Page 1

CRRFTSMRN

MODEL NUMBER 91T.258692 owner’s manual

Assembly

Operation

Customer Responsibilities

Service and Adfustments

Repair Parts

CAUTION: Read and follow all safety rules and instructions before operating this equipment

Ea

FOR CONSUMER ASSISTANCE HOT LINE, CALL THIS TOLL FREE NUMBER: t-e00-65&^5917

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Page 2

SAFETY RULES

IMPORTAMT: THiS CUTTiNG MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING OBJECTSFAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH

A

GENERAL OPERATION

Read, undersland, and ioltow alt Instrucllons In tha manual

and on ihe macWne befora siaillng-

Only allow responsibte adults, who are familiar wHh the

InsltucUons, lo opérala the machina.

Clear the ares of ob|ects such as rocks, toys, wire, a!c ,

which could ha pteksd up and Ihrown by Iha blade

Basura lha area is oleerof oihar people balare mowing Stop

machine if anyone anlars ihe area

Nevar carry passengers

Do not mow In reverse unless sbsolulely nacessary Always

look down and behind before end while backing

Be aware of tha mower discharge direcllon and da not point

II at anyone, Do not operate the mower without sHhar the

entire grass catcher or the guard in place,

Stow down before turning

Newer leave a running machine unallended Always fum off

blades, set parking Brake, slop engine, and remove keys

before dfsmouniing

Turn off blades when not mowing.

Stop engine before removing grass oatcher or unologging

chute.

Mow only In daylight or goad artifiolai iightDo not oparate Ihe machine while under the Inlloence of

alcohol or drugs.

Walsh for Irelllo whart opsratlng near or crossing roadways.

Usa BXlra cbís when loading or unloading the machine Info

a trailer or truck.

(I.

SLOPE OPERATION

Slopes are a major factor related to toss-of-conlro! and

iipover accidents, which can resul! in severe injury or death.

All slopas require extra caution. !i you cannot back up the

slope or if you feel uneasy on it, do not mow It.

DOi

Mow up end down slopes, not across,

Rsfflove obstsctes such as rocks, tree limbs, slo.

Watch for holes, ruts, or bumps. Uneven terrain could

overturn the machine Tall gross can hide obsias/ss

Use slow spaed. Choose a low gear so that you will not have

lo slop or shift while on the slope.

Follow the manufactureds recommendalions lor wheel

Weights or counlarwetghts to improve slablllty.'

Uss extra care with grass catohars or other aliachments.

These can change Ihe stability of the machine

Keep alt movamant on the slopes s/owand gradual Do not

make sudden changes in speed or direction.

Avoid starting or slopping on a slope, if tires lose iraciiort,

disengage Ihs blades and proeasd slowly sfra/ghf down ihe

slope -

DO NOT;

• Doifol turn on slopes unless necessary, andihen, lum slowly

and gradually downhill, if possible

• Oonofmowrreardrop-DffSjditohea, or embankments. The

mower could suddenly turn over tl a wheel Is over lha edge

of a cliff or ditch, or it an edge caves irt,

• Do rfot mow on wet grass. Reduced IraoUon could cause

sliding

• Do not try to stabilize Ihe machine by putting your loot on the

ground.

• Do not use grass catohar on steep slopes

Safe Operation Practices for Ride-On Mowers

til. CHILDREN

Tragic accidents can occur if the operator i$ not aiert to the

presence of children. Children are often attracted to lha

maohitie arid the mowing activity Never assume that

children will remain where you last saw them,

• Keep children out of tha mowing area and under tha watcfiful

oars of anolhar responsible adult

Be alert and lurn machine off If children enisr the erea

Before and when becking, look behind and down for small

children

Never carry children. They may fall off and be settausly

injured or intedare with safe machine operation.

Newer allow children lo operate the maoNne,

Use extra care when approaching blind comers, shrubs,

trees, or oiher objects that may obscure vision,

!V. SERVICE

• UBeexIrBcareinbandlinggasoilneandolherfusIs. Theyere

Hammabis and vapors are explosive

• Use only an approved container.

- Never remove gas cap or add fuel wHh the engine

running Allow ongirta to cool belora ralueling. Do not

smoke.

* Never refuel the machine Indoors-

•• Never store the machine or fuel oonlalnsr Inside where

there Is an open liams, such as a water heater

• Never run a machlns inslda a closed area,

• Keep nuts and bolls, espBolally bteda atfachmenl bolls, light

end keep equipment In good oondWon

» Never tamper wilh safety devices Check ihoir proper

Dporetion regulatly

• Keep machine free of press, leaves, or other debn's build-up

Clean oil or fuel spillage Allow machine to cool before

storing.

• Slop and inspaot the aquipment (f you slrika an obJacL

Rapatr, И necessary, belora rastartlng,

» Navar make adjustmenl® or repairs with ihs engine running

t Grass calohercomponsnls are subject lo wear, damage, and

detBiloratlon, which could expose moving parts or allow

objects lo be thrown, Frequently check components and

rapiacs with manufacturer's recommended parts, vrhsn nec

essary

• Mower bladsB are sharp and can cut. Wrap tha btadefs} or

weerflgvBS, and use extra caution whan servicing them-

• Check braks oparallon frsquenUy, Adjust and servloo as

required.

Look tor this symbol to point out im

portant safety precBuHons. It means

Á

CAUTION!!! SECOME ALERTHf VOUR

SAFETY IS INVOLVED.

CAUTION: Always disconnect spark plug

wire and pface wire where it cannot contact

spark plug In order lo prevent accldenia!

Á

starting when selling up, transporting,

adjusting or making repairs..

A WARNING A

The engine exhaust from this product con

tains chemicals known to the State of Califor

nia to cause cancer, birth defects, or other

reproductive harm.

A

Page 3

CONGRATUI-ATIONS on your purchase of a Sears

Tractor 11 has been designed, engineered and manulactured to give you the best possible dependability and

periartnance

Should you experience any probiern you cannot easily

remedy, please contact your nearest Sears Authorized

Service Centsr/Dspartment We have competent, welltrained technicians and the proper foals to service or repair

this tractor.

Please read and retain this manual The instructlorts will

enable you to assemble and maintain your tractor p roperly.

Always observe the “SAFETY RULES".

MODEL

NUMBER

917 25S692

SERIAL

NUMBER.

DATEOFPURCHASE.

THE MODELANDSERIALNUMBERS WILL BE FOUND

ON A PLATE UNDER THE SEAT.

YOU SHOULD RECORD BOTH SERIALNUMSER AND

date of purchase and keep in a safe place

FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement Is available on this prod

uct. Corrtact your rtearest Sears store for details.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules,

• Followa regular schedule in matfilalning, caring for and

using your tractcr.

• Follow the Instructions under "Customer Responsibili

ties" arid "Storage" sections of this owner's manual.

PRODUCT SPECIFICATIONS

HORSEPOWER:.. ’ tso

GASOLINE GAPACfTY

AND TYPE:

OIL TYPE (API-SF/SG/SH):SAE 30 (above Sa^Fj

Oil CAPACITY:

SPARK PLUG:

(GAP; .OaS'i

VALVE CLEARANCE: INTAKE: 003“ - 006"

GROUND SPEED (MPH):

TIRE PRESSURE; FRONT; 14PSI

CHARGING SYSTEM: 15 AMPS @ 3600 RPM

BATTERY:

SLADE BOLT TORQUE: 30-35 Ft LBS

WARNING; This tractor Is equipped wllh art Internal

combustion srrgine and should not be used on or near any

unimproved forest-covered, brush-covered or grass-cov

ered land unless the engine's exhaust system Is equipped

with a spark arrester meeting applicable local or state laws

(If any). If a spark arrester Is used, it should be maintained

In effective wctrklrtg order by the operator.

In the state of CalHornla the above is required by law

(Seclion 4442 of the California Public Resources Code)

Ofherstatss may have similar laws, Federal laws apply on

federal lands A spark arrester tor the muffler Is available

through your nearest Sears Authorized Service Center/

Department (See REPAIR PARTS section of this manual).

3.S GALLONS

UNLEADED REGULAR

SAE SW-30 (below 32'’F)

W/ FILTER: 4 0 PINTS

W/0 FILTER: 3 5 PINTS

CHAMPION RV17YG

EXHAUST: .013"- 016"

FORWARD: 5.5

REVERSE^ 2 4

REAR: 1QPSI

AMP/HR: 30

MIN CCA: £4D

CASE SIZE; U1R

LIMITED TWO YEAR WARRANTY ON CRAFTSMAN RIDING EQUIPMENT

Fnr two (2) years frotn the date of purEiiese, it this Craftsman Riding Equipmem is mainfstnad. lubricated and tuned up aocarding

to the instructions tn the owner's manual, Seats will repair or replace, tree ol charge, any parts found to bs dafeclive in material or

workmanship

This Warranly does not covac

‘ Expendebla items which become worn during norma! ибо, such as blades, spark plugs, air cleaners, belts, eic,

• Tire replacemanl or repair ceased by punctures from outside ob)ects, such as rtalte, thorns, slumps, or glass.

• Repairs necessary because of oparaior abuse, negifgence, Impropor storage or accident or iha failure to maintain the

egutpcneni accordltig to the instructions contained in the owner's manusl,

• Riding equipment used far oonranefcial or rental purposes

LIMITED 90 DAY WARRANTY ON BATTERY

For ninety {00} days from dale ol purchase, It any baltary Irsclutfed wlih this riding equipment proves defective in malerfal or

workmanship and our tasting datsrrnines the battery will nol hold a charge, Sears will replace the bettery at no cherga

IN-HOME WARRANTY SERVICE ON YOUR CRAFTSMAN RIDING EQUIPMENT IS AVAILABLE AT NO-CMARGE FOR 30

DAYS FROM THE DATE OF PUfiGHASE. PLEASE CONTACT YOUR NEAREST SERVICE CENTER, AFTER 30 DAYS FROM

THE DATE OF PURCHASE, WARRANTY SERVICE IS AVAILABLE BY TAKING YOUR CRAFTSMAN RIDING EQUIPMENT TO

YOUR NEAREST SEARS SERVICE CENTER, (ÍN-HOME WARRANTY SERVICE WILL STIlt BE AVAlLABLe AFTER 30 DAYS

FROM THE DATE OF PURCHASE BUT A STANDARD TRIP CHARGE WILL APPLY) THIS WARRANTY APPLIES ONLY

WHiLE THIS PRODUCT IS IN THE UNITED STATES.

This Warranly gives you specific legal rights, and you may siso have other rights which may very from slate to slate.

SEARS, ROEBUCK AND CO„ D/017 WA, HOFFMAN ESTATES. IL 60179

Page 4

TABLE OF CONTENTS

SAFETY RULES

.............................

PRODUCT SPECIFICATIONS__....

CUSTOItflER RESPONSIBILITIES....

WARRANTY......................

TRACTOR ACCESSORIES

ASSEMBLY

OPERATION

.....................

........................

.

»»r»É.«-r.rr*.+

.

.

—..........

INDEX

A

Acosssoriee

Adjustments:

Air Filter, Engine..,,

Air Screen, Errglne ,.....................................................

Assembly, ,,,.,

BallSYi

Beit:

Biade:

Brake Adjustment

Carburetor Adjuslmenl

Controls, Tractor

Customer ResponsiblWes

Cufling Height, Mower

.......

....

-,

Brett®,

..................

Garbureior.,.

Mows

Fronl-Ta-Bßck

Sida-To-SIde

Throltie Control Cable .......

Charging , ..

Cleaning

Starting with Weak Battery

Storage ...........

TermlnQls

Motion Drive

RErnovai/Replacernenl -, 23

Mower Böl!(s)

Rsmovai/Reptecament

Sharpening.

RepiacBmenl

Engine;

Air Filler.

Ait Screen .......

Gooiing Fins,,.-,. ■

Engine Oil

Fuel Fitter .....................

Spark Piug(s), . „

Tractor:

Baiieiy

В1зс1з — -. ,

Lifbrioation Chart

Mairtlertance Schedule .,

Tire Care

Traneaxie ,,

...........

..........

.................

..........-........

...

...... ., - 7-10

В

...............

..............

..................

..................' - —,■

........

..

.................

............... .

C

.......

...............

..........

,

.............

....................

..........................

-------

----------

...............

............

E

Electrical:

InlEflticke and Relays -

Schematio........

Wiring Diagram

.................

------

.......

.

..... -,

.

.........

........ ..

, ,,.

........

------...... 17

.........

---

-----.. -

.

--------

..... , 6

- . 25

.-

.....

21

......

........

. , 10

.........

.

.......

.......

26

------

------

.......17

...

22

....... 25

,,11

,16-19

___

, , Iß

,-.... 18

„, 14,16

....

-...19

...

18

....

......

___

0,17,23

......

... ,.13

....

..24

___

- .-.30

17

16

16

16

29

22

18

20

25

19

,17

24

16

17

В

.....

............. 3

-.3,16-19 STORAGE.....

.....

....

—11-15

Engine;

AtrFlIlBr -■

Air Screen , .......... ......

CoDiiftB Fine -

ОЙ Chengs , , - •....................... 18

OH Level

OHTypa. - ,

Preparation

Repair Parts

Starting

Storage

Filter;

Air, Filter

File! . ........................... IP

Fuai:

Type.....

Storage ..........................i...... „ 26

Fuse ... - 24

Hood Removai/lnsiallBlion.

ievelifiB Mower Deck

Lubrication;

Chari...............

Engine , ,

Maintenance Scheduis

Mowar:

Adjustment, Front-io-Back

Adjustnient, Side-io-Side

Blade Йвр!асеггтвп1. ...

Blade Sharpening

Ctriiinp Height ■ , ........

insSellation,.,,

Operation .....................

Hsrnaval

Mowing Tips

Muilier

Spark Arrester

Oil:

Cold Weather Conditions

Engine.

Storage

Operation ......... - ..........

.

......

2

MAINTENANCE SCHEDULE

SERVICE AND ADJUSTMENTS.....

.

.

3 THOUBLESHOOTIN G

----- 5

*..,...7-10 REPAIR PARTS - ENGINE

REPAIR PARTS - TRACTOR.......

...........................

........

PARTS ORDERING/SERVICE........

.......... . -

...............................

....

................................. 16

..................................

- „, „

..............

..........................

..........................

----------------------

.............

.................................. ................ .................................

....

....... ., 19

14

14,18

14

26

Operating Mower .

18

Opiions:

.16

Accessories

Sperk Arrester

Parking Brake

Parts Bag

Parts, Repiacemenl/Repair.

Product Speclllcalions .

F

....................................

..............................

H

M

--------------

.........

- - -. ..

...

........ . - -

..........

.........

.................

О

.......

.......

......

............

..........

-,

.

:

•

.

• 14

.. ,21

.

...20

.

. 20

-.,17

.20

3,38

14,18

.. 26

11-15

Repair Parts

18

Salely RuIbs

Seat -,..

Service and Adjusiments .

Carburetor

Fuse............

34

30

16

. IB

10

.„17

13

, 14

, 15

19

.18

Hood Rerrtovakirtsiallation

Motion Drive Beit

Romovai/HeplacamBnl .,..23

Mower Beltlsj

Bemovai/Repiacemsnt 22

Mower Adjuslmeni

' FronHo-BSek „ . , . 21

Slde-to-Slda

Mower Removaidnslaiiation.,,..20

Tira Care.,....................

Slops Guide Sheet , . „59

Spark Plug(s|

SpecilieBtlons- . - ............ 3

Starting the Engine , ,, .,,,, ..........14-16

SteeringWhesi ,—

Stopping the Tractor

Storage,

.........................................

ThroUis Control Cable Adjustment. 25

Tires .

...

TroubtsshQOltog Chart. 27-20

Transaxle .,,,

Warranty

Wiring Diagram

Wiring Schematio.......................... 29

.......

-.i. 16

.

.........................

...................

...............

......................

.

.

........

.

........

...............

.............48-57

.

...

.

BACK COVER

.................

............ ....

.

.....

.......

.....................

..............

............... , „.-7,23

....

............

........... ..

.................................

.................

.....

............................ - 10

W

.......

.............. „ . 30

20-25

...,„...,26

27-28

30-47

-

. .... a

20-25

20

„,,8,17,23

..........

... 19

.......13

26

8,17,23

3

....

14

...... S

3,30

12-13

, .40-57

30-47

...

3

30-47

,, , 2

- .2S

. .24

24

Page 5

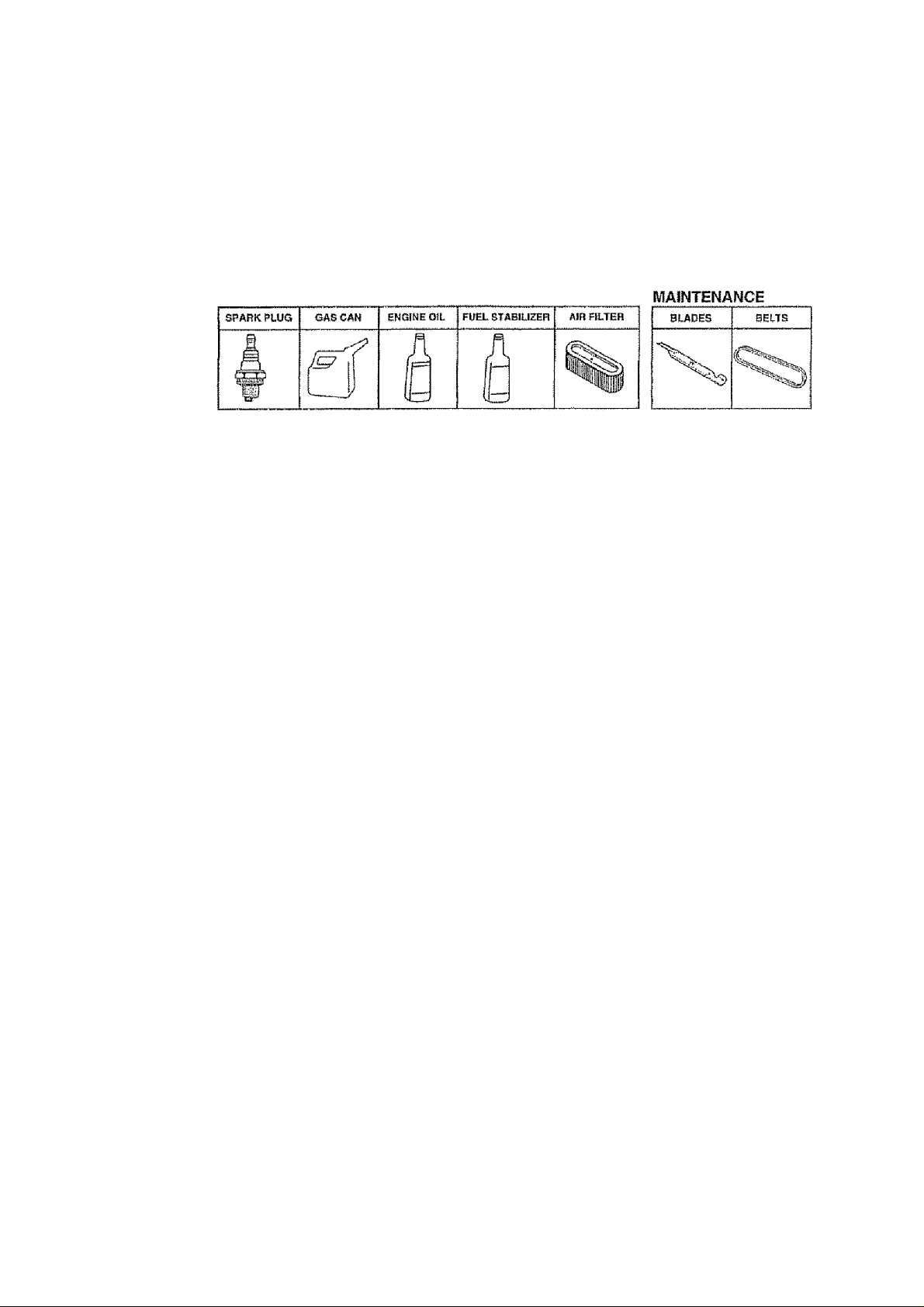

ACCESSORIES AND ATTACHMENTS

These accessoriss and altachmenls were availabte through most Sears retatt dutlels and se rvSce cente rs when the tractor was purchased

Most Sears stores can order these items tor you when you provide the mode! number of your tractor.

ENGINE

PERFORMANCE

Sears offers a wide variety of attBchments that fit your tractor. Many of these are listed below with brief axpienaiiona of how they can help

you- This list was current at the lime of pubitoatlon: however, It may change in future years ■ more altaohmanls may be added, changes

may be made in these attachments, or some may no longer bo available or fit your mods! Contact your nearest Sears store for the

accessories and attachments that are available for yoor tractor.

Most of Ibesa altaohments do not require additional hitches or conversion kits {those that do are inrSoatad) and are cfBaigned far easy

attaching and detaching

AEBATOH promoies deep too! growth lor a healthy tawn Ta

pered 2.5-)nch bIbo! spikes mounted on tO-inch diameter discs

puncture hefes in soft at otase Intervafe to fet moisture soak In

Steel weight tray for increased penetration

BAGGER tats you collect grass clippings and leaves for e

healthier, neater looking lawn. Two Permanex containers hold

30-gallon plaslic bags "

BUMPER proiecls Ifonl end of tractor from damage

CARTS make hauling easy Variety of siaes available, plus

Bccessoriss such as Bids panel kits, tool caddy, car! ¿over,

pfotective mat and doily,

GORING AERATOR lakes small plugs oul of soil !c afiow mois

ture and nutrfenta to reach grass roots, 36-Inch svrath 24

hardened steel coring tips 150 lb capacity weigh! tray.

EASY OIL DRAIN VALVE makes oil changes aasier. faster

FRONT NOSE ROLLER cemers In front of mowar deck to reduce

chances of "scalping" on unevan termin.

QANG HITCH laic you tow2 or 3 pulf-behind altachíTíenls al once,

such as sweepers, dethalchers, aatatots (not for use wllh rollers,

carts or other heavy atlachmente)

GAUGE WHEELS on both sides of the mower deck reduce

chances of "scalping“ on uneven terrain For mower decks no! so

equipped

MULCH RAKE/DETHATCHER Icosens soil and Hips thatch and

matlBd loaves to lawn eurlBoe lor easy pickup. Twenty spring tine

iselh Usefutlopreparebare areas foraeedlng. Available for front

or rear mounting. HIGH PERFORMANCE REEL-AGTiON

SPRING TINE DETHATCHER covers 36-inch wide path and

losses thatch into large hopper . Mounts behind Iractor.

MULCHING CLOSE-OUT PLATE KIT, orree fnslallsd, lels you

mulch, discharge or bag dippings {baggar optional) wilhoul

changing blades. For models not equipped as 3-tn-l CorivettiblB

mowers Saa "MOWER" In the Repair Ports saclion of this

manual.

RAMP TOPS AND FEET Isl you load and onload Iraclor from a

pickup truck Use with 2x0 or 2x10 iumber.

ROLLER far smoother lawn surface. 36-inch wide, 10-inch

diameterwatar-tight drum holds up to 3901bs. ol weigh!. Rounded

edges prevent harm to turt. AdjustabiB scrapsr aulomalicaliy

cfaans drum.

SNO W B LADE for snow removal only. 14-inch high, 4 8 -inch wide

blade clears 42-inchpalh when angled teftor right. Raises, towers

with side fever Adjustable skids; repteoeable, reversible scraper

bap (Use with lire chains and wheel weights and/or rear drawbar

weight.)

SNOWTMROWER hasAO-fnch swath. Orutn-iyps auger handles

powdery and weWiaavy snow Mounts easily with simple pin

arrangement, Discharge chute adjusts from Iractor seal. 6-Inch

diameter spout discharge© enow 10 to 60 íoei. Lili cunlrolied al

tractor seal. (Use with chains and wheel weights and/or rear

drawbar weight)

SPRAYERS use 12-vo!l DC stectric molor thel connocis to the

tractor ballery or other 12-voil source. Includas booms lor

automalto spraying and hand held wand lor spot spraying Wand

has adjuslabla spray patiern. For applying herbicides, insecti

cides, fungicidas and liquid iertiilzers

SPREADER/SEEDERS mate saeding, fertilizing, and weed kflltng easy. Broadcast spreaders are also usefuilor granular dsicers and sand

SWEEPERS la! you colled grass clippings and leaves

TILLER has 5 hp angina and 36-inch swath !o prepare seed bods,

GUllivate and compost garden residue Tiller has its own butiWn

lift and depth cemt ral eyslem and doss NOT require a sleeve hitch.

Fits any lawn, yard or garden tractor. Simply hook up to the tractor

drawbar and gol Optional accessories converl unit for

dethalching. aerating, hilling . without tools

TIRE CHAINS are heavy duty; closely spaced extra-large cross

links give smooth rida, oulslarnJIng iraetton.

TRACTOR CAB has heavy duly vinyl labrfc over tubular steel

frame, ASS piasifc top; clear piasite windshield oflars 360 degree

vlstblilly. Hinged metal doors with catch. Keeps operalor warm

and dry flemava vinyl sides and wlndshlBlda lor use as suh

protector in summer, Optionai accesaortes inoludai tinted/

tempered solid safely glass windshield with hand operated wipeq

12-volt amber caullon light for mounting on cab top

VACSfor powerful coilecllan o! heavy grass clippings and leaves.

Optionai wand attachment to pick up debris in hard-to-reach

places VAC/CH1PPER includes a chipper-shredder

WEIGHT BRACKET far drawbar lor snow removal applications.

Uses (1) 55 lb. weigh!

WHEEL WEIGHTS for rear wheals provide needed traction for

snow removal or dozing heavy malefials

Page 6

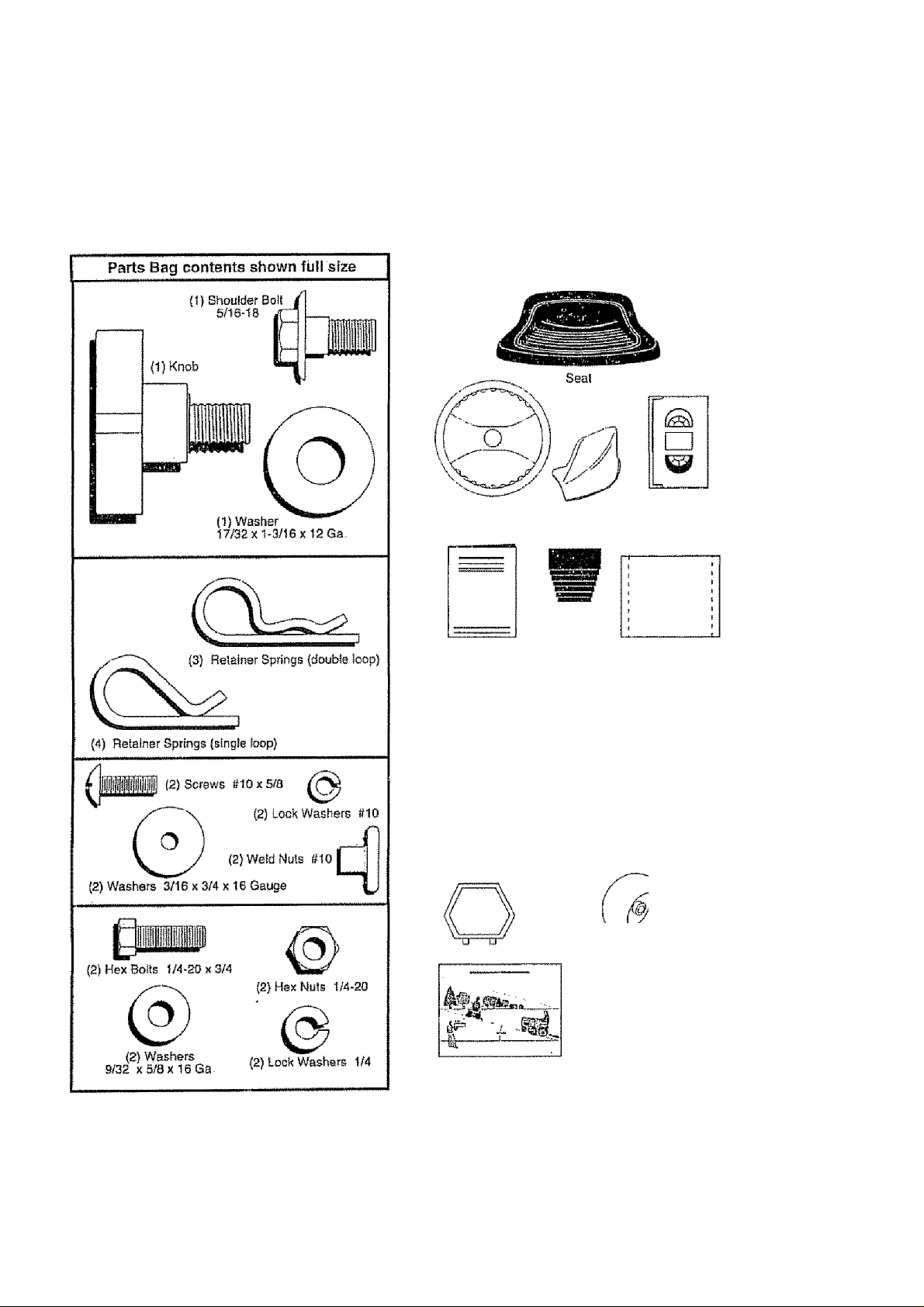

CONTENTS OF HARDWARE PACK

Parts packed separately In carton

Steering

Whesi

Manual

Mulcher

Plate

Steering

Sleeve

Video

Cassette

Parts Bag

Parts bag contents not shown full size

¡2) Washers 3/B

{2) Shoulder

Bolls

(2) Center'

lock Nuts

(2) Front Link Assemblies

Steering

Wheel

Insert

X 7/8x14 Gauge

IJ

'^(2) Gauge

Wheels

Slope Sheet

(2) Keys

Cl^£i=rz=a

latch Hook

Assemblies

Page 7

ASSEMBLY

Youf new Iraclor has been assembled at the faclofy with sKception of those parts iait unassembled lor shipping purposes.

To ensure safe and proper operation of your tractor alt parts and hardware you assemble must be tightened securely Use

the correct tools as necessary to tosure proper lightness - '

TOOLS REQUIRED FOR ASSEMBLY

A sachet wrench set will make assembly easier Standard

wrench sizes are listed,

(2) 7/16" wrenches Piters

(1) 9/16" wrench Tire pressure gauge

(1) 3/4" Socket w/drive ratchet Phillips Screwdriver

Utility knife

When right or left hand is mentioned In this manual, it

means when you are in the operating position (seated

behind the stserihg wheel)

TO REMOVE TRACTOR FROM CARTON

UNPACK CARTON

• Remove all accessible loose parts and parts cartons

irom carton (See page 6).

• Cut, from top to bottom, along lines on all four corners

of carton, and lay panels flat

• Remove mower and packing materials

• Check lor any additional loose parts or cartons and

remove-

FIG. 1

BEFORE ROLLING TRACTOR OFF SKID

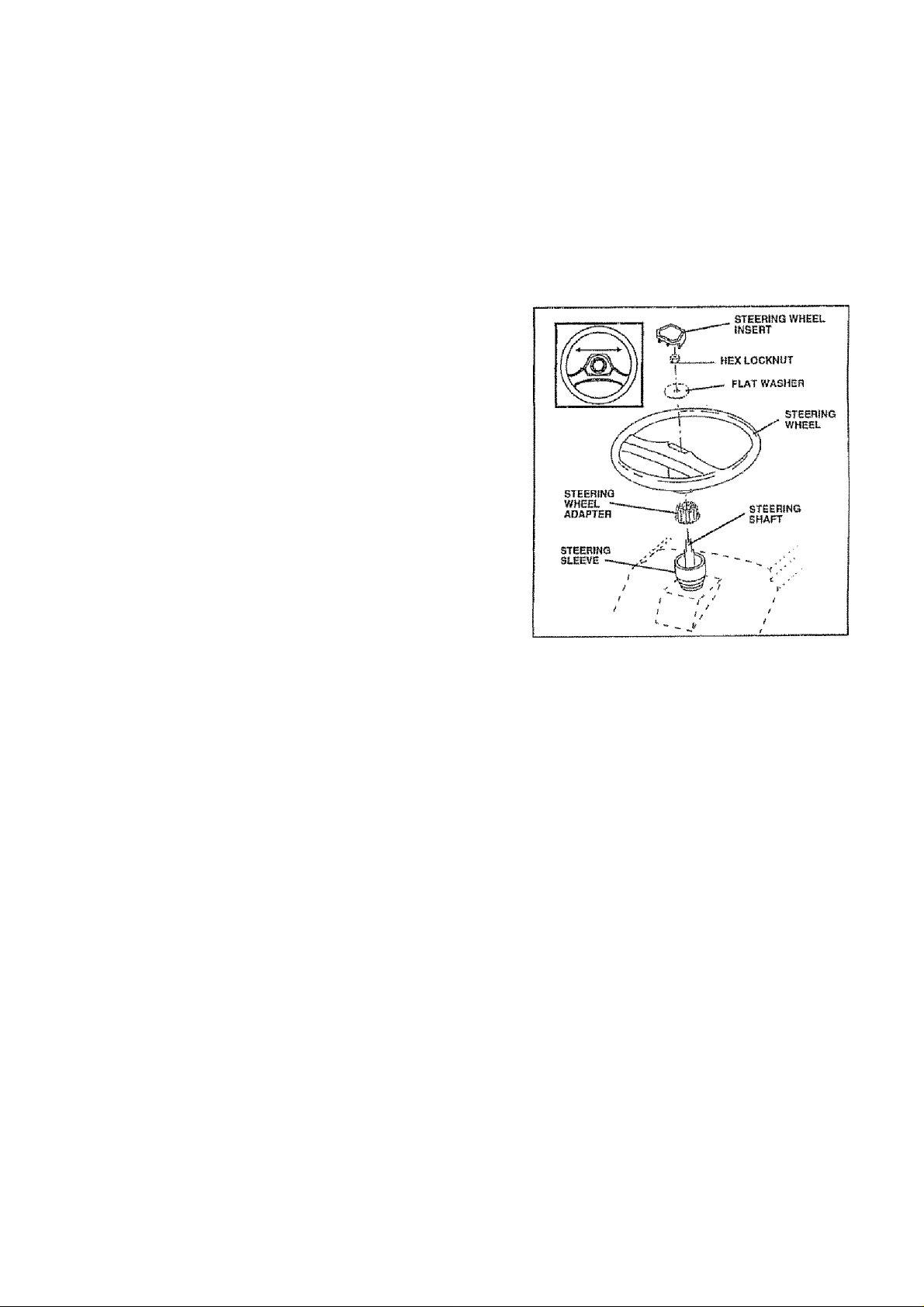

ATTACH STEERING WHEEL (See Fig. 1)

' Remove locknut and large flat washer from steering

shaft-

• Position front wheals of the tractor so they are pointing

straight forward

• Slida the steering sleeve over the steering shaft

• Position stsering wheel so cross bars are horizontal

(left to right) and slide onto adapter

• Secure steering wheel to steering shalt with locknut

and targe flat washer pravlously removed, Tighten

securely.,

• Snap stsering wheel insert into center of steering

wheel.

• Remove protective materials from tractor hood arrd

grilt-

lIVtPORTANT; CHECK FOR AND REMOVE ANY STAPLES

IN S KtO TH AT M AY P UNCTU RE TIRESWHERET RAGTOR

IS TO ROLL OFF SKID

TO ROLLTRACTOR OFF SKID (See Operation

section for location and function of controls)

• Prsssllftleverpiungerand raise attachment lilt Isverto

its highest position.

• Release parking brake by depressing dutch/brake

pedal

• Place freewheel control in freewheeling position to

disengage transmission (See 'TO TRANSPORT' In

the Operation section of this manual)

» Roll tractor backwards off skid.

Page 8

ASSEMBLY

HOW TO SET UP YOUR TRACTOR

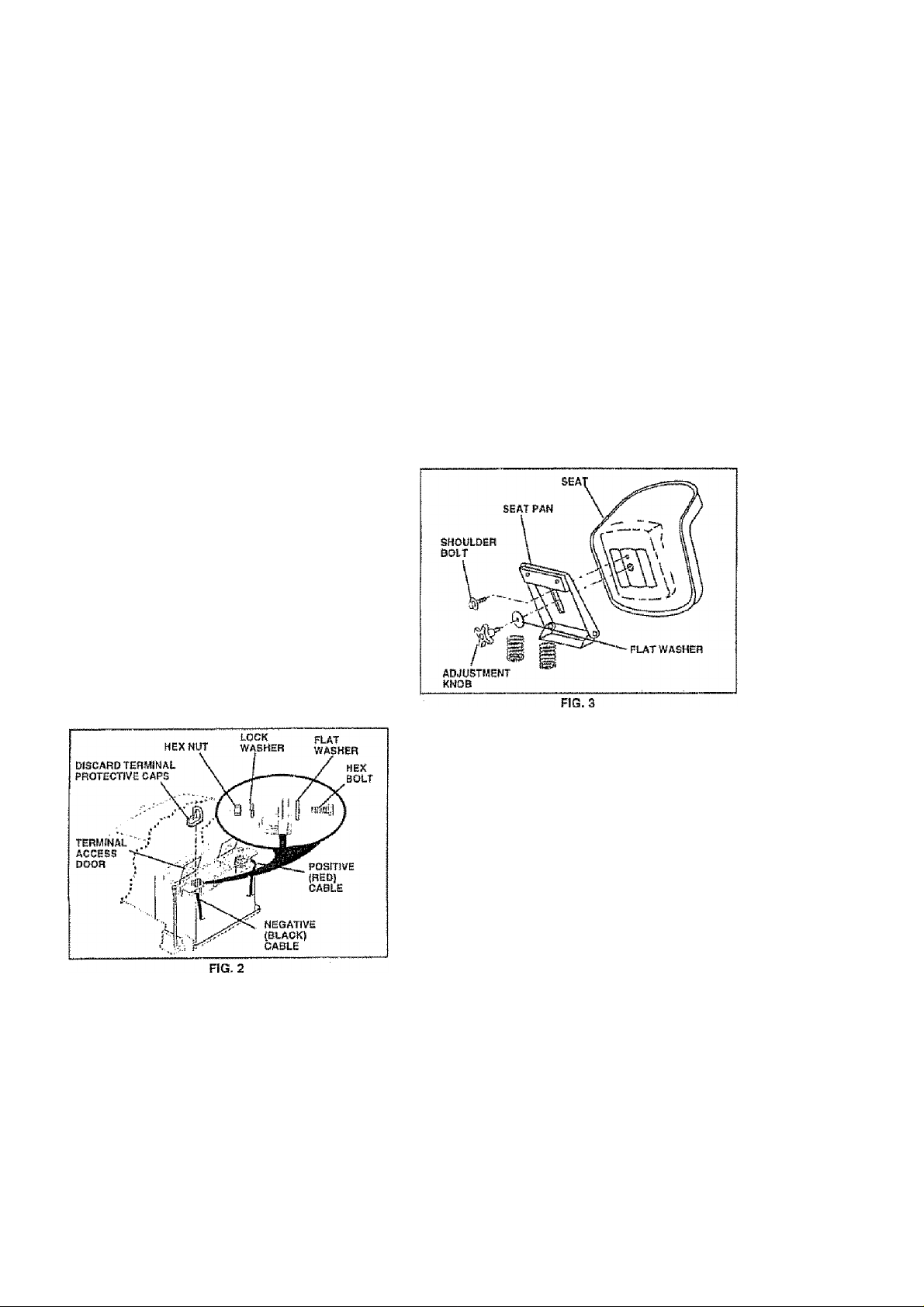

CONNECT BATTERV (See Fig. 2)

CAUTION; Do not short battery termfBals by alio wing a wrench or any other

object to contact both terminals at the

A

• Lif! hood to raised position

• Open terminal access doors, remove terminal protec

• it this battery is put into Service after month and year

• First connect RED battery cable to positive (+j battery

• Connect BLACK grounding cable to negative (-) bat

• Close terminal access doorsUse terminal access doors for:

• inspectton for secure connections {to tighten hard

• Inspsclion lor corrosion

' Testing battery.

» Jumping (if required).

same time, Sefore connecting battery,

remove metal bracelets, wrlstwatch

bands, rings, etc.

Positive terminal must be oormeoted

first to prevent sparking from acciden

tai grounding.

tive caps and discard.

indicated on label {label located between terminals)

charge battery for minimum of one hour at 6-10 amps.

terminal with hex bolt, flatwasher, lock washer and hex

nut as shown. Tighten securaty,

tery terminal with remaining hex boll, flat washer, lock

washer and hex nut, Tighten securely.

ware).

Periodic charging.

fNSTALL SEAT (See Fig. 3)

Adjust seat before tightening adjustment knob.

• Remove cardboard packing on seat pan

• Place seat on seal pan and assemble shoulder bolt.

• Assemble adjustment knob and flat washer loosely.

Do not tighten.

• Tighten shoulder bolt securely.

• Lower seat into operating position and stl on seat.

• Slid« seat until a comfortable position is reached which

allows you ¡0 press clutciVbrake pedal all the way

down

» Get off seat without moving its adjusted postlion..

• Raisa seal and ilghtert adjustment knob securely.

CHECK TIRE PRESSURE

The tifss on your tractor were overinflaled at the factory lor

shipping purposes- Correct tire pressure Is Important tor

best cutting performafioe.

• Reduce tire pressure to PS! shown in ''PRODUCT

SPECIFlCATiONS” on page 3 of this manual

CHECK BRAKE SYSTEM

After you ieam how to operate your tractor, check la ses

that the braka is properly adjusted. Ses “TO ADJUST

BRAKE" in the Service and Adjustments section d1 this

manual.

Page 9

ASSEMBLY

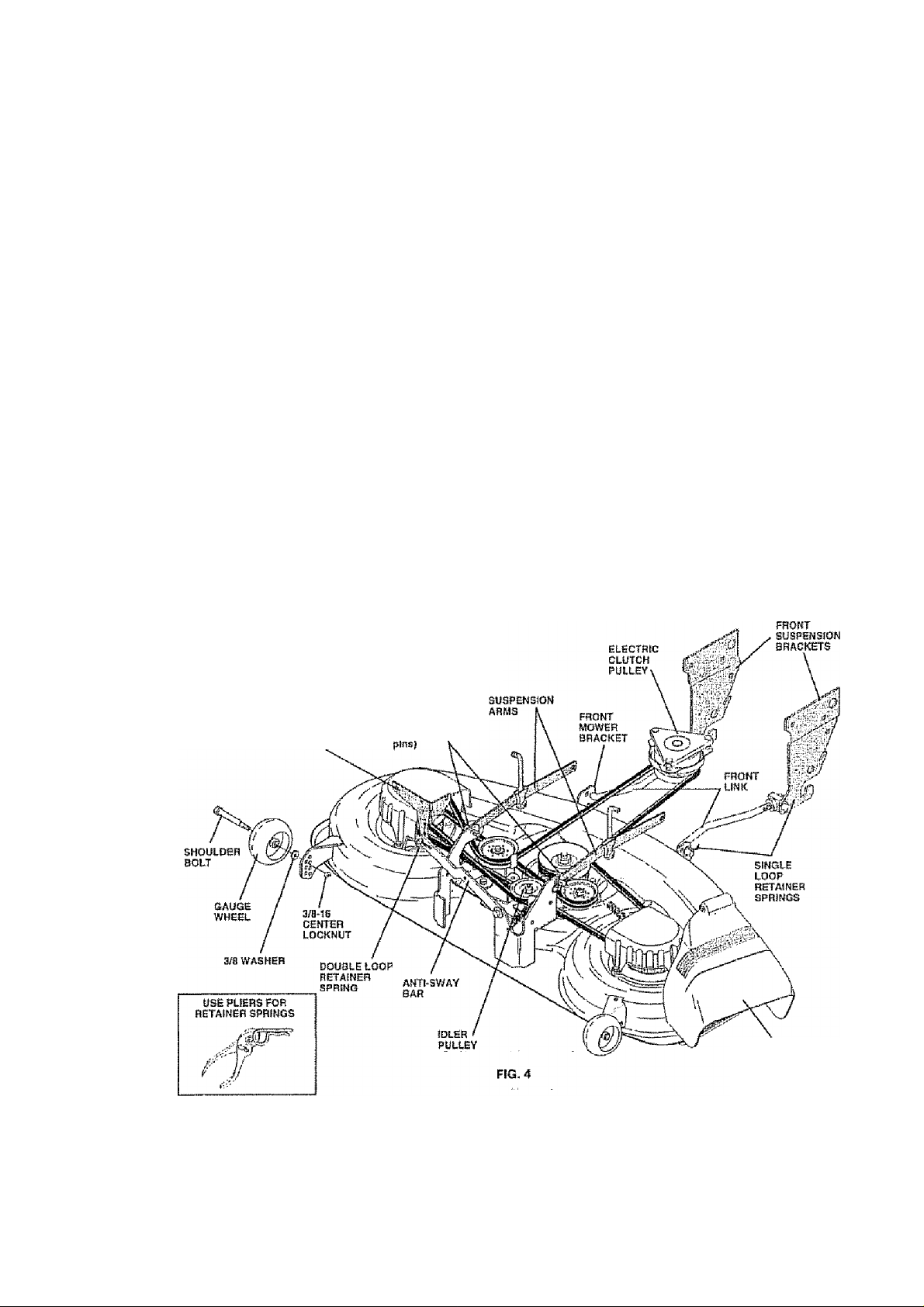

INSTALL MOWER AND DRtVE BELT

(See Figs. 4 and 7)

Ba sure iraclor is on level surface and mower sospenston

arms are raised with aitachmeni lift conirol,. Engage park

ing brake.

• Cut and remove ties securing anti-sway bar and balls.

Swing anti-sway bar to left side of mower deck.

• Slide mower undartractor with discharge guard to right

side of tractor,

IMPORTANT: CHECK SEIT FOR PROPER ROUTING IN

ALL MOWER PULLEY GROOVES. INSTALL BELT INTO

ELECTRIC CLUTCH PULLEY GROOVE.

• Install one front link In top hole of the H.H., front mower

bracket and R.H. front suspenatoh bracket. Retain

with two single loop retainer springs as shown

• Install second iron! link In L. H, front suspenslort bracket

only and retain with single loop retainer spring as

shown.

• Turn height adjustment knob counterclockwise until it

stops

» Lower mower linkage with aitachmeni lift control.

• Place the L.H, suspension arm on outward pointing

deck pin. If necessaty, rock and raise front of mower

to align deck pin wlln the hole in suspension arm

Retain with double loop retainer spring with loops

down as shown,

Slide left side oi mower back a nd install the unattached

front link in top hots of the LH, front mower bracket.

Retain with single loop retainer spring as shown

DOUBLE LOOP

rtSTAlNEB SPRING

(OUlWJircl pOPRilnp

deck ■ '

• Place the R.H suspension arm on outward pointing

deck pin. if necessary, rock and raise front of mower

to align deck pin with the hols in suspension arm.

Retain with double loop retainer spring with loops down

as shown

• Connect anti-sway bar to chassis bracket under left

footrest and retain with double loop retainer spring

• Turn height adjustrrrent knob cloclcwlss to remove

slack from mower suspension.

• Raise mower to highest position.

• Assemble gauge wheels (See ”TO ADJUST GAUGE

WHEELS" in the Operation ssction of this manual).

CriBC^fv MOwvBiFt lf#BVBL-NBoS

For best cutting results, mower should be property leveled,

See “TO LEVEL MOWER HOUSING" in the Service and

Adjustments section of this manual.

CHECK FOR PROPER POSITION OF ALL

BELTS

See the figures that are shown for replacing motion, mower

drive, and mower biada drive belts in the Service and

Adjustmenis section of this manual Verify that the belts

are routed correctly

DISCHARGE GUARD

Page 10

ASSEIVIBLY

IhhF ■ M i IlHF llMI S

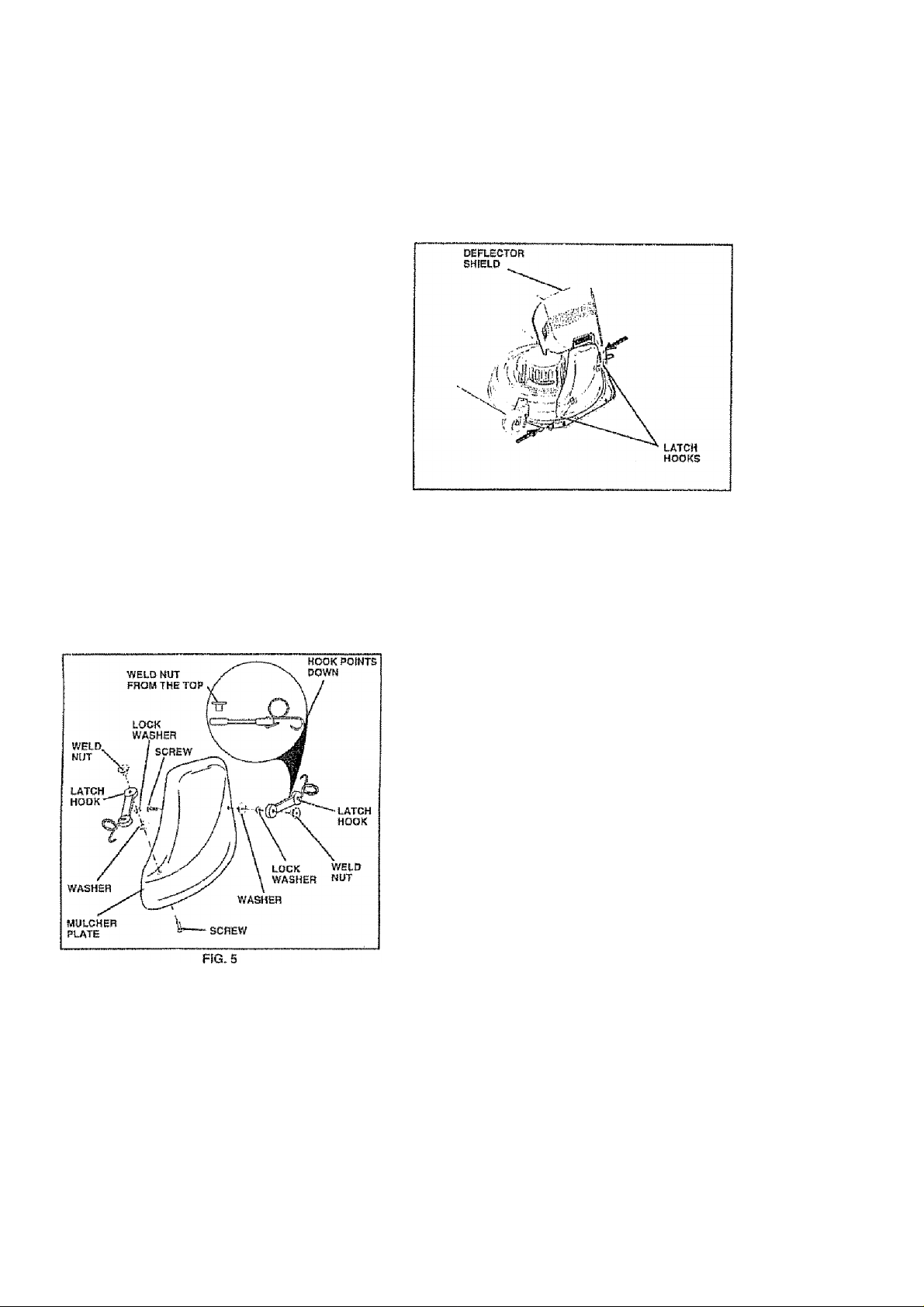

NSTALL iviuLCHER PLATE (See Figs, 5 ana 6)

• tnslall two ialcfi hooks to mulcfier ptote using screw,

washer, lock washer, and weld nui as shown,

NOTE: Pre-assemble weld nul to latch hook by inserting

weld nut from the lop with hook pointing down-

• Tighten hardware securely,

• Raise and hold deitecfor shield in upright position.

• Place troni of mulcher plate over front of mower deck

operiing and slide into place, as shown,

• Hook front iatch into hole on front of mower deck.

• Hook rear latch into hole on back of mower deck

CAUTiON: Do not remove discharge

guard from mower. Raise and hold

guard when attaching muicher plate

and aliow it to rest on plate while in

opamtlon.

FIG. 6

TO CONVERT TO BAGGING OR

DISCHARGING

Sfmpfy remove muicher plate and store in a safe ptace.

Your mower is now ready tor discharging or instatlallon of

optional grass catcher accessory,

NOTE: it is not necessary to change biadss. The muicher

blades are designed for discharging and bagging ateo

^CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRACTOR. WE WISH TO ASSURE THATYOU RECEIVE

THE BEST PERFORMANCE AND SATISFACTION FROM

THIS QUALITY PRODUCT

PLEASE REVIEW THE FOLLOWING CHECKLIST;

/ All assambly Insirucllons have been compieted

/ No remaining loose parte in carton.

/ Battery Is properly prepared and charged {Minimum

1 hour at 6 amps),

/ Seat is adjuslsd comfortably and tightened seciireiy.

/ All tires are properly inflated. (For shipping purposes,

the tires were overfnflaled at the factory).

/ Be sure mower deck is properly iaveled s(deHo*side/

front-to-rear for best cutting rasuits, (Tires must be

properly Irttlated tor ieveling),

/ Check mower and drive belts. B e sure they are routed

properly around pulleys and inside ati belt keapars.

/ Check wiring. See that alt connect tons a re still secure

and wires are properly clamped.

/ Before driving tractor, be sure freewheel control is In

drive position

WHILE LEARNING HOW TO USE YOUR TRACTOR. PAY

EXTRA ATTENTION TO THE FOLLOWING IMPORTANT

ITEMS;

/ Engine ollls at proper levs!.,

/ Fuel tank Is fiiied with fresh, clean, regular unleaded

gasoline,

/ Become familiar with all conirois ' their location and

lunGtion. Operate them before you start the eriptne,

/ Be sure brake system is irr safe operating condition.

/ It is important to purge the transmission before operat

ing your tractor for the first Urns Foliow proper starting

and irarismlsstorr purging Instructions (See 'TO START

ENGINE" and "PURGE TRANSMISSION" In the Op

eration section o! this manual).

10

Page 11

OPERATION

These symbois may appsaron your traoior or tn Dtarafore suppfted with the product- Learn and itrtdersiand their meaning

n A $

BATTERY

©

ENGINE ON

a

FUEL

Ik

Í

CAUTION OR

WARNING

STOP

ENGINE OFF

REVERSE FORWARD

OIL PRESSURE

l\l £

CHOKE MOWER HEIGHT

D

n

REVERSE

N

NEUTRAL

.Î.

FAST SLOW

4 a| a

CLUTCH LIGHTS ON LIGHTS OFF

© G?

differential PARKING BRAKE

LOCK LOCKED

H L

HIGH LOW

(©)II

PARKING BRAKE

UNLOCKED

If

MOWER LIFT

DANGER, KEEP HANDS AND FEET AWAY

ATTACHMENT

CLUTCH ENGAGED

ATTACHMENT

CLUTCH DISENGAGED

HYDROSTATIC FREE WHEEL

(Hydro Models only)

11

IGNITION

Page 12

OPERATION

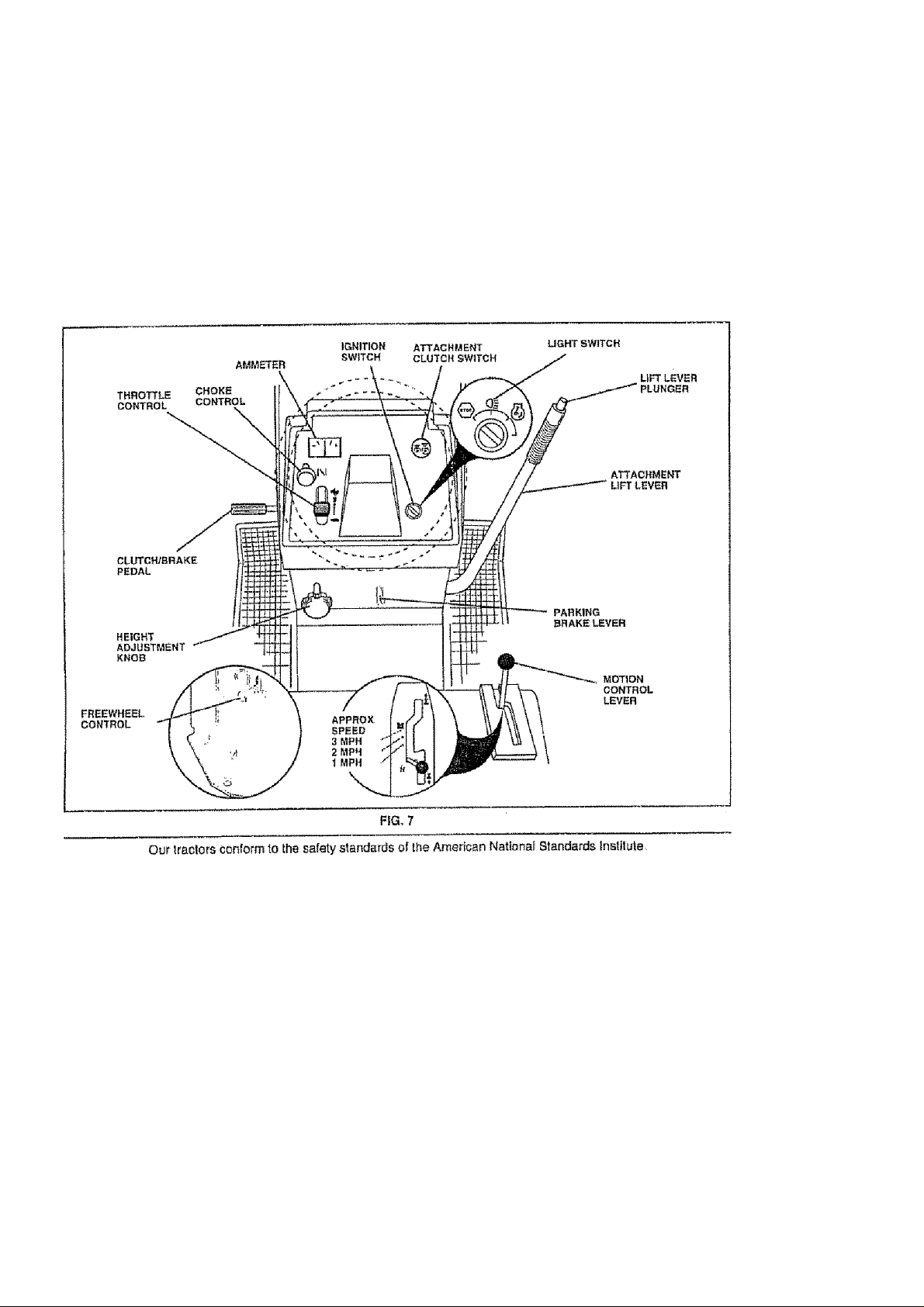

KNOW YOUR TRACTOR

READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR.

Compafe the Illustrations with your tractor to familiarize yourself with the location ol various controls and adjustments - Save

this manual for luture reference, ,

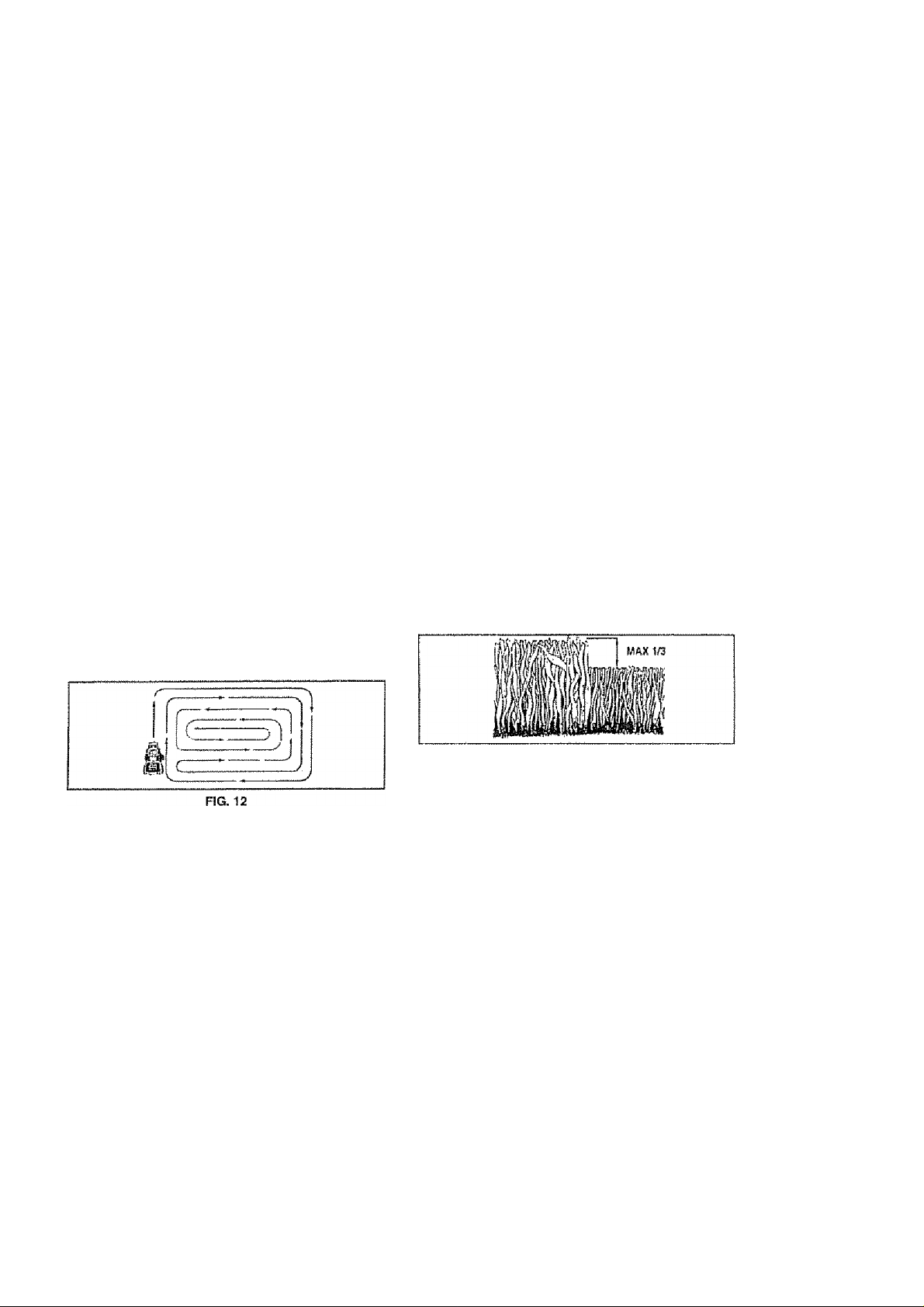

ATTACHMENTCLUTCH SWITCH' Usedtoarrgagemower

blades or other attachments mounled to your tractor

ATTACHWIENT LIFT LEVER - Used to raise and lower

mower deck or other attachments mounted to your tractor,

CLUTCH/BRAKE PEDAL - Used for declutching and

braking the tractor and starting the engine,

HEIGHT ADJUSTMENT KNOB - Used to adjust the mower

height, ,

LIGHT SWITCH - Turns the headlights on and off,

MOTION CONTROL LEVER *- Selects the speed and

dtreciion of the tractor.

12

IGNITtON SWITCH - Used !o slart and stop the engine

PARKING BRAKE LEVER - Locks ciutch/brake peda! into

the brake position.

THROTTLE CONTROL - Used to conirof atrgine speed.

LIFT LEVER PLUNGER - Used to release attachment lift

lever when changing Its position,

CHOKE CONTROL - Used when starting a cold engine

AMMETER - Indicates charging (t) or dischatgIrtg (-) of

battery

FREEWHEEL CONTROL - Disengages Iransrnission for

pushing or slowly towing the tractor with the engine o!f

Page 13

OPERATION

The operation of any tractor can result in foreign objects thrown into the eyes, which can

result In severe eye damage. Always wear safety glasses or eye shields while operating

your tractor or performing any odjostmenls or repairs. We recommend a wide vision safety

mask over the spectacles or standard safety glasses.

HOW TO USE YOUR TRACTOR

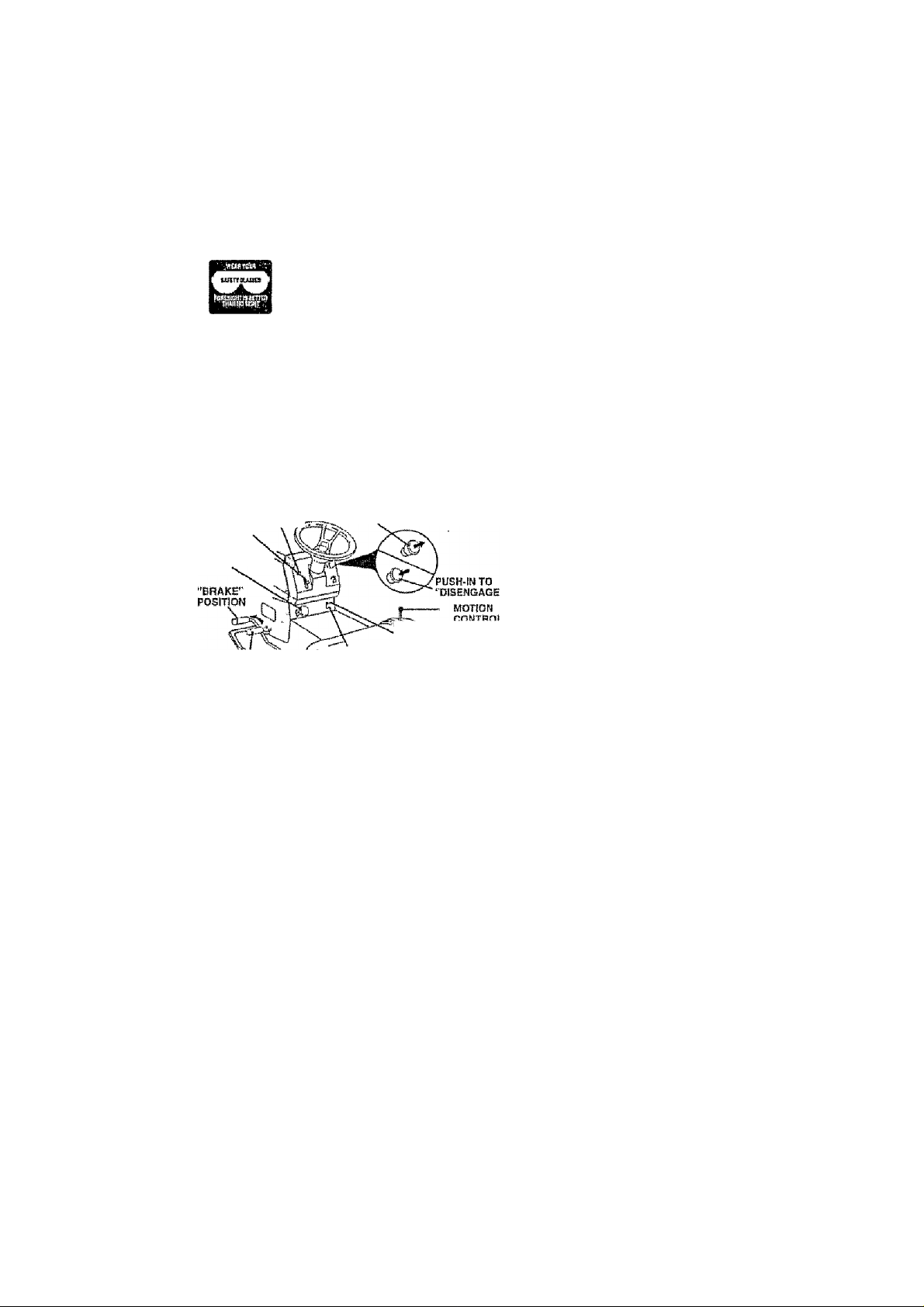

TO SET PARKING BRAKE (See Fig. 8)

Youf tractor Is equipped with an opsrato r presence sensing

switch. When engine Is running, any attempt by the

operator to leave the seat without lirst satling the parking

brake wiil shut off the engine

• Depress clutchArake pedal Into full "BRAKE" position

and hold.

• PtacB parking brake lever in "ENGAGED” position and

release pressure Irofn ciutch/braks pedal, Pedal should

remain in "BRAKE"position, Maks sure parking brake

will hold iractor secure.

THflOTTΠCONTROL

CONTROU

HEIGHT

ADJUSTPEMT

KNOB

CLUTCHfflRAKE PEDAL

"DRIVE" POSITION

CHOKE

ATTACHMENT CLUTCH SWITCH

PULL OUT TO "ENGAGE"

'■"DISENOAOED” "ENGAGEB"

POSrnOH POSITION

PARKING Brake

FIG, 8

STOPPING (See Fig. 8)

MOWER BLADES -

• Move atlachment clutch switch to “DISENGAGED”

position

GROUND DRIVE -

• Depress clulch/brake pedal into full "BRAKE" position.

• Move motion control lever to neutral (N| position.

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED

ENGINE -

• Move throttle control to stow position -

NOTE; Failure to move throllle control to slow position and

allowing engine to Idle before stopping may cause engine

to "backfire",

• Turn Ignition key to "OFF" position and remove key.

Always remove key when leaving tractor to prevent

unauthorlzBct use,

• Never use choke to stop engine

NOTE: Under certain conditions when tractor Is standing

idle with the engine running, hot engine exhaust gases may

cause '‘browning’’ of grass. To eliminate this possibility,

always stop engine when stopping Iractor on grass areas

CAUTION: Always stop tractor com

pletely, as described above, before teav-

A

Ing the operator's position; to amply

grass catoher, ate.

13 sama adjustment hole

TO USE THROTTLE CONTROL (See Fig, 8)

Always operate engine at full throttle.

• Operating engine at less than full fhrotlfe reduces the

battery cBarging rate

• Full throille offers the best mower performance,

TO USE CHOKE CONTROL (See Fig. 8)

Use choke eonfrol whsneveryou are starting a cold engine

Oo not use to start a warm engine

• To engage choSo control, puilknob out Slowly push

knob in to disengage

TO MOVE FORWARD AND BACKWARD (See

Ffg. 8)

The direction and speed of movement is controlled by the

mofion conlrol lever.

• Start tractor with motion control lever In neutral (N)

position,

• Release parking brake and clutcb/brake pedal

• Slowly move motion control ¡ever to desired position

TO ADJUST MOWER CUTTING HEIGHT

(SeB Fiq. 8)

The cutting height is controlled by turning the height adjust

ment knob in desired direction,

• Turn knob clockwise to raise cutting height

• Turn knob Gotmterolockwiss {K~>) to lower cutting

height.

The cutifng height range is approximately 1-1/2" to 4“ The

heights are measured from the ground to the blade lip with

the engine not running These heights are approximate

and may vary depending upon soil Gondllions, height of

grass and types of grass being mowed,

• The average lawn should be cut to approximately 2-1/2

inches during the cool season and to over 3 inches

during hot months. For heailtiier and belter looking

lawns, mow oUen and after moderate growth

• For best cutting performance, grass over e inches in

height should be mowed twice. Make the first cut

relatively high; the second to desired height

TO ADJUST GAUGE WHEELS (See Fig. 8)

Gauge wheels are properly adjusied when they are slightly

off the ground when mower is at the desired culting height

In operating position. Gauge wheels then keep the deck in

proper position to help prevent scalping in most terrain

conditions

• Adjust gauge wheels wlih tractor on a Hat level surface

• Adjust mower to desired cutting height [See 'TO AD

JUST MOWER CUTTING HEIGHT in the Operation

section of this manual),

• With mower in desired height of cut position, gauge

wheels should be assembled so they are slighily off the

ground. Install gauge wheel in appropriate hole with

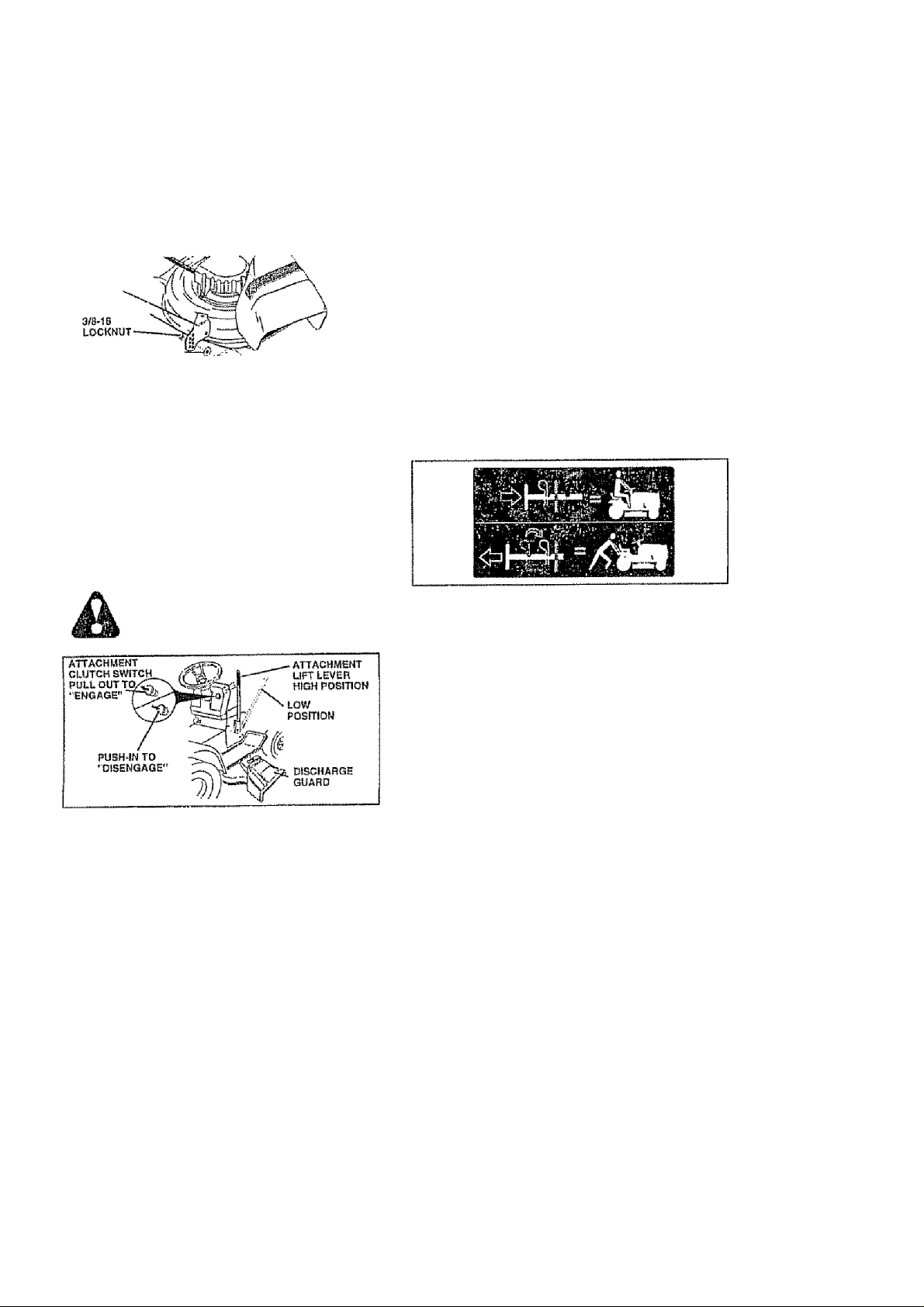

shoulder boil, 3/3 washer, and 3/B-16 locknut and

tighten securely,

• Repeat for opposite side installing gauge wheel in

Page 14

OPERATION

GAUESE WHEEL

MOUNTIHQ

BRACKET

3/a WASHER

GAUGE WHEEL ■

TO OPERATE MOWER (See Fig. 10)

Your tractor !a equipped with an operator presence sensing

switch. An^ attempt by the operator to leave the seat with

the engine running and the attachment ciuteh engaged will

shut oJf the englrte-

• Sslact desired height of cut-

• Lower mower with attachment lift control,

• Start mower blades by engaging attachment clutch

control.

- TO STOP MOWEH BLADES - disengage attachment

clutch control.

CAUTION; Do not operals the mower

without either the entire grass catcher,

on mowers so equipped, or the dis

charge guard In place.

TO OPERATE ON HiLLS

CAUTION: Do not drive up or downhills

with slopes greater than IS“ and do not

drive across any slope.

• Choose the slowest speed before starting up or down

hills.

• Avoid Stopping or changing speed on hills,

• (f slowing is necessary, move throttle controi lever to

slower position.

• ft stopping is absolutely necessary, push ciutchfbrake

pedal qufckty to brake position and engage parking

Brake,

• Move motion control lever to neutral (N) position,

Ifi/IPOBTANT: THE MOTION CONTftOL LEVER DOES

ШТ RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED

• To restart tnovament, slowly release parking brake and

olufchfbrakB pedal

• Slowfy move motion control lever to slowest setting.

• Маки ail turns siowlv.

-------BOLT

FIG. 9

* •

FIG. 10

J' ,4,71 SHOULDER

14 rtamaoB mav occur.

TO TRANSPORT (See Fig. 11)

When pushing or towing your tractor, be sure to disengage

IransmtBsion by placing freewheel control in freewheeling

position. Free wheel control is located at the rear drawbar

of tractor,

• Raise attachment lift to highest position with attach

ment lift control

• Puli freewheel control knob out and hold in position by

inserting retairrs rsprlng I nto forward hole of control rod.

• Do not push or tow tractor at more than two (2) У PH.

• To »engage transmission, reverse above procedurs,.

NOTE: To protect hood from damage when Iransportlng

your tractoron atruckor a trailer, be sure hood Is closed and

secured to tractor. Use an appropriate means of tying hood

to tractor (ropB, cord, etc).

FIG. 11

BEFORE STARTING THE ENGINE

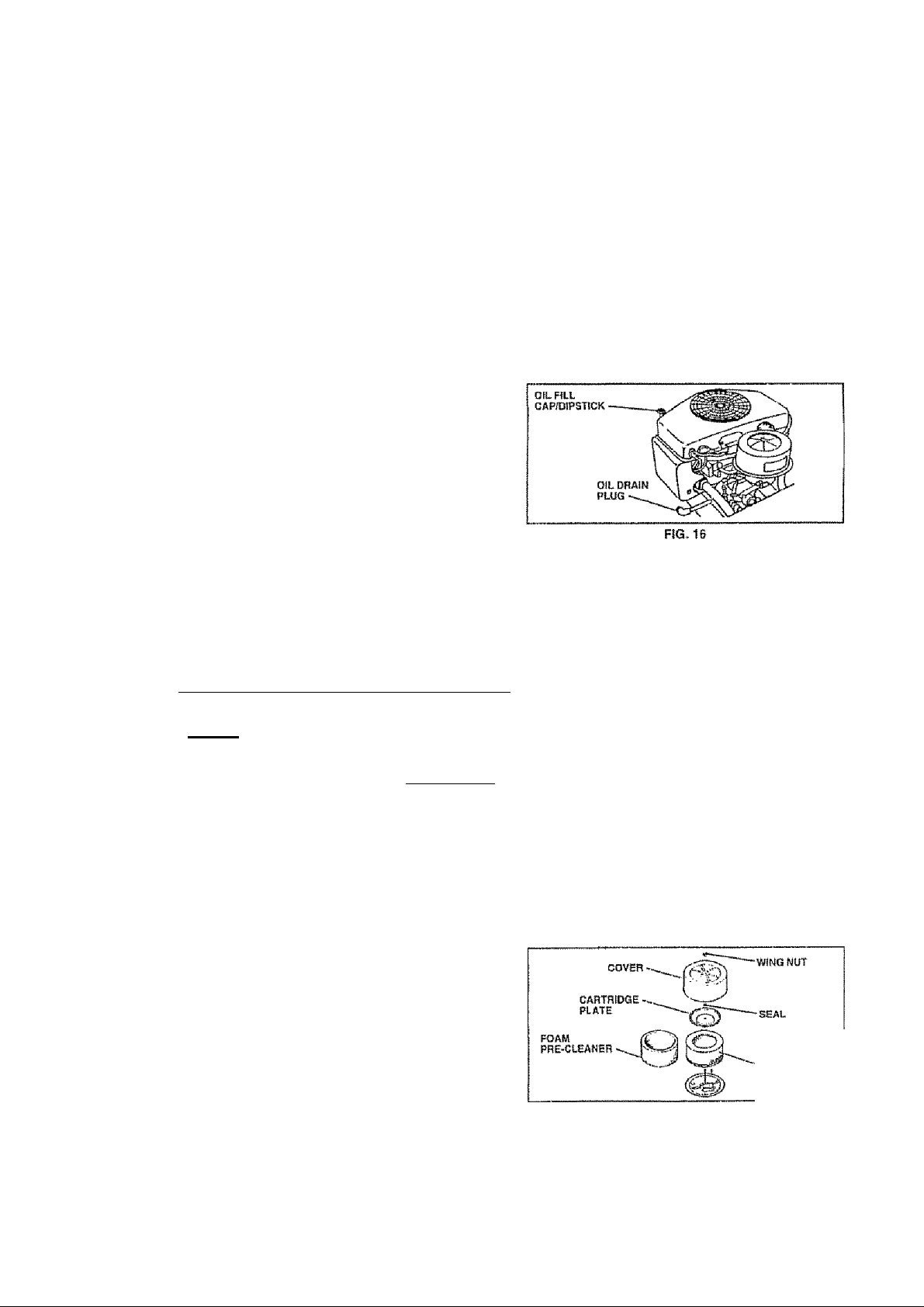

CHECK ENGINE OIL LEVEL {See Fig. 18)

' The engine in your tractor has been shipped, from the

(actory, already filled with summer weight oi(

• Check engine oil with tractor on level ground.

■ Remove olì fill cap/dipslick and wipe clean, reinsert the

dipstick and push It all the way down into the tubs, wait

for a few seconds, remove and read oil level. If

necessary, add oil until TULL" mark on dipstick Is

reached. OonotoverfiìL

• For cold weather operation you should change oil for

easier starting (See '"OIL VISCOSITY CHART" In the

Customer Responsibilities saction of this manual).

• To change engine oil. see the C ustomer Responsibili

ties section in this manual

ADD GASOLINE

• Fill fuel tank Use fresh, clean, regular unleaded

gasoilne with a minimum of 07 octane. (Use of leaded

gasoline will Increase carbon and lead oxide deposits

and reduce valve lilei. Do not mix oil with gasoline.

Purchase fuel irt quantities that can bs used within 30

days to assure fuel freshness

typOBTANT: WHEN OPERATING IN TEMPERATURES

BELOW SS^EKTC). USE FRESH, CLEAN WINTER GRADE

GASOLINE TO HELP INSURE GOOD GOLD WEATHER

STARTING

WARNING; Experience Indicates lhal alcohol blended

fueis (called gasohoi or using ethanol or msfhanoi) can

attract moislurs which leads to separation and lormatlon of

adds during storage. Acidic gas can damage the fuel

system of an engine white In storage. To avoid engine

problems, the fuel system should be emptied before stor

age of 30 days or longer. Drain the gas tank, start the

engine and tei it run until the fuel lines and carburetor are

empty. Use fresh fusi next seasori. See Storage Instruc

tions for additional information. Never usa engine or

carburetor cleaner producis In the fuel tank or permanent

Page 15

OPERATION

CAUTION: Fill to bottom of ges tank

filter neck, Oo not overfill. Wipe off any

A

spilled oi! or fuel. Do not store, spill or

USB gasoline near art open (lame.

TO START ENGINE (See Fig. 8)

When starting the engine for the first time or if the engine

has run out of fuel, It wiil take extra cranking time to move

fuel from the tank to the engine,

• Ba sure freewheel control is in the transmission en

gaged position.

• Sit on seat in operating position, depress clutch/brake

pedai and set parking brake

• Pfaoe motion cortlrol lever in neutra! (N) position

• Move attachment clutch to "DISENGAGED" posiiion

• Move throtlie control to fast position

» Pull choke control oul tor a cold engine start attempt

For a warm engine start attempt the choke control may

not be needed- .

Note: Before starting, read the warm and cold starting

procedures below

• Insert key into Ignition and turn key ciockwise io"START

position and reiease key as soon as engine starts Do

not run starter conitmiQusly lor rnore than fifteen sec

onds per minute if lha engine does not start after

several attempts, push choke control in, wait a few

minutes and try agairt, if engine still does not start, pul!

the choke control oul and retry

WARM WEATHER STARTING {50° F and above)

• When engine starts, slowly push choke conlrot In urilil

the engine begins to run smoothiy. If the engine starts

to run roughly, pull the choke control oul slightly for a

lew seconds and then continue to push the control in

slowiy

« The attachtnenls and ground drive can now be used. it

the engine does not accept the load, restart the engine

and allow it to warm up lor one minute using the choke

as described above

COLD WEATHER STARTtNG (50" F and beiow)

' When engine starts, slowly push choke contro! In until

the engine begins to run smoothiy Continue to push

the choke control in small steps aifowlng the engine to

accept small changes in speed and load, until the

choke control is fully in. If the engine starts to run

roughly, puli the choke control out slightly for a few

seconds and then continue to push the control in

slowly. This may require art engine warm-up period

from several seconds to several minutes, depending

on the temperature.

HYDROSTATIC TRANSMISSION WARM UP

• Before driving the unit In cold weather, the transmis

sion should be warmed up as lollows;

• Be sure the tractor is on level ground.

• Piace the motion control iever in neutral.

Reiease the parking brake and let theclulch/brake

slowly ratum to operaling position,

• Allow one minute (or trarrsmisBlon to warm up.

This can be dons during the engine warm up

period

’ The attachments ca n be used during the engine warm

up period after the transmission has been warmed up

and may require the choke control bo pulled oul slightly.

15

NOTE; If at a high altitude (above 3000 feet) or in cold

Eemperalofes (below 32 F) the carburetor fuel mixture may

need to be adjusted for best engine performance. See “TO

ADJUST CARBURETOR" In the Service and Adjustments

section of this manual.,

PURGE TRANSMISSION

CAUTION: Never engage or disengage

£k

m

To ensure proper operation and perlormanca, It is recom

mended that the transmission be purged before operating

tractor for the first time. This procedure wili remove any

trapped air inside the transmission which may have devel

oped during shipping of your tractor

IMPORTANT; SHOULD ¥OUR TRANSMISSION REQUIRE

REMOVAL FOR SERVICE OR REPLACEMENT, IT

SHOULD BE PURGED AFTER REINSTALLATION

BEFORE OPERATING THE TRACTOR.

• Place tractor saieiy on level surface with engine off and

• Disengage transmission by piecing freewheel control

• Si(tinglntheifactorseat,startengine After the engine

• Move motion control iever to full forward position and

NOTE: During this procedure iitere will be no movement of

drive wheels. The air Is being removed from hydraulic drive

system-

• Move motion controi iever to neutral (N) position. Shut

• Engage transmission by placing freewheel control in

• Sitting in the tractor seat, start engine. After the engine

• Slowly move motion controi lever forward, alter the

• Your, tractor Is now purged and now ready for normal

freewheel lever while the engine is run

ning.

parking brake set

In freewheeling position (Ses "TO TRANSPORT in

this section of manual)

is running, move Ihrollfe control to slow posiiion. With

motion control lever in neutrai (N) position, slowly

disengage clutch/brake pedal,

hold lor five (5) seconds. Move lever to fu!l reverse

posiiion and hold for five (6) seconds- Repeat this

procedure liime (3) times.,

off erigine and set parking brake,

driving position (See “jO TRANSPORT in this section

of manual)

is running, move throttle control to half (1/2) speed.

With motion corrtrol ¡ever In neutral (N) position, slowly

disengage ctutch/brake peda!

tractor moves approximately five (5) feet, slowly move

motion control lever to reverse position. After the

tractor moves approximately live (5) feet return the

motion control Isverto the neutrai (N) position. Repeat

this procedure with the motion contro! ¡ever ihres (3)

times,

operation

Page 16

OPERATION

MOWING TIPS

• Tire chains cannoS be used when the mower housing is

attached to tractor

• Mower should be property ieveled for best mowing

performance- See 'TO LEVEL MOWER HOUSING" in

the Service and Adjustments section of this manual.

• The left hand side of mower should be used for trimmini,

• Drive so that clippings are discharged onto the area

that has been cut Have the cut area to the right of the

machine. This will resull in a more even dislribution of

dippings and more urrifortn cutting.

• When mowing large areas, start by turning to the right

so that clippings will discharge away from shrubs,

fersoes, driveways, etc. After one or two rounds, mow

in the opposite direction making left hand turns unfll

finished {See Fig. 12)..

• if grass is extremely tali, it should be mowed iwice to

reduce toad and posslbie fire hazard from dried cilpplngs. Make first cut reiaiiveiy high; ths second to the

desired height

• Do not mow grass when it is wet, Wet grass will plug

mower and ieave undesirable ciumps, Allow grass to

dry before mowlng.

• Always operaie engine at futí throftle when mowing to

assura better mowing performance and proper dis

charge of material. Regulate ground speed by select

ing a low enough gear to give I he mower cutting

performance as well as the qualify of cut desired

• Whan oparating attachments, select a ground speed

that wii! suit the terrain and give best performance of

the attachment being used.

MULCHING MOWING TIPS

ttiPOfîTANT; FOR BEST PERFORMANCE. KEEP

MOWER HOUSING FREE OF BUîLT-UP GRASS AND

TRASHi CLEAN AFTER EACH USE

• The special mulohlng blade will rscut Ihe grass clip

pings many times and reduce them in size so that as

they fall onto the lawn they will disperse into fhe grass

arto net be noticed. Also, the mulched grass wiii

biodegrade quickly to provide nutrients for the lawn.

Always mulch with your highest engine (blade) speed

as this will provide the best recutting action of ths

blades,

• Avoidcuttingyouriawnwhenitlswet Weigrasstends

to form clumps and Interferes with the mulching action

The bast time to mow your lawn Is the early aflsmoon.

At ihlstime the grass has drlsd and the newly cut area

wifi not be exposed to tha direct sun.

• Forbesf results, actjustthe mower cuHing height so that

the mower cuts off oniy the fop one-third of the grass

blades {See Fig. 13) For extremely heavy mulcting,

reduce your width of cut on each pass and mow slowly.

• Certain types of grass and grass conditions may re-

(*isiitria fKa! ¡sfrctisi Hci itïhÎaKîsH a cor'rntTf^ ilma Itî r>rrtn-

LjLIîf Lr \r rC*4 îrt11 ^+1 wCt Liw Î Ï ^wI IL# li I i Ifc* IL^ vLrl 11

pletely hide the dippings. When doing a second cut,

mow across or perpendicular to the first cul path.

• Change your cutting pattern from week to week- Mow

north to south one week then change to east to west the

next week, This will help prevent malting and graining

of the lawn..

16

FiG. 13

Page 17

CUSTOMER RESPONSIBILITIES

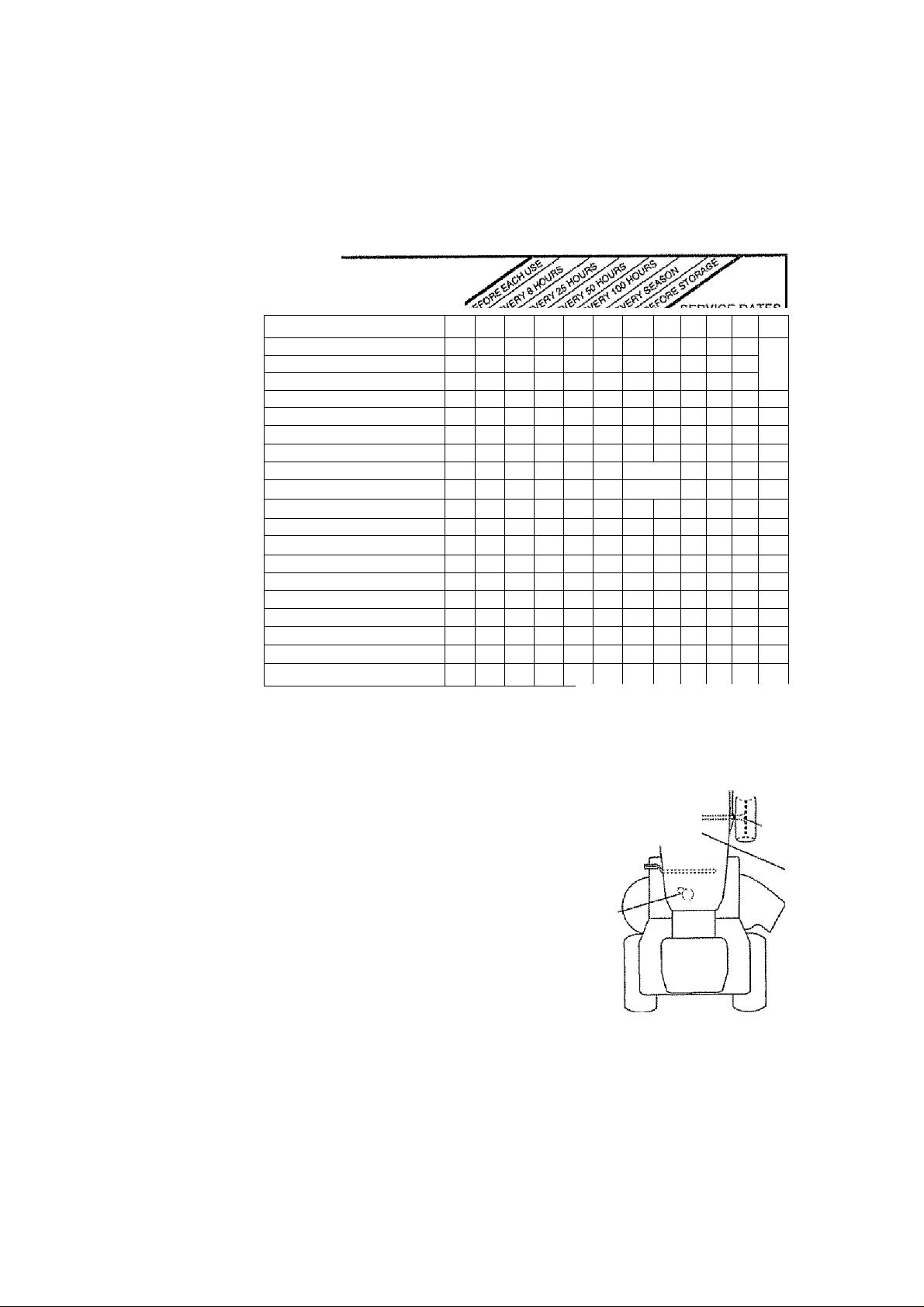

MAINTENANCE SCHEDULE

FILL IN DATES

AS YOU COMPLETE

Check Brake Oporallon ,

Check Tire Prasaurs

Cheek tor Loose Fasteners

Shafpen/PtAplAca Mower Blades

Lubrication Chert

Check Satisfy LeveWTecharge

Clean Baltery and Terminals

Check Tránsasele Cooling

Adjust Blade BelSCs) Tension

Adjust Motion Drive Bel!(s) Tension

Check Errgine Oil Level

, Changa Engine OH ,

Ctean Air Filter

Clean Air Screen

Inspect Mullier/Spsrk Arrester

Replace Oli Filter (It equipped)

Clean Engine Cooling Fins tr'2

Replace Spark Plug

Replans Air Filler Papar Cartridge

Replace Fuel Filler

Î • more ofien wiicn oparailng under a haavy toad or In high ambisfii toinpsratUicssi

2.« Sfifvtea ^CTQ flllon whî3n operaling In dlity or dosly tondMIons

3 - ir equipped wiHi ¿1! llllGf, chsrtp o9 every 50 hoMiS-

4 '■ Replaça blades mcfo pfton when mpwlfts in sandy self

✓ ✓

✓ ✓

✓

✓

t/

1/ ✓

1/

l><2,3

✓ a

GENERAL RECOMMENDATIONS

The warranty on Shis Sractor does not cover items thaS have

been subjected to operator abifse or negligence- To

receive full value from the Warranty, ope rator must mainlain

tractor as instruciad !n this manual.

Some adjustments will need to be made perlodleatly to

properly maintain your tractor.

Alt adjustments In the Service and Adjustments section at

this manual should bs checked at least once each season.

• Once a year you should replace the spark plug, clean

or replace air filler, and check blades and bsiis for

wear. A new spark plug and clean air filter assure

proper air-fuel mixture and help your engine run better

and last longer

(D SPINDLE ZERK gp^OLE ZERK®

® FRONTWHEEL-^"

©ATTACHMENT

t/v

1/

î/s

l/i

✓

*/

V^.2

i/

«/

✓ 2

1/

5 ■■ If equipped adjuBtablo systom,

B ' Ngi required If equipped vrfsb rnalnlenar^ce-hert baHsry

7 ■ Tlghien frsnl ails pivoi ttoll W 35 ft •■lbs maximum

Do no? ovefflgWen.

LUBRICATION CHART

BEARÎNG ZERK LL

CLUTCH

PiVOTfS)

FRONT WHEEL®

BEARING ZERK

'ENGINE®

BEFORE EACH USE

• Check engine oil level.

► Check brake operation

» Check tire pressure.

• Check for loose fasteners.

© SAÊ 30 OR tBW30 MOTOR OIL

® GENERAL PURPOSE GREASE

(D fjEpER TO CUSTOMER RESPONSIBIUTIES "ËNG1KE" SECTION

IMPORTANT: DQ NOT OIL OB GREASE THE P1VOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS, VISCOUS LUBRI

CANTS WILL ATTRACT DUST ANO DIRT THAT WILL SHORTEN

THE LIFE OF THE BELF-LUBRtCATINQ BEARINGS. tF YOU

FEÊL THEY MUST BE LUBRICATED, USE ONLY A DRY, POW-

■¡7 DEREO GRAPHITE TYPE LUBRICANT SPARINGLY-

Page 18

CUSTOMER RESPONSIBILITIES

TRACTOR

Always observe saleiy rules when periarming any mainte

nance,

BRAKE OPERATION

!f tractor requires more than six (6) feet stopping distance

at high speed in highest gear, then brake must be adjusted,

(See “TO ADJUST BRAKE" In the Service and Adjust

ments section of this martual).

TIRES

• Maintain proper air pressure In ail tires (See “PROD

UCT SPECIFICATtONS" on page 3 of this mantiai|,

• Keep tires free o! gasoline, oil, or Insect control chemi

cals which can harm rubber,

• Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage.

NOTE: To seat tire punctures and prevent fiat tires dua to

slow teaks, lira sealant may be purchased from your iocai

parts dealer. Tire sealant also prevents tire dry rot and

corrosion,

BLADE CARE

For best results mower blades must be kepi sharp. Re

place bent or damaged blades,

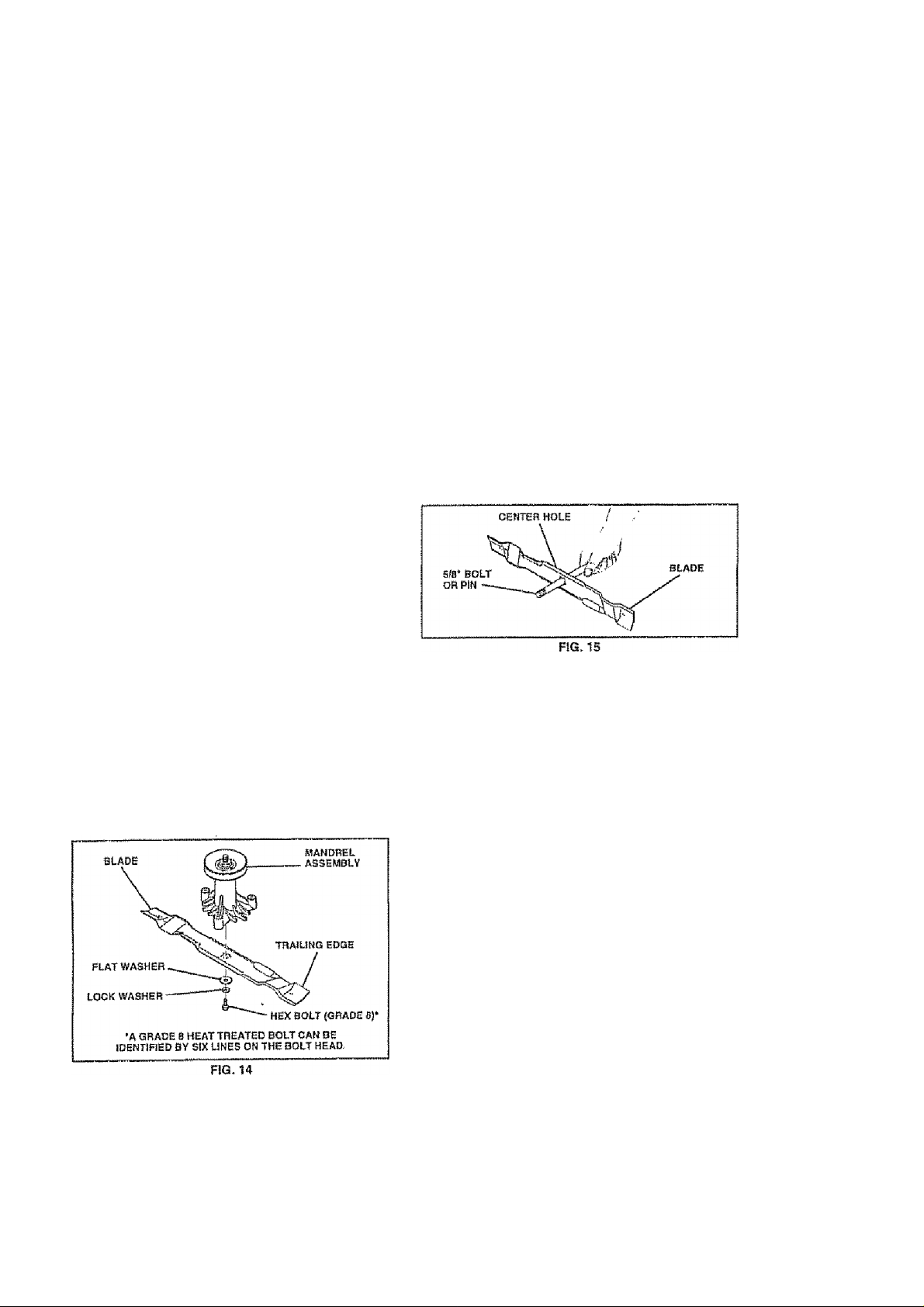

BLADE REMOVAL (See Fig. 14)

• Raise mower to highest position to allow access to

btades-

• Remove hex bait, lock washer and fiat washer securing

blade.

• Install new or resharpened blade with trailing edge up

towards deck as shown.

• Reassemble hex boll, lock washer and flat washer In

exact Older as shown.

• Tighten bolt securely (30-35 Ft Lbs torque)

i MP О RTAN T: BLA D E 8 OLT1S G R ADE a HE AT TR E ATED

NOTE; We do not reconnmend sharpening blade - but if you

do, be sure the blade is balanced.

TO SHARPEN BLADE (See Fig. 15)

Care should be taken to keep the blade balanced. An

unbalanced blade wiil cause excessive vibration and everrtual damage to mower and engine.

• the blade can be sharpened with a 1!te or on a grinding

wheel. Do not attempt to sharpen while on the mower-

• To chsck blade balance, you will naed a S/0’ diameter

steel bolt, pin, or a cone balancer. (When using^ a cone

balancer, follow the inslmotians supplied with bal

ancer.)

• Slide blade on to an unthrsaded portion of the steel bolt

orpin and hold the boll or pin parallel with the ground,

If blade Is balanced, It should remain in a horizontal

position If either end of the blade moves downward,

sharpen the heavy and until the blade is balanced,

NOTE: Do not use a nail for batanclng blade The lobes of

the center hole may appear to be centered, but are not

BATTERY

Your tractor has a battery charging system which Is sulficisnt for normal Use- However, periodic charging oi the

battery with an automotive charger will extend its life.

• Keep battery and terminals dean

• Keep battery bolts tight

• Keep small vent holes open

» Recharge at 6-10 amperes for 1 hour,

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and terminals can cause

the battery to “leak" power.

• Remove terminal guard.

• Disconnect BLACK battery cable first then RED

battery cable and remove battery from tractor.

• Rinse tha battery with plain water arrd dry

• Cleart terminals andbatlery cable ends with wire brush

until bright

• Coat terminals with grease or pelroteum jelly-

• Reinstall battery (See “CONNECT BATTERY' in the

Assembly section of this manual),

IB

Page 19

CUSTOMER RESPONSIBILITIES

V-BELTS

Check V-beits for deierioraiion and wear alter 10G hours of

operation and replace If nacsssary. The bells are not

adjusiabia Replace bells if they begin lo slip from wear

TRANSAXLE COOLING

The fan and cooling fins of IransmissiQfi should be kept

clean to assure proper cooling-

Do not atlampt to clean fan or transmission while engine Is

running or while the transmission Is hol-

• inspect cooling fan to be sure fan blades are infact and

clean

• Inspect cooling tins for dirt, grass clippings and other

materials- To prevent damage to seals, do not use

compressed air or high pressure sprayer to clean

cooiing fins-

TRANSAXLE PUMP FLUID

The transaxle was sealed at the factory and fiuid mainte

nance is not required for the life of the transaxie, Should the

transaxle ever teak or require servicing, cofttact your near

est authortzed service centar/department-

ENGINE

LUBRICATION

Only use high quality detergent oil rated with API service

classilicatlon SF, SG or SH. Select the oH's SAE viscosity

grade according to your expected operating lemperalure.

SAE VISCOSITY SRADES

1 I r

30* M' W 60' SO'

jr

TEMPESATURE RAUBE AtmCiPATEQ SETOSe NEXT Oil CHANSE

NOTE: Aithough multi-vtscosliy oils |SW30,10W30 etc }

Improve Starling irt cold weather, these multi-viscosity oils

will result in increased oil consumption when used above

3a“F. Check your engine oil level more frequently to avoid

possible engine damage from running low on oil

Change the oi! after every 50 hours of operation or at least

onceayearif the tractoris not usedlorSO hours In one year.

Check the crankcase oi! level before starting the engine

and after each eight {B) hours of operation-, Tighten oil fill

cap/dipstick securely each time you check the oil level.

TO CHANGE ENGINE OIL (See Fig. 18)

Determine temperature range expected before oil change.

All oil must meet API service ciasslficaflon SF, SQ or SH.

• Be sure tractor Is on level surface

• Oii will drain more freely when warm.

• Catch oil In a suitable corrtalner

• Remove oil (ill cap/dipstick. 8e careful not to allow dirt

• Remove drain plug.

•Hf -w

to enter the engine when changing oil

________№______

EF 30* * 40* i

19

After oil has drained compieleiy, replace oii drain plug

and tighten securely.

Refill engine with olí through oii fill dipstick tuba. Pour

slowly. Do not ovsrfill. For approximate capacity see

"PRODUCT SPECIFICATIONS"

manual

Use gauge on oil fill cap/dIpsHck for checking isvet. Be

sure dipstick is in al! fha way for accurate reading.

Keep Oil at “FULL" ilne on dipstick

on page 3 oi this

.

..........

AIR FILTER {See Fig. 17)

Your engine will not run properly using a dirty air tilter.

Claan the loam pre-cleaner after every 25 hours of operatiori or every season. Service paper cartridge every 100

hours of operation or every season, whichever occurs first

Service air cleaner more olten under dusty conditions

• Remove wing nut and cover,

• Remove sea! and cartridge plate.

TO SERVICE PRE-CLEANER

• Slide foam pre-cleaner off cartridge

• Wash it in liquid detergent and water

• Squeeze it dry in a clean cloth. Allow It lo dry,

» Saturate It In engine olt Wrap it In clean, absorbent

cloth and squeeze to remove excess oil

TO SERVICE CARTRIDGE

• Replace a dirty, bent, or damaged cartridge

NOTE; Do not wash the papercartridge or use pressurized

air, as this wilt damage the cartridge.

• Reinstali the pre-cleaner (cleaned and oiled) over the

paper cartridge.

• Reassemble air cleaner, cartridge plate, and seal

• InstalitheaircteanercDverandwirjgnut Tightsnwing

nut1/2l«rnto1 fuliturnafternutconladscovsr Donot

overtighten.

0ABTRIBGÉ

FIG. 17

Page 20

CUSTOMER RESPONSIBILITIES

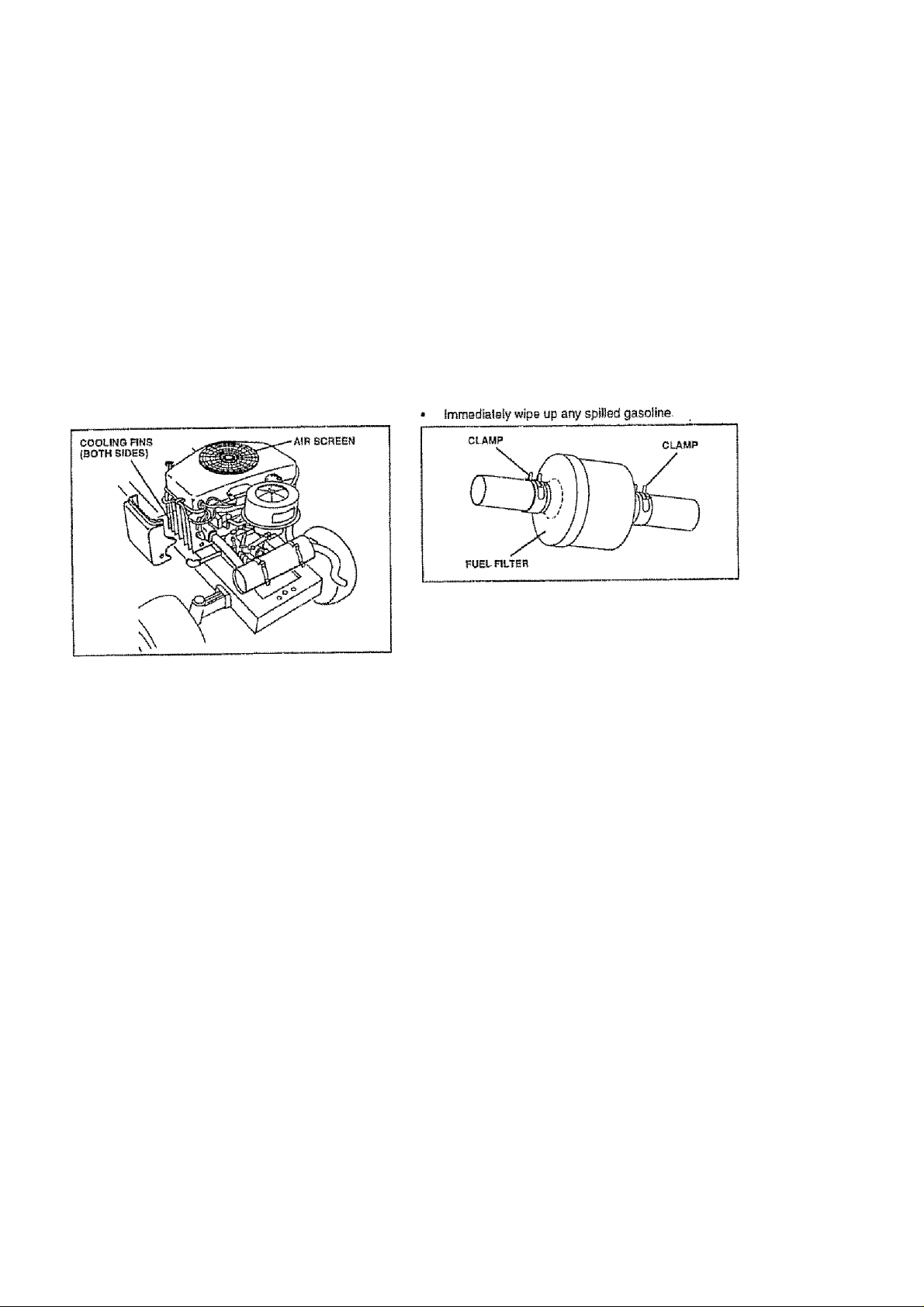

CLEAN AIR SCREEN (See Fig. 18)

Air screen must be kept free of dirl and chaff lo_ prevent

engine damage (rorn overheating Clean with a wire brush

or compressed air to remove dirt and stubborn dried gum

fibers.

ENGINE COOLING FINS (See Fig. 18)

Remove any dust, dirt or oil from engine cooilng lins to

prevent engine damage from overheating. Engine blower

housing must be removed. Remove side panels and hood

{See *TO REMOVE HOOD AND GRiLL ASSEMBLY"in the

Service and Adjustments section of this manual)

F)G..ia

ENGINE OIL FILTER

Replace the engine oil iiiter every season or every other oil

change II the tractor is used more than 100 hours in one

year,

MUFFLER

inspect and replace corroded muffler and spark arrester (if

equipped) as It could create a lire hazard and/or damage

IN-LINE FUEL FILTER (See Fig. 19)

The fuei filter should be replaced once each season. If fuel

filter becomes ologgad, obstructing fuel flow to carburetor,

replacemetit Is required.

• \¥iih engine coo!, remove filter artd plug fuel line

sactlona

• Place new fuei filter In position In fuel fine with arrow

pointing towards carburetor.

• Ba sura thera are no fuel line leaks and clamps are

properly positioned.

FiG. 19

CLEANING

• Clean engine, battery, seat, finish, etc of all foreign

matier

• Keep finished surfaces and wheels free of all gasoline,

oil, stcl

• Protect painted surfaces with aulomotfve type wax.

We do not recommend using a garden hose to clean your

tractor uniess the eiectrical system, muffler, air filter and

carburetor are covered to keep water out. Water In engine

cart result 1n a shortened artgine life.

SPARK PLUGS

Replace spark plugs al the beginning of each mowing

season or after every 100 hours of operation, whichever

occurs first Spark plug type and gap setting are shown In

"PRODUCT SPECIFICATIONS" on page 3 of this manual

20

Page 21

SERVICE AND ADJUSTMENTS

CAUTION: BEFORE PERFORWIING ANY SERVICE OR ADJUSTMENTS:

• Depress cluteh/brake psdal fully and set parking brake.

• Place motion control lever In neutral (N) position.

A

TRACTOR

REMOVE MOWER (See rig. 20)

» Place attachmeni clutch in "DISENGAGED” posltlon» Turn height adjustment Knob lo lowest setlJng.

» Lower mower to fls lowest posiiion.

• Remove retainer spring holding artli-swaybar to chas

sis bracket and disengage anti-swaybarfram bracket.

« Reraovs retainer springs Irom suspension arms at

deck and disengage arms from deck

« Raise attachment Kfl to its highest position.

• Remove two retainer springs irom each front link and

remove links.

• Slide mower forward and remove belt from electric

clutch pulley-

• Slide mower out from under right side of tractor,

IMPORTANT: )F AM ATTACHMENT OTHER THAN THE

¡MOWER DECK tS TO BE MOUNTED ON THE TRACTOR,

REMOVE THE FRONT LINKS.

INSTALL MOWER

W

Follow procedure described in "INSTALL MOWER AND

DRIVE BELT' In the Assembly section of this manual

• Place attachment clutch in “DISENGAGED" position,

• Turn ignition key "OFF” and remove key.

• Make sure the blades and ail moving parts have completely stopped.

• Disconnect spark plug wire from spark plug and place wire where It cannot come in contact

with plug.

ADJUSTMENT

TO LEVEL MOWER HOUSING

Adjust the mower while tractor is parked on level ground or

driveway. Make sure tires are properly inflated (See

"PROOUCTSPeC!F1CATIOIMS”cri page 3 of this manual).

If tires are over or undorinflated, you w! II not properly adjust

your mower

SIDE-TO-SIDE ADJUSTMENT iSse Figs, 21 and 22)

• Raise mower to its highest postiion-

• At the midpolnf of both sides oi mowe r, measure height

from bottom edge of mower to ground 0 istance "A" on

both sides ol mowaf should be Ihe same or within 1/4“

of each other,

• If adjustment Is necessary, make adjustmant on one

side of mower only.

« To raise one side of mower, lighten tilt link adjustment

nul on that side.

• To lower one side of mower, loosen lilt link adjustment

nul on lhal side.

NOTE; Each full turn of adjustment nut will change mower

height about 1/0"

• flacheck measurements after adjusting,

21

Page 22

SERVICE AND ADJUSTMENTS

FBONT-TO-BACK ADJUSTMENT (See Figs 23 and 24)

tivlFORTANT: DECK MUST BE LEVEL SIDE*TO-S!DE. !F

THE FOLLOWING FFtONT-TO-BACK ADJUSTMENT IS

NECESSARY, BESURE TO ADJUST BOTH FRONTUNKS

EQUALLY SO MOWER WILL STAY LEVEL SiDE-TO-

SIDE

To obtain the best culling results, the mower housing

should be adjusted so that the front Is approximately 1 /8“ to

1/2” tower than the rear whan the mower Is In its highest

position.

Check adjustment on right side of tractor- Measure dislarsce “D" directly in front and behind the mandrel at bottom

edge of mower housing as shown

• Before making any necessary adjustments, check that

both front links are equal in length Both links should be

approximalety 10-3/6".

• if links are not egual in ierigth, adjust one link to same

length as other iink,

» To tower front of mower loosen nut "E” on both front

links art equal number of turns

• When distance "D" is 1/6“ to 1/2" lower at front than

rear, lighten nuis "F' against tFunntoh on both front

links.

‘ To raise front of mower, loosen nut "F'lromlrunnioft on

both front finks. Tighten nut “E" on both front links an

equal number ol turns,

• When distance ”D" Is 1/B" to 1/2" lower at froM thari'

rear, tighten nut "F" against trunnion on both front links.

• Reoheck side-to-side adjustment.

MOWiR DRIVE BELT REMOVAL (See Fig. 25)

' Park tractor on a ievel surface Engage parking brake.

• Remove four screws from L,H mandrel cover and

remove cover.

• Roll bait over the top of LH. mandre! putey.

• Remove belt Irom eieciric clutch pulley.

• Remove belt from Idler pulleys.

• Remove any dirt or grass dippings which may have

accumulated around mandrels and entire upper deck

surface,

• Check primary idler arm and two Idlers to see that they

rotate treeiy.

• Be sure spring Is securely hooked to primary tdier arm

and boll in mower housing.

MOWER DRIVE BELT INSTALUTION (See Fig. 25)

• Install belt in both idlers. Make sure belt is in both belt

keepers at the idlers as shown,

• Install new bait onto electric clutch puliey,

• Rol! belt into upper groove of LH mandrel puliey

• Carefully check bell routing making sure belt is in the

grooves correctly and inside belt keepers

• Reassemble LH. mandrel cover.

Page 23

SERVICE AND ADJUSTMENTS

TO REPLACE MOWER BLADE DRIVE BELT

(See Fig. 26)

Park Ite tractor on level surface Engage parking brake.

Remove mowerdrJ ve belt (See ‘TO REPLACE MOWER

DRIVE BELT" In this section of this manual),

Remove mawer (See TO REMOVE MOWER" in this

section of this manual).

Remove four screws from R H, mandrel cover and

remove cover Unhook spring from bolt on mower

housing,

Carefully roll belt off R,H, mandrel pulley.

Remove belt from center mandrel pulley, idler pulley,

and L.H. mandrel pulley

Remove any dirt or grass which may have accumuiated around mandrels and entire upper deck surface.

Check secondary idler arm and Idler fo see that they

rotate freely.

Be sure spring is hooked in secondary Idler arm and

sway-bar bracket

Install newbeJt in lower groove of L.H, mandrel pulley,

Idler puliey, and cenler mandrel puiley as shown

Roil belt over R..H, mandrel pulley Make sure belt Is In

all grooves properly

Reconnect spring to bolt in mower housing and relnstatl R H - martdre! cover,

Reinstall mower to tractor (See "INSTALL MOWER

AND DRIVE BELT' in the Assambly section of this

manual). .

Reassemble mower drive belt (See "TO REPLACE

MOWER OfliVE BELT in this section Of this manual).

TO ADJUST BRAKE (See Fig. 28)

Your tractor is equipped with an adjustable brake system

which is mounted on the side of the iransaxie,

!f tractor requires mors than six (6) feet stopping distance

athigh speed in highest gear, then brake must be adjusted

• Depress clutch/braks pedal and engage parking brake.

• Measure distance between brake operating arm and

not “A" 0(1 brake rod.

• I f distance Is other than 1 -3/4”, loosen jam nut and turn

nut "A“ until distance becomes 1-3/4" Retighten jam

nut against nut "A".

• Road test tractor fo rproper stopping distance as stated

above. Readjust it necessary. If stopping distance is

still greater than six (6) (eel In highest gear, further

maintenance is necessary. Contact your nearest au

thorized service center/departmenl.

WITH PARKIMe BRAKS "ENGAGED"

NUT ‘ A‘‘

JAM NUT

TO ADJUST ATTACHMENT CLUTCH (See

Fig. 27)

The electric clutch should provide years of service. The

clutch has a built-in brake that stops the pulley within 5

seconds. Eventually, the internal brake will wear which

may cause the mower blades to not engage, or, to not stop

as required, Adjusiments should be made by your nearest

authorized service center/department

• Make sure attachment dutch and ignition switches are

in "OFF position,

• Adjust the three nylon locknuts until space between

clutch plate and rotor measures ,012“ at all three slot

locations

NOTE: Affsr installing a new electric clutch, run tractor at

full throttle and engage and disengage eteclrtc dutch 10

cycles to wear In dutch plats,

cut in the side of brake plate.

23

DO NOT TOUCH THtS NUT Г FOHTMEB SRAKE ADJUST

MENT tS NECESSARY CONTACT YOUR NEAREST AUTHO

RIZED SERVICE GEHTEFmEPARTMENT

FIG, 28

TO REPLACE MOTION DRIVE BELT

(See Fig. 29)

Park the tractor on level surface Engage parking brake

For assistance, there Is a belt installation guida decal on

bottom side of left footrest

• Remove trtower (See ‘TO REMOVE MOWER" in this

section of this manual )

• Disconnect dutch wire harness

• Remove dutch locator.

• Remove upper belt keeper.

• Remove bail from stationary idier and ciutching Idiar.

• Puli bait slack toward rear of tractor. Carefully remove

belt upwards from transmission input puiley and over

cooling fan blades

• Pull belt toward frontof tractor and remove downwards

from around electric clutch

• Install new belt by reversing above procedura

Page 24

SERVICE AND ADJUSTMENTS

IMPORTANT: MAKE SURE UPPER BELT KEEPER !S

POS!T!ONED PROPERLY BETWEEN LOCATOR TABS

and elec tric clu tc h w ire CONNECTION IS

SECURE.

ELECTRIC.

CLUTCH

yppER BELT

KEEPER

LOCATOR ■"

TABS

CLUTCHING

IDLER

STATIONARY

idler

TRANSMIBSIOK

INPUT PULLEY