Craftsman 536772330 Owner’s Manual

Operator's Manual

Edger

475 Series Engine

9 Inch Blade

Model 536.772330

CAUTION: Before using this

product, read this manual and

follow all of its Safety Rules and

Operating Instructions.

CRFIFTSMFIN°

Manual del usario

(pagina 41)

Orilladora

475 Motor De la Serie

de 9 pulgada lamina

Modelo 536.772330

PRECAUCION: Antes de usar este

producto, lea este manual y siga todas

las reglas de seguridad e instrucciones

de operaci6n.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

1740548 www, sears,com/craftsman TP899-4491-02-EG-C

Craftsman Edger Warranty ......... 2

Operator Safety ................... 3

Symbols And Warnings ............ 3

Operator Safety Rules ................... 6

Assembly ......................... 8

Parts Packed Separately In Carton ........ 8

Removal From The Carton ............... 8

How To Raise The Handle ................ 9

How To Operate The Edger .............. 15

Edging Tips ............................ 16

Maintenance ...................... 17

Maintenance Chart ..................... 17

Recommended Maintenance ............. 17

How To Remove The Belt ................ 18

HowTo Replace The Blade ............... 19

Engine Maintenance ..................... 20

Storage ................................ 23

Features .......................... 10

Operation ......................... 11

Before Starting The Engine ............... 11

HowTo Start The Engine ................. 13

How To Stop ........................... 14

How To Use The Depth Control Lever ...... 14

ONE YEAR FULL WARRANTY ON CRAFTSMAN EDGER

When assembled, operated and maintained according to all supplied instructions, if this

Craftsman Edger fails due to a defect in material or workmanship within one year from the

date of purchase, return it to any Sears store, Sears Parts & Repair Center, or other Crafts-

man outlet in the United States for free repair (or replacement if repair proves impossible).

This warranty does not include Edger spark plugs, blades or belts, which are expendable

parts that can wear out from normal use in less than one year.

This warranty applies for only 90 days if this Edger is ever used for commercial or rental pur-

poses.

This warranty gives you specific rights, and you may also have other rights which vary from

state to state.

Troubleshooting .................. 24

Product Specifications ............ 25

Power Ratings .......................... 25

Illustrated Parts List ............... 29

Edger ................................. 29

Engine ................................ 32

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

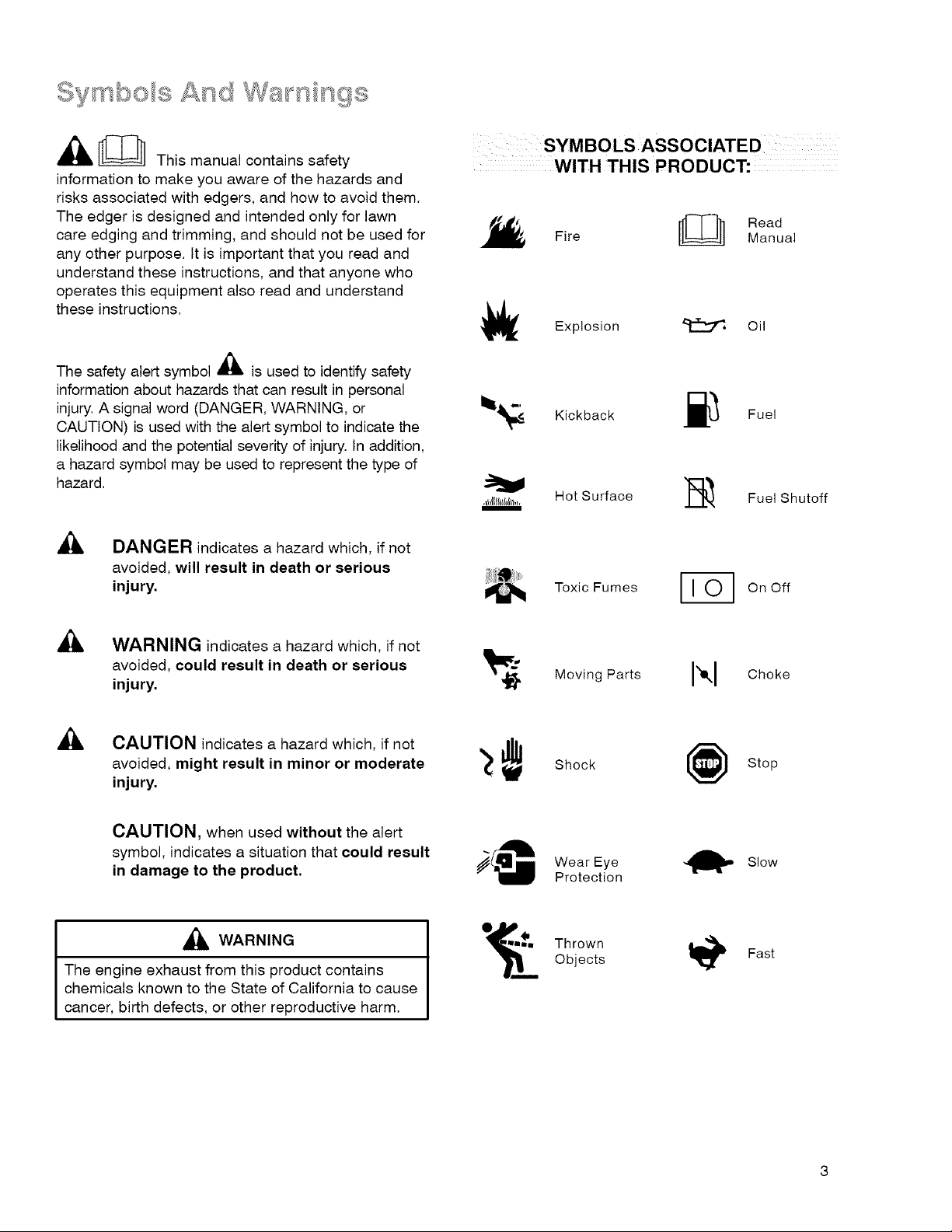

[[_ This manual contains safety

information to make you aware of the hazards and

risks associated with edgers, and how to avoid them.

The edger is designed and intended only for lawn

care edging and trimming, and should not be used for

any other purpose. It is important that you read and

understand these instructions, and that anyone who

operates this equipment also read and understand

these instructions.

WITH THIS PRODUCT:

Fire

Explosion _ Oil

[[_ Read

Manual

The safety alert symbol _ is used to identify safety

A

information about hazards that can result in personal

injury. A signal word (DANGER, WARNING, or

CAUTION) is used with the alert symbol to indicate the

likelihood and the potential severity of injury. In addition,

a hazard symbol may be used to represent the type of

hazard.

DANGER indicates a hazard which, if not

avoided, will result in death or serious

injury.

WARNING indicates a hazard which, if not

avoided, could result in death or serious

injury.

A

AI_ CAUTION indicates a hazard which, if not

avoided, might result in minor or moderate

injury.

_ Kickback ._ Fuel

,,_,l_II_l,_,,,Hot Surface ]_ Fuel Shutoff

Toxic Fumes _ On Off

Movin0Parts I'1

Shock Stop

Choke

CAUTION, when used without the alert

symbol, indicates a situation that could result

in damage to the product.

_1_ WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

Wear Eye

Protection

O_ Thrown 11_

Objects

Slow

Fast

WARNING

WARNING

When Adding Fuel

• Stop the engine. Let engine cool at least 2

minutes before removing the gas cap.

• Fill fuel tank outdoors or in well-ventilated

area.

• Do not overfill fuel tank. Fill tank to

approximately 1-1/2 inches below top of neck

to allow for fuel expansion.

• Keep gasoline away from sparks, open

flames, pilot lights, heat, and other ignition

sources.

• Check fuel lines, tank, cap, and fittings

frequently for cracks or leaks. Replace if

necessary.

• If fuel spills, wait until it evaporates before

starting engine.

When Starting Engine

• Make sure spark plug, muffler, fuel cap and air

cleaner are in place.

• Do not crank engine with spark plug removed.

• If engine floods, set choke to OPEN/RUN

position, place throttle in FAST and crank until

engine starts.

• If there is natural or LP gas leakage in area, do

not start engine.

• Do not use pressurized starting fluids because

vapors are flammable.

WARNING

• Start and run engine outdoors.

• Do not start or run engine in enclosed area,

even if doors or windows are open.

WARNING

When Operating Equipment

• Do not tip engine or equipment at angle which

causes gasoline to spill.

• Do not choke carburetor to stop the engine.

Move the throttle control to the stop position to

stop the engine.

When Transporting Equipment

• Transport with fuel tan EMPTY,

When Storing Gasoline Or Equipment With

Fuel In Tank

Store away from furnaces, stoves, water

heaters or other appliances that have pilot

light or other ignition source because they can

ignite gasoline vapors.

• Before starting the engine, make sure to raise

the blade.

• When starting engine, pull the starter cord

slowly until resistance is felt, then pull rapidly.

• Remove all external equipment/engine loads

before starting engine.

• Direct-coupled equipment components such as,

but not limited to, blades, impellers, pulleys,

sprockets, etc., must be securely attached.

WARNING

IWARNING

• Operate equipment with guards in place.

• Keep hands and feet away from rotating parts.

• Tie up long hair and remove jewelry.

• Do not wear loose-fitting clothing, dangling

drawstrings or items that could become

caught.

• Before unclogging the blade or making

repairs, stop the engine by moving the throttle

control to the stop position. Disconnect the

wire from the spark plug.

• Before you adjust the wheels or change the

position of the blade, stop the engine by

moving the throttle control to the stop position.

• Never leave the unit unattended while the

engine is running.

• Keep bystanders away from machine.

WARNING

) . = • = . _ =

It"i'T_'T'_ I_ [.I,,.I..l!li.]i!

°Rl

Before performing adjustments or repairs:

• Disconnect the spark plug wire and keep it

away from the spark plug.

• Use only correct tools.

• Do not tamper with governor spring, links or

other parts to increase engine speed.

When testing for spark:

• Use approved spark plug tester.

• Do not check for spark with spark plug

removed.

WARNING

• Always wear safety glasses or eye shields while

you assemble, operate or perform maintenance

to the unit.

Allow muffler, engine cylinder and fins to cool

before touching.

Remove accumulated debris from muffler area

and cylinder area.

Install and maintain in working order a spark

arrester before using equipment on

forest-covered, grass-covered, brush-covered

unimproved land. The state of California

requires this (Section 4442 of the California

Public Resources Code). Other states may

have similar laws. Federal laws apply on

federal land.

, WARNING

• Never sharpen the blade, always replace.

Sharpening the blade will cause the blade

to shatter.

• Before doing an adjustment, maintenance

or repair, disconnect the spark plug wire

and keep it away from the spark plug.

Operator Safety Rules

Before Use

• READ AND FOLLOW ALL INSTRUCTIONS -

Read the instruction manual carefully. Be

thoroughly familiar with the controls and the proper

use of the Edger. Know how to stop the Edger and

disengage the controls quickly.

• DRESS PROPERLY - Wear safety glasses or eye

shields to protect your eyes from thrown objects.

Do not wear loose clothing or jewelry. They can be

caught in moving parts. Use of sturdy gloves and

safety footwear is recommended. Wear footwear

that will improve footing on slippery surfaces. Do

not operate product when barefoot or wearing open

sandals. Always wear safety footwear, and pants or

slacks that cover your legs.

• STAY ALERT - Watch what you are doing - use

common sense. Do not operate product when

fatigued or under the influence of alcohol or drugs.

• KEEP OPERATING AREA CLEAR - Keep the

area of operation clear of all persons, particularly

small children and pets.

• INSPECT AREA - Thoroughly inspect the area

where the Edger is to be used and remove all

foreign objects. Objects struck by the cutting

member can cause severe injuries to persons.

Fuel Safety

• Allow muffler and engine areas to cool before

touching.

• Handle fuel with care; it is highly flammable.

• Use an approved container.

• Turn engine OFF and let engine cool at least 2

minutes before removing the gas cap.

• Check fuel supply before each use. Do not overfill

fuel tank. To allow for fuel expansion, fill fuel tank

to approximately 1-1/2 inches below top of fuel

tank neck. Replace gasoline cap securely.

• Fill fuel tank outdoors with extreme care. Never fill

fuel tank indoors or near appliances with pilot

lights, heaters, or other ignition sources. Replace

fuel tank cap securely and wipe up spilled fuel.

• Never remove the fuel tank cap or add fuel to a

running or hot engine.

• Never store fuel or Edger with fuel in the tank

inside a building where fumes may reach an open

flame or other ignition source.

Operating Safety

• Read and follow all instructions in this manual

carefully.

6

• Never operate the product without guards, plates

or other protective devices in place. Operate

product from position where guards block the line

of sight to the cutting member.

• Never allow children to operate the Edger. Keep

them away while it is operating. Never allow adults

to operate the Edger without proper instruction.

• Do not operate this machine if you are taking drugs

or other medication which can cause drowsiness or

affect your ability to operate this machine.

• Do not use this machine if you are mentally or

physically unable to operate it safely.

• To protect your eyes from foreign object that may

be thrown from the Edger, always wear safety

glasses or eye shields during operation or while

performing an adjustment or repair.

• Do not put hands or feet near or under rotating

parts including cutting area. Keep both hands on

handles when blade is rotating. Cutting member

coasts after turn off.

• Do not attempt to remove cut material nor hold

material to be cut when engine is running or when

cutting member is moving.

• Exercise extreme caution when operating on or

crossing drives, walks, or roads. Stay alert for

hidden hazards or traffic.

• Exercise caution to avoid slipping or falling. Don't

overreach or stand on unstable support. Keep good

footing and balance at all times.

• Use only for edging or trimming the type of growth

as described in the operating instructions. Do not

abuse the product. Do not use the product on

graveled surfaces.

• Never operate the Edger at high transport speeds

on slippery surfaces. Do not use product in rain or

wet locations. Look behind and use care when

backing.

• Stay alert for uneven sidewalks, holes in terrain or

other similar conditions when using product.

Always push slowly over rough ground.

• Never direct discharge of material toward

bystanders nor allow anyone near the area of

operation. Use care in directing discharge to avoid

glass enclosures, automobiles, and similar objects.

• Keep children and pets away while operating.

• Never operate the Edger without good visibility or

light.

• Do not run the engine indoors. The exhaust fumes

are dangerous, containing CARBON MONOXIDE,

an ODORLESS and DEADLY gas.

• Make sure that spark plug, muffler, fuel cap and air

cleaner are in place when operating.

• Make sure spark plug is disconnected when

clearing jammed material from cutting member. Do

not crank engine with spark plug remove.

• Iffuelspills,waituntilitevaporatesbeforestarting

engine.

• Takeallpossibleprecautionswhenleavingthe

Edgerunattendedorduringtransport.Stopthe

engine.

• DonotoverloadtheEdgercapacitybyattempting

totilltoodeepattoofastarate.

Maintenance / Repair / Adjustments

Safety / Storage

• Follow maintenance instructions given in Manual.

• Do not change the engine governor settings or

overspeed the engine.

• To reduce the risk of fire, do not allow excessive

grass, leaves, or grease to accumulate on the

product.

• After striking a foreign object, stop the engine.

Remove the wire from the spark plug, and keep the

wire away from the plug to prevent accidental

starting. Thoroughly inspect the Edger for any

damage. Repair the damage before restarting and

operating.

• Do not operate product with a damaged or

excessively worn cutting member.

• Have repairs made by a qualified dealer or

repairman. See that only identical replacement

parts are used.

• If Edger should start to vibrate abnormally, stop

engine and check immediately for the cause.

Vibration is generally a warning of trouble.

• Stop the engine whenever you leave the operating

position. Also, disconnect the spark plug wire

before unclogging the blade and when making any

repairs, adjustments, or inspections.

• When cleaning, repairing, or inspecting, shut off the

engine and make certain all moving parts have

stopped. Remove the wire from the spark plug, and

keep the wire away from the plug to prevent

accidental starting.

• Never attempt to make any adjustments while the

engine is running.

• When not in use, disconnect spark plug lead and

store product indoors in a dry place locked or

otherwise inaccessible to children.

• SAVE THESE INSTRUCTIONS

Parts Packed Separately In Carton

1 - Owner's Manual (not shown)

1 - Container Of Oil

2 - Hair Pin

1 - Control Rod

WARNING

• Always wear safety glasses or eye shields while

you assemble, operate or do maintenance to

the unit.

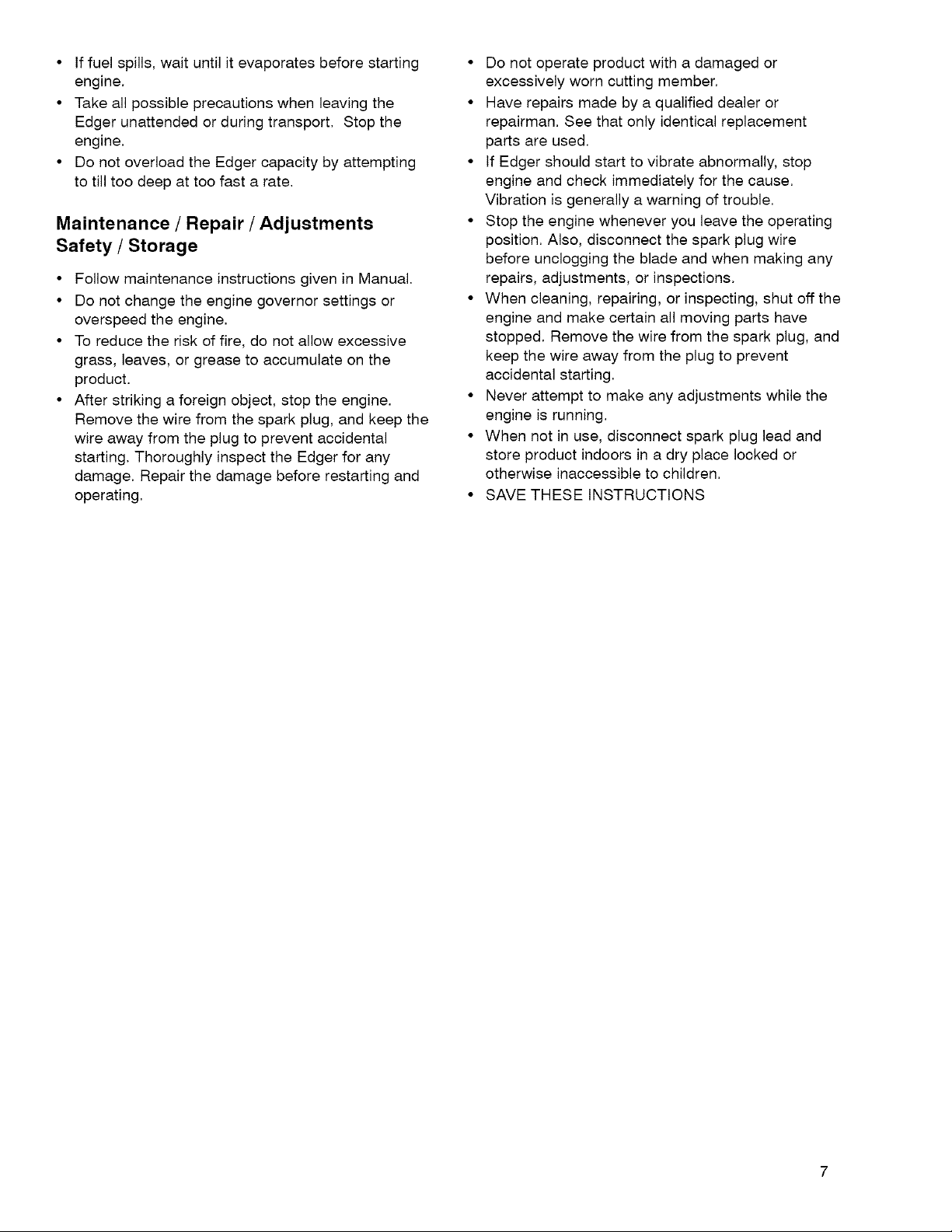

Figure 1 shows the product completely assembled.

References to the right or left side are from the

viewpoint of the operator's position behind the unit.

1 - Control Rod

_--- /u I!

1 - Container of Oil

L i

2 - Hair Pin

Removal From The Carton

1

Remove the bottle of oil and parts bag from the

carton.

2

Cut down all four corners of the carton.

3

Remove the packing material positioned around

the front and rear of the unit. Leave the packing

material on the bottom of the unit until the control

rod is assembled. This will keep the front wheel in

a stable position.

Lift the machine out of the carton and place on a

hard level surface.

Figure 1: Product Completely Assembled

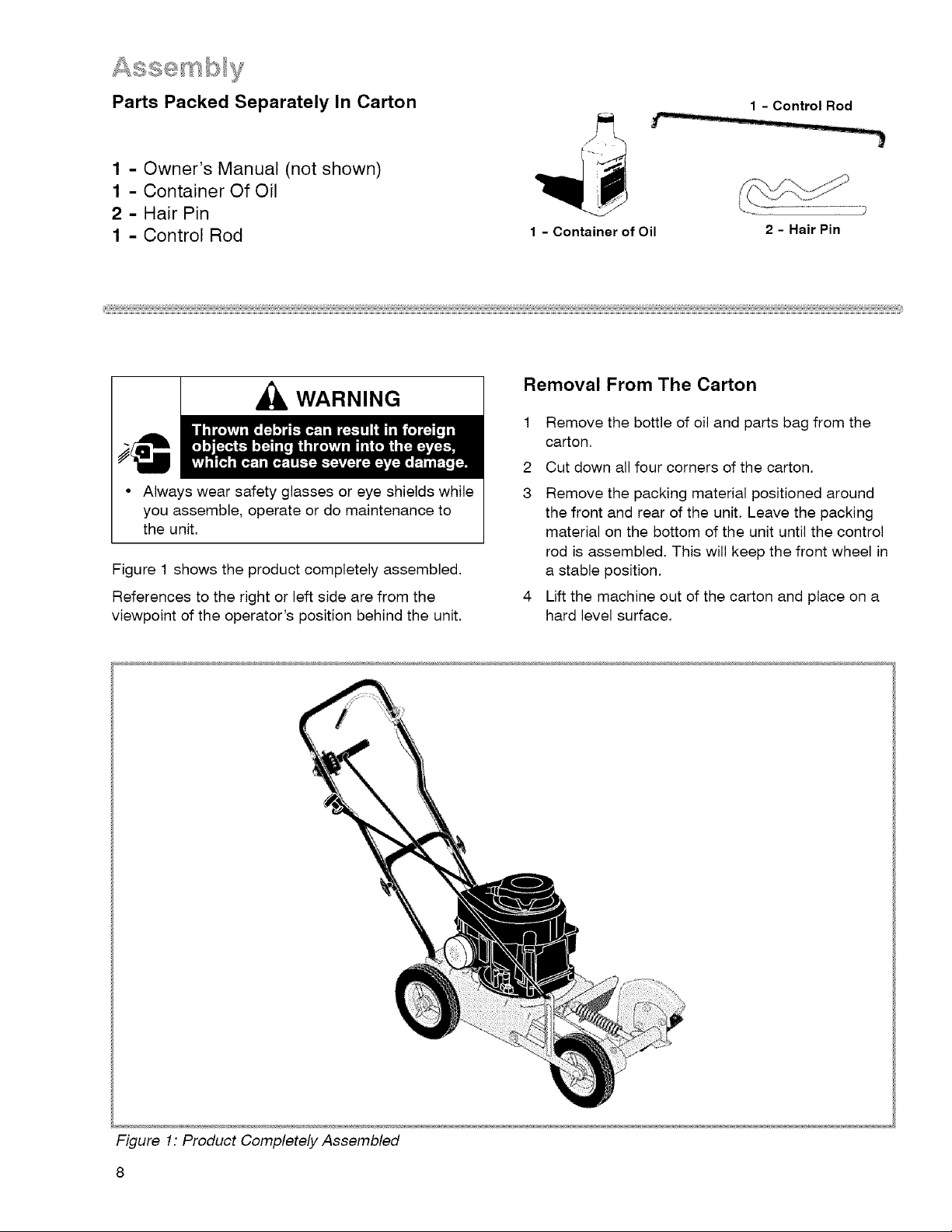

How To Raise The Handle

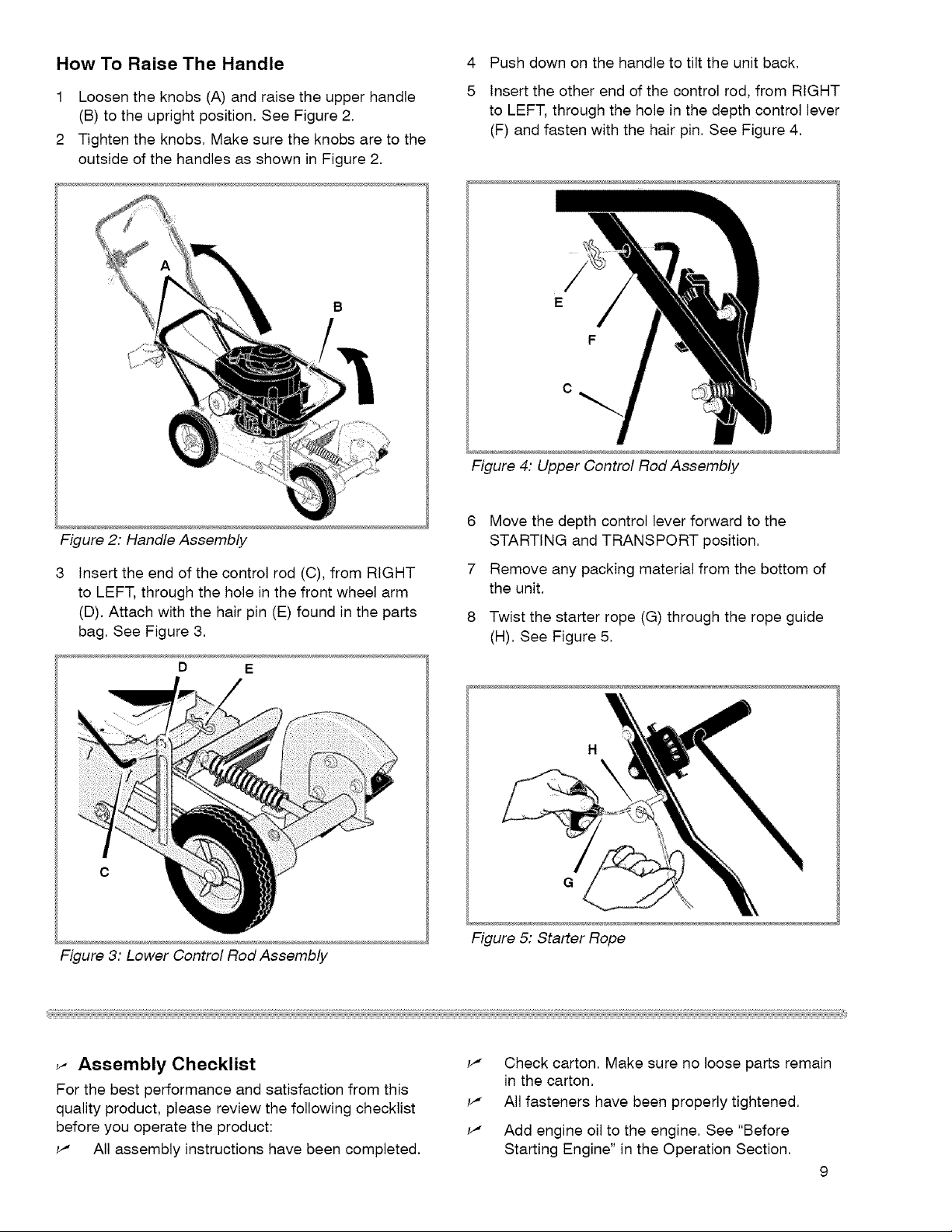

45Push down on the handle to tilt the unit back.

1 Loosen the knobs (A) and raise the upper handle

(B) to the upright position. See Figure 2.

2 Tighten the knobs. Make sure the knobs are to the

outside of the handles as shown in Figure 2.

Figure 2: Handle Assembly

Insert the end of the control rod (C), from RIGHT

to LEFT, through the hole in the front wheel arm

(D). Attach with the hair pin (E) found in the parts

bag. See Figure 3.

Insert the other end of the control rod, from RIGHT

to LEFT, through the hole in the depth control lever

(F) and fasten with the hair pin. See Figure 4.

E

F

c

Figure 4: Upper Control Rod Assembly

6

Move the depth control lever forward to the

STARTING and TRANSPORT position.

7

Remove any packing material from the bottom of

the unit.

8

Twist the starter rope (G) through the rope guide

(H). See Figure 5.

D E

C

Figure 3: Lower Control Rod Assembly

_- Assembly Checklist _"

For the best performance and satisfaction from this

quality product, please review the following checklist _'

before you operate the product: _,

_' All assembly instructions have been completed.

Figure 5: Starter Rope

Check carton. Make sure no loose parts remain

in the carton.

All fasteners have been properly tightened.

Add engine oil to the engine. See "Before

Starting Engine" in the Operation Section.

9

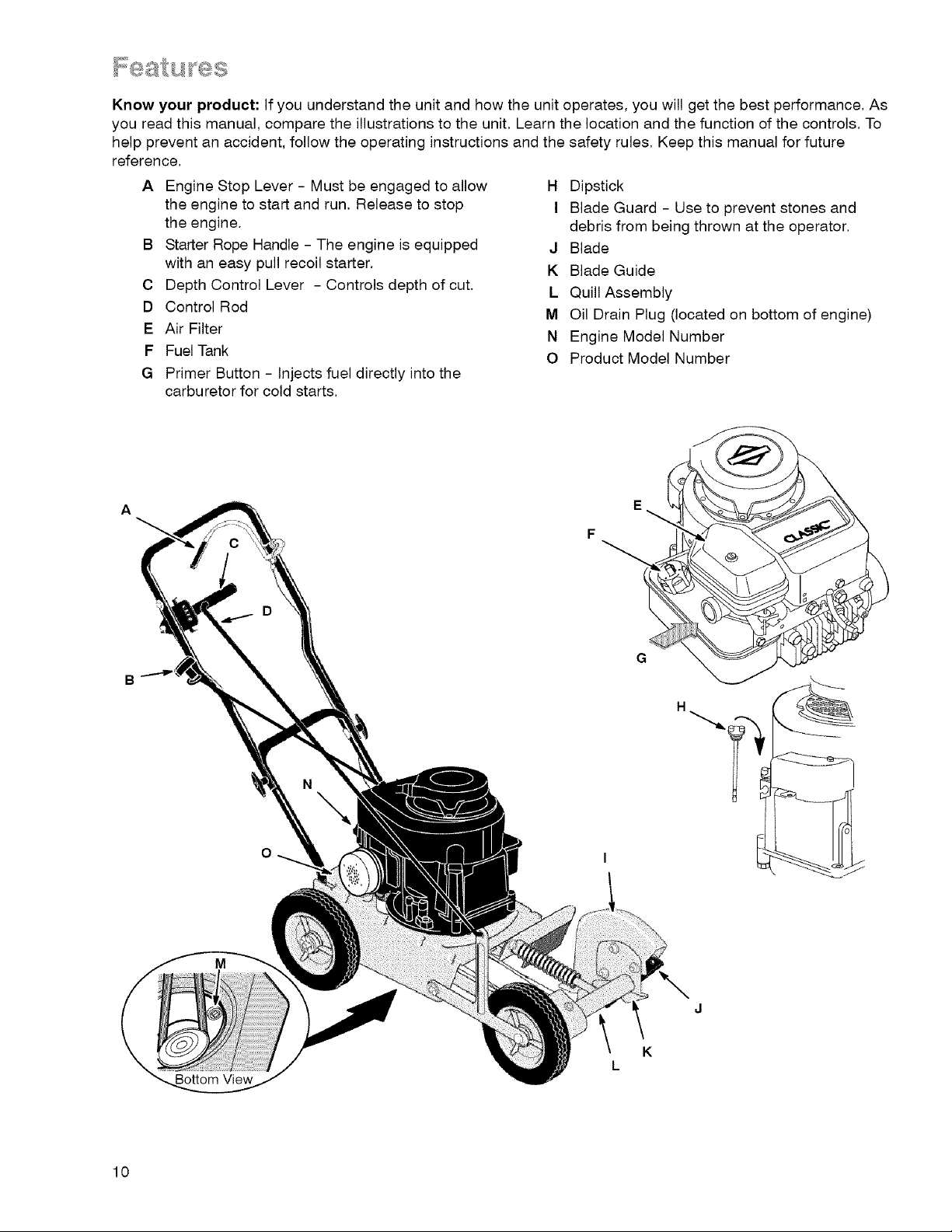

Knowyourproduct:Ifyouunderstandtheunitandhowtheunitoperates,youwillgetthebestperformance.As

youreadthismanual,comparetheillustrationstotheunit.Learnthelocationandthefunctionofthecontrols.To

helppreventanaccident,followtheoperatinginstructionsandthesafetyrules.Keepthismanualforfuture

reference.

A EngineStopLever- Mustbeengagedtoallow

theenginetostartandrun,Releasetostop

theengine.

B StarterRopeHandle- Theengineisequipped

withaneasypullrecoilstarter.

C DepthControlLever- Controlsdepthofcut,

D ControlRod

E AirFilter

F FuelTank

G PrimerButton- Injectsfueldirectlyintothe

carburetorforcoldstarts,

A

D

H Dipstick

I BladeGuard- Usetopreventstonesand

debrisfrombeingthrownattheoperator,

J Blade

K BladeGuide

L QuillAssembly

M OilDrainPlug(locatedonbottomofengine)

N EngineModelNumber

O ProductModelNumber

E

Bottom View

G

H

O

K

L

j

J

10

Eye Protection

Before Starting The Engine

Read "Operator Safety Rules" section prior to using

this product.

CAUTION

This engine was shipped from the factory without

oil. If you start the engine without oil, the engine

will be damaged beyond repair and will not be

covered under warranty.

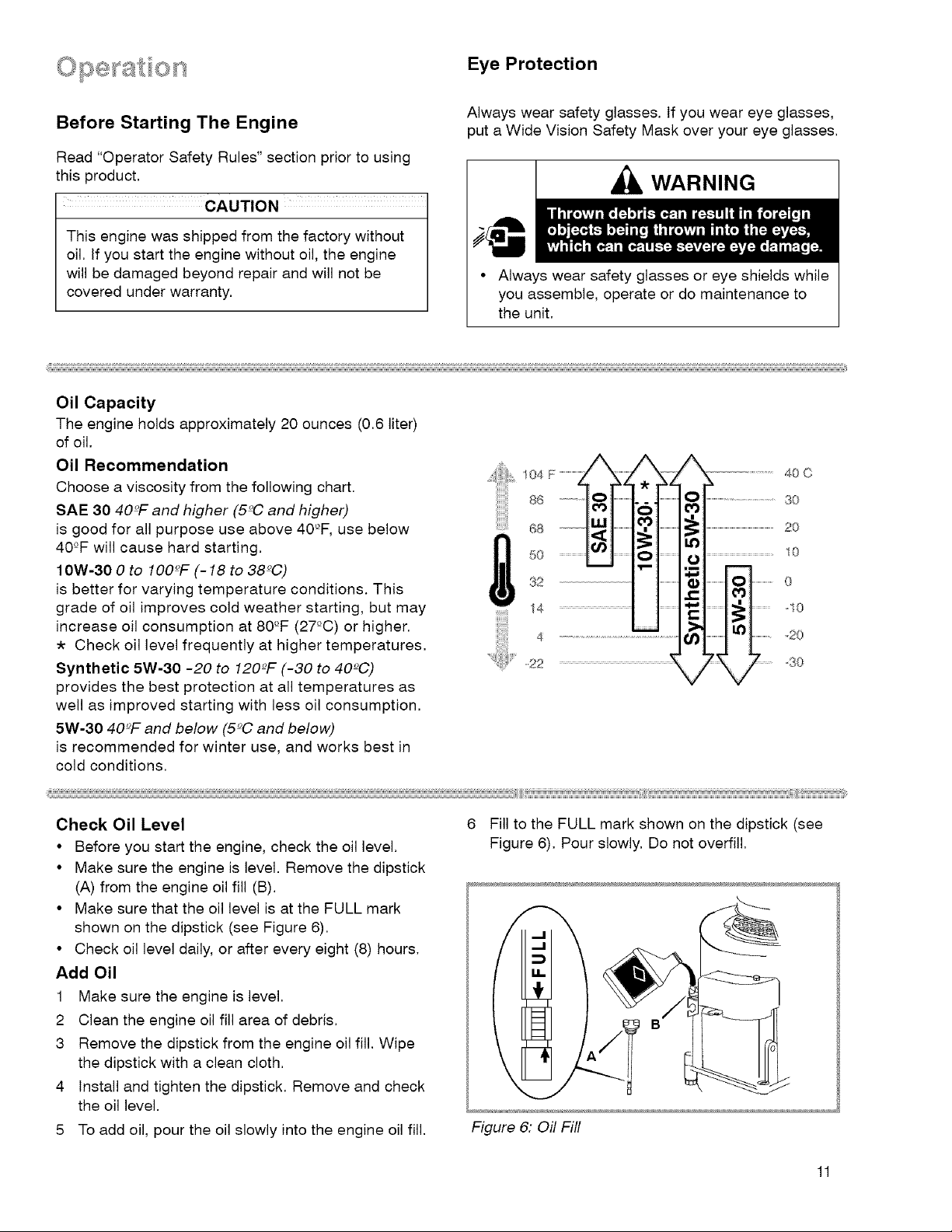

Oil Capacity

The engine holds approximately 20 ounces (0.6 liter)

of oil.

Oil Recommendation

Choose a viscosity from the following chart.

SAE 30 40°F and higher (5°0 and higher)

is good for all purpose use above 40°F, use below

40°F will cause hard starting.

10W-30 0 to IO0_F (- 18 to 38c'C)

is better for varying temperature conditions. This

grade of oil improves cold weather starting, but may

increase oil consumption at 80°F (27°C) or higher.

Check oil level frequently at higher temperatures.

Synthetic 5W-30 -20 to 120_'F (-30 to 40_C)

provides the best protection at all temperatures as

well as improved starting with less oil consumption.

5W-30 40_F and below (5°C and below)

is recommended for winter use, and works best in

cold conditions.

Always wear safety glasses. If you wear eye glasses,

put a Wide Vision Safety Mask over your eye glasses.

WARNING

• Always wear safety glasses or eye shields while

you assemble, operate or do maintenance to

the unit.

04 F

86

68

5O

32

14

.22

40 O

30

20

10

0

o0

20

-30

Check Oil Level

• Before you start the engine, check the oil level.

• Make sure the engine is level. Remove the dipstick

(A) from the engine oil fill (B).

• Make sure that the oil level is at the FULL mark

shown on the dipstick (see Figure 6).

• Check oil level daily, or after every eight (8) hours.

Add Oil

1 Make sure the engine is level.

2 Clean the engine oil fill area of debris.

3 Remove the dipstick from the engine oil fill. Wipe

the dipstick with a clean cloth.

4 Install and tighten the dipstick. Remove and check

the oil level.

5 To add oil, pour the oil slowly into the engine oil fill.

6 Fill to the FULL mark shown on the dipstick (see

Figure 6). Pour slowly. Do not overfill.

Figure 6: Oil Fill

11

Gasoline Requirements

All gasoline is not the same. If a starting or

performance problem is encountered after new

gasoline has been used, try another service station or

change brands.

This engine is designed to operate on gasoline. The

emission control system for this engine is EM (Engine

Modifications).

Type of gasoline to use

Always use gasoline that meets these requirements:

• Clean, fresh, unleaded gasoline.

• A minimun of 87 octane/87 AKI (91 RON). At

altitudes over 5,000 feet, see "High-altitude use".

• Gasoline with up to 10% ethanol (gasohol) or up

to 15% MTBE (methyl tertiary butyl ether), is

acceptable.

• Use of any gasoline other than those approved

above will void the engine warranty. Some

areas require that fuel pumps be marked if the

gasoline contains alcohols or ethers. If you are not

sure if your gasoline contains alcohol or ethers that

are different than those approved above, then

check with the service station operator.

• Do not modify the engine fuel system or

carburetor to run on alternative fuels.

• Never mix oil with gasoline.

Gasoline Storage

Follow these guidelines when storing gasoline for

longer than 30 days:

• If fuel stabilizer is used, you do not need to drain

gasoline prior to storage.

• If no fuel stabilizer is used, then always remove

gasoline from engine during storage.

Fuel stabilizer

• If you do not want to remove the gasoline, add a

fuel stabilizer to any gasoline left in the fuel tank. A

fuel stabilizer will minimize gum deposits and acids.

If the fuel tank is almost empty, mix the fuel

stabilizer with fresh gasoline in a separate

container and add the mixture to the fuel tank.

Always follow the instructions on the stabilizer

container. Start the engine. Let the engine run for 3

minutes to allow the mixture to reach the

carburetor.

High-altitude use

At higher altitudes (over 5,000 feet), 85 octane / 85

AKI (89 RON) gasoline can be used. Operation at

high altitude may require a high-altitude carburetor jet

kit to improve performance and decrease fuel

consumption.

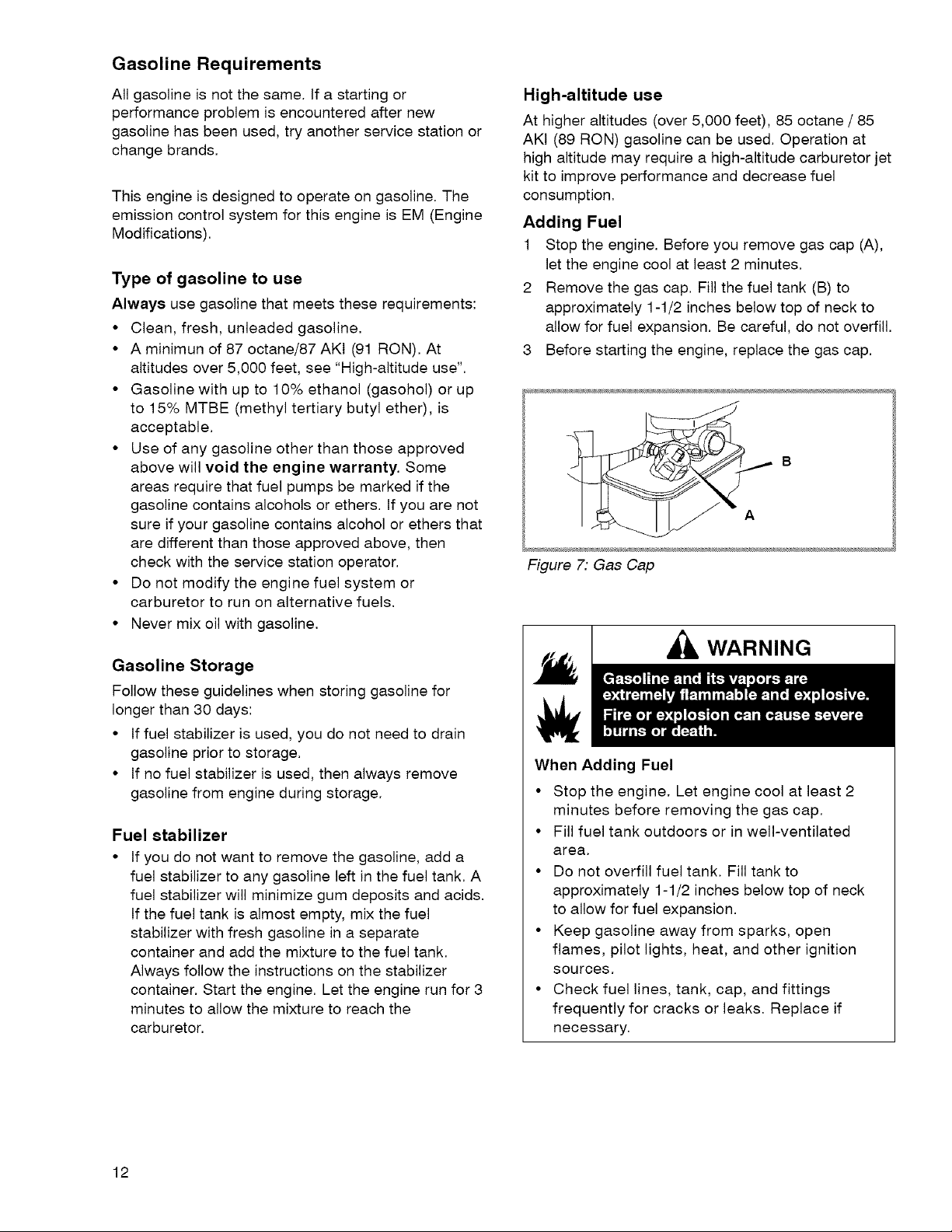

Adding Fuel

1 Stop the engine. Before you remove gas cap (A),

let the engine cool at least 2 minutes.

2 Remove the gas cap. Fill the fuel tank (B) to

approximately 1-1/2 inches below top of neck to

allow for fuel expansion. Be careful, do not overfill.

3 Before starting the engine, replace the gas cap.

Figure 7: Gas Cap

WARNING

When Adding Fuel

• Stop the engine. Let engine cool at least 2

minutes before removing the gas cap.

• Fill fuel tank outdoors or in well-ventilated

area.

• Do not overfill fuel tank. Fill tank to

approximately 1-1/2 inches below top of neck

to allow for fuel expansion.

• Keep gasoline away from sparks, open

flames, pilot lights, heat, and other ignition

sources.

• Check fuel lines, tank, cap, and fittings

frequently for cracks or leaks. Replace if

necessary.

12

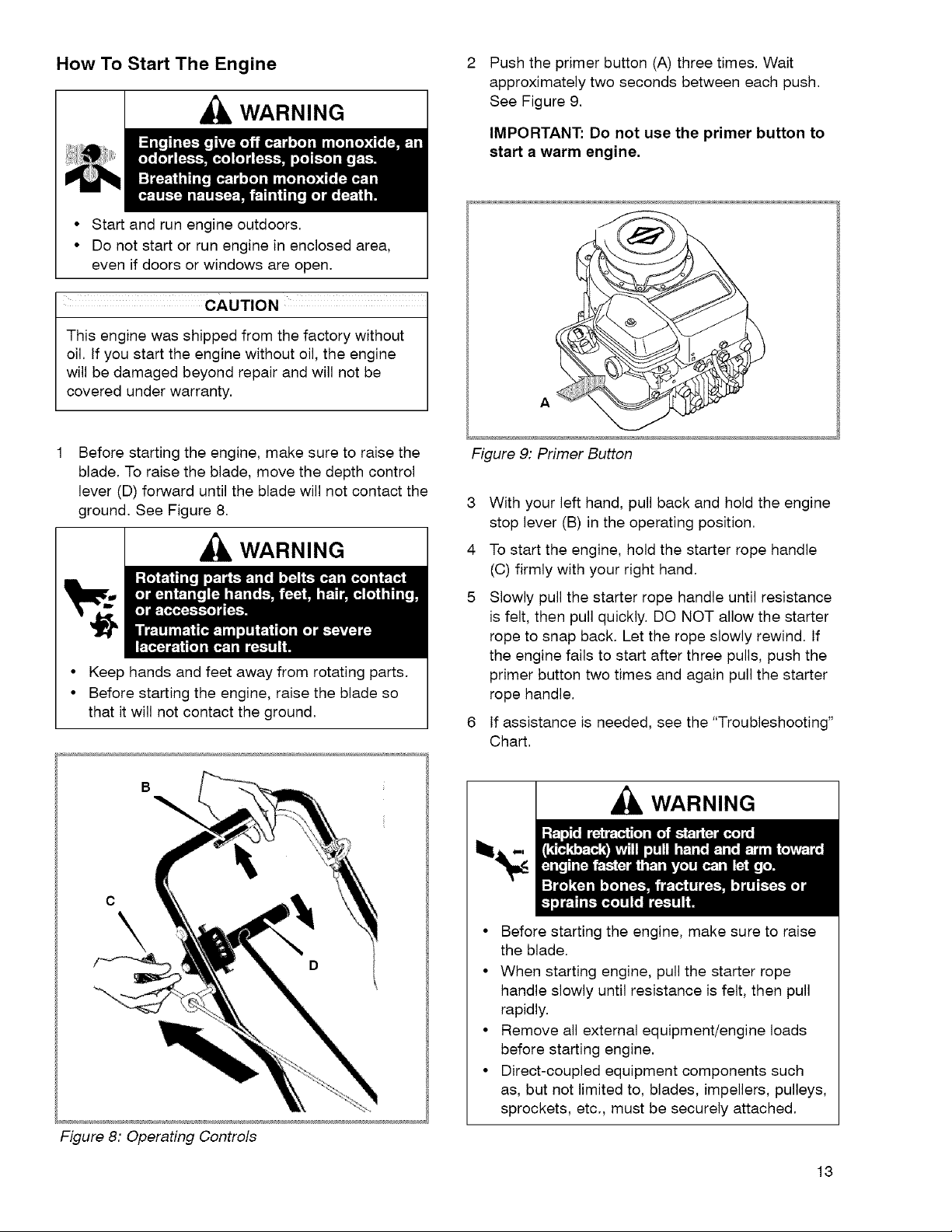

How To Start The Engine

WARNING

• Start and run engine outdoors.

• Do not start or run engine in enclosed area,

even if doors or windows are open.

CAUTION

This engine was shipped from the factory without

oil. If you start the engine without oil, the engine

will be damaged beyond repair and will not be

covered under warranty.

Push the primer button (A) three times. Wait

approximately two seconds between each push,

See Figure 9,

IMPORTANT: Do not use the primer button to

start a warm engine.

A

Before starting the engine, make sure to raise the

blade. To raise the blade, move the depth control

lever (D) forward until the blade will not contact the

ground. See Figure 8.

WARNING

• Keep hands and feet away from rotating parts.

• Before starting the engine, raise the blade so

that it will not contact the ground.

B

\

c

Figure 9: Primer Button

3 With your left hand, pull back and hold the engine

stop lever (B) in the operating position.

4 To start the engine, hold the starter rope handle

(C) firmly with your right hand.

5 Slowly pull the starter rope handle until resistance

is felt, then pull quickly. DO NOT allow the starter

rope to snap back. Let the rope slowly rewind. If

the engine fails to start after three pulls, push the

primer button two times and again pull the starter

rope handle.

If assistance is needed, see the "Troubleshooting"

Chart.

WARNING

\

Figure 8: Operating Controls

• Before starting the engine, make sure to raise

the blade.

• When starting engine, pull the starter rope

handle slowly until resistance is felt, then pull

rapidly.

• Remove all external equipment/engine loads

before starting engine.

• Direct-coupled equipment components such

as, but not limited to, blades, impellers, pulleys,

sprockets, etc., must be securely attached.

13

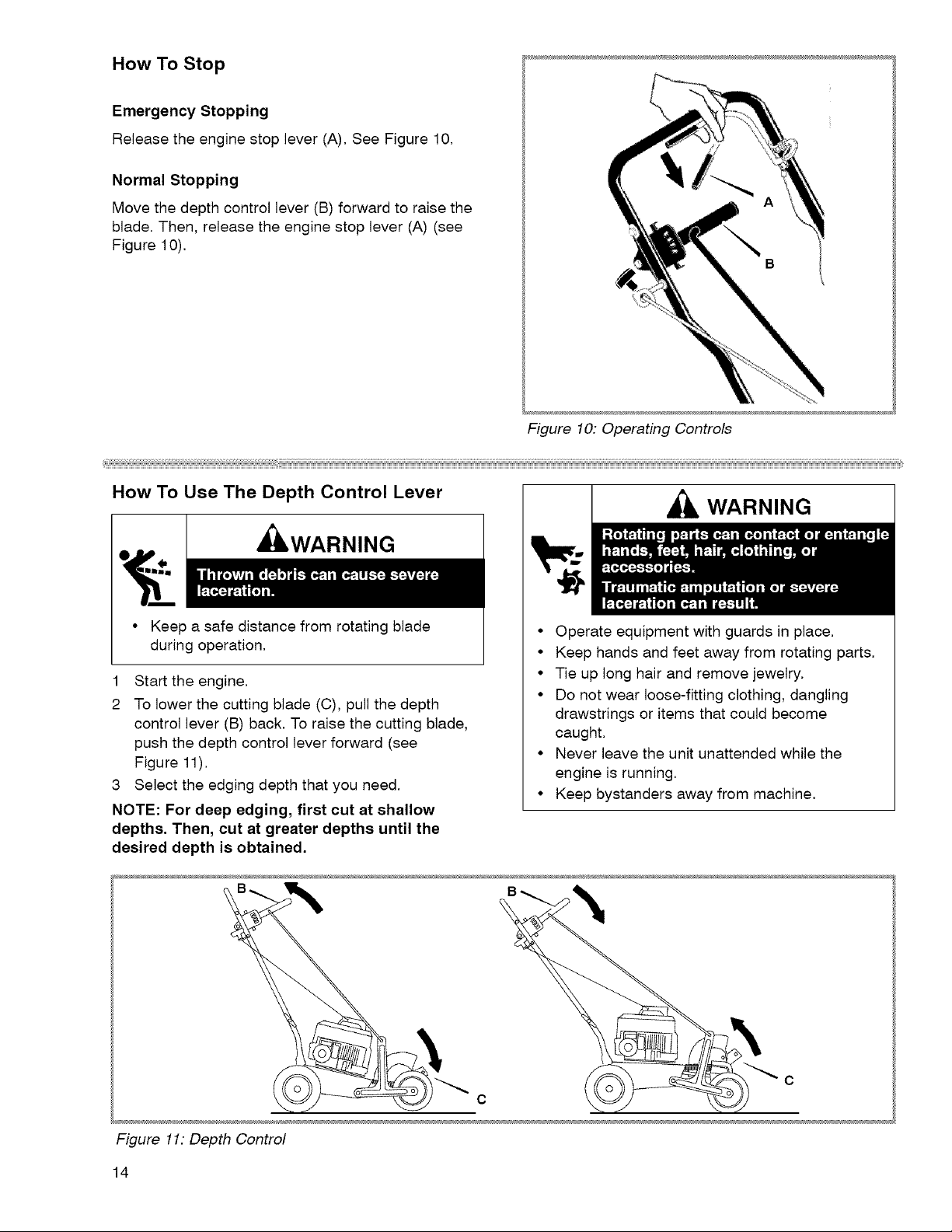

How To Stop

Emergency Stopping

Release the engine stop lever (A). See Figure 10.

Normal Stopping

Move the depth control lever (B) forward to raise the

blade. Then, release the engine stop lever (A) (see

Figure 10).

Figure 10: Operating Controls

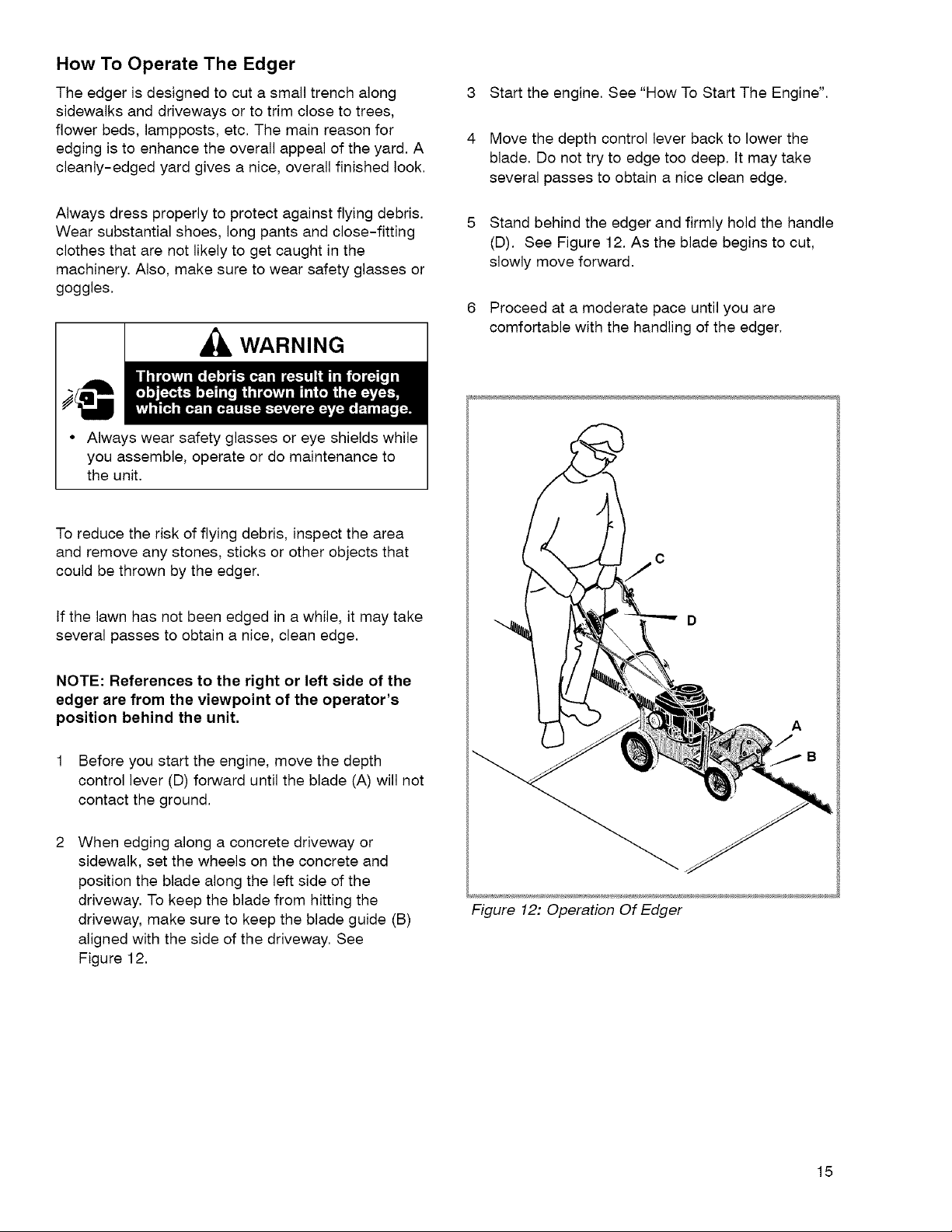

How To Use The Depth Control Lever

_,WARNING

• Keep a safe distance from rotating blade

during operation.

1 Start the engine.

2 To lower the cutting blade (C), pull the depth

control lever (B) back. To raise the cutting blade,

push the depth control lever forward (see

Figure 11).

3 Select the edging depth that you need.

NOTE: For deep edging, first cut at shallow

depths. Then, cut at greater depths until the

desired depth is obtained.

WARNING

• Operate equipment with guards in place.

• Keep hands and feet away from rotating parts.

• Tie up long hair and remove jewelry.

• Do not wear loose-fitting clothing, dangling

drawstrings or items that could become

caught.

• Never leave the unit unattended while the

engine is running.

• Keep bystanders away from machine.

B

Figure 11:Depth Control

14

c

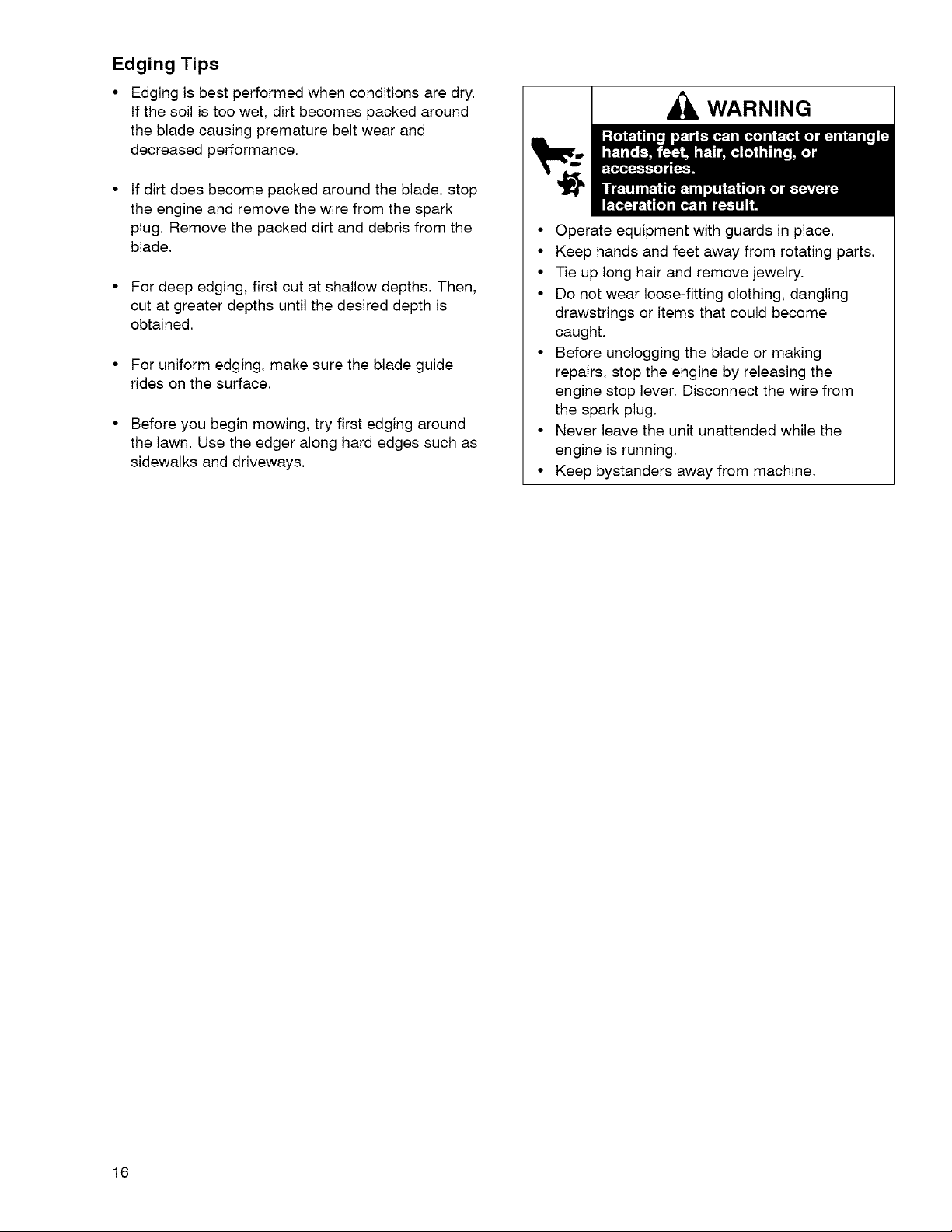

How To Operate The Edger

The edger is designed to cut a small trench along

sidewalks and driveways or to trim close to trees,

flower beds, lampposts, etc. The main reason for

edging is to enhance the overall appeal of the yard. A

cleanly-edged yard gives a nice, overall finished look.

Always dress properly to protect against flying debris.

Wear substantial shoes, long pants and close-fitting

clothes that are not likely to get caught in the

machinery. Also, make sure to wear safety glasses or

goggles.

WARNING

• Always wear safety glasses or eye shields while

you assemble, operate or do maintenance to

the unit.

To reduce the risk of flying debris, inspect the area

and remove any stones, sticks or other objects that

could be thrown by the edger.

3 Start the engine. See "How To Start The Engine".

4 Move the depth control lever back to lower the

blade. Do not try to edge too deep. It may take

several passes to obtain a nice clean edge.

5 Stand behind the edger and firmly hold the handle

(D). See Figure 12. As the blade begins to cut,

slowly move forward.

6 Proceed at a moderate pace until you are

comfortable with the handling of the edger.

c

If the lawn has not been edged in a while, it may take

several passes to obtain a nice, clean edge.

NOTE: References to the right or left side of the

edger are from the viewpoint of the operator's

position behind the unit.

1 Before you start the engine, move the depth

control lever (D) forward until the blade (A) will not

contact the ground.

When edging along a concrete driveway or

sidewalk, set the wheels on the concrete and

position the blade along the left side of the

driveway. To keep the blade from hitting the

driveway, make sure to keep the blade guide (B)

aligned with the side of the driveway. See

Figure 12.

D

Figure 12: Operation Of Edger

15

Edging Tips

• Edging is best performed when conditions are dry.

If the soil is too wet, dirt becomes packed around

the blade causing premature belt wear and

decreased performance.

If dirt does become packed around the blade, stop

the engine and remove the wire from the spark

plug. Remove the packed dirt and debris from the

blade,

• For deep edging, first cut at shallow depths. Then,

cut at greater depths until the desired depth is

obtained.

• For uniform edging, make sure the blade guide

rides on the surface.

• Before you begin mowing, try first edging around

the lawn. Use the edger along hard edges such as

sidewalks and driveways.

WARNING

• Operate equipment with guards in place.

• Keep hands and feet away from rotating parts.

• Tie up long hair and remove jewelry.

• Do not wear loose-fitting clothing, dangling

drawstrings or items that could become

caught.

• Before unclogging the blade or making

repairs, stop the engine by releasing the

engine stop lever. Disconnect the wire from

the spark plug.

• Never leave the unit unattended while the

engine is running.

• Keep bystanders away from machine.

16

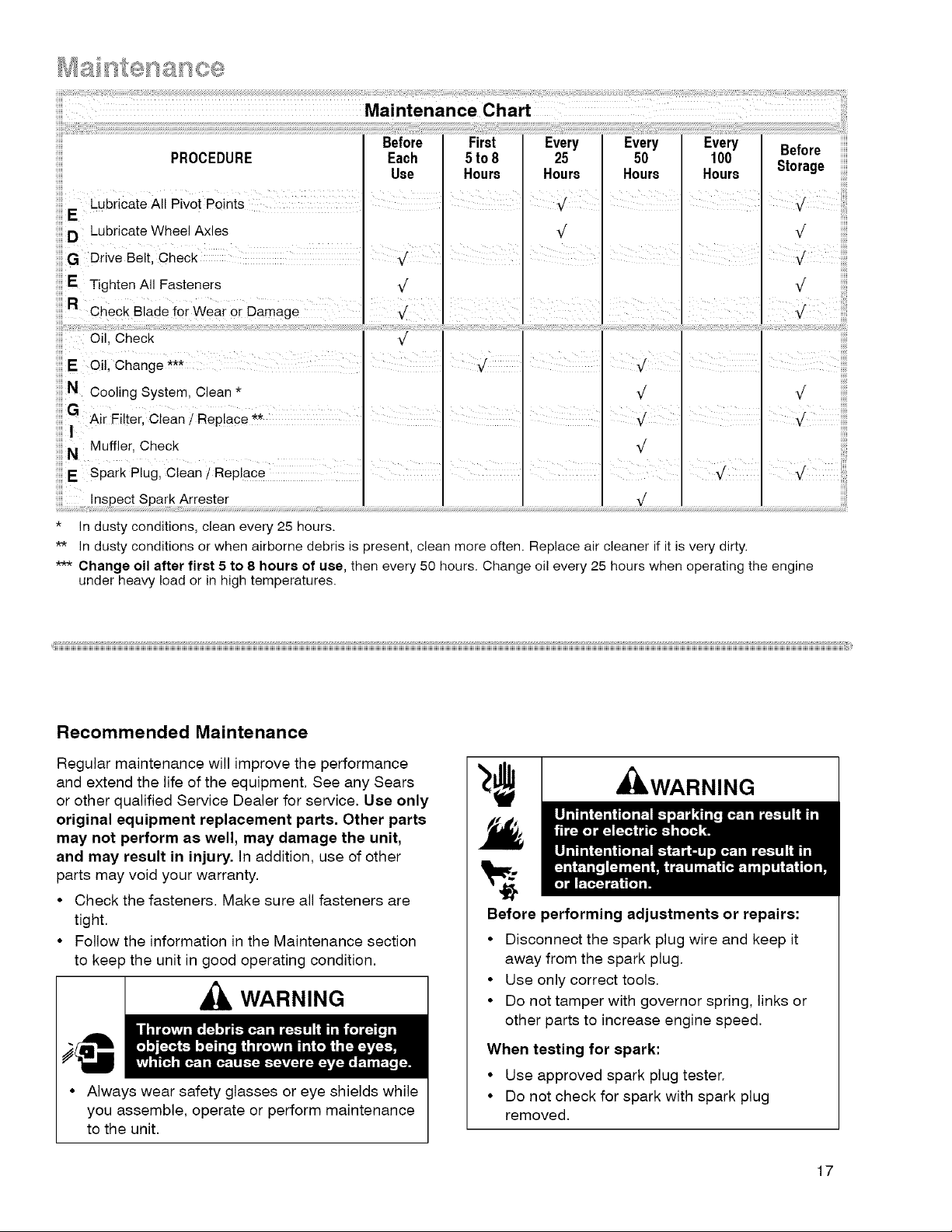

* In dusty conditions, clean every 25 hours.

** In dusty conditions or when airborne debris is present, clean more often. Replace air cleaner if it is very dirty.

*** Change oil after first 5 to 8 hours of use, then every 50 hours. Change oi! every 25 hours when operating the engine

under heavy load or in high temperatures.

Recommended Maintenance

Regular maintenance will improve the performance

and extend the life of the equipment. See any Sears

or other qualified Service Dealer for service. Use only

original equipment replacement parts, Other parts

may not perform as well, may damage the unit,

and may result in injury, In addition, use of other

parts may void your warranty.

• Check the fasteners. Make sure all fasteners are

tight.

• Follow the information in the Maintenance section

to keep the unit in good operating condition,

WARNING

Before performing adjustments or repairs:

• Disconnect the spark plug wire and keep it

away from the spark plug.

• Use only correct tools.

• Do not tamper with governor spring, links or

other parts to increase engine speed.

WARNING

• Always wear safety glasses or eye shields while

you assemble, operate or perform maintenance

to the unit.

When testing for spark:

• Use approved spark plug tester.

• Do not check for spark with spark plug

removed.

17

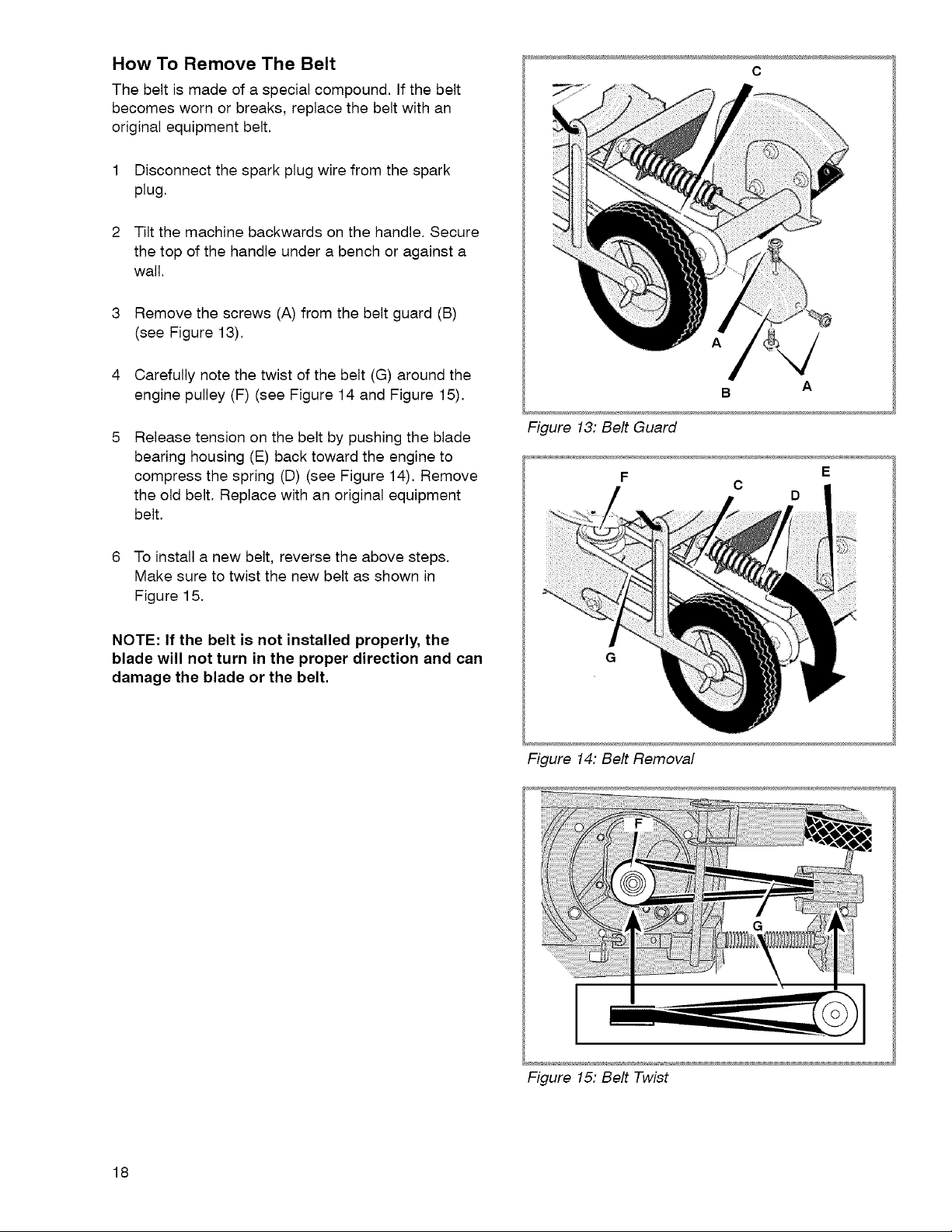

How To Remove The Belt

The belt is made of a special compound. If the belt

becomes worn or breaks, replace the belt with an

original equipment belt.

1 Disconnect the spark plug wire from the spark

plug.

2 Tilt the machine backwards on the handle. Secure

the top of the handle under a bench or against a

wall,

3 Remove the screws (A) from the belt guard (B)

(see Figure 13).

o

A

4 Carefully note the twist of the belt (G) around the

engine pulley (F) (see Figure 14 and Figure 15).

Release tension on the belt by pushing the blade

bearing housing (E) back toward the engine to

compress the spring (D) (see Figure 14). Remove

the old belt. Replace with an original equipment

belt.

6 To install a new belt, reverse the above steps.

Make sure to twist the new belt as shown in

Figure 15.

NOTE: If the belt is not installed properly, the

blade will not turn in the proper direction and can

damage the blade or the belt.

Figure 13: Belt Guard

F E

Figure 14: Belt Removal

B A

C

D

18

Figure 15: Belt Twist

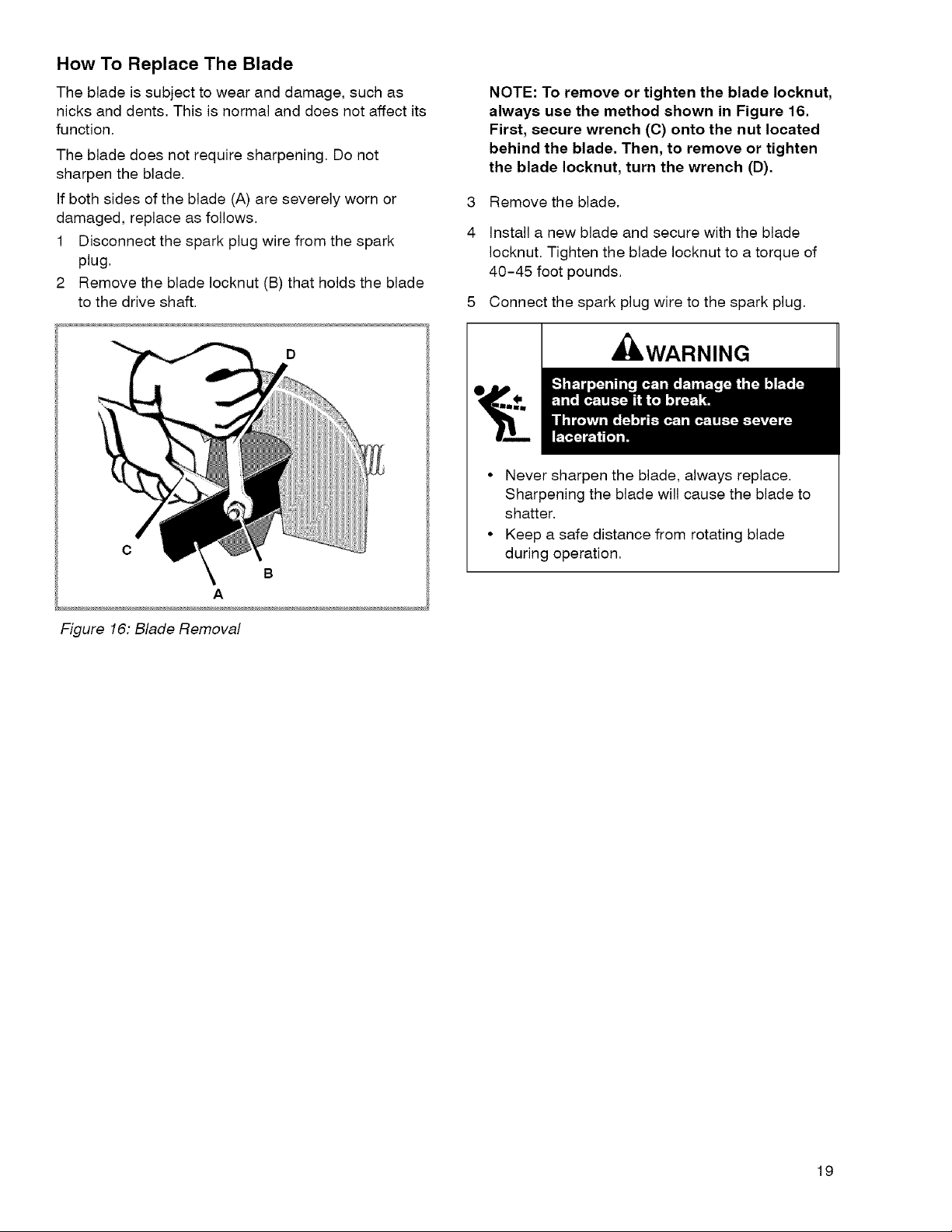

How To Replace The Blade

The blade is subject to wear and damage, such as

nicks and dents, This is normal and does not affect its

function.

The blade does not require sharpening, Do not

sharpen the blade.

If both sides of the blade (A) are severely worn or

damaged, replace as follows.

1 Disconnect the spark plug wire from the spark

plug.

2 Remove the blade Iocknut (B) that holds the blade

to the drive shaft.

c

B

A

NOTE: To remove or tighten the blade Iocknut,

always use the method shown in Figure 16.

First, secure wrench (C) onto the nut located

behind the blade. Then, to remove or tighten

the blade Iocknut, turn the wrench (D).

3

Remove the blade.

4

Install a new blade and secure with the blade

Iocknut. Tighten the blade Iocknut to a torque of

40-45 foot pounds.

Connect the spark plug wire to the spark plug.

IbWARNING

• Never sharpen the blade, always replace.

Sharpening the blade will cause the blade to

shatter,

• Keep a safe distance from rotating blade

during operation,

Figure 16: Blade Removal

19

Engine Maintenance

CAUTION

All the components used to build this engine must

remain in place for the proper operation of this

engine.

Emission Control

Maintenance, replacement or repair of the emission

control devices and systems may be performed by

any non-road engine repair establishment or

individual. However, to obtain no charge repairs under

the terms and provisions of the Sears warranty

statement, any service or emission control part repair

or replacement must be performed by a factory

authorized dealer. See the Emission Warranty.

Carburetor Adjustment

Never make unnecessary adjustments to the

carburetor. The carburetor was set at the factory to

operate efficiently under most applications. However,

if adjustments are required, see any Sears or other

qualified service dealer for service.

CAUTION

The manufacturer of the equipment on which this

engine is installed specifies top speed at which the

engine will be operated. DO NOT EXCEED this

speed.

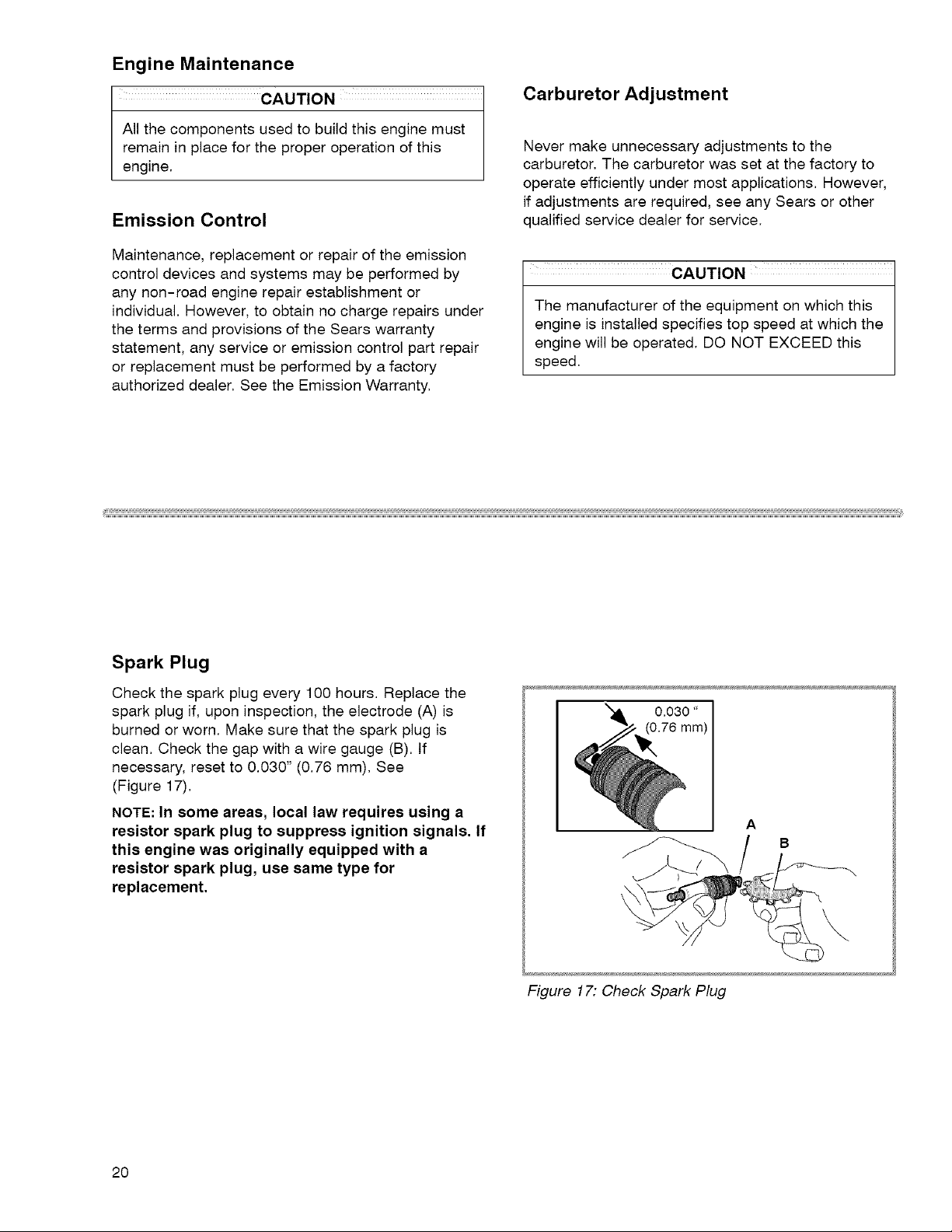

Spark Plug

Check the spark plug every 100 hours. Replace the

spark plug if, upon inspection, the electrode (A) is

burned or worn. Make sure that the spark plug is

clean. Check the gap with a wire gauge (B). If

necessary, reset to 0.030" (0.76 mm). See

(Figure 17).

NOTE: In some areas, local law requires using a

resistor spark plug to suppress ignition signals. If

this engine was originally equipped with a

resistor spark plug, use same type for

replacement.

A

B

Figure 17: Check Spark Plug

2O

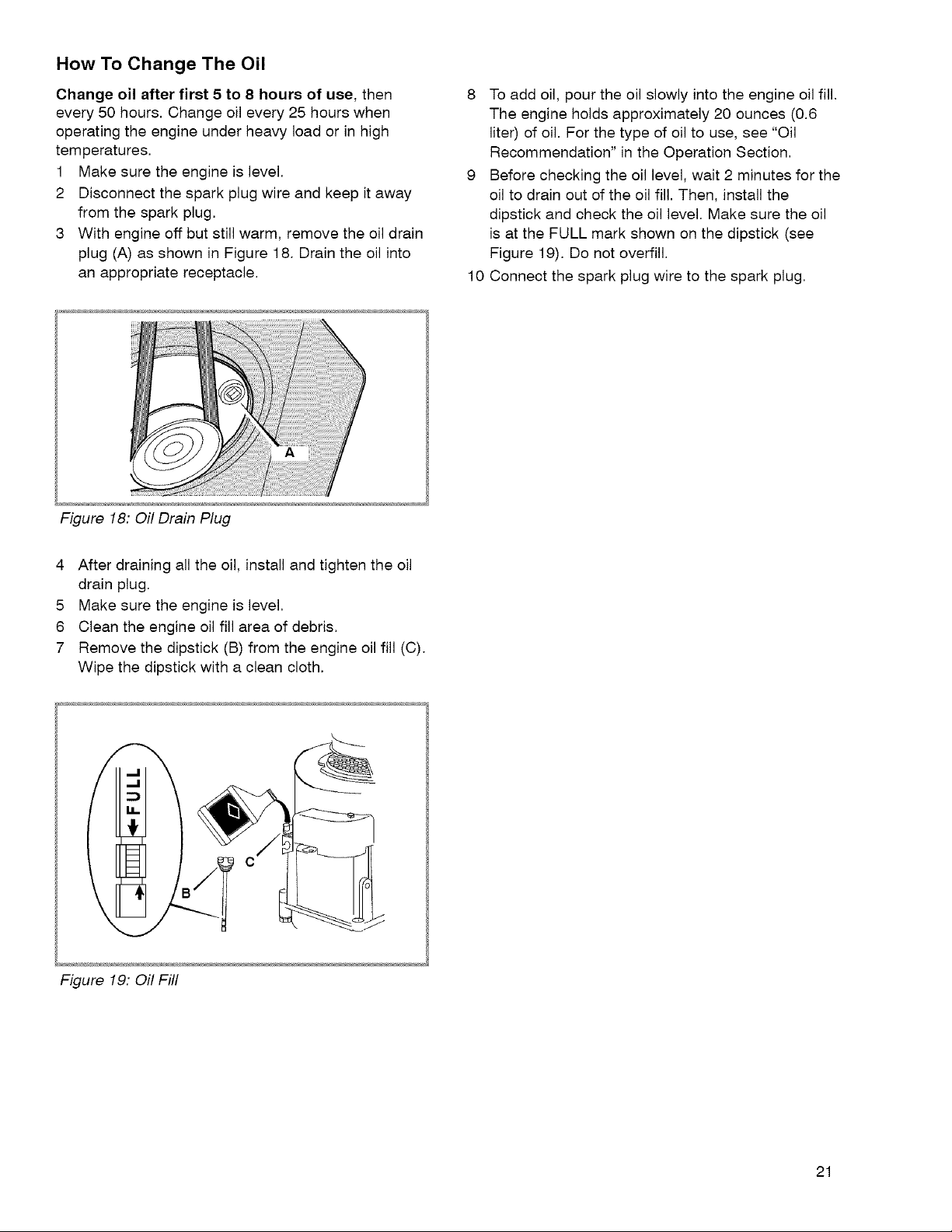

How To Change The Oil

Change oil after first 5 to 8 hours of use, then

every 50 hours. Change oil every 25 hours when

operating the engine under heavy load or in high

temperatures.

1 Make sure the engine is level.

2 Disconnect the spark plug wire and keep it away

from the spark plug.

3 With engine off but still warm, remove the oil drain

plug (A) as shown in Figure 18. Drain the oil into

an appropriate receptacle.

Figure 18: Oil Drain Plug

8 To add oil, pour the oil slowly into the engine oil fill.

The engine holds approximately 20 ounces (0.6

liter) of oil. For the type of oil to use, see "Oil

Recommendation" in the Operation Section.

9 Before checking the oil level, wait 2 minutes for the

oil to drain out of the oil fill. Then, install the

dipstick and check the oil level. Make sure the oil

is at the FULL mark shown on the dipstick (see

Figure 19). Do not overfill.

10 Connect the spark plug wire to the spark plug.

4 After draining all the oil, install and tighten the oil

drain plug.

5 Make sure the engine is level.

6 Clean the engine oil fill area of debris.

7 Remove the dipstick (B) from the engine oil fill (C).

Wipe the dipstick with a clean cloth.

Figure 19: Oil Fill

21

Loading...

Loading...