Page 1

CRRFTSMRN

MODEL NUMBER 917.259561

Assembly

Operation

Customer Responsibilities

Service and Adjustments

Repair Parts

OWNER’S MANUAL

f3

from previously built enqines. Befo

CAUTION: Read and follow all safety rules and instructions before operating this equipment.

FOR CONSUMER ASSISTANCE HOT LINE, CALL THIS TOLL FREE NUMBER: 1-800-659-5917

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Page 2

SAFETY RULES

Safe Operation Practices for Ride-On Mowers

IMPORTANT: THIS CUTTING MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING OBJECTS.

FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH.

GENERAL OPERATION

Read, understand, and follow all instructions in the manual

and on the machine before starting.

Only allow responsible adults, who are familiar with the

instnjctions, to operate the machine.

Clear the area of objects such as rocks, toys, wire, etc.,

which could be picked up and thrown by the blade.

Be sure the area is clear of other people before mowing. Stop

machine if anyone enters the area.

Never carry passengers.

Do not mow in reverse unless absolutely necessary. Always

look down and behind before and while backing.

Be aware of the mower discharge direction and do not point

it at anyone. Do not operate the mower without either the

entire grass catcher or the guard in place.

Slow down before turning.

Never leave a running machine unattended. Always turn off

blades, set parking brake, stop engine, and remove keys

before dismounting.

Turn off blades when not mowing.

Stop engine before removing grass catcher or unclogging

chute.

Mow only in dayiight or good artificial light.

Do not operate the machine while under the influence of

alcohol or drugs.

Watch for traffic when operating near or crossing roadways.

Use extra care when loading or unloading the machine into

a trailer or truck.

II. SLOPE OPERATION

Slopes are a major factor related to loss-of-control and

tipover accidents, which can result in severe injury or

death. All slopes require extra caution. If you cannot back

up the slope or if you feel uneasy on it, do not mow it.

DO:

Mow up and down slopes, not across.

Remove obstacles such as rocks, tree limbs, etc.

Watch for holes, ruts, or bumps. Uneven terain could

overturn the machine. Tall grass can hide obstacles.

Use slow speed. Choose a low gear so that you wili not have

to stop or shift while on the slope.

Follow the manufacturer’s recommendations for wheel

weights or counterweights to improve stability.

Use extra care with grass catchers or other attachments.

These can change the stability of the machine.

Keep all movement on the slopes s/ow and gradual. Do not

make sudden changes in speed or direction.

Avoid starting or stopping on a slope. If tires lose traction,

disengage the blades and proceed slowly sfra/g/jf down the

slope.

DO NOT:

• Do not turn on slopes unless necessary, and then, turn slowly

and gradually downhill, if possible.

• Do not mow near drop-offs, ditches, or embankments. The

mower could suddenly turn over if a wheel is over the edge

of a cliff or ditch, or if an edge caves in.

• Do not mow on wet grass. Reduced traction could cause

sliding.

• Do not try to stabilize the machine by putting your foot on the

ground.

• Do not use grass catcher on steep slopes.

A

III. CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the

machine and the mowing activity. Never assume that

children will remain where you last saw them.

■ Keep children out of the mowing area and under the watchful

care of another responsible adult.

• Be alert and turn machine off if children enter the area.

• Before and when backing, took behind and down for small

children.

• Never carry children. They may fall off and be seriously

injured or interfere with safe machine operation.

• Never allow children to operate the machine.

• Use extra care when approaching blind comers, shrubs,

trees, or other objects that may obscure vision.

IV. SERVICE

• Use extra care in handling gasoline and other fuels. They are

flammable and vapors are explosive.

- Use only an approved container.

- Never remove gas cap or add fuel with the engine

running. Allow engine to cool before refueling. Do not

smoke.

- Never refuel the machine indoors.

- Never store the machine or fuel container inside where

there is an open flame, such as a water heater.

• Never run a machine inside a closed area.

• Keep nuts and bolts, especially blade attachment bolts, tight

and keep equipment in good condition.

• Never tamper with safety devices. Check their proper

operation regularly.

• Keep machine free of grass, leaves, or other debris build-up.

Clean oil or fuel spillage. Allow machine to cool before

storing.

• Stop and inspect the equipment if you strike an object.

Repair, if necessary, before restarting.

• Never make adjustments or repairs with the engine running.

• G rass catcher components are subject to wear, damage, and

deterioration, which could expose moving parts or allow

objects to be thrown. Frequently check components and

replace with manufacturer's recommended parts, when nec

essary.

• Mower blades are sharp and can cut. Wrap the blade(s) or

wear gloves, and use extra caution when servicing them.

• Check brake operation frequently. Adjust and service as

required.

Look for this symbol to point out important

safety precautions. It means

A

A

CAUTIONIII BECOME ALERTIII YOUR

SAFETY IS INVOLVED.

CAUTION: Always disconnect spark plug

wire and place wire where it cannot contact

spark plug in order to prevent accidental

starting when setting up, transporting,

adjusting or making repairs.

A WARNING A

The engine exhaust from this product contains

chemicals known to the State of California to

cause cancer, birth defects, or other reproduc

tive harm.

A

__________

Page 3

CONGRATULATIONS on your purchase of a Sears

Tractor. It has been designed, engineered and manufac

tured to give you the best possible dependability and

performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Authorized

Senrice Center/Department. We have competent, well-

trained technicians and the proper tools to service or repair

this tractor.

Piease read and retain this manual. The instructions will

enabie you to assembieand maintain your tractor properly.

Always observe the “SAFETY RULES".

MODEL

NUMBER

917.259561

SERIAL

NUMBER

DATE OF PURCHASE

THEMODELANDSERIALNUMBERSWILLBE FOUND

ON A PLATE UNDER THE SEAT.

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this prod

uct. Contact your nearest Sears store for details.

PRODUCT SPECIFICATIONS

HORSEPOWER:

GASOLINE CAPACITY

AND TYPE:

OIL TYPE (API-SF/SG/SH): SAE 30 (above 32“F)

OIL CAPACITY:

SPARK PLUG:

(GAP: -030’)

VALVE CLEARANCE:

GROUND SPEED (MPH):

TIRE PRESSURE:

CHARGING SYSTEM;

BATTERY:

19.5

3.5 GALLONS

UNLEADED REGULAR

SAE 5W-30 (below 32°F)

W/ FILTER: 3.5 PINTS

W/0 FILTER: 3.0 PINTS

CHAMPION RC12YC

INTAKE: .004* - .006*

EXHAUST: .004"-.006*

FORWARD:

1st 1.1

2nd 1.5

3rd 2.3

4th 3.5

5th 4.4

6th 5.7

REVERSE: 1.7

FRONT: 14PSI

REAR: 10PSI

16 @ 3600 RPM

AMP/HR: 30

MIN. CCA: 240

CASE SIZE: U1R

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a reguiarschedule in maintaining, caring for and

using your tractor.

• Follow the instructions under “Customer Responsibili

ties” and “Storage” sections of this owner’s manual.

WARNING: This tractor is equipped with an internal

combustion engine and should not be used on or near any

unimproved forest-covered, brush-covered or grass-cov

ered land unless the engine’s exhaust system is equipped

BLADE BOLT TORQUE: 30-35 FT. LBS.

with a spark arrester meeting applicable local or state laws

(if any). If a spark arrester is used, it should be maintained

in effective working order by the operator.

In the state of California the above is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on

federal lands. A spark arrester for the muffler is available

through your nearest Sears Authorized Service Center/

Department (See REPAIR PARTS section of this manual).

LIMITED TWO YEAR WARRANTY ON CRAFTSMAN RIDING EQUIPMENT

For two (2) years from the date of purchase, if this Craftsman Riding Equipment is maintained, lubricated and tuned up according

to the instructions in the owner's manual, Sears will repair or replace, free of charge, any parts found to be defective in material or

workmanship.

This Warranty does not cover:

• Expendable items which become worn during normal use, such as blades, spark plugs, air cleaners, belts, etc.

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or glass.

• Repairs necessary because of operator abuse, negligence, improper storage or accident or the failure to maintain the

equipment according to the instructions contained in the owneris manual.

• Riding equipment used for commercial or rental purposes.

LIMITED 90 DAY WARRANTY ON BATTERY

For ninety (90) days from date of purchase, if any battery included with this riding equipment proves defective in material or

workmanship and our testing determines the battery will not hold a charge, Sears will replace the battery at no charge.

IN-HOME WARRANTY SERVICE ON YOUR CRAFTSMAN RIDING EQUIPMENT IS AVAILABLE AT NO-CHARGE FOR 30

DAYS FROM THE DATE OF PURCHASE. PLEASE CONTACT YOUR NEAREST SERVICE CENTER. AFTER 30 DAYS FROM

THE DATE OF PURCHASE, WARRANTY SERVICE IS AVAILABLE BY TAKING YOUR CRAFTSMAN RIDING EQUIPMENT TO

YOUR NEAREST SEARS SERVICE CENTER. (IN-HOME WARRANTY SERVICE WILL STILL BE AVAILABLE AFTER 30 DAYS

FROM THE DATE OF PURCHASE BUT A STANDARD TRIP CHARGE WILL APPLY,) THIS WARRANTY APPLIES ONLY

WHILE THIS PRODUCT IS IN THE UNITED STATES.

This Warranty gives you specific legal rights, and you may also have other rights which may vary from slate to state.

^

________

SEARS, ROEBUCK AND CO., D/817 WA, HOFFMAN ESTATES, IL 60179

Page 4

TABLE OF CONTENTS

SAFETY RULES.......

PRODUCT SPECIFICATIONS

CUSTOMER RESPONSIBILITIES

_______

......

_____ ___ _ _______

________________

.......................

3,15>19

....... 3

WARRANTY.............................................................. 3

TABLE OF CONTENTS................................................4

INDEX.........................................................................4

TRACTOR ACCESSORIES

........................................

5

ASSEMBLY..............................................................7-9

INDEX

Accessories.............................................. .5

Adjustments:

Brake

.................................................

Carburetor

Mower:

Front-To-Back

Side-To-Side

Throttle Control Cable......................24

Air Filter, Engine

Air Screen, Engine....................................18

Assembly..................................................7-9

Battery:

Charging...........................................7-8

Cleaning

Connecting.......................................7-8

Starling with Weak Battery

Storage

Terminals...........................................17

Belts:

Blade:

Brake Adjustment.....................................22

Carburetor Adjustment

Controls, Tractor......................................11

Customer Responsibilities

Cutting Height, Mower

..............................................

Motion Drive

Removal/Replacement

Mower Blade Drive

Removal/Replacement

Sharpening........................................16

Replacement.....................................16

Engine:

Air Filter

Air Screen, Engine

Battery...........................................17

Cooling Fins, Engine

Engine Oil.....................................17

Fuel Filter

Spark Plugs..................................19

T raclor:

Blades...........................................16

Lubrication Chart.........................15

Maintenance Schedule................15

Tire Care

A

.........................................

............................

...............................

.......................................

B

............................................

..............

...............

...............

C

............................

.................

.......................................

.......................

...................

.....................................

...............................

.............................

15-19

8,16,23

22

25

21

21

18

17

23

26

22

22

25

18

18

18

19

12

Electrical:

Interlocks and Relays

Schematic...............................29

Wiring Diagram........................30

Engine:

Air Filter

..................................

Air Screen

Cooling Fins, Engine

Oil Change..............................17

Oil Level

.............................

Oil Type..................................17

Preparation

Repair Parts.......................48-53

Starting...................................14

Storage

..................................

Filters:

Air

..........................................

Fuel

.......................................

Fuel:

Type.......................................13

Storage...................................26

Fuse

.............................................

Gauge Wheels.................................8

Hood Removal/lnstallation

Leveling Mower Deck.....................21

Lubrication Chart

Maintenance Schedule

Mower:

Adjustment, Front-to-Back

Adjustment, Side-to-Side

Blade Sharpening

Blade Replacement

Cutting Height

Installation...............................20

Operation................................13

Removal.................................20

Mowing Tips

..................................

Muffler...........................................19

Spark Arrester

Mulcher Plate

2

OPERATION

MAINTENANCE SCHEDULE................................... 15

SERVICE AND ADJUSTMENTS

STORAGE

TROUBLESHOOTING

REPAIR PARTS - TRACTOR

REPAIR PARTS - ENGINE

PARTS ORDERING/SERVICE

E

...............

..............................

................

13,17

.............................

F

G

H

...............

L

............................

M

...................

........

..........

....................

.................

.........................

......................

3,40

..................................

........................................................

...........................

10-14

20-25

................................................................

..........................................

..............................

...................................

...................

BACK PAGE

27-28

30-47

48-53

O

Oil:

24

18

.18

18

Cold Weather Conditions

Engine............................................. 17

Storage

Operation.............................................11-14

Operating Mower......................................13

Options:

Accessories........................................5

Spark Arrester...............................3,40

.............................................

..........

P

13

26

18

19

24

24

15

15

21

21

16

16

12

14

Parking Brake

Parts Bag....................................................6

Parts, Replacement/Repair................30-47

Product Specifications

Repair Parts

Safety Rules

Seat..............................................................8

Service and Adjustments...................20-25

Brake.................................................22

Carburetor

Fuse

Hood Removal/lnstallation

Motion Drive Belt

Mower Blade Drive Belt

Mower Adjustment:

Mower Installation

Mower Removal

Tire Care

Slope Guide Sheet

Spark Plugs

Specifications.............................................3

Starting the Engine

Steering Wheel......................................7,23

Stopping the Tractor

Storage

Throttle Control Cable Adjustment

Tires

9

..................................................

Trouble Shooting Chart

Transaxle Repair Parts.......................46-47

Warranty

Wiring Diagram.........................................30

Wiring Schematic.....................................29

.....................................

.............................

R

........................................

S

...............................................

........................................

................................................

.............

Removal/Replacement

Removal/Replacement

Front-to-Back.............................21

Side-to-Side

..............................................

.....................................................

.................................................

...............................

...............................

...................................

...................................

............................

...............................

T

W

..............

..............

...........................

8,16,23

........

8,16,23

.....................

26

13,17

26

11-12

3

30-47

2

25

24

24

22

22

21

20

20

55

19

13-14

12

26

24

27-28

....3

Page 5

ACCESSORIES AND ATTACHMENTS

These accessories and attachments were available through most Sears retail outlets and service centers whervthe tractor was purchased.

Most Sears stores can order these items for you when you provide the modei number of your tractor.

ENGINE

SPARK PLUG

GAS CAN ENGINE OIL FUEL STABIUZER

AIR FILTER

MAINTENANCE

PERFORMANCE

Sears offers a wide variety of attachments that fit your tractor. Many of these are listed below with brief explanations of how they can help

you. This list was current at the time of publication; however, it may change in future years' more attachments may be addeci, changes

may be made in these attachments, or some may no longer be available or fit your model. Contact your nearest Sears store for the

accessories and attachments that are available for your tractor.

Most of these attachments do not require additional hitches or conversion kits (those that do are indicated) and are designed for easy

attaching and detaching.

AERATOR promotes deep root growth for a healthy lawn. Ta

pered 2.5-inch steel spikes mounted on 10-inch diameter discs

puncture holes in soil at close intervals to let moisture soak in.

Steel weight tray for increased penetration.

BAGGER lets you collect grass clippings and leaves for a

healthier, neater looking lawn. Two Permanex containers hold

30-gallon plastic bags.

BUMPER protects front end of tractor from damage.

CARTS make hauling easy. Variety of sizes available, plus

accessories such as side panel kits, tool caddy, cart cover,

protective mat and dolly.

CORING AERATOR takes smalt plugs out of soN to allow mois

ture and nutrients to reach grass roots. 36-inch swath. 24

hardened steel coring tips. 150 lb. capacity weight tray.

EASY OIL DRAIN VALVE makes oil changes easier, faster.

FRONT NOSE ROLLER canters in front of mower deck to reduce

chances of “scalping” on uneven terrain. '

G A N G HITCH lets you tow 2or3pull-behind attachments at once,

such as sweepers, dethatchers, aerators (not for use with rollers,

carts or other heavy attachments).

GAUGE WHEELS on both sides of the mower deck reduce

chances of “scalping” on uneven terrain. For mower decks not so

equipped.

MULCH RAKE/DETHATCHER loosens soil and flips thatch and

matted leaves to lawn su rf ace for easy pickup. Twenty spring tine

teeth. Useful to prepare bare areas for seeding. Available forfront

or rear mounting. HIGH PERFORMANCE REEL-ACTION

SPRING TINE DETHATCHER covers 36-inch wide path and

tosses thatch into iarge hopper. Mounts behind tractor,

MULCHING CLOSE-OUT PLATE KIT, once installed, lets you

mulch, discharge or bag clippings (bagger optional) without

changing blades. For models not equipped as 3-in-1 Convertible

mowers. See “MOWER” in the Repair Parts section of this

manual.

RAMP TOPS AND FEET let you load and unload tractor from a

pickup truck. Use with 2x8 or 2x10 lumber.

ROLLER for smoother lawn surface. 36-inch wide, 18-inch

diameter water-tight drum holds up to 390 lbs. of weight. Rounded

edges prevent harm to turf. Adjustable scraper automatically

cleans drum.

SNOW BLADE for snow removal only. 14-inch high, 48-inch wide

blade clears 42-inch path when angled left or right. Raises, lowers

with side lever. Adjustable skids; replaceable, reversible scraper

bar. (Use with tire chains and wheel weights and/or rear drawbar

weight.)

SNOWTHROWER has 40-inch swath. Drum-type auger handles

powdery and wet/heavy snow. Mounts easily with simple pin

arrangement. Discharge chute adjusts from tractor seat. 6-inch

diameter spout discharges snow 10 to 50 feet. Lift controlled at

tractor seat. (Use with chains and wheel weights and/or rear

drawbar weight.)

SPRAYERS use 12-volt DC electric motor that connects to the

tractor battery or other 12-volt source. Includes booms for

automatic spraying and hand held wand for spot spraying. Wand

has adjustable spray pattern. For applying herbicides, insecti

cides, fungicides and liquid fertilizers.

SPREADER/SEEDERS make seeding, fertliizing, and weed kill

ing easy. Broadcast spreaders are also useful Tor granular de

icers and sand.

SWEEPERS let you collect grass clippings and leaves.

TILLER has 5 hp engine and 36-inch swath to prepare seed beds,

cultivate and compost garden residue. Tiller has Its own built-in

lift and depth control system and does NOT require a sleeve hitch.

Fits any lawn, yard or garden tractor. Simply hook up to the tractor

drawbar and go! Optional accessories convert unit for

dethatching, aerating, hilling...without tools,

TIRE CHAINS are heavy duty; closely spaced extra-large cross

links give smooth ride, outstanding traction.

TRACTOR CAB has heavy duty vinyl fabric over tubular steel

frame, ABS plastic top; clear plastic windshield offers 360 degree

visibility. Hinged metal doors with catch. Keeps operator warm

and dry. Remove vinyl sides and windshields for use as sun

protector in summer. Optional accessories include: tinted/

tempered solid safety glass windshield with hand operated wiper;

12-volt amber caution light for mounting on cab top.

VACS for powerful collection of heavy grass clippings and leaves.

Optional wand attachment to pick up debris in hard-to-reach

places. VAC/CHIPPER includes a chipper-shredder.

WEIGHT BRACKET for drawbar for snow removal applications.

Uses (1) 55 lb. weight.

WHEEL WEIGHTS for rear wheels provide needed traction for

snow removal or dozing heavy materials.

Page 6

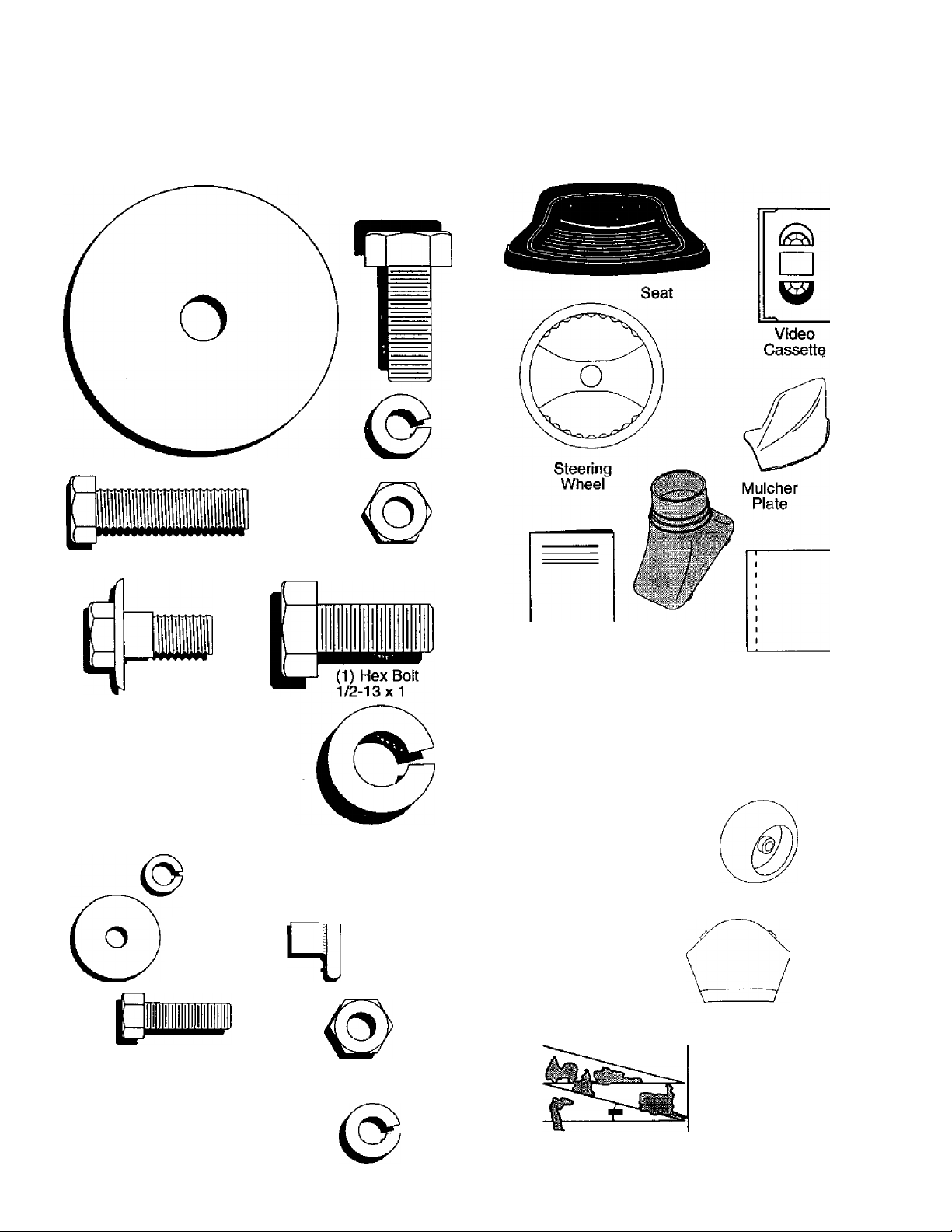

CONTENTS OF HARDWARE PACK

Parts Bag contents shown full size

(1) Hex Bolt

3/8-16x1

(1 ) Large Flat Washer (1 ) Lockwasher 3/8

(1) Hex Bolt 5/16-18 X 1-1/4 Locknut 5/16-18

Parts packed separately in carton

(1) Shoulder

Bolt 5/16-18

@

(2) Hex Bolts 1/4-20x3/4

(2) Lock (2) Screws

Washers #10x^8

(2) Washers

3/16x3/4

X16 Gauge

(1) Washer

17/32X

1-3/16.x 12

Gauge

(1 ) Lock Washer 1/2

#10 f

(2) Hex Nuts 1/4-20

0

(2) Weld

Nuts #10

Steering

Manual

Parts bag contents not shown full size

(2) Shoulder

Bolts

Steering Wheel

Adapter

(2) Latch Hook

Assemblys

Boot

Parts Bag

(2) Washers 3/8

X 7/8 x 14 Gauge

Wheels

(2) Center

lock Nuts

(2) Keys

Steering

Wheel

Insert

Steering

Extension

Shaft

(2) Gauge

(2) Washers 9/32 x 5/8 x 16 Gauge

(2) Lock Washers 1/4

Slope Sheet

Page 7

ASSEMBLY

Your new tractor has been assembled at the factory with exception of those parts left unassembled for shipping purposes.

To ensure safe and proper operation of your tractor all parts and hardware you assemble must be tightened securely. Use

the correct tools as necessary to insure proper tightness.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly easier. Standard

wrench sizes are listed.

(1) 3/4“ Socket w/drive rächet

(2) 7/16" wrenches Phillips Screwdriver

(2) 1/2" wrench Tire pressure gauge

(1) 9/16" wrench Utility knife

When right or left hand is mentioned in this manual, it

means when you are in the operating position (seated

behind the steering wheel).

INSERT

3^8 HEX BOLT

3/8 LOCK WASHER

LARGE FLAT

WASHER

TO REMOVE TRACTOR FROM CARTON

UNPACK CARTON

• Remove all accessible loose parts and parts cartons

from carton (See page 6).

• Cut, from top to bottom, along lines on all four corners

of carton, and lay panels flat.

• Check for any additional loose parts or cartons and

remove.

BEFORE ROLLING TRACTOR OFF SKID

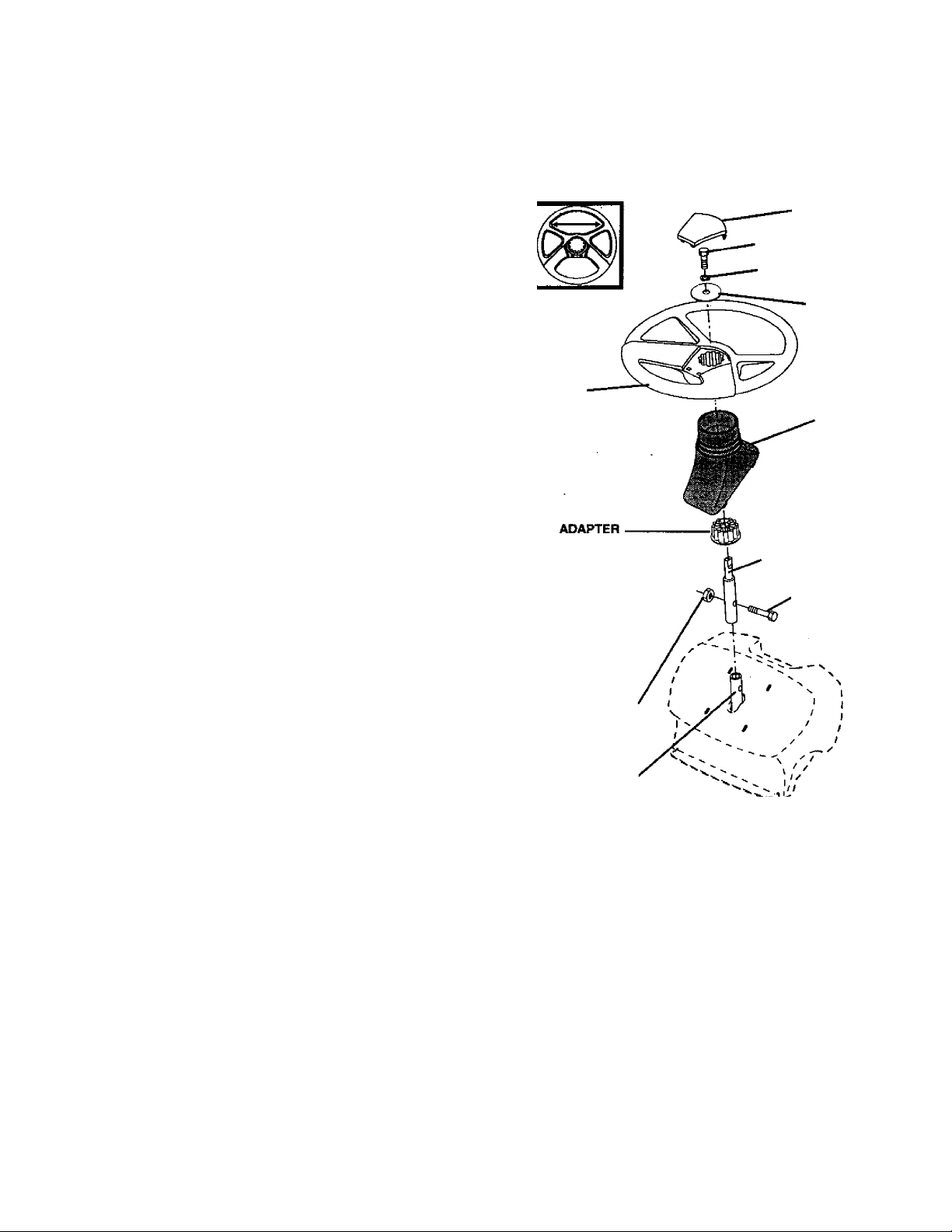

ATTACH STEERING WHEEL (See Fig. 1)

ASSEMBLE EXTENSION SHAFT AND BOOT

• Slide extension shaft onto lower steering shaft. Align

mounting holes in extension and lower shafts and

install 5/16 hex bolt and locknut. Tighten securely.

IMPORTANT; TIGHTEN BOLT AND NUT SECURELY TO

18-22 FT. LBS TORQUE,

• Place tabs of steering boot over tab slots in dash and

push down to secure.

INSTALL STEERING WHEEL

• Position front wheels of the tractor so they are pointing

straight forward.

• Slide steering wheel adapter onto steering shaft exten

sion.

• Position steering wheel so cross bars are horizontal

(left to right) and slide inside boot and onto adapter,

• Assemble large flat washer, 3/8 lock washer, 3/8 hex

bolt and tighten securely.

• Snap steering wheel insert into center of steering

wheel.

• Remove protective materials from tractor hood and

grill.

IMPORTANT: CHECK FOR AND REMOVE ANY STAPLES

IN SKID THAT MAY PUNCTURE TIRES WHERETRACTOR

IS TO ROLL OFF SKID.

STEERING

WHEEL

EXTENSION SHAFT

5/16 LOCKNUT

LOWER

STEERING

SHAFT

STEERING

BOOT

5/18 HEX BOLT

FIG.1

TO ROLL TRACTOR OFF SKID (See Operation

section for location and function of controls)

• Press lift lever plunger and raise attachment lift lever to

its highest position,

• Release parking brake by depressing clutch/brake

pedal.

• Place gearshift lever in neutral (N) position.

• Roll tractor backwards off skid.

• Remove banding holding discharge guard up against

tractor.

Page 8

ASSEMBLY

HOW TO SET UP YOUR TRACTOR

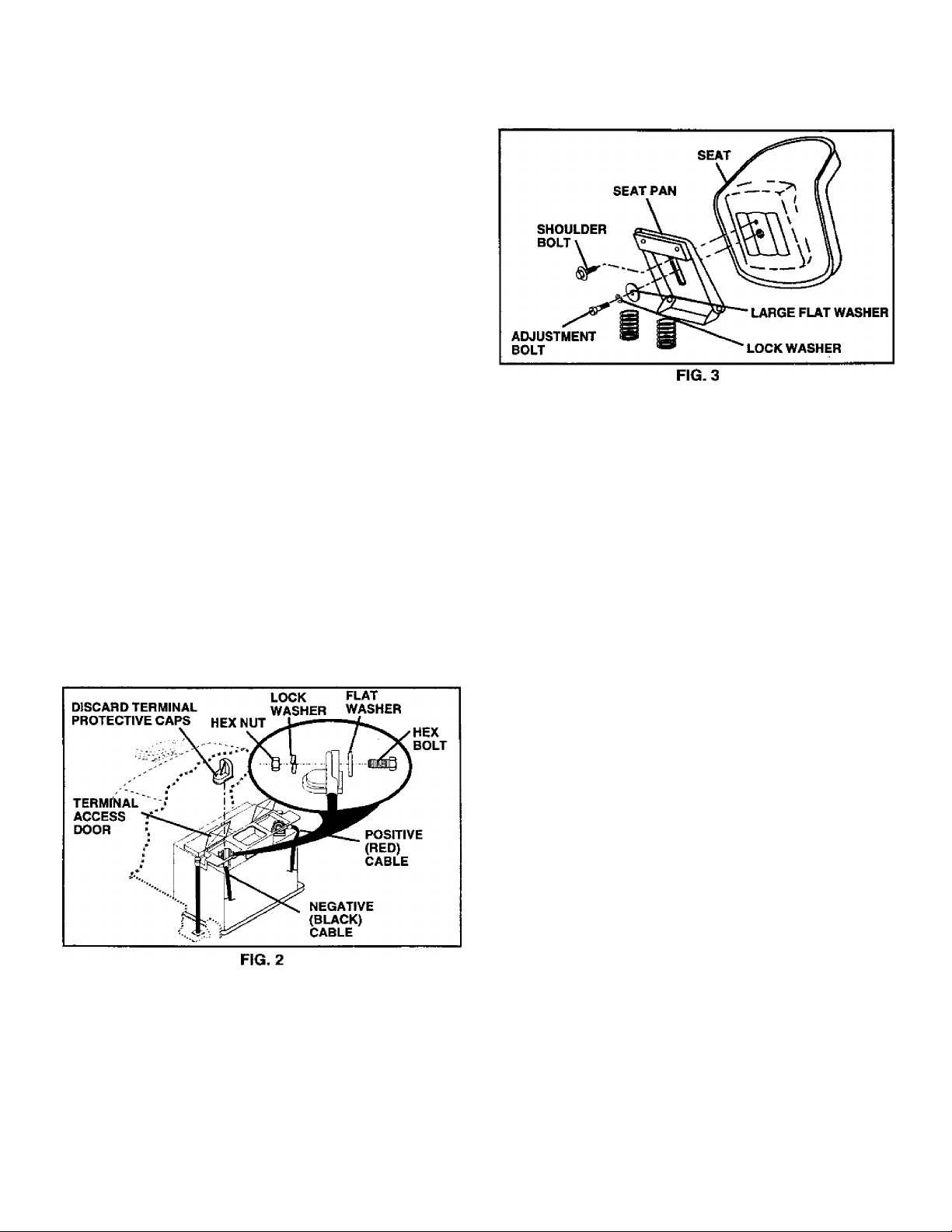

CONNECT BATTERY (See Fig. 2)

CAUTION; Do not short battery termi

nals by allowing a wrench or any other

object to contact both terminals at the

same time. Before connecting battery,

A

• Lift hood to raised position.

• Open terminal access doors, remove terminal protec

tive caps and discard.

• If this battery is put into service after month and year

indicated on label {label located between terminals)

charge battery for minimum of one hour at 6-10 amps.

• First connect RED battery cable to positive (+) battery

terminal with hex bolt, flat washer, lock washer and hex

nut as shown. Tighten securely.

• Connect BLACK grounding cable to negative (-) bat

tery terminal with remaining hex bolt, flat washer, lock

washer and hex nut. Tighten securely.

• Close terminal access doors.

Use terminal access doors for;

• Inspection for secure connections (to tighten hard

ware).

• Inspection for corrosion.

• Testing battery.

• Jumping (if required).

• Periodic charging.

remove metal bracelets, wristwatch

bands, rings, etc.

Positive terminal must be connected

first to prevent sparking from acciden

tal grounding.

CHECK TIRE PRESSURE

The tires on your tractor were overinflated at the factory for

shipping purposes. Correct tire pressure is important for

best cutting peiiformance.

• Reduce tire pressure to PSI shown in “PRODUCT

SPECIFICATIONS” on page 3 of this manual.

CHECK DECK LEVELNESS

For best cutting results, mower housing should be properly

leveled. See TO LEVEL MOWER HOUSING” in the

Service and Adjustments section of this manual.

CHECK FOR PROPER POSITION OF ALL

BELTS

See the figures that are shown for replacing motion and

mower blade drive belts in the Service and Adjustments

section of this manual. Verify that the belts are routed

correctly.

INSTALL SEAT (See Fig. 3)

Adjust seat before tightening adjustment bolt.

• Remove cardboard packing on seat pan.

Place seat on seat pan and assemble shoulder bolt.

• Assemble adjustment bolt, lockwasherandflatwasher

loosely. Do not tighten.

• Tighten shoulder bolt securely.

• Lower seat into operating position and sit on seat.

• Slide seat until a comfortable position is reached which

allows you to press clutch/brake pedal all the way

down.

• Get off seat without moving its adjusted position.

• Raise seat and tighten adjustment bolt securely.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor, check to see

that the brake is properly adjusted. See ‘TO ADJUST

BRAKE” in the Service and Adjustments section of this

manual.

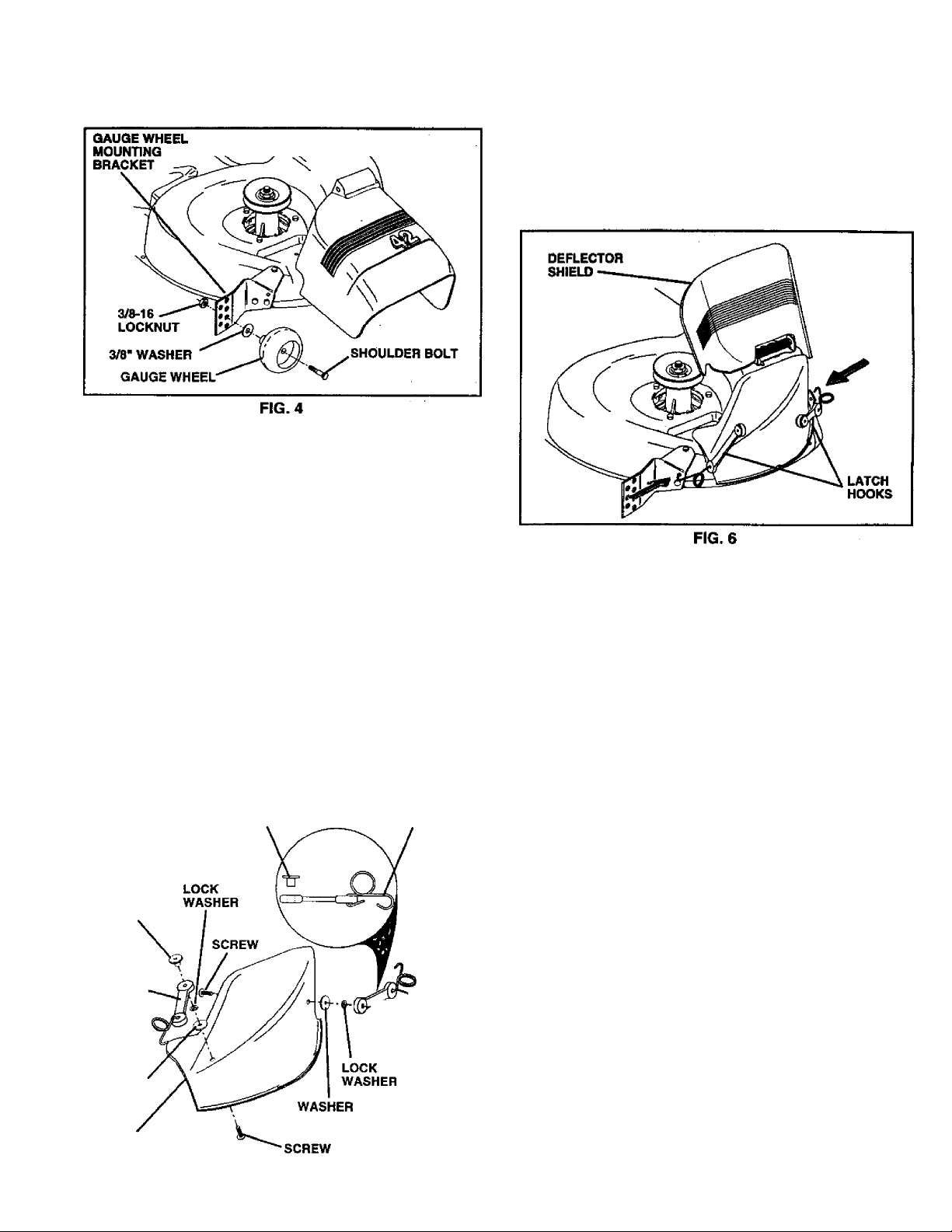

ASSEMBLE GAUGE WHEELS TO MOWER DECK (See Fig. 4)

The gauge wheels are designed to keep the mower deck in

proper position when operating mower. Be sure they are

properly adjusted to ensure optimum mower performance.

• Assemble gauge wheeis with tractor on a flat level

surface.

• Adjust mower to desired cutting height (See TO AD

JUST MOWER CUTTING HEIGHT’ in the Operation

section of this manual).

• With mower in desired height of cut position, gauge

wheels should be assembled so they are slightly off the

ground. Install gauge wheel in appropriate hole with

shoulder bolt, 3/8 washer, and 3/8-16 locknut and

tighten securely.

• Repeat for opposite side installing gauge wheel in

same adjustment hole.

8

Page 9

ASSEMBLY

INSTALL MULCHER PLATE (See Figs. 5 & 6)

• Install two latch hooks to mulcher plate using screw,

washer, lock washer, and weld nut as shown.

NOTE: Pre-assemble weld nut to latch hook by inserting

weld nut from the top with hook pointing down.

• Tighten hardware securely.

• Raise and hold deflector shield in upright position.

• Place front of mulcher plate over front of mower deck

opening and slide into place, as shown.

• Hook front latch into hole on front of mower deck.

• Hook rear latch into hole on back of mower deck.

CAUTION: Do not remove discharge

guard from mower. Raise and hold

A

WELD

NUT

LATCH

HOOK

WASHER

MULCHER

PLATE

guard when attaching mulcher plate

and allow it to rest on plate while in

operation.

WELD NUT FROM THE TOP

HOOK POINTS DOWN

■ LATCH

HOOK

WELD

NUT

TO CONVERT TO BAGGING OR

DISCHARGING

Simply remove mulcher plate and store in a safe place.

Your mower is now ready for discharging or installation of

optional grass catcher accessory.

/CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRACTOR, WE WISH TO ASSURE THAT YOU RECEIVE

THE BEST PERFORMANCE AND SATISFACTION FROM

THIS QUALITY PRODUCT.

PLEASE REVIEW THE FOLLOWING CHECKLIST:

/ All assembly instructions have been completed.

/ No remaining loose parts in carton.

/ Battery is properly prepared and charged. (Minimum

1 hour at 6 amps).

/ Seat is adjusted comfortably and tightened securely.

✓ All tires are properly inflated. (For shipping puiposes,

the tires were overinflated at the factory).

/ Be sure mower deck is properly leveled side-to-side/

front-to-rear for best cutting results. (Tires must be

properly inflated for leveling).

/ Check mower and drive belts. Be sure they are routed

properly around pulleys and inside all belt keepers.

/ Check wiring. See that all connections are still secure

and wires are properly clamped.

WHILE LEARNING HOWTO USE YOUR TRACTOR, PAY

EXTRA ATTENTION TO THE FOLLOWING IMPORTANT

ITEMS:

/ Engine oil is at proper level.

/ Fuel tank is filled with fresh, clean, regular unleaded

gasoline.

/ Become familiar with all controls - their location and

function. Operate them before you start the engine.

/ Be sure brake system is In safe operating condition.

FIG. 5

Page 10

OPERATION

These symbols may appear on your tractor or in literature supplied with the product. Learn and understand their meaning.

- +

A

a:

BATTERY

©

ENGINE ON

FUEL

CAUTION OR

WARNING

STOP

REVERSE FORWARD

FAST SLOW

<' a| a

ENGINE OFF OIL PRESSURE CLUTCH LIGHTS ON LIGHTS OFF

l\l

CHOKE MOWER HEIGHT DIFFERENTIAL PARKING BRAKE UNLOCKED

LOCK LOCKED

R N H L (®)|I

la

REVERSE NEUTRAL HIGH LOW

I

MOWER LIFT

DANGER, KEEP HANDS AND FEET AWAY

ATTACHMENT

CLUTCH ENGAGED

np

ATTACHMENT

CLUTCH DISENGAGED

10

PARKING BRAKE

«

IGNITION

4 =

HYDROSTATIC FREE WHEEL

(Hydro Models only)

Page 11

OPERATION

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Compa r© the ill ustrations with your tractor to fami liarize yourself with the locations of various controls and adjustments. Save

this manual for future reference.

Our tractors conform to the safety standards of the American National Standards Institute.

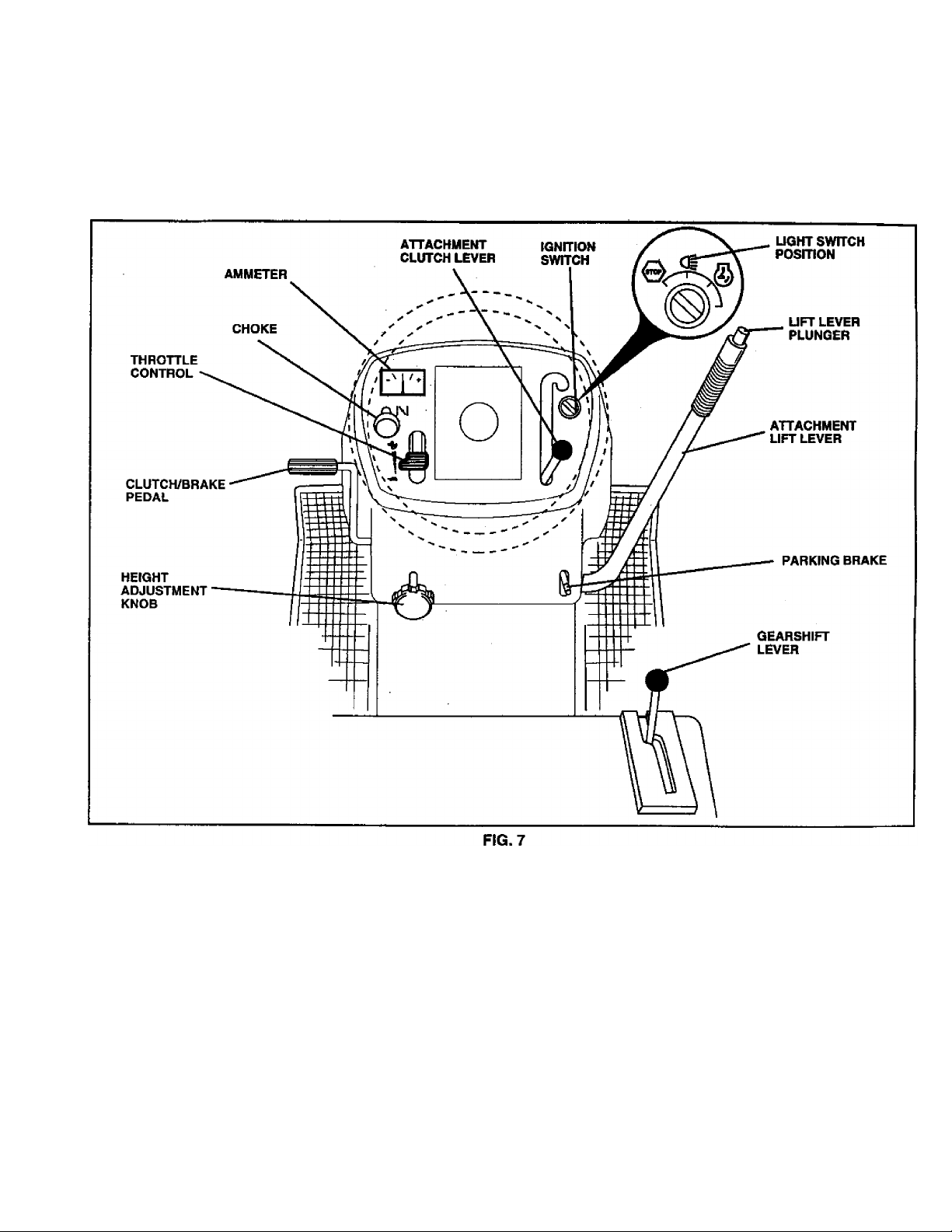

ATTACHMENT CLUTCH LEVER: Used to engage the

mower blades, or other attachments mounted to your

tractor.

LIGHT SWITCH: Turns the headlights on and off.

THROTTLE CONTROL: Used to controi engine speed.

CHOKE CONTROL; Used when starting a cold engine.

CLUTCH/BRAKE PEDAL: Used for declutching and brak

ing the tractor and starting the engine.

PARKING BRAKE: Locks clutch/brake pedal into the

brake position.

11

GEARSHIFT LEVER: Selects the speed and direction of

tractor.

ATTACHMENT LIFT LEVER: Used to raise and lower the

mower deck or other attachments mounted to your tractor.

LIFT LEVER PLUNGER; Used to release attachment lift

lever when changing its position.

IGNITION SWITCH: Used for starting and stopping the

engine.

HEIGHT ADJUSTMENT KNOB: Used to adjust the mower

cutting height.

AMMETER: Indicates battery charging {+) or discharging

(-)■

Page 12

OPERATION

The operation of any tractor can result in foreign objects thrown into the eyes, which can

result In severe eye damage. Always wear safety glasses or eye shields while operating your

tractor or performing any adjustments or repairs. We recommend a wide vision safety mask

over the spectacles or standard safety glasses.

HOW TO USE YOUR TRACTOR

TO SET PARKING BRAKE (See Fig. 8)

Yourtractor is equipped with an operator presence sensing

switch. When engine is running, any attempt by the

operator to leave the seat without first setting the parking

brake will shut off the engine.

• Depress clutch/brake pedal into full “BRAKE” position

and hold.

• Place parking brake lever in “ENGAGED” position and

releasepressurefromclutch/brakepedal. Pedaishould

remain in “BRAKE” position. Make sure parking brake

wiii hold tractor secure.

THROTTLE

CONTROL

CHOKE

CONTROL

“BRAKE”

POSITION

CLUTCH/BRAKE PEDAL

“DRIVE” POSITION

ATTACHMENT CLUTCH LEVER

“ENGAGED” POSITION

“DISENGAGED”

POSITION

PARKING BRAKE

"ENGAGED"

posmoN

GEARSHIFT

LEVER

“DISENGAGED”

POSITION

HEIGHT ADJUSTMENT KNOB

FIG. 8

CAUTION: Always stop tractor com-

, as described above, before leav*

K

A

_ ) operator’s position; to empty

grass catcher, etc.

TO USE THROTTLE CONTROL (See Fig. 8)

Always operate engine at full throttle.

• Operating engine at less than full throttle reduces the

battery charging rate.

• Full throttle offers the best bagging and mower perfor

mance.

TO USE CHOKE CONTROL (See Fig. 8)

Use choke control whenever you are starting a cold engine.

Do not use to start a warm engine.

• To engage choke control, pull knob out. Slowly push

knob in to disengage.

TO MOVE FORWARD AND BACKWARD

(See Fig. 8)

The direction and speed of movement is controlled by the

gearshift lever.

• Start tractor with clutch/brake pedal depressed and

gearshift lever in neutral (N) position.

• Move gearshift and range shift levers to desired posi

tion.

• Slowly release clutch/brake pedal to start movement.

IMPORTANT: BRING TRACTOR TO A COMPLETE STOP

BEFORE SHIFTING OR CHANGING GEARS. FAILURE

TO DO SO WILL SHORTEN THE USEFUL LIFE OF YOUR

TRANSAXLE.

STOPPING (See Fig. 8)

MOWER BLADES -

• Move attachment clutch lever to “DISENGAGED” po

sition.

GROUND DRIVE -

• Depress clutch/brake pedal into full “BRAKE” position.

• Move gearshift lever to neutral (N) position.

ENGINE-

• Move throttle control to slow position.

NOTE: Failure to move throttle control to slow position and

allowing engine to idle before stopping may cause engine

to “backfire”.

• Turn ignition key to “OFF” position and remove key.

Always remove key when leaving tractor to prevent

unauthorized use.

• Never use choke to stop engine.

NOTE: Under certain conditions when tractor is standing

idle with the engine running, hot engine exhaust gases may

cause “browning" of grass. To eliminate this possibility,

always stop engine when stopping tractor on grass areas.

12

TO ADJUST MOWER CUTTING HEIGHT

(See Fig. 8)

The cutting height is controlled by turning the height adjust

ment knob in desired direction.

• Turn knob clockwise (/^) to raise cutting height.

• Turn knob counterclockwise ()^^) to lower cutting

height.

The cutting height range is approximately 1 -1/2" to 4". The

heights are measured from the ground to the blade tip with

the engine not running. These heights are approximate

and may vary depending upon soil conditions, height of

grass and types of grass being mowed.

• The average lawn should be cut to approximately 2-1/2

inches during the cool season and to over 3 inches

during hot months. For healthier and better looking

lawns, mow often and after moderate growth.

• For best cutting performance, grass over 6 inches in

height should be mowed twice. Make the first cut

relatively high; the second to desired height.

Page 13

OPERATION

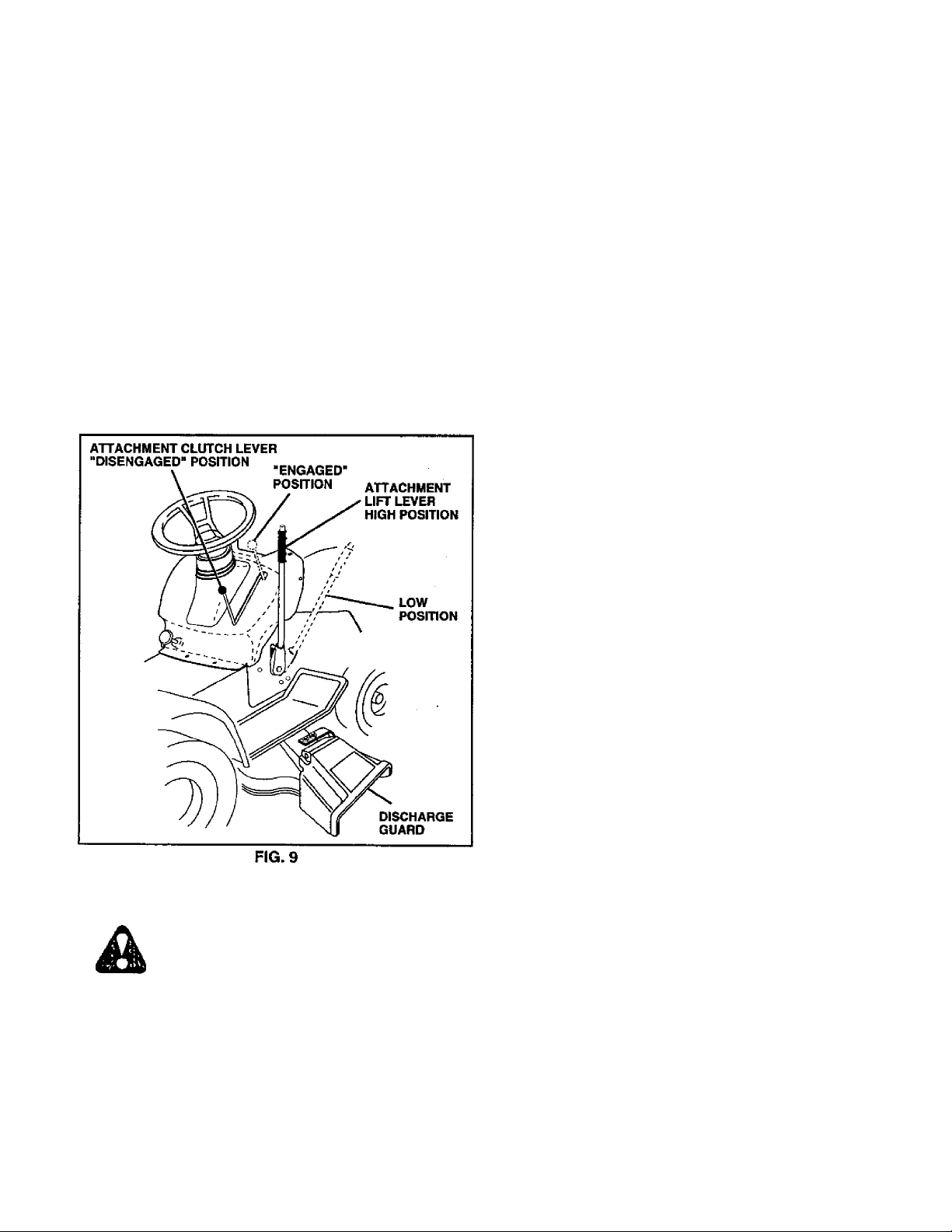

TO OPERATE MOWER (See Fig. 9)

Yourtractor is equipped with an operator presence sensing

switch. Any attempt by the operator to leave the seat with

the engine running and the attachment clutch engaged will

shut off the engine.

• Select desired height of cut.

• Lower mower with attachment lift control.

• Start mower blades by engaging attachment clutch

control.

• TO STOP MOWER BLADES * disengage attachment

clutch control.

CAUTION: Do not operate the mower

without either the entire grass catcher,

A

on mowers so equipped, or the dis

charge guard in piace. .

• To restart movement, slowly release parking brakeand

clutch/brake pedal.

• Make ait turns slowly.

TO TRANSPORT

• Raise attachment lift to highest position with attach

ment lift control.

• When pushing or towing your tractor, be sure gearshift

lever is in neutral (N) position.

• Do not push or tow tractor at more than five (5) MPH.

NOTE: To protect hood from damage when transporting

you r tractor on a truck or a trails r, be su re hood is closed and

secured to tractor. Use an appropriate means of tying hood

to tractor (rope, cord, etc.).

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL (See Fig. 15)

• The engine in your tractor has been shipped, from the

factory, already filled with summer weight oil.

• Check engine oil with tractor on level ground.

• Remove oil fill cap/dipstick and wipe clean, reinsert the

dipstick and screw cap tight, wait for a few seconds,

remove and read oil level. If necessary, add oil until

“FULL” mark on dipstick is reached. Do not overfill.

• For cold weather operation you should change oil for

easier starting (See “OIL VISCOSITY CHARr in the

Customer Responsibilities section of this manual).

• To change engine oil, see the Customer Responsibili

ties section in this manual.

TO OPERATE ON HILLS

CAUTiON: Do not drive up or down

hills with slopes greater than 15° and

do not drive across any slope.

Choose the slowest speed before starting up or down

hills.

Avoid stopping or changing speed on hills.

If slowing is necessary, move throttle control lever to

slower position.

If stopping is absolutely necessary, push clutch/brake

pedal quickly to brake position and engage parking

brake.

Move gearshift lever to 1st gear. Be sure you have

allowed room for tractor to roll slightly as you restart

movement.

ADD GASOLINE

• Fill fuel tank. Use fresh, clean, regular unleaded

gasoline with a minimum of 87 octane. (Use of leaded

gasoline will increase carbon and lead oxide deposits

and reduce valve life). Do not mix oil with gasoline.

Purchase fuel in quantities that can be used within 30

days to assure fuel freshness.

IMPORTANT: WHEN OPERATING IN TEMPERATURES

BELOW 32°F(0°C), USE FRESH. CLEAN WINTER GRADE

GASOLINE TO HELP INSURE GOOD COLD WEATHER

STARTING.

WARNING: Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or methanol) can

attract moisture which leads to separation and formation of

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems, the fuel system should be emptied before stor

age of 30 days or longer. Drain the gas tank, start the

engine and let it run until the fuel lines and carburetor are

empty. Use fresh fuel next season. See Storage Instruc

tions for additional information. Never use engine or

carburetor cleaner products in the fuel tank or permanent

damage may occur.

CAUTION: Fill to bottom of gas tank

fillerneck. Do not overfill. Wipe off any

spilled oil or fuel. Do not store, spill or

use gasoline near an open flame.

13

Page 14

OPERATION

TO START ENGINE (See Fig. 8)

When starting the engine for the first time or if the engine

has run out of fuel, it wilt take extra cranking time to move

fuel from the tank to the engine.

• Sit on seat in operating position, depress clutch/brake

pedal and set parking brake.

• Place gear shift lever in neutral (N) position.

• Move attachment clutch to “DISENGAGED” position.

• Move throttle control to fast position

• Puil choke control out for a cold engine start attempt.

For a warm engine start attempt the choke control may

not be needed.

Note: Before starting, read the warm and cold starting

procedures below.

• Insert key intoignitionandtumkeyclockwiseto“START”

position and release key as soon as engine starts. Do

not run starter continuously for more than fifteen sec

onds per minute. If the engine does not start after

several attempts, push choke control in, wait a few

minutes and try again. If engine still does not start, pull

the choke control out and retry.

WARM WEATHER STARTING (50“ F and above)

• When engine starts, slowly push choke control in until

the engine begins to run smoothly. If the engine starts

to run roughly, pull the choke control out slightly for a

few seconds and then continue to push the control in

slowly.

• The attachments and ground drive can now be used. If

the engine does not accept the load, restart the engine

and allow it to warm up for one minute using the choke

as described above.

COLD WEATHER STARTING (50° F and below)

• When engine starts, slowly push choke control in until

the engine begins to run smoothly. Continue to push

the choke control in small steps allowing the engine to

accept small changes in speed and load, until the

choke control is fully in. if the engine starts to run

roughly, pull the choke control out slightly for a tew

seconds and then continue to push the control in

slowly. This may require an engine warm-up period

from several seconds to several minutes, depending

on the temperature.

• The attachments can be used during the engine warm

up period and may require the choke control be pulled

out slightly.

NOTE: If at a high altitude (above 3000 feet) or in cold

temperatures (below 32 F) the carburetor fuel mixture may

need to be adjusted for bestengine performance. See ‘TO

ADJUST CARBURETOR” in the Service and Adjustments

section of this manual.

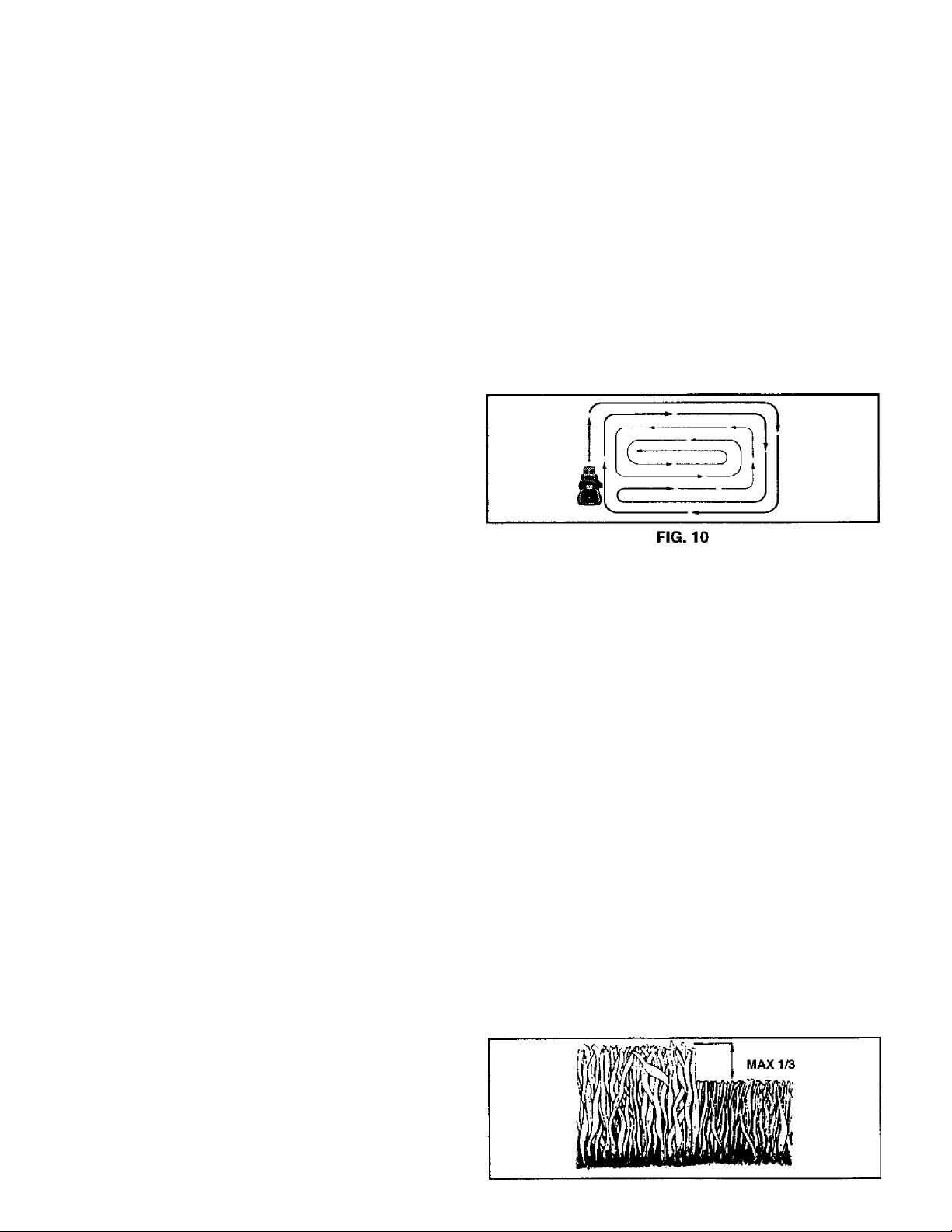

MOWING TIPS

• Tire chains cannot be used when the mower housing is

attached to tractor.

• Mower should be properly leveled for best mowing

performance. See TO LEVEL MOWER HOUSING” in

• the Service and Adjustments section of this manual.

• The left hand side of mower should be used for trim

ming.

• Drive so that clippings are discharged onto the area

that has been cut. Have the cut area to the right of the

tractor. This will result in a more even distribution of

clippings and more uniform cutting.

• When mowing large areas, start by turning to the right

so that clippings will discharge away from shrubs,

fences, driveways, etc. After one or two rounds, mow

14

in the opposite direction making left hand turns untii

finished (See Fig. 10).

If grass is extremely tall, it should be mowed twice to

reduce load and possible fire hazard from dried clip

pings. Make first cut relatively high; the second to the

desired height.

Do not mow grass when it is wet. Wet grass will plug

mower and leave undesirable clumps. Allow grass to

dry before mowing.

Always operate engine at full throttle when mowing to

assure better mowing performance and proper dis

charge of material. Regulate ground speed by select

ing a low enough gear to give the mower cutting

performance as well as the quality of cut desired.

When operating attachments, select a ground speed

that will suit the terrain and give best performance of

the attachment being used.

MULCHING MOWING TIPS

IMPORTANT: FOR BEST PERFORMANCE, KEEP

MOWER HOUSING FREE OF BUILT-UP GRASS AND

TRASH. CLEAN AFTER EACH USE.

• The special mulching blade will recut the grass clip

pings many times and reduce them in size so that as

they fall onto the lawn they will disperse into the grass

and not be noticed. Also, the mulched grass will

biodegrade quickly to provide nutrients for the lawn.

Always mulch with your highest engine (blade) speed

as this will provide the best recutting action of the

blades.

• Avoid cutting your lawn when it is wet. Wet grass tends

to form clumps and interferes with the mulching action.

The best time to mow your lawn is the early afternoon.

At this time the grass has dried and the newly cut area

will not be exposed to the direct sun.

• For best results, adjust the mower cutting height so that

the mower cuts off only the top one-third of the grass

blades (See Fig. 11). For extremely heavy mulching,

reduce your width of cut and mow slowly.

• Certain types of grass and grass conditions may re

quire that an area be mulched a second time to com

pletely hide the clippings. When doing a second cut,

mow across or perpendicular to the first cut path.

• Change your cutting pattern from week to week. Mow

north to south one week then change to east to west the

next week. This will help prevent matting and graining

of the lawn.

FIG. 11

Page 15

CUSTOMER RESPONSIBILITIES

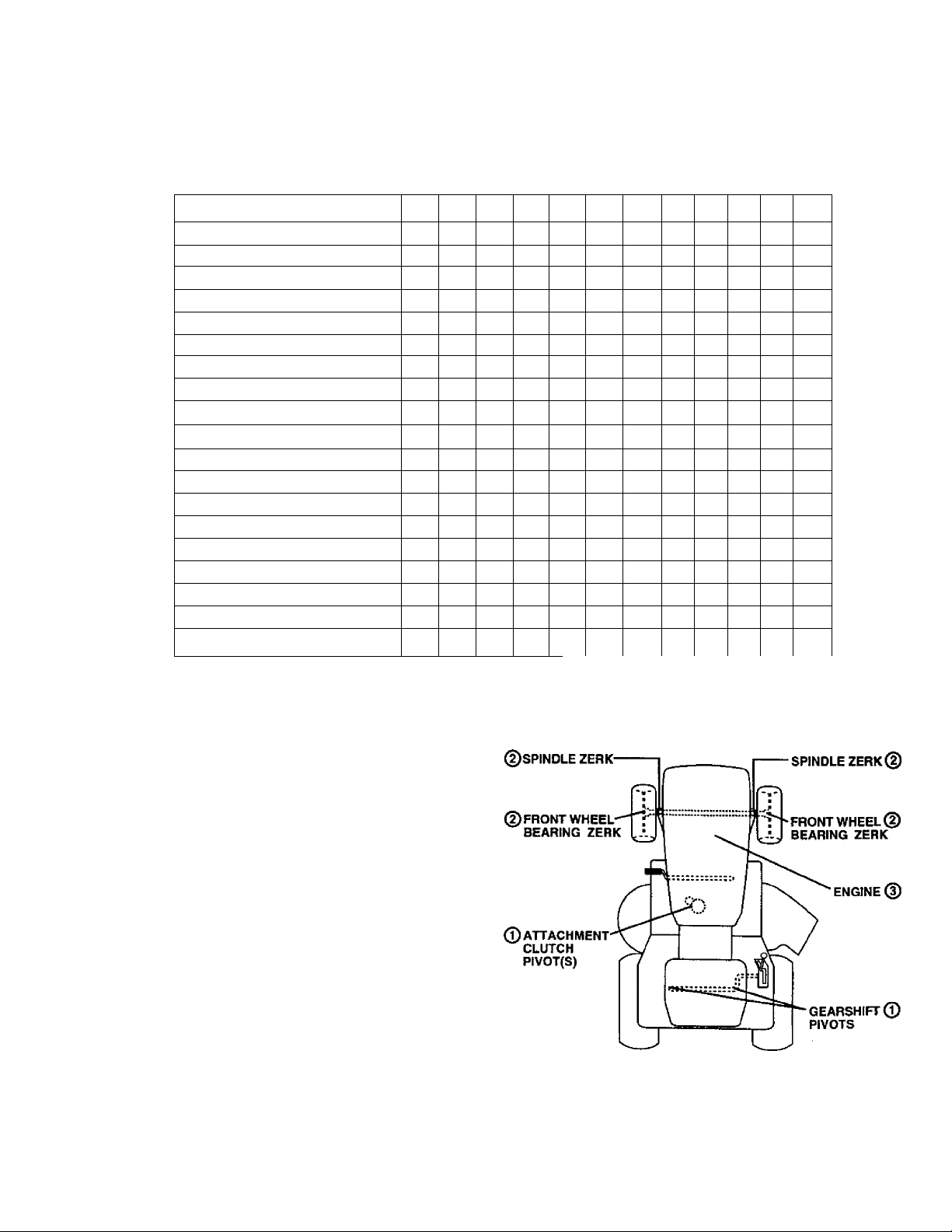

MAINTENANCE SCHEDULE

FILL IN DATES

AS YOU COMPLETE

Check Brake Operation

Check Tire Pressure

Check for Loose Fasteners

Shaipen/Replace Mower Blades

Lubrication Chart

Check Battery Level/Recharge

Clean Battery and Terminals

Check Transaxle Cooling

Adjust Blade Bett(s) Tension

Adjust Motion Drive Belt(s) Tension

Check Engine Oil Level

Change Engine Oil

Clean Air Filler

Clean Air Screen

Inspect Muffler/Spark Arrester

Replace Oil Filter (If equipped)

Clean Engine Cooling Fins

Replace Spark Plug

Replace Air Filter Paper Cartridge

Replace Fuel Filter

. riiwiw wiiwii UMUQI a I loavy ruau wi m Jiiyii aniUlC

2 - Service more often when operating in dirty or dusty conditions.

3 - If equipped with oil filter, change oil every 50 hours.

4 - Replace blades more often when mowing in sandy soil. ■

✓

✓

✓

✓

✓

✓

✓ r

✓ 4

✓

✓ e

✓

✓

✓ s

✓ s

✓

t^2,3

✓ 2

✓ 2

✓

4^2

✓ 2

✓

✓ 2

5 - If equipped with adjustable system.

6 - Not required if equipped with maintenance-free battery.

7 - Tighten front axie pivot bolt to 35 ft.-lbs. maximum.

✓

✓

✓

✓

✓

✓

Do not overtighten.

GENERAL RECOMMENDATIONS

The warranty on this tractor does not cover items that have

been subjected to operator abuse or negligence. To

receive ful I va I ue from the warranty, operator must maintai n

tractor as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your tractor.

All adjustments in the Service and Adjustments section of

this manual should be checked at least once each season.

• Once a year you should replace the spark plug, clean

or replace air filter, and check blades and belts for

wear, A new spark plug and clean air filter assure

proper air-fuel mixture and help your engine run better

and last longer.

BEFORE EACH USE

• Check engine oil level.

• Check brake operation.

• Check tire pressure.

• Check for loose fasteners.

LUBRICATION CHART

0 SAE 30 OR 10W30 MOTOR OIL

© GENERAL PURPOSE GREASE

© REFER TO CUSTOMER RESPONSIBILITIES "ENGINE” SECTION

IMPORTANT: DO NOT OIL OR GREASE THE PIVOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS. VISCOUS LUBRI

CANTS WILL ATTRACT DUST AND DIRT THAT WILL SHORTEN

THE LIFE OF THE SELF-LUBRICATING BEARINGS. IF YOU

FEEL THEY MUST BE LUBRICATED, USE ONLY A DRY, POW-

1g DERED GRAPHITE TYPE LUBRICANT SPARINGLY.

Page 16

CUSTOMER RESPONSIBILITIES

TRACTOR

Always observe safety rules when performing any mainte

nance.

BRAKE OPERATION

If tractor requires more than six (6) feet stopping distance

at high speed in highest gear, then brake must be adjusted.

(See TO ADJUST BRAKE" in the Service and Adjust

ments section of this manual).

TIRES

• Maintain proper air pressure in all tires (See “PROD

UCT SPECIFICATIONS” on page 3 of this manual).

• Keep tires free of gasoline, oil, or insect control chemi

cals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage.

NOTE: To seal tire punctures and prevent flat tires due to

slow leaks, tire sealant may be purchased from your local

parts dealer. Tire sealant also prevents tire dry rot and

corrosion.

BLADE CARE

For best results mower blades must be kept sharp. Re

place bent or damaged blades.

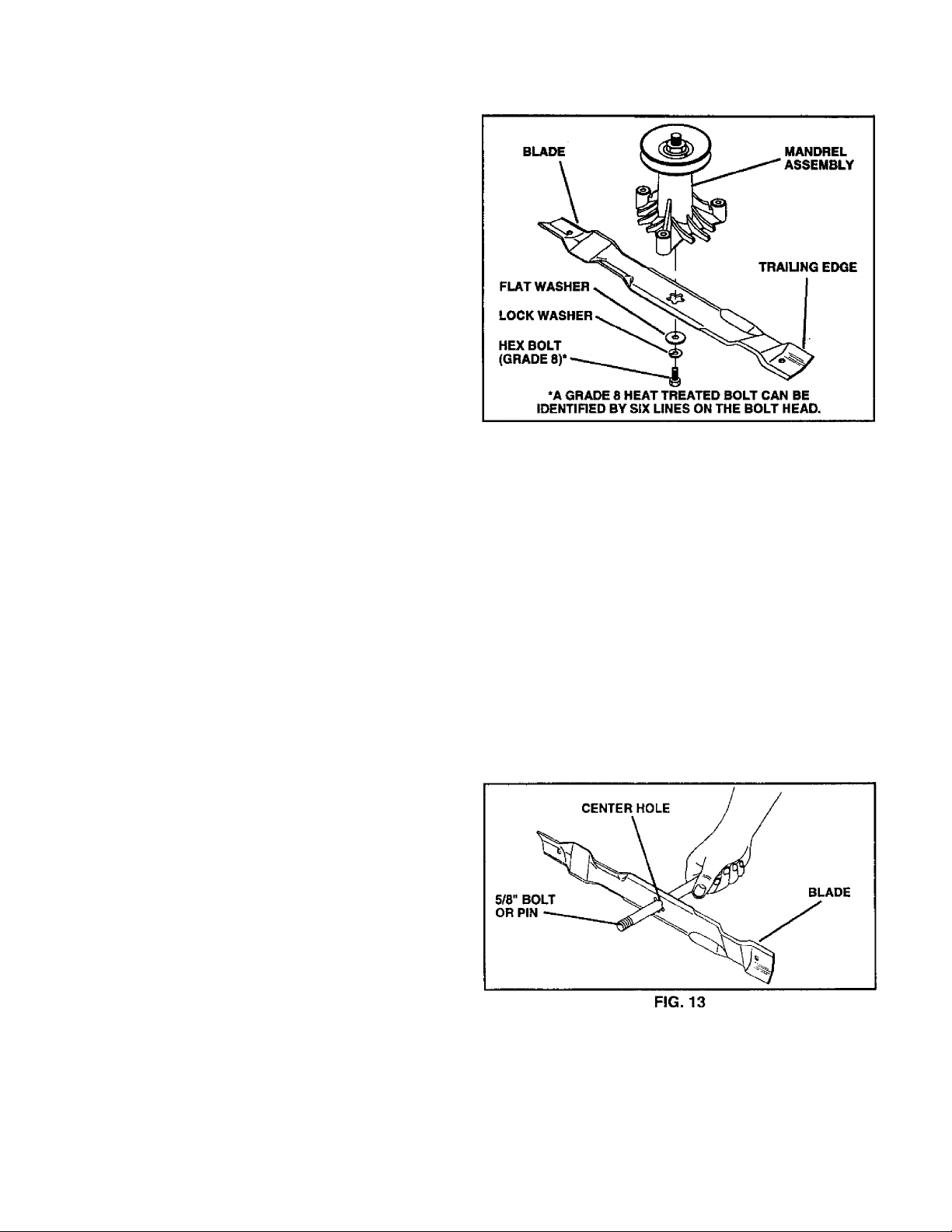

BLADE REMOVAL (See Fig. 12}

• Raise mower to highest position to allow access to

blades.

• Remove hex bolt, lock washer and flat washe r secu ring

blade.

• install new or resharpened blade with trailing edge up

towards deck as shown.

• Reassemble hex bolt, lock washer and flat washer in

exact order as shown.

• Tighten bolt securely (30-35 Ft. Lbs. torque).

IMPORTANT: BLADE BOLT IS GRADE 8 HEATTREATED.

NOTE: Wedo not recommend sharpening blade - but if you

do, be sure the blade is balanced.

FIG. 12

TO SHARPEN BLADE (See Fig. 13)

Care should be taken to keep the blade balanced. An

unbalanced blade will cause excessive vibration and even

tual damage to mower and engine.

• The blade can be sharpened with a file or on a grinding

wheel. Do not attempt to sharpen while on the mower.

• To check blade balance, you will need a 5/8" diameter

steel bolt, pin, or a cone balancer. (When using a cone

balancer, follow the instructions supplied with bal

ancer).

• Slide blade on to an unthreaded portion of the steel bolt

or pin and hold the bolt or pin parallel with the ground.

If blade is balanced, it should remain in a horizontal

position. If either end of the blade moves downward,

sharpen the heavy end until the blade is balanced.

NOTE: Do not use a nail for balancing biade. The lobes of

the center hole may appear to be centered, but are not.

16

Page 17

CUSTOMER RESPONSIBILITIES

BATTERY

Your tractor has a battery charging system which is suffi

cient for normal use. However, periodic charging of the

battery with an automotive charger will extend its life.

• Keep battery and terminals clean.

• Keep battery bolts tight.

• Keep small vent holes open.

• Rechargeât 6-10 amperes fori hour.

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and terminals can cause

the battery to “leak" power.

• Remove terminal guard.

• Disconnect BLACK battery cable first then RED bat

tery cable and remove battery from tractor.

• Rinse the battery with plain water and dry.

• Clean terminals and battery cable ends with wire brush

until bright.

• Coat terminals with grease or petroleum jelly.

• Reinstall batteiy (See “CONNECT BATTERY” in the

Assembly section of this manual).

V-BELTS

Check V-belts for deterioration and wear after 100 hours of

operation and replace if necessary. The belts are not

adjustable. Replace belts if they begin to slip from wear.

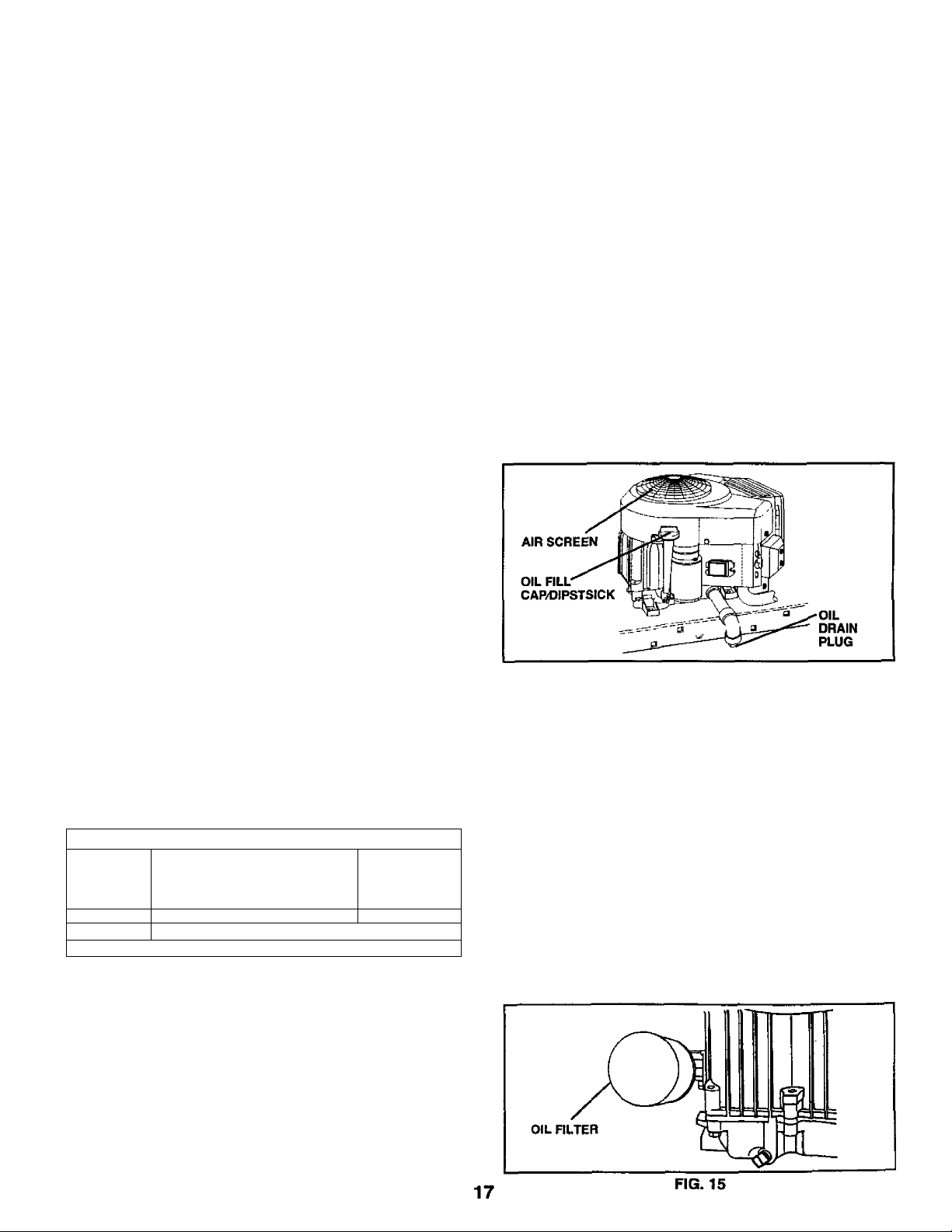

TO CHANGE ENGINE OIL (See Fig. 14)

Detemiine temperature range expected before oil change.

All oil must meet API service classification SF, SG or SH.

• Be sure tractor is on level surface.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

• Remove oil fill cap/dipstick. Be careful not to allow dirt

to enter the engine when changing oil.

• Remove drain plug.

• After oil has drained completely, replace oil drain plug

and tighten securely.

• Refill engine with oil through oil fill dipstick tube. Pour

slowly. Do not overfill. For approximate capacity see

“PRODUCT SPECIFICATIONS” on page 3 of this

manual.

• Use gauge on oil fill cap/dipstickforchecking level. Be

sure dipstick cap is tightened securely for accurate

reading. Keep oil at “FULL” line on dipstick.

TRANSAXLE COOLING

Keep transaxle free from build-up of dirt and chaff which

can restrict cooling.

ENGINE

LUBRICATION

Only use high quality detergent oil rated with API service

classification SF, SG or SH. Select the oil’s SAE viscosity

grade according to your expected operating temperature.

SAE VISCOSITY GRADES

IHi^

Op -20"

°C .30" 20“ .10" 0" 10“ 20" 30" 40"

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

NOTE: Although multi-viscosity oils (5W30, 10W30 etc.)

improve starting in cold weather, these multi-viscosity oils

will result in increased oil consumption when used above

32°F. Check your engine oil level more frequently to avoid

possible engine damage from running low on oil.

Change the oil after every 50 hours of operation or at least

once a year if the tractor is not used for50 hours in one year.

Check the crankcase oil level before starting the engine

and after each eight (8) hours of operation. Tighten oil fill

cap/dipstick securely each time you check the oil level.

0' 30" 32" 40" eo"

80“ 100“

FIG. 14

ENGINE OIL FILTER (See Fig. 15)

Replace the engine oil filter every season or every other oil

change if the tractor is used more than 100 hours in one

year.

• Unscrew old filter by turning counterclockwise. Use a

suitable container to catch oil.

• Apply a thin coating of new engine oil to rubber gasket

on replacement oil filter.

• Install replacement oil filter by turning clockwise until

rubber gasket contacts mounting surface, then tighten

filter an additional 1/2 to 3/4 turn.

• Fill crankcase with new oil (See ‘TO CHANGE EN

GINE OIL" in this section of this manual). For approxi

mate capacity see “PRODUCT SPECIFICATIONS” on

page 3 of this manual.

• Start engine and check for oil leaks. Correct any leaks

before placing engine into full operation.

Page 18

CUSTOMER RESPONSIBILITIES

AIR FILTER (See Fig. 16)

Your engine will not run properly using a dirty air filter.

Clean the foam pre-cleaner after every 25 houre of opera

tion or every season. Service paper cartridge every 100

hours of operation orevery season, whichever occurs first.

Service air cieaner more often under dusty conditions.

Faiiure to clean or service air cleaner will cause engine to

run rich and could cause spark plug fouling.

• Unhook clips on both sides of air cieanre and remove

cover.

TO SERVICE PRE-CLEANER

Slide foam pre-cleaner off cartridge.

Wash it in liquid detergent and water.

Squeeze it dry in a clean cloth.

Saturate it in engine oil. Wrap it in clean, absorbent

cloth and squeeze to remove excess oil.

if very dirty or damaged, replace pre-cleaner.

Reinstall pre-cleaner over cartridge.

Reinstall air cleanercover and reattach clips to sides of

air cleaner body.

TO SERVICE CARTRIDGE

Remove knob and cartridge plate.

Carefully remove cartridge to prevent debris from

entering carburetor.

Clean cartridge by tapping gently on flat surface. If very

dirty or damaged, replace cartridge.

Reinstall cartridge plate, cover plate, knob and

precleaner.

• Reinstall aircleanercover and reattach clips to sides of

air cleaner body.

IMPORTANT: PETROLEUM SOLVENTS, SUCH AS

KEROSENE, ARE NOT TO BE USED TO CLEAN THE

CARTRIDGE. THEY MAY CAUSE DETERIORATION OF

THE CARTRIDGE. DO NOT OIL CARTRIDGE. DO NOT

USE PRESSURIZED AIR TO CLEAN OR DRY

CARTRIDGE.

CARTRIDGE

CARTRIDGE

PLATE

COVER

FIG. 16

CLEAN AIR SCREEN (See Fig. 14)

Air screen must be kept free of dirt and chaff to prevent

engine damage from overheating. Clean with a wire brush

or compressed air to remove dirt and stubborn dried gum

fibers.

ENGINE COOLING FINS (See Fig. 17)

Remove any dust, dirt or oil from engine cooling fins to

prevent engine damage from overheating. Air guide covers

must be removed. Remove side panels and hood (See “TO

REMOVE HOOD AND GRILL ASSEMBLY” in the Service

and Adjustments section of this manual).

18

FIG. 17

Page 19

CUSTOMER RESPONSIBILITIES

MUFFLER

Inspect and replace corroded muffler and spark arrester (if

equipped) as it could create a fire hazard and/or damage.

SPARK PLUGS

Replace spark plugs at the beginning of each mowing

season or after every 100 hours of operation, whidhever

occurs first. Spark plug type and gap setting are shown in

“PRODUCT SPECIFiCATIONS” on page 3 of this manual.

IN-LINE FUEL FILTER (See Fig. 18)

The fuel fitter shou Id be replaced once each season. If fuel

filter becomes clogged, obstructing fuel flow to carburetor,

replacement is required.

• With engine cool, remove fiiter and plug fuel line

sections.

• Place new fuel filter in position in fuel line with arrow

pointing towards carburetor.

• Be sure there are no fuel line leaks and clamps are

properly positioned.

• Immediately wipe up any spilled gasoline.

CLEANING

• Clean engine, battery, seat, finish, etc. of all foreign

matter.

• Keep finished surfaces and wheels free of all gasoline,

oil, etc.

• Protect painted surfaces with automotive type wax.

We do not recommend using a garden hose to clean your

tractor unless the electrical system, muffler, air filter and

carburetor are covered to keep water out. Water in engine

can result in a shortened engine life.

19

Page 20

CAUTION: BEFORE PERFORMING ANY SERVICE OR ADJUSTMENTS:

A

TRACTOR

SERVICE AND ADJUSTMENTS

Depress clutch/brake pedal fully and set parking brake.

Place gearshift lever In neutral (N) position.

Place attachment dutch in “DISENGAGED” position.

Turn ignition key “OFF” and remove key.

Make sure the blades and all moving parts have completely stopped.

Disconnect spark plug wire from spark plug and place wire where it cannot come in contact with

plug.

TO REMOVE MOWER (See Fig. 19)

Mower will be easie r to remove from the rig ht side of tractor.

• Place attachment clutch in “DISENGAGED” position.

• Move attachment lift lever fonvard to lower mower to its

lowest position.

• Roll belt off engine pulley.

• Disconnect clutch rod from clutch lever by removing

retainer spring.

• Disconnect anti-sway bar from chassis bracket by

removing retainer spring.

• Disconnect suspension arms from rear deck brackets

by removing retainer springs.

• Disconnect front links from deck by removing retainer

springs.

• Raise lift lever to raise suspension arms. Slide mower

out from under tractor.

IMPORTANT: IF AN ATTACHMENT OTHER THAN THE

MOWER IS TO BE MOUNTED TO THE TRACTOR,

REMOVE THE FRONT LINKS.

TO INSTALL MOWER (See Fig. 19)

• Raise attachment lift lever to its highest position.

• Slide mower under tractor with discharge guard to right

side of tractor.

• Lower lift lever to its lowest position.

• Install mower in reverse order of removal instructions.

CLUTCH LEVER

CLUTCH ROD

RETAINER

SPRING

ENGINE

PULLEY

RETAINER

SPRINGS

(BOTH SIDES)

RETAINER

SPRINGS

(BOTH SIDES)

FIG. 19

20

Page 21

SERVICE AND ADJUSTMENTS

TO LEVEL MOWER HOUSING

Adjust the mower while tractor is parked on level ground or

driveway. Make sure tires are properly inflated (See

“PRODUCT SPECIFICATIONS” on page 3of this manual).

If tires are over or under!nflated, you will not properly adjust

your mower.

SIDE-TO-SIDE ADJUSTMENT (See Figs. 20 and 21)

• Raise mower to its highest position.

• At the midpoint of both sides of mower, measure height

from bottom edge of mower to ground. Distance “A" on

both sides of mower should be the same or within 1 /4"

of each other.

• If adjustment is necessary, make adjustment on one

side of mower only.

• To raise one side of mower, tighten lift link adjustment

nut on that side.

• To lower one side of mower, loosen lift link adjustment

nut on that side.

NOTE: Each full turn of adjustment nut will change mower

height about 1/8".

• Recheck measurements after adjusting.

FRONT-TO-BACK ADJUSTMENT (See Figs. 22 and 23)

IMPORTANT: DECK MUST BE LEVEL SIDE-TO-SIDE. IF

THE FOLLOWING FRONT-TO-BACK ADJUSTMENT IS

NECESSARY, BE SURE TO ADJUST BOTH FRONT LINKS

EQUALLY SO MOWER WILL STAY LEVEL SIDE-TOSIDE.

To obtain the best cutting results, the mower housing

should be adjusted so that the front is approximately 1/8" to

1/2" lower than the rear when the mower is in its highest

position.

Check adjustment on right side of tractor. Measure dis

tance “D” directly in front and behind the mandrel at bottom

edge of mower housing as shown.

• Before making any necessary adjustments, check that

both front links are equal in length. Both links should be

approximately 10-3/8".

• If links are not equal in length, adjust one link to same

length as other link.

• To lower front of mower loosen nut “E” on both front

links an equal number of turns.

• When distance "D” is 1/8" to 1/2" lower at front than

rear, tighten nuts “F” against trunnion on both front

links.

• To raise front of mower, loosen nut “F" from trunnion on

both front links. Tighten nut “E" on both front links an

equal number of turns.

• When distance “D” is 1/8" to 1/2" lower at front than

rear, tighten nut "F” against trunnion on both front links.

• Recheck side-to-side adjustment.

FIG. 21

LIFT UNK

ADJUSTMENT NUT

21

BOTH FRONT LINKS MUST BE EQUAL IN LENGTH

FRONT LINKS

TRUNNION

FIG. 23

Page 22

SERVICE AND ADJUSTMENTS

TO REPLACE MOWER BLADE DRIVE BELT (See Fig. 24)

The mower blade drive belt may be replaced without tools.

Park the tractor on level surface. Engage parking brake.

BELT REMOVAL ■

• Remove mower from tractor (See TO REMOVE

MOWER* in this section of this manual).

• Work belt off both mandrel pulleys and idler pulleys.

• Pull belt away from mower.

BELT INSTALLATION -

• Install new belt in reverse order of removal.

• Make sure belt is In all pulley grooves and inside all belt

guides.

• Install mower in reverse order of removal instructions.

TO REPLACE MOTION DRIVE BELT

(See Fig. 26)

Park the tractor on level surface. Engage parking brake.

For assistance, there is a belt installation guide decal on

bottom side of left footrest.

• Remove mower (See ‘TO REMOVE MOWER” in this

section of this manual.)

• Remove upper belt keeper.

• Remove belt from stationary idler and clutching idler.

• Pull belt slack toward rear of tractor. Remove belt

upwards from transaxle pulley by deflecting bell keep

ers.

• Pull betttoward front of tractor and remove downwards

from around engine pulley.

• Install new belt by reversing above procedure.

IMPORTANT: MAKE SURE UPPER BELT KEEPER IS

POSITIONED PROPERLY BETWEEN LOCATOR TABS.

TO ADJUST BRAKE (See Fig. 25)

Your tractor is equipped with an adjustable brake system

which is mounted on the right side of the transaxle.

If tractor requires more than six (6) feet stopping distance

at high speed in highest gear, then brake must be adjusted.

• Depress clutch/brake pedal and engage parking brake.

• Measure distance between brake operating arm and

nut “A” on brake rod.

• If distance is other than 1 -1/2“, loosen jam nut and turn

nut “A” until distance becomes 1-1/2“. Retighten jam

nut against nut “A”.

• Road test tractor for proper stopping distance as stated

' above. Readjust if necessary. If stopping distance is

still greater than six (6) feet in highest gear, further

maintenance is necessary. Contact your nearest au

thorized service center/department.

Page 23

SERVICE AND ADJUSTMENTS

TRANSAXLE SHIFTER LINKAGE AND AD

JUSTMENT (See Figs. 27 and 28)

The transaxie should be in neutral when the gear shift lever

is in the neutral (N) (lock gate) position. The adjustment is

preset at the factory; however, if adjustment is needed,

proceed as follows:

• Make sure transaxle is in neutral (N).

• Loosen two locknuts on tie rod.

• Turn center rod until gearshift lever falls into neutral

lock gate on fender console.

• Tighten locknuts securely.

TO REMOVE WHEEL FOR REPAIRS (See Fig. 29)

• Block up axle securely.

• Remove axle cover, retai ning ring and washers to al low

wheel removal (rear wheel contains a square key - Do

not lose).

• Repair tire and reassemble.

• On rear wheels only: align grooves in rear wheel hub

and axle. Insert square key.

• Replace washers and snap retaining ring securely in

axle groove.

• Replace axle cover.

NOTE: To seal tire punctures and prevent flat tires due to

stow leaks, tire sealant may be purchased from your local

parts dealer. Tire sealant also prevents tire dry rot and

corrosion.

WASHERS

RETAINING

RING

TO ADJUST STEERING WHEEL ALIGNMENT

If steering wheel crossbars are not horizontal (left to right)

when wheels are positioned straightforward, remove steer

ing wheel and reassemble per instructions in the Assembly

section of this manual.

FRONT WHEEL TOE-IN/CAMBER

The front wheel toe-in and camber are not adjustable on

your tractor. If damage has occurred to affect the front

wheel toe-in or camber, contact your nearest authorized

service center/department.

23 * RED cable last from both batteries.

AXLE COVER

SQUARE KEY (REAR

WHEEL ONLY)

FIG. 29

TO START ENGINE WITH A WEAK BATTERY

(See Fig. 30)

CAUTION: Lead-acid batteries gener

ate explos i ve gases. Keep sparks, flame

and smoking materials away from bat

A

If your battery is too weak to start the engine, it should be

recharged. If “jumper cables” are used for emergency

starting, follow this procedure:

IMPORTANT: YOUR TRACTOR IS EQUIPPED WITH A12

VOLT NEGATIVE GROUNDED SYSTEM. THE OTHER

VEHICLE MUST ALSO BE A 12 VOLT NEGATIVE

GROUNDED SYSTEM. DO NOT USE YOUR TRACTOR

BATTERY TO START OTHER VEHICLES.

TO ATTACH JUMPER CABLES -

• Connect each end of the RED cable to the POSITIVE

(+) terminal of each battery, taking care not to short

against chassis.

• Connect one end of the BLACK cable to the NEGA

TIVE (-) terminal of fully charged battery.

• Connect the other end of the BLACK cable to good

CHASSIS GROUND, away from fuel tank and battery.

TO REMOVE CABLES, REVERSE ORDER -

• BLACK cable first from chassis and then from the fully

charged battery.

teries. Always wear eye protection

when around batteries.

Page 24

SERVICE AND ADJUSTMENTS

“POSITIVE” (+)

--------------

LH. PANEL

BOLT

^

"NEGATIVE” (-)

u

jI

_______

.a__Q_

FIG. 30

TO REPLACE HEADLIGHT BULB

• Raise hood.

• Pull bulb holder out of the hole in the backside of the

grill.

• Replace bulb in holder and push bulb holder securely

back into the hole in the backside of the grill.

• Close hood.

INTERLOCKS AND RELAYS

Loose or damaged wiring may cause your tractor to run

poorly, stop running, or prevent it from starting.

• Check wiring. See electrical wiring diagram in the

Repair Parts section of this manual.

TO REPLACE FUSE

Replace with 30 amp automotive-type plug-in fuse. The

fuse holder is located behind the dash.

TO REMOVE HOOD AND GRILL ASSEMBLY (See Fig. 31}

• Raise hood.

• Unsnap headlight wire connector.

• Stand in front of tractor. Grasp hood at sides, tilt toward

engine and lift off of tractor.

• To replace, reverse above procedures.

ENGINE

TO ADJUST THROTTLE CONTROL CABLE (See Fig. 32)

The throttle control has been preset at the factory and

adjustment should not be necessary. Check adjustment as

described below before loosening cable. If adjustment is

necessary, proceed as follows:

• With engine not running, move throttle control lever to

fast position.

• Check that swivel is against stop. If it is not, loosen

cable clamp screw and pull cable back until swivel is

against stop. Tighten cable clamp screw securely.

TO ADJUST CHOKE CONTROL (See Fig. 33)

The choke control has been preset at the factory and

adjustment should not be necessary. Check adjustment as

described below before loosening cable. If adjustment is

necessary, proceed as follows:

• With engine not running, move choke control (located

on dash panel) to full choke position.

• Loosen knob and remove cover assembly from air

cleaner.

• Choke should be closed. If it is not, loosen casing

clamp screw and move choke cable until choke is

completely closed. Tighten casing clamp screw se

curely.

• Replace air cleaner cover assembly and tighten knob.

TO ADJUST CARBURETOR (See Fig. 34)

The carburetor has been preset at the factory and adjust

ment should not be necessary. However, minor adjust