Craftsman 636795454 Owner’s Manual

NB04D-9150/I

Sears]

owner's

manual

MODEL NO.

636.795454

CAUTION:

Read Rules for

Safe Operation

and Instructions

Carefully

I:RRFTSM

37.7 cc GASBRUSHWACKEWo".

• Assembly • Maintenance

• Operation • Repair Parts

Sears, Roebuck and Co., Chicago, Ill. 60684 U.S.A.

NB04D.9150/| 6/82 PRINTED IN JAPAN

° _......

_'_ :1'"Y'E-,_.R'_WA_ R_A-NT_'_O N CR_'A:I=TS MA_N _'-'_" _ _""_

_SHWACKER _M• 636. 795454

_CKER_M.• fails toperform properly, due toa defect inmaterial or workmanship with-

_ in one (1) year from date of purchase Sears will repair it free of charge

_TM. isusedfor commercial or rental purposes,this warranty applies for only 90 days from date

_ of purchase.

_ y

_VICE IS AVAILABLE 8Y SIMPLY CONTACTING THE NEAREST SEARS STORE OR SERVICE

__c legal rights0 and you may also have other rights which vary from state to state.

_t_ - ' ...... Sears, Roebuck & Co•

_'_'; _]_ Sears Tower

_",_,_ ........... Chicago Illinois 60684

_Z=HXZI._H==Zr== _ _•I X P 1 t

'_':" ' rOv ' _ _ _'_W' _ _ " _ "_" ...... '__ __ ' _ _"_ _,'_" '_ '_ _ "

GHOUT THE UNITED STATES.

c ase,Sears will rep_ , •

%

SAFETY RULES AND PRECAUTIONS

Proper safety precautions must be observed• Like all power

equipment, this unit must be handled carefully..DO NOT

EXPOSE YOURSELF OR OTHERS TO DANGER. Follow

these simple rules:

1. Always wear safety goggles for eye protection• Dress

properly, do not wear loose clothing or jewelry that

could become caught in moving parts of the unit. Safe

footwear should always be worn,

2. Inspect the entire machine for loose parts. (Nuts, bolts,

screws, etc.)

3. DO NOT USE any attachment with this' power head

other than those manufactured by the manufacturer of

the engine• Serious injury to the user or damage to the

engine could result.

4. Keep the handles free of oil and fuel.

5. Always use the proper safety handle and hanging band

when cutting.

6.

Do not smoke while mixing fuel or filling the tank.

7.

Do not mix fuel in an enclosed room or near open

flames.

8.

Always mix and store the fuel in a properly marked

container that is approved for such usage.

9,

Never remove the fuel tank cap while the engine is

running.

10.

Never start or run the engine inside a closed room or

building. Fumes from the exhaust contain dangerous

carbon monoxide•

11.

Never attempt to make engine adjustments while the

unit is running and strapped to the operator. Always

make engine adjustments with the unit resting on a flat,

clear surface•

12. Do not use the unit if it is damaged or poorly adjusted•

13. Inspect the area to be cut and remove all debris that

could become entangled in the blade• Also remove any

objects that the unit may sling during cutting•

14. Keep children away• Onlookers should be kept at a safe

distance from the Work area, at least 30 feet.

15. Do not use this unit for any job other than those for

which it is intended as described in this manual.

16. Do not use this unit to cut or trim anything over waist

high•

17. Do not overreach• Keep proper footing and balance at all

times. Do not run unit standing on a ladder or any other

unstable footing•

18. Keep hands and feet clear of the blade while unit is in

use.

19• Do not run the unit at high speed when not cutting.

20. Do not use the unit when you are tired.

21. Maintain the unit with care. Always keep the blade

sharp. Follow instructionsforchanging accessories.

22. Do not store ina closed.areawhere fuelvapors can reach

an open flame from hot water heaters,furnaces, etc.

23. Use only replacement parts that are identicalto original

equipment parts when servicingthe unit. These partsare

available from your dealer• The use of any other

accessory or attachment may create a potential hazard,

CAUTION: The operation ofa,_y BRUSH-

WACKER_.M.TrImmer can result in foreign

objects being thrown into the eyes, which

can result in severe eye damage. Always

wear safety glasses or eye shields before

commencing power tool operation. We recommend Wide

Vision Safety Mask for over spectacles or standard safety

glasses, available at Sears Retail or Catalog Stores•

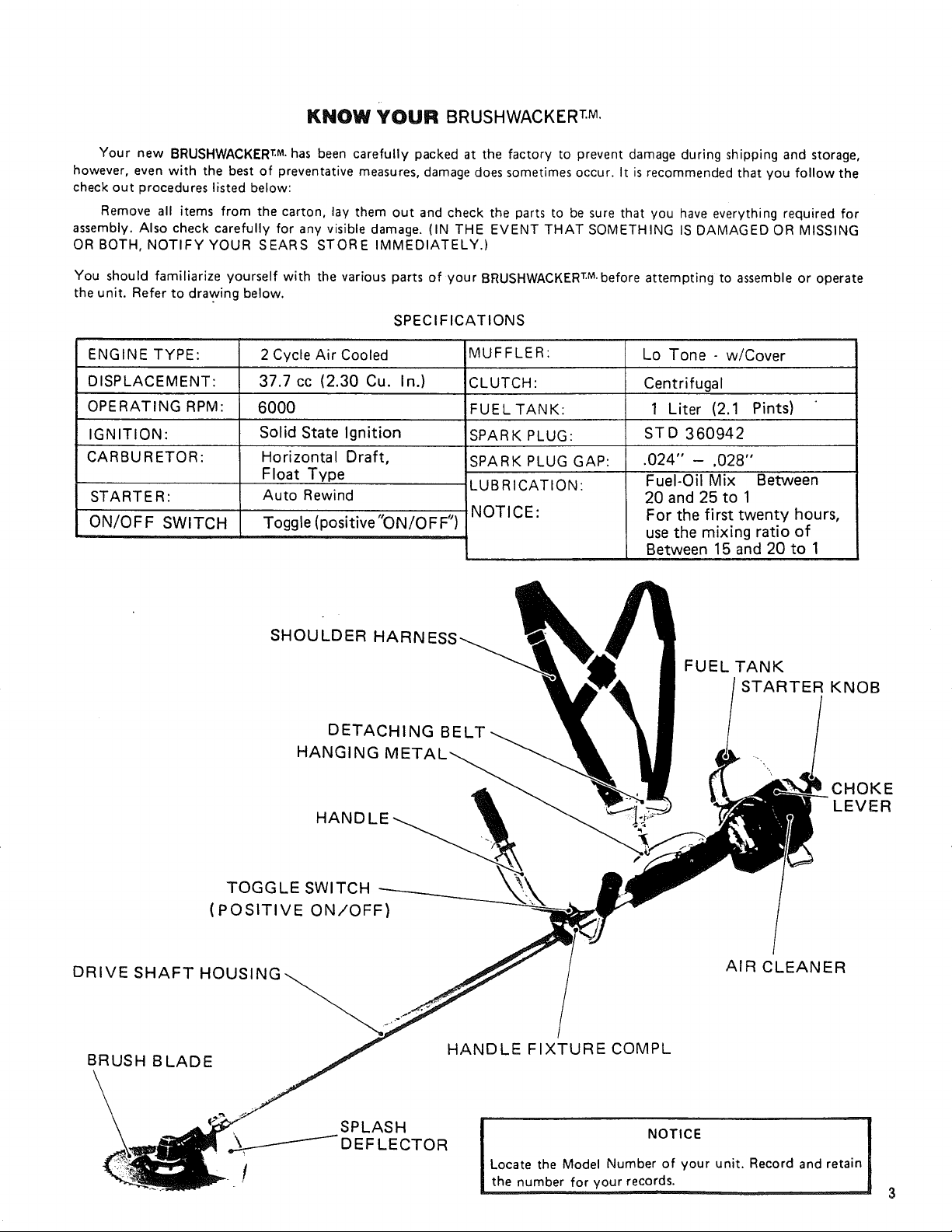

KNOW YOUR BRUSHWACKERTM

Your new BRUSHWACKERT.M. has been carefully packed at the factory to prevent damage during shipping and storage,

however, even with the best of preventative measures, damage does sometimes occur. It is recommended that you follow the

check out procedures listed below:

Remove all items from the carton, lay them out and check the parts to be sure that you have everything required for

assembly. Also check carefully for any visible damage. (IN THE EVENT THAT SOMETHING IS DAMAGED OR MISSING

OR BOTH, NOTIFY YOUR SEARS STORE IMMEDIATELY.)

You should familiarize yourself with the various parts of your BRUSHWACKERT.M. before attempting to assemble or operate

the unit. Refer to drawing below.

SPECIFICATIONS

ENGINE TYPE:

DISPLACEMENT:

OPERATING RPM:

IGNITION:

CARBURETOR:

STARTER:

ON/OFF SWITCH

2 Cycle Air Cooled

37.7 cc (2.30 Cu. In.)

6000

Solid State Ignition

Horizontal Draft,

Float Type

Auto Rewind

Togg le (positive "ON/O FF")

SHOULDER HARNESS

DETACHING BELT

HANGING MET

HANDLE

MUFFLER:

CLUTCH:

FUEL TANK:

SPARK PLUG:

SPARK PLUG GAP:

LUBRICATION:

NOTICE:

Lo Tone - w/Cover

Centrifugal

1 Liter (2.1 Pints)

STD 360942

.024" - .028"

Fuel-Oil Mix Between

20 and 25 to 1

For the first twenty hours,

use the mixing ratio of

Between 15 and 20 to 1

FUEL TANK

STARTER KNOB

CHOKE

LEVER

TOGGLE SWITCH

(POSITIVE ON/OFF)

DRIVE SHAFT HOUSING _,,_.

BRUSH BLADE

_._--_-_ D EF LECTOR

/

SPLASH

AIR CLEANER

HANDLE FIXTURECOMPL

NOTICE

Locate the Model Number of your unit. Record and retain

the number for your records.

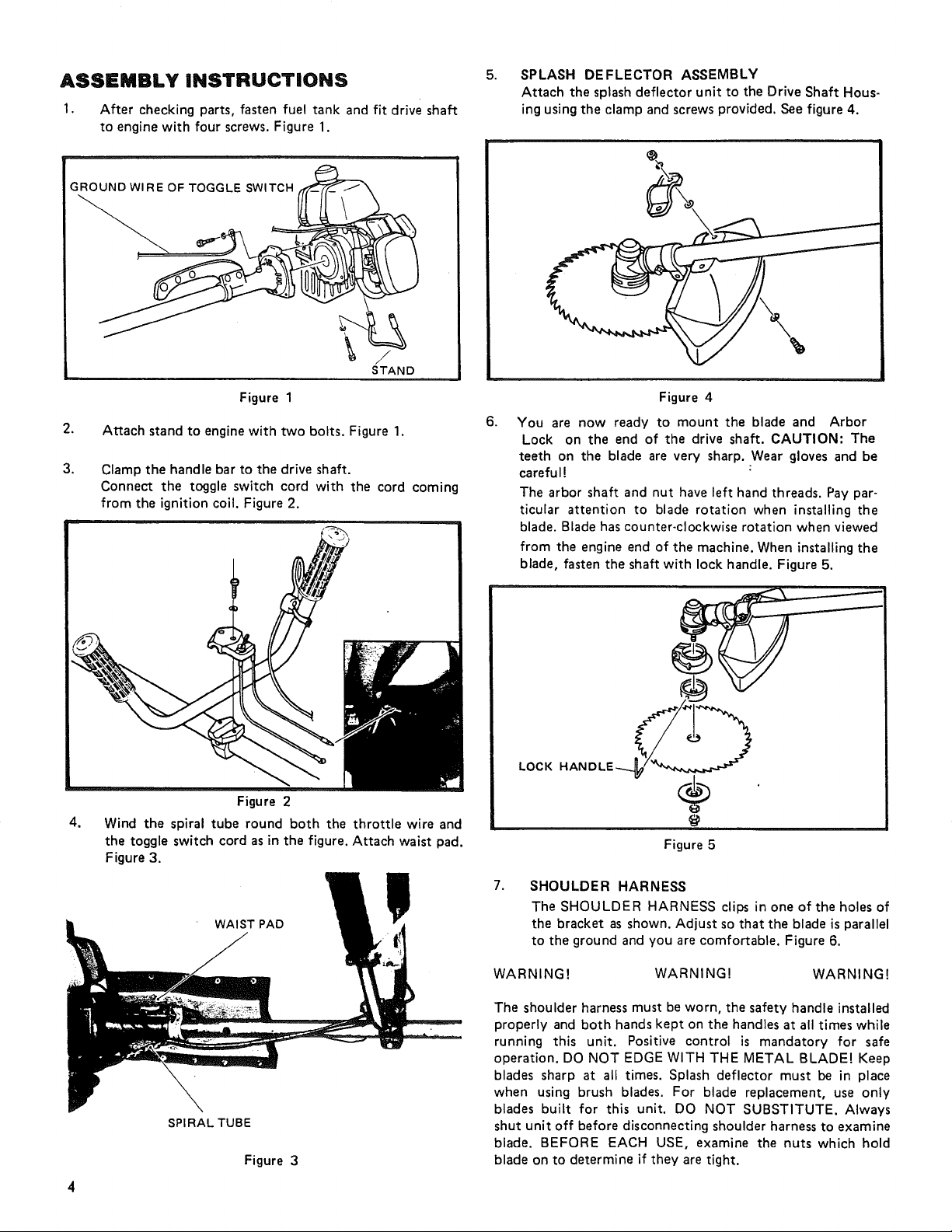

ASSEMBLY INSTRUCTIONS

1. After checking parts, fasten fuel tank and fit drive shaft

to engine with four screws. Figure 1.

GROUND WIRE OF TOGGLE SWITCH

/

STAND

5. SPLASH DEFLECTOR ASSEMBLY

Attach the splash deflector unit to the Drive Shaft Hous-

ing using the clamp and screws provided. See figure 4.

Figure 1

.

Attach stand to engine with two bolts. Figure 1.

3.

Clamp the handle bar to the drive shaft.

Connect the toggle switch cord with the cord coming

from the ignition coil. Figure 2.

Figure 2

4=

Wind the spiral tube round both the throttle wire and

the toggle switch cord as in the figure. Attach waist pad.

Figure 3.

WAIST PAD

Figure 4

6.

You are now ready to mount the blade and Arbor

Lock on the end of the drive shaft. CAUTION: The

teeth on the blade are very sharp. Wear gloves and be

careful!

The arbor shaft and nut have left hand threads. Pay par-

ticular attention to blade rotation when installing the

blade. Blade has counter-clockwise rotation when viewed

from the engine end of the machine. When installing the

blade, fasten the shaft with lock handle. Figure 5.

LOCKXANO

@

Figure 5

7.

SHOULDER HARNESS

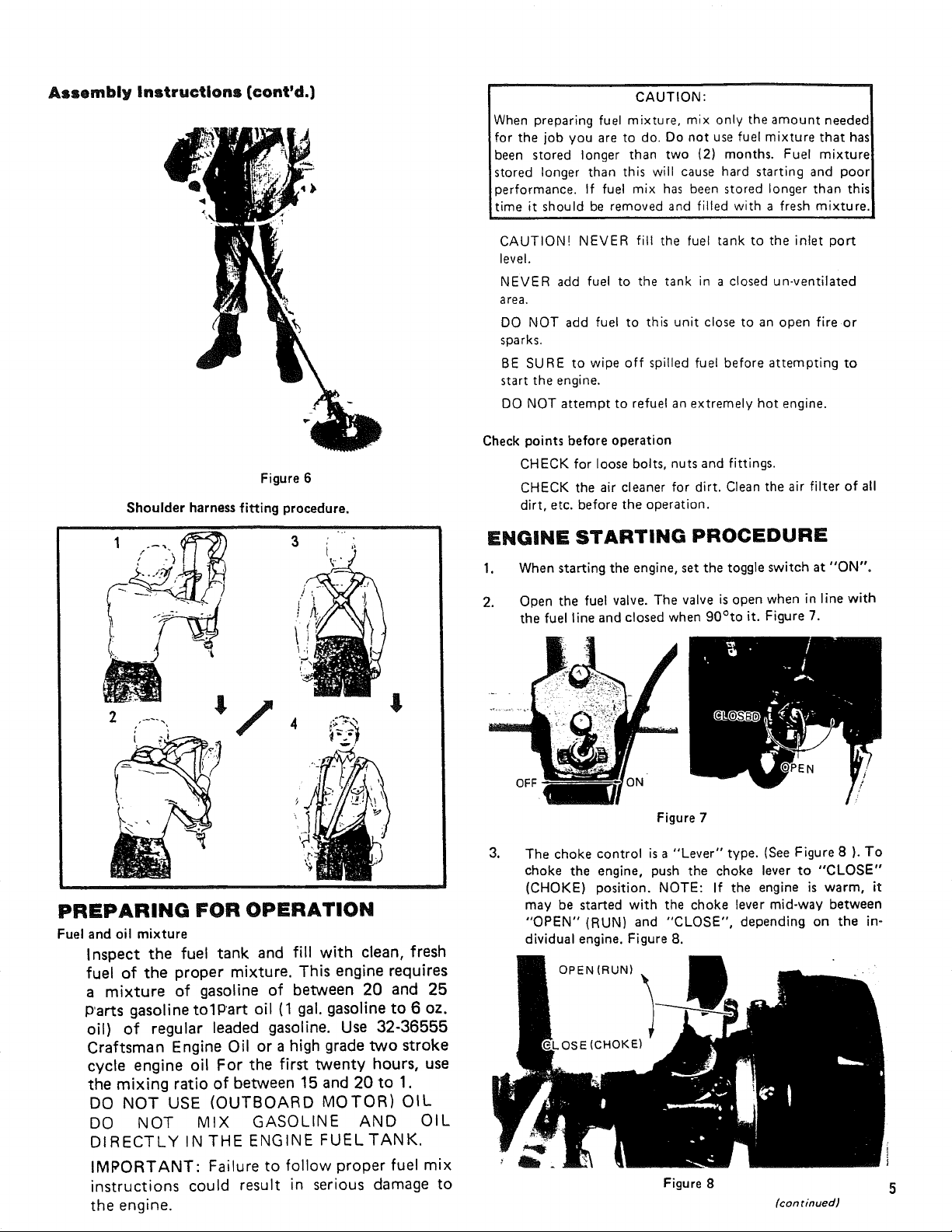

The SHOULDER HARNESS clips in one of the holes of

the bracket as shown. Adjust so that the blade is parallel

to the ground and you are comfortable. Figure 6.

SPIRAL TUBE

Figure 3

WARNING! WARNING! WARNING!

The shoulder harness must beworn, the safety handle installed

properly and both hands kept on the handles at all times while

running this unit. Positive control is mandatory for safe

operation. DO NOT EDGE WITH THE METAL BLADE! Keep

blades sharp at all times. Splash deflector must be in place

when using brush blades. For blade replacement, use only

blades built for this unit. DO NOT SUBSTITUTE. Always

shut unit off before disconnecting shoulder harness to examine

blade. BEFORE EACH USE, examine the nuts which hold

blade on to determine if they are tight.

Assembly Instructions [€ont'd.|

Figure 6

Shoulder harnessfitting procedure,

CAUTION:

When preparing fuel mixture, mix only the amount needed

for the job you are to do. Do not use fuel mixture that has

been stored longer than two (2) months. Fuel mixture

stored longer than this will cause hard starting and poor

performance. If fuel mix has been stored longer than this

time it should be removed and filled with a fresh mixture.

CAUTION! NEVER fill the fuel tank to the inlet port

level.

NEVER add fuel to the tank in a closed un-ventilated

area,

DO NOT add fuel to this unit close to an open fire or

sparks.

BE SURE to wipe off spilled fuel before attempting to

start the engine.

DO NOT attempt to refuel an extremely hot engine,

Check points before operation

CHECK for loose bolts, nuts and fittings.

CHECK the air cleaner for dirt. Clean the air filter of all

dirt, etc. before the operation.

ENGINE STARTING PROCEDURE

I/

PREPARING FOR OPERATION

Fuel and oil mixture

Inspect the fuel tank and fill with clean, fresh

fuel of the proper mixture. This engine requires

a mixture of gasoline of between 20 and 25

parts gasoline tolPart oil (1 gal. gasoline to 6 oz.

oil) of regular leaded gasoline. Use 32-36555

Craftsman Engine Oil or a high grade two stroke

cycle engine oil For the first twenty hours, use

the mixing ratio of between 15 and 20 to 1.

DO NOT USE (OUTBOARD MOTOR) OIL

DO NOT MIX GASOLINE AND OIL

DIRECTLY IN THE ENGINE FUELTANK.

IMPORTANT: Failure to follow proper fuel mix

instructions could result in serious damage to

the engine.

1. When starting the engine, set the toggle switch at "ON"°

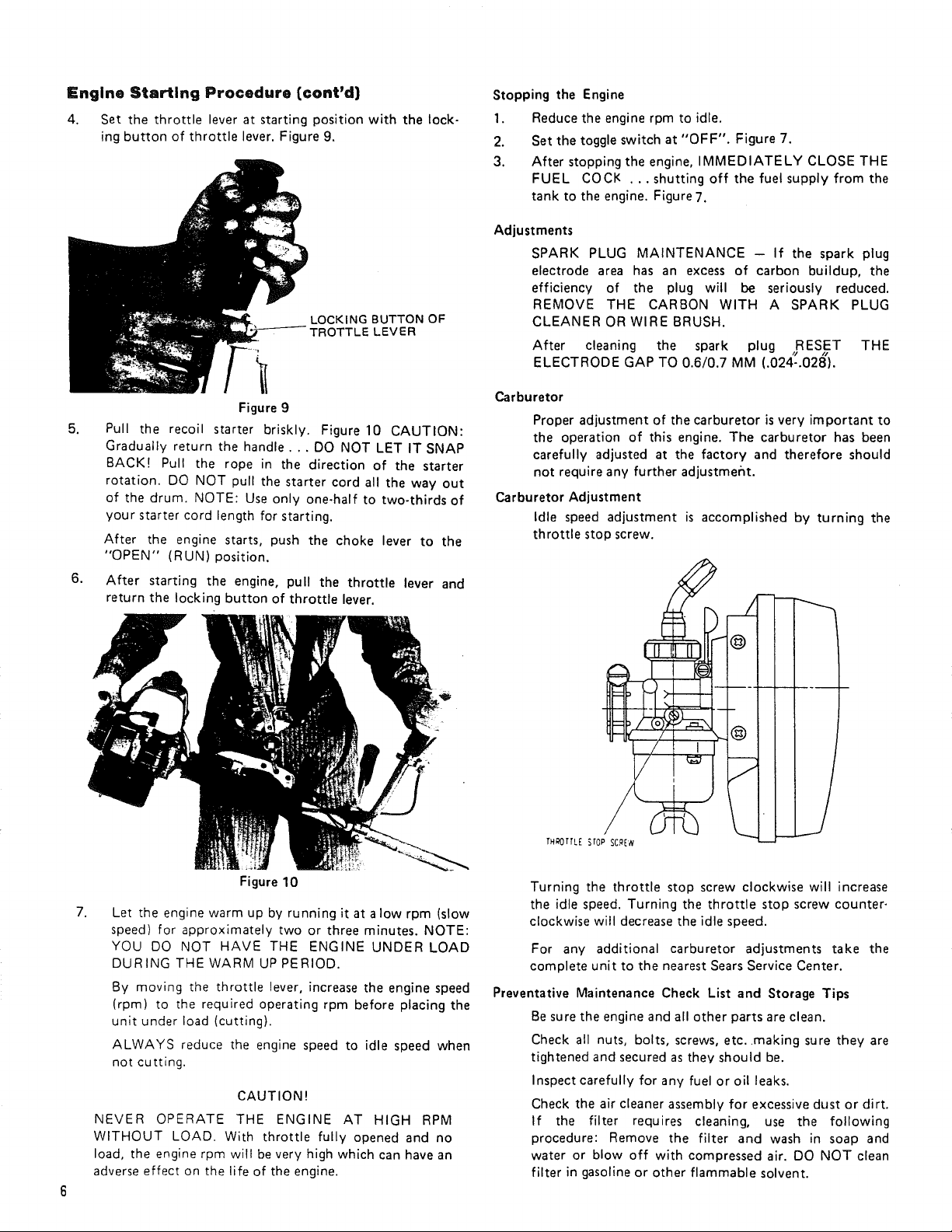

2. Open the fuel valve. The valve is open when in line with

the fuel line and closed when 90°to it. Figure 7.

OFF ON

Figure 7

.

The choke control is a "Lever" type. (See Figure 8 ). To

choke the engine, push the choke lever to "CLOSE"

(CHOKE) position. NOTE: If the engine is warm, it

may be started with the choke lever mid-way between

"OPEN" (RUN) and "CLOSE", depending on the in-

dividual engine. Figure 8.

OPEN (RUN) .

Figure 8

(con tinued)

Engine Starting Procedure {cont'd}

4. Set the throttle lever at starting position with the lock-

ing button of throttle lever. Figure 9.

LOCKING BUTTON OF

LEVER

Stopping the Engine

1. Reduce the engine rpm to idle.

2. Set the toggle switch at "OFF". Figure 7.

3. After stopping the engine, IMMEDIATELY CLOSE THE

FUEL COCK ...shutting off the fuel supply from the

tank to the engine. Figure 7.

Adjustments

SPARK PLUG MAINTENANCE -- If the spark plug

electrode area has an excess of carbon buildup, the

efficiency of the plug will be seriously reduced.

REMOVE THE CARBON WITH A SPARK PLUG

CLEANER OR WIRE BRUSH.

After cleaning the spark plug RESET THE

ELECTRODE GAP TO 0.6/0.7 MM (.024-.028).

Figure 9

5. Pull the recoil starter briskly. Figure 10 CAUTION:

Gradually return the handle... DO NOT LET IT SNAP

BACK! Pull the rope in the direction of the starter

rotation. DO NOT pull the starter cord all the way out

of the drum. NOTE: Use only one-half to two-thirds of

your starter cord length for starting.

After the engine starts, push the choke lever to the

"OPEN" (RUN) position,

6. After starting the engine, pull the throttle lever and

return the locking button of throttle lever.

Carburetor

Proper adjustment of the carburetor is very important to

the operation of this engine. The carburetor has been

carefully adjusted at the factory and therefore should

not require any further adjustmefit.

Carburetor Adjustment

Idle speed adjustment is accomplished by turning the

throttle stop screw.

THROTrLE StOP SCRE,Y

Figure 10

7.

Let the engine warm up by running it at a low rpm (slow

speed) for approximately two or three minutes. NOTE:

YOU DO NOT HAVE THE ENGINE UNDER LOAD

DURING THE WARM UP PERIOD.

By moving the throttle lever, increase the engine speed

(rpm) to the required operating rpm before placing the

unit under load (cutting).

ALWAYS reduce the engine speed to idle speed when

not cutting.

CAUTION_

NEVER OPERATE THE ENGINE AT HIGH RPM

WITHOUT LOAD. With throttle fully opened and no

load, the engine rpm wilt be very high which can have an

adverse effect on the life of the engine.

Turning the throttle stop screw clockwise will increase

the idle speed. Turning the throttle stop screw counter-

clockwise will decrease the idle speed.

For any additional carburetor adjustments take the

complete unit to the nearest Sears Service Center.

Preventative Maintenance Check List and Storage Tips

Be sure the engine and all other parts are clean.

Check all nuts, bolts, screws, etc. making sure they are

tightened and secured as they should be.

Inspect carefully for any fuel or oil leaks.

Check the air cleaner assemblyfor excessive dust or dirt.

If the filter requires cleaning, use the following

procedure: Remove the filter and wash in soap and

water or blow off with compressed air. DO NOT clean

filter in gasoline or other flammable solvent.

Loading...

Loading...