Page 1

owner's

manual

MODEL NO.

636.796912

CAUTION:

Read Rules for

Safe Operation

and Instructions

Carefully

êêl9501201

8619S01201 r/88

CRAFTSMAN

37.7 cc GAS POWER BLOWER

® Assembly ® Maintenance

® Operation «Repair Parts

Sears, Roebuck and Co., Chicago, III 60684 U.S.A.

PRINTED IN JAPAN

Page 2

TWO YEAR LIMITED WARRANTY ON CRAFTSMAN

POWER BLOWER 636.796912

For tvvo years from date of purchase, when this POWER BLOWER is maintained, lubricated, and tuned up according to

the operating and mainlenance instructions in the owner's manual, Sears will repair free of charge any defect in material or

workmanship.

This warranty excludes blower pipes, spark plug, and air cleaner: which are expendable pans and become worn during

normal USB.

If this POWER SLOWER is used for commercial or rental purposes, this warranty applies for only 30 days from the date

of purchasa.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER/DEPARTMENT IN THE UNITED STATES, This warranty applies only while this product is in use in the United States,

This warranty gives you specific legal rights, and you may also have other rights which very from state to state.

SEARS, ROEBUCK AND CO.

DEPT. 698/731A

SEARS TOWER

CHICAGO, ILLINOIS 60684

,4|li

INTRODUCTION

The Sears Power Blower, Mode! 636.796912 is a lightweight, high performance 2 cycle two stroke,

gasoline powered blower, which is designed for autumn leaves, driveway and sidewalk sweeping, gutter

cleaning, light snow and debris removal. The blower works faster and more efficiently than rakes or

brooms. Excellent balance, a vibration damping system and light weight ensure comfortable, safe

and fatigue-free operation.

This manual provides instructions for assembly, operation and maintenance for your unit. Be sure to

read this manual before operation.

IMPORTANT

RULES FOR SAFE OPERATION

1. Gasoline

(1) Handle gasoline with care. It is high inflammable.

(2) Use proper gasoline-oil fuel mixture. See P. 4.

(3) Refuel before starting work.

(4) Do not refuel a hot engine.

{5} Avoid spilling fuel or oil. Always wipe unit dry before using.

(6) Move at least 3 meters (10 feet) away from the fueling point before starting engine.

(7) Always store gasoline in approved container.

2. Operation

(1) Do not operate in unventilated area,

(2) Do not allow bystanders in work area.

{35 Always wear light clothing.

Page 3

{4) Aiways wear safety glasses and a face filter mask.

Wear ear protectors where possible.

{5} Do not touch muffler, spark plug and rotating parts,

(6) Do not run the machine without flexible corrugated pipe and spent pipe or the engine

may be damaged,

(7) Do not use the machine in such a way that the end of spout pipe may be covered,

Check

ns Aiways check periodically for efficient and safe operation.

(2) Before Storing, drain fuel tank and carburetor.

(3) Wash air cleaner element with neutral detergent and dry it well.

(4) Remove dust from blower.

(5) Tighten bolts further if they are loose.

(6) Replace damaged parts.

(7) Always use proper parts for replacement.

SECTION i.

SECTION II,

SECTION ill.

SECTION IV,

SECTION V.

SECTION VI.

SECTION Vtl.

SECTION Vlil.

SECTION IX.

SECTION X.

SECTION XI.

TABLE OF CONTENTS

TECHNICAL SPECIFICATIONS ..........................

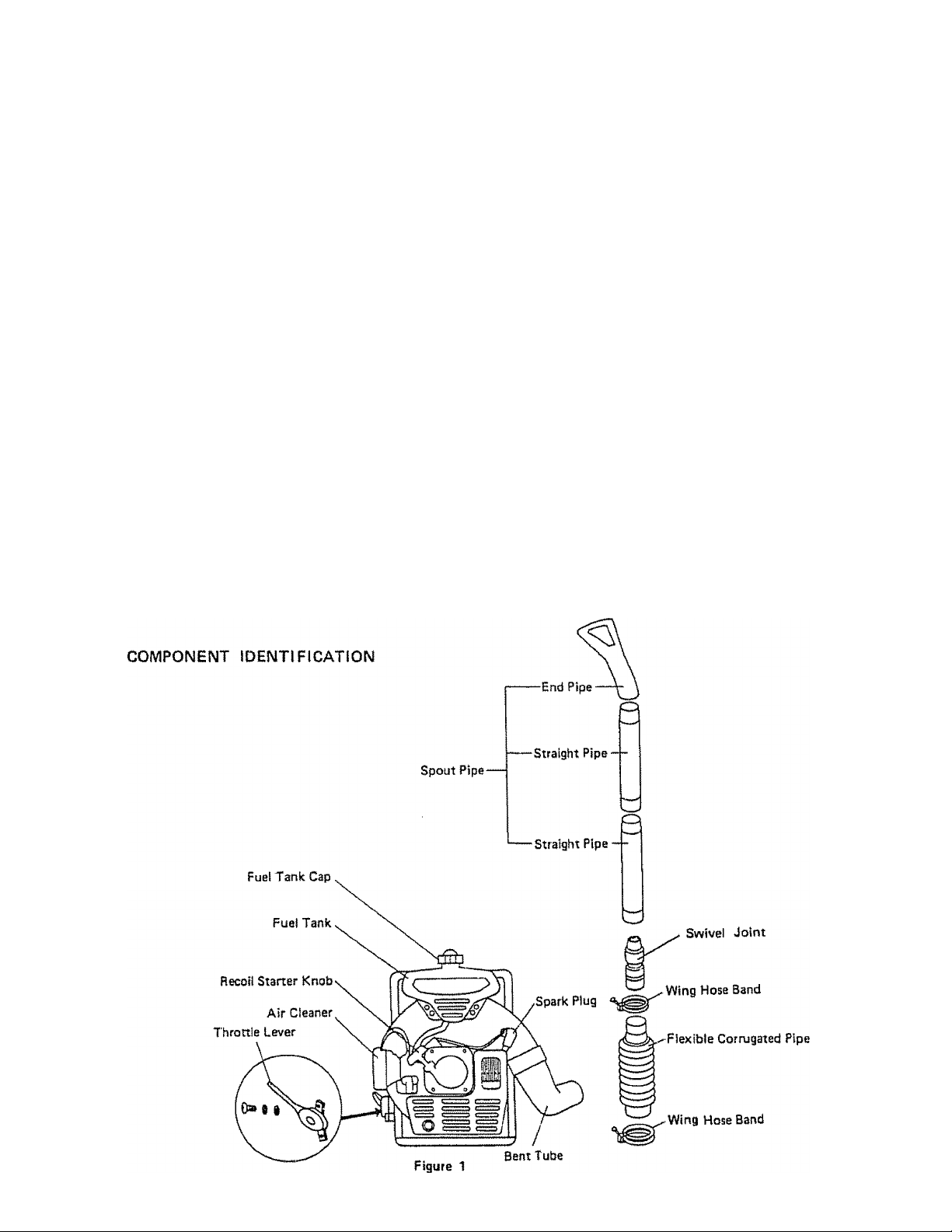

COMPONENT IDENTIFICATION

......................

ASSEMBLY INSTRUCTIONS.............................

PREPARATION FOR USE

STARTING THE ENGINE

STOPPING THE ENGINE

...........................

..

...................................

.......

..........................

OPERATING THE POWER BLOWER ....

CHECK AND MAINTENANCE

...........................

STORAGE AFTER USE......................................

TROUBLESHOOTING , .,

SPARE PARTS LIST ...

........

................. . . . .

....................

...............................

.

..................................................... 4

..

.................

.

. 4

................................................. . 5

.

..................................................... 5

.............

........................................ 5

...................................................... 6

...........................................................

.

..................................................

. 6

...................................................... 7

.

..................................................... a

......................................................10

Page

6

Page 4

TECHNICAL SPECIFICATIONS Mode! 636.796912

Dimensions :

Weight, dry ;

Fuel capacity ;

Engine Type :

Displacement :

Ignition system ;

Carburetor ;

Spark plug ;

Spark plug gap :

Starter ;

Max. air volume :

Max. air speed :

Muffler :

Fuel :

*Specifications are subject to change without notice.

LxWxH = 450x490x495mmf17.7 in. x 19.3 in.x 19.5 in.)

8 kg !17.6 lbs.)

2.4 litre iO.634 gal.)

Air cooled two stroke

37.7 cc {2.3 cu.in.)

Solid State ignition

Float type

S.T.D. 360942

0.6-0.7 mm (.024 - .028")

Automatic recoil

11 m^/min. (385 cu.ft./min.)

83 m/sec. (273 ft/sec.)

Spark arrester

Fuel-Oil Mix Between 20 and 25 to 1

For the first twenty hours, use the mixing ratio of between 15

and 20 to 1

Page 5

m. ASSEMBLY INSTRUCTIONS

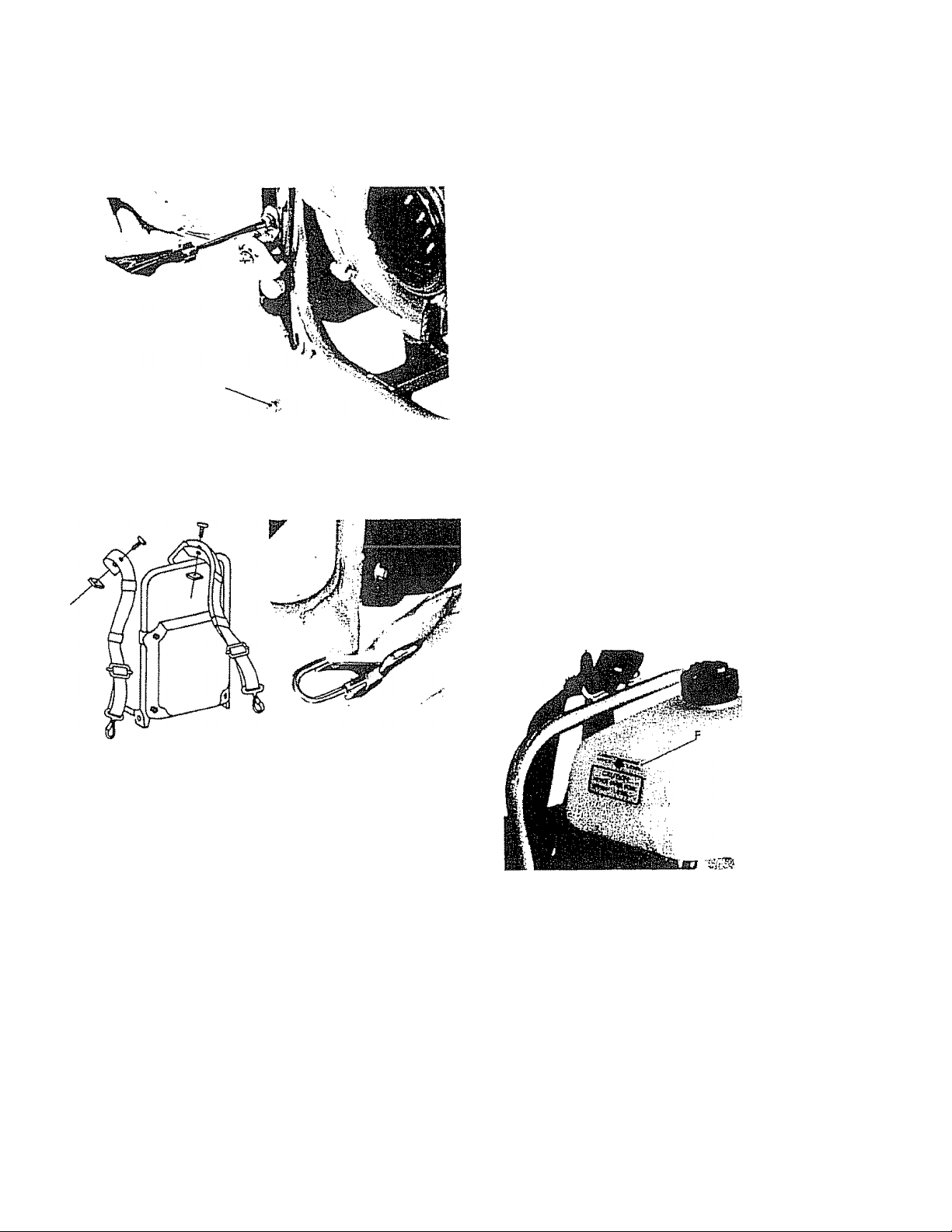

1. Attach throttle lever to the machine. (Fig, 2)

Note; Ensure that the lever can be operated normally.

Screw

Figure 2

2, Attach shoulder straps to the machine. (Fig, 3}

Note: Adjust the straps to fit your body.

WARNING; Experience indicates that alcohol blended fuels

icalled gasohol or using ethanol or methanol) can attract

moisture which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel system of an

engine while in storage.

To avoid engine problems, the fuel system should be emptied

before storage for 30 days or longer Drain the gas tank, start

the engine and let it run until the fuel lines and carburetor

are empty. Use fresh fuel next season. See Storage Instructions

for additional information.

Never use engine or carburetor cleaner products in the fuel

tank or permanent damage may occur,

CAUTION:

• When preparing fuel mixture, mix only the amount

needed for the job you are to do Do not use fuel mixture

that has been stored longer than two (2) months. Fuel

mixture stored lortger than this will cause hard starting

and poor performance, if fuel mix has been stored

longer than this time it should be removed and filled

with a fresh mixture.

• Use only a good grade of regular gasoline,

0 Use only a reputable brand of 2-cycle, air cooled engine

oil. Sears Chain Saw Oil is especially suited to this

engine,

• For the first twenty hours, use the mixing ratio of be

tween 15 and 20 to 1

Figure 3

3. Assemble blower pipes, (Fig, 1)

Note: Assemble pipes securely or they may separate

. while operating.

IV. PREPARATION FOR USE

1, Ensure again that all parts are assembled normally and

that all nuts and bolts are properly tightened

2. Adjust shoulder straps to fit your body so that pads rest

comfortably on your shoulder or you will be tired

3 Fuel and oil mixing

(1) Mixing ratio of fuel and oil: 20— 25:1

Example; 20 : 1 = gasoline 1 gal, : oil 7 oz,

25 : 1 = gasoline 1 gal, : oil 6 oz

(2) Pour half the gasoline into the container, add oil and

shake to ensure thorough mixing. Now add the

remainder of gasoline and shake again

Fill the tank with fuel without spilling.

4.

i1) Do not fill fuel above fuel limit level. (Fig. 4)

(2) Wipe all spilled fuel with a dry cloth,

(3) Always attach the fuel strainer, (Fig, 11)

(4) Tighten fuel cap securely,

uei limit level

Figure 4

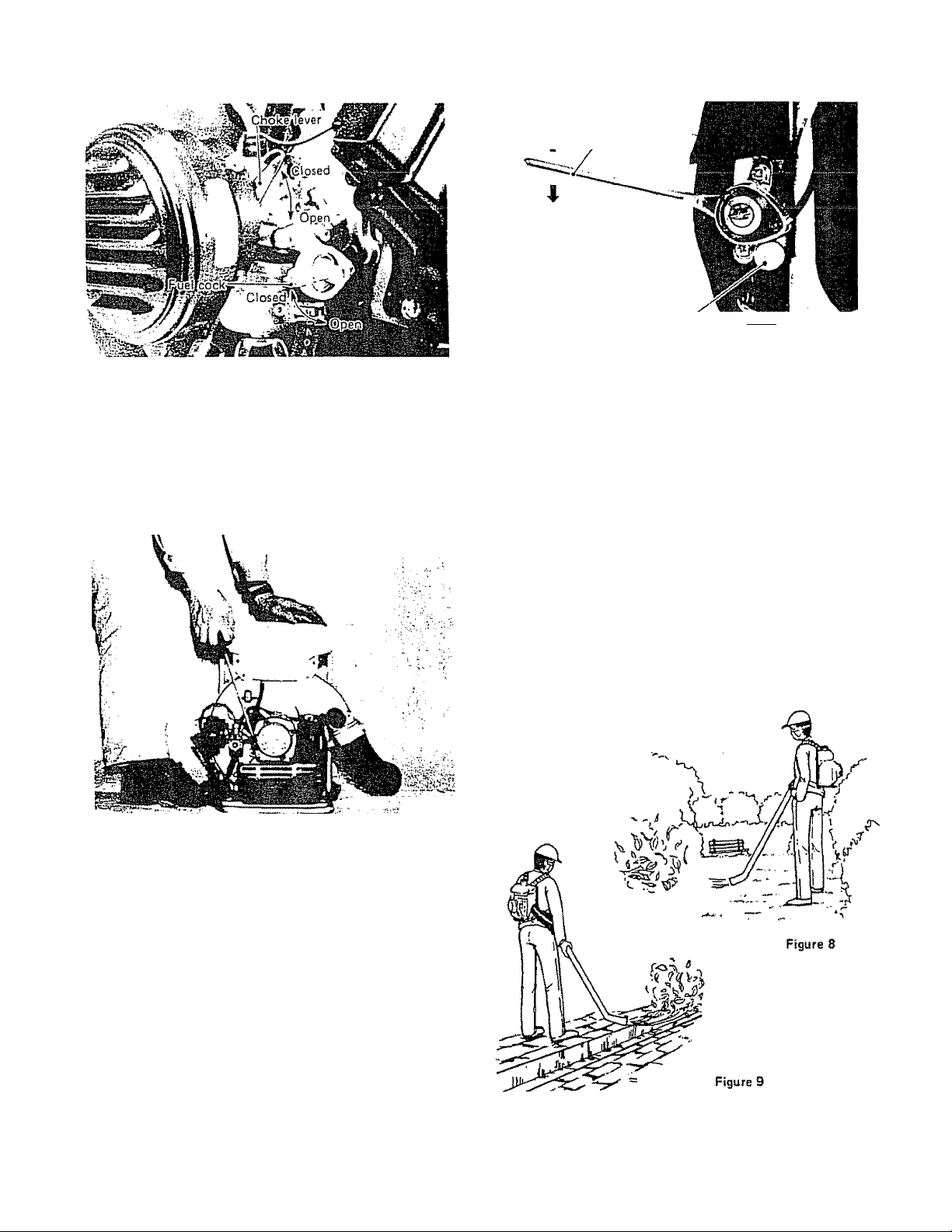

V. STARTING THE ENGINE (Fig. 5 & 6)

1. Open fuel cock, (Fig 5)

2, Close choke Sever, (Fig. 5)

Note; In winter, close fully, but in summer or when the

engine is warm, open partly or fully.

Page 6

Figure S

3. Push up throttle lever, (Fig. 7)

4. Holding the machine by your left hand and putting your

left foot on the machine frame, give a strong and straight

pull to recoil starter by your right hand. (Fig. 6j

CAUTION

Do not pull off rope, but return it gently with care.

UP (Highspeed)

“I“ Throttle lever

DOWN (Low speed)

StQPTOtfoffllM^ ’

Figure 7

VII. OPERATING THE POWER BLOWER

1, Adjust shoulder straps correctly to make the machine fit

your body .

2, After the engine fires, put the machine on your back

without inclining.

3. The velocity of air stream can be controlled from a gentle

breeze to a high-speed blast by throttle lever,

4. Select the best speed for each application of the blower.

Example: low speed for blowing dry leaves from lawn

and high speed for moving gravel or dirt from

driveway, (Fig. 8 & 9)

Figure 6

5. After the engine fires, open choke lever gradually to re

duce engine speed

6, Warm up the engine at tow speed

Note; winter: about 5 min. summer: 2 — 3 min.

VI. STOPPING THE ENGINE

1, Push down throttle lever to reduce engine speed.

2, Stop the engine by pushing stop button. (Fig. 7)

3, Put the machine down on the ground and close fuel cock.

CAUTION

о Do not point the blower pipe in the direction of people

or animals.

• Always wear safety glasses and use-a dust mask,

e Do not operate in unventilated area.

Page 7

VIH. CHECK AND MAINTENANCE

1. Air cleaner (Fig. 10)

(1) Remove air cleaner cover and take out air filter.

(2) Accumuiated dust on the air filter will reduce engine

efficiency and increase fuel consumption,

{3} Wash air filter and dry it wetl,

CAUTION

Do not use gasoline and inflammable solvent to clean the

filter.

Air cleaner case

Air filter

Carburetor (Fig. 13)

4,

(1) Carburetor has been correctly adjusted at the factory

for optimum performance.

To adjust idling speed, turn the throttle stop screw

(2)

(turning it clockwise increases engine speed and

turning it counterclockwise reduces the speed).

Idling speed must be adjusted to me minimum

(3)

constant speed.

Figure 10

Fuel strainer (Fig, 11)

(1) Fuel tank is fitted with a fuel strainer located under

filler cap- Do not remove this strainer when filling

the tank.

(2) The strainer should be removed and cleaned at

regular intervals.

Fuel tank cap

'Fuel strainer

-Packing B

Figure 11

3, Spark plug (Fig. 12)

(1) Clean or replace the piug if fouled with oily black

deposits,

(2) Replace the plug if the center electrode is rounded

at the end or if the ground electrode is worn,

(3) Adjust the gap 0,6 — 07 mm ( 024 — ,028").

B, MUFFLER AND EXHAUST PORT (Fig. 14)

in the event that the engine should lose power and overheat,

the muffler should be removed and checked for excessive

deposits. Carbon build up in the exhaust port should be

removed with a piece of wood, removing that particles of

carbon deposits from the muffler flange area and wash the

complete unit in a suitable solvent.

Spark arrester

Screw

Figure 14

Page 8

IX. STORAGE AFTER USE

5. Store the unit in a dry atmosphere and keep out dust.

1, Correctly preparing your Sears Power Blower for extend

ed storage will be amply rewarded by an increased service

life and trouble-free performance,,

2 Drain fuel tank and carburetor thoroughly,

Drain carburetor through drain cock,

3, Remove spark plug, pour one teaspoon of engine oil into

cylinder and pull recoil starter gently to distribute the

oil. Replace spark plug securely.

4. Thoroughly clean the unit and coat unprotected surfaces

with oil to prevent rust.

K TROUBLE SHOOTING

Refer to the chart to locate the problem and take the appropriate action.

Table 1

Fuel is not

reaching Fuel line hose clogged „ Clean.

carburetor

Fuel is not

— reaching -------------—^

cylinder

6

c

О I

Z ^

Ignition coil

-in goodcondition

It is important to prevent gum deposits from forming in

essentia! fuel system parts such as the carburetor, fuel filter,

fuel hose^ or tank during storage. Also, experience indicates

that alcohol blended fuels {called gasohol or using ethanol or

methanoll can attract moisture which leads to separation and

formation of acids during storage. Acidic gas can damage the

fuel system of an engine while in storage.

To avoid engine problems, the fuel system should be emptied

before storage of 30 days or longer. Follow these instructions:

1

___ PisTon.& cytinder worn..,..

-----

Strainer dogged

i

-----

Carburetor out of order ,

, Wire connection defective .

High-tension cord

‘ connection defective

...........

...... Replace,

Clean.

Disassembie and check.

Heconnect

Repair as necessary.

.

Ш

’ ti

LI,

R

-No spark at plug -

X

ti

« c

X «

Û-0

«

Э

- c

о a

a

x: K

¡r 2

-If

. «

a

a

x:

H

Li

о

a

* w

Fuel does

not keep

funning

Accelera

tion and

low speed function

defective

Carburetor _

overflow

Engine does

' not crank *

. Insulator cracked

. Spark gap incorrect.

. Covered with carbon

, Fouled with fuel

Starting procedures

■ incorrect

Fuel valve clogged with

dust .............

Fuel passage in carburetor

clogged with dust

□

Fuel leaking from fixing

■ surfaces of carburetor

Carburetor does

■ not work normally

Crankcase and cylinder

‘ pressure leaks

Fuel inlet needle valve

- clogged with dust

Exhaust pipe sticky

■ with fuel

. Searing damaged ,

■ Piston and cvlirtder seized.

, Crankshaft worn

’ crankcase

......................

..................................

......................

....................

Crankshaft contacting

.

.................

_____

, Replace plug.

, Adjust.

, Clears or replace.

. Clean or replace.

. Start correctly

. Clean,

. Disassemble and replace

, Retighten.

, Replace,

.........

................................................

.. Stop leakage,

.

.. Clean.

This is because fuel mixture

is too rich,

■ Start the engine several times

with choke lever fully open.

_____

, Disassemble and replace

. Disassemble and replace,

. Disassemble and replace,

, Disassemble and replace,

Page 9

Table 2

3

U»

.£

•o a

n

c

'm

c

m

. Engine

overheatsd

. Firing function.

defective

, Carburetor _

defective

_ Other

troubles

Improper fuel, used

Spark plug defectiva

' ibumt!

............

..............

As cooling fins dog, air

' does not pass well '

Excessive deposits itt

■ combustion chamber

. Plug damaged or fouled..,,...... Replace or clean.

Combustion poor due to , . .

defective wiring ’

Needle setting

'incorrect

Carburetor overflow

. Air cleaner dogged

Compression insufficient

(piston ring stuck or

worn out)

Cylinder chrome plating

' peeled or worn out ......................

Exhaust port dogged with

' carbon

Throttle is not fully

’ open

Mvui Check wiring,

................

..

...........

...

..........

..............

.................................

Use fuel with correct mixing ratio,

' ' Never use gasoline of poor quality.

...... Replace.

.

..... Clean fins,

....... Disassemble and remove carbon.

Readjust,,

........ Refer to Table 1,

Clean as necessary.

Disassemble, check and replace

, if necessary.

. Replace cylinder,

. Clean as necessary.

.

, Readjust,

Page 10

SEARS POWER BLOWER PARTS LIST - MODEL 636.796912

Figure 15

Page 11

SEARS POWER BLOWER PARTS LIST • MODEL 636.796912

Figure 15

KEY

NO.

1

2

3

4

S

6

7 NF04S-11Ì4 1

8

9

to

11

12

13

16

17

18

19

20

21

22

23

24 00218 0500 Q

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

PART

NO.

NF04S-01S0A 1

NFQ4S-1101-RB

NF04S.1102-RB

NF04S-1104F 1

NF04S-1107A 2

FL40-1109B-PB 1

NF04S.11I5

FH04S-1104

Ft40-1110

0420 22938 0

FL40-201IA-RB

FL40-2012A 1

NF40.2101A 2

EC024Ì83 1

EC02Ì44

FL40-3101A

FL40<S102

FL40-5011

FL40-5012

EC02-720

00113 0618 0

00165 0612 0 3

00218 0600 0

00218 1000 0

00227 0400 0

00310 0500 0

00311 0600 0

00311 1000 0

00312 0500 0

00312 0600 0

00320 0400 0

00320 0500 0 2

00320 0600 0 10

00320 1000 0

00431 0514 0

G0431 0512 0

00435 0518 0

QTY.

1

1

1

4

. 9

1

1 Nut (M4l

4

DESCRIPTION

Muffier mounting plate ass'y

1

1 Volute ease {rear!

!

1

1

1

1

1

1

1

5

8

1

4

4

1

1

4

1

7

Volute case {fronti

Bent tube

Screw (MS X 671

Engine cover

Impeller spacer

Cover

Plug

Impeller

Plug ¡rubberl

Frame compì.

Shoulder pad compì.

Vibrailon^jroof rubber

Fuel tank cap ass'y (Incl. 161

Packing A

Fuel tattk

Fuel-line hose

Throttle lever

Throttle ^Ire

■Stoptiution

Boll ÌM5 X 18!

Bolt (M6 X 12!

Nut |M5)

Nut ÌM6!

Nui^iM10)_3

Washer (M51

Washer (M61

Washer (MIO!

Washer !M51

Washer {MB!

Spring washer {M4!

Spring washer (M51

Spring washer <M6i

Spring washer {MIDI

Screw (pan head! (MS x 14!

Screw (pan head! (M5 x 12!

Screw ass'y (M5 x 18!

KEY

NO.

40 00431 0610 0

41

42 00626 3085 0

43 EC03-6103

44 ,

45

46

47

48 .

49

SO

51

52

PART

NO.

00431 0616 0

FL40-3103

FL40-9106

0561 13998 2

0641 27999 0

ECOSA-6111

HS021I-2028-RB

NB30K-6103 2

PS03-5111

00436 0512 0

QTY.

2

4

1 0 ring

1

1

1

2

1

1

2

1

I

DESCRIPTION

Screw (pan head! (M6 x 10!

Screw (pan head! (M6 x 16!

Fuel-line hose proieeiion tube

Plate

Labe!

Clamp (Hose! __

Fuel strainer

Packing

Plate

VibratiQO-proof rubber

Plug (rubberl

Screw ass'y

Page 12

SEARS POWER BLOWER PARTS LIST-MODEL 636.796912

Figure 18

Page 13

SEARS POWER BLOWER PARTS LIST - MODEL 636.796912

Figure 16

KEY

NO.

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

PART

NO.

1

2

3

4

S

6

7

8

9

10

11

12

13

14

15

16

17

18

19

EC044J72

0440 12999 J

0440 15997 1

060015988 0 2

EC034)71

0119 05994 0

0105 06934 0 6

EC044)125

EC03-109A

EC044191A

eC04-104c

eCQ3-115

0119 05995 0

EC04TÌ222

EC04-206/2B

EC04-207A

6C04-210A

0565 11999 0

0610 12996 1

EC0441516A

EC04-0S13A

A50103212700

243051821009

451050800009

A54103200100

A55003210001

A600032000QO

A60102600000

A56002600291

141051251002

A60S03210000

A57120950000

QTY.

1

1

1

4

1

1

1

1

2

4

1

1

1

2

2

1

1

1

1

4

4 Washer (M5)

1

1

1

1

1

1

1 Return spring

1

A57202700QOD 1

EC0443378

EC04-3122

00433 0520 0

FL40-9105/2A

1

1

3

1

EC044)71BA 1

11100100100

DESCRIPTION

Crank case ass'v (Ind. 2 ihru 7)

Oil seal (fronif

Oil seal iresri

Ball bearing

Crank case packing

Ì

Boll isockei head} (MB x 30}

Stud (M6)

Cylinder compì, (incl. 7)

Cylinder packing

Reed ass'v

Carburetor bracket

Reed bracket packing

Bolt (socket head! (MS x 18)

Crank shaft ass'v

Piston

Piston pin

Piston ring

Clip

Needle bearing

Recoil starter compì. (Incl. 21 thro24i

Recoil starter ass'v iincl. 25 ihru33)

Starter case B

Serev» IMS X 18}

Reel

Ratchet

Spiral spring

Friction spring

Friction plate

Bind screw (M5 x 12)

Starter rope

Starter knob

Mufller compì.

Mu!((or gasket

Screw ass'v (M5 X 20)

Label (model)

Magneto compì. (Incl. 39, 401

t

Flywheel

KEY

NO.

40

41

42

43

44

45 -

46

47

48

49

50

51

52

53

54 EC044)379ATA

55

56

PART

NO.

QTY.

11400331000

KM614388C

0650 14995 0

0170 08996 0

0203 08999 0

00218 0500 0

00310 OBOO 0

00320 0600 0 6

00434 0420 0

00532 0310 0

0566 05998 0

00310 0S00 0 1

0CM31 0510 0

00S32 0320 0

0043104100

0022704000

DESCRIPTION

1 Ignition coil

1

1

1

1

Plug cap

Spark plug

Nut (left) (MB)

Spring washer (M8)

6 Nut (M6)

1 Washer (M8)

Spring washer (M6)

2

1

1

Screw ass'v (M4 x 20)

Woodrulf key

Clamp

Washer (M5)

1

1

1

Screw (pan head) (M5 x 101

WoodruH key

Spark arrester

1 Screw (pan head) (M4 x 10)

1

Nut (M4)

Page 14

SEARS POWER BLOWER PARTS LIST-MODEL 636.796912

Figure 17

Page 15

SEARS POWER BLOWER PARTS LIST - MODEL 636.796912

Figure 17

KEY PART

NO.

1

2

3

A

5

6

7

a

9

^10

n

12

13

14 VM15/173

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

EC04-0682A 1

CK/31

832-16001

J8-3N05

MD14/40

VM14c1/38tJ

VM1S/24A

VM16/200

VM12/43

MD13/44

M21/15

VM24/148

N102-221

VMl 5/353

VM1S/264

VMl 5/351

VM13/139

BS2-00031

EC03-S0010

VM13/68A

VM13/326

82=43630

B34/83

VM13/215

VMl 5/331

VM18/164A

CW2»0416

VMl 5/348

VM13/210

CW2-0414

EC044)335B

0736 36998 0

00436 0410 0

EC04-3304A

EC04-3305

NO.

QTY.

1

1

1

1

1

1

1

1 Cap

1

1

1

1

1 Needle ass'y

1

1

1

1

1

1

1

1

1

1

1 Nut

1

1

2

1

1

2

1

1

4

1

2

DESCRIPTION

Carburetor compì. Unci. 2 !hni 31}

Cock body ass'y

Piston waive {#T.0i

Jet needle

E nng

Spring seat

Spring

Top

Cable guide

Cable gdjuster lock nut

Cable adjuster

Mam let (#77.51

Float arm

Float pin

Gasket

Float

Float chamber body

Guide screw ass'y

O ring

Clip

Bolt

Washer

Spring

Throttle stop screw

Spring washer cross screw

Gasket

Filter

Spring washer cross screw

Air cleaner ass'y Unci, 33,35, 361

Label

Screw ass'y (M4 x 10}

Air cleaner cap

Element

Page 16

SEARS POWER BLOWER PARTS LIST - MODEL 636.796912

Figure 18

Page 17

SEARS POWER BLOWER PARTS LIST - MODEL 636.796912

Figure 18

KEY

NO.

!

2

3

4

5

6

7

8

9

10

11

12

13 0715 06999 0

14 0713 21999 0

15

PART

NO.

NF04S-0903/1

FL40-9001

NF31-097B

NF04S-9121

FL40-9120

FL40-9121

NF40-7120

FL40-9012

FL40-9014

0717 04999 0

6619501201

0700 00994 0

0710 08999 0

QTY.

1

1

1

1

1

1

1

1

1

DESCRIPTION

Wing hose band (big!

Shoulder band ass'v

Wing hose band

Corrugated pipe

2

1

1

1 Plus driver

1

1

Straight pipe

End pipe

Hoso ctarop

Swivel joint

Tool kit {tncl.10,12 throlSi

Wrench Isocket head)

Owner's manual |FL40-9107/4i

Tool bag

Box wrenchS21 M/M)

Double-end wrench (8 x 10 M/Ml

Page 18

OWNER^S

MANUAL

SEARS POWER BLOWER

The model number of your power blower is

located on the label on recoil starter of the

engine.

The serial number of your power blower is

located on the label on the fan housing.

MODEL NO.

636.796912

HOW TO ORDER

REPAIR PARTS

2.

When ordering repair parts, always give the

following information:

(1) IVJodel number:

{2) Name of item:

{3) Part number

(4) Part description

All parts listed may be ordered from any Sears

Service Center or most Sears stores.

(1) If the parts you need are not stocked

locally, your order wilt be electronically

transmitted to a Sears Repair Parts Distri

bution Center for handling.

636.796912

37.7 ccGAS POWER

BLOWER

6619501201 Sold by Sears, Roebuck and Co., Chicago, IL60684 U.S.A. Printed in Japan

Loading...

Loading...