Craftsman 580.750901 User Manual

Operator's Manual

2200 PSi* @ 1.8 GPM

Model No. 580.750901

®

• Safety

HOURS: Mort. - Fri. 8 a.m. to 5 p.m. (CT)

Assembly

Operation

WARNING

Beforeusing this product, readthis

manualand follow all Safety Rules

and Operating instructions.

* This pressure washer is rated in accordance to the Pressure Washer Manufacturers Association

(PWMA) standard PW101-2010 (Testing and Rating Performance of PressureWashers),

* Esta limpiadora a presi6n est_ clasificada conforme a la norma PW101-2010 (comprobad6n y clasificaci6n de rendimiento de limpiadoras

a presi6n) de la Asociaci6n defabricantes de bombas a presi6n (Pressure Washer Manufacturers Association, PWMA).

Seats Brands Management Catpetatien, Heffman Estates, ML 60179 U.S.A.

visit ourCraftsmanwehsite:www.eraftsman.eom

Part No. 80005127 Draft - (02/08/2013)

Antes de utilizar el producto, lea este

manualy siga todas las Reglasde

Seguridad e Instrucciones de Usa.

ADVERTENCJA

Maintenance

• Parts

• Espafiol, p. 32

WARRANTY.......................................... 2

REPAIRPROTECTIONAGREEMENT........................ 2

SAFETYRULES...................................... 3-5

FEATURESANDCONTROLS.............................. 6

ASSEMBLY........................................ 7-10

OPERATION....................................... 11-14

SPECiFiCATiONS..................................... 15

MAINTENANCE.................................... 16o20

(;RAFTSMANTWOYEARFULLWARRANTY

FORTWOYEARSfrom the dateof purchase, this product is warranted against any defectsin material or workmanship. A

defective product will receivefree repair or replacementif repair is unavailable.

Forwarranty coveragedetailsto obtain free repair or replacement,visit the web site:www.craftsman.com

This warranty coversONLYdefects in matedal and workmanship. Warranty coveragedoes NOTinclude:

o Expendableitems that can wear out from normal usewithin the warranty period, such as spray guns, hoses,nozzle

extensions, nozzles,spraytips, filters or spark plugs.

o Product damage resulting from user attempts at product modification or repair or caused by product accessories.

o Repairs necessarybecauseof accident or failure to operateor maintain the product according to all supplied

instructions.

o Preventivemaintenance,or repairsnecessarydueto improper fuel mixture, contaminated or stale fuel.

This warranty is void if this product is ever usedwhile providing commercial services or if rented to another person.

This warranty givesyou specific legal rights, and you may also haveother rights which vary from stateto state.

Sears Brands Management Cerperatien, Heffman Estates, ML60179

Congratulations on making a Smartpurchase.

Your new Craftsman® product is designed and manufactured

for years of dependableoperation. But likeall products; it

may require repair from time to time. That'swhen havinga

Repair ProtectionAgreement can saveyou money and

aggravation.

Nere's what the Repair Protection Agreement* includes:

o Expertservice by our 10,000 professional repair

specialists

o Unlimited service and no charge for parts and labor on

all covered repairs

o Praduet replacement up to $1500 if your covered

product can't be fixed

o Discount of 25% from regular price of serviceand related

installed parts not covered bythe agreement; also, 25%

off regular price of preventivemaintenancecheck

o Fasthelp by phone- we carlit Rapid Resolution - phone

support from a Sears representative.Think of us as a

"talking owner's manual".

Onceyou purchasethe Repair Protection Agreement,a

simple phone call is all it takes for you to schedule service.

You can carl anytimeday or night, or schedule a service

appointment online.

The Repair ProtectionAgreement is a risk-free purchase, if

you cancelfor any reasonduring the product warranty

period,we will provide a furl refund. Or, a prorated refund

anytime afterthe product warranty period expires. Purchase

your Repair Protection Agreement today!

Same limitationsand exclusions apply. Far prices and

additional information in the U.S.A. eaii 1-800-827-6655.

* Coverage in Canadavaries an same items. Far fuji

details, call Sears Canadaat 1-800-361-6665.

Sears Installation Service

ForSearsprofessional installation of home appliances,

garagedoor openers, water heaters,and other major home

items, in the U.S.A.or Canadacall 1-800-4-MY-NOME®.

® 2013

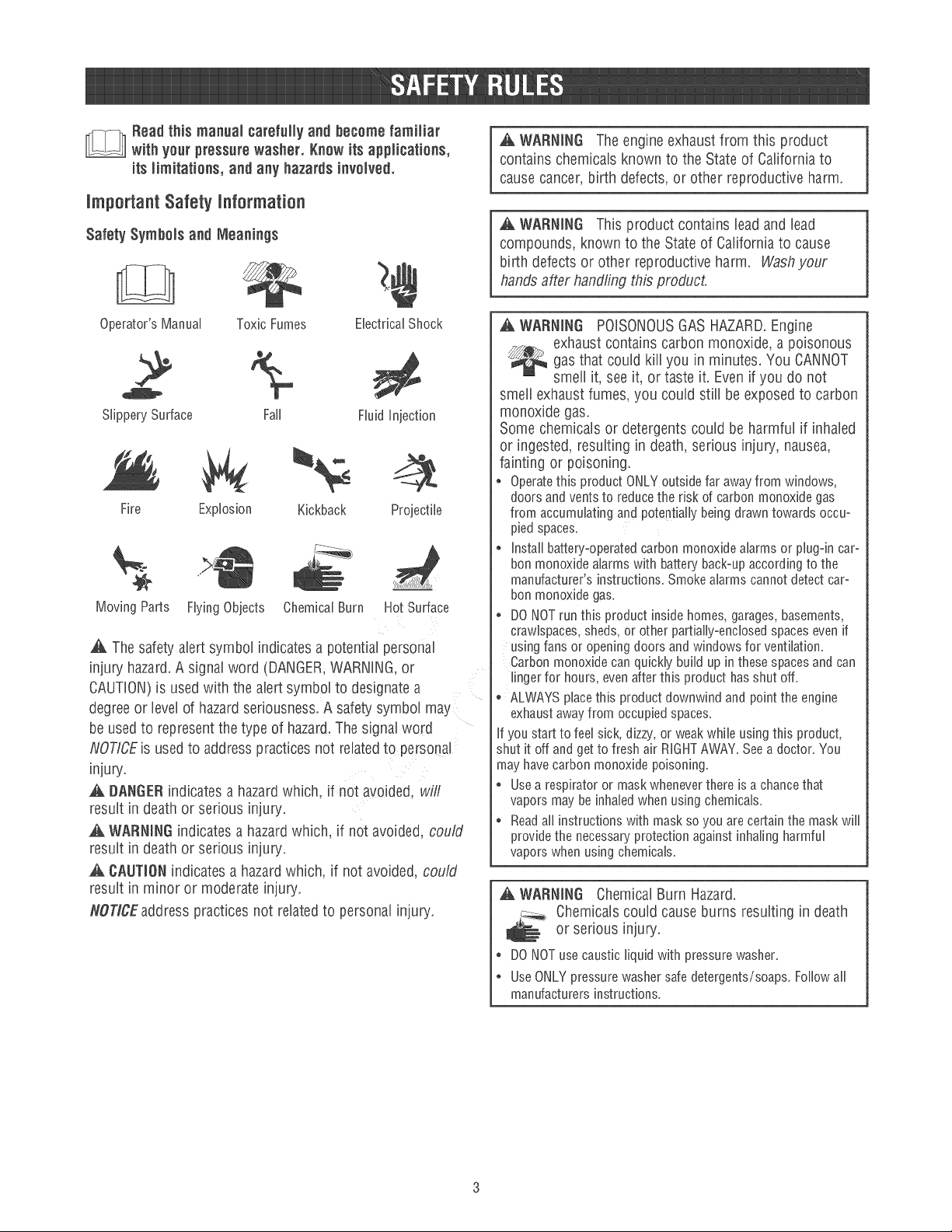

Readthis manual carefully and become familiar

with yourpressurewasher. Know itsapplications,

itslimitations, and any hazardsinvolved.

A WARNENG Theengine exhaustfrom this product

contains chemicals known to the Stateof Californiato

cause cancer, birth defects,or other reproductive harm.

A. WARNING This product contains lead and lead

compounds, known to the State of Californiato cause

birth defects or other reproductive harm. Washyour

hands after handiing t,_isproduct.

ElectricalShock

SlipperySurface

Fire Explosion Kickback

Moving Parts Flying Objects ChemicalBurn Hot Surface

Fall

FMd injection

Projectile

Thesafety alert symbol indicatesa potential personal

injury hazard,A signalword (DANGER,WARNING,or

CAUTION)is used with the alertsymbol to designatea

degreeor levelof hazardseriousness.A safety symbol may

be used to representthe type of hazard.The signalword

NOT/CEis usedto address practices not relatedto personal

injury.

A DANGERindicatesa hazardwhich, f not avoided wiii

result in deathor serious injury.

A WARNINGindicatesa hazardwhich, if not avoided, could

result in deathor serious injury.

A CAUTIONindicates ahazardwhich, if not avoided, could

result in minor or moderate injury.

NOTICEaddress practices not relatedto personal injury.

A WARNING POISONOUS GAS HAZARD. Engine

exhaust contains carbon monoxide, a poisonous

gas that could kill you in minutes. You CANNOT

smell it, see it, or taste it. Even if you do not

smell exhaust fumes, you could still be exposed to carbon

monoxide gas.

Some chemicals or detergents could be harmful if inhaled

or ingested, resulting in death, serious injury, nausea,

fainting or poisoning.

, Operatethis product ONLYoutside far awayfrom windows,

doors and vents to reducethe risk of carbon monoxide gas

from accumulating and potentially being drawn towards occu-

pied spaces.

* Install battery-operatedcarbon monoxide alarms or plug-in car-

bon monoxide alarms with battery back-up according to the

manufacturer's instructions. Smoke alarms cannot detect car-

bon monoxide gas.

* DO NOTrun this product inside homes, garages,basements,

crawlspaces, sheds, or other partially-enclosed spaceseven if

using fans or openingdoors and windows for ventilation.

Carbon monoxide can quickly build up inthese spacesand can

linger for hours, evenafter this product has shut off.

o ALVVAYSplacethis product downwind and point the engine

exhaustawayfrom occupied spaces.

if you start to feel sick, dizzy, or weakwhile using this product,

shut it off and get to fresh air RIGHTAWAY. Seea doctor. You

may have carbon monoxide poisoning.

* Usea respirator or maskwhenever there is a chancethat

vapors may be inhaledwhen using chemicals.

* Readall instructions with mask soyou are certain the mask will

provide the necessaryprotection against inhaling harmful

vapors when using chemicals.

A WARNING ChemicalBurn Hazard.

Chemicals could cause burns resulting in death

or serious injury.

* DO NOTuse caustic liquid with pressure washer.

* Use ONLYpressurewasher safe detergents/soaps. Followall

manufacturers instructions.

WARNINGStartercordkickback(rapidretraction)will

pullhandandarmtowardenginefasterthanyou

canletgowhichcouldcausebrokenbones,

fractures,bruises,orsprainsresultinginserious

injury.

oNEVERpullstartercordwithoutfirstrelievingspraygun

pressure.

Whenstartingengine,pullcordslowlyuntilresistanceisfelt

andthenpullrapidlytoavoidkickback.

Aftereachstartingattempt,whereenginefailstorun,always

pointsprayguninsafedirection,pressredbuttonandsqueeze

sprayguntriggertoreleasehighpressure.

Firmlygraspspraygunwithbothhandswhenusinghigh

pressurespraytoavoidinjurywhenspraygunkicksback.

A WARNING Riskof electrocution.

Contactwith power source could causeelectric

shock or burn resulting in deathor serious injury.

NEVERspraynearpowersource.

A WARNING The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

Spray gun traps high water pressure, even when engine is

stopped and water is disconnected, which could result in

serious injury.

o if cut byfluid, call physician immediately. DONOTtreat as a

simple cut.

o DONOTallow CHILDRENto operate pressure washer.

o NEVERrepair high pressure hose. Replaceit.

o NEVERrepair leaking connections with sealantof any kind.

Replaceo-ring or seal.

o NEVERconnect high pressure hose to nozzleextension.

Keephigh pressure hoseconnected to pump and spray gun

while system is pressurized_

o ALWAYS pointspray gun in safedirection, pressred button

andsqueezespray gun trigger to releasehigh pressure, every

time you stop engine_

NEVERaimspray gun at people,animals, or piants_

o DO NOTsecure spraygun in open position_

o DO NOTleavespray gun unattendedwhile machine is runni%

o NEVERusea spray gun which does not have a trigger lock or

trigger guard in placeand in working order_

Always be certain spray gun, nozzlesand accessoriesare

correctly attached_

,a, WARNING Fuel and its vapors are extremely flammable

and explosive which could cause burns,

fire or explosion resulting in death or

serious injury.

WHENADDING OH BRAiNiNG FUEL

, Turn pressurewasher engineOFFand let it cool at least 2

minutes before removingfuel cap. Loosen cap slowly to relieve

pressure in tank.

, Fill or drain fuel tank outdoors.

, DONOToverfill tank. Allow spacefor fuel expansion.

. iffuel spills, wait until it evaporates beforestarting engine.

Keepfuel awayfrom sparks, open flames, pilot lights, heat, and

other ignition sources.

Checkfuel lines,tank, cap and fittings frequently for cracks or

leaks. Replaceif necessary.

DONOTlight a cigarette or smoke.

WHENSTARTINGEQUIPMENT

* Ensurespark plug, muffler, fuel cap,and air cleanerare in place.

* DO NOTcrank enginewith spark plug removed.

WHENOPERATINGEQUIPMENT

DO NOToperatethis product inside any building, carport,

porch, mobile equipment, marine applications, or enclosure.

DONOTtip engine or equipment at anglewhich causes fuel to

spill.

DONOTspray flammabb fiquids.

WHENTRANSPORTING,MOVING OR REPAiRiNG EQUIPMENT

Transport/move/repair with fuel tank EMPTYor with fuel shutoff

valveOFF.

DONOTtip engine or equipment at angle which causes fuel to

spill.

Disconnectspark plug wire.

WHENSTORINGFUEL OH EQUIPMENTWITH FUEL iN TANK

Store away from furnaces, stoves,water heaters,clothes

dryers, or other appliancesthat have pilot light or other ignition

source becausethey could ignite fuel vapors.

A WARNING Exhaust heat/gases could ignite

combustibles, structures or damage fuel

tank causing a fire, resulting in death or

serious injury.

Contact with muffler area could cause burns resulting in

serious injury.

DO NOTtouch hot parts and AVOIDhot exhaust gases.

Allow equipment to cool beforetouching.

Keepat least5 feet (1.5 m) of clearanceon ail sides of pressure

washer including overhead.

it is a violation of California PuNic ResourceCode,Section

4442, to use or operate the engine on any forest-covered,

brush-covered, or grass-covered land unlessthe exhaust

system is equippedwith a spark attester, as defined in Section

4442, maintained in effective working order. Otherstates or

federaljurisdictions may havesimilar laws.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain aspark attester designed for the exhaust system

installed on this engine.

Replacement parts must bethe sameand installed in the same

position as the original parts.

_k WARNING Use of pressure washer could create

puddles and slippery surfaces causing

_ you to fall resulting in death or serious

T- injury.

Kickback from spray gun could cause you to fall resulting

in death or serious injury.

, Operate pressurewasher from a stable surface.

* Thecleaning areashould have adequateslopes and drainageto

reducethe possibility of a fall due to slippery surfaces.

* Beextremely careful if you must usethe pressurewasher from

a ladder,scaffolding, or any other similar location.

* Firmly grasp spray gunwith both hands when using high

pressure spray to avoid injury when spray gun kicks back.

,a, WARNING Riskof eyeor bodily injury.

Spraycould splash back or propel

objects resulting in serious injury.

* Always wear indirect vented (chemical splash) safety goggles

markedto comply with ANSI Z8X1 when using or in vicinity of

this equipment.

* NEVERsubstitute safety glasses or dry-condition goggles for

indirect vented safety goggles.

* Always wear protectiveclothing such asa long-sleeved shirt,

long pants and close-toed shoes.

* NEVERoperate pressure washer when barefoot or wearing

sandalsor shorts.

_k WARNING Unintentionalsparking could cause fire or

electric shock resulting in death or

serious injury.

WHENADJUSTINGOR MAKINGREPAIRSTOYOURPRESSURE

WASHER

* Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WRENTESTINGFORENGINESPARK

* Use approvedspark plug tester.

* DONOT checkfor spark with spark plug removed.

WARNING Starter and other rotating parts could

entanglehands, hair, clothing, or accessories

resulting in serious injury.

, NEVERoperate pressure washerwithout protectivehousing or

covers.

° DO NOTwear looseclothing, jewelry or anything that could be

caught in the starter or other rotating parts.

, Tie up long hair and removejewelry.

A CAUTION Excessively high operating speeds could

result in minor injury.

Excessively low operating speeds impose a heavy load.

, DO NOTtamper with governor spring, links or other partsto

increase enginespeed. Pressurewasher suppliescorrect rated

pressure and flow when running at governedspeed.

* DO NOTmodify pressure washer inany way.

NOTICE High pressure spray could damagefragile items

including glass.

, DONOTpointspraygunatglasswhenusingred(0°) spraytip.

* NEVERaimspraygunat plants.

NOTICE Improper treatment of pressure washer could

damageit and shorten its life.

o If you havequestions about intended use,ask dealeror contact

qualified servicecenter.

* NEVERoperate units with broken or missing parts, or without

protective housing or covers.

° DO NOTby-pass any safety device on this machine_

° DONOTtamper with governed spee&

DONOToperate pressurewasher above rated pressure_

° DONOTmodify pressurewasher inany way_

* Before starting pressure washer in cold weather, check all parts of

the equipment to be sure ice has not formed there_

* NEVERmove machineby pulling on hoses_Usehandleprovided

on uniL

* This equipmentis designedto be used with Searsauthorized parts

ONLY_if equipment is used with parts that DONOTcomply with

minimum specifications, userassumesall risks and liabilities_

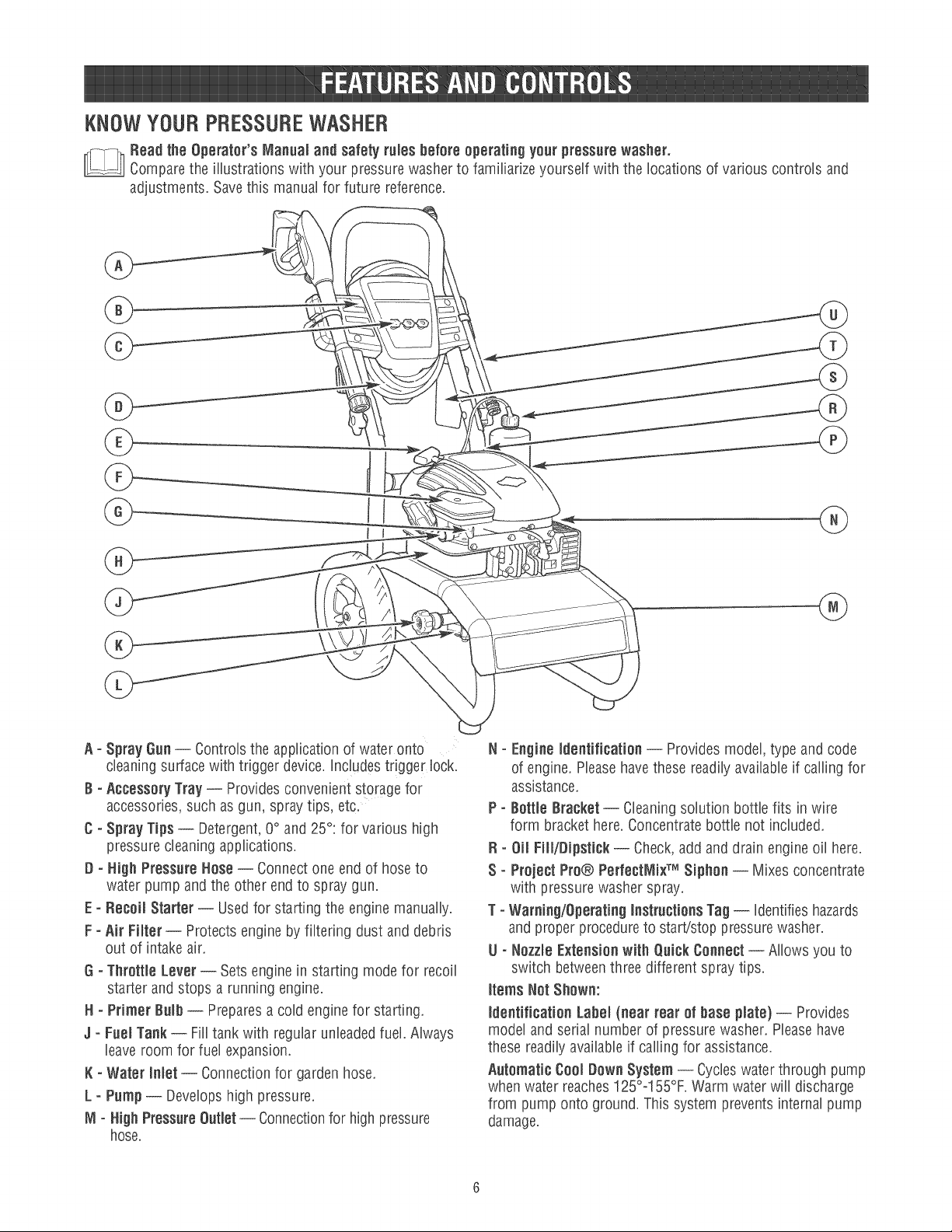

KNOWYOURPRESSUREWASHER

Readthe Operator's Manual and safety rules before operating yourpressurewasher.

Comparethe illustrations with your pressurewasher to familiarizeyourself with the locations of various controls and

adjustments. Savethis manualfor future reference.

@

A ° Spray Gun-- Controlsthe application of water onto

cleaningsurfacewith trigger device.Inc!udestrigger lock.

B ° Accessory Tray -- Provides convenient storage for

accessories, such as gun, spray tips, etc.

C° Spray Tips -- Detergent,0° and 25°: for various high

pressure cleaning applications.

D ° High Pressure Hose-- Connectone end of hoseto

water pump and the other end to spray gun.

E - Re€ell Starter -- Usedfor starting the engine manually.

F - Air Filter -- Protectsengine by filtering dust and debris

out of intake air.

G ° Threttle Lever -- Sets enginein starting mode for recoil

starter and stops a running engine.

Id- Primer Buih -- Preparesa cold enginefor starting.

a ° Fuel Tank -- Filltank with regular unleadedfuel. Always

leaveroom for fuel expansion.

K - Water Iniet -- Connection for garden hose.

L ° Pump -- Develops high pressure.

IVl° High Pressure0utlet -- Connectionfor high pressure

hose.

@

N° Engine Identificatien -- Providesme@l, type and code

of engine. Pleasehavethese readilyavailableif calling for

assistance.

P ° Battle Bracket -- Cleaningsolution bottle fits in wire

form brackethere. Concentratebottle not included.

R- 0ii Fill/Dipstick -- Check,add and drain engine oil here.

S ° Preject Pre@ PerfectMiWMSiphen -- Mixes concentrate

with pressurewasher spray.

T ° Warning/0perating Instructiens Tag -- identifieshazards

and proper procedureto start/stop pressurewasher.

U - NezzieExtensien with Quick Ceneect-- Allows you to

switch betweenthree different spray tips.

items Net Shawn:

_dentificatian Label(near rear of base plate} -- Provides

model and serial number of pressurewasher. Pleasehave

these readily available if calling for assistance.

Automatic Ceel Dawn System -- Cycleswater through pump

when water reaches125°o155%.Warm water will discharge

from pump onto ground. This system preventsinternal pump

damage.

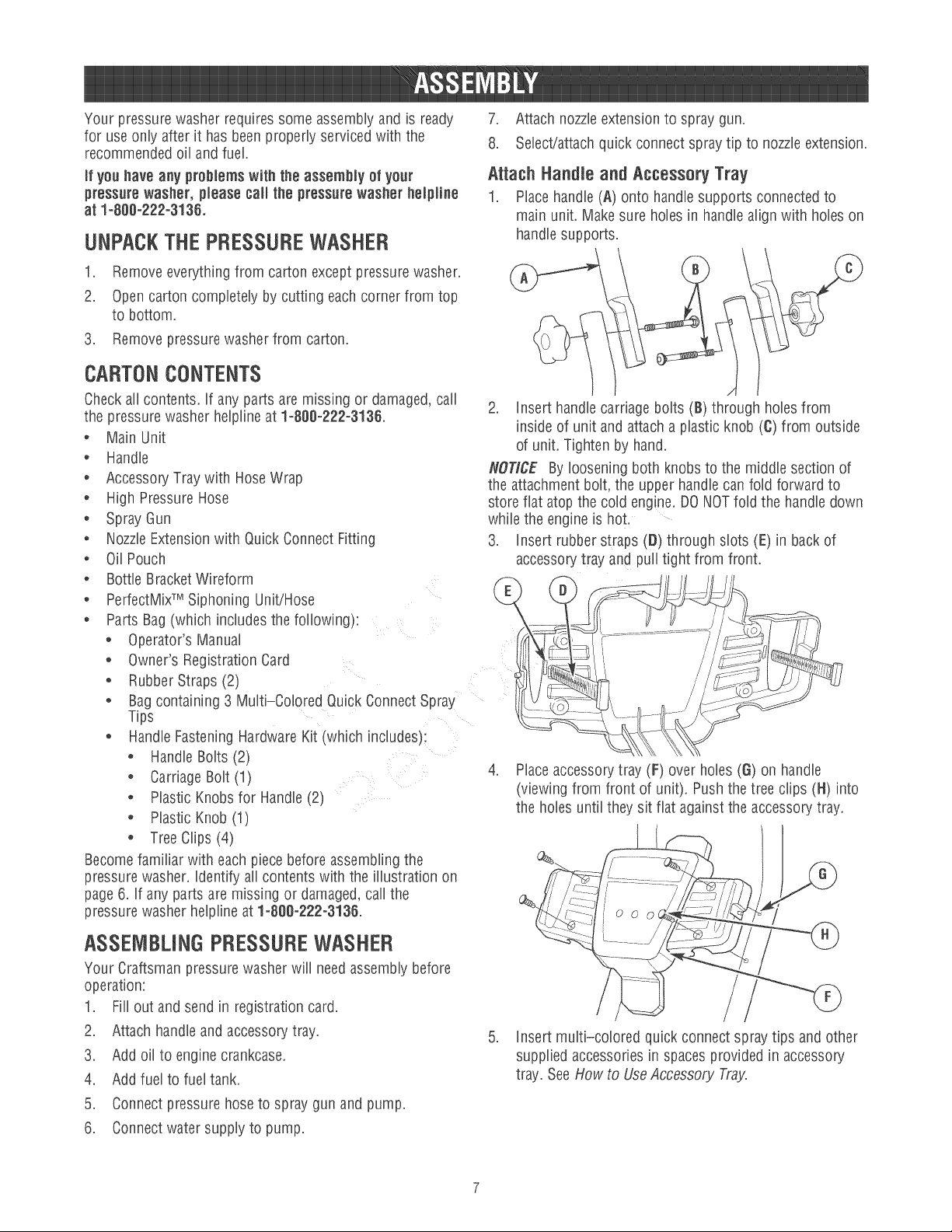

Yourpressurewasherrequiressomeassemblyandisready

foruseonlyafterithasbeenproperlyservicedwiththe

recommendedoilandfuek

_fyouhave any problemswith the assembly of yeur

pressurewasher, pJeasecaJJth8 pressurewasher heJpJiNe

at 1-800-222-3136.

UNPACKTHEPRESSUREWASHER

1. Removeeverythingfrom carton except pressurewasher.

2. Opencarton completely by cutting each corner from top

to bottom.

3. Removepressure washer from carton.

CARTON CONTENTS

Checkall contents, if any parts are missing or damaged,call

the pressure washer helplineat 1o800o222o3136.

* Main Unit

* Handle

* AccessoryTray with HoseWrap

* High PressureHose

* SprayGun

* NozzleExtensionwith Quick ConnectFitting

* Oil Pouch

* Bottle BracketWireform

* PerfectMixTM Siphoning Unit/Hose

* Parts Bag(which includes the following/:

* Operator'sManual

* Owner's Registration Card

* RubberStraps (2)

* Bagcontaining 3 Multi-Colored Quick Connect Spray

Tips

* HandleFasteningHardware Kit twhich includes}:

* HandleBolts (2)

° CarriageBolt (1)

, Plastic Knobsfor Handle(21

, Plastic Knob (1)

, TreeClips (4)

Becomefamiliar with eachpiece beforeassemblingthe

pressure washer, identify all contents with the illustration on

page 6. if any parts are missing or damaged, callthe

pressure washer helpline at1o800o222o3136

7. Attach nozzleextension to spray gun.

8. Select/attach quick connect spraytip to nozzleextension.

Attach Handteand Accessory Tray

1. Placehandle(A) onto handle supports connectedto

main uniL Make sure holes in handlealign with hobs on

handlesupports.

2. insert handle carriage bolts (B) through hobs from

inside of unit and attach a plastic knob (C)from outside

of uniL Tighten by hand.

NOTICE Byloosening both knobs to the middle section of

the attachmentbolt. the upperhandle canfold forward to

store fiat atop the cold engine.DONOTfold the handle down

while the engine is hot.

3. insert rubber straps (D) through slots (E) in backof

accessorytray and pull tight from fronL

4. Placeaccessorytray (F) over hobs (G) on handle

(viewing from front of unit). Pushthe tree clips (H) into

the hobs until they sit fiat against the accessory tray.

ASSEMBLINGPRESSUREWASHER

Your Craftsman pressure washer will needassembly before

operation:

1. Fill out and sendin registration card.

2. Attach handle andaccessorytray.

3. Add oil to engine crankcase.

4. Add fuel to fuel tank.

5. Connectpressure hose to spray gun and pump.

6. Connectwater supplyto pump.

5. insert multi-colored quick connect spray tips and other

supplied accessoriesin spaces provided in accessory

tray. SeeHow to UseAccessory Tray,

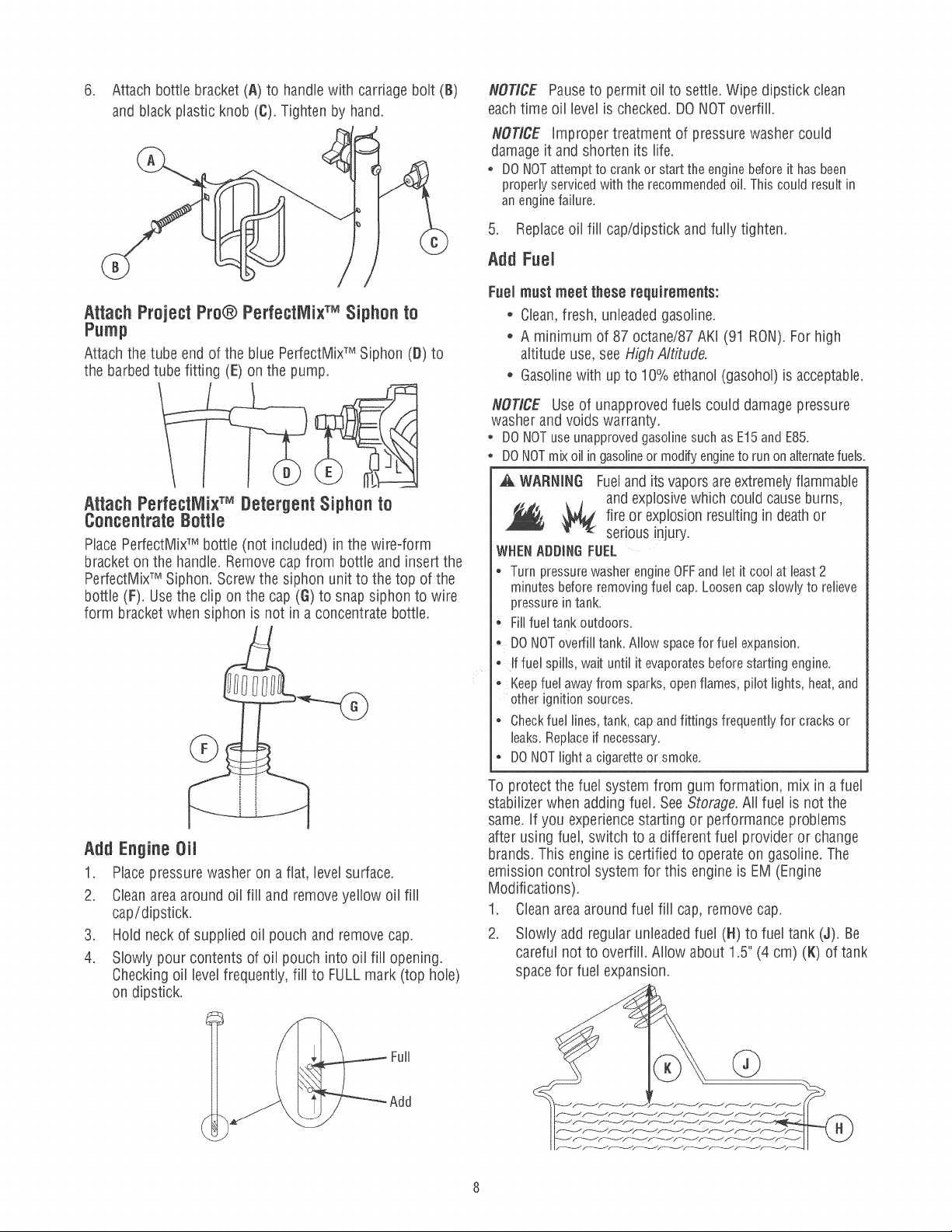

6. Attach bottle bracket(A) to handlewith carriage bolt (B)

and black plastic knob (C). Tighten by hand.

NOTICE Pauseto permit oil to settle. Wipe dipstick clean

eachtime oil level is checked. DONOToverfill.

NOTICE improper treatment of pressure washer could

damage it and shorten its life.

, DONOT attemptto crank or startthe engine before it has been

properly serviced with the recommended oil. This could result in

an engine failure.

5. Replaceoil fill cap/dipstick and fully tighten.

@

Attach Project Pro@ PerfectMix TM Siphon to

Attachthe tube end of the blue PerfectMixTM Siphon (t}) to

the barbedtube fitting (E) on the pump.

Attach PerfectNix TM Detergent Siphon to

Concentrategettie

PlacePerfectMixTM bottle (not included) in the wire-form

bracket on the handle.Removecapfrom bottle and insert the

PerfectMixTM Siphon.Screw the siphon unit to the top of the

bottle (F). Usethe clip on the cap (G)to snapsiphon to wire

form bracketwhen siphon is not in a concentrate bottle.

Add Fuel

Fuel must meet these requirements:

* Clean,fresh, unleadedgasoline.

* A minimum of 87 octane/87AKI (91 RON).For high

altitude use, see HighAltitude.

° Gasolinewith upto 10% ethanol (gas@@ is acceptable.

NOTICE Use of unapproved fuels could damage pressure

washer and voids warranty.

DONOTuse unapprovedgasoline such as E15and E85.

DONOTmix oil in gasolineor modify engineto run onalternatefuels.

,a, WARNING Fuel and its vapors are extremely flammable

and explosive which could cause burns,

fire or explosion resulting in death or

serious injury.

WHENADDING FUEL

Turn pressurewasher engineOFFand let it cool at least 2

minutes before removingfuel cap. Loosen cap slowly to relieve

pressure in tank.

Fiii fuel tank outdoors.

* DONOT overfill tank. Allow spacefor fuel expansion.

oif fuel spills, wait until it evaporatesbefore starting engine.

Keepfuel awayfrom sparks, open flames, pilot lights, heat, and

other ignition sources.

Checkfuel lines,tank, cap and fittings frequently for cracks or

leaks. Replaceif necessary.

DONOTlight a cigarette or smoke.

Add Engine 0it

1. Placepressure washer on a fiat, levelsurface.

2. Cleanarea around oil fill and remove yellow oil fill

cap/dipstick.

3. Hold neck of supplied oil pouch and removecap.

4. Slowly pour contents of oil pouch into oil fill opening.

Checkingoil level frequently, fill to FULLmark (top hob)

on dipstick.

I Full

To protectthe fuel system from gum formation, mix in a fuel

stabilizerwhen adding fuel. See Storage.All fuel is not the

same.if you experiencestarting or performance problems

after using fuel, switch to a different fuel provider or change

brands. This engine is certified to operate on gasoline. The

emission control system for this engine is EM(Engine

Modifications).

1. Cleanareaaround fuel fill cap, removecap.

2. Slowly add regular unleadedfuel (H) to fuel tank (S).Be

careful not to overfill. Allow about 1.5" (4 cm) (K) of tank

space for fuel expansion.

3. Installfuelcapandletanyspilledfuelevaporatebefore

startingengine.

CAUTION! Alcohol-blended fuels (called gasohol, ethanol or

methanol) can attract moisture, which leadsto separationand

formation of acids during storage.Acidic gas can damagethe

fuel system of an enginewhile in storage.

To avoidengine problems, the fuel system should betreated

with a fuel preserver or emptied before storage of 30 days or

longer, if adding a fuel preserver,fill the fuel tank with fresh

fuel. if only partially filled, air in the tank will promote fuel

deterioration during storage, if fuel preserver is not used,

drain the fuel tank, start the engine and let it run until the fuel

lines and carburetor are empty, Usefresh fuel next season.

See Storagefor additional information.

NEVERuseengine or carburetor cleanerproducts inthe fuel

tank as permanent damagemay occur.

At altitudes over 5,000 feet (1524 meters), a minimum

85 octane/ 85 AKI (89 RON)gasoline is acceptable.To

remain emissions compliant, high altitude adjustment is

required. Operationwithout this adjustment will cause

decreasedperformance, increasedfuel consumption, and

increased emissions. Seea qualified Searsdealer for high

altitude adjustment information. Operationof the engineat

altitudes below 2,500 feet (762 meters) with the high altitude

kit is not recommended.

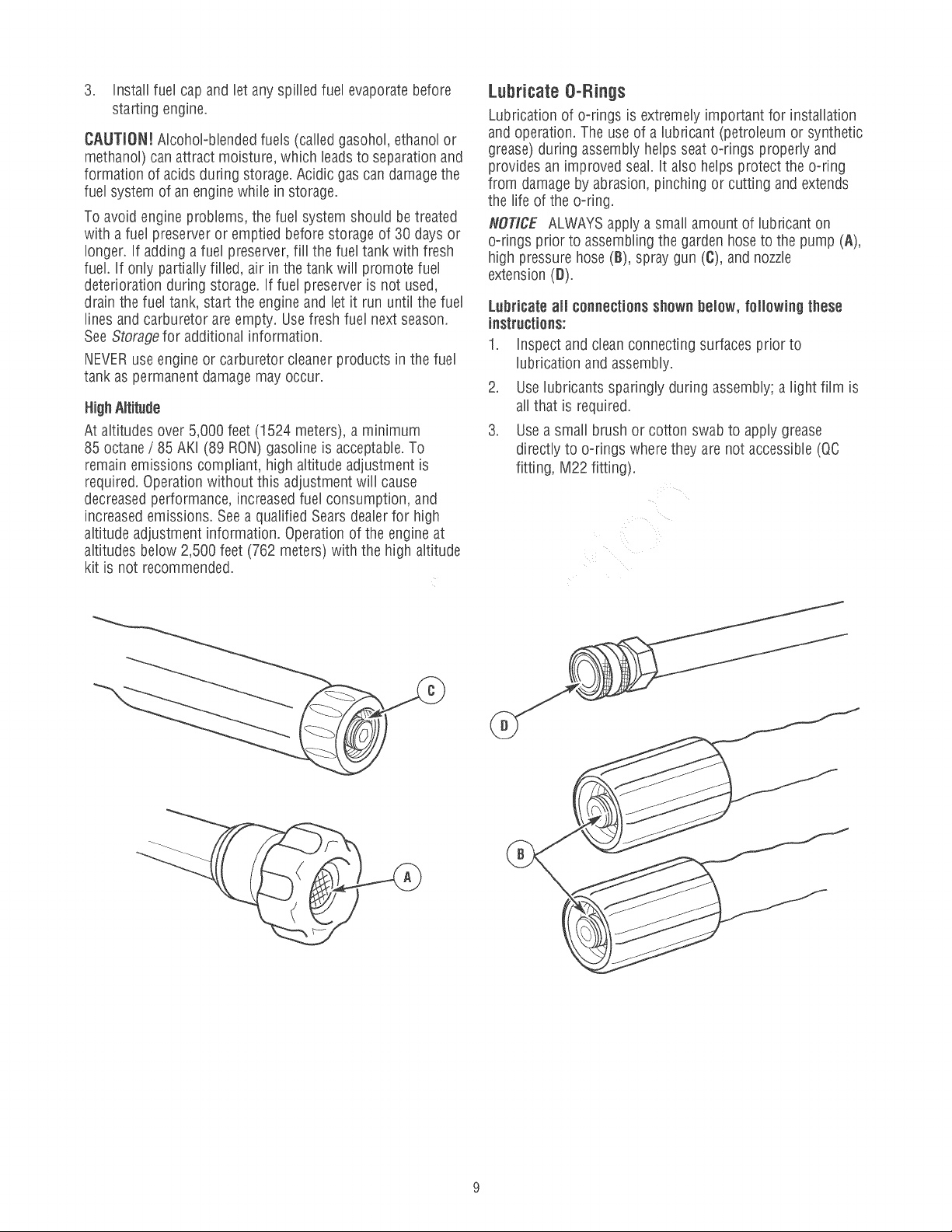

Lubricate OoRings

Lubrication of o-rings is extremely important for installation

and operation_The useof a lubricant (petroleum or synthetic

grease)during assembly helps seat o-rings properly and

provides an improved seal. it alsohelps protect the o-ring

from damageby abrasion, pinching or cutting and extends

the life of the o-ring_

HOT/CE ALWAYSapply a small amount of lubricant on

o-rings prior to assemblingthe garden hoseto the pump (A),

high pressurehose (B),spray gun (C), and nozzle

extension(t}).

Lubricateaii cenne¢_iensshewn beiew, feiiewing _hese

instruc_iens:

1. inspect and clean connecting surfaces prior to

lubrication and assembly.

2_ Uselubricants sparingly during assembly;a light film is

all that is required.

3. Usea small brush or cotton swab to applygrease

directly to o-rings wherethey are not accessible (QC

fitting, M22 fitting)_

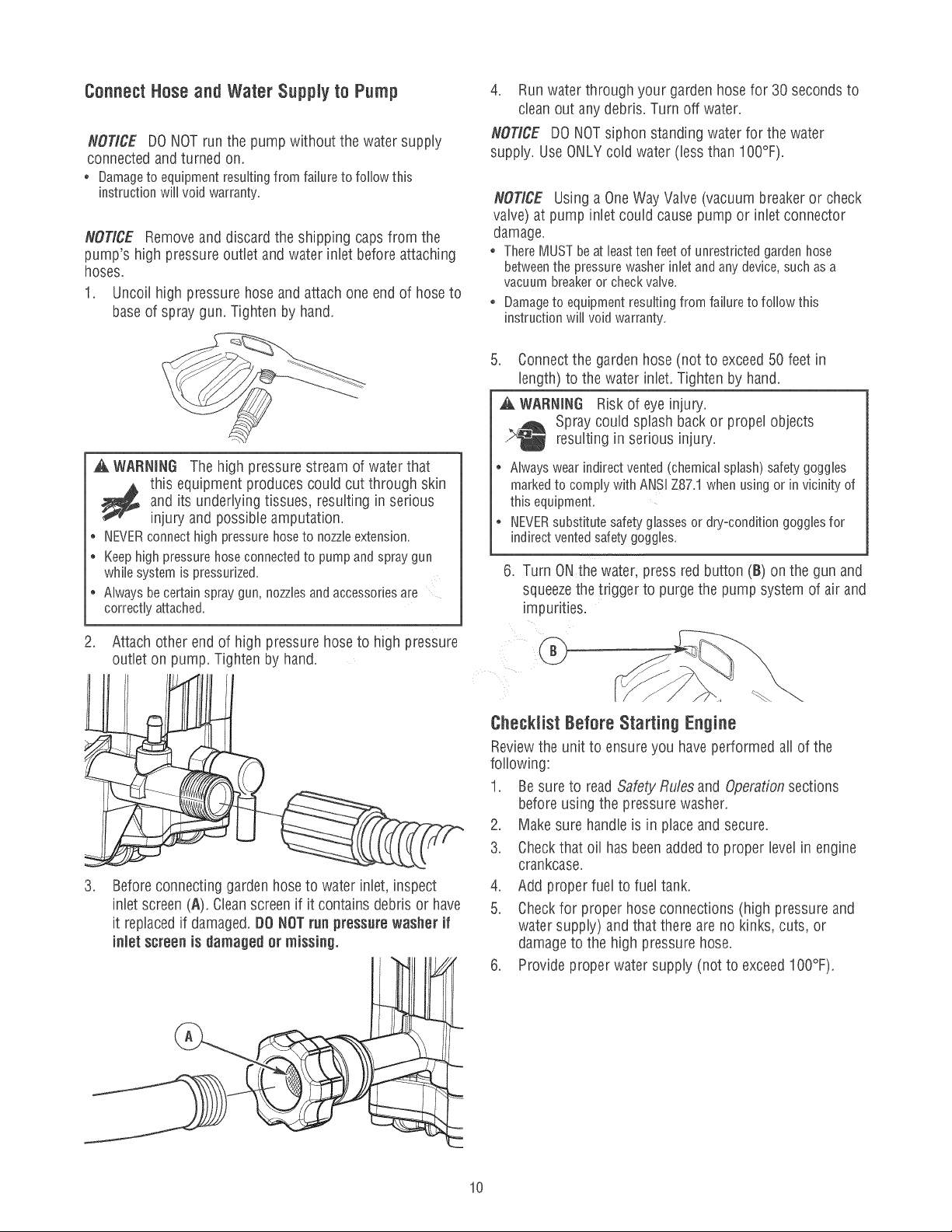

Connect Hose and Water Supply to Pump

NOTICE DONOTrun the pump without the water supply

connectedand turned on.

, Damagetoequipmentresultingfrom failuretofollowthis

instructionwill voidwarranty.

NOTICE Removeand discardthe shipping caps from the

pump's high pressure outlet and water inlet before attaching

hoses.

1. Uncoil high pressure hose and attachone end of hoseto

baseof spray gun. Tighten by hand.

4. Run water through your garden hosefor 30 seconds to

cleanout anydebris. Turn off water.

NOTICE DONOTsiphon standing water for the water

supply. UseONLY cold water (less than 100%).

NOTICE Using a OneWayValve (vacuum breakeror check

valve) at pump inlet could cause pump or inlet connector

damage.

ThereMUSTbeatleasttenfeetof unrestrictedgardenhose

betweenthe pressurewasherinletandanydevice,suchasa

vacuumbreakeror checkvalve.

* Damageto equipment resulting from failure to follow this

instruction will void warranty.

5. Connectthe garden hose (not to exceed50 feet in

length) to the water inlet. Tighten by hand.

A WARNING Risk of eyeinjury.

Spray could splash backor propel objects

resulting in serious injury.

WARNING The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

* NEVERconnect high pressure hose to nozzleextension.

* Keep high pressure hose connected to pump and spray gun

while system is pressurized.

* Always be certain spray gun, nozzlesand accessoriesare

correctly attached.

.

Attach other end of high pressure hose to high pressure

outlet on pump. Tighten by hand.

.

Beforeconnectinggarden hoseto water inlet, inspect

inlet screen (A). Cleanscreen if it contains debris or have

it replacedif damaged.DO NOTrun pressurewasher if

inlet screen isdamaged or missing.

* Always wear indirect vented (chemical splash) safety goggles

markedto comply with ANSUZ87.1 when using or in vicinity of

this equipment......

* NEVERsubstitute safety glasses or dry-condition goggles for

indirect vented safety goggles.

6. Turn ONthe water, press red button (B) on the gun and

squeezethetrigger to purgethe pump system of air and

impurities.

Checklist Before Starting Engine

Reviewthe unit to ensureyou haveperformed all of the

following:

1. Be sure to readSafety Ru/esand Operationsections

before using the pressure washer.

2. Make sure handle is in place and secure.

3. Checkthat oil has been addedto proper level in engine

crankcase.

4. Add proper fuel to fuel tank.

5. Checkfor proper hose connections (high pressure and

water supply) andthat there are no kinks, cuts, or

damageto the high pressure hose.

6. Provide proper water supply (not to exceed100%).

10

ifyouhaveanyproblemsoperatingyourpressurewasher,

pleasecallthepressurewasherhelplineat1-888-222-3136.

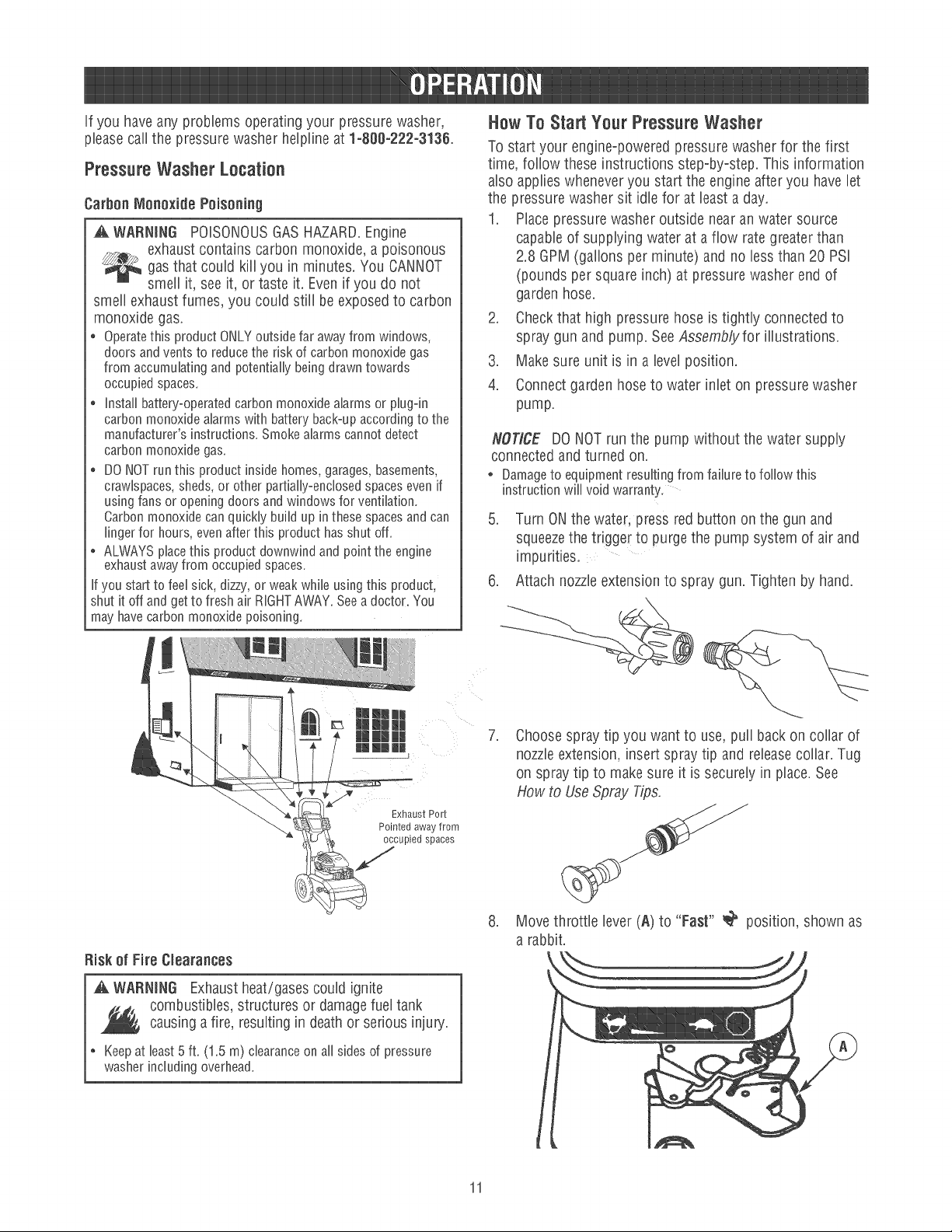

Pressure Washer Location

Carben IVlenexidePeisening

WARNING POISONOUS GAS HAZARD. Engine

exhaust contains carbon monoxide, a poisonous

gas that could kill you in minutes. You CANNOT

smell it, see it, or taste it. Even if you do not

smell exhaust fumes, you could still be exposed to carbon

monoxide gas.

, Operatethis product ONLYoutside far awayfrom windows,

doors and vents to reducethe risk of carbon monoxide gas

from accumulating and potentially being drawn towards

occupied spaces.

Install battery-operatedcarbon monoxide alarms or plugqn

carbon monoxide alarms with battery back-up according to the

manufacturer's instructions. Smoke alarms cannot detect

carbon monoxide gas.

DO NOTrun this product inside homes, garages,basements,

crawlspaces, sheds, or other partially-enclosedspaces even if

using fans or openingdoors and windows for ventilation.

Carbon monoxide canquickly build up in these spacesand can

linger for hours, evenafter this product has shut off.

ALVVAYSplacethis product downwind and point the engine

exhaustawayfrom occupied spaces.

if you start to feel sick, dizzy,or weak while using this product,

shut it off and getto fresh air RIGHTAWAY. See a doctor. You

may havecarbon monoxide poisoning.

How To Start Your Pressure Washer

To start your engine-powered pressurewasher for the first

time, follow these instructions step-by-step. This information

alsoapplies wheneveryou start the engine after you have let

the pressure washer sit idle for at bast a day.

1. Placepressurewasher outside nearan water source

capableof supplying water at a flow rate greaterthan

2,8 GPM(gallons per minute) and no less than 20 PSi

(pounds per squareinch) at pressure washerend of

garden hose.

2, Checkthat high pressure hose is tightly connected to

spray gun and pump. SeeAssembly for illustrations.

& Makesure unit is in a levelposition,

4. Connectgarden hoseto water inlet on pressurewasher

pump.

NOTICE DONOTrun the pump without the water supply

connectedand turned on.

Damageto equipmentresultingfromfailureto followthis

instructionwill voidwarranty.

.

Turn ONthe watec press red button on the gun and

squeezethe trigger to purge the pump system of air and

impurities.

.

Attach nozzleextensionto spray gun. Tighten by han&

./v

Exhaust Port

Pointed away from

occupied spaces

Risk ef Fire Clearances

A WARNING Exhaustheat/gasescould ignite

combustibles, structures or damagefueltank

causing afire, resultingin deathor seriousinjury.

* Keepat least5 ft. (1.5 m) clearanceon all sides of pressure

washer including overhead.

7. Choose spraytip you want to use, pull back on collar of

nozzleextension, insert spray tip and releasecollar_Tug

on spray tip to make sure it is securely in place.See

How to Use Spray Tips.

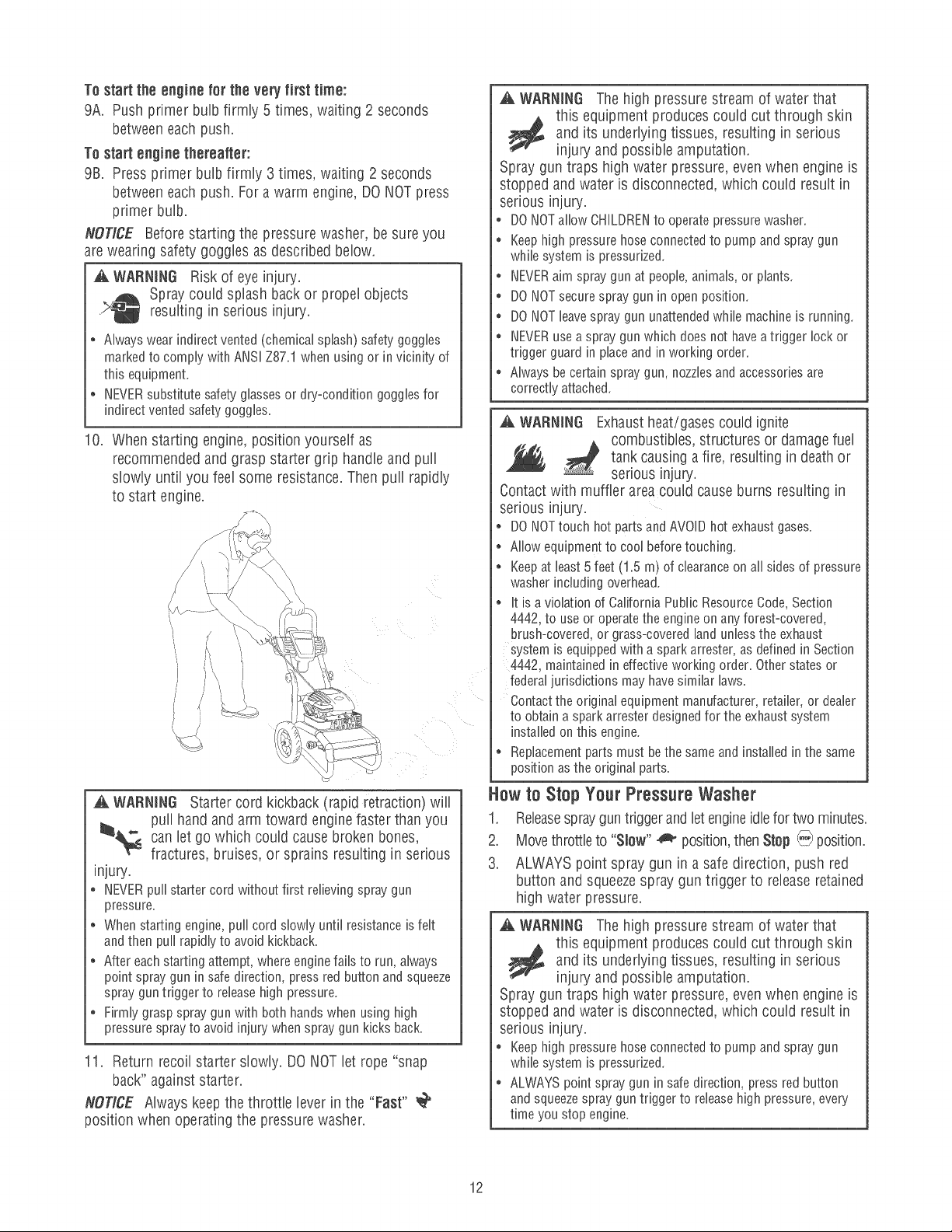

8. Movethrottle lever (A) to "Fast" _ position, shown as

a rabbit.

11

Testart the engine fer the very first time:

9£ Push primer bulb firmly 5 times, waiting 2 seconds

between each push.

Testart engine thereafter:

9B. Press primer bulb firmly 3 times, waiting 2 seconds

between each push. Fora warm engine, DONOTpress

primer bulb.

NOTICE Beforestarting the pressure washer, be sureyou

are wearing safety goggbs asdescribed below.

WARNING Riskof eye injury.

Spraycould splash back or propel objects

resulting in serious injury.

o Always wear indirect vented (chembaI spbsh) safety goggles

markedto comply with ANSI Z87.1 when using or in vicinity of

this equipment.

NEVERsubstitute safetygbsses or dry-condition goggles for

indirect vented safety goggles.

0. Whenstarting engine, position yourself as

recommendedand grasp starter grip handle and pull

slowly until you feel some resistance.Then pull rapidly

to start engine.

,a, WARNING The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

Spray gun traps high water pressure, even when engine is

stopped and water is disconnected, which could result in

serious injury.

DONOTallow CHILDRENto operatepressure washer.

Keephigh pressure hoseconnected to pump and spray gun

while system is pressurized.

NEVERaim spraygun at people,animals, or plants.

DO NOTsecure spray gun in open position.

DO NOTleavespray gun unattendedwhile machine is running.

NEVERuseaspray gun which does not have a trigger lock or

trigger guard in placeand in working order.

Alwaysbe certain spray gun, nozzlesand accessoriesare

correctly attached.

,a, WARNING Exhaust heat/gases could ignite

combustibles, structures or damage fuel

tank causing a fire, resulting in death or

serious injury.

Contact with muffler area could cause burns resulting in

serious injury.

o DO NOTtouch hot parts and AVOIDhot exhaust gases.

Allow equipment to cool beforetouching.

Keepat least5 feet (1.5 m) of clearanceon all sides of pressure

washer including overhead.

I1isa violation of California PuNic ResourceCode, Section

4442. to use or operate the engine on any forest-covered,

brush-covered, or grass-covered land unlessthe exhaust

system is equippedwith a spark arrester,as defined in Section

4442. maintained in effective working order. Otherstates or

federaljurisdictions may havesimilar laws.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain a sparkarrester designedfor the exhaustsystem

installed onthis engine.

Replacementparts must bethe same and installed in the same

position asthe original parts.

A WARNING Starter cord kickback (rapid retractiom will

pull hand and arm toward engine faster than you

I_a_< can let go which could cause broken bones,

fractures, bruises, or sprains resulting in serious

injury.

NEVERpull starter cord without first relieving spraygun

pressure,

o When starting engine, pull cord slowly until resistanceisfelt

andthen pull rapidly to avoid kickback.

After eachstarting attempt, where enginefails to run, always

point spray gun in safe direction, pressred button and squeeze

spray guntrigger to releasehigh pressure.

o Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks back.

1. Return recoil starter slowly. DONOTlet rope "snap

back" against starter.

NOTICE Always keepthe throttle leverin the "Fast" @

position when operating the pressurewasher.

New te Step Yeur Pressure Washer

1. Releasesprayguntriggerandlet engineidlefor two minutes.

2. Move throttle to "Slew" 4_- position, then Step (3 position.

3. ALWAYS point spray gun in a safe direction, push red

button and squeeze spray gun trigger to release retained

high water pressure.

A WARNING The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

Spray gun traps high water pressure,evenwhen engine is

stopped and water is disconnected, which could result in

serious injury.

Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

12

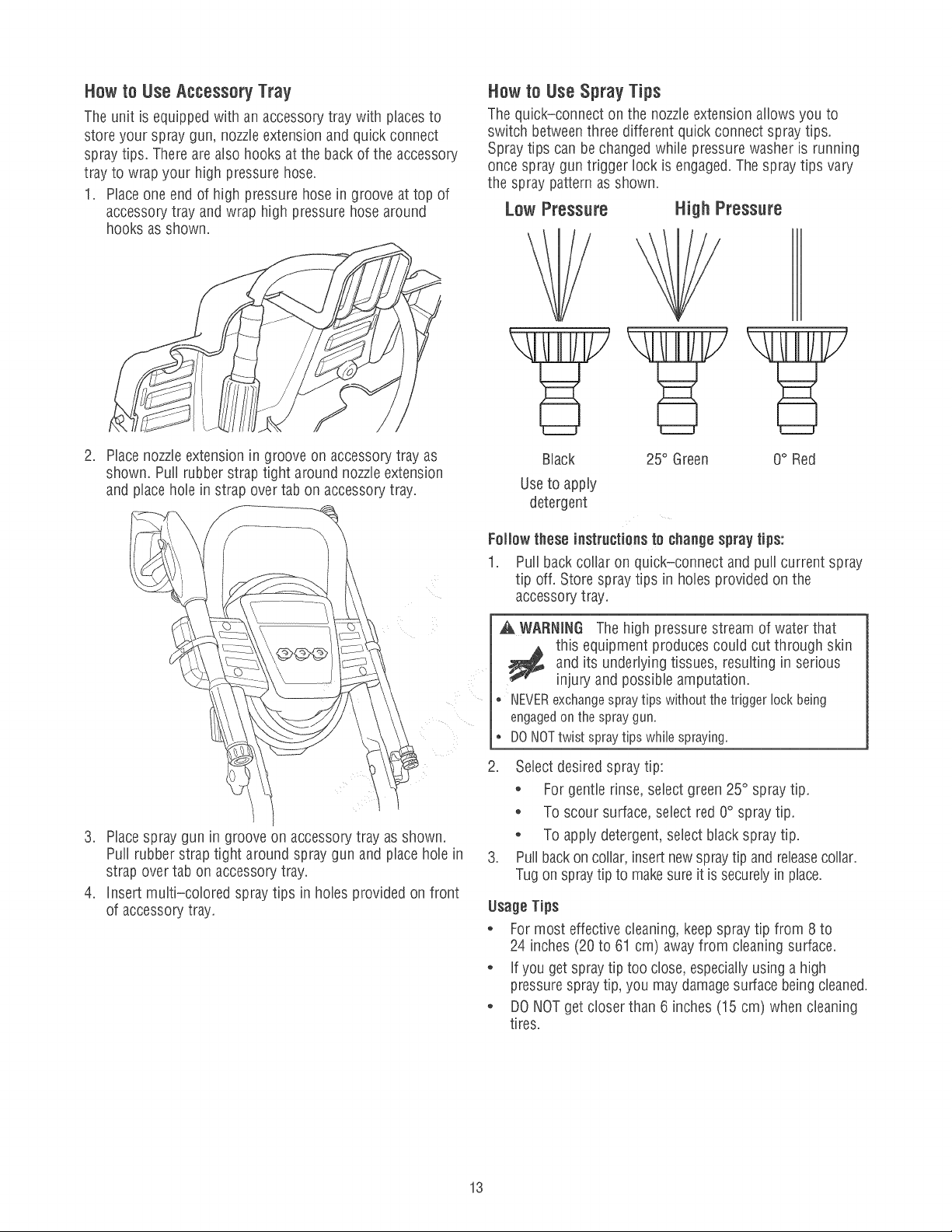

Haw to Use Accessory Tray

The unit is equipped with an accessorytray with placesto

store your spray gun, nozzleextension and quick connect

spray tips. Thereare also hooks at the backof the accessory

tray to wrap your high pressure hose.

1. Placeoneend of high pressure hose in groove at top of

accessorytray and wrap high pressure hosearound

hooks as shown.

.

Placenozzleextension in groove on accessory tray as

shown. Pull rubber straptight around nozzleextension

and place hole in strap overtab on accessorytray.

A

/ \

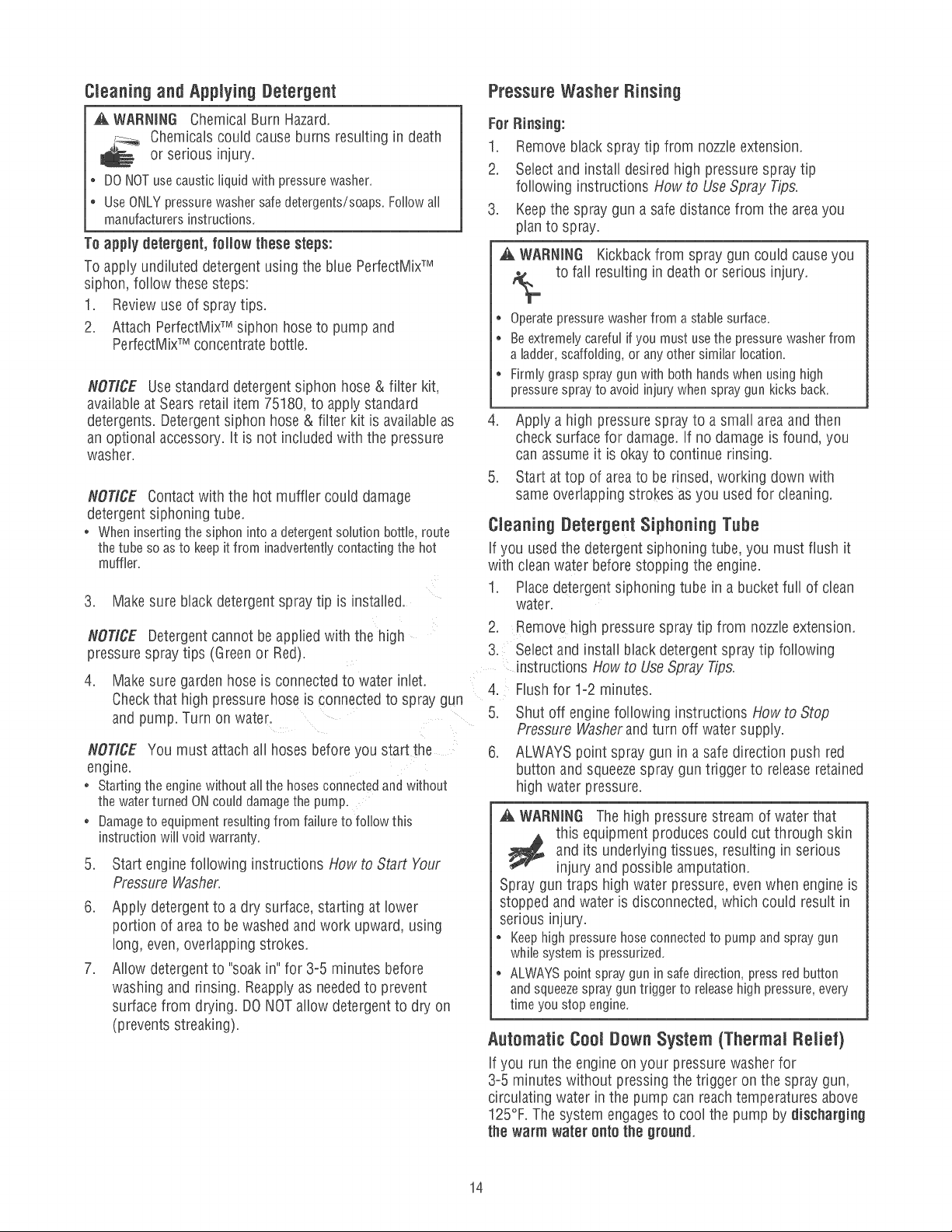

Haw to Use Spray Tips

The quick-connect on the nozzleextensionallows you to

switch betweenthree different quickconnect spray tips.

Spray tips can be changed while pressurewasher is running

once spray gun trigger lock is engaged.Thespray tips vary

the spray pattern as shown.

Law Pressure

Black 25° Green 0° Red

Useto apply

detergent

Fallew these instructienste change spray tips:

1. Pull back collar on quick-connect and pull current spray

tip off. Store spray tips in holes provided on the

accessorytray.

High Pressure

3. Placespraygun in groove on accessorytray asshown.

Pull rubber strap tight around spray gun and place hole in

strap over tab on accessorytray.

4. insert multi-colored spray tips in hobs provided on front

of accessorytray.

,A WARNING The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

o NEVERexchangespraytipswithoutthetriggerlockbeing

engagedonthe spraygun.

o

DONOTtwistspraytips whilespraying.

2.

Select desired spray tip:

* Forgentle rinse, select green 25° spray tip.

. To scour surface, select red 0° spray tip.

. To apply detergent, selectblack spraytip.

.

Pullbackon collar, insert newspraytip andreleasecollar.

Tugon spraytip to makesure it issecurelyin place.

UsageTips

* Formost effective cleaning, keep spray tip from 8 to

24 inches (20 to 61 cm) away from cleaning surface.

* if you getspraytip too close, especiallyusing a high

pressurespraytip, you maydamagesurface beingcleaned.

* DONOTget closerthan 6 inches (15 cm) when cleaning

tires.

13

CleaningandApplying Detergent

WARNING ChemicalBurn Hazard.

Chemicals could cause burns resulting in death

or serious injury.

* DO NOTuse caustic liquid with pressure washer.

* Use ONLYpressurewasher safe detergents/soaps. Follow aiI

manufacturers instructions.

Toapply detergent, follow these steps:

To apply undiluted detergent using the blue PerfectMWM

siphon, follow these steps:

1. Reviewuse of spray tips.

2. Attach PerfectMWMsiphon hose to pump and

PerfectMixTM concentrate bottle.

NOTICE Use standarddetergent siphon hose & filter kit,

availableatSears retail item 75180,to apply standard

detergents. Detergent siphon hose& filter kit is available as

an optional accessory, it is not included with the pressure

washer.

NOTICE Contactwith the hot muffler could damage

detergent siphoning tube.

, Wheninsertingthesiphon ntoadetergentsolutionbottle,route

thetubesoasto keepitfrom inadvertentlycontactingthe hot

muffler.

3. Make sure black detergent spray tip is installed.

NOTICE Detergentcannot beapplied with the high

pressure spray tips (Greenor Red_.

4. Make sure garden hose is connectedto water inlet.

Checkthat high pressure hoseis connectedto spray gun

and pump. Turn on water.

NOTICE You must attach all hoses before you start the

engine.

, Starting the engine without all the hoses connected and without

the water turned ON could damagethe pump.

* Damageto equipment resulting from failure to foUlowthis

instruction will void warranty.

.

Start enginefollowing instructions How to Start Your

Pressure Washer.

6.

Apply detergentto a dry surface, starting at lower

portion of areato be washedand work upward, using

long, even,overlapping strokes.

.

Allow detergent to "soak in" for 3-5 minutes before

washing and rinsing. Reapplyas neededto prevent

surfacefrom drying. DONOTallow detergentto dry on

(prevents streaking).

Pressure Washer Rinsing

For Rinsing:

1. Removeblack spray tip from nozzleextension.

2. Select and install desiredhigh pressure spraytip

following instructions How to UseSpray Tips.

3. Keepthe spraygun a safedistancefrom the areayou

planto spray.

A WARNING Kickbackfrom spray gun could causeyou

to fall resulting in deathor serious injury.

,, Operate pressurewasher from a stable surface.

,, Be extremely careful if you must use the pressurewasher from

a ladder,scaffolding, or anyother similar location.

* Firmly grasp spray gun with both handswhen using high

pressure spray to avoid injury when spray gun kicks back.

4. Apply a high pressure spray to a small areaand then

check surfacefor damage, if no damageis found, you

can assume it is okayto continue rinsing.

5. Start at top of areato be rinsed, working down with

same overlapping strokes as you usedfor cleaning.

Cleaning Detergent $iphening Tube

If you usedthe detergentsiphoning tube, you must flush it

with cleanwater beforestopping the engine.

1. Placedetergent siphoning tube in a bucket full of clean

water.

2. Removehigh pressure spray tip from nozzleextension.

3. Select andinstall black detergentspraytip following

instructions How to UseSpray Tips.

4. Flushfor 1-2 minutes.

5, Shut off engine following instructions How to Stop

Pressure Washerand turn off water supply.

6. ALWAYSpoint spray gun in a safe direction push red

button and squeezespray gun trigger to release retained

high water pressure.

A WARNING The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

Spray gun traps high water pressure,evenwhen engine is

stopped and water is disconnected, which could result in

serious injury.

, Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

* ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

Autematic Cool Down System (Thermal Relief}

if you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray gun,

circulating water in the pump can reachtemperatures above

125%. The systemengagesto cool the pump by discharging

the warm water ante the ground.

14

ENGINETECHNICALiNFORMATiON

This is a single cylinder, L-head,air cooled Model 100000

engine.The EmissionControl System for this pressure

washer is warranted for standards set by the Environmental

Protection Agency and the California Air Resources Board.

Certification does not grant the purchaser,owner or operator

of this engine any additional warranties with respectto the

performance or operational life of this engine.Theengine is

warranted solely according to the product and emissions

warranties stated elsewherein this manuak

Power Ratings

Thegross power rating for individual gas engine models is

labeled in accordancewith SAE(Society of Automotive

Engineers)codeJ1940 (Small Engine Power & Torque

Rating Procedure), and rating performance has been

obtained and corrected in accordancewith SAEJ1995

(Revision 2002°05). Torque values are derived at 3060 RPM;

horsepower values are derived at 3600 RPM.Thegross

power curves can beviewed at

www.BRIGGSandSTRATTON.COM.Net power values are

taken with exhaust and air cleanerinstalled whereas gross

power values are collectedwithout these attachments. Actual

gross engine power will behigher than net engine power and

is affected by, among other things, ambient operating

conditions and engine-to-enginevariability. Given the wide

array of products on which enginesare placed,the gas

engine may not developthe ratedgross power when used in

a given piece of power equipment. This difference is due to a

variety of factors including, but not limited to. the variety of

engine components (air cleaner, exhaust, charging, cooling,

carburetor, fuel pump, etc.), application imitations, ambient

operating conditions (temperature, humidity, altitude}, and

engine-to-enginevariability. Dueto manufacturing and

capacity limitations, Briggs & Stratton maysubstitute an

engine of higher rated power for this Seriesengine.

PRODUCTSPECiFiCATiONS

Pressure Washer Specifications

Outlet Pressure .......................... 2,200 PSi*

Flow Rate................................. 1.8 GPM

DetergentMix ........................ Use as directed

Water Supply Temperature .......... Not to exceed100%

Engine Specifications

Bore ............................. 2.562in. (65.08mm)

Stroke ............................ 1.875in. (47.65mm)

Displacement ......................... 9.67 in. (158cc)

SparkPlug

Type:............... Briggs & Stratton 802592 or 5095

SetGapTo: ...................... O.030inch(0.76mm)

ArmatureAir Gap:........... 0.006-0.010in.(O.15-O25mm)

Valveclearancewithvalvesprings installedandpiston 1/'4in.

(6 mm) pasttop deadcenter(checkwhenengineiscold).

Intake.................... 0.005-0.007in.(0.13-0.18mm)

Exhaust .................. 0.007-0.009in.(0.18-0.23mm)

FuelCapacity............................... 1.0Quarts

OilCapacity...................... 18 Ounces(0.53 liter)

NOTICE Forpractical operation, the engine load should not

exceed85% of rated power. Enginepower will decrease

3-1/2% for each1,000 feet _300meters) above sealeveland

1% for each 10° F (5.6° C) above77° F(25° C). it should

operatesatisfactorily at an angle up to 15°,

This pressure washer is ratedin accordanceto the

PressureWasher ManufacturersAssociation (PWMA)

standard PW101-2010 _Testingand Rating Performance of

PressureWashersl.

15

OWNER'SRESPONSiBiLiTiES

Foiiow the houriy or caiendarintervais, whichever occurs

first. More frequent serviceis required when operating in

adverseconditions noted below.

o Changeengine oil

o Check/clean water inlet screen1

o Checkhigh pressure hose

o Checkdetergentsiphoning tube

o Checkspray gun and assembly for leaks

o Cleandebris

o Checkengineoil level

Emissions Control

Maintenance, replacement, or repair of the emissions

control devices and systems may be performedby any non-

roadengine repair establishment or individual. However,

to obtain "no charge" emissions control service, the work

must be performed by afactory authorized dealer.Seethe

Emissions Warranty.

Before Each Use

1. CheckengineoiUReveL

2. Cleandebris.

3. Checkwater inlet screen for damage.

4. Check

5. Check

6. Check

7. Purge

high pressure hose for leaks.

detergent siphoning tube for damage.

gun and nozzleextension assemblyfor leaks.

pump of air and contaminants.

PRESSUREWASHERlVlAINTENANCE

o Service engineair cleaner'

o Changeengine off_

o Inspect muffler and sparkarrestor

o Service spark plug

o Cleancooling system_

Clean if clogged. Replace if perforated or torn,

2Service more often under dirty or dusty condmons.

GeneralRecommendations

Regular maintenancewill improve the performance and

extendthe life of the pressure washer.Seeany Searsor

other qualifiedservice dealerfor service.

The pressurewasher warranty doesnot coveritems that

havebeen subjected to operator abuseor negligence.To

receivefull value from the warranty, the operator must

maintain pressurewasher as instructed in this manual

including proper storage as detailedin Storage.

Someadjustments will needto be made periodically to

properly maintain your pressure washer.

All service and adjustments should be made at bast once

eachseason.Follow the requirementsin the Maintenance

Schedulechart above.

NOtiCE Oncea year you should dean or replacethe spark

plug and replacethe air filter. A new spark plug and dean air

filter assure proper fuel-air mixture and help your engine run

better and last longer.

Pump Oil

DONOTattempt any oil maintenance on this pump. The

pump is pro-lubricated and sealedfrom the factory, requiring

no additional maintenancefor the life of the pump.

Clean Debris

Daily or before use, dean accumulated debris from pressure

washer. Keeplinkage,spring and controls dean. Keeparea

around and behind muffler free from any combustible debris.

inspect coding air dots and openings on the pressure

washer. Theseopenings must bekept dean and

unobstructed.

Pressurewasher parts should be kept dean to reduce the

risk of overheating and ignition of accumulated debris.

* Usea damp cloth to wipe exterior surfaces dean.

NOTICE improper treatment of pressurewasher could

damageit and shorten its life.

, DONOTinsertanyobjectsthroughcodingdots.

o Usea soft bristle brush to loosen caked on dirt, oil, etc.

o Usea vacuum cleanerto pick up loose dirt and debris.

Check and Clean hid Screen

Examinegarden hose iniet screen.Ciean if it is dogged or

replaceif it is torn.

Check High Pressure Hose

High pressure hoses candevelop leaksfrom wear, kinking,

or abuse, inspect hose beforeeach use.Check for cuts,

leaks,abrasions, bulging of cover, or damageor movement

of couplings, if any of these conditions exist, replacehose

immediately.

,A WARNING The high pressure stream of water that

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

* NEVERrepairhighpressurehose.Replaceit.

* ReplacementhoseratingMUSTequalorexceedmaximum

pressureratingofunit.

16

Check Detergent Siphoning Tube

Examinedetergent tube and dean if clogge& The tube

should fit tightly on the barbed fitting_Examinethe tube for

leaks or tears. Replacethe tube if damaged.

Detergent Siphening Check BaH

Occasionallycheck ball in detergentsiphoning system may

become stuck from storage, dried soap, or minerals in water.

Thecheck ball can be freed by performing the following:

HOT£E Beforeperforming this procedure, be sure you are

wearing safety goggles asdescribed below.

WARNING Riskof eye injury.

Spraycould splash back or propel objects

resulting in serious injury.

o Always wear indirect vented (chemical splash) safetygoggles

markedto comply with ANSi Z87.1 when using or in vicinity of

this equipment.

NEVERsubstitute safetyglasses or dry-condition goggles for

indirect vented safety goggles.

Check Spray Gan and Nezzie Extension

Examinehoseconnectionto spraygun and makesureit is

secure.Testtrigger bypressingit and makingsureit springs

backinto placewhenyou releaseit.Donotdepressredbutton

andtesttrigger.You shouldnot beableto presstrigger. Replace

spraygun immediatelyif it failsany of thesetests.

Spray Tip Maintenance

A pulsing sensationfelt while squeezingthe spray gun

trigger may becaused by excessivepump pressure.The

principal causeof excessivepump pressure is aspray tip

clogged or restricted with foreign materials, such as dirt, etc.

To correct the problem, immediately cleanthe spray tip

following these instructions:

1. Shut off engine and turn off water supply.

2. ALWAYSpoint spray gun in a safe direction, press red

button and squeezespray gun trigger to releaseretained

high water pressure.

& WARNING The high pressure stream of water that

Shut off engine and turn off water supply.

2_

ALWAYSpoint spray gun in a safe direction, press red

button and squeezespray gun trigger to releaseretained

high water pressure.

A WARNIN6 The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

Spraygun traps high water pressure,evenwhen engine is

stopped and water is disconnected, which could result in

serious injury.

Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

3. Removedetergent siphoning hosefrom barbed fitting

on pump.

4. Using a firm, blunt object 7/64" in diameter or smaller,

by at bast 1" long, such as an Allenwrench, slowly

insert the object into the barbedfitting until you meet

resistance.This resistance isthe check ball.

5. Slowly push down until you fed the ball move slightly,

push no more than 1/8". Slight pressure may be

required to freethe ball.

6. Repeatsteps 4 and 5 if necessary.

7. Reinstall detergent siphoning hose onto barb fitting.

8. Treat with PumpSaveras described in Protecting the

Pump during storage to prevent reoccurrence.

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

Spray gun traps high water pressure,evenwhen engine is

stopped and water is disconnected, which could result in

serious injury.

Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

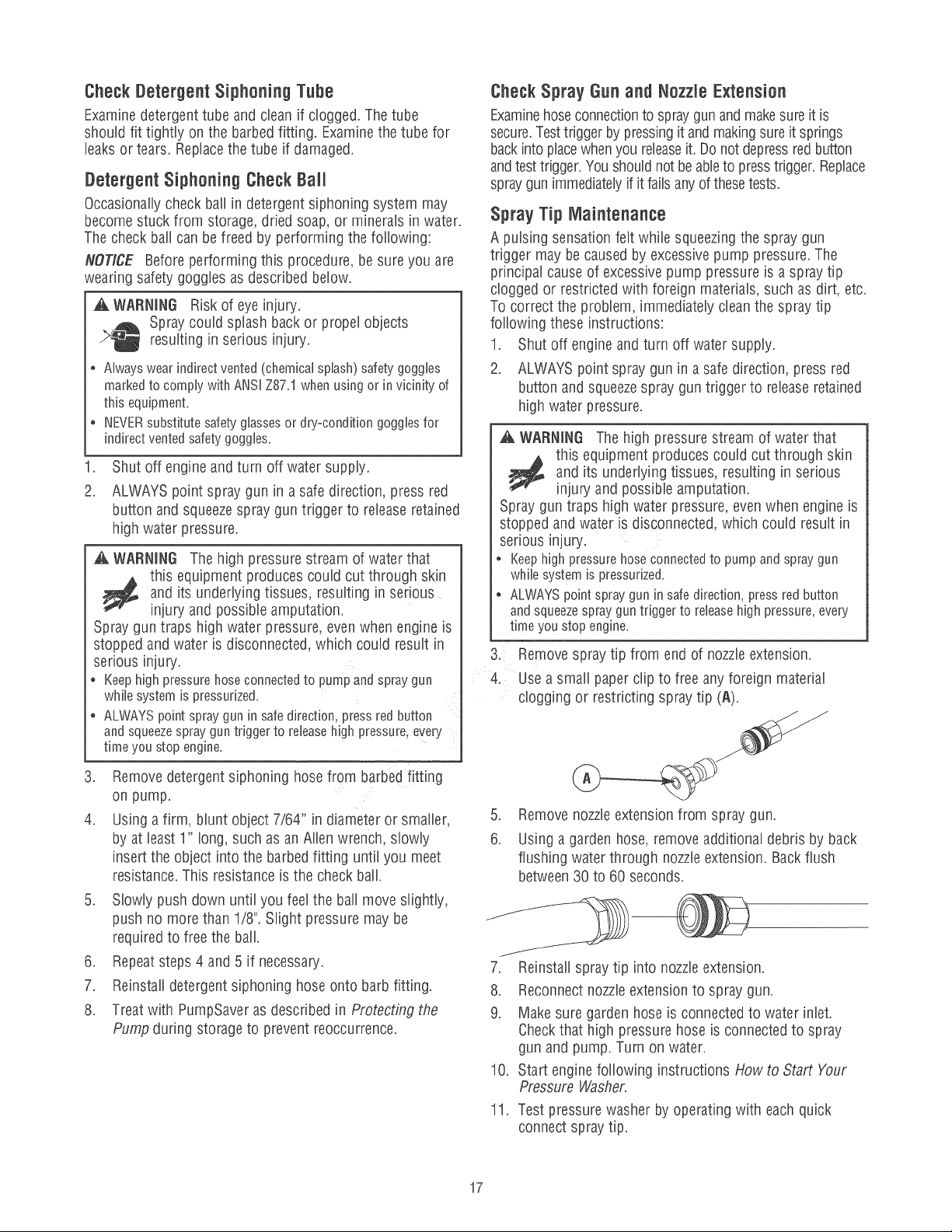

3. Removespray tip from end of nozzleextension.

4. Use a small paper clip to free any foreign material

clogging or restricting spray tip (A).

5. Removenozzleextensionfrom spray gun.

6. Using a garden hose, remove additional debris by back

flushing water through nozzleextension. Backflush

between30 to 60 seconds.

7. Reinstall spray tip into nozzleextension.

8. Reconnect nozzleextensionto spray gun.

9. Make sure garden hose is connectedto water inlet,

Checkthat high pressure hoseis connectedto spray

gun and pump. Turn on water.

10. Start enginefollowing instructions How to Start Your

Pressure Washer.

11. Test pressurewasher by operating with each quick

connect spray tip.

17

Loading...

Loading...