I

1 6+16!i i iii I

L4{HOf I ,%:,_." = _,

i Is_@ _T! !iI'3'=_= ¢-_A"= "

=__,_.e li.,%i°.=llo,,l _IIs_ If,

JA993695

C IsslOllSel

£_v ell tge

CAUTION: ALWAYS DISCChh.,'N ECT SPARK PLUG WiRE AND PLACE WIRE \,VHERE IT CANNOT

CONTACT SPARK PLUG TO PREVENT ACCIDENTAL STARTING WHEN SE17"ING-UP,

TRANSPORTING, ADJUSTIh_G OR MAKllqG REPAIRS TO YOUR MOWER.

FEDERAL REGULATIONS REQUIRE OPERATOR PRESENCE BLADE STOP CONTROLS TO MINIMIZE THE RISK

OF CONTACT !N JURY. YOUR MOWER IS EQUIPPED W1TH SUCH COkTROLS, DO NOT ATTEMPT TO DEFEAT

THE FUNCTION OF TH, E OPERATOR PRESENCE CON] ROL UNDER ANY CIRCUMSTANCES,

TRAININg:

e Read the owner's manual car@uliy. Became ta,,mitiar

with !he eonlrots and know how to Operate this mower

properly. Learn how to stop the mower quick%

e DO NOT allow childran Io use this mower. Never allow

adults to use the mower without p_oper instRictians.

e Keep the area of operalion clear of all persons, espe ÷

cially smait children end petS,

e Use the mower only as the man[ facturer intended and

as described in _}s manual.

e When not using your mower, slore it indoors in a do',

high or locked-up place - out of reach, of ehiidren.

DO NOT nperale mower if it bee been dropped or

damaged in any manner. Always have damage repaired

before using the mower, o

DO NOY use acce£soq.., atlachments not recommended

by the manufacturer- it may be hazardous.

e Use only product manufacturer's genuine replacement

paris Failure to do so may cause poor fit and possible

iniuo'

PAEPARAT!ON:

60biects struc¢ by the lawn mower s, I! be thrown ann

can cause severe iniuo_ _o pel-sdns. Atways check the

a_ea to ee mowed and cleariiof aHstones, sticks, wres,

bones, eta

_ Dress properly - Wear onJy solid shoes when mowing

Neve mow when barefoot or wearing open eandaJs

e Ah',ays wear safety glasses or eye shields when staRmg

and whi!e USir,g your lawn mower

e DO NOT til! gas tank when the engine is running

indoors or when engme is _ot. Allow 1he engine to coo

for several min,u_es before fi!iing Ue gas tank Cean off

any spilted gasoline before starling the engine.

Never make wt/ee height adjustrneuls while the engine

is fur n ng

e Mow only in day! ght or good adificial light.

e DO NOT operate mower in wet grass. Always be sure of

your fodung -keep a f rm ..... on the handies and walL-

hey'or run

OPERATION:

e DO 'IOT change ,_negovernor settings or overspeed the

eT_gir'e

_* DO NOT put hands or feel near or under rotat::ng parts

Keeocea ottned}sch_rgeopening at all tines.

¢ Stop the engine whey, ever you cave Abe ii]ower, mefo_e

crossing drives, ,*,,a!t s o_ reeds.

I _ ,,y .-¢.,- o..... s._-., T©__OC,., P_R THIS oV ,,_8,JL POlr,,rT

OU]- , .'_Oc"T_v_._, .,-,'rT,. S/kFFTY_ ........ _'

TIONS tT _,m"..__,-s,_'d_...,_ ATTENT!OtU u_.. B i:-_

L,L)'",,-_'_:ALEA-{ !! YOt.IR SAFE] "_ iS

t , OL,' L_,

_" DO IIOTcontinueto rut YOUr. mowerif you bil. a Ioreign

o,.-,l-_-_. Stop the _ngine. make ebsoiutety sure tee blade

and all moving paris have stopped, disconnect tP,e spark

plug vdre .from the spar_ plug lo preven_ aGoident_i

sta£ing, then inspect tee mower for damage and repair

before reata,qing and operating the mower

e if the mower should start te vibrate heavily, slop tee

eng he, check for the cause and repair. Remember,

heavy vibration is generally a sign ef trouble

e Stop the engine, wait _or blade and all moving parts to

stop, before cleani rig, unclogging chute, ren_oving grass

caLcher, repa_rng or inepecling ihe mower, Always

disconnect the spark piog wire and keepaway from plug

to prevent accidental starting.

e DO N©T run engine indoors - exhaust fumes are

dan,2ereus

6 Never cu_ grass s).'p'_lli_glhe mower towards you Mow

grass across the face o[ slopes, never up and down or

you cou!dioseyourfootin_ DO NOT mow excessively

steep sh',pes. Use caution when or)crating the mower on

unever: terrain or whe_ changing direction - mainta n

good footing

e Never aperafe _he mower without p_oper guards, pieces

or olher safety devices i-_ place.

OUSTOf_IERAESPONSIR4LITISS AND S'_ORAG6

¢ Check the blade and the engine mounting ba!ts often to

be sure they ae tightened sroper 7

Check atl bo)ts, nuts and screws at frequent intervais for

prooer _ightness to be sure mower is in safe working

condition.

e N_-ver s_ore mower with fuelinthe tank inside abuiidmg

where ignition sources are p_esent such as i_et water

hen,tar and space heeters, clothes dryers, and the !iRe

AI!os7 engine to cool before storing in any enclosure.

To reduce fro hazard, keep the engine _ree of grass,

leaves or excess va grease and oil,

if grass catcher is used with your mowe_, check it often

far deterioration end wear and repla, ce worn bags. Use

only rap adamant bags tha_ are recommended by and

comply wth specif ceticns of the n,,anufaclurer Oi your

mower

e )teen a sharp bade Or_ your morner

Tqe cuttinge_ges o!the mower b_ade are sharp and car"

tacerale (cut} skin lissue Care should be taken when

doing any repair work r:n or a,_'ound t',e mower blade. TO

p everH injury, _t_s recommended t_et gloves bewern or

the cutting edge be w_apped wit: newspaper or any

01her _u labia inatena_ when working on the blade.

l

1

COfdGRATULATIONS on your purchase of a Sea_s

Craftsman Lawn Mower. It has beeq designed, en-

.0 neered and manufactured to give you the best pos-

sib!e dependability and performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Service

Center!Department. We r_ave competent, welt-trained

te;chnicians and the proper tools to service Or repair th is

unit.

Please read and retain this manual. The instructions will

enable you to assemble and ma:,ntain your mower

properly. Always observe the "SAFETY RULES",

A Sears Maintenance Agreerner_! is availabie or _,tIqs

product Contac yournearestSearssterefordelails.

e Read and observe thesafety rules,

e Fo!Iow a reguiar schedule in maintaining, caring

for and using your mower.

e Follow the instructions under"Customer Respon-

sibilities'" and "Storage" seclions of this Owner's

Manual.

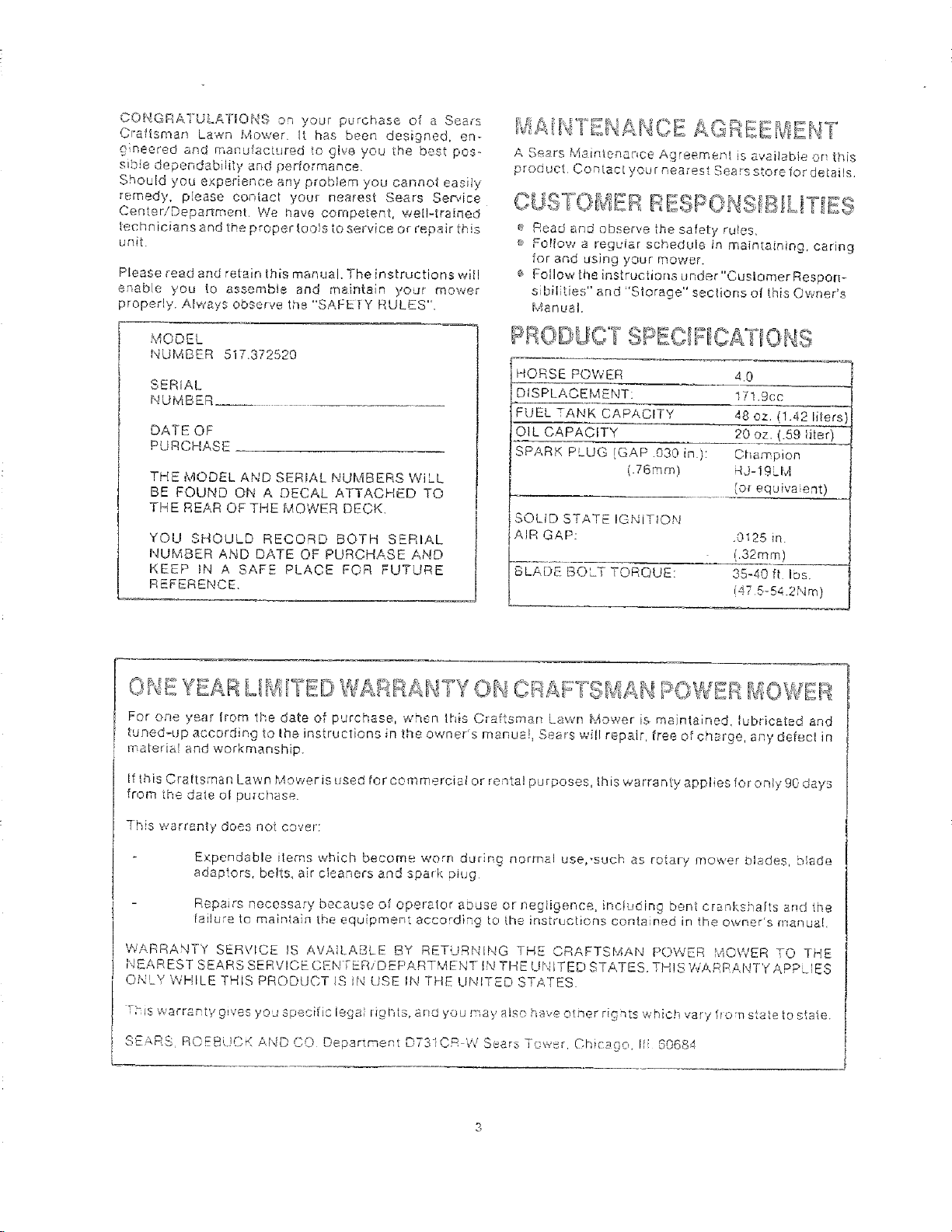

MODEL

PRO©UC SPECI - u,£ IOHS

IiUMBER 517.372529

SERIAL

NUMBEFI

DATE OF

PURCHASE

THE MODEL AND SERIAL NUMBERS WiLL

BE FOUND ON A DECAL ATTACHED TO

THE REAR OFTHE MOWER DECK.

YOU SHOULD RECORD BOTH SERIAL

NUMBER AND DATE OF PURCHASE AND

KEEP IN A SAFE PLACE FOR FUTURE

REFERENCE.

For one year lrom the date of purchase, when this Craftsman Lawn Mower is maintained, lubricated and

_uned-up a,_cord ng to lhe instructions in the owner's manua!, Saars will repair, tree o, ch_.rge, ony detect in

matedM and workmanship.

Iflhis Craftsman Lawn Moweris used forcommercialor rental purposes, lhiswarrantyappliesforonly90 days

from the date of purchase.

HORSE POWER 4.0

DISPLAC, EM ENT: 171.9cc

FUEL TANK CAPACITY 48 oz. (!.42 liters)

OIL CAPACITY 20 oz. (.59 liter).___

SPARK PLUG (GAP 039 in): Champion

(.76ram) RJ-19LM

{o_ equivalent)

SOL!D STATE IGNiT ON

AIR GAP: .0125 m.

L32mml

BLADE BOLT TORQUE: 35-40fl Is,s.

(47 5-54.2Nrn)

This warranty does not cover:

Expendable iIems which become worn during norms.I use,-such as rotary mower blades, b_ade

adaptors, belts, air cleaners and spa_k plug

Repairs necessary because of operator abuse or negligence, including bent cranks "_afts and fine

lailureto maintain the equipmentaccordi g to the instructions contained in the owner's ma_lua!

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN POWER MOWER TO THE

NEAR EST SEARS SERVICE CEN FER/DEPARTMENT !i',._TIdE UNITED STATES. TH! S WARRANTY APPLIES

ONLY WHILE THIS PRODUCT/S _N USE IN THE UNITED STATES.

i his warranty gwes you specific legai Hgl]ts and you may also have other rigsts which vary from state to state.

_<Rt n,.,,o,._,,.,_,FniIOw,_,tSD r'_epa£ment DT31CR WSearsTowsr, Chcaqo Iii 80684

T/- ,tsLL OF CONTE TS

SAFETY RULES ............................... 2

PRODUCT SPECIFICATIONS ................... 3

CUS! O_'.tiER RESPONSIBILiTiES . . , 3,11,12,13,14,15

WAR£ANTy ................................. 3

TABLE ©P CONTENTS ........................ 4

I[,!@EX ....................................... 4

MOWER ACCeSSORiES ....................... 4

A8 SI.E_,_BL"¢ .................................. 5

OPERATtOht .......................... 6,7,8,9110

$E£VtCE AND ADJUB"t°ME_;IT . ............. 16;,17

STORAGE ................................. I8

SERVICE F_ECO L'_;M_ N OAT tO}_,8S ............... 1I

TROUBLE S F_,OOTU4G ........................ 19

REPAIR PARTS - _'_4OWER.................. 20-24

REPAIR PAR"¢8 o ENG[_2E .................. 25-27

PARTS ©RDER_F_G/S_RVICE ......... BACK PAGE

A

Accessories ..................... 4

Adjustments:

C8rburdtor .................. ! 7

Engine Speed ................. !7

Height of Cut .................. 8

Wheel Adiuster ................. 8

Air Pilter ....................... 14

Assembly:

Handie ........................ 5

B

Blade:

Replacement .................. 12

Sharpening ................... 13

Controls:

Operator P_'esence Control Bar ., .7

Customer Responsibilities ......... 3

Air Filter ...................... 14

Blade Care/Replacement ........ 12

Engine ....................... 14

Lu bric_:ion ................... 1S

Spark Ptu:8.................... 14

Gear Reducer ................. 13

Cut[b_g Heights .................. 8

E

Engh_.e:

©i} Change ................... 1£

Specifications ................. 3

Starting ....................... 8

Storage ...................... 18

F

Filter, Air ....................... 14

G

Gasoline:

Storage ...................... 18

Tank Capacity .................. 3

Tyr_.e.......................... 8

Gear Reducer ................... "i3

L

Lubrication:

Engine ....................... 15

Gear Reducer ................. 1:3

Wheels ....................... 14

M

Maintenance:

Agreement ..................... 3

Mowing Tips .................... 1[)

O

Oii:

Change ...................... 15

Storage ...................... 18

Type .......................... 8

Operating Mower ........... 7,8,9,10

Operato_ Presence Controt ......... ?

P

Prm_er .......................... ,B

R

Repair!Rep:acement Par(s ..... 20-27

Responsibilities. Customer ......... 3

S

Safety Rules ..................... 2

Sen, ice and Adjustments:

Blade ..................... t2,!3

C_rbure_or .................... 17

Cutting Heig.ht ................. 8

H_ndle Height .................. 5

Engine ....................... !7

Rear Trail Shield ............... t7

Gear Reducer ................. 13

Se_ic_ Recorr_mendations ........ 11

Spark Plug ..................... 14

Specifica_;ons .................... 3

Starting the r_ngi_e ............... 8

Stopping the Mower .............. 8

Slot&go ........................ 18

T

Table of ContenLs ................ 4

1 rouble Shooting Paints .......... 19

W

Warranty ........................ 3

Wheels:

Adjusting }-ieighi ................ 8

L_;bricatiOn ................... 14

These accessories were eva.i able when (qe mowe_ was pufc_ased. They ate also availsb!e at _os _,Sears retail outlets cBtatog 8r_d

seP,'ice centers. ]'/os_ SeB_s storms can order repair parts for yo,_, when yOLs ero,,,ide tRe _odel n_ tuber of your rno¢_l"

8PARK P_UG " "I

f'_" I

AIR FILTQR MUFFLER GAS C;_4

L ....

_.NGtN £ OIL

I_- t

I

t 9TABiLIZL:R

t

I

J

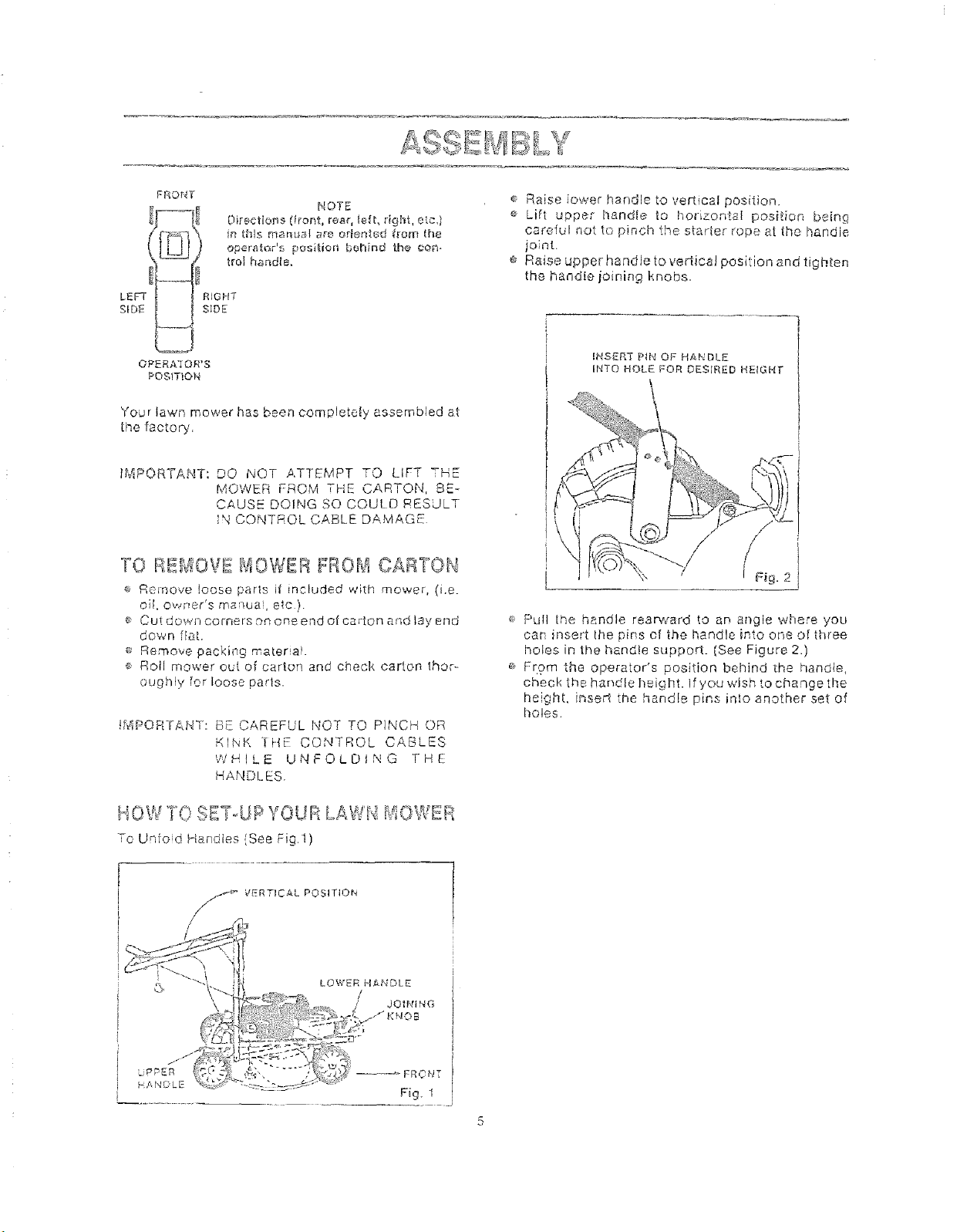

LEF_

SIDE

NOTE

Directions (Fron_, rear, le_t, right, etej

in tBIs manu_l are orbnt_d from _h_

operat_Ps position behind the com-

_rol handte.

RIGHT

SiDE

e Raise iower handle to vedical position.

¢ LiFt upper handle to horizontal position being

careful not to pinch the starlet rope at the handle

joint.

e Raise upper handle to vedical position and tighten

the isandle joining knobs.

O PE RA'I'O R'S

POSiTiON

Your lawn mower has been completely assembled at

the faotoo,.

iMPORTANT: DO NOT ATTEMPT TO LIFT THE

MOWER FROM THE CARTON, BE-

CAUSE DOING SO COULD RESULT

IN CONTROL CABLE DAMAGE

TO REB¢OVE _\40WER FROB_ CARTON

_, Remove loose paris if inchJded with mower, (i.e.

oil, owner's manual, e_o}.

e Cut down corrters on one end of carton and lay end

down flaL

Remove packing mater aL

¢ Roll mower out of carton and cheek carton lhor-

oughly for loose parts.

!MPORTANT: BE CAREFUL NOT TO PINCH OR

K!NK THE CONTROL CABLES

WHILE UNFOLDING ]HE

HANDLES.

!NSERE PIN OF HANDLE

INTO HOLE FOR DESIRED HEIGHT

\ / /

\,, I Fb. 2

Pull the handle rearward to an angle where you

can insed the pins of the handle into one of three

holes in the handle support. (See Figure 2.)

_o From the operator's position behind the handte,

check the handle height. If you wish to change the

heighL inset1 the handb pins inlo another set of

holes.

qOW TO SE _oUPYOUR _p,w_ i_/iO_AEh

To Unfod Handtes {See Fig1)

,_-{_ VERTICAL POSITION

........................ j

Fig. 1

5

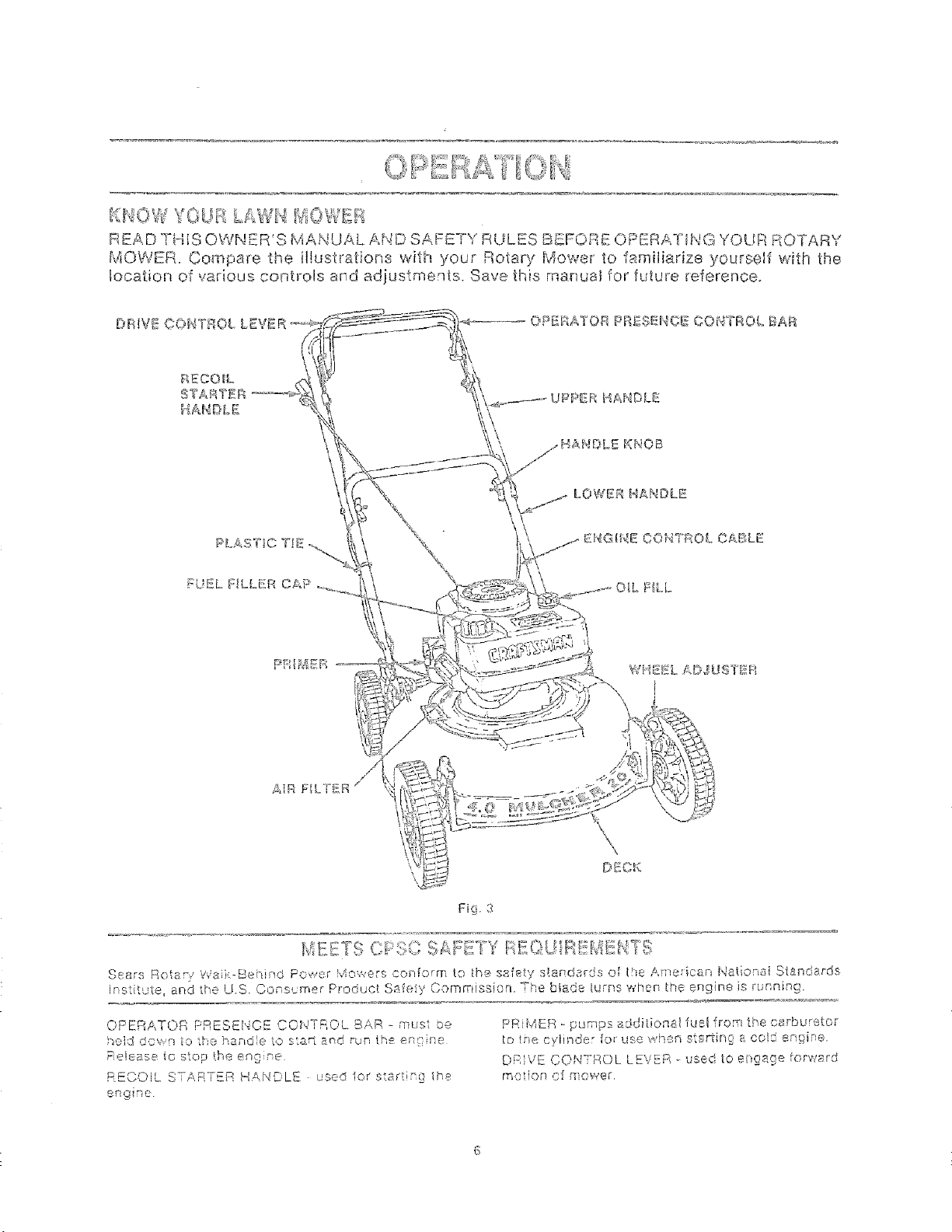

Kh OW YOUi: , LAWN !'¢:OWBB

READ THES OWNER'S I_4ANUAL AND SAFETY RULES B£FORE OPERAT!NG YOUR ROTARY

F4OWER. ©ompare the il!ustrstions with your Rotary Mower to familiarize yourself with the

location of various controls arid adjustments. Save finis manual for future reference.

\

DECK

Fin s

Sears Rotar,i Waik-Beisind PO,i,tc:r v1ovv_rs conform to lh® safety slands_.'s o lhe American ' "_'_"'

institute, and t.he U.S. Consumer Product Saleb' Commission. _he btadc turns when the engine is running.

OPERATOR PRESENCE CONTROL SAR - m[;st 0e

held down ko the handle to sta'i and run the en ne

Release ',ostop the engne

RECOIL STARTER HANDLE used lot start ng _,he

engir, e

' * _ IXati__. d_ Standards

F R I_s,ER - pumps additional fuel from the carburetor

_o t',_ cylinr_'e for Llge '_ 'hr_,ff_ 8_:_r-i- no _: Co_d ei-'giJ_e.

DR',k,'E CONTROL LLVE-_, used tO el?gage forward

ruction cf £]ower,

BEFOREUSINGYOURLAWNMOWERREFERTOFHE"SAFETYRULES"ASaHO_TN_'.4 _ONPAGEO_OFTHIS

MANdffLALWAYSBECAREFUL.

•TheoperationetanyLawnMowercanresultinIoreignob.;ecsben,9thownriteheeyes,whieilcan

_esuttin_eve_eeyedamage.Alwaysweersafety9_Ess_soreyeahieJd8beforesl_rtingpowertool

operationorwhilepedorminganyadiuslmentsorrepairs.WerecommendWideVtsionSafelyMask

foroverspectaclesorstandardglasses_vahabLatSearsRetailorCatalogStores,

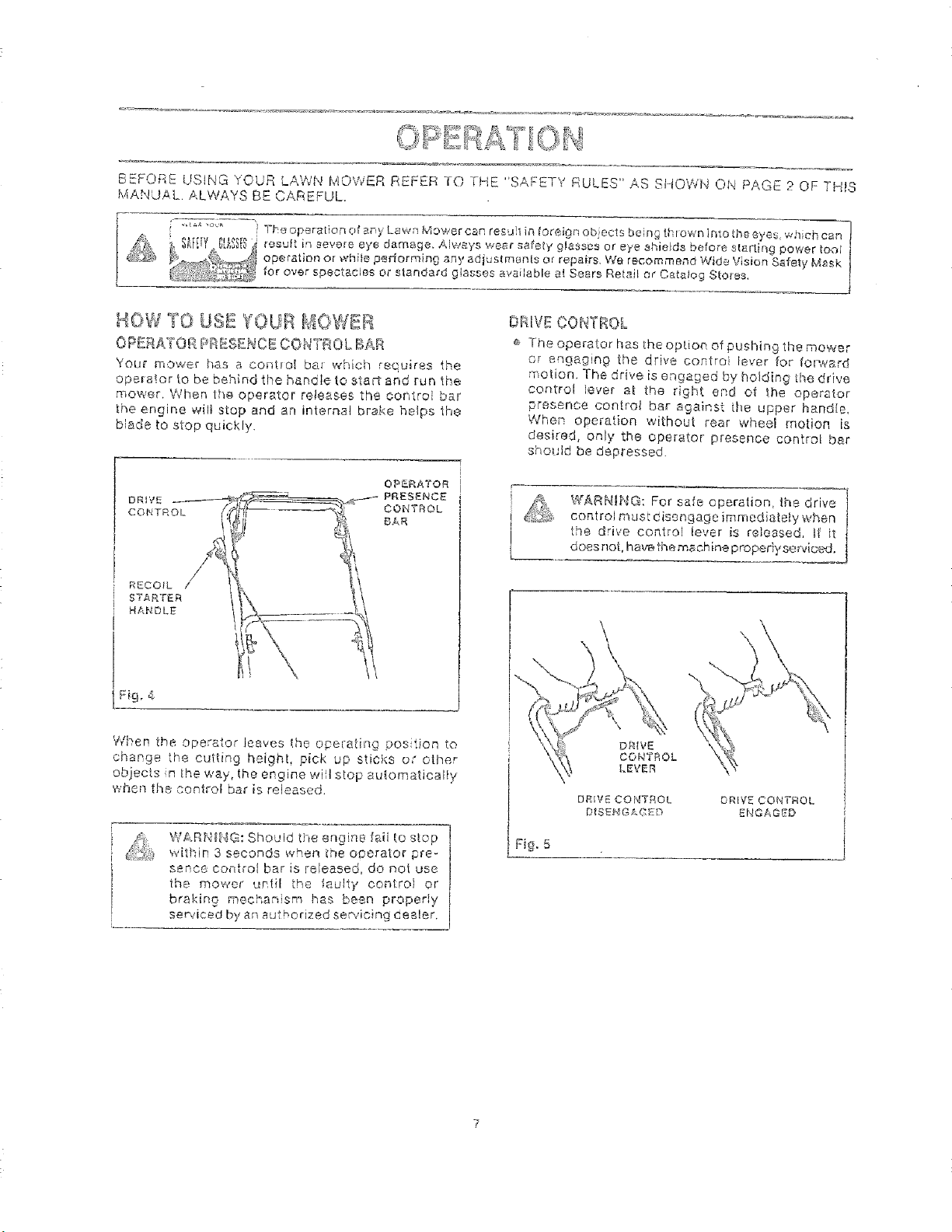

I IOWTO USEYOUR !:s OWER

0 P_£RATOt_PR[£Sg})CECO_ITROL BAR

Your mower t;as a control ba_ which requires the

opera',or to be behind the handteto slart and run the

mower. When the operator rebases the control bar

the engine wilt stop and an internal brake helps the

blade to stop quickly.

When the operetor leaves the operating position to

change the cutting height, pick up sticks o," other

objects n_heway, lheenginewilstopaulomaticaHy

when tile eonlrol bar is released.

DRIVE CONTROL

e -[he operator has [he option of pushing the mower

or engE..ging the drive control lever for to,ward

motion.-[he drive is engaged by holding the drive

control !ever at the right end ot the operator

presence control bar against the upper handle,

When operation without rear wheei motion is

desired, only the operator presence control bar

should be depressed.

WARNING: For safe operation, the drive

control must disengage immedialeiy when

the drive controi lever is released, _f it

does not, hays the mash ine properly ser,tlced.

\

\

\

DR_V£ CON'fROL

D_SENGAGEF>

O_;_IVE CONTROL

EWGAG_D

WARN_,_G: Should the _;ngin9 faU to stop

within 3 seconds when Ihe operator pre-

sence control bar is released, do not use

the mower until the faulty control or

braking mechanism !has been properly

sere/iced by an authorized sem4cing cos!or

Fi#. 5

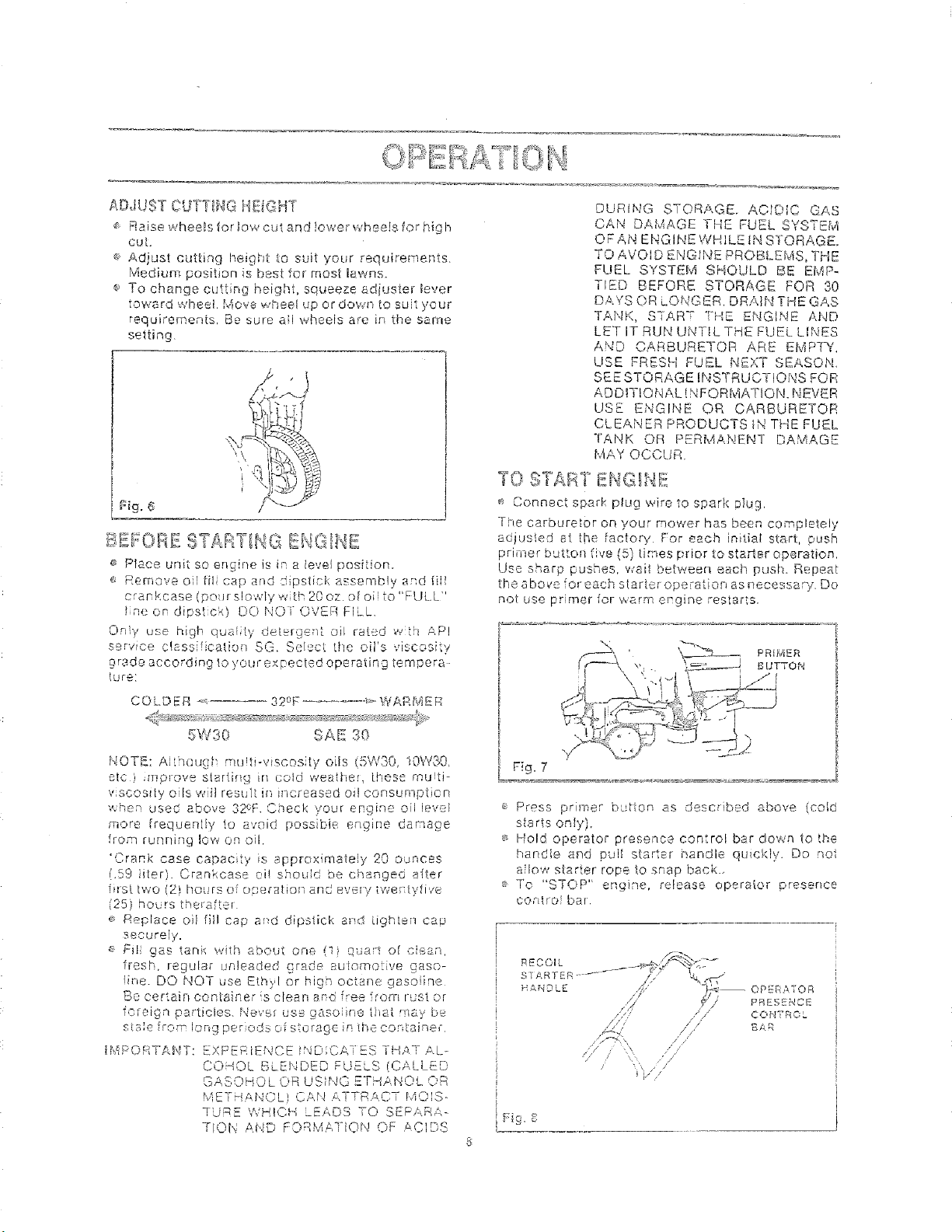

ADJUST CUTT_G HEI{_HT

_: Raise wheeDsiorlowcut and!owerwheelsforhi 9h

cut.

(0 Ad)ust cutting height o suit your requirements.

Medium positiDFI iS beet for most I_wns.

t To change cutting height, squeeze adiuster lever

toward wheel, Move wheel up or down to suit your

requirements, Be sure al wheeis are in the same

setting.

_0 _,r_Lsc; sAm_ IthacaENGINe

_s Place unit so engine is in a tevel position.

(; Remove oil fil cap and sipslick assembly and fill

crankcase (pour slowly wth 20 oz ol oil to "FULL"

Incor dipstck) DO NOFOVER FILL.

Ony use high qual;ty detergent oil rated wt_ API

serwce class fication SO. So!act the oil's viscosity

grade according _Oyourexpected operating tempera

Lure:

COLDER _ ...... 32°F ............... io"WARMER

DURING STORAGE. ACID;C GAS

CAN DAMAGE THE FUEL SYSTEM

O F AN ENG INE WHILE IN STORAGE.

TO AVOID EFqGII-,_E PROBLEMS, THE

FUEL SYSTEM SHOULD BE EMP-

TIED BEFORE STORAGE FOR 30

DAYS OR LONGER. DRAIN THE GAS

TANK, STAR T °_HE ENGtNF AND

LET IT RUN UNTIL THE FUEL LINES

AND CARBURETOR ARE EMPTh',

USE FRESH FUEL NEXT SEASON,

SEE STORAGE INSTRUCTIONS FOR

AD DIT_ONAL INFORMATION. NEVER

USE ENGINE OR CARBURETOR

CLEANER PRODUCTS iN TiRE FUEL

"rANK OR PERMANENT DAMAGE

MAY OCCUR_

TO STAR

_ Connect spark plug wire tO spark piug.

The carburetor on your mower has been completely

adjusted at the [actory For each initial start, push

primer bu_ton five {5) times prior to sta_er operation.

Use sharp pushes, wan between each push. Repeat

the above forgach starter operation as necessar},. Do

not use primer for warm engine restarts.

5W30 SAE 30

NOTE: Althougf mu!ti-viscosty oils (5W30, 10W30,

etc) mp_ove slatting mcotd weather, these rnu!ti-

v:scosdy oils w]il result in increased oi! consumption

when used above 32CF. Gheck your engine oil !oval

more [requent!y to avoid possibie engine damage

from running low on oil.

"CraRk case capsc_:y _s approximately 20 ounces

(.59 iiterl. Crankcase oi! should be changed alter

first two (2_ hours of ose_-a_ion and every twertytive

('25) hours therafte_

® Replace oii fill cap arid dipstick a_d tighten Cat

securely.

,_ Fill gas tank with about one (si qua'S of c!ean,

fresh, regular unleaded grade automotive gaso-

!ine. DO NOT use Ethyl or high octane gasoline

Be certain contsiRer s clean ard free ftorn rust or

foreign particles, Nave use gaso',}ne that may b_

stare from long per ods of storage inthe container

IMPORT'ANT: EXPERIENCE !NDCATES THATAL-

COHOL BLENDED FUELS (GALLED

GASOHOL OR USING ETHANOL C.'R

b_ETHANOLI CAN t, TTR/*CT MOIS.,

7URE WHICH LEADS TO SEPAR/,-

TiOIq AND FORMATION OF ACIDS

F,_g. 7

c Press primer button as desc,nbed above (cold

starts only).

_ Hold operator presence control bar down to the

handle and pulI starter isandle quickly. Do not

slow slarter rope to snap back.,

To "STOP" engine, release operator presence

cont_ Ol bat

RECOIL

STARTER ....

HANDLE

a/

, .!

pRESENCE

CONTROL

BAR

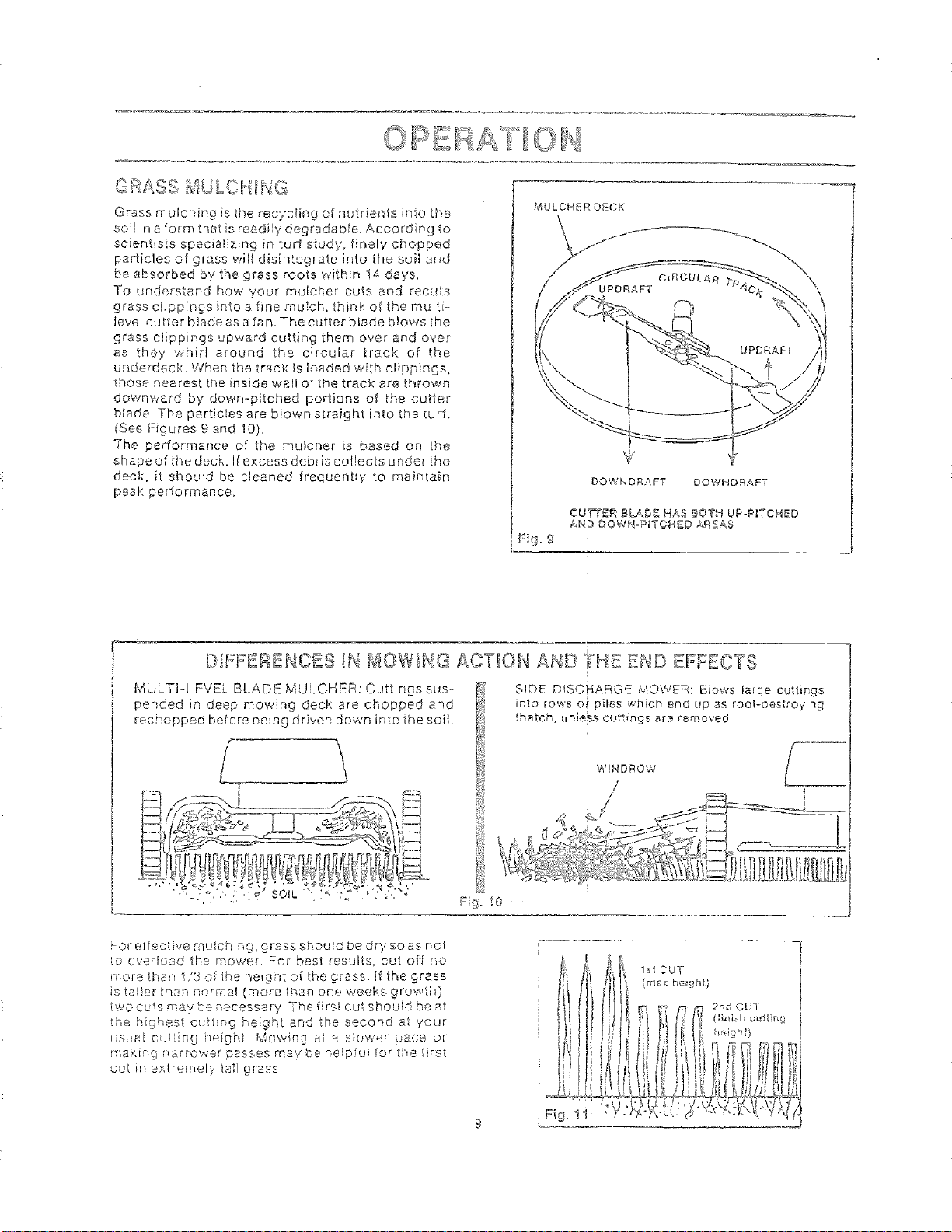

GRASS k' ULC

Grass mulching is the recycling of nutrients into the

Soft in a form thtt is readily degradabFe. Acco{ding to

scientists specia!izing in turf study, finely chopped

particles of grass wilt disintegrate into the soit and

be absorbed by the grass roots within t4 days,

To understand how your mulcher cuts and recurs

grass clippings into a fine mu_ch, tiqnk of the mu!tP

love cu tie r b_ade as a fan. The cutter bl3.de b!ows the

grass clippings upward cutting them over and ore, _

as they whirl around the circular track of the

undardeck. When the _raek is loaded wi,_h clippings,

1i_ose nearest the inside, wall of the track are _hrown

downward by down-pi_ched portions of the cutter

bIade. The particles are blown straight into the tud.

(See Figures 9 and 10).

The performance of the mulcher is based on the

shape of the deck. If excess debris col}ec_:s u nder the

deck. it shouid be c_eaned frequently to maintain

peak perfformance.

Mu LCHEFZDECK

\

fA! FtSA NCc s IN #IOW NG ACTION A, D THE END - F,'ECTS

MULTi-LEVEL BLADE. MULCHER: Cutbngs sun- SIDE DISCHARGE MOWER: B_ows large cuttings

pended is deep mowing deck are chopped and into rows ot piles which end up as root-destroyin#

reersopped before being driven down into the soil. thatch, u nle'._ cudcings are removed

FI9, 10

FOr effective mulching, grass should be dry so as nct

to overloc_d the mowe_. For best results, cut off no

more H_an "_/3 of/he heig-_t o_the grass. If _he grass

is taller _han normal (more than one weeks gro%rth)i

tv/o cuts may be necessary. The firsl cut shouid be at

the highesl curt r_g height and the second at your

LSLal cut_in{t height Mo,_ving _:t s slower pace o[

mad _!::r_arrower _asses may be ',elpfu:, !or _-e first

cut in ex(remely tall grass.

I

WINDROW

OVERLAPP_[_G 3 I_[ERUNS

Overlap each run for r;-_aximum width wi_h a minimum

ot wheel tracks, Run the inside of _he front wheei

a_ong edge of uncul grass.

On hi/iside hsowina,_ when possible, P_-,_., air cleal]er

and carburetor on the uphilt side (see Figure 12_

Make sure tha_ the crank case is pro_er_y fil!ed wltl_

oil

Fig, 12

CAUTION: THE LEAST DANGEROUS

l

METHOD FOR MOWING ON HILLS

AND TEF;RACES IS TO CUT HORIZON-

TALLY ALONG THE SLOPE (AS IN FIG-

URE 12) INSTEAD OF UP AND DOWN

(AS IN FIGURE i3). I-HIS WILL PLACE

YOU AWAY FROM THE MOWER IFYOU

SLIP. IT WILL ALSO REDUCE SCALP-

tNG ON CROWNS OF H!LLS. EXERCISE

EXTREME CAUTION TO AVOID SLIP-

PING AND CONTACTING THE ROTAT-

ING BLADEWHILE MOWING ON HILLS.

BECAUSE OF THE INCREASED DANG ER

OF SLIPPING {EVEN ON LEVEL SUR-

FACES) NEVER MOW WHEN GRASS IS

WET OR DAMP. ALWAYS WEAR ADE-

QUATE FOOTWEAR.

\

\

\

CORRECT

CUT ALOHG "ri4E S:IO_

C,_: I4tLL (HORIZONTALLY)

If the mowing pstlerp and di,_ection o_

progress are char:ged each time

eve O, cutting wl help 1o eliminate

msttin 9, g_aning ant corrugation

lherebyenh_ncingtheappearanceof

your lawn. P,siead of curt}rig m crde5

icy ht_ various mo_ving pe(ternsshown

: : . _._ .-_ i_,i_l!llki:l;

i 'i_'' i : :1l

10

GEN!EFIAL RECO _R_E8',,_DAT_O I,_

_ C!ean the b'ndc,rside of your c,eck aite_- eaci_ use.

_,sOnce a year or every 25 operating hours you

should _eplace the spark plug, air |liter, and check

blade for wear. A new spark plug ar, d air fiiter

assures proper air-fuel mixture and helps your

engine run better and last longer.

® Cheek all fasteners and be sure they are tight.

e Follow the Service Recommendation Schedule.

DA_,[GEB: BEFORE TURNING THE

%

DECK ON THE LEFT SIDE, EMPTY YHE 1

_-,. EL tANK IN A ,_UIS,,,uLE CON- !

TAflqER. WEAR GLOVES TO PROTECT

AGAINST SHARP BLADE AND EDGES I

SERVICE RBCORB

Fi!l dates as you complete

service

Blade Sharpened

Blade Replaced

Engine Oil Change

Engine Oil Check

Air Fi!(er Repl,eced

Lubricate Mower t

Cleaning 1

Grass Calcher (ff applicabie)

Muffler

Gear Recucer Checked

Rear Wheels Lubrication

Drivebe!l Checked

S_arr, Ptug Replaced

SERVICE RBCOI_II'_:ENDATIONS $O_48DULE

First Evary

2 10

Hours Hours

EveQ_

25

H Ours

[j'_¢

E_,c,,_, Eveo'

50 Use

Hours

J

i

T

1 J

SERVICE DATES

t

!

J

Y i

(_. SAE 30W MOTOR OiL

(5W30)

@ SPRAY LUBRICANT

@ GREASE

TYPE "F" AUTOMATIC TRANSI,4ISS_ON

FLUID

//

@ i

& PII41ON

(COVEREP_ BY DUST SIIIELD)

CLEAI:4_t,!G

_T.We recommend that you clean ihe underside of

your mower afler each use

CAUT!ON: DISCONNECT SPARK PLUG|

WIRE FROM SPARK PLUG AND PLACE

WIRE WHERE IT CANNOT COME IN

CONTACT WITH THE SPARK PLUG. .

iNSPECTiNG CUTTER BLADE

® Cutter btade must be straight {see Figure 14).

Any _mpact severe enough to bend a blade has

also caused m_croscopic cracks in the blade.

Bent blades should be replaced because the

cracked portions could break off, becomi;_g

dangerous and capable of inflicbng serious

iniuries.

l

J

Fig. 15

_ The cutting ends of the blade should be in-

spected _or cracks developing at points marked

"A" s.nd i'B" in Figure t5. Tb, ese are developing

poin[s, either from ursharpened to sharpened

edges ot flora rounded to fiat areas of the bade.

Abraswe parhctes cause cracks by weanng the

steel during wowing. At the first sign of a crack,

the cutter blade should be replaced

CioIANG_NGBLADE

_:,Set [he mower on a driveway or concrete floor,

disconnect spark plug wire and _[p it over on its

left side so crank case oil will not draJr into the

carburetor and air filter,

e Put on gloves for protection against the blade

edges.

e As shows in Figure 16, use a piec,s of 2" x 4"

lumber about 14" long (rough metric equivalent:

4 _: 9 _. 3_ on} _s a stop. insert the step between

the cutler blade and the floor.

': L_se a wrench to remove the mounting bolt, lock-

washer and c_tter blade

® ins,'811 sharp curlier bade as shown in Figures i6

and 7. ,3e surebiade is correctlymeunted on the

adaptor inst_ the iockwasher aRd bo!t a.nd

make the bolt fnger tight

® Reinsert lhe 2 _:4stop between Use floor and the

cutter blade, but this time at the front ol the deck,

Tighten !he bolt with a wrench (to 35A0 ft. IbS. or

47.5--542 Nrn)

12

BLADE SHAF{PBN NG

r_ When sharpening the cutting edges o! the s,lade,

do not fm!iow the orig nsl angle of grind as shown

in "A" of Figure 18 !nstead, grind new ct;ttin 9

edges on a diaqonal as showr' in "B." Make sure

that each culting edge recek, es an amount of

g indin 9 necessary for the b:ade to remain

balanced

e_The remaining straight edge por_on of the blade

may be smoothed just enoug:; _o remove burrs.

¢ TO cheek balance, suspe_d blade on a screwdriver

or drill shank at center ho_e If one end hangs

down, gr nd more steel from _.hat end until blade

balances

ORIGINAL

EDGE

DO NOT RESHARPE_4 TO THIS PATTERN

V__ (1.3 cm)

M ;_ _:icTiUrCi _er£Ov_l

000

t

REQUIRED RESHARPENING PAT_;ERN

Fig. 18

Fief,i7

WARNING:ALOOSE8LADECANBE

DANGERO_.JSANDMAYMAKE]HE

ENGINEHARD] 0START.FAILURE]0

PROP!RLYASSEMBLE1"14ECU"TEF!

BLADEN _iHEADAPTORMAYRESULT

_;",CRACKStNTHECUTTERBLAOEOR

LOOSENI'-;GOFTHE MOUNTING

BOLT.E',-!qEROFTHESEDEVELOP-

I/,ENTSCOULDRESUiTfNSERIOUS

BODEYII'IJtIRYFPOMPIECESBEHqG

DSCHAiqG!:[)[-ROMUN©ERNEATH

TbiE_,40WER

!3

WARNING; INCORRECT RESHARPEN-

tNG OF CUTTER BLADE AS DISPLAYED

IN "A" OF FIGURE i8, COULD CAUSE

-_P'IE BLADE TIPS TO BREAK OFF

AFTER A SUDDEN IMPACT OF THE

B]_ADE WITI-t A FOREIGN OBJECT

DUR;NG OPERATION. BROKEN

PIECES OF THE BLADE T_iROWN

FROM THE MOWER COULD INFLICT

SERIOUS BODILY INJURY.

GEAR REDUCER OF

POWEE-@ROPELLED _/iODEL

The gear r_d_ce _s filled wth el at the iactory

Additional oJi will rot be required unoer _-ermal use.

E'er':,'25,'flours o: f leakage is apparent., remove the

pipep!_g(seeFg _9) Ire' evel is _ebw the hole. fll

untii el is Ie_e wills bet!era el ho!e Use Type _'F'

A::temafie TiafhsrrlfE.sior Fld_d

D: rot subs,iitute !dbricafi_ if rep£r is necessary, see

yoL suthorzed se_'.',c_r',(_ deaer

IMPORTAiqT: O_,er dlh_g or use oi-rnproper

uc,_,cani wilt ca,use prer_]a_u_e

.::ear red Jeer fa_ ure

_iI CABLE

--#--- t

FORWARD

i t 34-

CABLE

_!_GEAR R_DUCER

Fig. ,_

FRONT WHEELS

Lubrisa_e wheels and the supporl shafts once a

month or every 40 operating hours with SAP=- 30 oil.

Tip mower on _ls side and apply oil to axle and hub

Spin wheel to allow oil to move into bearing. Oil the

wheel stJppoF_ shafts at point where they enter dec},,.

,k,_ove indexing levers of height ,_djuslers beck and

forth to allow oil to move into bearing surfaces.

In extremely dusty condilions, wheels may become

light because of d,Js_ in bearing area. When this

condition occurs, remove the wheels.Olean a×le and

wheat bearing, surfaces with solvent or emery cloth.

then oil and reassemble. Torque to 190-285 in. tbs. (2

to 32 Nm)

REAR WHEELS,

Atfhe beginning of each season (or ever'i 50 operab

ins hours) lubricate the wneelsand pinions. Block up

mower at rear of deck u_til the rear wheels are clear

from ground.

\

PIN

AXLE

li Fig. 21

DRIVE SHAFT

HEIGHT ADo_US'TER

To avoid stiffnessi_ the height adjuster% IubrTcate

sdius_ers once every season or every 25 operating

hours with SAE 30 oil,A_pplya fiberalamount of o[ion

the washer _nd spacer of each adjuster. Move the

adjusters b_k and forth Io loosen if stiffness has

occurred.

SPARK PLUG

Change Your spark piug each year (or every 25

operaling hours) 1o make your engine saH eaa er and

_un better. Set spark ptua _p at .030 inches (.76rl+_m).

AIR .... '

F1Lt E__i

Yuur enoine will not run properly and may be datr, aoed

usiP 9 a clirt}l air fii_er. _ " +

i

COLLAR

!

i

i

r

fit, place theyr filler every 'fear (or every 25 operating

hours), moqe often if you mow in ve_ dusty, dirty

conditions. 0o not wash air filter.

TO CHANGE AIR _iLTER

¢ <:_emove iU-te air filter cover by lurning coun_er-

c!ockwise to the slot and pull away from collar

® Re_qove fiiter from inside of cover.

e Clean tb? inside of the coyer and the cotla_ to

remove tinY dirt, accurnJlation.

¢ Insert new filter into cover.

Put _.ir filier cover and filter into celia relignh_g the

_ab with the slot

e Push in on cover and turn clockwise to tighten.

Removelheax_e screwsand pul' off tnewhee!s. Apply

a liberal ar-_ount OI crease to pimon, line gear, whee

hub, and axle (see Fig 20).

Reir_stall the _heeb, makng sure lhe pmiar an,g

gears mesh properly. Be careful to insta!l the p_nions

on _ne sroper sides, as they are not interchangeab;e

Propulsion wil occur on!y if parts are correctly

installed (see F}g 21 )

SLOT ¢

Fig. 22

14

i

<

TO TIGHTEN

I

AIR F{L] ER COVER

t:K,MNE kUBRICATJO}I

You must change .'.he oil in the crank case _.fter the

first two (2) hours of operation and aher each 25

h,')urs of use thereafter. CHANGE THE OIL MORE

FR _QUENTL_' IF USED !l',_ SANDY OR E_UST¥ CON-

DIT_ONS.

CAUTION: DISCONNECT SPARK PLUG

W!RE FROM SPARK PLUG AND PLACE

WIRE WHERE IT CANNOT COME IN

CO,,, ACT WFFH SPARK PLUG

@AU,'T_ON; D ISCONN ECT SPAR K PLUG i

WIRE FROM SPARK PLUG AND PLACEI

WIRE WHE, RE IT CANNOT COME IN f

GONTACT ¢,J;-FHTHE SPARK PLUG, j

e Turn mower on its side with carburetor up.

e Okan the undersideolyour mower by scraping tO

remove build-up of grass and trash.

_,!OTE: We recommend that you clean the underside

of your mower after each use.

e (}rain the gas tank and then turn the mower on its

side with the carburetor side up and remove oil

drain plug

QIL OPd_IN PLUG

BOTTOb_ OF ENGraVE Fig. 23

_, Set the mower down and d¢ain oil into a flat pan

NOTE: Oil wUI drain more free y when warm

e Replace oil drain plug being sure to tighten iirr_dy

e RefilcranKcasewithot. Re_erto"BEFORESTART-

ING ENGINE" in operation secton on sage 8

o! this manual.

e Wipe up shy spilted oi! on mower

e Recornecl spark plug w_re to spark plug.

_PORTANT; !f liquid fertilizer is applied to the lawn,

wash underneath your deck after cul-

ring the lawn for the f}rst time after

fertilizing The fertiUze_ o_ the grass

clippings contains caustic potash

which is EXTREMELY CORROSIVE to

the aluminum deck. The deck will be

damaged if these clippings are not

washed awa?.

_ Clean yo,ur mower and engine oftente keep build-

up of trash from accumulating around engine. A

clogged _ngine runs hotter and shortens engine

tire.

I

NOT_:We Be NO F recommend using a garden hose

to c_ear_ rne_'_er urdees the electrical system, muffler,

air tilter andicarbu rotor are covered to keep water out.

Water in enqine car] result m shortening engine tile

Frequent!y ren eve grass clipp rigs, dirt and debris

from cooling fins a_r mlake screen and levers and

tint age. "This wi!} help ensure adequate cooling and

correct engine speed

!5

I

J

[

CAUTION; D!SCONNECT SPARK PLUG l

WiRE FROM SPAP, K PLUG AND PLACE I

WIRE WHERE t-T CANNOT COME tn

CONTACT WITH SPARK PLUG.

BELT REPLACE_FI_.HT

Inspect bel every 25 hour,S for wear Replacement

belts are available from your aulhorized sewicing

dealer. Follow the procedure given below.

e Oisconnecl soark plug wire trom the spa_k plug

_, Remove the bolts holding the belt cover to the

deck. Then slide out the cover.

e Slip the belt over and of 1 the gear reducer pulley

6- Tip the mower en its lelt side letting it rest on its

handles.

CAUTIOH: Do this procedure with iess

txan 1/4 tank of gasoine and the oil

diost c< must be tight.

_:, P_;l!_he beltthrough stot{n deck so that entire bait

is under deck.

_ Slip belt over end of blade and remove.

e Reverse the above procedure to install new belt

i

PULLEY

e Push cab@ into s!ot and tighten cable clamp

scFew

e lnstaiI spark p_ug wire on spark ph@.

e Tesl drive adjustment. If mower drive does not

release reaSjusi adding slack te the system.

If_(PORTAHT:

AFTER TIPPING MOWER UP FOR IN-

SPECTION OR ANY OTHER REASON

DO NOT ATTEMPT TO START ENGINE

UNT!L MOWER tS ALLOWED TO SET

iN NORMAL UPRIGHT POSITION FOR

AT LEAST 3 TO 5 MINUTES IT IS

IMPORTANT ""O GIVE OIL ENOUGH

TIME TO DRAIN BACK INTO ORANK

GASE iF AFTER 5 IvtlIUUTES, STARTER

©ORD STILL DOES NOT PULL EASILY,

@EMOVE THE SPARK PLUG, SLOWLY

©RANK ENGINE TO EXPEL ANY OIL

STILL TRAPPED _N CYLINDER, AND

REINSTAL_L SPARK PLUG. ENGINE

MAY NOW BE STARTED.

i

TRA8] I0!_ DRIVE ADJUSTL:_EHT

Parts wear or stretching of tXe _raction control cable

eventua b] may czuse excessive slipping whrcl_ Nrst

becomes apparent durrg maximum loading situa-

tions such as L!phi I rtowir!g.

e Disconnec8 he spark plug wre.

® Loosen CaD!e damp screw.

e PL;S) cabief omtses!otintheNa,'npand mes'e

to ti_e rght unli the slack _s removed from the

cable

I6,

BEAR TRAIL 9HIELD

The rear trail shield, attached between the rear

wheels of your mower, is provided to miIliiTilZe the

possiNlky that objects w!l be thrown ou_ the rear of

the mower into the operator mowing position.

if the shield becomes damaged, il should be replaced.

E_GiNB SPL_BD

Your ertgine speed has been factory set. Do not

attempt to irtcrease engine speed or it may res@_ in

personal injury. If you believe t,hst the engine is

running too !ast or too slow, take your mower to _n

authorized Sears Service Center for repair and

adjustment.

CARBURETOR

Your carburetor has a non-adjuslable fixed main tel

Ior mixture co,trot. If your engine does not operale

properly due to suspected carburetor problems, take

your mowerioan authorized Sears Service Center for

repair aPd adjustmen_

WARNING: CARBURETOR ADJUST-

MENT REQUIRES HIGH SPEED OP-

ERATION OF THE ENGINE DURING

_HE PROCESS. tT IS, ACCORDINGLY,

REQUIRED THAT A MATURE PERSON,

WELL-ACQUAINTED WITH THE DAN-

GERS OF IIvIPROPER PROCEDURE.

ASSIST BY CONTRO[ LING THE

ENGINE FROM THE OPERATOR'S PO -

S}TION WHILE T_-4E ADJ'jSTMENTS

ARE BEING MADE DO NOT PUT

RINGERS OR TOES NEAR THE MOWER

DECK DURING THIS ADJUSTMENT.

17

Your rnower and engine, should be p_-epared for cfl

season siorsge as follows:

MOWER

Clean underside of mower deck (See 'CLEAN-

IF;G" in Customer Responsibilities section of

manual}.

e Inspect and replace/sharpen blade, Jf required

(see "BLADE CARE" in Customer Responsibililies

section of e_anual).

e Lubricate as shown in Service Recommendation

chart on page 11 of manual.

HANDLE

e Whiie supporting the lower handle, press h,sndle

support in and down to release handle lrom the

suopo_:

¢ Loosen handle knobs. Fold upper handle rearward

lo horizontal position. Make sure !ower handie is

slightfy tilted back to prevent the cable from

stretching.

_' Bring lower handle over engine unl-il the upper

handle and tower h_xnd!e are in the lowest position

Make sure cables are not sharply bent.

FOt. D UPPER

HANDLE 3"0

PRESS IN z

SUPPORT / LOOSEN

BRACKETS KNOBS

t ,/1

REAR

i kJ

_RO_ G WAY, YOU MAY DAM-

AGE THE CONTROL CABLES

(SEE FIG. 27).

e Change oil (see "To Change Oi!" _q Customer

Responsibi!ities section of manua O.

@ Drain fudt and run engine untit _uel system is

empty.

FqPoRTANT:

IT/S tMPORTANr iO PREVENT

GUM DEPOSITS FROM. FORM-

ING iN ESSENTIAL FUEL SYS o

TEM PARTS SUCHASTHECAR.

BURETOR, FUEL FILTER, FUEL

HOSE, OR TANK DURING STOR-

AGE ALSO, EXPERIENCE iNDF

CATES THAT ALCOHOL BLEND °

ED FUELS (CALLED GASOHOL

OR US}NG ETHANOL OR ME-

THA NOL) CAN ATTRACT Me IS-

TURE WHICH LEADS TO SEPA-

RATION AND FORMATION OF

ACIDS DURING STORAGE. ACiD-

IC GAS CAN DAMAGETHE FUEL

S"_STEM OF AN ENGINEWHILE

1N STORAGE.

OTHER

@ Do not store gasoline from one season to

another

¢ Replace you_ _qasoiiP.e ca," ',_your can steals _o

rust. Rust an@or dirt in your gasoline can

caus_ problerns,

_ Do nol s[ore your mower under any plastic

eeve_-. Plastic cannoi breathe which allows

cor_densation !o form and can cause your

me'wen to rust

Fig. _,:.,:,,

F_n 27

iMisORTANT; W_-=_,_,-. FOLDING THE !HANDLE

PORTSTION, BE SURETC) FOLD

THE HANDLE AS SHOV';.N IN

F_G 26. IF "_._,_ FOLD TP:E UP-

PE,_ -ADDLE SECTION T:'4E

NEVERSTORE LTV a

MO!fLER WITPi GASOL NE lq THE TANK I

!NSI:_E A BUILDING WHERE PUMESI

t4AY REACH AN OPEN FLAME OR I

SPARK. ALLOW THE ENGINE TO COOL I

BEFORE STORINL'_ IN ANY ENCLO- I

SURE J

18

i

I

Too much Vtbre_o_

$tadar Rop= H_,_rd_o P_slt

_*rt_c_or_Drh'

H_rd to Push

1 girly Air Filter.

2 Out olgasoline.

3 Staie Gt_soline,

4 Spark plug wire is disconnecled.

5 Bed spark plug

6 W_ter in gasoline.

7 Loose blade or broken blade adaptor

8 Operator Preeer',ce Comtrol Bar in released

position.

9, Operator Presence Control Bar detective.

1 Rear of mower deckiblada dragging in

heavy grass.

2 Cuttmg too much grass.

3. Dirty air filter.

4 Build-up of grass, leaves, and trash under

mower deck.

5. Walkmg speed _o0 test

6 Too much oilin engine

1. Worn, bent or loo_e blade.

2 Wheel heights uneven.

3. Low engine speed.

4. Build-up of graSs, leaves and trash under

mower d_sk.

1 Worn or bent blade

2. Loose btade,

3 Benl engine crank sh,_ft

t qywheel brake is on when Operalor Presence

Control Bar is released

2. Bent engine crank shall

3. Blade adaptor sheared,

Blade dragging ir_ grass

1. Broken or discc_neet_:_ cable

2. Slipping or _!OW 6ngagemenk

3. Bell out ol pulley groove Or broken.

4 Pinion Or pin reve_d {no drive or free-

wheeling).

L High Grass or cutting beig_t too low

2 Rear of mower deeWblade

dragging it" h&_vy gra_

3 Handie ne,ght position nol right for you.

Replace Air Filter.

21

Fill gasoline tank.

Drain gas and refill with fresh gasoline.

4!

Connect wi_e to sp_.rk p!ug.

Replace spark plug.

6i

Drain tank and refill wilh h-esh, clean

gasoline.

Tighten blade nut _nd/or replace

btade adaptor.

Depress Operator Presence Control Bar.

!

Contact Se_rs Service Department.

I

ti

Raise rea_ of mower deck one (I) settir_g

higher than front.

2i

Set in ' Higher Cut" position

31

Clean or replace air filter.

Disconnect spark pug wire and clean

i

underside of mower housing.

5_

Cut at slower walking sDeed.

Ch_ck engine oil level

i

Replaceb_de Tighten bladenut.

Set all wheels at same height.

2j

Contact Sears Service DeeartmenL

3i

41

Disconnec_ spark plug wire & clean

I

underside ol mower housing.

!

Replace blade

Tighten blade nut,

31

Contact Sears Service Dep_rtmen[.

Depress Operator Presence Control Bar _o

t!

t@per handle before putiing on starter' rope.

Cow,tact Sears Service Department

Replace blade adaptor

-?i

Gel o','er tow grass and/o_ hard surface

to star( engirie.

iJ Contact Sea_ Sewice Dept_rtmenL

2. Adius(Traction Drive.

3 Sea"BELT REPLACEMENTS'

4 See page 14

Rai_ cutting height.

RMse rear of mower deo_ one (1) se_ing

higher than trent.

Adjust handle height to suit.

27

/

?

\22

4_

29

NO. PART NO, DESCRIPTION QTY,

i JA-99295-5 ° AXL E- WheeJ supped 4

2 JA-9937t- 1 NUT- He_ 4

3 JA-359_ 8-0 BOLT- H@i _dj 2

4 JA.-99128-7 ARM- Wheel hut. ad i. 2

5 JA-99364-0 WHEEL & TIRE 2

6 JA-9£3"65-6 SPRING* _ndex {ielt ff,ar_t} 1

JA-99365-7 SPRING* inde× (right front,', I

? JA-33662-3 KNOB- index spring 4

8 JA-99372-0 NUT- Hex flange {5/16-16} 2

9 [_,JA-99395-0 DECK- 29" PP I

[

10 jeJA-9940-0 DECAL- Wa;ning t

11 I_JA-33946-0 DECAL- CPSC warning 1

12 L_JA-99368-3 DECAL- 20" Mulcher 1

13 04098 ADAPTOR B[ ADE 1

I4 JA-40887-6 SCR _'V- Thd. forming 3

15 JA-40887÷8 SCREW- HeX waeher 5

16 JA--33654-4 D_FLECTOR REAR 1

I7 JA-35836 2 SPACER- Wheel _l. aai. 2

18 84001 WASHER- (5/16") 2

19 A-O4297 BLADE- Mulcher Kit 1

20 JA-44614-2 WASHER- Lock (3/8"}

21 JA-40120-9 SCREW, Ha× hd. I

22 JA-,q9367-3 DRIVE WHEEL 2

23 JA-99_80 I PINION (L N.) I

J,a-99480-0 PINION (R H) I

lnc!ud_:

{328-I6 _ I 1t2"}

',1/4-29 _ 3!4")

_3/8-24 x 2")

t

P A[_'f " FO, DE$CBIP:TIDN QTY.

NO,

24

J A 199471,',_0 PIN- Drh, e 2

25

JA-35107-7 WASHER 2

jA-99,0_7 ,1 SUPPORT- Drive wheel 2

2_

27

JA-9935_5-6 SPRING- index (left rear) 1

JA-99386-5 SPRING- ;nde× (righ[ rear} I

28

JA-35£1_-I SPACER- Real h!. a0i 2

29

JA-35B46-9 SR£1NG 1

JA 3Eg2"3-0 BRACKET !

30

31

JA-99_ 811-9 PULLEY- Odve 1

32

JA-42"25b-5 SCREW- S,¢,! {I/4-20 × 3!8") 1

33

34

35

36

37

39

4Q

41

_2

43

44

46

47

48

,_ _ , GEAR REDUCER (Nole se,wice 1

JA-3757,1-8 SPRING

0390_ BELT- Drive 1

JA-39507-8 COVEN- Orwe I

JA-45845-I EATON RING 1

JA-35340-6 WASHEgl 2

JA-3281 #- 7 WASHER AiR

JA-46z-03-T WASHER- Sprin9 2

jA-4169 -1 SCREW- Tnd zolHng I

3A-_053-3 C.AB LB - Tractior,

JA-35950-0 WASHER- Hardened 2

J#-99367 2 DECAL- Power propel ed

JA-46136-I P:N- RoII !

JA-99496-3 P{ ATE- Backing 1

JA 46302-9 KEY- Woodruff 2

jA-99,497 i CLAMP- Traction cable 1

143.424.3_2 ENGINE !

part See b,'eakdown.)

i

_'NOI _: See psg_- 24 for Gear Reducer 8reU_.dewr_

_']OT ILL_JSTRATED: O_,_[4_RS f_;AIMU_,L 18116

2I

i /_7

\

\

\

/

£3

/

\

\

\

\

\

\

\

\

\

\

\

\\

\

/

NO. PART NO. 8ESCRIPTION QTY.

1 JA-993B5- 0 OPERATOR PRESENCE 1

2 JA-993-5-5-0 DRIVE CONTROL LEVER 3

3 JA-gg3-GT-O BUSHING- Drive cOnlrol 2

JA-99373-I WAS,_ER -Ext. lock I

5 JA-991_5-2 EYEBOL T. ( I/4-20) I

8 JA-99rJ53- 3 CABLE- Traction 1

7 ,IA-g.q370_! NUT- Fle_ c/lock (1/4-20) i

8 JA-_EB-7 CABLE- Engine control I

9 J A-99363-8 HANDLE- Upper !

10 JA-g94104D HANDLE_ t o,_ver w/Pin 1

11 JA-44310-6 NUT- Hex (5/16-IB) 2

12 JA-3,.395543 HANDLE- Knob 2

13 JA-35910-2 BOLl-- Hat, die joining 2

14 JA-99056_7 STOP- Rope i

15 JA-9_9370-0 BOLT- Handle mtg. 2

16 JA-99372-0 NUT- Hex flange (5115 18) 4

11 JA-35923-9 SUPPORT 2

18 ,IA-45402-5 WASHER 2

lg JA 99371-0 BOLT- Handle suppcr[ 2

_) JA-gg368-2 SLEEVE- Dr, ve control I

21 JA-99163-6 TIE- Plastic !

22 JA-g9373-5 SCREW- (114-20 × 1 1/2") 1

23 JA-99373-0 NUT- (1/4÷20)

CONTROL BAR

23

_7

2

28

/

!

15

I

9

8

%

13

25

!3

!

QTY.

1

1

I

1

1

1

I

1

1

!

I

2

i

i

i

2

4

!

24

4_0

f4OBE[ _._!S{BIAL

f

I£4\

3t0

370D

x) _ 178

2_

2_

25

[ s£@:AIR P,&B i,5 LIsT

Ref'. P,u-t I _ =

No, No. Part Name i No,

Cylinder Assy. {incl Nos, 2 a 20)

I 26727

7 34214A

8 "33735

B 30200

1ZA 34,91}5

12B 33&58

!4 28277

t 5 3 {'6_

i6 31_A

17 31:_5

18 859548

19 31361

20 32600

•,_ 35905

48 35545

4,0 35_

41 35541

41 3CR5.42

41 3654.3

42 35547

42 35_48

42 35-r-49

43 20381

45 32875

46 32610A

48 27241

62 29914

70 3/-.3 si C

72 3c{72

73 ' 2%_ 3

75 27897

_1 30574

81 3,0030 A

82 335.91

83 30S'aBA

92 650815

93 Bf_>8i 6

00 %443 A

10! 6_.CI £

103 66(84

110 34861

119 aS0* 5&

I20 34342

125 :92:3C

i25 2935£

i26 293 ":S

I26 293:5C

:]O 0021:.

135 ?C895

33734

33148A

_35261

29!.9.3

65,9,_88

6"t 1C45¢

61fli2

Pin, Dowel

E!ement, Breather

Breather Assy. {IncL Non. B. 8, 9, 1_

S- /28)

Gasket. Breather

Screw, Hex washer hd. se f-tap Be:--_s,

10-24 x 9/16

Elbow, Breather tube

Tube. Breetbe_

Washer. Ftal

Red, Governer (Incl. No 14)

Lever. Governor

Ciamp, Governor lever

Screw. H,ex washer hd., 8-32 × 5/16

Spring, Extension

Seal, Oi!

C_ankshah Assy

Piston, Pin (I' Ring ,#,say, (Std.)

HncL Nos. 41, 42. 6" 43)

P{si.on, Pin & Rin£_ Assy. (,0_0 over-

sac) lind. Nos. 4_, 42. & 43)

Piston, Pin 8" Ring Aesy. (.020 ever

_ize) {Incl. Nee. 41, 42 8 43)

Piston 8- Pin Aaey. (Std_) Ilncl. No 43)

Piston 8- Pin Asey 8010 oversize)

(incl. No_ 43)

Piston S_ Pin Asey (.O2#l owweize)

(Incl. No. _3j

Ring Set, Pis:on (S[d.)

Pi W Set, Piston i.Ol0 oversize)

Ring Set, Pis:en tO20 overeizei

Ring. Piston _n retaining

Rod Assy., Connecting (Incl.No. 46}

Bolt. Connecting rod

VMve, Lifte_

Ca_.shafl (Mo_O]. C.cmpr-d._on Reicase)

Pump Ass'f. Oil

Gasket, Mounting flange

Flange, Mounting (inc!.Nes 72, 73,76

6 80)

Ptg, Oi drain {inct, No. 73)

Gasket, Oil piug {Not requirec with

ptastic eilplug)

See[ Oil

Shaft, Gevemo

Washer. Fta!

Gear Assy., Governor (tnci 40. 81}

Spool, Governer

Ring. Retaining

Screw, Hex hd. Soma, 1/4 20 x i-1 r4

Key, Fip<vhea[

:i%,vheel

Washer, BNtevile

Nut, Fhe,_hee{

Selki State Assv.

Cover. Spark plug

Scot-w. TOoK T-15 hex was_er hd.

Seres I0-24 × 1

Wire G r'.,_ rid

Gasket, CyHnder head

Head, Cy inder

Viva, _x>adel lard) InCi No 15]

"/a!ve, _.,haust (1'32' oversze} (bcl

Ne 15! }

is!re, !n:ake (Std) ilncl _s 161}

'Jalve, trial 9 ilz7,2 ' overs ze

ncl b,_e 157i

Screw He× fia,-ge i,o, 5 16 18 *, i i 2

Bp rk Pu'£ Resls',Or {Char'_aie< RJ-

19_@ Or enuk,alent

±€,_l

151

169

!72

174

178

182

184

185

186

1_O

t91

192

193

194

196

207

216

228

_4

23<i

23_

24

245

25O

260

261

262

275

277

28£

287

2_b

292

298

3COD

301

3(,",3

303

307

3(-8

310

313

327

370A

370D

eL-is

°_J..... _' _ L:_BEL I43o424352

Par{

] No.

316772

316"73

_27284A

327_

_631_

297_

_201

--287e5

31,38-4A

32658

65-0_¢ _

3sSS_

350-_3B

3&S_3B

349_5

3Z:.1¢C9

618973

84336

33085

863451

*34._,0A

65g_&2

o34_S8

357_,7

3BOGS

35055

3_2_83

3020J

3570-8

850795

:_C'60

8_3314

30795

28430

287_

3430A

35355

35577

"342_

35@8

6_2

3_578

34C2SI

3E392

34346

34144

8_688

590_6

36207

S[Jb_qg, \/ave

..... Lower valve spring

Gasket, Va}ve apdng box

Cover, Vave sprlnq box

Screw, He:: hd, Seres, 10-24 x ii2

Nut ;t'; Lockwasher, t/4-28

Screw, He× hd. I.'4-28 _.:7/8

Gasket, Carburetor

Pipe, ln_ake(Inal No. 224)

Lin,% Govt:rnor spring

Screw, HBx washe[ hd. Powedok,

14-20 x 3/8

Lever, Brake

Bracket, SE Brake (lr_cl. No. I_%)

Lnr., Cor_trol

Spring, Extensien

Ring, Retaining

Terminal As_f.

½nk- Throlt_

Letc..-,rR PM, Adib._l_ng

Screw, Hex hal. Seres, 1/4-20 x l

Gasket. _ntake pipe

Saree.', Hex washer hd. shou!der,

10-32 _ &q/_

Gasket, Air cleaner

Celat, Ai_ cleaner

Fi]ter, Air cleaner (Paper)

Cover, Air cleaner

Hous no. Blower

Screw, He_:washer hd. selBtao Sen*s,

10-24 x 9,'iG

t :-cad. "[/4 20 x 15/32 ]

MufflerAssy. (Inci No. 2_J

Screw. Hex hd., 1/4-20 x 2d/4

Hub, Starlet

Screw, Hex wasqer hd., 8-32 K 1/2

Line, Fuel

Clamp, Fuel line

Screw. Hex washer hd shakeDroof,

10-32 x 35/64

i

Fank Assy !nCl NO-; 292 _ 301)

Cap, Fuel

Tube, Oil fil!

Gaskel, F[}i hbe

"Q" Ring

_cra_s', HeX washer nd ehakeproof

10-22 × i/2

D pstick, Oi! fill

Spacer, Flywheel key

Plug, Starter

Decal, Inelr:_ct on

Decal, Primer

Carburetor {ncl. No 184)

S_e'. Rewied

Geske'. Set Nncl items marked "l

RPM Settiqg

High Spe_:: 3300_3500

"{ridicules Pa;'te Inc1udad m

Gasket St;t, Re; No a49

P_t Name

Hex washer hd. Powan'okScrew.

26

REWIND STARTER NO, 5fl_&21

NO,

25

27

28

2.9

31

35

40

44

48

16

]

2

4

5

6

7

631615

_1767

_t 184

8S_97_

83'i616

693_0B

6s_527

831700

6s_o2_

632019

83_02_

@31O22

_o47

632"67!

Bale34

D_SCR_PTION

Throttle Shaft S" Lever Ass'i.

Throttle Return Spring

Dus( Seal Washer

Dust Sea_

Th _od:le Shutter

Throttle Shutter Screw

Fuel Fitting

F_oei Bowt

FJoat Shah

Float

-0"" Ring, @oat Bov,'l to body

Intel Needle, Seat B" Clip (tncl. No.

31)

Spring Clip

Primer Bulb/Relaine_ Ring

Nigh Speed BOWl Nut

8ov_,[ Nut Washer

We_ch Plug, Atmospheric Ver!l

PART

I2

I0

£

_._,[ r,'O. i

"5_ S_arter, Rewind

1 580_J.99_ Pin, Sptln 9 (Incl. No. 4)

2 Washer

3 Reteinez

4 Washer

5 F._GS£8 Spring, B:ake

6 5_0816 Doq, S_arler

7 %O.317 S bring, Do#

8

59_!8 PLIley

9

_0_i9 Spring, Rewind

10

5.90_ O Cover, SDrin_

tl

'_'_10¢_.2 Housing Ass,_ , Btarte_

590%35 Rope, Ste,'xe,_ "Length _q' 6 9;64"

13

59_ Handla, Staq_r

8ia.;

DESCRlPTIOH

27

Loading...

Loading...