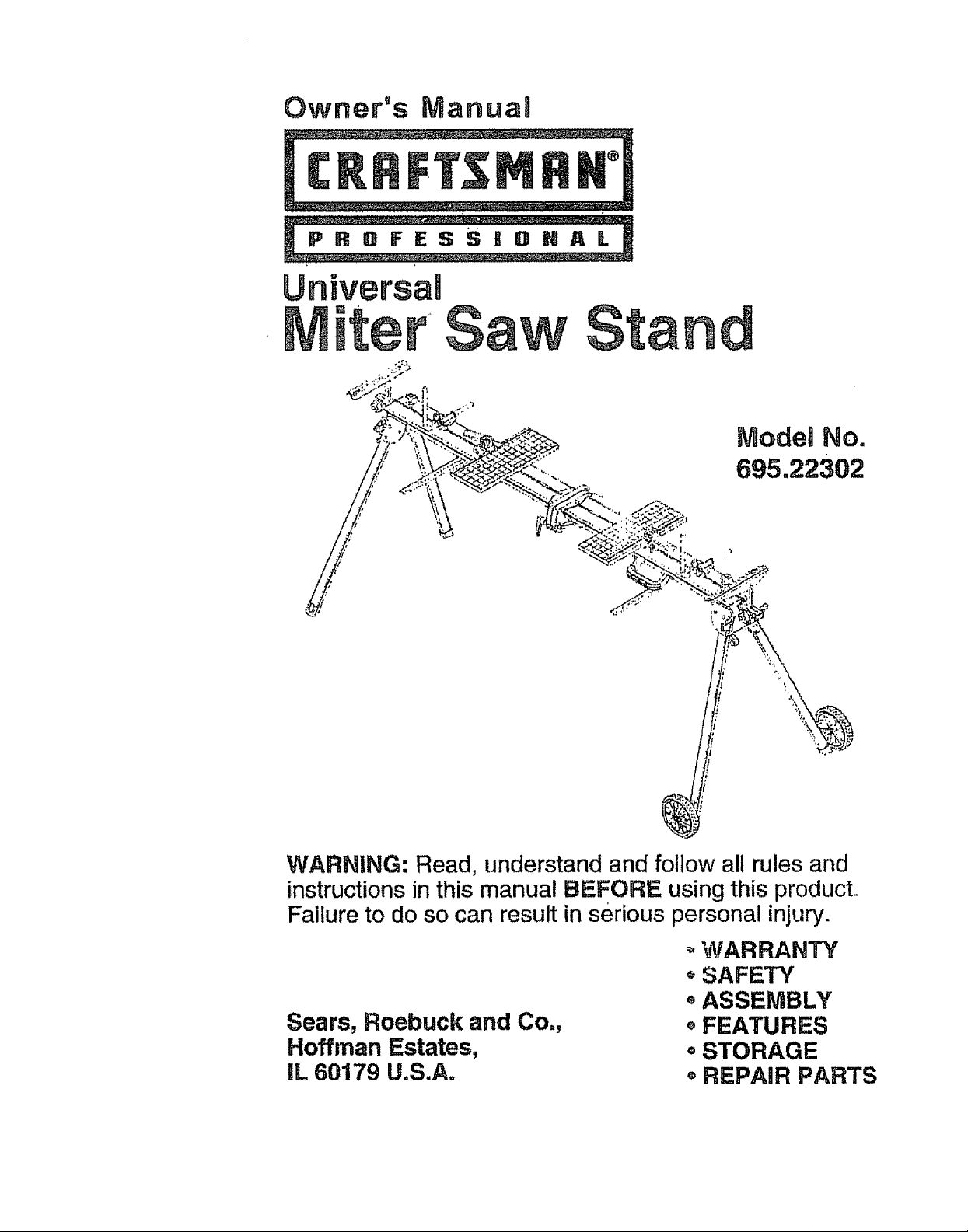

Craftsman 69522302 Owner’s Manual

Owner's ManuaU

Model No.

695.22302

WARNING: Read, understand and follow all rules and

instructions in this manual BEFORE using this product,.

Failure to do so can result in serious personal injury.

_,WARRANTY

SAFETY

eASSEMBLY

Sears, Roebuck and Co.,

Hoffman Estates,

IL 60179 U.S.A.

eFEATURES

=STORAGE

REPAIR PARTS

Warrant-j......................................................... ,.

Safety Instructions.._...................... ,...............

Description, Specifications ...............................

Unpacking, Carton Contents ........................... .

Assembly..........................:................................

Miter Saw Compatibility ....................................

Mounting Other Tools .......................................

Usage...............................................................

Page

Pages

Page

pages

Pages

Page

Page

Page

Storage.., .......................................................... Pages

Repair Parts ...................................................... Pages

ONE-YEAR FULL WARRANTY ON CRAFTSMAN PROFESSIONAL

UNIVERSAL MITER SAW STAND

If this CRAFTSMAN PROFESSIONAL product fails due to a defect in

material or workmanship wthin one year from the date of purchase,

RETURN IT TO ANY SEARS STORE OR OTHER CRAFTSMAN

OUTLET IN THE UNITED STATES FOR FREE REPLACEMENT.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

3-'5

7-9

10-27

28

29

30- 32

33

34- 35

Sears, Roebuck and Co., Depto 817WA, Hoffman Estates, IL 60179

2

1. DONOT standor climbon miter saw stand, it couldtip over

causing serious injury.

2. BE SURE all locking pins are in the set-up position holes BEFORE

using your miter saw and miter Saw stand.

3. ALWAYS firmly attach miter saw. DO NOT attempt to use your miter

saw stadd until the miter saw is fastened firmly to the boards.

4, ONLY use your miter saw stand on a hard, dry, flat, and level surface.

5. BE SURE that any bench top tool used with this stand is firmly

attached to the boards.

6. BE SURE the board clamps are tightly clamped to the stand when the

bench top tool is in use.

7. ALWAYS keep all guards in place. BE SURE all power tool guards

are in good working order and are in proper adjustment

8. ALWAYS keep your hands away from the cutting area.

9. DO NOT mount a table saw onto this stand. The direction of feed on a

table saw iScounter to the axis of best stability on this stand.

Aggressive feeding Ofsheet materials into a table saw could cause the

stand to tip.

10. ALWAYS use clamps or a vise to hold work when practical. Using

clamps or a vise to hold work is safer than using your hand. Italso

frees both hands to operate the saw.

BE SURE to read and understand all instructions in

this manual and the miter saw's operating manual before using it on the

stand. Failure to follow all instructions can result in electric shock, fire

and/or serious persona! injury.

WORK AREA SAFETY

1. ALWAYS keep your work area clean and well lit. Cluttered benches

and dark areas invite acciderits.

2. DO NOT operate power tools in explosive atmospheres, such as in

the presence of flammable liquids, gases, or dust. Power tools

create sparks that may ignite the dust or _umes.

3. ALWAYS keep bystanders, children, and visitors away while

operating a power tool. Distractions can cause you to lose control.

3

ELECTRICAL SAFETY

1. Double insulated tools are equipped with a polarized plug (one blade

is wider than the other). This plug will fit in a polarized outlet only

one way. if the plug does not fit fully into the outlet, reverse the plug.

if it still does not fit, contact a qualified electrician to install a

polarized outlet. DO NOT change or alter the plug in any way.

2. Double insulation eliminates the need for the three-wire grounded power

cord and grounded power supply system. Applicable only to Class tl

(double insulated) tools.

3. Before plugging in the tool, BE SURE that the outlet voltage supplied is

within the voltage marked on the tool's data plate. DO NOT use "AC only"

rated tools with a DC power supply.

4. ALWAYS avoid body contact with grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is grounded.

5. if operating the power tool in damp locations is unavoidable, ALWAYS

use a Ground Fault Circuit Interrupter to supply power to your tool.

ALWAYS wear electrician's rubber gloves and footwear in damp

conditions.

6. DO NOT expose power tools to rain or wet conditions. Water entering a

power tookwill increase the risk of electric shock°

7. DO NOT abuse the cord. NEVER use the cord to carry the tools or pull

the plug from the outlet. Keep cord away from heat, oil, sharp edges or

moving parts. Replace damaged cords immediately. Damaged cords

increase the risk of electric shock.

8. When operating a power toot outside, ALWAYS use an outdoor extension

cord marked '"W-A" or "W'. These cords are rated for outdoor use and

reduce the risk of electric shock.

NOTE: The extension cord must have adequate wire size AWG

(American Wire Gauge) for safe, efficient use. Smaller gauge wires, have

greater capacity (16 gauge wire has more capacity than 18 gauge wire).

PERSONAL SAFETY

1. ALWAYS stay alert, watch wha, you are doing, and use common sense

when operating a power tool. DO NOT use tool while tired or under the

influence of drugs, alcohol or medication. A moment of inattention while

operating power too_s may result in serious persona! injury.

2. ALWAYS dress properly. DO NOT wear loose clothing or jewelry.

Pull back long ha=r. Keep your hair, clothing, and gloves away from

moving parts. Loose clothing, jewelry, or long hair can be caught in

moving parts°

3. ALWAYS avoid accidental starting. BE SURE switch is in the "Off"

position before plugging in. Do not carry tools with your finger on

the switch. Carrying tools with your finger on the switch or plugging in

tools that have the switch in the "On" position invites accidents.

4

PERSONAL SAFETY (cont.)

4. ALWAYS remove adjusting keys or wrenches before turning the

tooJ on. A wrench or a key that is left attached to a rotating part of the

tool may result in personal injury,

5. DO NOT overreach. ALWAYS keep proper footing and balance _it all

times. Proper footing and balance enables better control of the tool in

unexpected situations.

6. ALW'AYS use safety equipment. Always wear eye protection. Dust

mask, non-skid safety shoes, hard hat, or hearing protection must,be

used for appropriate conditions

SAFE TOOL USE AND CARE

1. ALWAYS use clamps or other practical ways to secure and support

the workplece to a stable platform. Holding the work by hand or against

your body is unstable and may lead to loss of control,

2. DO NOT force the tool. Use the correct tool for your application.

The correct too! will do the job better and safer at the rate for which it is

designed.

3. DO NOT use the tool if the Switch does not turn it "On" or "Off". Any

tool that cannot be controlled with the switch is dangerous and must

be repaired.

4. ALWAYS disconnect the plug from the power source before making

any adjustments, changing, accessories, or storing the tool. Such

preventive safety measures reduce the risk of starting the tool

accidentally.

5. ALWAYS store idle tools out of the reach of children and other

untrained persons. Tools are dangerous in the hands of untrained users.

6. ALWAYS maintain tools with care. Keep cutting tools sharp and :

clean. Properly maintained tools with sharp cutting edges are less likely

to bind and are easier to control

7. ALWAYS check for misalignment or binding of moving parts,

breakage of parts, and any other condition that may affectthe

tool's operation, if damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools. •........

4'

USE OF ACCESSORIES THAT ARE NOT

RECOMMENDED FOR USE WITH YOUR TOOL MAY CREATE A

HAZARDOUS CONDITION.

8. ALWAYS use only accessories that are recommended for your tool.

Accessories that may be suitable for one tool can become hazardous

when used on another tool.

5

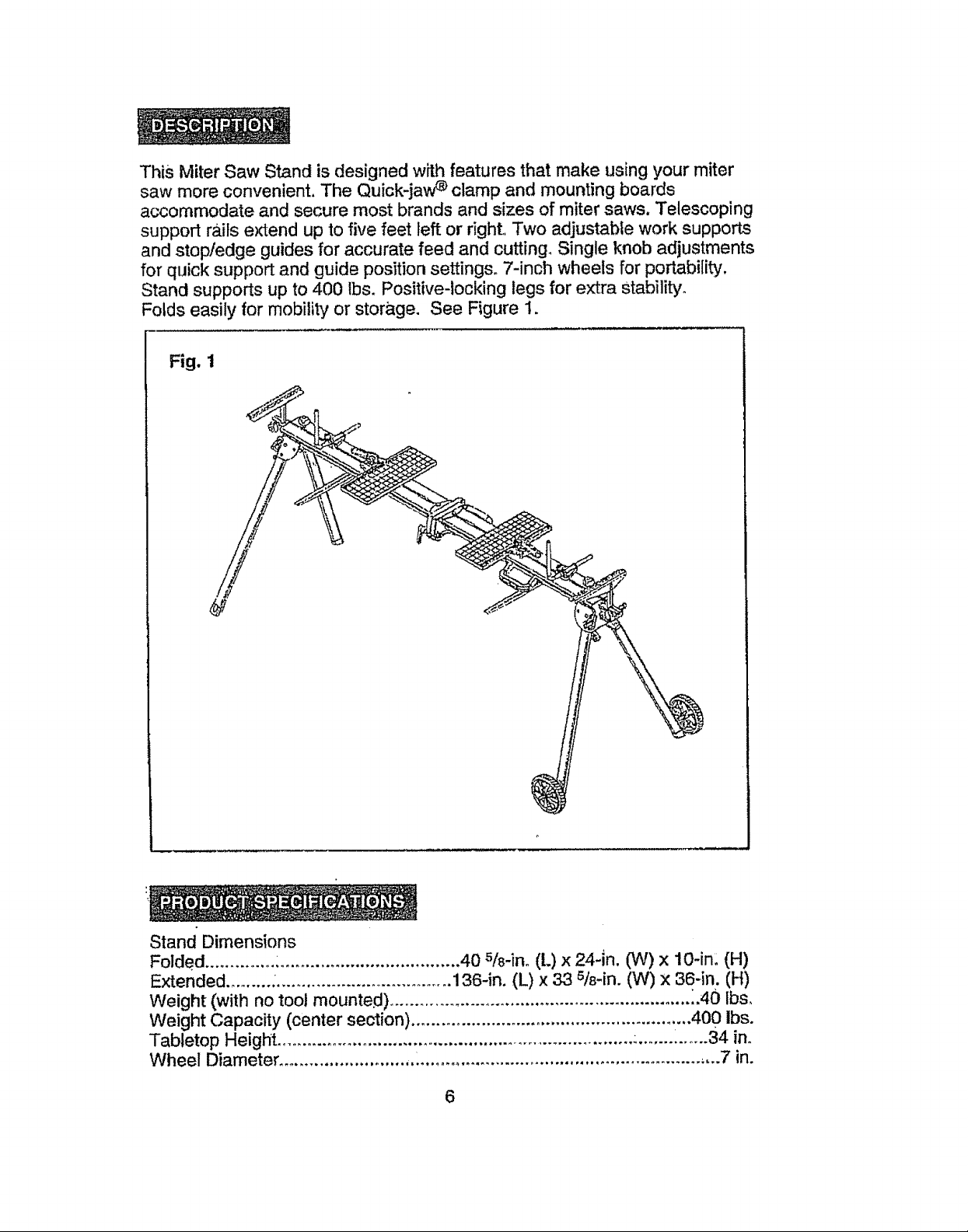

This Miter Saw Standis designedwith featuresthat make usingyour miter

saw moreconvenient.The Quick-jaw_ clampand mountingboards

accommodateand securemostbrands andsizes of mitersaws.Telescoping

supportrailsextend upto five feet leftor right. Two adjustableworksupports

andstop/edge guidesfor accuratefeedand cutting.Single knob adjustments

for quicksupport and guide position settings. 7-inch wheels for portability,

Stand supports up to 400 Ibs. Positive-locking legs for extra Stability.

Folds easily for mobility or storage. See Figure 1.

Fig. 1

Stand Dimensions

Folded .............. :.................................... 40 s/8-in. (L)x 24-in. (W)x 10-in: (H)

Extended ......... ..................................... 136-in. (L) x 33 5/8-in. (W) x 36-in. (H)

Weight (with no tool mounted) ............................................................ _.40 Ibs,

Weight Capacity (center section) ........................................................ 400 ibs.

Tabletop Height ......................................................................... :........i...... 34 in.

Wheel Diameter ........................... 1........................................................ ,,..7 in.

6

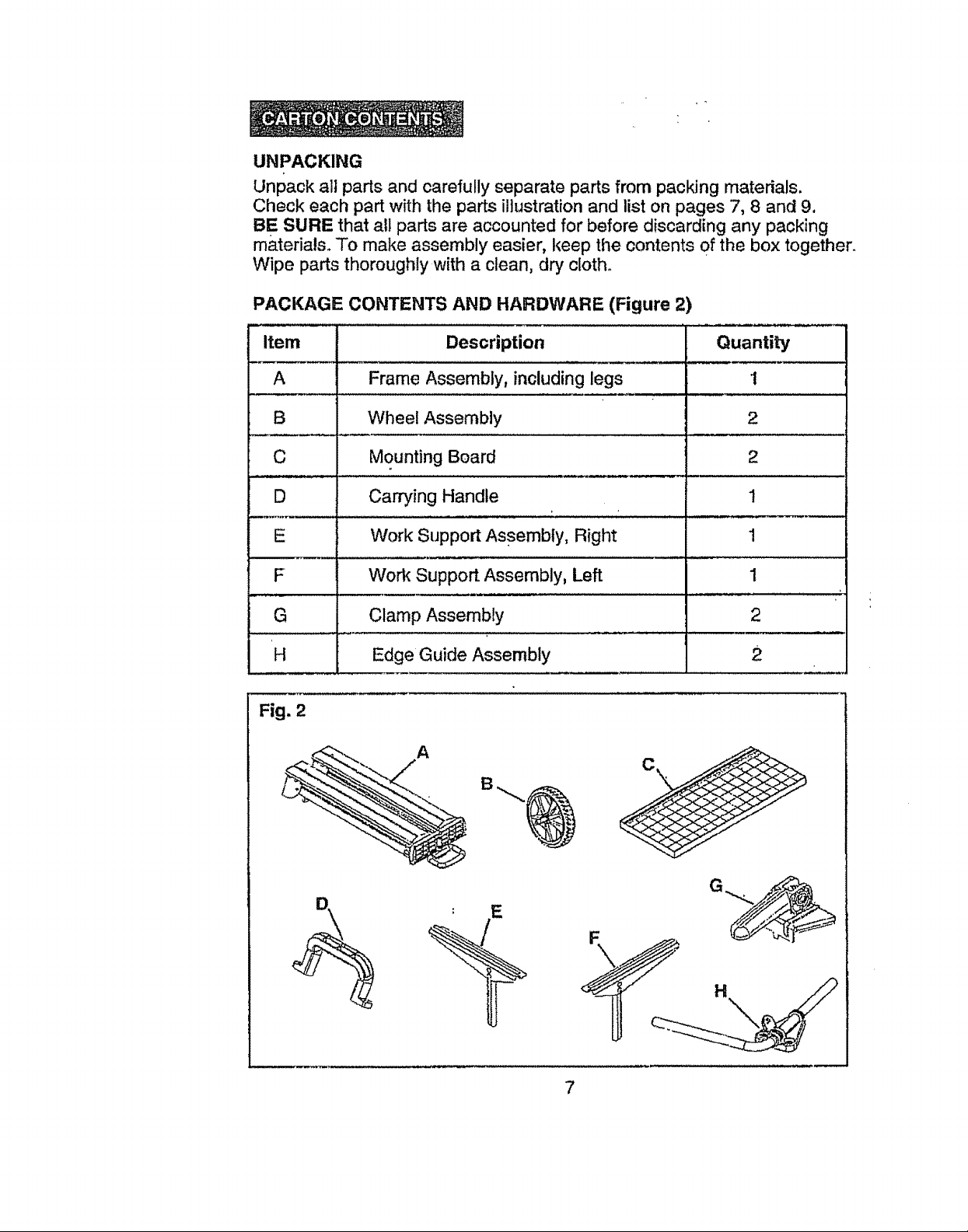

UNPACKING

Unpack all parts and carefully separate parts from packing materials.

Check each part with the parts illustration and list on pages 7, 8 and 9,

BE SURE that all parts are accounted for before discarding any packing

materials° To make assembly easier, keep the contents of the box together.

Wipe parts thoroughly with a clean, dry cloth,,

PACKAGE CONTENTS AND HARDWARE (Figure 2)

Item

A

B

C

D

E

F

_ Li_

G

H

Fig. 2

Description Quantity

Frame Assembly, including legs 1

Wheel Assembly 2

Mounting Board 2

Carrying Handle

Work Support Assembly, Right

Work Support Assembly, Left

Clamp Assembly

Edge Guide Assembly

A

1

1

2

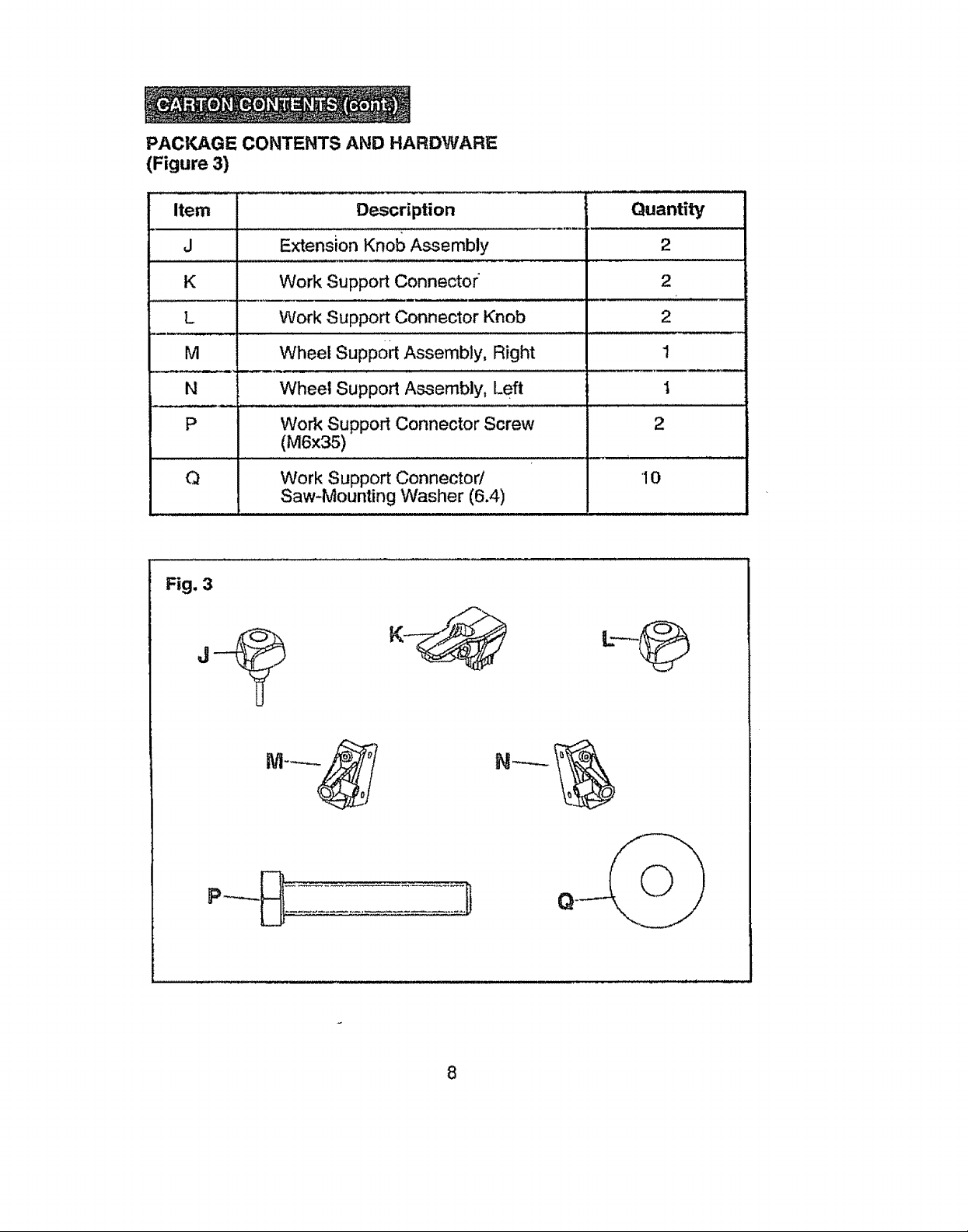

PACKAGE CONTENTS AND HARDWARE

(Figure 3)

Item De_scr_ption Quantity

J

K

L

M

N

P

Q

Fig. 3

Extension Knob Assembly

Work Support Connector

Work Support Connector Knob

Wheel Supp0rt Assembly, Right

Wheel Support Assembly, Left

Work Support Connector Screw

(M6x35)

Work Support Connector/

Saw-Mounting Washer (6.4)

2

2

2

1

1

2

, ,,L ,,,,uL , ,,,,,,

10

8

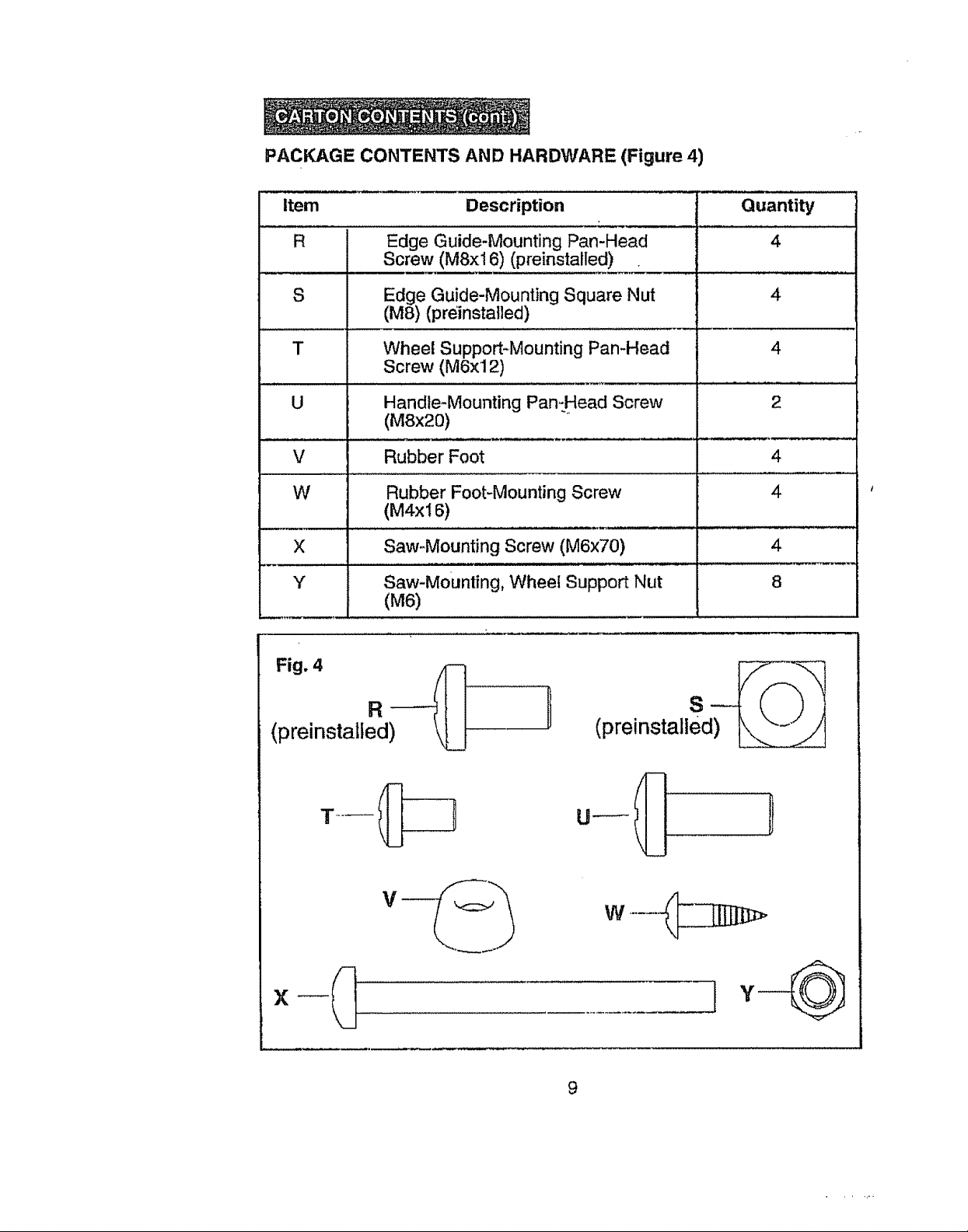

PACKAGE CONTENTS AND HARDWARE (Figure 4)

Item Description " " Quantity

R Edge Guide-Mounting Pan-Head 4

Screw (M8x16) (preinstalled) •

S Edge Guide-Mounting Square Nut

(MS) (weinstatled)

Wheel Support*Mounting Pan-Head 4

Screw (M6x12)

U Handle-Mounting Pan,-Head Screw 2

(M8x20)

V Rubber Foot 4

W Rubber Foot-Mounting Screw 4

(M4x16)

X Saw.Mounting Screw (M6x70) 4

Y Saw-Mounting, Wheel Support Nut 8

(M6)

Fig. 4

R

-- tl

(preinstalted) '___!

_

(prelnstalled) _,._-__,/'1

°-I[j !

9

FAILURE TO HEED ALL SAFETY AND OPERATING

INSTRUCTIONS AND WARNINGS REGARDING USE OF THIS

PRODUCT CAN RESULT IN SERIOUS BODILY INJURY,

Tools Needed

, #2 Phillips Screwdriver oTwo Adjustable Wrenches

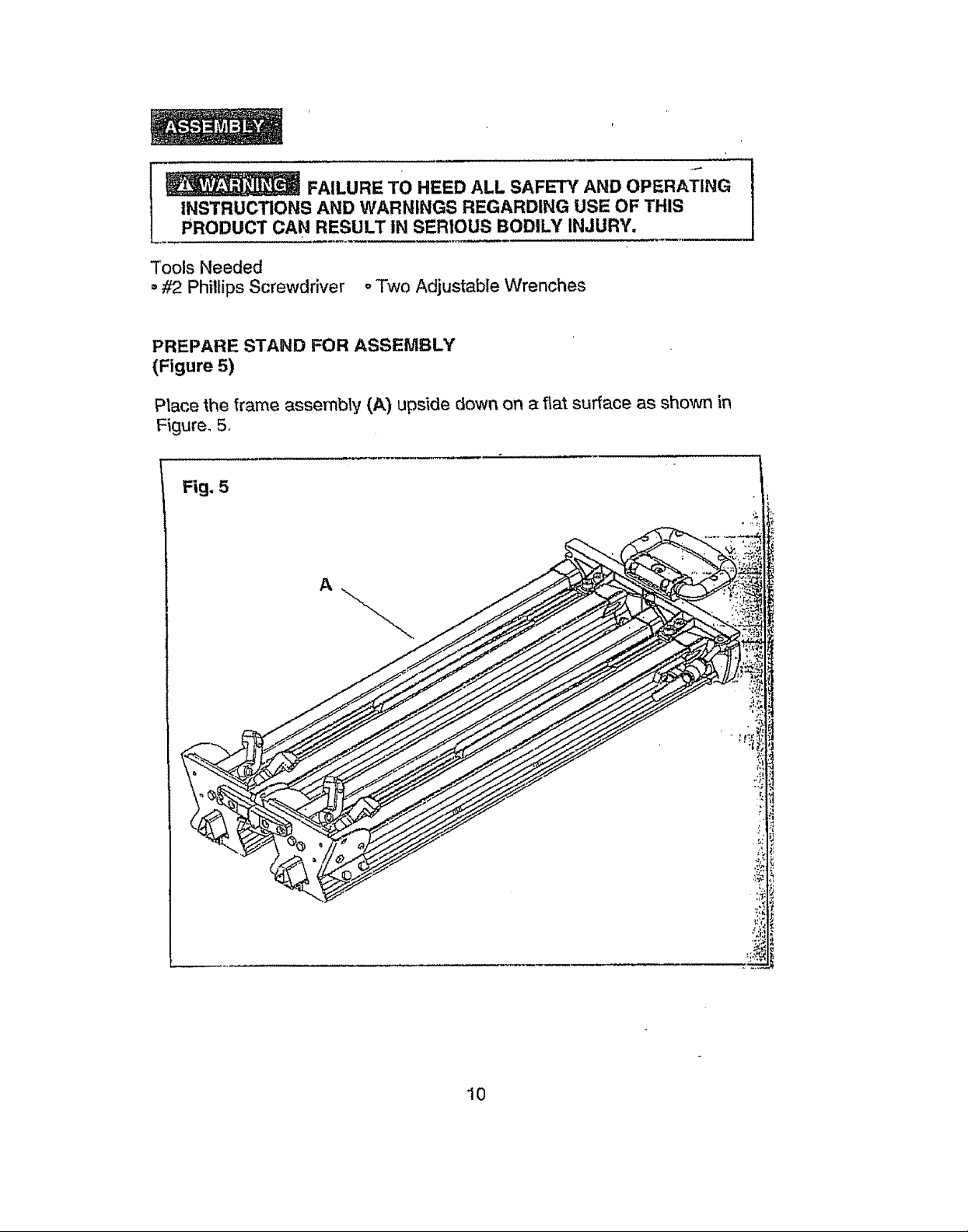

PREPARE STAND FOR ASSEMBLY

(Figure 5)

Place the frame assembly (A) upside down on a flat surface as shown in

Figure. 5_

Fig, 5

A

10

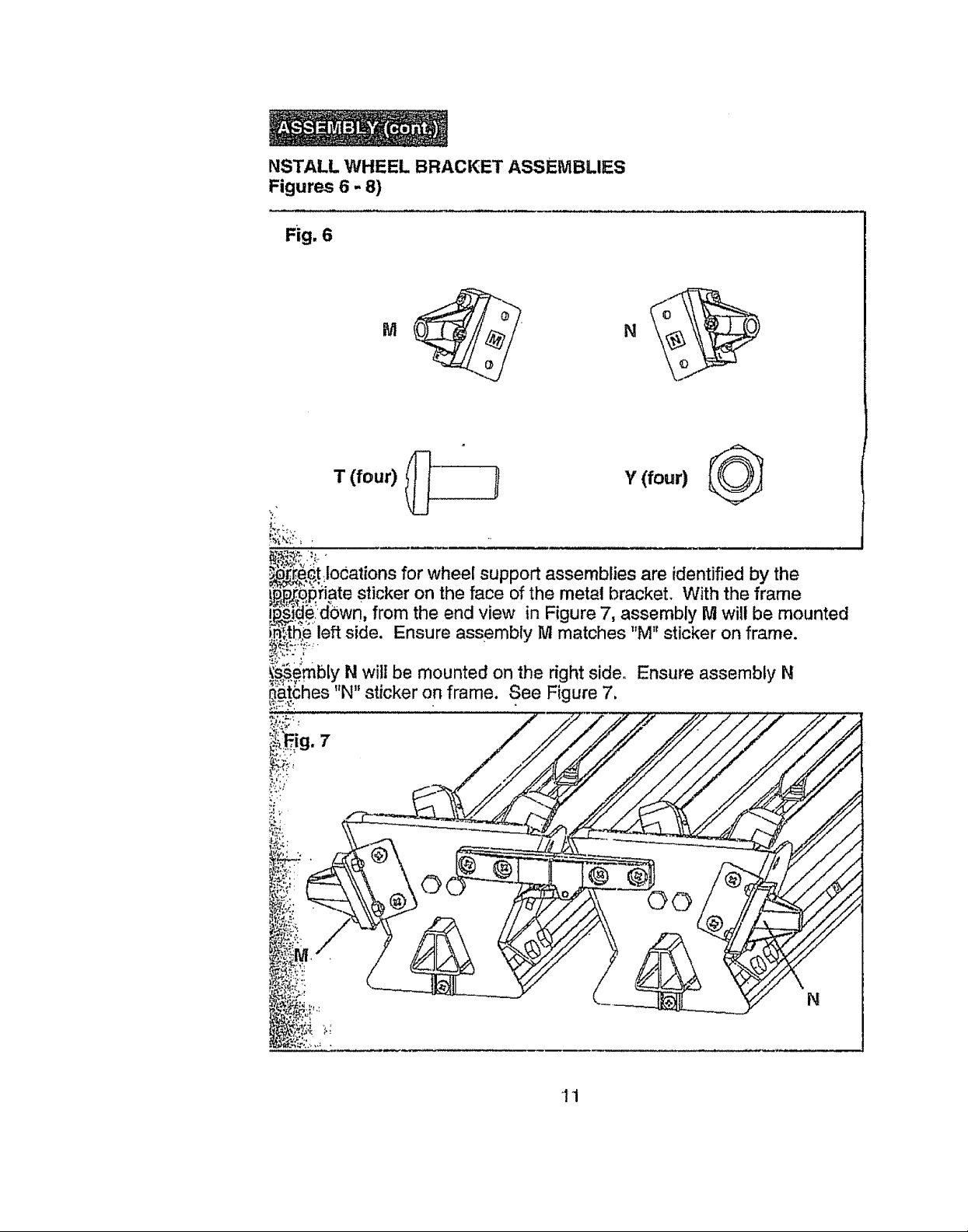

NSTALL WHEEL BRACKET ASSEMBLIES

Figures 6 - 8)

Fig. 6

M

,_r_[_ct locations for wheel support assembhes are fdentJfied by the

_,,p_._)iate sticker on the face of the metal bracket. With the frame

'_'_°:_'"-_eldi3wn,from the end view in Figure 7, assembly M will be mounted

'_ _"" • 1t Tit "

i_:tt_e left side. Ensure assembly M matches M st cker on frame.

_embly N wit| be mounted on the nght sldeo Ensure assembly N

_:_;_hes "N" sticker on frame. See Figure 7,

g. 7

11

N

Loading...

Loading...