Page 1

Sears. Roebuck and Co., Chicago, IE. 60684 US. A.

8209S00101 4/88

PRINTED IN JAPAN

Page 2

/ ,i‘‘

.....

' \ у» .'7 \ X г'i^.N X.>''"*'KV,X yX-;*—‘V-.X

■' ■ ■ - r ■ ^ ,. ,fr-:^ \/г - ,, . -/‘¡fy • V,XX ‘‘-"i.. • ''

^ Щ ^ Щ 0!^

•i»r

TWO YEAR LIMITED WARRANTY ON CRAFTSMAN

BUSHWACKER 836.796670

For two years from date of purchase, when this BUSHWACKER is maintained, lubricated, and tuned up accordtrtg to the

operating and maintenence instructions in the owner's manuai. Sears will repair free of charge any defect in material or

workmanship

This warranty excludes blades, spark plug., and air cleaner; which ara expendable parts and become worn durlno normoi

use.

If this BUSHWACKER is used for commercie! Or rental purposes, this warranty applies for only 30 days from the data of

g purchase.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER/DEPART-

« (WENT IN THE UNITED STATES. This warranty applies only while this product is in use in the United States.

This warranty gives you specific legal rights, and you may also have other rights which very from state to state

SAFETY RULES AMD PRECAUTIOMS

1 Before each operation, make sure that the screws are not

loose or missing, that the components are not damaged,

and that the blades are not chipped off or cracked. If a

blade is chipped or cracked replace it with a new one.

2, Do not attempt engine or blade adjustments or refuel

ing before allowing the engine and muffler to cool,

a. Do not remove the fuel tank cap while the engine is

running or when it is still hot.

b. Clean off fuel tank cap area before refueling,. Do not

smoke white refueling.

c. Take care not to spilt any fuel. If it is spilled, wipe it

off.

d. Never operate on gasoline only As this engine is of

2-cycle type, use mixed fuel whose mixture ratio is

16:1 (1 gal, gasoline to 8 oz. oil) and a proper lubri

cation oil such as Sears Catalog Number 36555,

3. Do not operate the machine when your physical condi

tion is not good. Never touch the plug cap during opera

tion to protect yourself from electric shock.

4 Never operate the machine wherever ventilation is not

enough,

5 Before starting the engine, make sure that the blade does

not touch anything In startup of the engine, be careful

not to turn the blade toward bystranders. Position

BUSHWACKER securely.(in startup, place BUSHWACK

ER in a level place so as to prevent the blade from

moving )

6 Wear sale clothes (safety shoes, goggles, earmuffs, gloves,

etc i Never wear loose clothing or jewelry while operat

ing your BUSHWACKER,

SEARS, ROEBUCK AND CO '

DEPT.698/731A

SEARS TOWER

CHICAGO, ILLINOIS вОбВЛ

7. Do not admit any persons or animals within the working

area (30 feet or lass from the site). When plural operators

work together in the same place, maintain at least a

30 feet distance from each other and exchange warning

shouts if necessary. Pay special attention to keep by

standers, especially children away from the working site.

8 Stop the engine and pay special attention to the blades

whenever you carry the BUSHWACKER from one place

to the next before and after operation.

9

Never let any child handle the machine.

10.

Use BUSHWACKER only for cutting of young trees,

grass, etc. of which diameter is 0.2" or less. Never use

BUSHWACKER to cut metals or other hard materials.

11.

Never operate BUSHWACKER In a bad weather condi

tion (rain, snow, strong wind, abnormal atmospheric

temperature, etc )

12.

Keep this manual in place so that one can refer to it

repeatedly for safety operation and to teach possible

users how to operate the machine.

VUFAR VOUn

CAUTION: The operation of any BUSH

WACKER can result in Foreign objects

being thrown into the eyes, which can

result in severe eye damage. Always wear

safety glasses or eye shields before com

mencing power tool operation., We re

commend Wide Vision Safety Mask for over spectacles or

standard safeb/ glasses, available at Sears Retail or Catalog

Stores,

Page 3

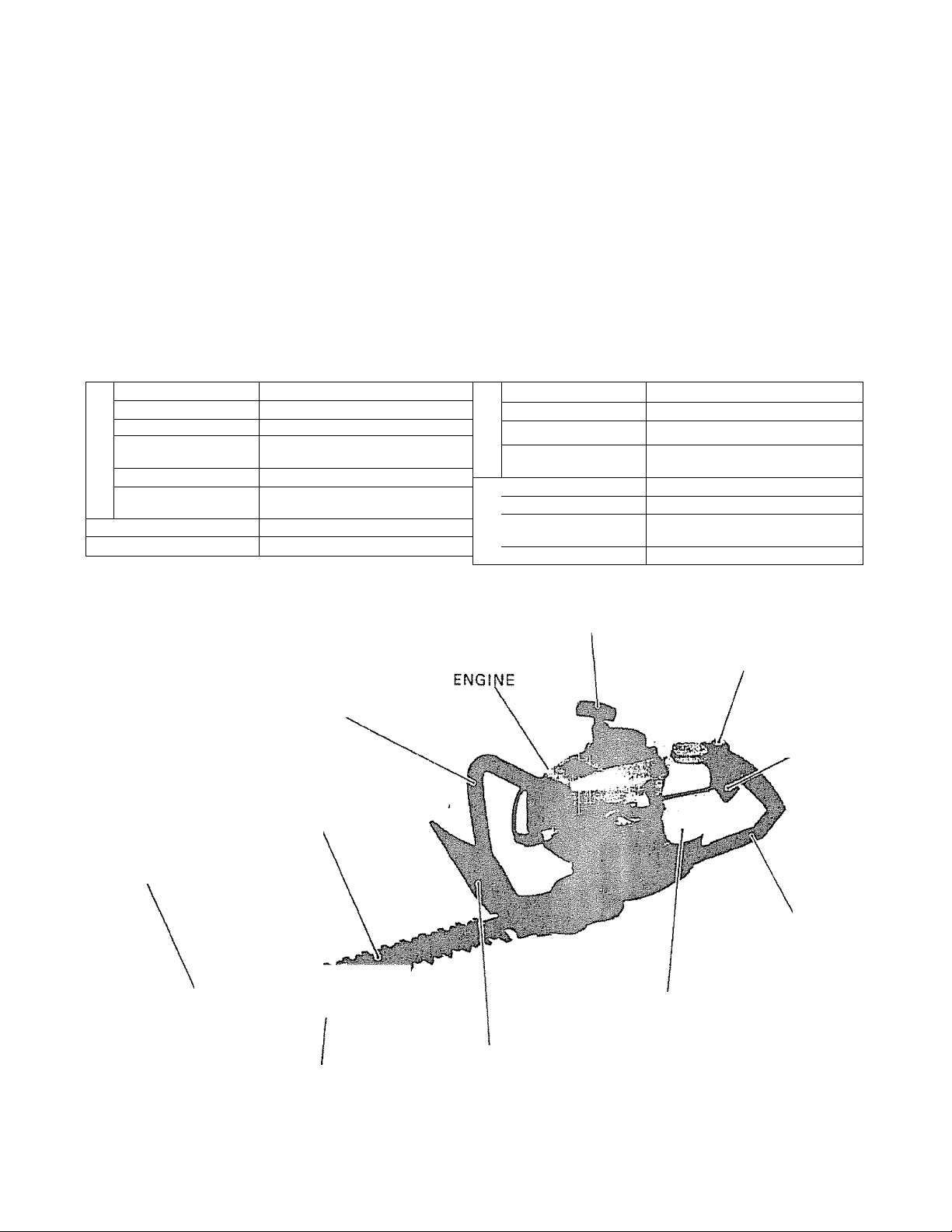

Know ¥OyR BUSHWACKER

Your new BUSHWACKER has been carefuhy packed at the factory to prevent damage during shipping and storage,

however, even with the best of preventative measures, damage does sometimes occur It is recommended that you follow the

check out procedures listed below: _

Remove all items from the carton, lay them out and check the parts to be sure that you have everything required for

assembly. Also check carefully for any visible damage.. (IN THE EVENT THAT SOMETHING IS DAMAGED OR MISSING

OR BOTH, NOTIFY YOUR SEARS STORE IMMEDIATELY )

You should familiarize yourself with the various parts of your BUSHWACKER before attempting to assemble or operate

the unit Refer to drawing below.

SPECIFICATIONS

TYPE 2 cycle air-cooled

DISPLACEMENT

Ш

CARBURETOR Diaphragm type

s

FUELTANK

5

CAPACITY

z

LU

SPARKPLUG ■

20.3 cc {1.24 Cu. In.)

17.5 U.S. ft. oz, {0.5E1

NGK BM7A or CHAMPION CJ 6«

LUBRICATION Fuel oil Mixed 16 to 1

{1 gal. gasoline to 8 oz. oil)

DRYWEIGHT

DIMENSION

10.5 lbs (4.8 kg)

35.5 X 8.7 X 8.6 in.

‘SEARS CATALOG NUMBER-36402

FRONT HANDLE

GUIDE PLATE

OVERALL LENGTH

Ш

TOOTH PITCH 0.98"

LJ

<

ENGINE RPM

Ш

CUTTING STROKES

PER MINUTE

DRIVE SYSTEM

CLUTCH TYPE

CLUTCH ENGAGE.

MENT

BLADE DRIVE

STARTER KNOB

18"

8000 rpm

32 2 times/sec (8000 rpm)

Dry Centrifugal

3800 rpm ±200 rpm

Double cam drive

START/STOP SWITCH

THROTTLE

LEVER

UPPER BLADE

REAR HANDLE

FUEL TANK

SHIELD

LOWER BLADE

Specifications are subject to change without notice.

Page 4

PREP4B1MG FOR OPERATIOM

Fuai and oil mixture

inspect the fuel tank and fill with clean, fresh fuel of

the proper mixture This engine requires a mixture of

16 parts gasoline to 1 part oil |1 gal gasoline to 8 oz

oil) Use 71-36555 Craftsman Engine Oil or a high grade

two cycle engine oil.

WARNING: Experience indicates that alcohol blended fuels

(called gasohol or using ethanol or methanol) cart attract

moisture which leads to separation and formation of acids

during storage Acidic gas can damage the fuel system of an

engine while in storage.

To avoid engine problems, the fuel system should be emptied

before storage for 30 days or longer. Drain the gas tank, start

the engine and let it run until the fuel lines and carburetor

are empty,- Use fresh fuel next season See Storage Instructions

for additional information

Never use engine or carburetor cleaner products in the fuel

tank or permanent damage may occur.

DO NOT MIX GASOLINE AND OIL DIRECT

LY IN THE ENGINE FUEL TANK.

IMPORTANT: Failure to follow proper fuel mix

instructions could result in serious damage to

the engine

5, To avoid a burn, do not touch the engine during the

operation or immediately after stopping, the engine.

Handle the engine after it is completely cooled.

6, Never operate BUSHWACKER on unstable ground or

standing on tiptoe Never use it while climbing a ladder,

7, Do not use the BUSHWACKER continuously for a long

time. It is normal to take a break of 10 to 20 minutes

after every 50-minute operation.

8, Never leave the BUSHWACKER running unattended,

9, if there is any trouble during operation, be sure to stop

the engine first, (Move the switch to STOP )

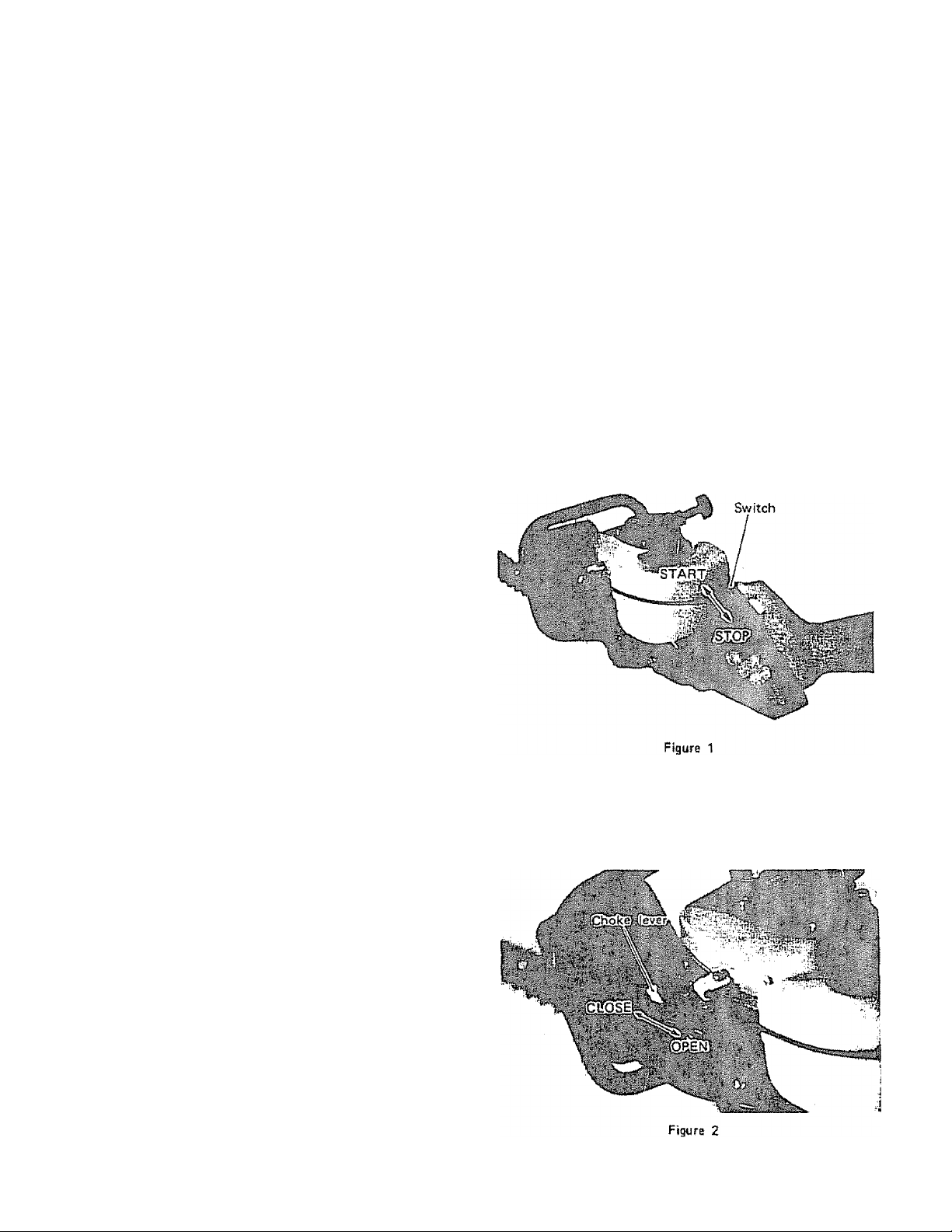

STARTIMCi AUD STOPPING

1, When starting the engine, set the switch to START.

(Figure 1)

CAUTION:

When preparing fuel mixture, mix only the amount needed

for the job you are to do Do not use fuel mixture that has

been stored longer than two (2) months Fuel mixture

stored longer than this will cause hard starting and poor

performance If fuel mix has been stored longer thart this

time it should be replaced and filled with a fresh mixture.

CAUTION! NEVER over Fill Fuel Tank

NEVER add fuel to the tank in a closed un-ventilated area,

00 NOT add fuel to this unit near an open fire or sparks.

BE SURE to wipe off spilled fuel before attempting to start

the engine,

DO NOT attempt to refuel an extremely hot engine.

Check paints before operation

CHECK for loose bolts, nuts and fittings

Clean the air filter of all dirt, etc before the operation.

PRECAyTIOMS I3UR1MG OPERATIOIS

1. if the blades have stopped orr account of a branch

caught during the trimming, be sure to stop the engine

and eliminate the branch. Refrain from cutting too

hard or too thick a branch lover X" in diameter),

2. When the machine is running, never touch the blades

Never point the blades toward a person.

3 Hold BUSHWACKER firmly with both hands.

The choke control is a "Lever" type, (See. Figure 2). To

2

choke the engine, push the choke lever to "Close"

position, NOTE: If the engine is warm, it may be

started with the choke lever mid-way between "OPEN"

and "CLOSE", depending on the individual engine.

4, The engine speed must not be excessive but just enough

to do the cutting

Page 5

3. Puii the throttle lever a little, push the throttle knob

. and lock the throttle lever at the starting position,

(Figure 31

Figure 3

4, Pull the recoil starter several times. (At this time, hold

the machine securely so as to keep it fixed,)

(Figure 4)

The carburetor is not filled with fuel. Pull the starter 7 to

8 times to feed up fuel from tank to carburetor.

without a load, otherwise the engine will run at a high

speed reducing engine life.

Stopping the Engine

1 Reduce the engine rpm to idle by releasing the throttle

2, Set the stop switch to stop. (Figure 1)

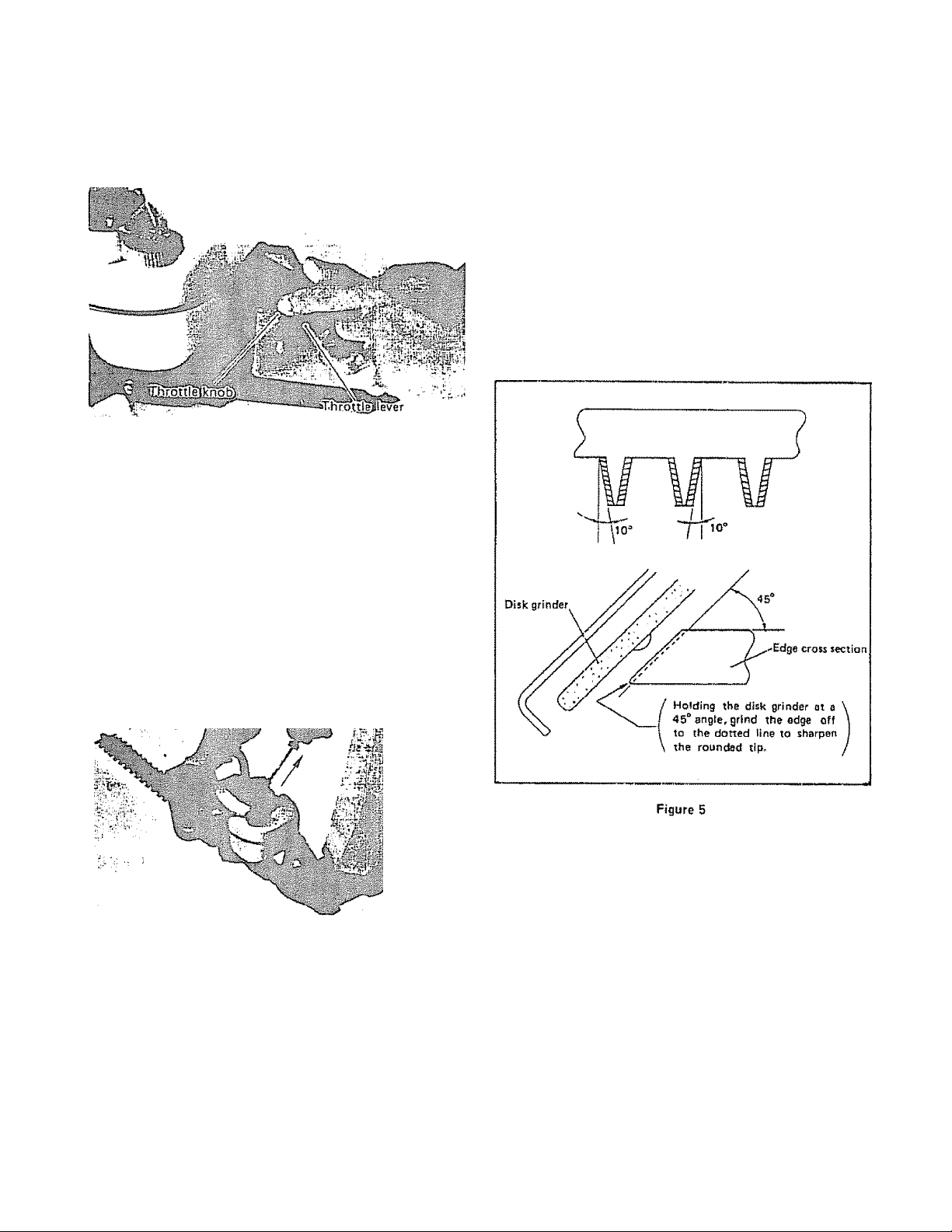

Blade sharpening

If the edges are rounded and do not cut well arty more,

grind off only the shaded portions. Do not grind the

contact surfaces (sliding surfaces) of the top and bottom

edges. (Figure 5)

Caution: — Never let go of the starter rope from its fully ex

tended state. Return the starter rope to its original

position while holding it securely.

— Be careful not to break the starter rope.

■

'■-I

Figure 4

5. After starting, open the choke lever by degrees to the full

. and reset the throttle lever to the low speed, while check

ing the engine operating state.

Caution: — In starting of the engine and during operation, be

fully careful to keep bystanders or obstacles off

the operating side and confirm safety requirements

for operation.

6, After starting the engine, warm up the engine (for about

■ 5 minutes at medium speed). Immediately after starting,

speed up the engine slowly Never open the throttle fully

Note: 1) Before grinding, be sure to secure die blade

firmly

2) Wear gloves, protective glasses, etc.

3) An edge ground too much at a time or ground

many times will loose its hardened layer It

becomes rounded and dull very quickly in

use. Order replacement blades from Sears Re

pair parts.

Adjustments

SPARK PLUG MAINTENANCE - If the spark plug

electrode area has an excess of carbon buildup, the

efficiency of the plug will be seriously reduced.

REMOVE THE CARBON WITH A SPARK PLUG

CLEANER OR WIRE BRUSH

After cleaning the spark plug RESET THE

ELECTRODE GAP TO 024- 028 .

Page 6

Carburetor

Proper adjustment of the carburetor is very important to

the operation of this engine. The carburetor has been

carefully adjusted at the factory and therefore should

not require any further adjustment,.

Adjustment of Engine Idling

If the blade happens to run in idling, adjust the cable

adjuster of the throttle wire to stop blade movement in

idling.

SLAiSB AWUSTMSMT

(Performed with engine stopped.)

The blades wear with use when you notice a decrease in

cutting performance adjust the blades as follows.

(1) Loosen lock nut.

(2) Tighten truss head screw lightly until it stops

turning. Then turn it back one-fourth to one half

turn.

(3) Tighten lock nut. Lubricate the blades after adjust

ments.

STORAGE AFTER OP6RATIOÜ

1 Clean every part, repair faulty sections, and apply a thin

coat of oil on metal parts to prevent rust. In cleaning

the machine, always use a dean cloth. Never use strong

solvents, such as gasoline

2, If the BUSHWACKER will not be used for a long

period of time, drain the fuel from the tank, then start

the engine and keep the engine running until it consumes

all the fuel left in the carburetor.

3. Store the BUSHWACKER in a clean and dry place.

Always keep children away from the machine.

4 Remove the spark plug, inject a small amount of engine

oil through the spark plug hole. Then puli the recoil

starter a few times to put a thin coat of oil on the cylin

der, Install the spark plug again when the piston has

stopped at a top dead center.

It is important to prevent gum deposits from forming in

essential fuel system parts such as the carburetor, fuel filter,

fuel hose, or tank during storage Also, experience indicates

that alcohol blended fuels (called gasohol or using ethanol or

methatiol) can attract moisture which leads to separation and

formation of acids during storage Acidic gas can damage the

fuel system of Jtv engine while in storage

To avoid irrobleitrs, the fuel system should be emptied

before stor.itji; ni 30 days or ¡onoer. Follow these instructions:

(4) Start the engine and operate the blades at high

the speed for a minute or so,

(5) Stop the engine and carefully feel the blades with

your hand. If they are just warm to the touch, you

have made the proper adjustments, but if they are

too hot for you to keep touching them, repeat

steps #1. #2 and #3 above backing off slightly more

on the screw

Note; Never fail to stop the engine before making the

adjustments.

PRS¥BMTATiVl ^AlMTEIIATOl CHECK

LIST AMO STORAGE TIPS

Be sure the engine and all other parts are dean.

Check all nuts, bolts, screws, etc. making sure they are

tightened and secured as they should be.

inspect carefully for any fuel or oil leaks.

Check the air cleaner assembly for excessive dust or dirt.

If the filter requires cleaning, use the following

procedure: Remove the filter and wash in soap and

water or blow off with compressed air. DO NOT clean

filter in gasoline or other flammable solvent,

Inspect the muffler exhaust port (tall pipe). If there Is

any clogging, remove carbon particles adhering to it.

Page 7

mSMTEH^WeE

1, In every 10--20 hours. Inject one or two ounces of

grease through a grease nipple installed in the gear case

of the BUSHWACKER- Be sure the engine is stopped

while greasing the gear case

iiiiiiiiiiiiiiininiiiiti!iniiiiii!ii!iiiiiiii!iifMini!iiii!iiiiiiimiiiiii[iii!ii[inmmiitiiiiii!iii!nmiimim!iti(iiimiiiimmiiii!i!itiimi!mimt!!tiii(fiifiH!iiiitmmmm!iiitiimmi!iminiitti

2 Stop the engine before lubricating the blades during the

cutting c>peration. Frequent lubrication using a light

weight oil during cutting will greatly add to blade life.

MEMO

Page 8

SEARS BUSHWACKER PARTSLIST-MODEL 636. 796670

Figure 7

Page 9

SEARS BUSHWACKER PARTSLIST-MOOEL 636.786670

FiBure 7

KEY

NO.

1

2 900-140/0

3

4

5

6

7

8 118-112

9

10

11

12

13

14 118-108

IS

16

17

18

19

20

21

22

23

24 027-146

25

26

27

28 900-340

29

30

31

32

33

34

35

36

37 118-131

38

39 118-100

40 900-256

41

42

118-110

118-121 1

118-111

118-001

118-115 1

302-050

118-114 1

118-113

118-109

SOO-141/1. 5

900-142''

MO-100/ 6

900-321'

900-320'

900-348

900-301

900-321900-320

900-347 1

027-142

118-103

900-349

118-130

900-203

900-301 2

900-3EX)

118-132

902-001

901-101

901-061

118-102

118-135

900-255

118-133 1

PART

NO,

QTY

1

-1

1

1

1

1

1

1

1 Screw (M4 X 30)

1

1

1

1

1

1

1

1

1 Drum collar

1 Uppercase

2 Bolt (M6 X SQHWasher/Sprlng washer 8c washer!

1

2

2 Flange nut {M5J

3

1

1 Nipple, grease (M5)

1

1

1

1

1

2

1

2

DESCRIPTION

Rear handle asi'y Unci. 2—15)

Screw (M4 X 10) 44 9QQ-04Q

Holder, cable

Plate, wire

START/STOP «witch

Throttle lovar

Snap ring

Pin,lever 50 900-258 2 Bolt iM5 X 20)(Washer/Spfing washer)

Spring 51

Fixing knob 52 008-247

Roar handle (U

Screw (M4 X 16)

Rear handle (R)

Hexagon nut (M4)

Plain washer (M6)

Spring washer {M!6)

Bolt (M6 X 50)

Hexagon nutCM6)

Plain washer (M6)

Spring washer (MS)

Boit(M6x40)

Drum

Front handle (incl, shield!

Bolt (M6 X 15)iV¥ashof/Spring washer)

• Lock nut (M6)

Hexagon U-not tM6)

Guide plate

Bearing

Bearing

Pinion

Gear, crank

Crank

Rod BSs’y

Screw {MS X 10)

Screw (M5 X 16)

Upper blade

KEY PART

NO. NO.

43 901-061

45 030-110

47

48

49 900-257 5

118-101 1

118-134

118-104

008-250

OTY

2

2 Screw (M3 X S)

1

1

1

3 Washer

3 Screw

DESCRIPTION

Bearing

Plato, rcxf slide

Fell

Lower blade

Lower case

Bolt {M5 X leHWasher/Spring washer)

Page 10

SEARS BUSHWACKER PARTSLIST-MODEL 636.796670

Page 11

SEARS BUSHWACKER PARTSLIST-MODEl. 638.796670

Fi^re B

KEY PART

NO.

1 EC02E-S0120A

2 CmO-l 2999-1 2

3

4 EC026-1103A

S EC02ER-1107B

6

7

8

9

10

It

12

13 0565D7999-0 2 Clip

14 EC02ER-5119-RB 1 Fun covar

15 EC02E-0512 1 Recoil starter compì.

17

18

19

20

21

22

23

24 5215005150

25

26

27

28

29

30

31

32

33

34

35

36

3?

38

39

40

41 1140-0470000 1 Ignition coil

42

43

44

45

0600-12M2-0

0650-14981-0 f

EC02E-1104B 1

EC02ERÌ116A-RB 1 Cylinder cover

EC02E-0201D 1 Crank shoft compì.

EC02E-2104B 1 Piston

ECXI2E-2106

EC02E-2107 2 Piston ring

5216005140 t

5215005020

521S005130

5215005030

5215005040 1

5215005010 1 Stoner case

5215005050 1 Wave washer

5216(K)5110 1

521|№12p 1 Washer

521S00506Ò

EC02ERT1312 1

EC01A-302Q 2

EC02EF-3164 2

EC02ER-3133A-TA

EO)2E.3145/1 1 Spark arrester

EC02ER-6106B

5216004002 1

ECOlR-6501 1 Spacer

ÉC02ER-0610 1 Rubber tube

EC01A-6070 1

EC06A-O412 1 Clamp

EC02ER-0702

11104)340000 1

EC02-0S0B

EC01A-7001 1 Gromet

0654-00998-2 1

EC06A-0726 1 Lead compì. (B)

NO. QTY. DESCRIPTION

1

2

1

1

1

1 Piston pm

1 Spiral spring

1

1 Ree!

1

1

1 Muffler cover

1 Fuel tank

1

1 Plug cap compì. {Incl. 44)

Crank ease compì, iincl. 2 ~41

Oil sea!

Ball bearing

Crank case packing

Cylinder

Spark plug (NGK BM7Aor CHAMPION CJ 6 )

Cylinder packing

Cincl. 17 — 27)

Starter knob

Starter rope

Doa

Starter puilev

Retainer

Center screw ¡M5I

Muffler ass'v

Muffler gasket

Muffler clamping bolt

Fuel tank cap compì.

Hose clamp

Magneto comp!, find. 40,41)

Fly wheel

P)ug cap spring

KEY

NO. NO.

46

47

48 EC02ER-3128A 1 Heat msuiaior packing

49 EC02E-3112A 1 Gasket fWY)

50

51 EC02E-S111/1 1 Plate

52 00532-0310-1 1 Woodruff key

53

54

55 43-53

56

5? 108-147 1

58 106-17 1 Packing filter

59

60

61 EC02E-S113 1 Tapping screw ÌB) (M5x20)

62

63 00113-0616-0) 1 Bolt Bss’y CM6x16l

64 00312-0600-0 1 Washer ÌM6)

65 (»431-0516-0 2

66

67 00436-0518-0

68 0119-05987-0 2 Bolt (Socket head) (M6x18)

71

72

73

74 ÈC02ER-5121

75

76

77 NB02A-201A

78 NB26-2102

79

80

81 NS02A-206 2

82 NBQ2A-207

83

84

PART

EC02ET1309A

00217-0500-0 2

118-124

EC01A-6040

5-2328

125-59 1 Filter felt

NB23-2001

EC02E-S102 2 Tappmg screw ÌAÌ ¡M5xl6)

EC03F-399S A. 2

00435-0525» 3

00411-0620-0 2

EC02-9522

EC02JR-5120 1

EC02ER-0903

N816-2051

NB26-2103 2

NB16F-2104

00312-0500-0

EC04-9112

QTY,

1 Heat insulator (incl. 47)

1 Spacer

1

1

1

1

8

2 ±Seraw ass’v (M5k22)

1 Label

1

1

1 Holder

2

) Spring (Clutch)

2 Washer (B)

i

1

DESCRIPTION

Nut (M5)

Filter

Body ass’v filter

Clip filter

Retainer filter

Holder clamping holt ass’v (M6x14)

Washer

Screw (M5x16l

Screw ass'v (M5x25)

Screw ass’v iMSxf 8)

Screw (M6x20!

Labe!

Throttle wire

Clutch compì, (incl. 73 '-'-83)

Clutch shoe

Clutch bolt

Washer (A)

Washer (M5)

Label

Page 12

SEARS BUSHWACKER PARTSLIST-MODEL 636.796670

Figure Э

26

Page 13

SEARS BUSHWACKER PARTSLIST4W0DEL 636.736670

Figure 3

KEY

NO.

•1

*2

3

4

S 95-99

5

7

8

9

10

11

12 16-103

13 112-183

14 16-104 1 Bing-''0"

15 16-71

16

17

18

19 98-323

20 96-314

21

22

23 EC02E-3123

24 EO)2E-3104a

2S EC02E-3108 2

26

27

28 ECQ1A-3072A

29

30

31 00436-a512-0 h) 1 Screw assembly (M5k12}

32

33

PART

NO.

EC02ER-0606

34Í14 1

S-2238

92-258

157-280 1

92-257 1

92-146. 1 Gaskat-moterína diaphragm

95-526

21-168

122-211 2

136-90

52-30 1

167-91

96-323Y

96-325Ì^

EC02E-3141A 1

EC02E-3114A 1

eC02E-310G

EC02ER-3130

00217-05000 N

00431-0555-0 M

QTY. DESCRIPTION

1 Carbursior compì, (¡nel. 2 —27}

1 8odv aisembly-pump

1 Goskot-pump

1

1 Diaphragm assembly-matering

t

1

1 Jatí^l

1 Ring-ípring nitainíng

1 Washar

1

1

1 ScrBw-idla adjust

2 Scraw-coJIar throttfa

4 Scraw-mctoring covar

1

1 Air claanor píate

1 Pravaot píate

1

1

1

2

Valva asiombiv-throttle

Diaphregm-purop

PlBte-pump

Goikat-plBta

Covor-metanng diaphragm

Slaova-mounting

Ring-packing

Swival

Bnikat-idle adjust

Spring idlo adjust

Wire holdar

Spacer

Choka levar

Rubbor soat

Elamont

Air cleaner cap

Nut (M5Í

Screw assamhly (M5k65l

KEY

NO. NO.

1

2 ÉC01A-0904

PART

5a)9500101

OTY.

1

1

DESCRIPTION

Owner’s manual

Toot kit

Page 14

The Model Number will be found on the top of recoil starter. Always

mention the Model Number when requesting service or repair parts

for your unit.

All parts listed herein may be ordered from any SEARS, ROEBUCK

AND CO. OR SIMPSONS'SEARS LIMITED service units or most

retail stores.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION AS SHOWN IN THIS LIST

MODEL NO.

636.796670

How to Order

Repair Parts

1. ThePART NUMBER

2 The MODEL NUMBER

of the Bushwacker

3 The PART DESCRIPTION

4, The NAME OF ITEM-

20.3cc Gas Bushwacker

63B. 796670

If the parts you need are not stocked locally, your order will be

electronically transmitted to a Sears Repair Parts Distribution center

for expedited handling

When you buy merchandise

from Sears you get an extra

something that nobody else

can offer . . Sears Service.

Across town or across the

country. Sears Service follows

you, providing trustworthy,

competent service technicians

using only Sears specified

factory parts

SIAtS SERVICE

IS AT YOUR SERVICE

52flaaomoi 4/8s

Your Sears Merchandise takes on added value when you discover

that Sears has Service Units throughout the country, Each is staffed

by SearsTtained, professional technicians using Sears approved

methods.

Sears, Roebtick and Co., Cbicago, ILL 60684 US.A.

PRINTED IN JAPAN

Loading...

Loading...