Page 1

52

owner's

manuah

MODEL NO.

636.796670

CAUTION:

Read Rules for

Safe Operation

and instructions

Carefully

e Assembly

. Operation

BUSHWACKER

o Maintenance

o Repair Parts

Sears, Roebuck and Co., Chicago, IIL 60684 U.S.A.

5209500101 4/89 PRINTED IN JAPAN

Page 2

TWO YEAR LIMITED WARRANTY ON CRAFTSMAN

BUSHWACKER 636.796670

Fo_ two years from date o{ purchase when this BUSHWACKER is maintain6_, tubricated, and tuned up according to the

operating and maintenance instructions in the owner's manual. Sears will repair free of charge any defect In material or

workmanship

This warranty excludes blades, spark plug_and air cleaner: which are expend_He part., and become worn during normat

USe,

t# this BUSHWACKER }s used for commercial or rental purposes, this warranty applies for only 30 dayt from the data of

purchase.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER/DEPART-

MENT tN THE UNITED STATES. This warranty applies onty while this product is in usein the United Statas_

This warranty gives yOU specific tagal tieht_= and you may atso have other rights which very from scare to state,,

SAFETY RULES AND PRECAUTIOHS

Before each operation, make sure that the screws are not

loose or missing, that the components are not damaged,

and that the blades are not chipped off or cracked. If a

blade is chipped or cracked replace it with a new one,

,

Do not attempt engine or blade adjustments or refuel-

ing before allowing the engine and mufffer to coo!,

a. [30 not remove the fuel tank cap while the engine is

running or when it is still hal

b, Clean off fuel tank cap area before refueling.. Do not

smoke while refueling_

c Take care not to spill any fuel. If it is spilled, wipe it

off

d Never operate on gasoline only As this engine is of

2-cycle type, use mixed fuel whose mixture ratio is

t6:1 (1 Bat gasoline to 8 oz. oil) and a proper lubri-

cation oil such as Sears Catalog Number 36555.

3. Do not operate the machine when your physical condi-

tion is not good. Never touch the plug cap during opera,.

lion to protect yourself from etectric shock..

4 Never operate the machine wherever ventilation is not

enough,

5 Before starting the engine, make sure that the blade does

not touch anything In startup of the engine, be careful

not to turn the blade toward bystranders. Posit_on

BUSHWACKER securel% (In startup, place 8USHWACK-

ER in a level place so as to prevent the blade from

moving )

6 Wear safe clothes (safety shoes, goggles, earmuffs, gloves,

etc ) Never wear loose clothing or jewelry while operat-

ing your BUSHWACKER

SEARS, ROEBUCK AND CO

DEPT, 698/731A

SEARS "TOWER

CHICAGO, ILLiNOiS 60684

7. Do not admit any persons or animals within the working

area (30 feet or lessfrom the site),.When plural operators

work together in the same place, maintain at least a

30 feet distance from each other and exchange warning

shouts if necessary° Pay special attention to keep by.

standers, especially children away from the working site.

8 Stop the engineand pay special attention to the blades

whenever you carry the BUSHWACKER from one place

to the next before and after operation.

9. Never let any child handle the machinm

!0_ Use BUSHWACKER only for cutting of young trees,

grass, etc, of which diameter is 0°2" or tess, Never use

BUSHWACKER to cut motets or other hard materials,

11, Never operate BUSHWACKER in a bad weather condi-

tion (rain, snow, strong wind, abnormal atmospheric

temperature, etc.)

12_ Keep this manual in place so that one can refer to it

repeatedly for safety operation and to teach possible

users how to operate the machine,

CAUTION: The operation of any BUSH-

WACKER can result in Foreign objects

being thrown into the eyes, which can

result in severe eye damage. Always wear

safety glasses or eye shields before com-

mencing power tool operation., We re_

commend Wide Vision Safety Mask for over spectacles or

standard safety! glasses, available at Sears Retail or Catalog

Stores,

Page 3

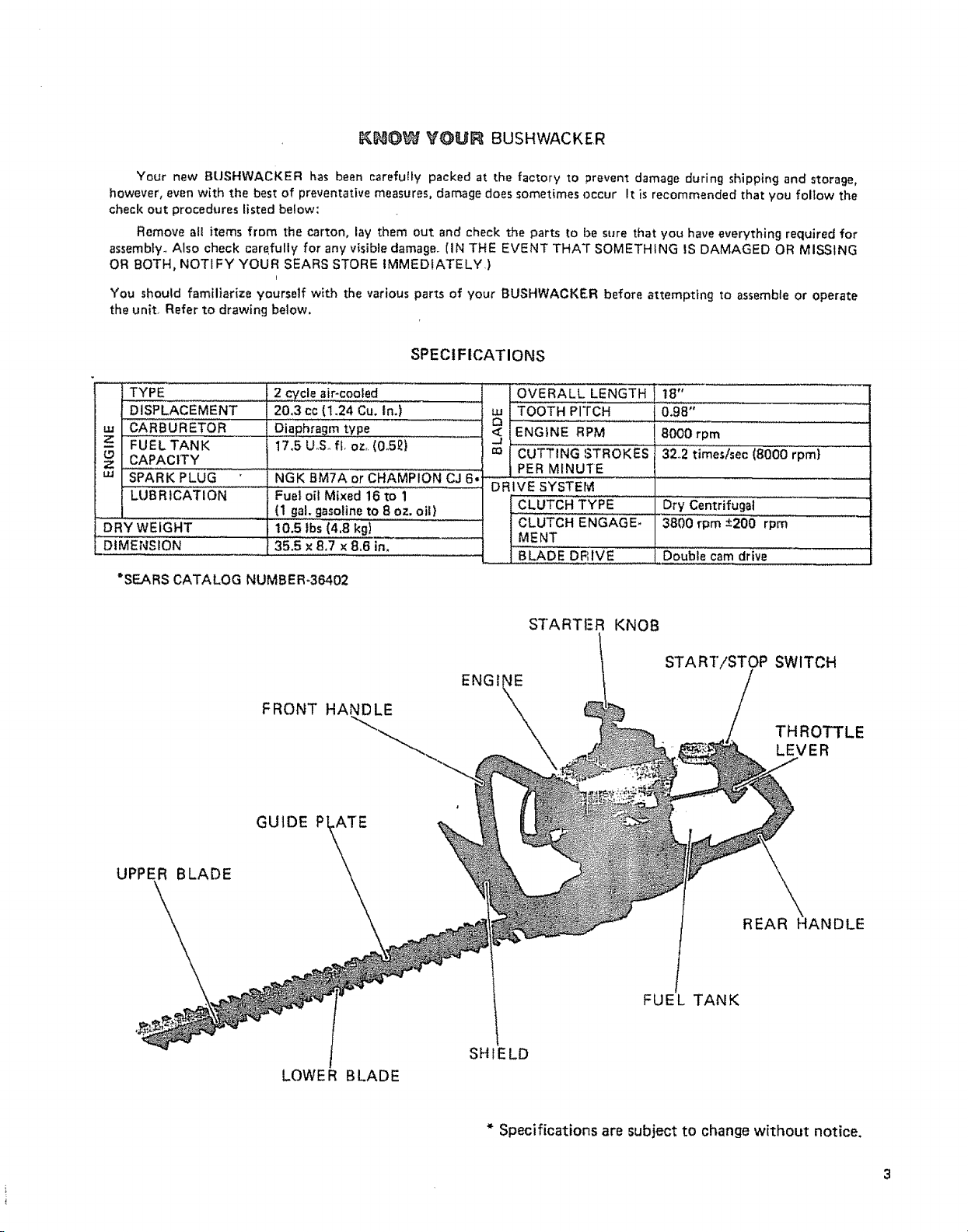

KNOW YOUR BUSHWACKER

Your new B[JSHWACKER has been carefully packed at the factory to prevent damage during shipping and storage,

however, even with the best of preventative measures, damage does sometimes occur It is recommended that you follow the

check out procedures listed below:

Remove all items from the carton, lay them out and check the parts Io be sure that you have everything required for

assembly. Also check carefully for any visible damage. (IN THE EVENT THA'F SOMETHING IS DAMAGED OR MISSING

OR BOTH, NOTIFY YOUR SEARS STORE IMMEDIATELY,)

You should familiarize yourself with the various parts of your BUSHWACKER before attempting to assemble or operate

the unit, Refer to drawing below.

i

SPECIFICATIONS

TYPE

DISPLACEMENT

u_ I CARBURETOR

z l FUEL TANK

_ !CAPACtTY

SPARK PLUG

LUBRICATION

J

DRYWEIGHT

DIMENSION

2 cycle air-cooled

2013 cc 1i,24 Cu' In,)

O ,p.ragmtype ..................

17,5 UoSoff. oz,. (0°5£)

NGK BM7A or CHAMPION CJ 6.

Fuel oil Mixed 16 to 1

(1 gal. gasoline to 8 oz, oil)

t0.5 ibs (4.8 kg)

35.5 × 8,7 x 8,6 in,

"SEARS CATALOG NUMBER-36402

FRONT HANDLE

I OVERALL LENGTH i 18"TOOTH PITCH j 0.98"

CUTTING STROKES 32°2 times/see (8000 rpm}

i ENGINE RPM 8000 rpm

....... PER MINUTE

DRIVE SYSTEM

CLUTCHTYPE Dry Centrifugal

CLUTCH ENGAGE. 3800 rpm -+200 rpm

MENT

BLADE DRIVE Double cam drive

STARTLER KNOB

ENG

START/STOP SWITCH

TH ROTTLE

LEVER

UPPER BLADE

GUIDE P_T i

LOWER BLADE

REAR HANDLE

FUEL TANK

SHIELD

* Specifications are subject to change without notice,

Page 4

PREPARaHG FOR OPERATaON

Fuel and oil mixture

inspect the fuel tank and flit with clean, fresh fuel of

the proper mixture This engine requires a mixture of

t6 parts gasofine to t part oil (1 gal gasoline to 8 oz

oil) Use 71-36555 Craftsman Engine Oil or a high grade

b_vo cycle engine oi!.

WARNING: Experience indicates that alcohol blended fuels

{called gasohot or using ethanol or methanol) can attract

moisture which leads to separation and formation of acids

during storage Acidic gas can damage the fuel system of an

engine while in storage

To avoid engine problems, the fuel system should be emptied

before storage for 30 days or longer. Drain the gas tank, start

the engine and let it run until the fuel lir_es and carburetor

are empty,. Use fresh fuel next season See Storage Instruct{arts

for additional information

Never use engine or carburetor cleaner products in the fuel

tank or permanent damage may occur.

5. To avoid a burn, do not touch the engine during the

operation or immediately after stopping the englne_

Handle the engine after it is completely cooled.

6 Never operate BUSHWACKER on unstable ground or

standing on tiptoe Never use it while climbing a ladder,

Do not use the 8USHWACKER continuously for a tong

7.

time. It is. normal tO take a break of 10 to 20 minutes

after every 50_minute operation.

Never leave the 8USHWACKER running unattended,

8

9

If there is any trouble during operation, be sure to stop

the engine first. (Move the switch to STOP.}

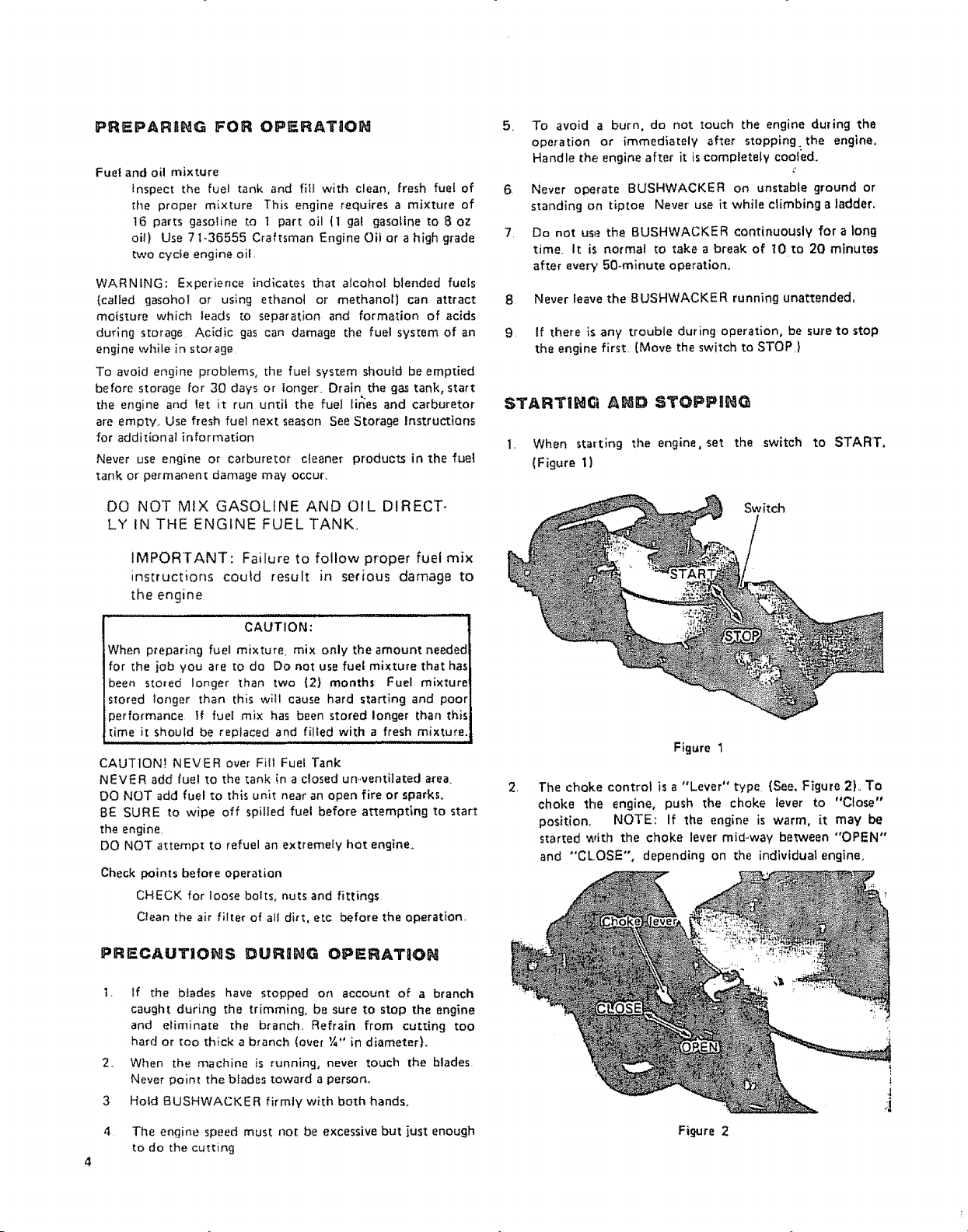

STARTINCI _,ND STOPPING

1. When starting the engine, set the switch to START,

(Figure 1)

DO NOT MIX GASOLINE AND OIL DIRECT-

LY tN THE ENGINE FUEL TANK,

IMPORTANT: Failure to follow proper fuel mix

instructions could result in serious damage to

the engine

CAUTION:

Nhen preparing fuel mixture mix only the amount needed

for the job you are to do Do not use fuel mixture that has

been stored longer than two (2} months Fuel mixture

stored longer than [his will cause hard starting and poor

iperformance tf fuel mix has been stored longer t:han this

itime it should be replaced and filled with a fresh mixture.

CAUTION! NEVER over Fill Fuel Tank

NEVER add fuel to the tank in a closed un-ventilated are&

DO NOT add fuel to this unit near an open fire or sparks.

BE SURE to wipe off spilled fuel before attempting to start

the engine,

DO NOT attempt to refuel an extremely hot engine.

Check points before operation

CHECK for loose bolts, nuts and fittings

Clean the air lifter of all dirt, etc before the operation_

PRSCAUTIONS DURSNG OPERATION

Switch

Figure 1

2_

The choke control is a "Lever" type (See. Figure 2L To

choke the engine, push the choke lever to "Close"

position. NOTE: If the engine is warm, it may be

started with the choke lever mid-way between "OPEN"

and "CLOSE", depending on the individual engine.

If the blades have stopped on account of a branch

caught during the trimming, be sure to stop the engine

and eliminate the branch. Refrain from cutting too

hard or too thick a branch (over ¼°' in diameterL

2.

When the machine is running, never touch the blades

Never point the blades toward a person.

3

Hold 8USHWACKE R firmly with both hands.

4

The engine speed must not be excessive but iust enough

to do the cutting

Figure 2

Page 5

3. Puli the throttle lever a little, push the throttle knob

and lock the throttle lever at the starting position.

(Figure 3}

Figure 3

4, Pull the recoil starter several times_ (At this time, hold

the machine securely so as to keep it fixed.)

(Figure 4)

The carburetor is no'. filled with fuelo Pull the starter 7 to

8 times to feed up fuel from tank to carb_retor.

without a load, otherwise the engine will run at a high

speed reducing engine life.

Stopping the Engine

I Reduce the engine rpm to idle by releasing the throttle

2 Set the stop switch to stop. (Figure 1)

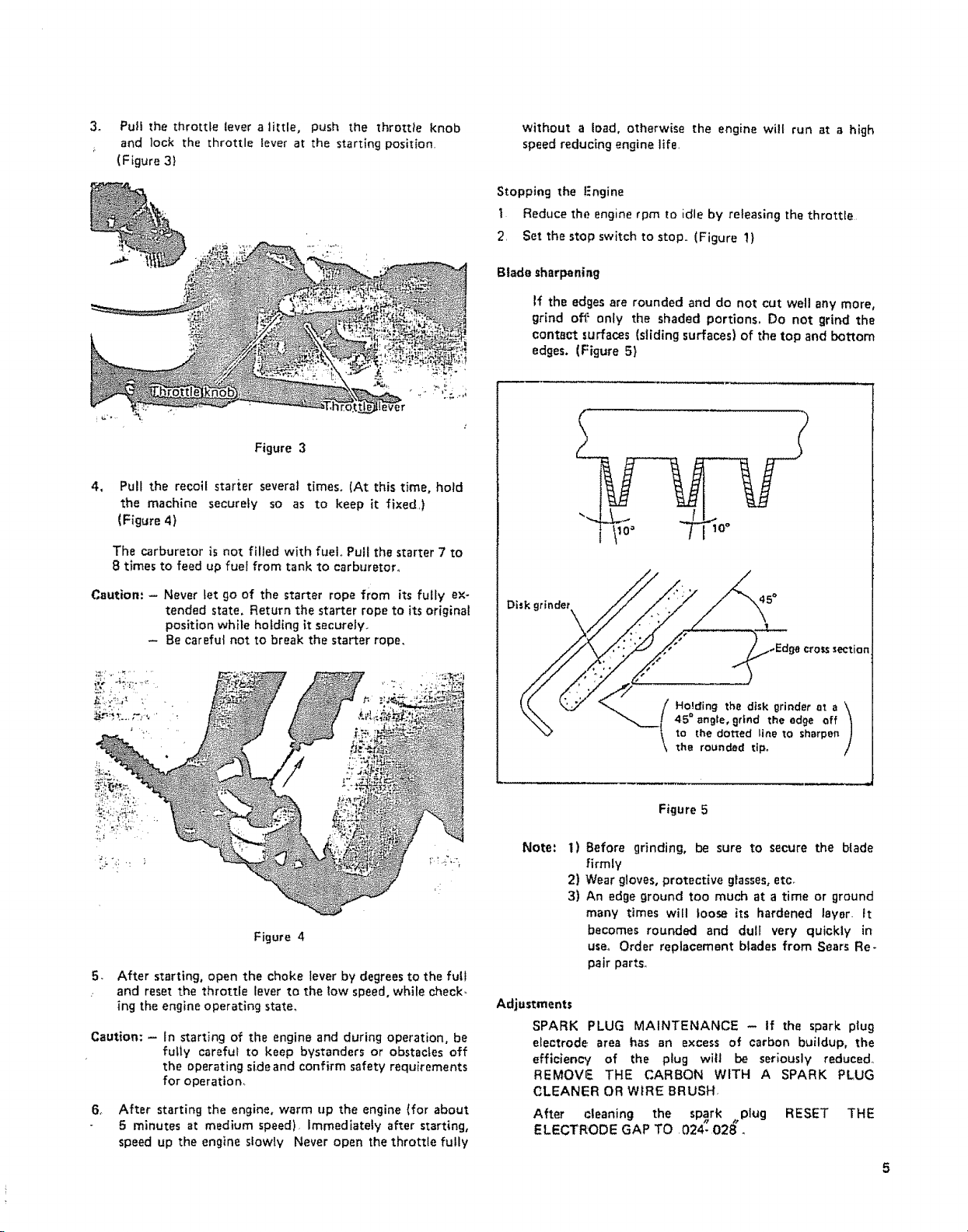

Blade sharpening

If the edges are rounded and do not cut well any more,

grind oft= only the shaded portions, Do not grind the

contact _urfaces (sliding surfaces) of the top and bottom

edges, (Figure 5}

Caution: - Never let go of the starter rope from its fully ex-

tended state. Return the starter rope to its original

position while holding it securely.

-- Be careful not to break the starter rope,

Figure 4

5. After s_arting, open the choke lever by degrees to the full

and reset the throttle lever to the low speed, while check..

ing the engine operating state.

Caution: - tn starting of the engine and during operation, be

fully careful to keep bystanders or obstacles off

the operating sideand confirm safety requirements

for operatlo n.

6. After starting the engine, warm up the engine (for about

5 minutes at medium speed). Immediately after starting,

speed up the engine slowly Never open the throttle fully

Disk grinder

\

Holding the disk grinder at a

45 ° angle, 9rind the edge aff

to the dotted line to sharpen

_he rounded tip,

Figure 5

Note:

1) Before grinding, be sure to secure the blade

firmly

2) Weargloves,protective glasses,etc_

3) An edge ground too much at a time or ground

many times will loose its hardened layer, it

becomes rounded and dull very quickly in

use° Order replacement blades from Sears Re-

pair parts.,

Adjustments

SPARK PLUG MAINTENANCE - If the spark plug

electrode area has an excess of carbon buildup, the

efficiency of the plug will be seriously reduced..

REMOV_ THE CARBON WITH A SPARK PLUG

CLEANER OR WIRE BRUSH

After cleaning the spark ,,plug RESET THE

ELECTRODE GAP TO 024-028.

c_oss zectia

Page 6

Carburetor

Proper adjustment of the carburetor is very important to

the operation of this engine. The carburetor has been

carefully ad)usted at the factory and therefore should

not require any further adiustmenL

Adjustment of Engine Idling

{f the blade happens to run in idling, adjust the cable

adjuster of the throtde wire to stop blade movement in

idling_

Figure 6

STORAGE AFTER OPERATION

1

Clean every part, repait faulty sections, and apply a thin

coat of oil on metal parts to prevent rusL In cleaning

the machine, always use a dean cloth, Never use strong

solvents, such as gasoline

2,

if the BUSHWACKER will not be used for a iong

period of time, drain the fuel from the tank, then start

the engine and keep the engine running until it consumes

all the fuel taft in the carburetor.

_ILADI_ ADaUSTM_-_T

(Performed with engine stopped,)

The blades wear with use when you notice a decrease in

cutting performance adjust the blades asfollows°

Upper blade

Cross-sectional view of blades

H)

Loosen lock nuL

(2)

Tighten truss head screw lightly until it stops

turning. Then turn it back one-fourth to one half

tum.

(3)

Tighten lock nut. Lubricate the blades after adjust-

ment_..

{4)

Stalt the engine and ooerate the blades at high

the _peedfor a minute or so.

(5)

Stop the engine and carefully feel the blades with

your hand, If they are just warm to the touch, you

have made the proper adjustments, but if they are

too hot for you to keep touching them, repeat

steps #1. #'2 and #3 above backing off slightly more

on 'the screw.

Note: Never fail to stop the engine before making the

adjustments.

3. Store the BUSHWACKER in a clean and dry place.

Always keep children away from the machine.

Remove the spark plug. inject a smell amount of engine

oil through the spark piug hole. Then pull the recoil

starter a few times to put a thin coat of oil on the cylin..

der.. Install the spark plug again when the piston has

stopped at a top dead center.

It is important to prevent gum deposits from forming in

essential fu[:] system parts such as the carbure[or_ fuel filter,

fuel hose, or tank during storage Also, experience indicates

that alcohol h_er_ded_uels(caUed gasohol or using ethanol or

methm_o!) r.a_ attract moisture which leads to separation and

_ormatio_ ol acids durinq storage Acidic gas can damage the

fu_:l system ol Jr_engine while in storage

To avoid t_N!li_)=: problems, {he fuel system should be emptied

b(:h)re star._!iJ., (}I 30 (lays or ionrjer. Follow these instructions:

PR_VI_ITATIIVI_ MAINTI_I_ANC_ CHI_CK

LIST AND STORAQt_ TIPS

Be surethe engineand all other pmts areclean,

Check all nuts, bolts, screws, etc..making sure they are

tightened and secured as they should be.

inspect Carefully for' any fuel or oil leeks.

Check the air cleaner assembly for excessivedustor dirt_

If the filter requires cleaning, use the following

procedure: Remove the filter and wash in soap and

water or blow off with compressedair. DO NOT clean

filter in gasolineor other flammable solvent,

Inspect the muffler exhaust port /,tail pipe). If thece is

any clogging, remove carbon particles adhering to iL

Page 7

_AB_TS_A_C_

In every 10--20 hours, inject one or two ounces of

grease through a grease nippFe installed in the gear case

of the BUSHWACKER Be sure the engine is stopped

while greasing the gear case

Figure 7

__________________________________________________________________________u_______________________________________1111111111111____________________________________________l________________________________________________________

2 Stop the engine before tubricatirrg the blades during the

cutting operation, Frequent lubrication using a light

weight oil during cutting will greatly add to blade life,

Figure 8

MEMO

Page 8

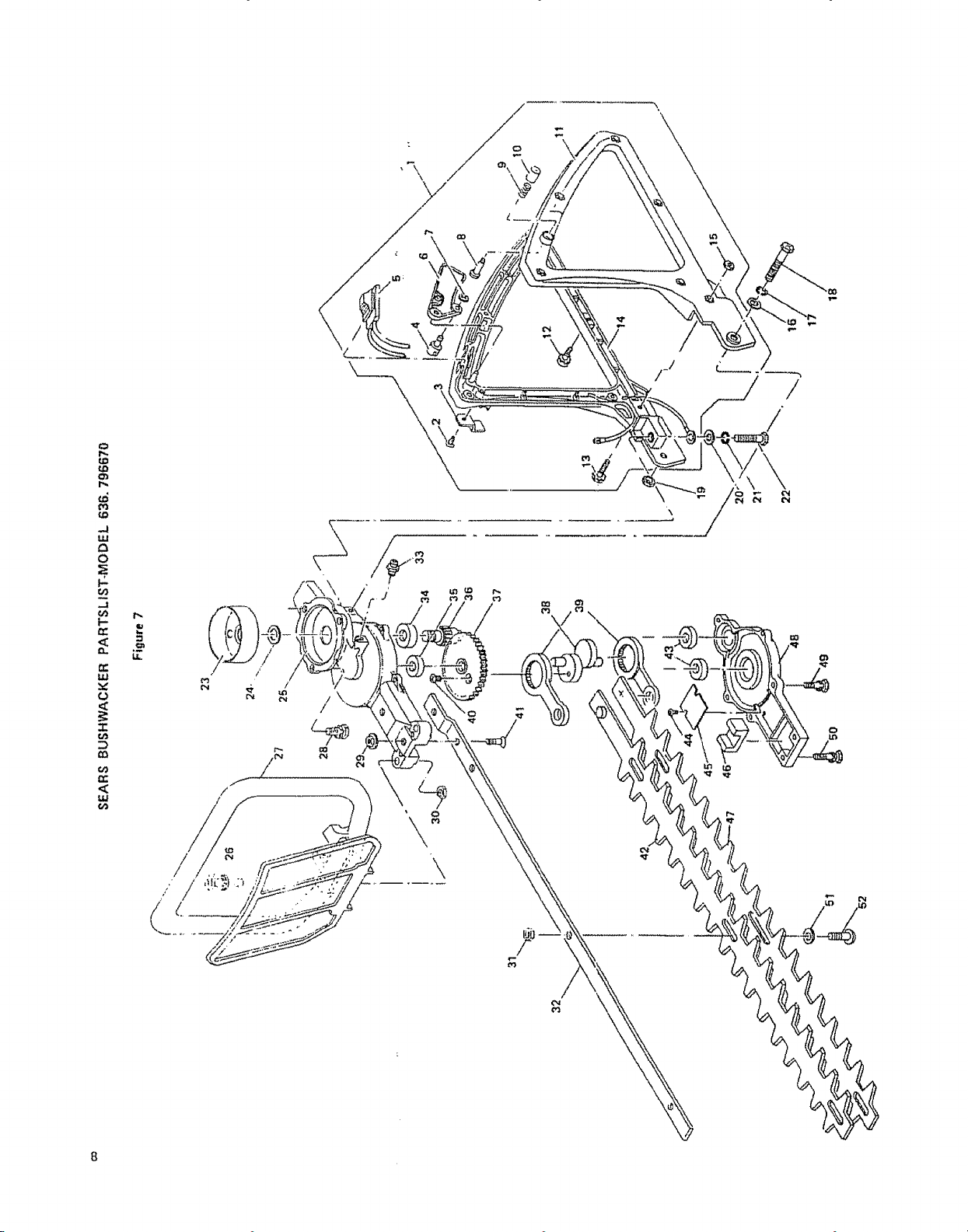

r_O

Cr_

LU

0

i-

LL_

0_

\

€_

r_

\

U_

Page 9

×= _

U_

cI

€_

r,,

x_

o

.J

E

<

..=

r_

U.

U_

(n

m

rr

<

u_

u_

W

Page 10

Q

l")"l

i,L!

Q

0

€.d)

t,,-

i.i,t

z

U.I

L,

lO

Page 11

r_

0

t-

,,,,i

w

z

o

w

>:

t-

o

o

I,&

I-,

t_

-6

2

o

Z

8

,rj

S

11

Page 12

C3

r,,

c_

.J

LU

C_

0

Ct)

©

\°

.J

0:

LU

r_

U_

<_

LLI

12

Page 13

o

p,,

,,.,,I

I.u

Q

0

,J

W

Z

"= _,8

.Q

€,.I

x'.

IJ,I

o

lull

0

o

13

Page 14

The Model Number will be found on the top of recoil st artero Always

mention the Model Number When requesting service or repair parts

for your unit.

All parts listed herein may be ordered from any SEARS, ROEBUCK

AND CO,. OR SIMPSONS_SEARS LIMITED service units or most

retail stores.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION AS SHOWN IN THIS LIST,

MODEL NO.

636.796670

How to Order

Repair Parts

1. The PART NUMBER

2, TheMODEL NUMBER

of the Bushwacker

3 The PART DESCRIPTION

4, The NAME OF ITEM-

20.3cc Gas Bushwacker

636. 79667{I

if the parts you need are not stocked _ocalty, your order will be

eIectronicatly transmitted to a Sears Repair Parts Distribution center

for expedited handling

When you buy merchandise

from Sears you get an extra

something that nobody else

can offer .... Sears Service.

Across town or across the

country, Sears Service follows

you, providing trustworthy,

competent service technicians

using only Sears specified

factory parts.

Your Sears Merchandise takes on added value when you discover

that Sears has Service Units thioughout the country, Each is staffed

SEARS SERVICE

by Sears_Trained, professionail technicians using Sears approved

methods..

IS AT YOUR SERVICE

Sears, Roebuck and Co., C]-doago, lli 60684 U.S.A.

82005801014/89 PRINTED IN JAPAN

Loading...

Loading...