Craftsman 517798580 Owner’s Manual

SW S

25cc 2-cycle Engine

17" Swath Gasoline

WEEDWACKER ®

Model No.

517.798580

Operator's Manual

®

Consumer Helpline

Telephone Numbers

located on Page 32.

Caution;

Read and Follow all Safety

Rules and Instructions Before

Operating This Equipment.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

2/28/96 P/N 19816 Rev. 0

Tableof Contents.................................2

SafetyRules& SymbolDefinition ....2,3

Warranty..............................................3

Index ....................................................4

Assembly.............................................5

Operation..........................................6-8

Maintenance...................................9-10

Service& Adjustments.......................10

Storage..............................................10

Troubleshooting............................11-12

Parts..............................................14-19

Spanish.........................................20-3t

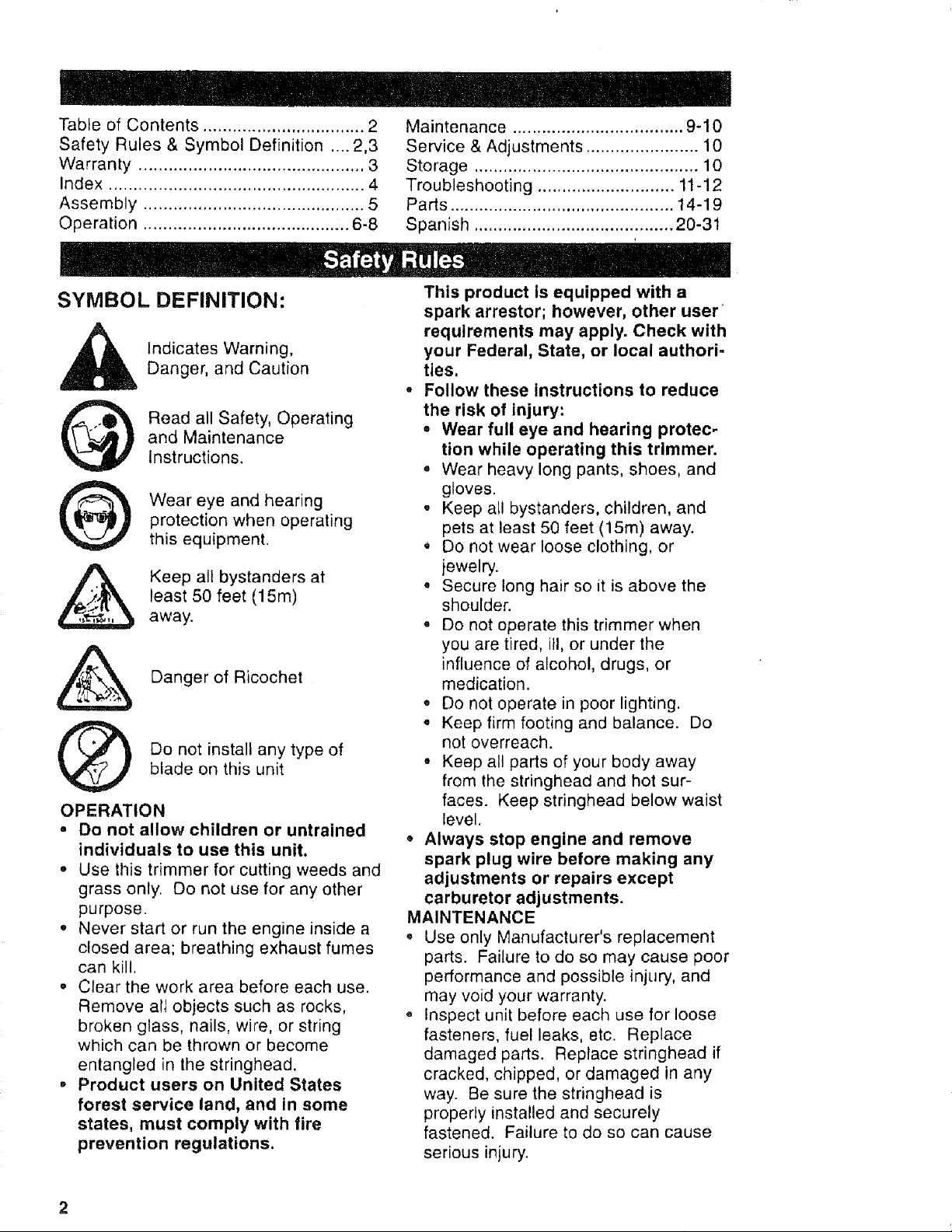

SYMBOL DEFINITION:

Indicates Warning,

A

@

O

Q o not install any type of

OPERATION

• Do not allow children or untrained

individuals to use this unit.

• Use this trimmer for cutting weeds and

grass only. Do not use for any other

purpose.

• Never start or run the engine inside a

closed area; breathing exhaust fumes

can kill.

° Clear the work area before each use.

Remove all objects such as rocks,

broken glass, nails, wire, or string

which can be thrown or become

entangled in the stringhead.

° Product users on United States

forest service land, and In some

states, must comply with fire

prevention regulations.

Danger, and Caution

Read all Safety, Operating

and Maintenance

Instructions.

Wear eye and hearing

protection when operating

this equipment.

Keep all bystanders at

least 50 feet (15m)

away.

Danger

of Ricochet

blade on this unit

This product is equipped with a

spark arrestor; however, other user

requirements may apply. Check with

your Federal, State, or local authori-

ties.

° Follow these instructions to reduce

the risk of injury:

° Wear full eye and hearing protec-

tion while operating this trimmer.

° Wear heavy long pants, shoes, and

gloves.

. Keep all bystanders, children, and

pets at least 50 feet (15m) away.

, Do not wear loose clothing, or

jewelry.

° Secure long hair so it is above the

shoulder.

° Do not operate this trimmer when

you are tired, ill, or under the

influence of alcohol, drugs, or

medication.

° Do not operate in poor lighting.

° Keep firm footing and balance. Do

not overreach.

° Keep all parts of your body away

from the stringhead and hot sur-

faces. Keep stringhead below waist

level.

• Always stop engine and remove

spark plug wire before making any

adjustments or repairs except

carburetor adjustments.

MAINTENANCE

o Use only Manufacturer's replacement

parts. Failure to do so may cause poor

performance and possible injury, and

may void your warranty.

• Inspect unit before each use for loose

fasteners, fuel leaks, etc. Replace

damaged pads. Replace stringhead if

cracked, chipped, or damaged in any

way. Be sure the stringhead is

properly installed and securely

fastened. Failure to do so can cause

serious injury.

2

• Make sure all deflectors and handles

are properly and securely attached.

° Use only monofilament string in the

cutting head. Do not use any other

cutting attachment.

• The stringhead will spin during

carburetor adjustments. Wear

protective equipment and observe all

safety instructions.

• Before storing, allow the engine to

cool.

• Empty the fuel tank and restrain the

trimmer from moving before transport-

ing in a vehicle.

REFUELING (DO NOT SMOKE!)

• Mix and store fuel in a container

approved for gasoline.

° Mix fuel outdoors where there are no

sparks or flames.

• Select bare ground, stop engine and

allow to cool before refueling.

• Loosen fuel cap slowly to release

pressure and to keep fuel from

escaping around the cap.

_, Wipe spilled fuel from the unit, Move

10 feet (3m) away from refueling site

before starting engine.

WARNING

The engine exhaust from this

product contains chemicals

known to the State of California

to cause cancer, birth defects

or other reproductive harm.

CALIFORNIA PROPOSITION 65

FULL ONE-YEAR WARRANTY ON CRAFTSMAN ® WEEDWACKER ®

LINE TRIMMER

For one (1) year from date of purchase, when this Craftsman Gas Powered

WeedwackeP Line Trimmer is maintained, lubricated, and tuned up according to

the operating and maintenance instructions in the Operator's Manual, Sears will

repair, free of charge, any defect in materials or workmanship.

This warranty excludes nylon line, spark plug, spool retainer, and air filter, which

are expendable parts and become worn during normal use.

If this WeedwackeP Line Trimmer is used for commercial purposes, this warranty

applies for only 90 days from date of purchase. If this WeedwackeP Line

Trimmer is used for rental purposes, this warranty applies for only 30 days from

the date of purchase. This warranty applies only while this product is in use in the

United States.

WARRANTY SERVICE AVAILABLE BY RETURNING THE WEEDWACKER ®

TO THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., 1:)/817 WA, Hoffman Estates, IL 60179

A

Adjustments:

Carburetor ................................. 11,12

Air Filter:

Cleaning ......................................... 10

B

Before Starting Engine ........................ 7

C

Carton contents ................................... 5

Controls:

Choke Lever ..................................... 8

Primer Bulb ...................................... 8

Throttle Trigger ................................. 8

Stop Button ...................................... 8

Customer Responsibilities:

Air Filter .......................................... 10

Carburetor Adjustment .............. 11,12

Fuel Cap Filter ................................ 10

Spark Plug ...................................... 10

Stringhead ..................................... 8,9

E

Engine:

Before Starting Engine ..................... 7

Fuel .................................................. 7

Starting and Stopping ...................... 8

Storage ........................................... 10

F

Filter, Air ............................................. 10

Filter, Fuel Cap .................................. 10

Fuel ...................................................... 7

G

Grass Deflector .................................... 5

H

Handle .................................................. 5

I

Index .................................................... 4

M

Maintenance Schedule ........................ 8

O

Oil:

Type ..... See Fuel .............................. 7

Operation:

Before Starting Engine ..................... 7

Starting ............................................. 8

Stopping ........................................... 8

P

Product Specifications ......................... 4

R

Repair Parts .................................. 14-19

S

Safety Rules ..................................... 2,3

Spark Plug ......................................... 10

Starting ................................................. 8

Stopping ............................................... 8

Storage .............................................. 10

Stringhead:

Advance ........................................ 8,9

Installation ..................................... 8,9

Symbol Definitions ............................... 2

T

Table of Contents ................................. 2

Troubleshooting ............................ 11,12

W

Warranly .............................................. 3

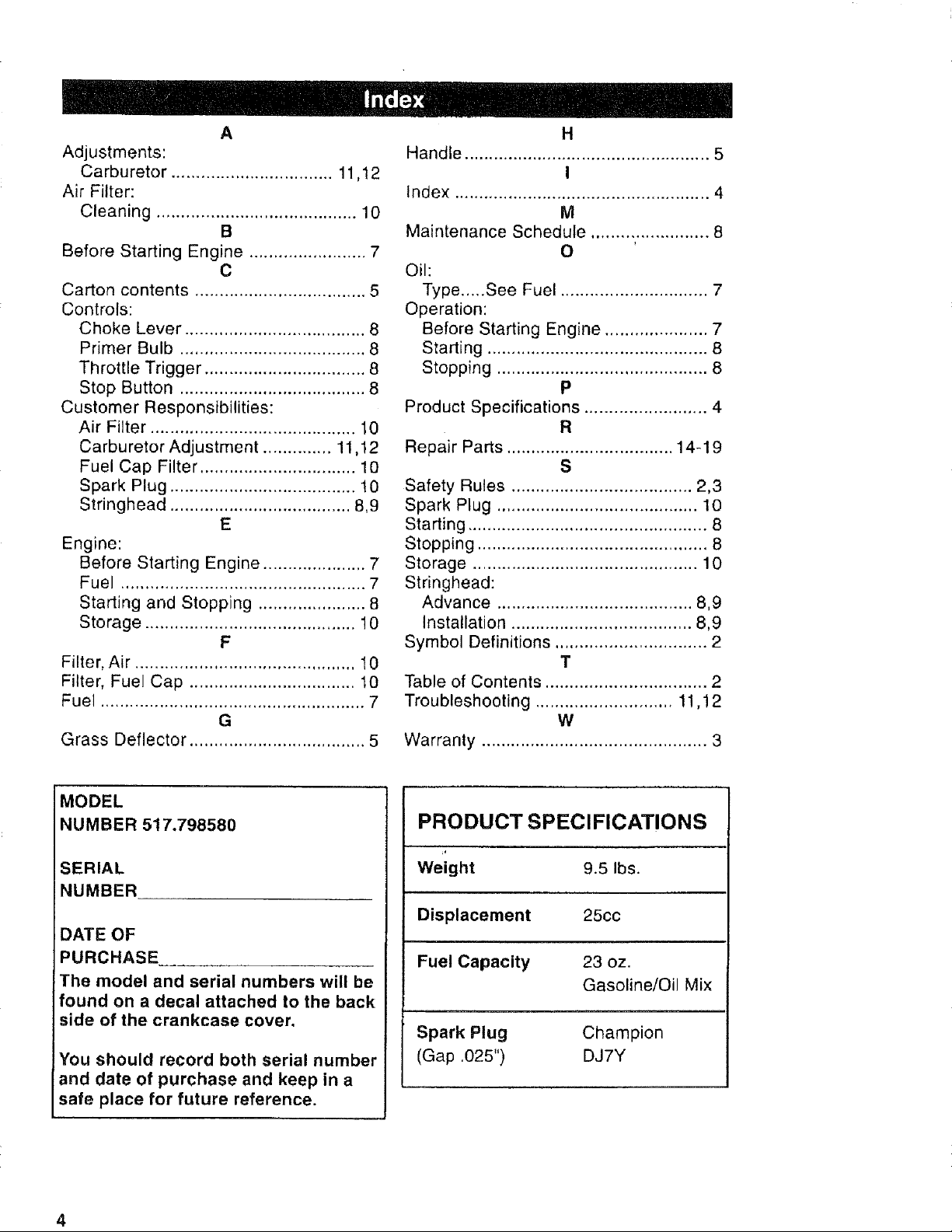

MODEL

NUMBER 517.798580

SERIAL

NUMBER

DATE OF

PURCHASE

The model and serial numbers will be

found on a decal attached to the back

side of the crankcase cover.

You should record both serial number

=and date of purchase and keep in a

safe place for future reference.

4

PRODUCT SPECI FICATIO N S

Weight 9.5 Ibs.

Displacement 25cc

Fuel Capacity 23 oz.

Gasoline/Oil Mix

Spark Plug Champion

(Gap .025") DJ7Y

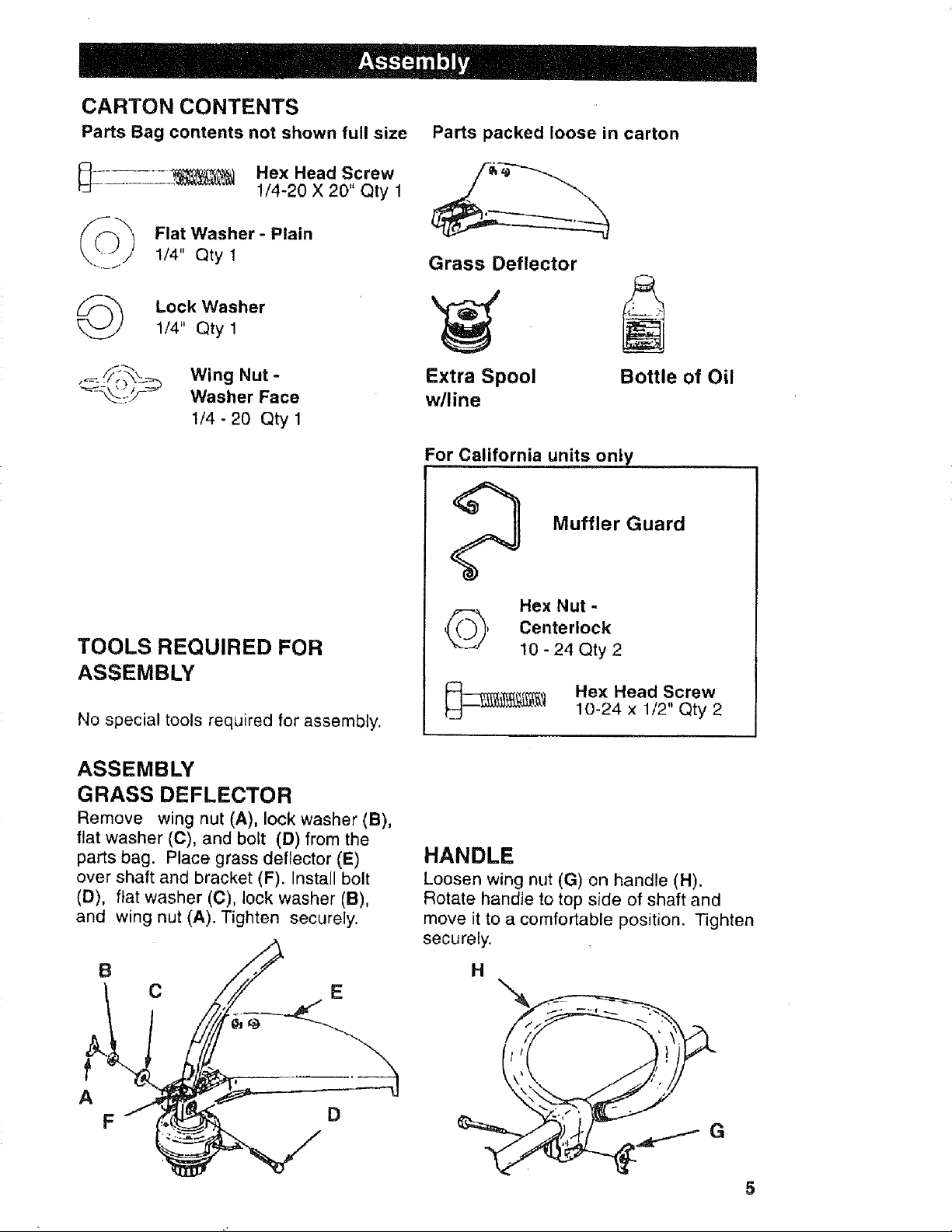

CARTON CONTENTS

Parts Bag contents not shown full size Parts packed loose in carton

_: ........ _ Hex Heal0, Screw

Flat Washer - Plain

1/4" Qty 1

(_) Lock Washer _'/ _

1/4" Qty 1

1/4-20 X Qty 1

Grass Deflector

,-../_-_ Wing Nut Extra Spool Bottle of Oil

"_-_-._-_ Washer Face w/line

1/4- 20 Qty 1

For California units only

Muffler Guard

Hex Nut -

Centerlock

TOOLS REQUIRED FOR

10 - 24 Qty 2

ASSEMBLY

Hex Head Screw

10-24 x 1/2" Qty 2

No special tools required for assembly.

ASSEMBLY

GRASS DEFLECTOR

Remove wing nut (A), lock washer (B),

flat washer (C), and bolt (D) from the

parts bag. Place grass deflector (E)

over shaft and bracket (F). install bolt

(D), flat washer (C), lock washer (B),

and wing nut (A). Tighten securely.

f

A

HANDLE

Loosen wing nut (G) on handte (H).

Rotate handJe to top side of shaft and

move it to a comfortable position. Tighten

securely.

H

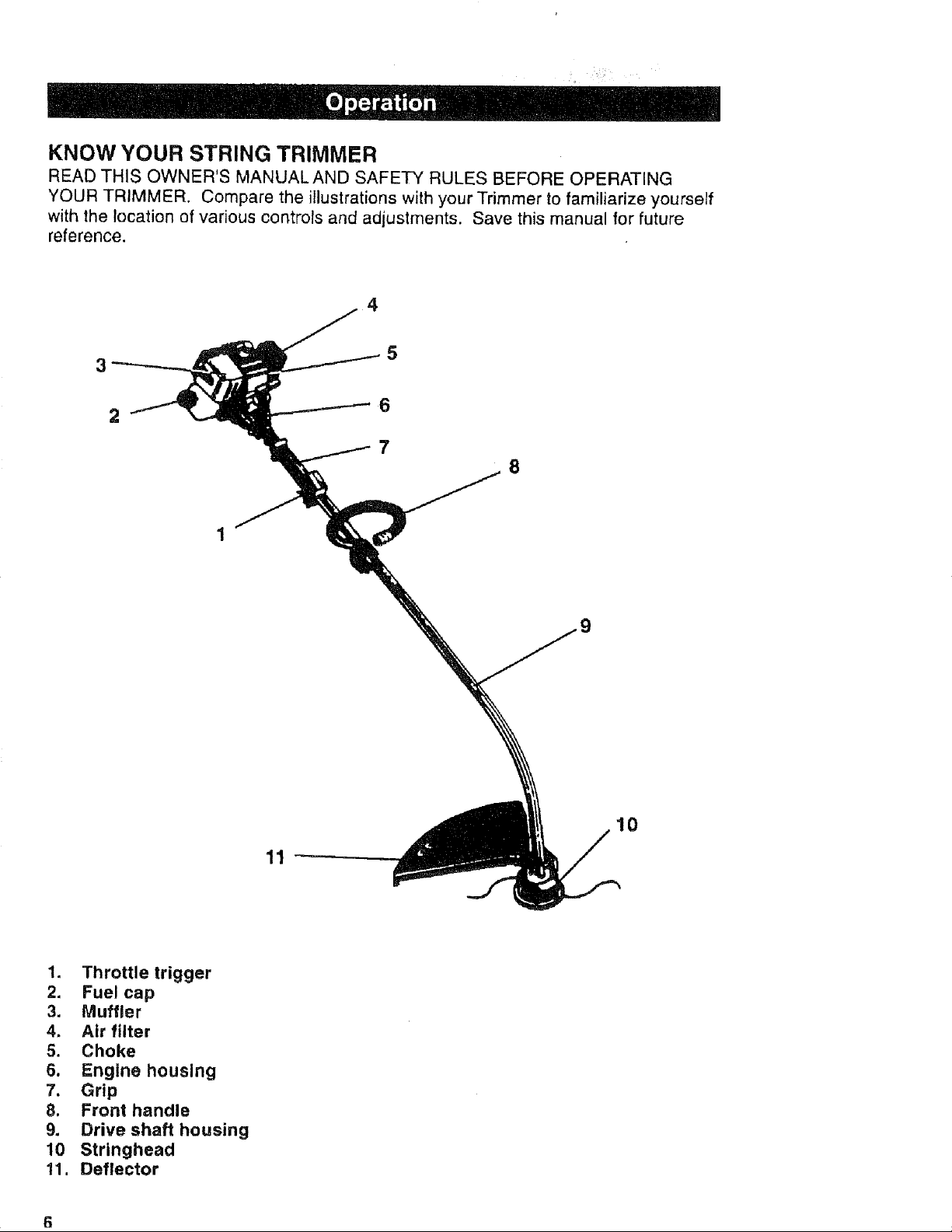

KNOW YOUR STRING TRIMMER

READ THIS OWNER'S MANUALAND SAFETY RULES BEFORE OPERATING

YOUR TRIMMER. Compare the illustrations with your Trimmer to familiarize yourself

with the location of various controls and adjustments. Save this manual for future

reference.

4

3

5

2

6

7

1. Throttle trigger

2. Fuel cap

3. Muffler

4, Air filter

5. Choke

6. Engine housing

7. Grip

8, Front handle

9. Drive shaft housing

10 Stringhead

11, Deflector

10

11

BEFORE STARTING ENGINE

FUELING

This engine is certified to operate on

unleaded gasoline intended for

automotive use.

This is a 2-cycle engine product and

requires pre-mixing gasoline and 2-

cycle oil. For normal homeowner use,

we recommend mixing fuel in a 1 or 2

gallon container approved for gasoline.

Use Craftsman®2=cycle engine oll No.

36549. Mix at the ratio of 40:1 (3.2 oz.

of oil to 1 gal. of gasoline).

Oil formulated for 50:1 should be mixed at

a 40:1 ratio.

Oil formulated at 100:1,24:1, 16:1 or non

2-cycle oil should not be used. They can

cause smoking, oily residues, spark plug

fouling, combustion chamber deposits,

hard starting, etc.; and may void your

warranty.

Do not use automotive oil or 2-cycle

outboard oil.

1. Loosen fuel cap slowly. Rest the cap

on a clean surface.

2. Carefully pour fuel into the tank. Avoid

spillage.

3. Immediately replace fuel cap and

hand tighten. Wipe up any fuel

spillage.

4. It is normal for smoke to be emitted

from a new engine after first use.

NOTE: Always shut off engine before

fueling. Never add fuel to a machine

with a running or hot engine. Move at

least 10 feet (3m) from refueling site

before starting engine. DO NOT

SMOKE!

_, WARNING

Experience indicates that atcohol blended

fuels (called gasohol or using ethanol or

methanol) can attract moisture which

leads to separation and formation of acids

during storage. Acidic gas can damage

the fuel system of an engine while in

storage. To avoid engine problems, the

fuel system should be emptied before

storage for 30 days or longer. Start the

engine and let it run until the fuel lines

and carburetor are empty. Use fresh fuel

next season. See Storage instructions for

additional information. Never use engine

or carburetor cleaner products in the fuel

tank or permanent damage may occur.

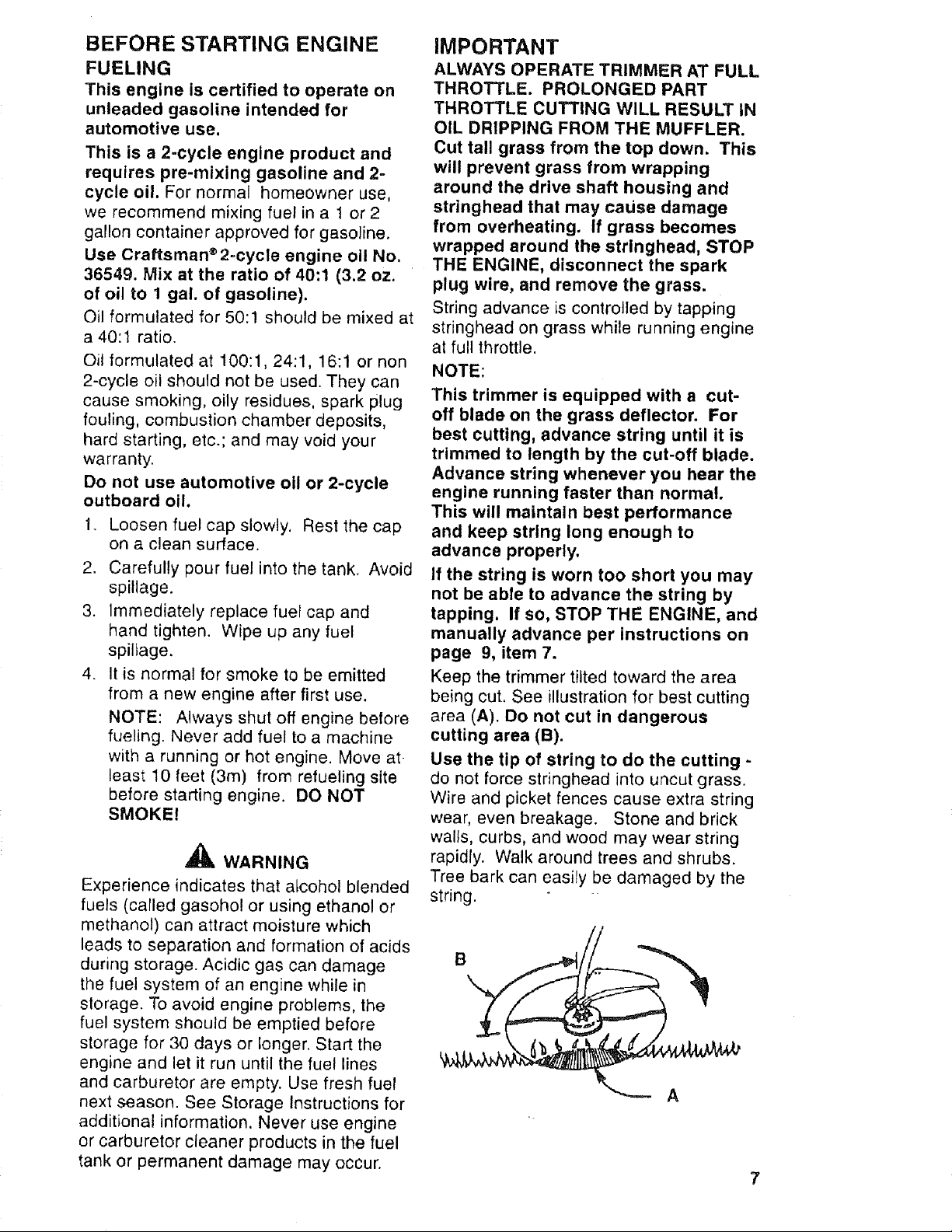

IMPORTANT

ALWAYS OPERATE TRIMMER AT FULL

THROTTLE. PROLONGED PART

THROTTLE CUTTING WILL RESULT IN

OIL DRIPPING FROM THE MUFFLER.

Cut tall grass from the top down. This

will prevent grass from wrapping

around the drive shaft housing and

stringhead that may cause damage

from overheating. If grass becomes

wrapped around the stringhead, STOP

THE ENGINE, disconnect the spark

plug wire, and remove the grass.

String advance is controlled by tapping

stringhead on grass while running engine

at full throttle.

NOTE:

This trimmer is equipped with a cut-

off blade on the grass deflector. For

best cutting, advance string until it is

trimmed to length by the cut-off blade.

Advance string whenever you hear the

engine running faster than normal.

This will maintain best performance

and keep string long enough to

advance properly,

If the string is worn too short you may

not be able to advance the string by

tapping, If so, STOP THE ENGINE, and

manually advance per instructions on

page 9, item 7.

Keep the trimmer tilted toward the area

being cut. See illustration for best cutting

area (A). Do not cut in dangerous

cutting area (B).

Use the tip of string to do the cutting -

do not force stringhead into uncut grass.

Wire and picket fences cause extra string

wear, even breakage. Stone and brick

walls, curbs, and wood may wear string

rapidly. Walk around trees and shrubs.

Tree bark can easily be damaged by the

string.

B

A

7

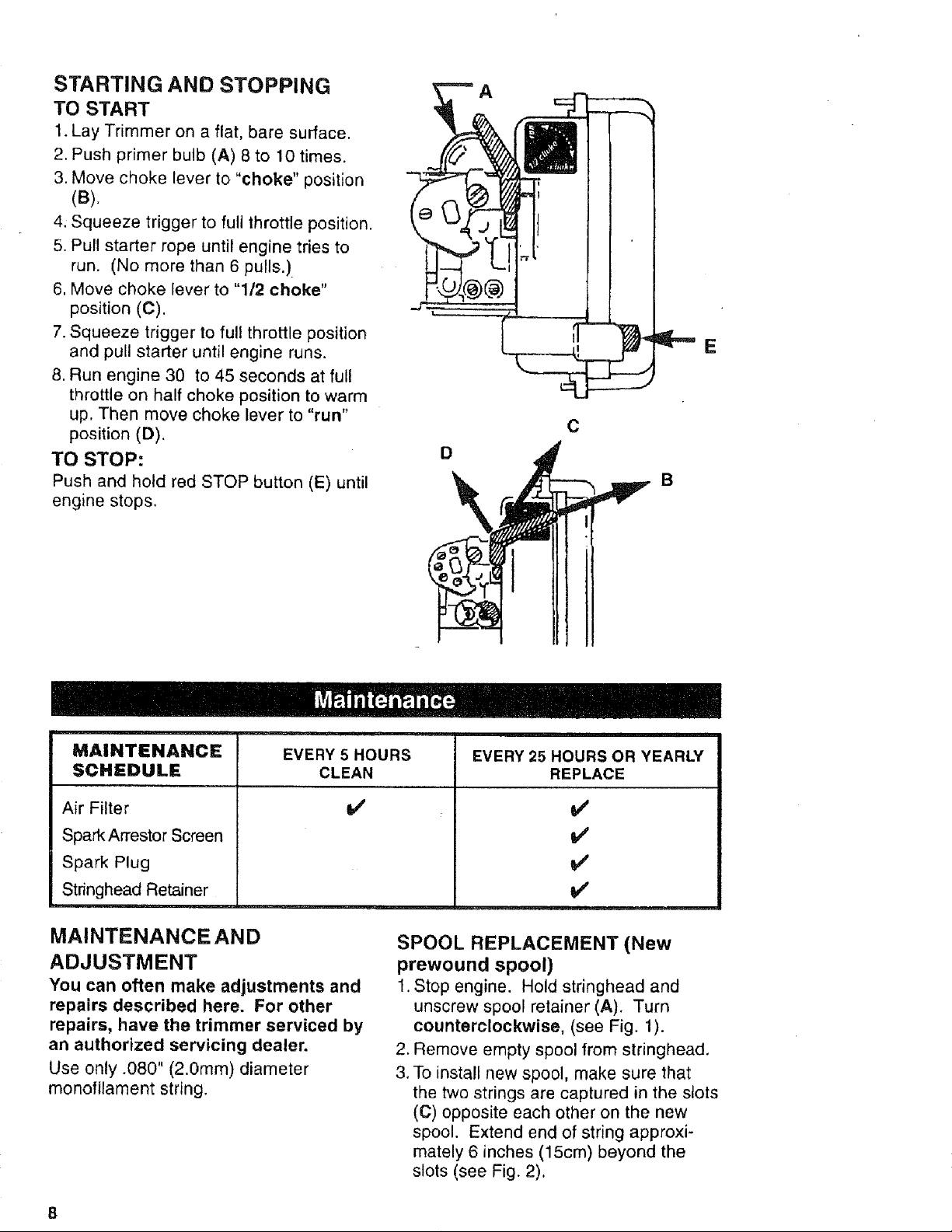

STARTING AND STOPPING

TO START

1. Lay Trimmer on a flat, bare surface.

2. Push primer bulb (A) 8 to 10 times.

3. Move choke lever to "choke" position

(B).

4. Squeeze trigger to full throttle position.

5. Pull starter rope until engine tries to

run. (No more than 6 pulls.)

6, Move choke lever to "1/2 choke"

position (C).

7. Squeeze trigger to full throttle position

and pull starter until engine runs.

8, Run engine 30 to 45 seconds at full

throttle on half choke position to warm

up, Then move choke lever to "run"

position (D).

TO STOP:

Push and hold red STOP button (E) until

engine stops.

A

E

C

D

B

MAINTENANCE

SCHEDULE

EVERY 5 HOURS

CLEAN

Air Filter

Spark Arrestor Screen

Spark Plug

Stringhead Retainer

MAINTENANCE AND

ADJUSTMENT

You can often make adjustments and

repairs described here. For other

repairs, have the trimmer serviced by

an authorized servicing dealer.

Use only .080" (2.0ram) diameter

monofilament string.

v'

EVERY25 HOURS OR YEARLY

REPLACE

is'

v'

v'

v'

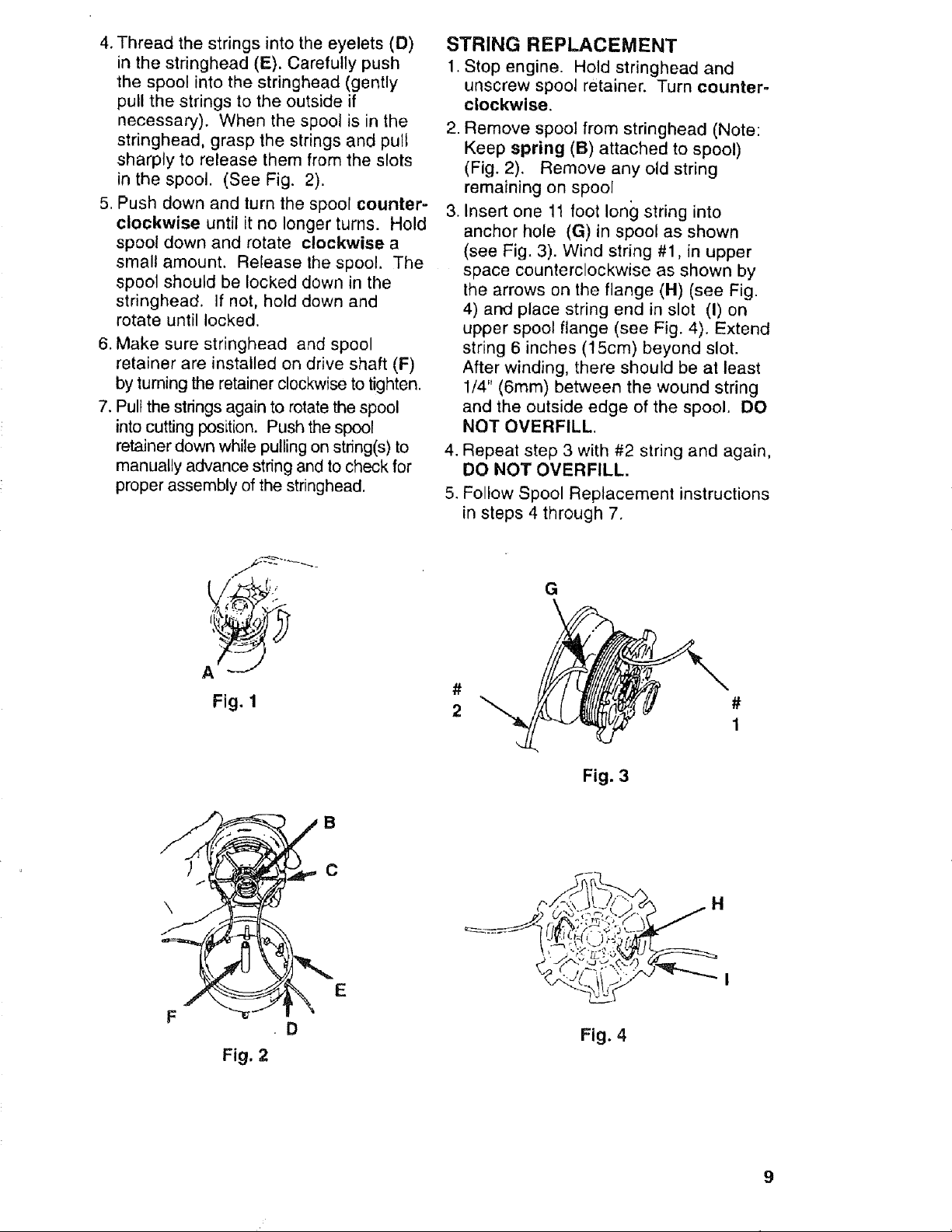

SPOOL REPLACEMENT (New

prewound spool)

1.Stop engine. Hold stringhead and

unscrew spool retainer (A). Turn

counterclockwise, (see Fig. 1).

2. Remove empty spool from stringhead.

3. To install new spool, make sure that

the two strings are captured in the stots

(C) opposite each other on the new

spool. Extend end of string approxi-

mately 6 inches (15cm) beyond the

slots (see Fig. 2),

4. Thread the strings into the eyelets (D)

in the stringhead (E). Carefully push

the spool into the stringhead (gently

pull the strings to the outside if

necessary). When the spool is in the

stringhead, grasp the strings and putt

sharply to release them from the slots

in the spool. (See Fig. 2).

5. Push down and turn the spool counter-

clockwise until it no longer turns. Hold

spool down and rotate clockwise a

small amount. Release the spool. The

spool should be locked down in the

stringhead. If not, hold down and

rotate until locked.

6. Make sure stringhead and spool

retainer are installed on drive shaft (F)

by turning the retainer clockwise to tighten.

7. Pull the strings again to rotate the spool

into cutting position. Push the spool

retainer down while pulling on string(s) to

manually advance string and to check for

proper assembly of the stringhead.

STRING REPLACEMENT

1. Stop engine. Hold stringhead and

unscrew spool retainer. Turn counter-

clockwise.

2. Remove spool from stringhead (Note:

Keep spring (B) attached to spool)

(Fig. 2). Remove any old string

remaining on spool

3. Insert one 11 foot long string into

anchor hole (G) in spool as shown

(see Fig. 3). Wind string #1, in upper

space counterclockwise as shown by

the arrows on the flange (H) (see Fig.

4) and place string end in slot (I) on

upper spool flange (see Fig. 4). Extend

string 6 inches (15cm) beyond slot.

After winding, there should be at least

1/4" (6ram) between the wound string

and the outside edge of the spool. DO

NOT OVERFILL.

4. Repeat step 3 with #2 string and again,

DO NOT OVERFILL.

5. Follow Spool Replacement instructions

in steps 4 through 7.

\

F

A "--t"

Fig. 1

Fig. 2

G

\

#

2

Fig. 3

B

C

E

Fig. 4

#

1

FUEL CAP FILTER

WARNING

A leaking fuel cap is a fire hazard and

must be replaced immediately.

The fuel cap contains a non-serviceable

filter and a check valve. A clogged fuel

filter'will cause poor engine performance.

If performance improves when the fuel

cap is loosened, check valve may be

faulty or filter clogged. Replace fuel cap

if required.

SPARK PLUG

This engine uses a Champion DJ-7Y

with .025" (0,63mm) electrode gap.

an exact replacement and replace

annually.

Use

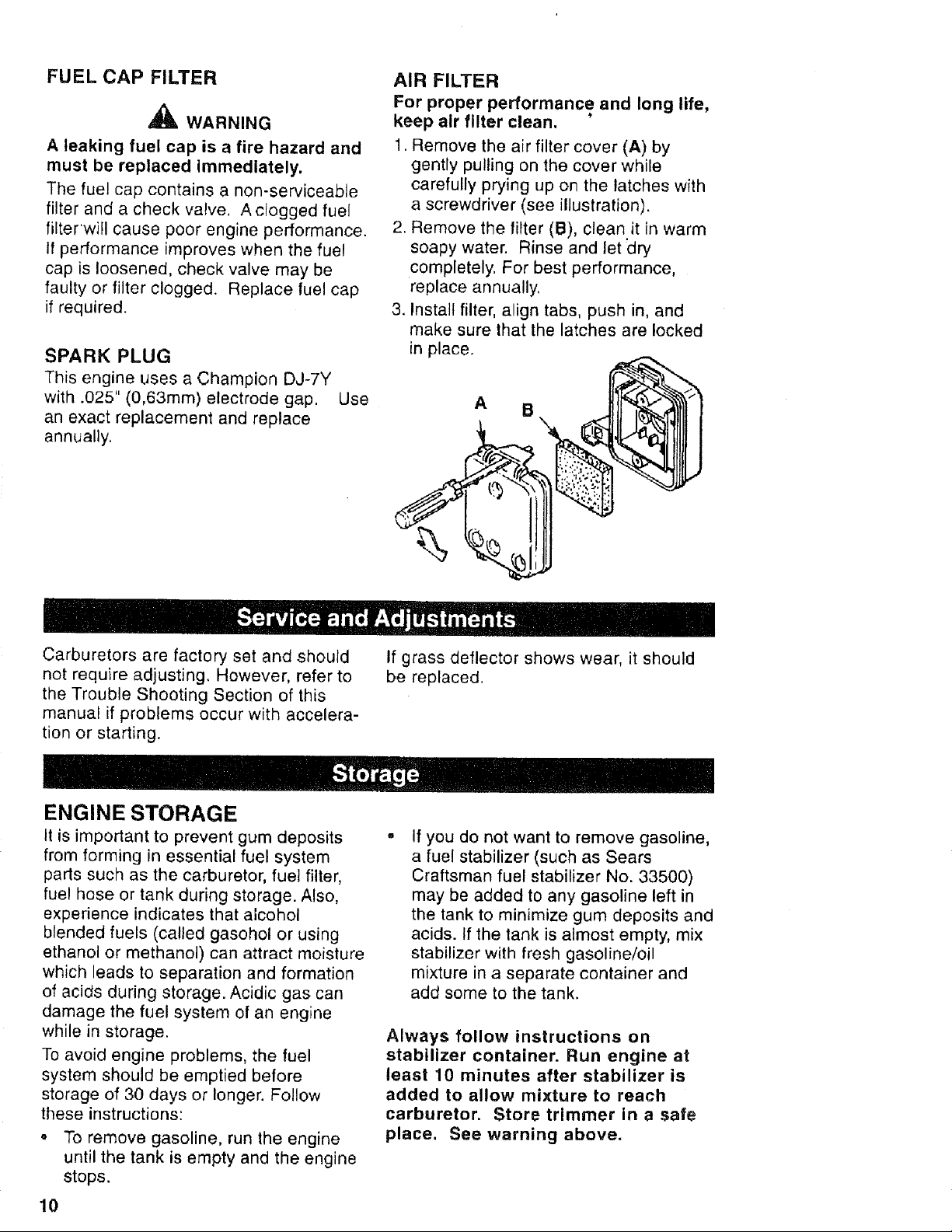

AIR FILTER

For proper performance and long life,

keep air filter clean. '

1. Remove the air filter cover (A) by

gently pulling on the cover while

carefully prying up on the latches with

a screwdriver (see illustration).

2. Remove the filter (B), clean it in warm

soapy water. Rinse and let 'dry

completely. For best performance,

replace annually.

3. Install filter, align tabs, push in, and

make sure that the latches are locked

in place.

A B

Carburetors are factory set and should

not require adjusting. However, refer to

the Trouble Shooting Section of this

manual if problems occur with accelera-

tion or starting.

ENGINE STORAGE

It _simportant to prevent gum deposits

from forming in essential fuel system

parts such as the carburetor, fuel filter,

fuel hose or tank during storage. Also,

experience indicates that alcohol

blended fuels (called gasohol or using

ethanol or methanol) can attract moisture

which leads to separation and formation

of acids during storage. Acidic gas can

damage the fuel system of an engine

while in storage.

To avoid engine problems, the fuel

system should be emptied before

storage of 30 days or longer. Follow

these instructions:

To remove gasoline, run the engine

until the tank is empty and the engine

stops.

If grass deflector shows wear, it should

be replaced.

If you do not want to remove gasoline,

a fuel stabilizer (such as Sears

Craftsman fuel stabilizer No. 33500)

may be added to any gasoline left in

the tank to minimize gum deposits and

acids. If the lank is almost empty, mix

stabilizer with fresh gasoline/oil

mixture in a separate container and

add some to the tank.

Always follow instructions on

stabilizer container. Run engine at

least 10 minutes after stabilizer is

added to allow mixture to reach

carburetor. Store trimmer in a safe

place. See warning above.

10

Loading...

Loading...