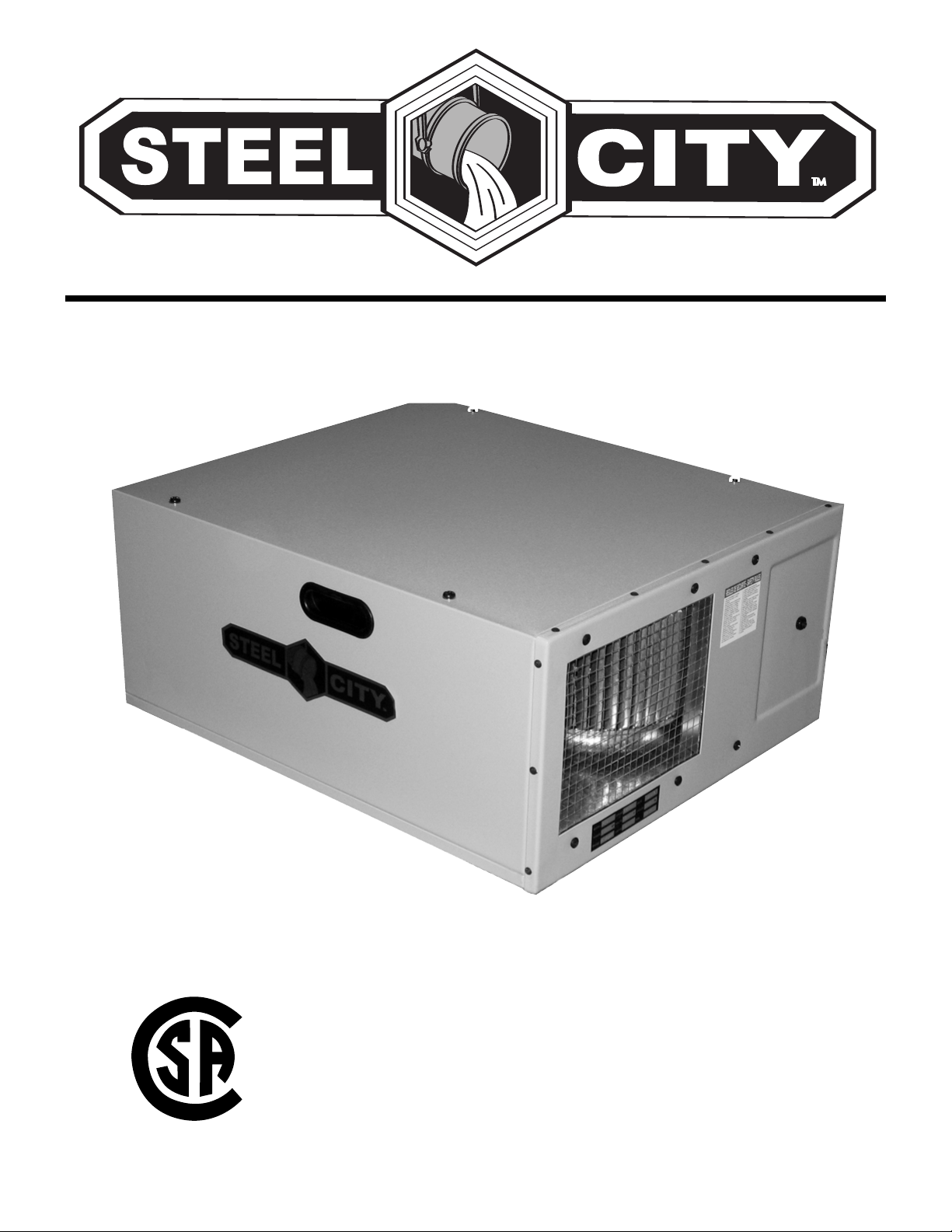

Page 1

User Manual

Read and understand this manual before using machine.

AIR CLEANER – SINGLE SPEED

Model Number

65100

®

CUS

STEEL CITY TOOL WORKS Manual Part No. OR70251

Page 2

THANK YOU

for purchasing your new Steel City Air

Cleaner. This air cleaner has been designed, tested, and

inspected with you, the customer, in mind. When

properly used and maintained, your air cleaner will provide

you with years of trouble free service, which is why it is

backed by one of the longest machinery warranties in the

business.

This air cleaner is just one of many products in the Steel

City’s family of woodworking machinery and is proof of our

commitment to total customer satisfaction.

At Steel City we continue to strive for excellence each and

every day and value the opinion of you, our customer. For

comments about your air cleaner or Steel City Tool Works,

www

.steelcitytoolworks.com

please visit our web site at

2

.

Page 3

TABLE OF CONTENTS

NTRODUCTION

I

SECTION 1 Warranty .................................................................................................................................................4

SECTION 2 Product Specifications ............................................................................................................................7

SECTION 3 Accessories and Attachments ................................................................................................................7

SECTION 4 Definition of Terms ..................................................................................................................................7

SECTION 5 Feature Identification ..............................................................................................................................8

SECTION 6 General Safety........................................................................................................................................9

SECTION 7 Product Safety ......................................................................................................................................11

SECTION 8 Electrical Requirements........................................................................................................................12

SECTION 9 Unpacking & Inventory..........................................................................................................................14

SECTION 10 Assembly ..............................................................................................................................................15

SECTION 11 Operations ............................................................................................................................................16

SECTION 12 Maintenance .........................................................................................................................................17

SECTION 13 Troubleshooting ....................................................................................................................................18

SECTION 14 Parts List..........................................................................................................................................20-21

INTRODUCTION

This user manual is intended for use by anyone working with this machine. It should be kept available

for immediate reference so that all operations can be performed with maximum efficiency and safety.

Do not attempt to perform maintenance or operate this machine until you have read and understand the

information contained in this manual.

Air Cleaner is intended to filter dry airborne wood dust only. It must be limited to non-explosive,

This

non-metallic atmosphere.

The drawings, illustrations, photographs, and specifications in this user manual represent your machine

at time of print. However

obligation to Steel City Tool Works.

This machine is not to be modified for any reasons.

, changes may be made to your machine or this manual at any time with no

3

Page 4

WARRANTY

STEEL CITY TOOL WORKS

5 YEAR LIMITED WARRANTY

Steel City Tool Works, LLC (“SCTW”) warrants all “STEEL CITY TOOL WORKS” machinery to be

free of defects in workmanship and materials for a period of 5 years from the date of the original retail

purchase by the original owner. SCTW will repair or replace, at its expense and at its option, any

SCTW machine, machine part, or machine accessory which in normal use has proven to be defective,

provided that the customer returns the product, shipping prepaid, to an authorized service center with

proof of purchase and provides SCTW with a reasonable opportunity to verify the alleged defect by

inspection. This warranty does not apply to defects due directly or indirectly to misuse, abuse,

negligence, accidents, or lack of maintenance, or to repairs or alterations made or specifically authorized

by anyone other than SCTW. Normal wear components are also excluded under this coverage. Every

effort has been made to ensure that all SCTW machinery meets the highest quality and durability

standards. We reserve the right to change specifications at any time due to our commitment to

continuous improvement of the quality of our products.

EXCEPT AS SET FOR

TIONS OR WARRANTIES WITH RESPECT TO ITS MACHINERY, OR ITS CONDITION,

MERCHANTABILITY, OR FITNESS FOR ANY PARTICULAR PURPOSE OR USE. SCTW

FURNISHES THE ABOVE WARRANTIES IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, WHICH ARE HEREBY SPECIFICALLY DISCLAIMED.

SCTW SHALL NOT BE LIABLE FOR ANY (A) SPECIAL, INDIRECT, INCIDENTAL, PUNITIVE

OR CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT LIMITATION LOSS OF PROFITS,

ARISING FROM OR RELATED TO THIS WARRANTY, THE BREACH OF ANY AGREEMENT OR

WARRANTY, OR THE OPERATION OR USE OF ITS MACHINERY, INCLUDING WITHOUT

LIMITATION DAMAGES ARISING FROM DAMAGE TO FIXTURES, TOOLS, EQUIPMENT,

PARTS OR MATERIALS, DIRECT OR INDIRECT LOSS CAUSED BY ANY OTHER PARTY, LOSS

OF REVENUE OR PROFITS, FINANCING OR INTEREST CHARGES, AND CLAIMS BY ANY

THIRD PERSON, WHETHER OR NOT NOTICE OF SUCH POSSIBLE DAMAGES HAS BEEN

GIVEN TO SCTW; (B) DAMAGES OF ANY KIND FOR ANY DELAY BY OR FAILURE OF SCTW

TO PERFORM ITS OBLIGATIONS UNDER THIS AGREEMENT; OR (C) CLAIMS MADE A

LEGAL

A

SUBJECT

SUCH CAUSE OF ACTION FIRST AROSE.

The validity, construction and performance of this Warranty and any sale of machinery by SCTW shall

be governed by the laws of the Commonwealth of Pennsylvania, without r

visions of any jurisdiction. Any action related in any way to any alleged or actual offer, acceptance or

sale by SCTW

this Warranty, shall take place in the federal or state courts in Allegheny County, Pennsylvania.

OF

, or any claim related to the performance of any agreement including without limitation

TH ABOVE, SCTW MAKES NO EXPRESS OR IMPLIED REPRESENTA-

PROCEEDING AGAINST SCTW MORE THAN ONE (1) YEAR AFTER

egard to conflicts of laws pr

o

-

STEEL CITY TOOL WORKS

4

Page 5

WARRANTY CARD

Name ________________________________________________

Street _______________________________________________

Apt. No. ______________________________________________

City _________________________ State ______ Zip __________

Phone Number_________________________________________

E-Mail________________________________________________

Product Description:_____________________________________

Model No.: ___________________________________________

Serial No. _____________________________________________

The following information is given on a voluntary basis

and is strictly confidential.

1. Where did you purchase your STEEL CITY machine?

Store: ____________________________________________

City:______________________________________________

2. How did you first learn of Steel City Tool Works?

___ Advertisement ___ Mail Order Catalog

___ Web Site ___ Friend

___ Local Store Other_______________________

3. Which of the following magazines do you subscribe to?

___ American Woodworker ___ American How-To

––– Cabinetmaker ___ Family Handyman

___ Fine Homebuilding ___ Fine Woodworking

___ Journal of Light Construction ___ Old House Journal

___ Popular Mechanics ___ Popular Science

CUT HERE

___ Popular Woodworking ___ Today’s Homeowner

!

___ WOOD ___ Woodcraft

___ WOODEN Boat ___ Woodshop News

___ Woodsmith ___ Woodwork

___ Woodworker ___ Woodworker’s Journal

___ Workbench Other_________________

8. How would you rank your woodworking skills?

___ Simple ___ Intermediate

___ Advance ___ Master Craftsman

9. How many Steel City machines do you own? _____________

10. What stationary woodworking tools do you own?

Check all that apply.

___ Air Compressor ___ Band Saw

___ Drill Press ___ Drum Sander

___ Dust Collection ___ Horizontal Boring Machine

___ Jointer ___ Lathe

___ Mortiser ___ Panel Saw

___ Planer ___ Power Feeder

___ Radial Arm Saw ___ Shaper

___ Spindle Sander ___ Table Saw

___ Vacuum Veneer Press ___ Wide Belt Sander

Other____________________________________________

11. Which benchtop tools do you own?

___ Belt Sander ___ Belt / Disc Sander

___ Drill Press ___ Band Saw

___ Grinder ___ Mini Jointer

___ Mini Lathe ___ Scroll Saw

___ Spindle / Belt Sander Other______________________

12. Which portable / hand held power tools do you own?

Check all that apply.

Check all that apply.

___

Belt Sander ___ Biscuit Jointer

___ Dust Collector ___ Circular Saw

___ Detail Sander ___ Drill / Driver

___ Miter Saw ___ Orbital Sander

___ Palm Sander ___ Portable Thickness Planer

___ Saber Saw ___ Reciprocating Saw

___ Router Other_______________________

4. Which of the following woodworking / remodeling shows do

you watch?

___ Backyard America ___ The American Woodworker

___ Home Time ___ The New Yankee Workshop

___ This Old House ___ Woodwright’s Shop

Other__________________________________________

5. What is your annual household income?

___ $20,000 to $29,999 ___ $30,000 to $39,999

___ $40,000 to $49,999 ___ $50,000 to $59,999

___ $60,000 to $69,999 ___ 70,000 to $79,999

___ $80,000 to $89,999 ___ $90,000 +

6. What is your age group?

___ 20 to 29 years ___ 30 to 39 years

___ 40 to 49 years ___ 50 to 59 years

___ 60 to 69 years ___ 70 + years

7. How long have you been a woodworker?

___ 0 to 2 years ___ 2 to 8 years

___ 8 to 20 years ___ over 20 years

13. What machines / accessories would you like to see added to the

STEEL

____________________________________________________

____________________________________________________

14. What new accessories would you like to see added?

____________________________________________________

____________________________________________________

15. Do you think your purchase represents good value?

es

___Y

16. Would you recommend STEEL CITY products to a friend?

Y

___

17. Comments:

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

es

CITY

line?

___ No

___ No

5

Page 6

OLD ON DOTTED LINE

F

Steel City Tool Works

P.O. Box 10529

Murfreesboro, TN 37129

PLACE

STAMP

HERE

FOLD ON DOTTED LINE

6

Page 7

PRODUCT SPECIFICATIONS

Motor Specifications:

ype Induction, Ball Bearing

T

Continuous Duty

orsepower 1/8

H

Amps 2.3

Voltage 120

Phase Single

Hertz 60

RPM 1180 (no load)

Product Specifications:

Noise Level (Decibel) 66 dB

CFM 850

Outer Filter 5 micron, electrostatic

Inner Filter 1 micron

Filter Cycle 16 times per hour

(20’ x 20’ x 8’)

Product Dimensions:

ootprint 28” x 24” (71cm x 61cm)

F

Length 28” (71cm)

Width 24” (61cm)

Height 12” (30.5cm)

Weight 55 Lbs. (25Kg)

Shipping Dimensions:

Carton Type Cardboard

Length 30-3/8” (77cm)

Width 26” (66cm)

Height 14.2 (36cm)

Gross Weight 68.2 Lbs. (31Kg)

ACCESSORIES AND ATTACHMENTS

!

WARNING

Use only accessories recommended for this machine.

Using other accessories may cause serious injury and

cause damage to the machine.

DEFINITION OF TERMS

Below are some terms that will help you to understand and setup your

and design your own

Air Cleaner or Ambient Air Cleaner – A machine used

to filter dry airborne wood dust.

Dust Collector – A machine used to collect fine wood

dust and chips.

Dust Collection System – A dust collector connected

to multiple woodworking machines utilizing various

types of hose/pipe and fittings.

Air Cleaner System.

Contact your local Steel City dealer for accessories, or

visit our website at: www.steelcitytoolworks.com.

Air Cleaner

C.F.M. = Cubic Feet/Minute – A measurement of the

amount of air volume that can move through a dust

collector in one minute.

measurement of the amount of the

Static Pressure –

resistance to airflow in a dust collection system.

One Micron – One micron is equal to one millionth of a

meter.

A

7

Page 8

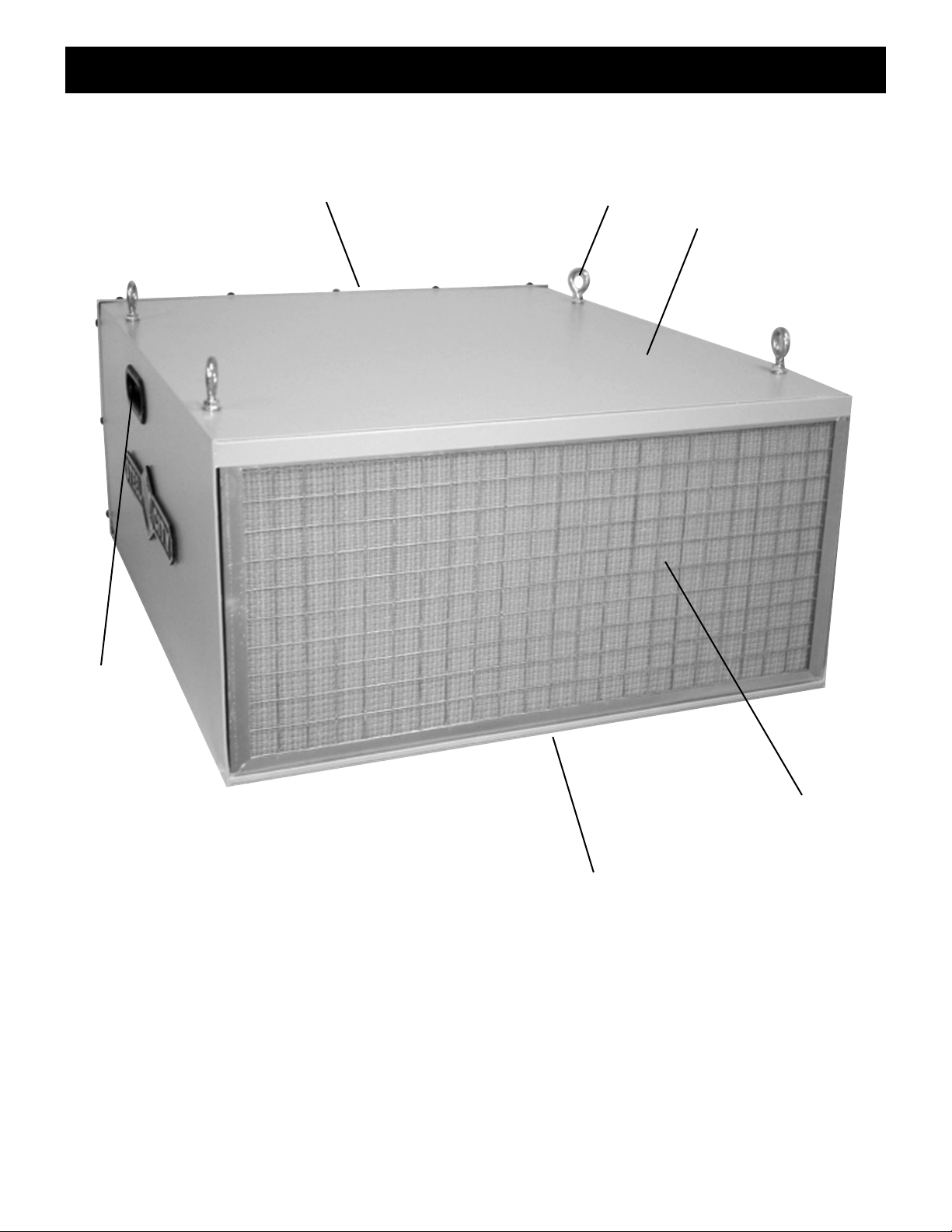

Fig. 1-1

FEATURE IDENTIFICATION

F

C

A

B

A.

Air Cleaner

B.

Handle

C.

Eye-bolt

D.

Electrostatic Filter

E. Intake Side

F. Exhaust Side

D

E

8

Page 9

GENERAL SAFETY

!

WARNING

TO AVOID serious injury and damage to the machine,

ead and follow all Safety and Operating Instructions

r

before assembling and operating this machine.

his manual is not totally comprehensive. It does not

T

and can not convey every possible safety and operational problem which may arise while using this

machine. The manual will cover many of the basic and

specific safety procedures needed in an industrial environment.

All federal and state laws and any regulations having

jurisdiction covering the safety requirements for use of

this machine take precedence over the statements in

this manual. Users of this machine must adhere to all

such regulations.

Below is a list of symbols that are used to attract your

attention to possible dangerous conditions.

!

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or

death.

!

DANGER

Indicates an imminently hazardous situation which, if

not avoided, WILL result in death or serious injury.

!

WARNING

Exposure to the dust created by power sanding, sawing, grinding, drilling and other construction activities

may cause serious and permanent respiratory or

other injury, including silicosis (a serious lung disease), cancer, and death. Avoid breathing the dust,

and avoid prolonged contact with dust. The dust

may contain chemicals known to the State of

California to cause cancer, birth defects or other

reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other

masonry products.

• Arsenic and chromium from chemically-treated

lumber.

Always operate tool in well ventilated area and provide for proper dust removal. Use a dust collection

system along with an air filtration system whenever

possible. Always use properly fitting NIOSH/OSHA

approved respiratory protection appropriate for the

dust exposure, and wash exposed areas with soap

and water.

!

WARNING

Indicates a potentially hazardous situation which, if not

avoided, COULD result in death or serious injury.

!

CAUTION

Indicates a potentially hazardous situation, if not avoid-

MAY result in minor or moderate injury. It may also

ed,

be used to alert against unsafe practices.

CAUTION

CAUTION used without the safety alert symbol indi-

cates a potentially hazardous situation which, if not

avoided, may result in property damage.

NOTICE

This symbol is used to alert the user to useful information about proper operation of the machine.

1. To avoid serious injury and damage to the machine,

read the entire User Manual before assembly and

operation of this machine.

!

WARNING

2. AL

WAYS

throw debris into the eyes during operations,

which could cause severe and permanent eye

damage. Everyday eyeglasses are NOT

glasses. ALWAYS wear Safety Goggles (that

comply with ANSI standard Z87.1) when operating power tools.

wear eye protection.

Any machine can

safety

9

Page 10

!

WARNING

3. ALWAYS wear hearing protection. Plain cotton is

ot an acceptable protective device. Hearing

n

equipment should comply with ANSI S3.19

Standards.

!

WARNING

4. ALWAYS wear a NIOSH/OSHA approved dust

mask to prevent inhaling dangerous dust or airborne particles.

10.

SECURELY anchor this unit into a supporting struc-

ure when suspending it from the ceiling. Always

t

keep a minimum of 7 feet between the bottom of

the unit and the floor surface to allow for sufficient

head clearance. Use only a chain rated for a minimum of 150 lb. working load to adequately hold the

nit. Use steel S-hooks that are at least 1/4” in

u

diameter to suspend the unit from the ceiling. Lagtype bolts used to suspend the unit from the ceiling

must be threaded at least 1-1/2” into the supporting

structural members.

11. SUPPORT this unit or securely clamp it to the work

surface when it is used in a portable application to

eliminate potential movement and/or damage from

falling.

DO NOT operate this unit without the filters in

12.

place.

MAKE CERTAIN that the intake and exhaust areas

13.

are clean prior to starting the unit. A clogged intake

or exhaust can cause a fire and/or explosion.

5. ALWAYS keep the work area clean, well lit, and

organized. DO NOT work in an area that has slippery floor surfaces from debris, grease, and wax.

6. ALWAYS unplug the machine from the electrical

receptacle when making adjustments, changing

parts or performing any maintenance.

7. DO NOT leave the air cleaner plugged into the

electrical outlet. Unplug air cleaner from the outlet

when not in use and before servicing, changing

filters, unclogging and cleaning.

8. DO NOT use this unit to filter metal dust. Combining wood and metal dust can create an explosion or

fire hazard. This air cleaner is intended for use

where only dry airborne dust is present. Its use

should be limited to non-explosive, non-metallic

atmospheres.

9.

NOT

DO

smoke; fire or explosions can result.

use this machine to dissipate fumes or

!

WARNING

14. KEEP all fingers, arms, and hands away from

the fan. Avoid all exposure to rotating parts to

prevent injury.

!

WARNING

15. DO NOT handle the plug or air cleaner with wet

hands.

16. DO NOT pull the air cleaner by the power cord.

NEVER allow the power cord to come in contact

with sharp edges, hot surfaces, oil or grease.

10

Page 11

PRODUCT SAFETY

. Serious personal injury may occur if normal safety

1

precautions are overlooked or ignored. Accidents

are frequently caused by lack of familiarity or failure

to pay attention. Obtain advice from supervisor,

instructor, or another qualified individual who is

amiliar with this machine and its operations.

f

2. Every work area is different. Always consider safety first, as it applies to your work area. Use this

machine with respect and caution. Failure to do so

could result in serious personal injury and damage

to the machine.

3. Prevent electrical shock. Follow all electrical and

safety codes, including the National Electrical Code

(NEC) and the Occupational Safety and Health

Regulations (OSHA). All electrical connections and

wiring should be made by qualified personnel only.

!

WARNING

4. TO REDUCE the risk of electrical shock. DO

NOT use this machine outdoors. DO NOT

expose to rain. Store indoors in a dry area.

!

WARNING

9. DO NOT handle the plug or air cleaner with

wet hands.

10. NEVER use the air cleaner near any flammable or

combustible liquids.

NEVER use the air cleaner to dissipate fumes or

11.

smoke. NEVER pick up anything that is burning or

smoking, such as cigarettes, matches or hot ashes.

12. USE only as described in this manual. USE accessories only recommended by Steel City.

DO NOT pull the air cleaner by the power cord.

13.

NEVER allow the power cord to come in contact

with sharp edges, hot surfaces, oil or grease.

REPLACE a damaged cord immediately. DO NOT

14.

use a damaged cord or plug. If the air cleaner is not

operating properly, or has been damaged, left outdoors or has been in contact with water.

15. DO NOT use the air cleaner as a toy. DO NOT use

near or around children.

STOP using this machine, if at any time you experi-

5.

ence difficulties in performing any operation.

Contact your supervisor, instructor or machine service center immediately.

6. Safety decals are on this machine to warn and

direct you to how to protector yourself or visitors

from personal injury. These decals

tained so that they are legible. REPLACE decals

that are not legible.

DO NOT leave the air cleaner plugged into the

7.

electrical outlet. Unplug air cleaner from the outlet

when not in use and before servicing, changing

bags, unclogging and cleaning.

8. ALWAYS turn the power switch “OFF” before

unplugging the air cleaner

.

MUST be main-

!

WARNING

16. DO NOT insert fingers or foreign objects into

the dust intake port. Keep hair, loose clothing,

fingers, and all body parts away from openings

and moving parts of the air cleaner.

PERIODICALLY INSPECT filter for any cuts, rips

17.

or tears. NEVER operate the air cleaner with a

damaged filter.

18. The air cleaner is designed for home use or light

commercial duty

19. CONNECT air cleaner to a properly grounded outlet

only. See grounding instructions.

ONLY.

11

Page 12

ELECTRICAL REQUIREMENTS

!

WARNING

O PREVENTelectrical shock, follow all electrical and

T

safety codes, including the National Electrical Code

(NEC) and the Occupational Safety and Health

Regulations (OSHA). All electrical connections and

wiring should be made by qualified personnel only.

GROUNDING INSTRUCTIONS

O REDUCEthe risk of electrical shock, DO NOT use

T

machine outdoors. DO NOT expose to rain. Store

indoors in a dry area.

DO NOT connect the machine to the power source

before you have completed the set up process. DO

NOT connect the machine to the power source until

instructed to do so.

!

WARNING

This machine MUST BE GROUNDED while in use to

protect the operator from electric shock.

In the event of a malfunction or breakdown, GROUND-

ING provides the path of least resistance for electric

current and reduces the risk of electric shock. This

machine is equipped with an electric cord that has an

equipment-grounding conductor and a grounding plug.

The plug MUST be plugged into a matching electrical

receptacle that is properly installed and grounded in

accordance with ALL local codes and ordinances.

If a plug is provided with your machine DO NOT modify

the plug. If it will not fit your electrical receptacle, have

a qualified electrician install the proper connections to

meet all electrical codes local and state. All connections

must also adhere to all of OSHA

IMPROPER ELECTRICAL

ment-grounding conductor can result in risk of electric

shock. The conductor with the green insulation (with or

without yellow stripes) is the equipment-grounding con

ductor.DO NOT connect the equipment-grounding con

ductor to a live terminal if repair or replacement of the

electric cord or plug is necessary

Check with a qualified electrician or service personnel if

you do not completely understand the grounding

instructions, or if you are not sure the tool is properly

grounded.

mandates.

CONNECTION

.

of the equip

PLUGS/RECEPTACLES

!

WARNING

• Electrocution or fire could result if this machine is

not grounded properly or if the electrical configuration does not comply with local and state electrical

codes.

• MAKE CERTAIN the machine is disconnected

from power source before starting any electrical|

work.

• MAKE SURE the circuit breaker does not exceed

the rating of the plug and receptacle.

The motor supplied with your machine is a 120 volt,

alternating current, 60 hertz, single phase motor. It is

shipped wired for 120 volt application. Never connect

the green or ground wire to a live terminal.

-

-

-

This tool is intended for use on a circuit that has an

electrical receptacle as shown in Figure 1-1. Figure 1-1

shows a NEMA approved 3-wire, 15 amp electrical plug

and receptacle that have a grounding conductor. If a

properly grounded electrical receptacle is not available,

an adapter as shown in Figure 1-2 can be used to temporarily connect this plug to a 2-contact ungrounded

receptacle. The adapter has a rigid lug extending from it

that MUST be connected to a permanent earth ground,

such as a properly grounded receptacle box. THIS

ADAPTER IS PROHIBITED IN CANADA.

12

Page 13

Fig. 1-1

EXTENSION CORDS

!

WARNING

To reduce the risk of fire or electrical shock, use the

proper gauge of extension cord. When using an

extension cord, be sure to use one heavy enough to

carry the current your machine will draw.

The smaller the gauge-number, the larger the diameter

of the extension cord is. If in doubt of the proper size of

an extension cord, use a shorter and thicker cord. An

undersized cord will cause a drop in line voltage resulting in a loss of power and overheating.

Fig. 1-2

!

CAUTION

USE ONLY a 3-wire extension cord that has a 3-prong

grounding plug and a 3-pole receptacle that accepts the

machine’s plug.

If you are using an extension cord outdoors, be sure it

is marked with the suffix “W-A” (“W” in Canada) to indicate that it is acceptable for outdoor use.

Make certain the extension cord is properly sized, and

in good electrical condition. Always replace a worn or

damaged extension cord immediately or have it

repaired by a qualified person before using it.

Protect your extension cords from sharp objects, excessive heat, and damp or wet areas.

MINIMUM RECOMMENDED GAUGE FOR EXTENSION CORDS (AWG)

120 VOLT OPERATION ONLY

LONG

25’

0 to 6 Amps 18 AWG 16 AWG 16 AWG

6 to 10 Amps 18 AWG 16 AWG 16 AWG

50’ LONG 100’ LONG

10 to 12 Amps 16 AWG 16 AWG 14 AWG

13

Page 14

UNPACKING & INVENTORY

his Air Cleaner will require a minimal amount of

T

assembly.

Remove all of the parts from the shipping box and lay

hem on a clean work surface. Compare the items to

t

figure 1-2, verify that all items are accounted for before

discarding the shipping box.

!

WARNING

If any parts are missing, do not attempt to plug in the

Fig. 1-1

ower cord and turn “ON” the Air Cleaner. The Air

p

Cleaner should only be turned “ON” after all the parts

have been obtained and installed correctly. For missing

parts, contact Steel City at 1-877-SC4-TOOL.

CAUTION: Make certain shipping blocks have been

removed from between cabinet and blower assembly,

before unit is turned on. You will have to remove the

filters to access shipping blocks.

The following items are to be provided in the shipping

box:

A. Air Cleaner

A

Fig. 1-2

B. Eye-bolt 5/16-18 x 1-1/2” (4)

C. Flange nut 5/16-18 (4)

C

D. Rubber Pad (4)

D

B

14

Page 15

ASSEMBLY

!

WARNING

1. DO NOT assemble the Air Cleaner until you are

sure the tool IS NOT plugged in.

2. DO NOT assemble the Air Cleaner until you are

sure the power switch is in the “OFF” position.

3. For your own safety, DO NOT connect the machine

to the power source until the machine is completely

assembled and you read and understand the entire

Owner’s Manual.

The Air Cleaner can be used as a portable or stationary

unit. As a portable unit it can be moved and placed

near the work to be done. As a stationary unit it can be

hung overhead in the shop. Determine which type of

use is best fitted for your applications and proceed to

that section in the assembly instructions.

PORTABLE UNIT ASSEMBLY

MAKE CERTAIN THE AIR CLEANER IS DISCONNECTED FROM THE POWER SOURCE.

1. Place the Air Cleaner on its side. Locate the selfadhesive rubber pads supplied with the unit.

Carefully place one rubber pad on each bottom

corner of the Air Cleaner. The rubber pads will help

eliminate vibration and noise.

Fig. 2-1

B

A

4. Figure 2-2 shows one of the four eye-bolts (E)

assembled to the top of the Air Cleaner.

adjust the height of the Air Cleaner, loosen flange

nuts (F) and rotate eye-bolts as necessary

TANT:

threaded at least eight complete turns into tapped

hole in top of Air Cleaner. Make certain the flange

nuts are tightened down against the surface of the

Air Cleaner after height adjustments are made.

For safety reasons, eye-bolts must be

NOTE: To

IMPOR

.

Fig. 2-2

-

CAUTION: For operator safety, we sugest that the

unit be clamped down when used on a workbench

or positioned on sawhorses.

2. There are two lifting handles located on each side

of the air cleaner. These handles should be used to

carry the Air Cleaner from place to place. To avoid

damage to the air filters, carry the air cleaner with

the filters positioned away from your body.

CAUTION: This Air Cleaner weighs approximately

55 pounds.

STATIONARY UNIT ASSEMBLY

!

WARNING

THIS TOOL WEIGHS APPROXIMATELY 55 POUNDS.

MAKE CERTAIN THE UNIT IS SECURELY SUPPORTED WHEN MOUNTING TO A CEILING OR OVERHEAD SUPPORT.

1. Remove four screws, one of which is shown at (A)

from top of Air Cleaner (B). See figure 2-1.

Thread a flange nut 5/16-18 approximately

2.

half-way onto the eye-bolt 5/16-18 x 1-1/2” ).

3. Thread the eye-bolt with the flange nut assembled

into the hole where screw was removed in STEP 1.

NOTE: Thread each eye-bolt eight complete turns

into threaded hole.

E

F

!

WARNING

NEVER SECURE MOUNTING HARDWARE TO

DR

YWALL, DROP CEILING TILE/FRAME OR NON-

STRUCTURAL MEMBERS.

!

WARNING

KEEP A MINIMUM OF SEVEN FEET BETWEEN BOTTOM OF AIR CLEANER AND THE FLOOR.

DO NOT

unit from the ceiling. We recommend that a chain

should be used and rated for a minimum of a 150

pound working load to firmly support the Air Cleaner.

IMPORTANT: When determining a location to mount

the unit, the Air Cleaner will operate more efficiently

when the air flow is unrestricted. Do not locate the unit

in a corner or near any heating or cooling vents.

15

use rope, cable or power cord to suspend the

Page 16

OPERATIONS

AUTION:Make certain shipping blocks have been

C

removed from between cabinet and blower assembly,

before unit is turned on.

!

WARNING

DO NOT operate this unit without the filters in place.

FUNCTION

his Air Cleaner is furnished with two filters: an outer

T

pre-filter which filters particles that are five microns and

larger, and a secondary disposable three-pocket inner

filter that captures 91% of the dust particles that are

one micron and larger (one micron = one millionth of

a meter). The Air Cleaner will filter the air in a room

measuring 20’ x 20’ x 8’ sixteen times an hour. If

desired, multiple units can be used to filter larger areas.

CONNECTING TOOL

TO POWER SOURCE

A separate electrical circuit should be used for your

tools. This circuit should not be less than #14 A.W.G.

wire and should be protected with a 15-amp time lag

fuse. Have a qualified electrician repair or replace damaged or worn cord immediately. Before connecting the

motor to the power line, make certain the switch is in

the “OFF” position and be sure that the electric current

is of the same characteristics as stamped on the motor

nameplate. All line connections should make good

contact. Running on low voltage will damage the motor.

ON/OFF SWITCH

The Air Cleaner is supplied with an in-line rocker switch

(A) located on the power cord. To START or STOP the

unit, press downward on the rocker switch.

NOTE: The Air Cleaner may produce a slight odor for

the first couple hours of operation due to the protective

coating which is applied to internal components. This

odor will dissipate and should be disregarded.

!

WARNING

DO NOT USE THIS UNIT TO FILTER METAL DUST.

Combining wood and metal dust can create an explosion or fire hazard. This Air Cleaner is intended for use

where only dry airborne dust is present. Its use should

be limited to non-explosive, non-metallic atmospheres.

!

WARNING

NEVER SECURE MOUNTING HARDWARE TO

DRYWALL, DROP CEILING TILE/FRAME OR NONSTRUCTURAL MEMBERS.

!

WARNING

KEEP A MINIMUM OF SEVEN FEET BETWEEN

BOTTOM OF AIR CLEANER AND THE FLOOR.

16

Page 17

MAINTENANCE

CHANGING AND CLEANING FILTERS

!

WARNING

Turn the power switch “OFF” and unplug the power

ord from its power source prior to any maintenance.

c

Fig. 1-1

A

1. Disconnect machine from power source.

2. Lift up and pull out on the bottom of the electrostatic filter (A). See figure 1-1.

. Both the electrostatic filter and the three-pocket

5

inner filter should be replaced once a year. The

electrostatic filter should be cleaned once a month

or more often depending on use. When there is a

eavy build up of dust on the electrostatic filter,

h

it should be cleaned. The three-pocket inner filter

cannot be cleaned. If either filter is torn, bent or

damaged in any way, it should be replaced immediately.

The electrostatic filter can be cleaned in one of

three methods. Method one is using a shop-vac to

remove the dust. Method two is using compressed

air to blow the dust out of the filter. Method three is

to wash with soap and water.

!

WARNING

Compressed air can be dangerous. For operator

safety, DO NOT exceed an air pressure of 30 PSI or

point air nozzle toward anyone or aim nozzle at

your own body. Always wear safety glasses and

dust mask when performing this procedure.

Fig. 1-2

B

Remove the three-pocket inner filter (B) in the

3.

same manner as the electrostatic filter.

See figure 1-2.

Install both filters in the reverse order in which they

4.

were removed. NOTE: Make certain the AIRFLOW

arrow on each fitler is pointing inward toward the

rear of the Air Cleaner.

LUBRICATION

The Air Cleaner has sealed lubricated bearings in the

motor housing that do not require any additional lubrication from the operator.

CAUTION: DO NOT USE FLAMMABLE MATERIALS

to clean Air Cleaner.

!

WARNING

Repairs to the Air Cleaner should be performed by

trained personnel only.

Authorized Service Center for authorized service.

Unauthorized repairs or replacement with non-factory

parts could cause serious injury to the operator and

damage to the Air Cleaner.

Contact your nearest Steel City

17

Page 18

TROUBLESHOOTING GUIDE

TO PREVENT INJURY TO YOURSELF or damage to the Air Cleaner, turn the switch to the “OFF” position and

unplug the power cord from the electrical receptacle before making any adjustments.

PROBLEM LIKELY CAUSE(S) SOLUTION

Motor does not

start.

Motor stalls

(resulting in

blown fuses or

tripped circuit

breakers)

Motor starts

slowly or fails to

come to full

speed

1. Switch not pressed in far enough or 1. Depress switch in or make sure switch is in the

switch in the “OFF” position. “ON” position.

2. Defective switch. 2. Have switch replaced.

3. Low line voltage. 3. Correct low line voltage condition.

4. Defective motor. 4. Have motor replaced/repaired.

NOTE: 2, 3, and 4 must be done by a qualified

service technician.

1. Circuit overload. 1. Reduce circuit load.

2. Low line voltage. 2. Correct low line voltage condition.

3. Incorrect fuses on circuit breakers. 3. Have correct fuses on circuit breakers installed.

Short circuit in motor; loose 4. Inspect terminals in motor for damaged insulation

4.

connections or worn insulation on and shorted wires and have them replaced.

lead wires.

1. Defective motor windings. 1. Have motor replaced/repaired.

Motor running

too hot

Frequent blowing

of fuse or circuit

breakers

1. Restricted air circulation due to dust 1A. Clean dust and restore normal air circulation.

accumulation. 1B. Clean filters.

Fuses or circuit breakers do not have

1.

sufficient capacity.

Circuit overloaded.

2.

1. Have correct fuses or circuit breakers installed.

Reduce circuit load (turn of

2.

f other appliances).

18

Page 19

u NOTES u

19

Page 20

PARTS

20

Page 21

PARTS LIST

EY PART

K

O. NO. DESCRIPTION QTY.

N

1 OR91322 CORD/SWITCH ASSEMBLY 1

2 OR91323 BUSHING 1

3 OR91324 HEX HEAD SCREW 1/4-20 x 5/8” 6

4 OR90070 LOCK WASHER 1/4” 6

OR70252 HOUSING END CAP 1

5

OR70255 I.D. LABEL 1

6

OR90716 PAN HEAD SCREW M4.2 x 12MM 16

7

OR91327 OUTLET GUARD 1

8

OR91328 FLANGE NUT 1/4-20 6

9

0 OR91329 BLOWER ASSEMBLY 1

1

1 OR90601 WARNING LABEL 1

1

2 OR91330 HEX HEAD SCREW 1/4-20 x 1” 4

1

3 OR90070 FLAT WASHER 1/4” 4

1

4 OR70407 MOTOR ASSEMBLY, 1/8 HP, AIR CLEANER 1

1

4A OR70356 MOTOR SPEC LABEL (NOT SHOWN) 1

1

15 OR91332 MOTOR BASE 1

6 OR91333 FAN ASSEMBLY 1

1

7 OR90310 HEX HEAD SCREW M8-1.25 x 16mm 1

1

18 OR91335 EYEBOLT 5/16-18 X 1-1/2” 4

19 OR91336 FLANGE NUT 5/16-18 4

0 OR94295 ROUND HEAD SCREW 5/16-18 x 3/4” 4

2

1 OR70253 C

2

22 O

23 OR70003 STEEL CITY LABEL, 300mm 2

R91339 HANDLE 2

ABINET ASSEMBLY 1

EY PART

K

O. NO. DESCRIPTION QTY.

N

4 OR91341 RUBBER PAD 4

2

5 OR91342 THREE-POCKET INNER FILTER 1

2

6 OR70282 ELECTROSTATIC FILTER 1

2

7 OR91345 SEAL 1

2

8 OR91346 FLANGE NUT M5 4

2

9 OR91347 SPACER 4

2

0 OR71168 SAFETY LABEL 1

3

1 OR72104 SPEC LABEL 1

3

/A OR70251 USER MANUAL, 65100 (NOT SHOWN) 1

N

OR70686 USER MANUAL, 65100 FRENCH (NOT SHOWN) 1

OR70687 USER MANUAL, 65100 SPANISH (NOT SHOWN) 1

OR70254 HARDWARE PACK for #65100, INCLUDES

OR91335 EYEBOLT 5/16-18 X 1-1/2” 4

OR91336 FLANGE NUT 5/16-18 4

OR91341 RUBBER PAD 4

21

Page 22

u NOTES u

22

Page 23

STEEL CITY

TOOL WORKS

www.steelcitytoolworks.com

u

5 Year Warranty

Page 24

24

Loading...

Loading...