles

and the seats in carburetor may result if

screw is turned in too tight.

PRELIMINARY SETTING

® Be sure you have a clean air filter, and

the throttle control cable is adjusted

properly (see "TO ADJUST THROTTLE

CONTROL CABLE" in the Service and

Adjustments section of this manual).

With engine off turn idle fuel adjusting

needle in (clockwise) closing it finger

tight and then turn out (counterclock-

wise) 1 turn.

29

Page 30

FBNALSETTING

Startengineandallowtowarmforfive

minutes.Makefinaladjustmentswith

enginerunningandshifb'motioncentro_

leverinneutrat(N)position.

Thehighidleissetatthefactoryand

cannotbeadjusted.

Idle - With throttle control

lever in slow position, engine should

idle at 1200 RPM tf engine idles too

stow or fast, turn idle speed adjusting

screw in or out until correct idle is

attained.

o Idlerue! needle Se_ - With throttle

contro_ lever in slow position, turn id!e

fuet adjusting needle in (clockwise) until

engine speed decreases and then turn

out (counterclockwise) approximately

3/4 turn to obtain the best low speed

performance.

. Recheck idle speed. Readjust if neces-

sary.

ACCELERATION TEST o

Move throttle contro_ lever from stow to

fast position. If engine hesitates or dies,

turn idle fuel adjusting needle out

(counterclockwise) 1/8 turn. Repeat test

and continue to adjust, if necessary,

until engine accelerates smoothly.

High speed stop is factory adjusted. Do

not adjusbdamage may result.

_MPORTANT: Never tamper with the

engine governor, which is factory set for

proper engine speed Overspending the

engine above the facory high speed set°

_,_.,,_ can be dangerous, if,you think the

_ i _......... high speed needs_,,g,n._ _....... d

adjusting, contact your nearest authorized

service center/department, which has

proper equipment and experience to make

any necessary adjustments.

30

Page 31

Immediatelyprepareyourtractorforstor-

ageattheendd the season or if the trac-

tor will not be used for 30 days or more.

_CAUT_ON: Never store the tractor with

gasoline in the tank inside a building

where fumes may reach an open flame or

spark. Allow the engine to cool before stor-

ing in any enclosure.

TRACTOR

Remove mower from tractor for winter

storage. This will allow you to clean it thor-

ough}y. Remove all did, grease, !eaves,

etc. Store in a clean, dry area.

* Clean entire tractor (See "CLEANING"

in the Maintenance section of this man-

ual).

Inspect and replace belts, if necessary

(See belt replacement instructions in the

Service and Adjustments section of this

manual).

Lubricate as shown in the Maintenance

section of this manual.

Be sure that all nuts, bolts and screws

are securely fastened, inspect moving

parts for damage, breakage and wear.

Replace if necessary.

Touch up all rusted or chipped paint sur-

faces; sand lightly before painting.

BATTERY

. Fully charge the battery for storage.

After a period of time in storage, battery

may require recharging.

* To help prevent corrosion and power

leakage during !ong periods of storage,

battery cables should be disconnected

and battery cleaned thoroughly (see

"TO CLEAN BATTERY AND TERMI-

NALS" in the Maintenance section of

this manual).

After cleaning, leave cables disconnect-

ed and place cables where they cannot

come in contact with battery terminals.

- If battery is removed from tractor for

storage, do not store battery directly on

concrete or damp surfaces.

ENGINE