Page 1

Save This Manual

For Future Reference

owner’s

manual

MODEL NO.

509347

509347 FITS THE

FOLLOWING RADIAL

SA WS:

113.19930, 113.197731,

113.197732, 113.19935 0

10-INCH RADIAL SAW

GUARD KIT

• assembly

FOR YOUR

SAFETY:

READ ALL

INSTRUCTIONS

CAREFULLY

Part No. SP5984 Printed in U.S.A.

• operating

• repair parts

Page 2

Table of Contents

Section Title Page

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Crosscutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Ripping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Cutting Aides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Repair Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

NOTE:

1. This manual is intended to be used along with your original saw manual. If you no longer have

your saw’s owners manual, call customer service at 1-800-325-1184. Have your saw’s model number when you call.

2. If you require this manual in Spanish or French, call 1-800-511-2628.

Si usted requiere que éste manual usuario en español o francés, llame 1-800-511-2628. Pedir formulario SP5984S-2.

Si vous nécesstent ce mode d’emploi en espagnol ou français, téléphonez au 1-800-511-2628.

Demander pour forme SP5984F-2

.

2

Page 3

Safety

This manual has safety information and

instructions to help users eliminate or

reduce the risk of accidents and injuries,

including:

1. Sever e cuts, and loss of fingers or other

body parts due to contact with the blade.

2. Eye impact injuries and blindness, from

being hit by a thrown workpiece, wo rkpiece

chips or pieces of blade.

3. Bodily impact injuries, broken bones and

internal organ damage from being hit by a

thrown workpiece.

4. Shock or electrocution.

5. Burns.

Major Hazards

Three major hazards are associated with

using the radial arm saw for ripping. They

are outfeed zone hazard, kickback and

wrong way feed.

This section only briefly explains these hazards. Read the ripping and crosscutting

safety sections for more detailed explanations of these and other hazards.

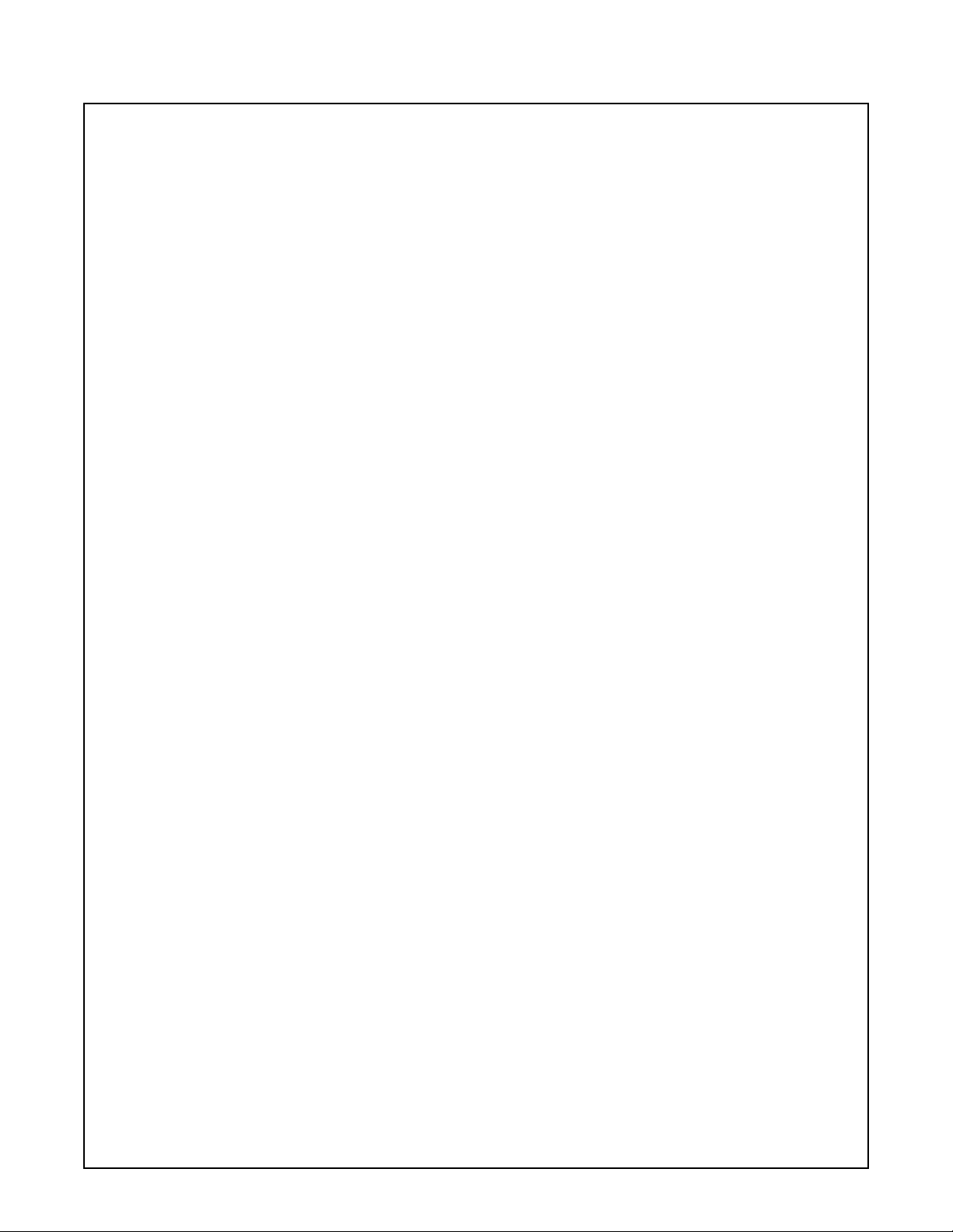

Outfeed Zone Hazard

Safety Symbol and Signal Words

An exclamation mark inside a triangle is the

safety alert symbol.

It is used to draw attention to safety information in the manual and on the saw. It is

followed by a signal word, DA NGER ,

WARNING or CAUTION, which tells the

level of risk:

DANGER

tion is not followed someone will be seriously injured or killed.

WARNI NG

tion is not followed someone could be seriously injured or killed.

CAUTION

tion is not follo w ed someone ma y be injur ed.

Read and follow all safety information

and instructions.

: means if the safety informa-

: means if the safety informa-

: means if the safety informa-

If you reach around the blade to the outfeed

side when ripping, and try to hold down or

pull the workpiece through to complete a cut,

the rotational f orce of the blade will pull your

hand back into the blade.

Fingers will be cut off.

Read and follow the information and

instructions under ripping safety.

3

Page 4

Safety

Kickback Hazar d

Kickback is the un controlled propell ing of the

workpiece back tow ard the user during ripping.

The cause of kickback is the binding or

pinching of the blade in the workpiece. Several conditions can cause the blade to bind

or pinch.

When a workpiece kicks back, it could hit

hard enough to cause internal organ injury,

broken bones, or death.

Read and follow the information and

instructions under ripping safety.

Wrong Way Feed Hazard

Wrong way feed is ripping by feeding the

workpiece into the outfeed side of the blade.

The rotational force of the blade can grab

and pull the workpiece.

Before you can let go or pul l back, the force

could pull your hand along with the workpiece into the blade. Fingers or hand could

be cut off.

The propelled workpiece could hit a

bystander, causing severe impact injury or

death.

Read and follow the information and

instructions under ripping safety.

4

Page 5

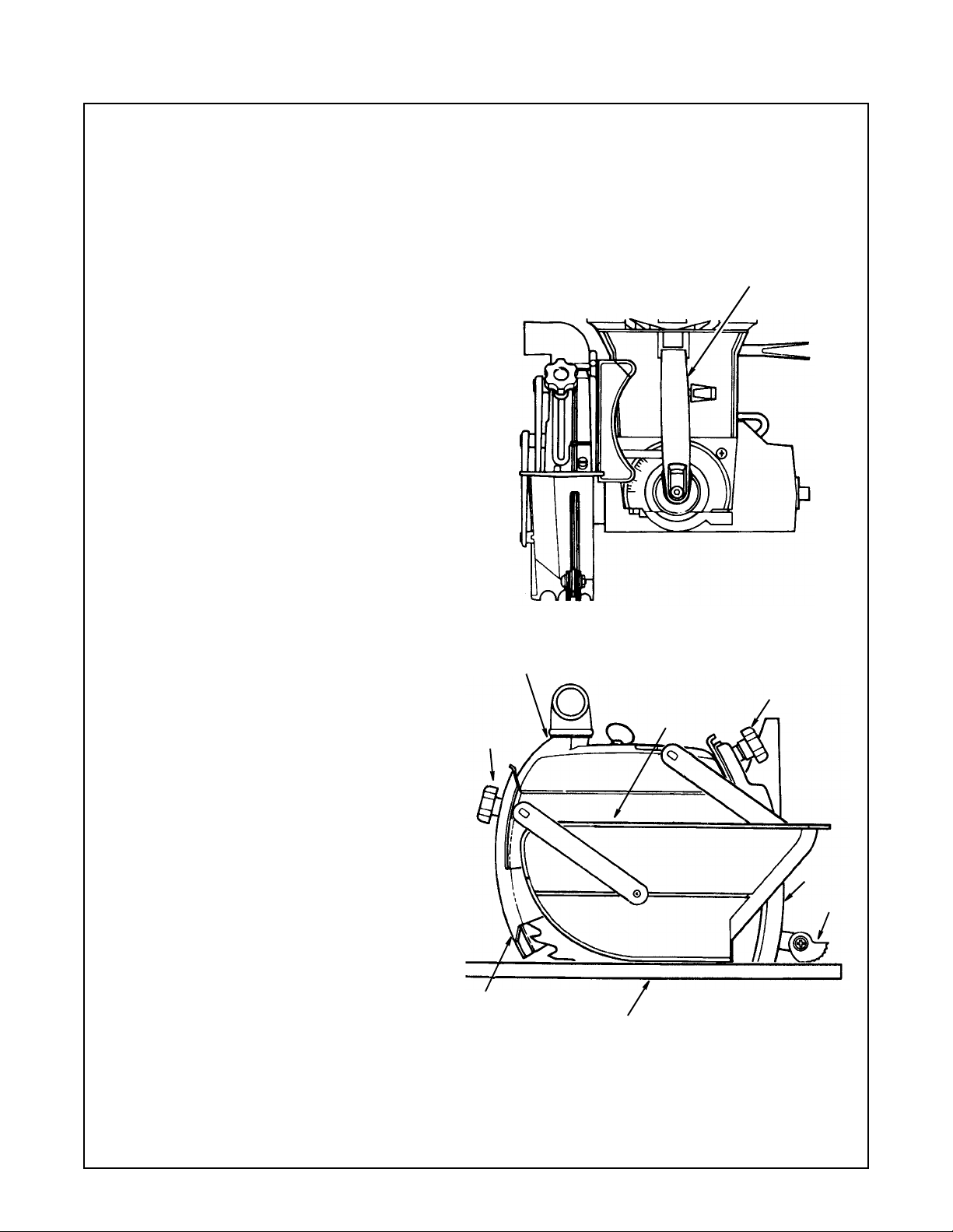

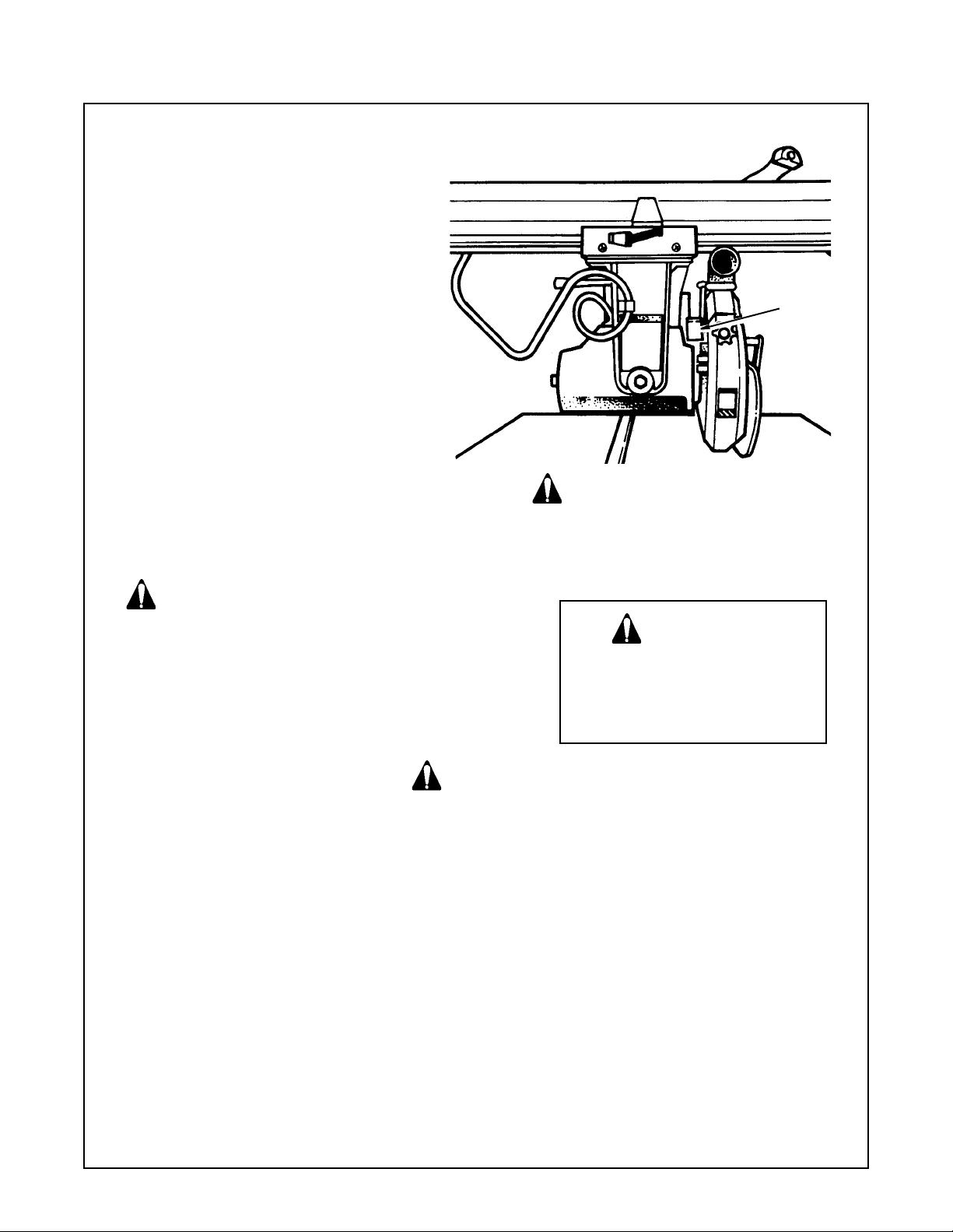

Guard Function and Features

The guard is a v ery important safet y feature,

designed to reduce the risk of injury associated with blade contact. Install the guard

correctly. Follow the specific instructions

in the ripping and crosscutting sections

to set and use the guard correctly f or

each type of cut.

Guard Features Include:

1. A non-moveable metal upper portion,

(Upper Guard) which is fastened to the

motor by the guard clamp screw, and which

fully covers the upper half of the blade.

2. A moveable clear plastic portion, (Plas-

tic Lower Guard) which partially covers the

lower half of the blade. It protects against

contact with the side of the blade during

crosscutting when blade is in its rearmost

position and the guard is resting on the

table, so the leading and trailing teeth of the

blade are not e xposed. It also protects

against contact with the outfeed side of the

blade during ripping, and acts as a barrier to

prevent wrong way feed.

Safety

Handle/Squeeze

Trigger

3. A squeeze trigger in the saw handle to

fully raise the clear plastic guard at the start

of a crosscut. Note: This is necessary because

the guard will not automatically raise to clear the

fence.

4. A hold down to be lowered to just clear

the top of the w orkpiece f or ripping. It a cts as

a barrier to the infeed side of the blade,

keeps the workpiece from fl uttering, and acts

as a sawdust deflector. It is locked/unlocked

by the hold down knob.

5. A riving knife to be lo wered to the table

for ripping. It k eeps the w orkpiece k erf open,

thereby reducing b lade pin ching and the risk

of kickback . It also acts as a barrier to the

hazardous outfeed side and prevents wrong

way feed. It is locked/ unlocked b y the riving

knife/pawls knob. When lo wered for crosscutting, it acts as a barrier to the leading

edge of the blade.

Upper Guard

Hold Down

Knob

Hold Down

Plastic Lower

Guard

Workpie ce

Pawls, Riving

Knife Knob

Riving

Knife

Pawls

5

Page 6

Safety

6. Set of pawls to be lowered to the workpiece surface for ripping. They allow the

workpiece to pass freely from infeed to outfeed side, but help stop the kickback motion

from outfeed to infeed side by grabbing into

the workpiece surface. Pawls must be reset

each time a different thickness workpiece is

cut.

7. A guard tab to manually raise the plastic

guard at the start of ripping unusual workpieces whose size/shape do not cause the

guard to raise automatically.

Hazards Associated wit h Clear Portion of Guard

The follo wing safet y information applies to al l

blades and accessories.

WARNING

Clear plastic portion of guard will not

provide any protection during crosscutting if blade is pulled over your

hand, or your hand enters blade path

from front or rear of blade. Fingers or

hand can be cut or cut off.

Guard Tab

CAUTION

Clear plastic portion of guard can get

caught or jam in fence or table kerfs.

Read and follow the warning on the

guard:

WARNING:

TO AVOID INJURY

SHUT OFF POWER

BEFORE CLEARING A

JAMMED LOWER GUARD

Clear plastic guard will increase risk of certain hazards:

• During rip and bevel cuts, narrow cut

off pieces can be pinched between

guard and blade. Cut-off pieces can

kickback.

• In bevel position blade teeth are fully

exposed. Fingers or hand can be cut

off.

6

WARNING

• Cut-off pieces can jam between

guard and blade. Turn saw off and wait

for blade to stop before freeing

jammed guard or blade.

• Workpiece or cut-off pieces can be

violently thrown by blade. Wear safety

goggles. Stand out of workpiece path.

Page 7

Safety Instructions

Read and follow all safety instructions.

Personal Safety Instructions

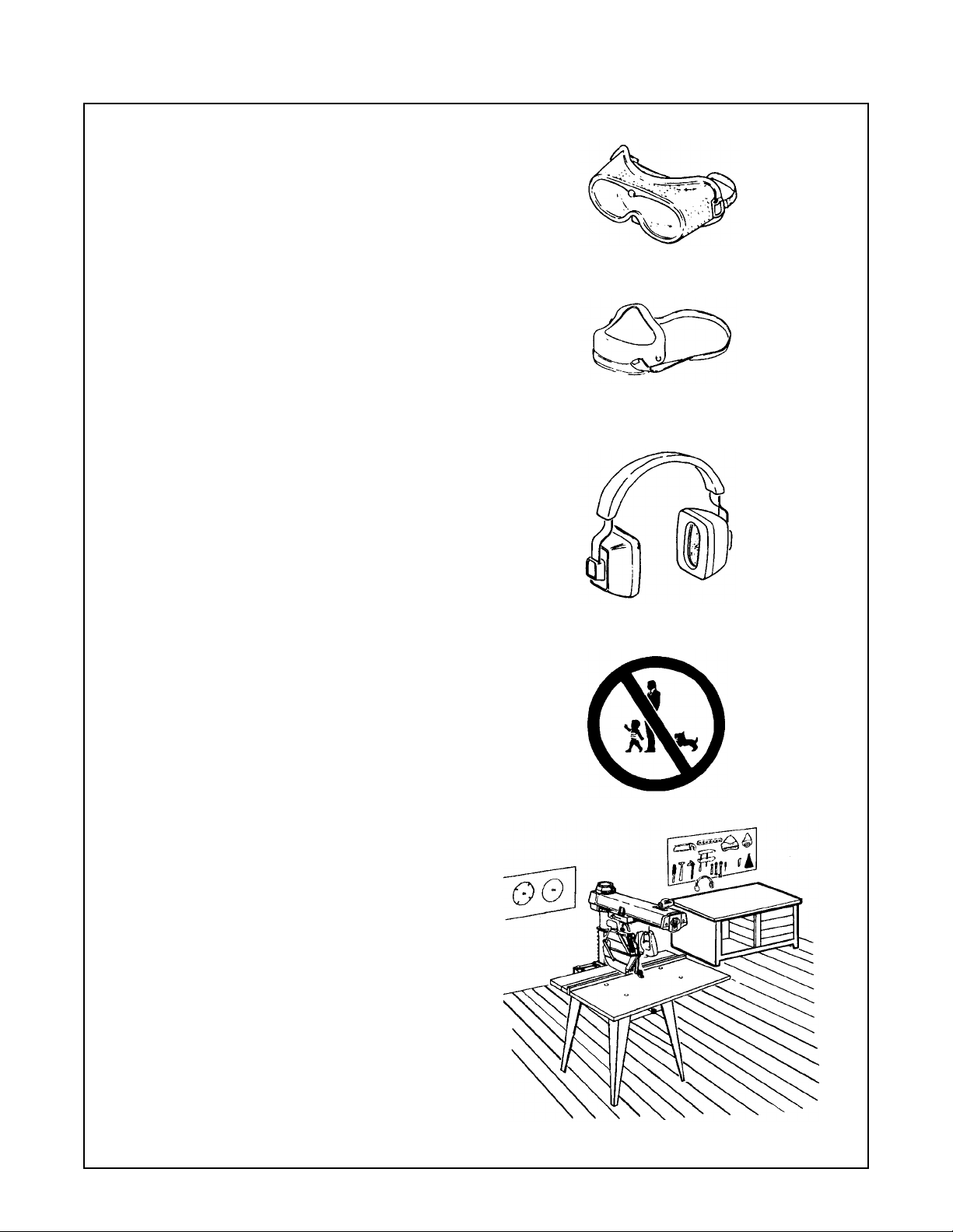

1. Wear safety goggles labeled ANSI Z87.1

(or in Canada CSA Z94.3-99) on the package. It means the goggles meet impact standards set by the American National

Standards Institute. Regul ar eyeglasses are

not safety goggles.

2. Wear close fitting clothes, short sleeved

shirts, and non-slip shoes. Tie up long hair.

Do not wear glov es , ties , je w elry, loose clothing, or long slee ves . These can g et caught in

the spinning blade and pull body parts into

the blade.

3. Wear dust mask to keep fr om inhal ing

fine particles.

4. Wear ear prote ctors, plugs or muffs i f you

use saw daily.

Safety

Safety Goggles

Dust Mask

5. Keep good footing and balance; do not

over-reach.

Work Area Safety Instructions

1. Keep children, pets, and visitors out of

work area; they could be hit by a thrown

workpiece, workpiece chips or pieces of

blade.

2. Turn saw off, remove yellow key, and

unplug before leaving work area. Do not

leave unti l blade has stopped spinning.

3. Make work area child-proof: remove yellow key to prevent accidental start-up; store

key out of sight and re ach; lock work area.

4. Keep floors clean and free of sawdust,

wax and other slippery materials.

5. Keep work area well lighted and uncluttered.

6. Use saw only in dry area. Do not use in

wet or damp areas.

Ear Protectors

7

Page 8

Safety

Saw Safety Instructions

1. Use guard, pawls and riving knife acco rding to instructions. Keep them in working

order.

2. Routinely check saw for broken or damaged parts. Repair or replace damaged

parts before using saw. Check new or

repaired parts for alignment, binding, and

correct installation.

3. Unplug saw before doing maintenance,

making adjustments, correcting alignment,

or changing blades.

4. Do not force saw. Use saw, blades and

accessories only as intended.

5. Have yellow key out and saw switched

off before plugging in power cord.

Workpiece Safety Instructions

6. Before turning on saw, clear table of all

objects except workpiece to be cut and necessary fixtures, clamps, or feather-boards.

7. If blade jams, turn saw off immediately,

remove yellow ke y, then free blade. Do not

try to free blade with saw on.

8. Turn saw off if it vibrates too muc h or

makes an odd sound. Correct any problem

before restarting saw.

9. Do not layout, assemble, or setup work

with saw on, or while blade is spinning.

10. Keep saw table clean.

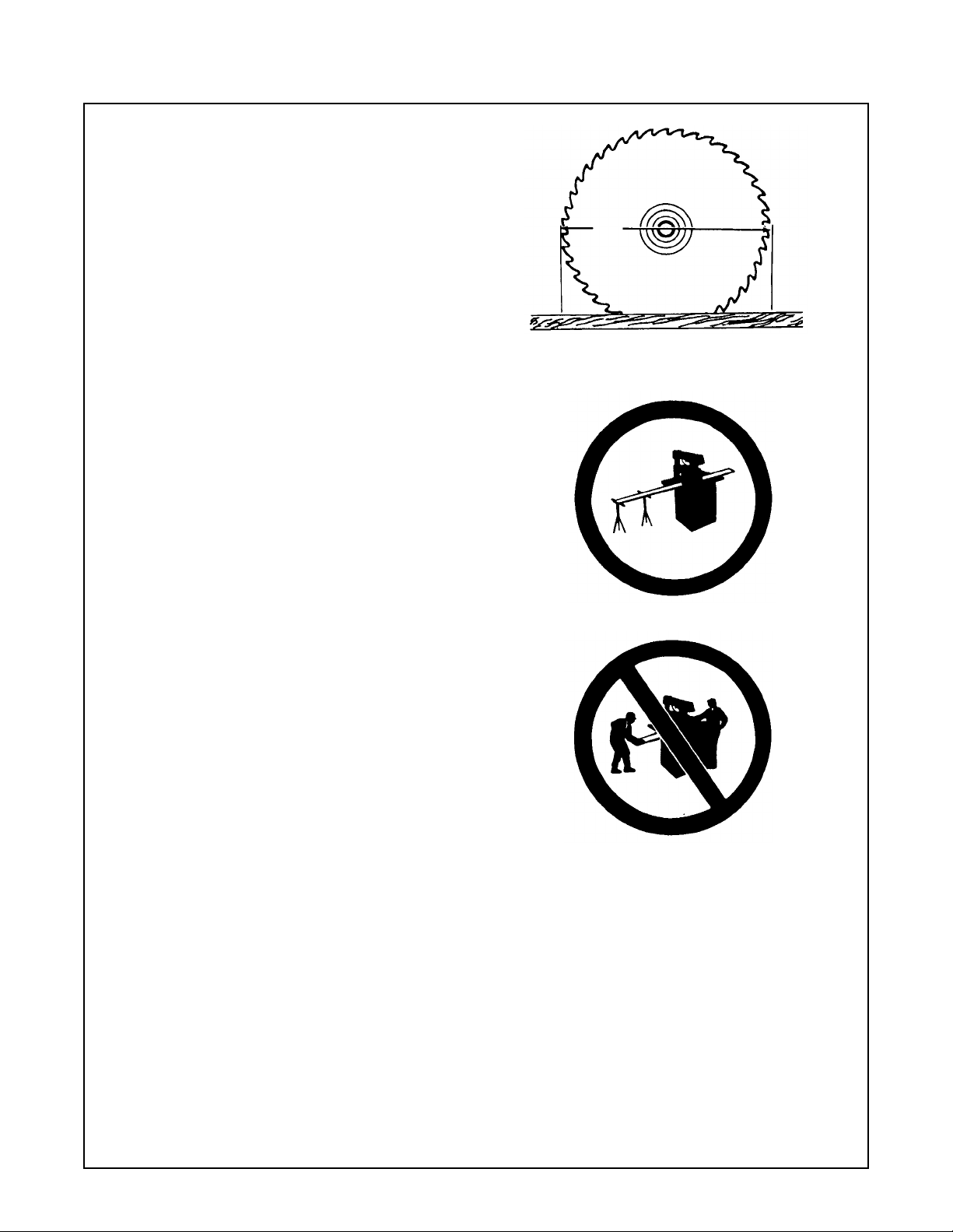

11. Store items awa y fr om sa w. Do not climb

on saw or stand on saw table to reach items

because saw can tip over.

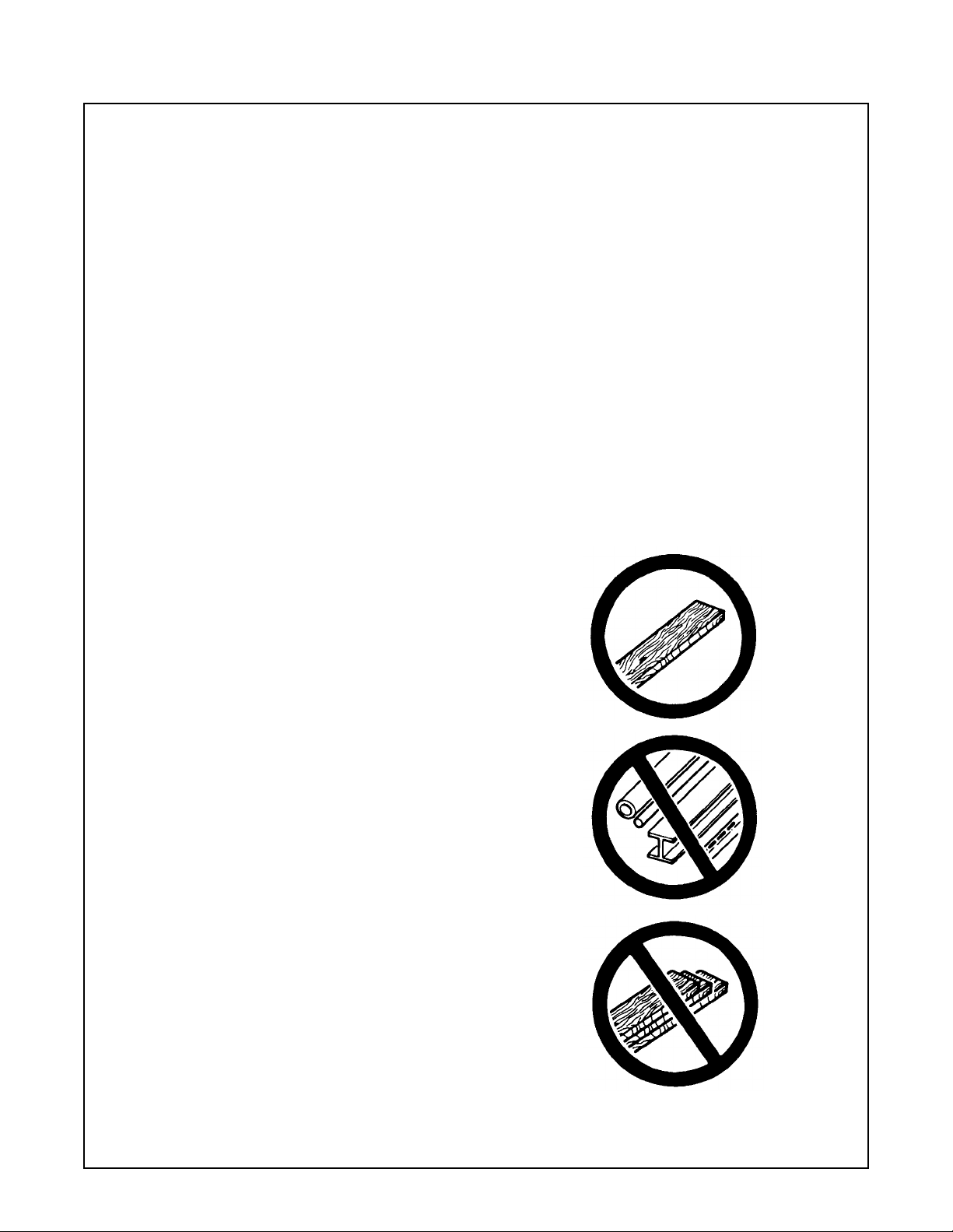

1. Cut only wood, woodlike or plastic materials.

Do not cut metal.

2. Cut only one workpiece at a time. Stacking or placing workpieces edge to edge can

cause user to lose control of workpiece.

8

Page 9

3. Rip only workpieces longer than the

diameter of the blade . Do not rip workpieces

that are shorter than the diameter of the

blade being used.

4. Workpieces that extend beyond the sa w

table can shift, twist, rise up from the tab le,

or fall as they are cut or afterwards. Support

workpiece with table extensions the same

height as the saw table.

5. To prevent tipping, support outer ends of

extensions with sturdy legs or an outrigger.

6. Do not use another person to help support workpieces or to aid by pushing or pulling on workpieces, because these actions

can cause kickback. Use table extensions.

Safety

Dia.

7. Use clamps or vice to hold workpiece. It’s

safer than using your hands.

Blade Safety Instr u ctions

1. Use only blades marked for at least 3450

rpm.

2. Use only 10" or smaller diameter blades.

3. Use blades for their recommended cutting procedures.

4. Keep blade sharp and clean.

5. Do not overtighten blade nut because

blade collar could warp.

6. Do not turn saw on and off in rapid

sequence because blade can loosen.

7. Blade should stop within 15 seconds after

saw is switched off . If blade tak es longer , the

saw needs repair. Contact Authorized Service Center.

9

Page 10

Safety

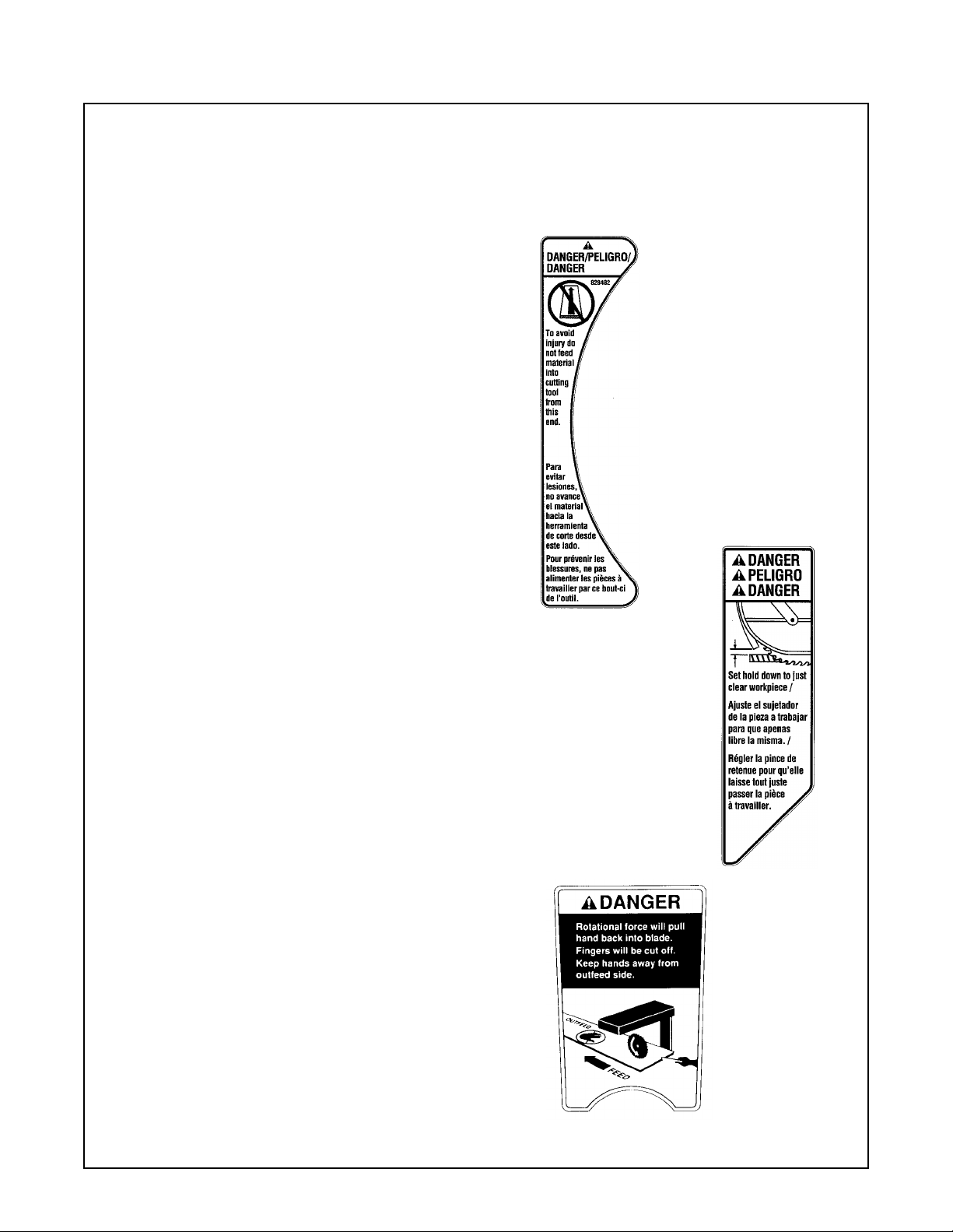

On-Product Safety Labels

There are several safety labels on the saw.

They alert the user to hazards explained in

the manual and remind the user how to

avoid the hazard.

At the outfeed side, to the right of the

guard near the saw handle is this safety

label to alert you to wrong way feed:

Note where they are located on the saw.

Read and follow the safety information

and instructions in these labels. Refer to

the manual for detailed e xplanations and

instructions.

On the infeed side of the guard is this

safety label to remind you to lower the

hold down to just clear the top of the

workpiece for ripping:

On the rear of the yoke, visible from the

infeed side when the saw is in a rip position,

is this safety label to alert you to outfeed

zone hazard:

10

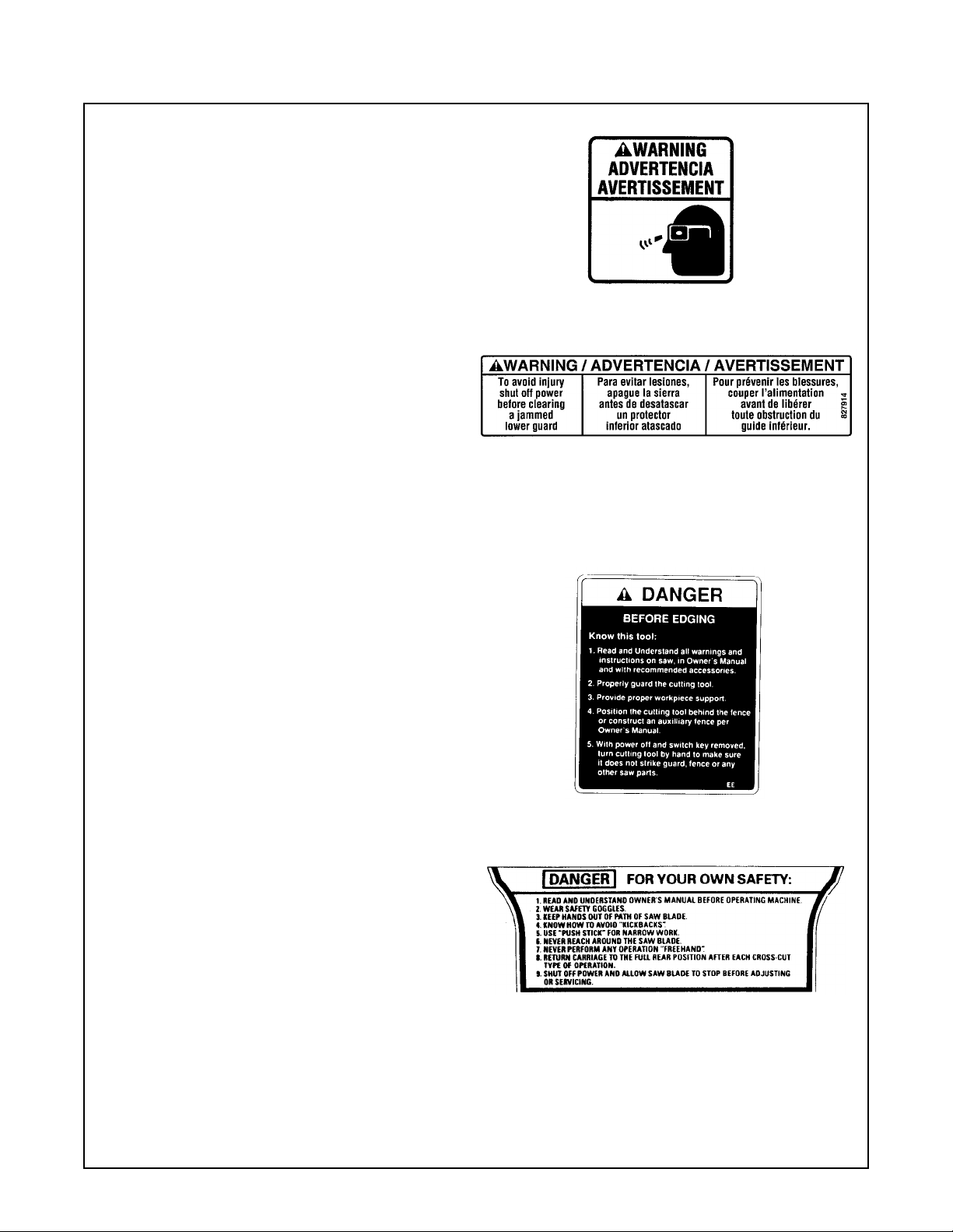

Page 11

Near the saw handle is this safety label to

alert you to thrown objects and to remind

you to wear safety goggles:

On the clear plastic guard is this OSHA

required label:

Safety

On the bottom surface of the motor , visib le

when the cutting tool is horizontal, is this

safety label alerting you to use a guard

when edge molding, and to position the

cutting tool behind the fence:

(see Accessories Section)

On the front of the yoke is this general

safety instruction label:

11

Page 12

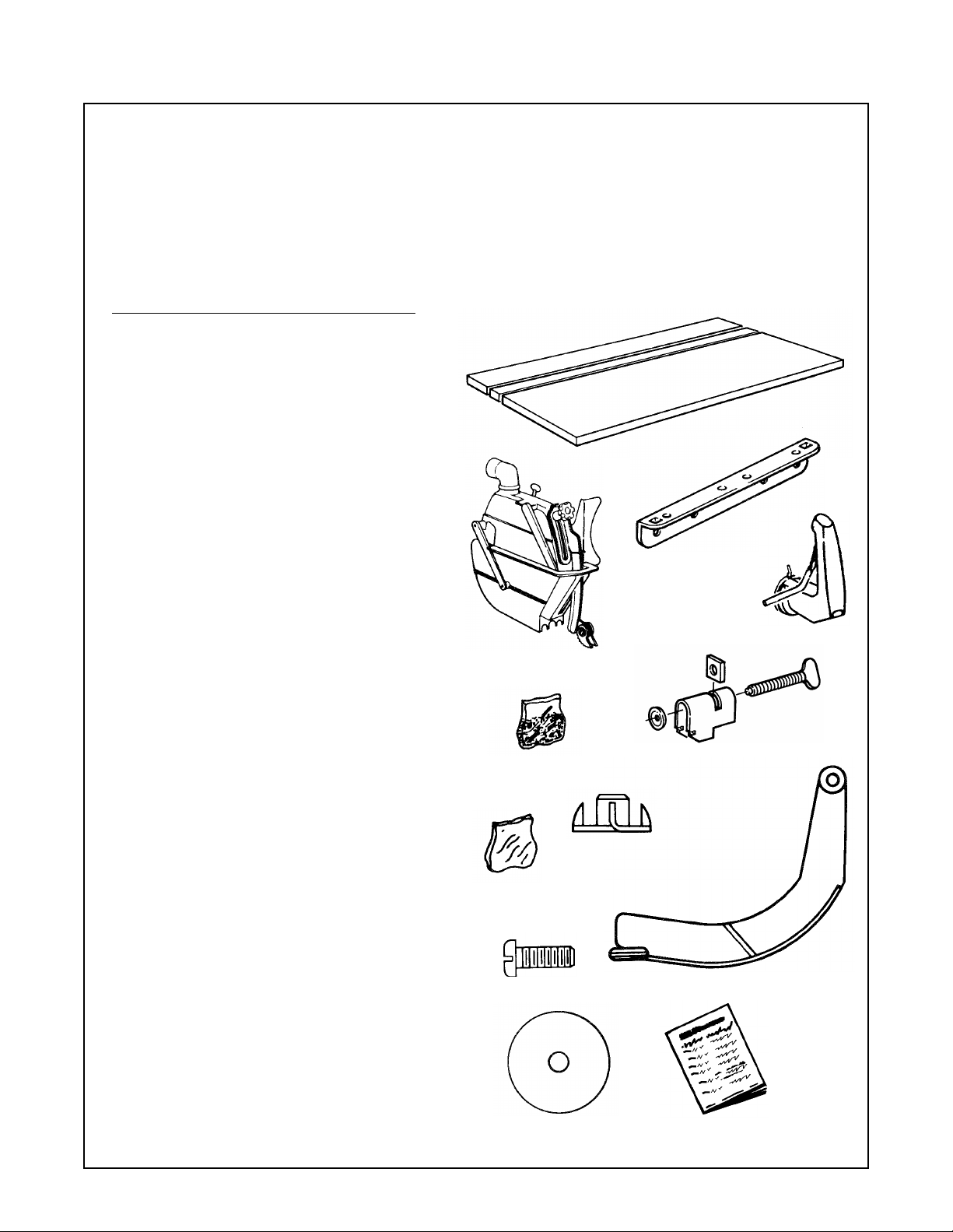

Assembly

Identify Parts

The following parts are included:

Note: Before beginning as sembly, check that all parts are included. If you are missing any part, do not assemb le guard.

Contact Emerson Tool Co. Service Center at 1-800-325-1184 to get the missin g part. Sometim es sm all part s can g et lost

in packaging material. Do not throw away any packaging until guard is put together. Check packaging for missing parts

before contacting Emerson Tool Co. A complete parts list (Repair Parts) is at the end of the manual. Use the list to identify the number of the missing part.

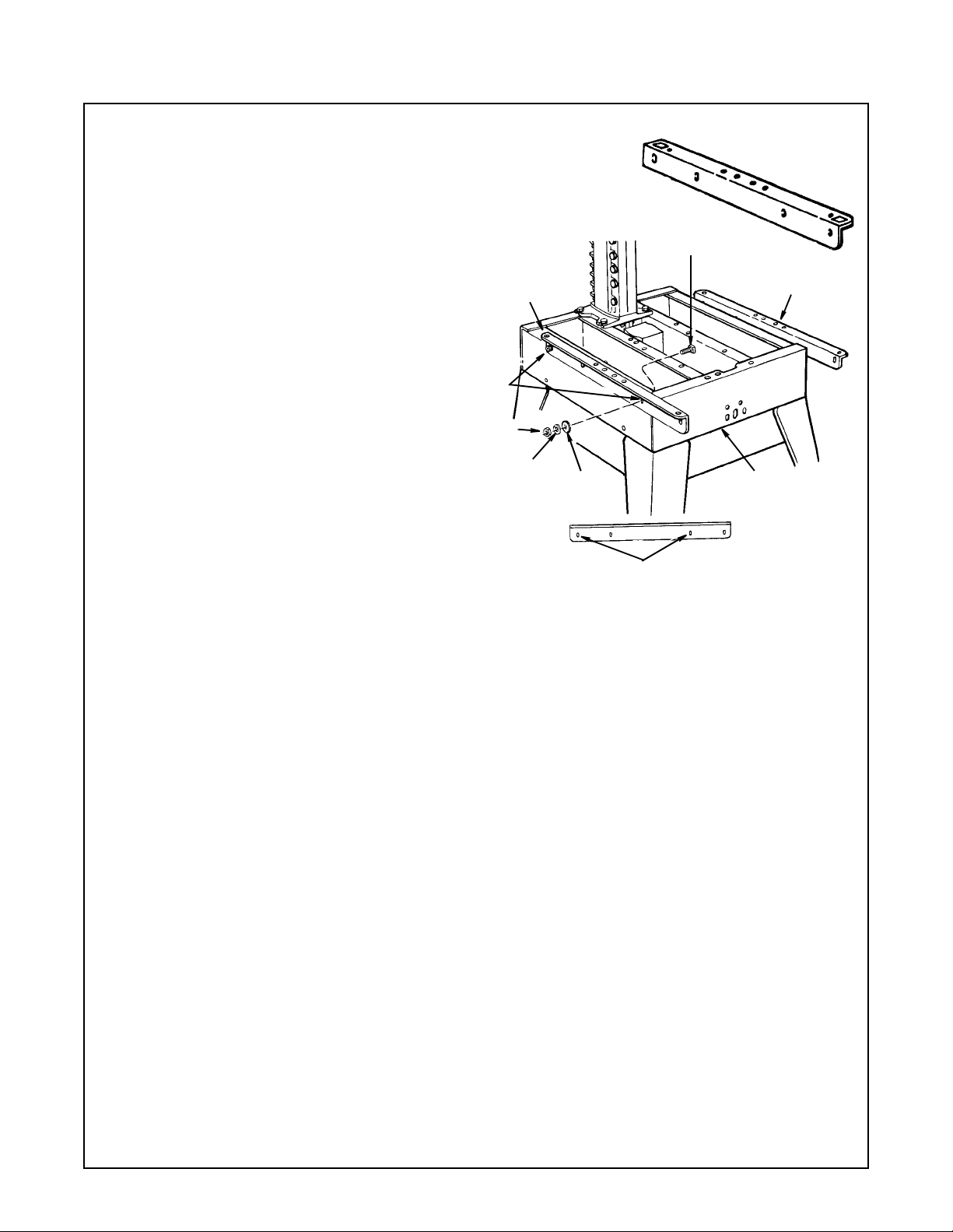

List of loose parts with model 509347

A. Guard Assembly ...... .. ............. .. ... ....... 1

B. Rear Table 40"..................................... 1

C. Spacer Table 40" ................................. 1

D. Front Table 40"..................................... 1

E. Table Support ........ .. .. ............. .. ... ....... 2

F. Handle Assembly........................ ......... 1

G.Bag of Loose Parts.............................. 1

Containing:

H. Table Clamp A sm......... .. .. ............. . 2

I. Tee Nut .......................................... 1

J. Bag of Loose P arts.............................. 1

Containing:

K. Gu ard Accessory........... .. .. ............ 1

L. Screw Plastite #8 x 1/2 .................. 1

M. Washer 3/16 x 1 x 1/16.................. 1

N. Instruction Form............................. 1

B

C

D

A

G

E

F

H

12

I

J

K

L

M

N

Page 13

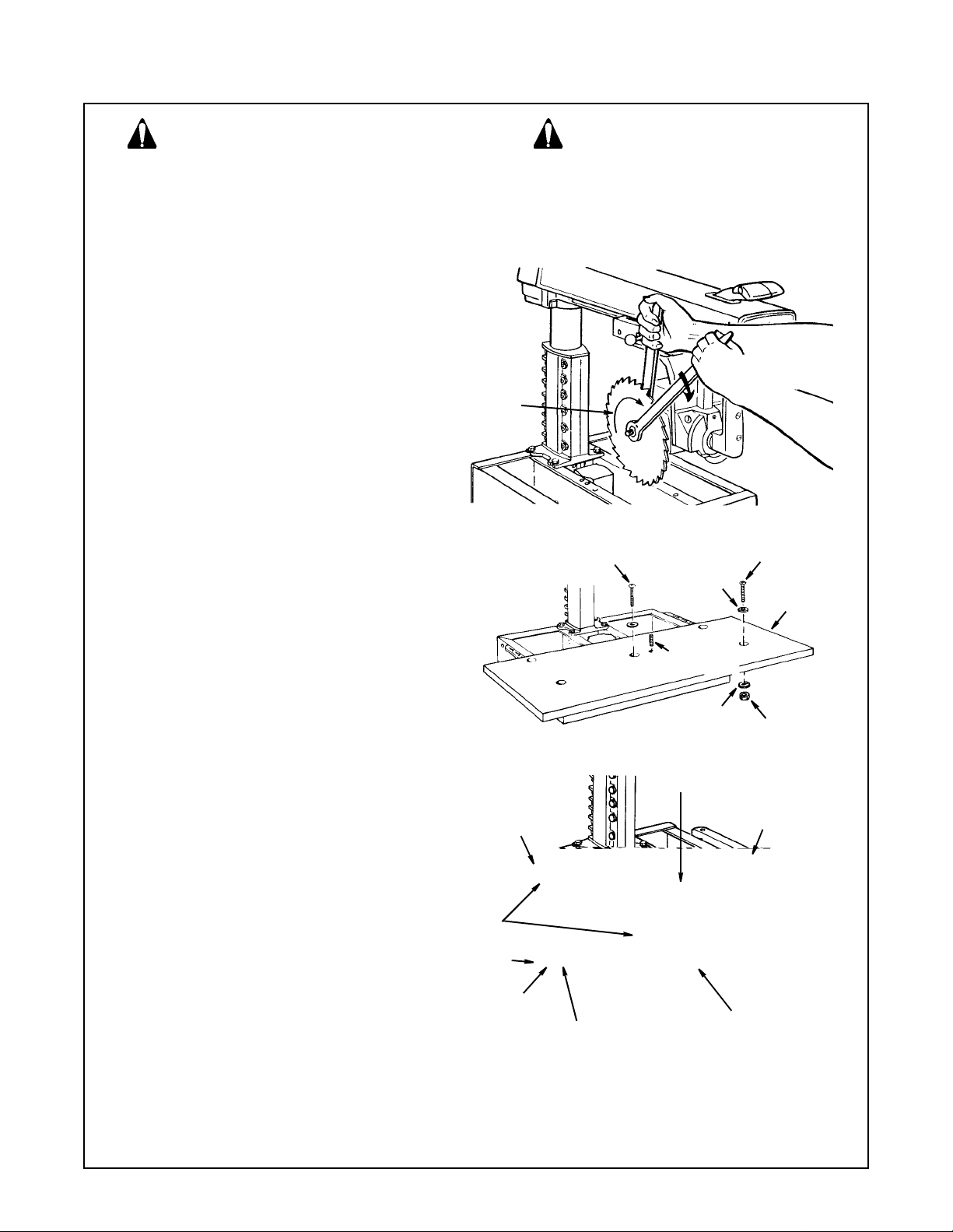

Assembly

WARNING

Plugging in saw during assembly

could result in electrical shock, or

severe cuts from contact with spi nning

blade.

Do not plug in saw at any time during

assembly.

Plug in saw only when it is to be used.

Remove Sawblade and Guard

1. Tighten carriage lock knob.

2. Loosen guard clamp screw, remove

guard.

3. Motor shaft has left hand threads. Hold

shaft wrench and rotate arbor wrench down

(clockwise).

4. Remove shaft n ut, outer collar, sawblade,

and inner collar. Dispose of guard but retain

shaft nut, outer collar sa wblade and inner

collar.

Remove Original Table Boards, and

Mounting Supports

NOTE

Nut) will be required for mounting retrofit

parts.

1. Loosen the table clamps and remove the

rear table, spacer table and rip fence.

Discard the rear table and spacer table.

Save the fence, it will be reused.

2. Remove the 1/4-20 x 1" cup point screw

from the T-Nut located in the front table.

Retain this screw for future use.

: All original hardware (except for T-

This retro fit guard kit required additional clearance behind fence. New

table boards are being supplied for

this reason.

Blade

Rotation

Table Mounting

Support

W ARNING

1/4-20 x 1-3/4"

Pan Hd. Screw

Square Hd. Screw

17/64"

Lockwasher

1/4-20 x 1"

Cup Point

Set Screw

Lockwasher

5/16-18 x 3/4

Pull Down

to Loosen

1/4-20 x 1"

Pan Hd. Screw

Front Table

Hex Nut

Table Mounting

Support

3. Remove all remaining nut, bolts, and

washers and lift off front table. Discard the

fro nt ta ble.

4. Remove nuts, bolts and washers that

secure the left and right table support channels. Discard the support channels.

Screws

Here

Nut

Lockwasher

Base

7/8" O.D.

Flat Washer

13

Page 14

Assembly

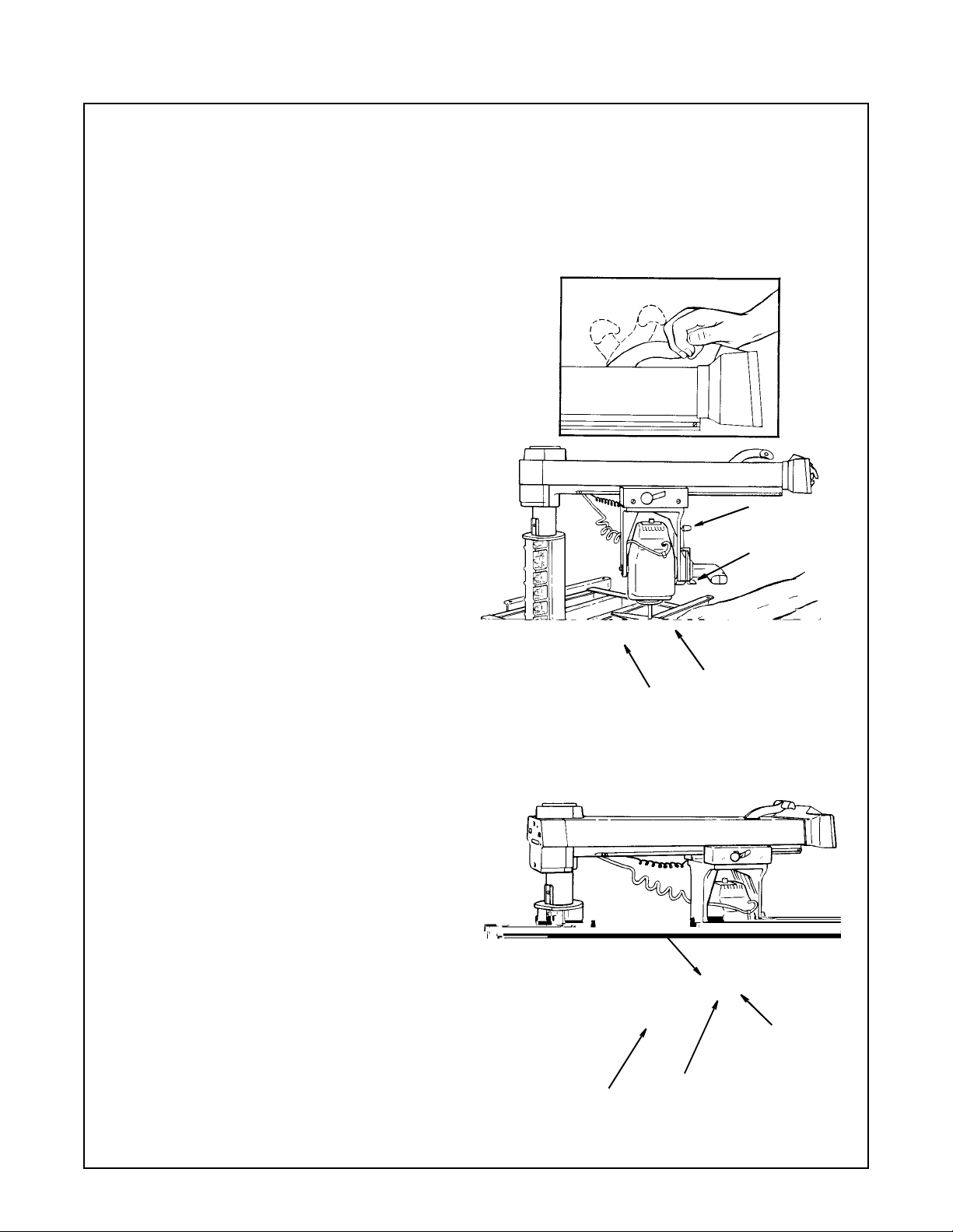

Attach new table supports

1. Set out:

- two table supports

- four 5/16" 18 x 3/4" long square head

screws

- four 11/32" x 7/8" x 1/16" flat washers

four 5/16" lockwashers

- four 5/16" hex nuts

- Attach supports to side frame, making

sure to use correct holes in table supports and side frame: Use two screws

per support (insert screws through base

and then support); on end of each screw

put a flat washer, lockw a sher and nut,

then finger tighten to table supports rest

in lower position.

Table Mounting

Support Channel

Screws

Here

Nut

Lockwasher

7/8" O.D.

Flat Washer

Square Hd. Screw

5/16-18 x 3/4

Table Mounting

Support Channel

Base

Front

Mount Rails Using These Holes

14

Page 15

Adjustments

l

Positioning Table supports/Installing Front Table/Leveling Front Table

NOTE

: The goal in adjusting the table suppo rts and leveling the front table is to make sure that the

table is the same distance from the radial arm at all points . This ensures that when the table and

blade are installed the clear ance between them will be equal at all points.

Positioning Table Supports

1. Release bev el loc k lev er , mo ve be v el inde x

lever to the left and rotate the motor to position arbor shaft down. Lock bevel lock.

2. Unlock and hold miter/arm lock lever in

index relea se position as shown. Posi tion arm

against left stop (approximately 50° miter).

Loosen carriage lock knob and position arbor

shaft directly over left hand channel.

NOTE

: F or saf ety reasons in accor dance with

the UL standard, stops hav e been provided t o

prevent 360° rotation of the radial arm.

3. Slide the arbor wrench handle between

end of motor shaft and table support to act as

a feeler gauge. Caref ully low er the motor with

elev ation crank until the end of shaft is just

touching the arbor wrench. The wrench

should slide back and forth with only slight

resistance. Tighten screw “A”.

Unlock

Lock

Index Release

Position

Bevel Index

Lever

Bevel Lock

Lever

NOTE:

Do not change this elevation setting

until both left and right hand table support

channels have ben adjusted.

4. Move arm and carriage to screw “B”.

Adjust position of table support so that the

arbor wrench just slips between the end of

the motor shaft and the support. Tighten

screw “B”.

5. Move arm and carriage to right hand table

support and level in the same manner as in

step 4.

6. Recheck both support channels to make

sure that tightening screws did not affect the

accuracy of the adjustment.

7. Elev ate the saw and return motor to horizontal position to provide clearance for ins tal lation of front work table.

Screw “A”

Wrench

Screw “A”

Arbor Wrench

Arbor

Table Mounting

Support Channe

(Left Hand)

Screw “B”

15

Page 16

Assembly

Installing Front Table

1. Set out:

- front table

- tee nut

- 1/4 " U-clip

- 1/4" diam. x 7/8" long cup point set

screw

- four 1/4" diam. x 1" long pan head

screws

- 1/4" dia. x 1-3/4" long pan head screw

- five 17/64" I.D. x 5/8" O.D. flat washers

- four 1/4" lockwashers

- four 1/4" diam. hex nuts

2. Identify top and bottom of table: top has

counterbored holes. Place tab le bottom

side up on solid surface. Hammer tee nut

into leveling hole. (This hold is not counterbored from the top).

Tee Nut

(Install from bottom)

~

3. Snap u-clip onto front edge of base so

hole lines up with hold just to the left of center notch.

4. Place table, top side up, on saw so center counterbored hole lines up with hole in uclip. NOTE:

Table will extend o v er front edge

of saw frame .

Table Mounting Holes

Top of Table

(Counterbored Holes Up

Channel

U-Clip

16

Page 17

5. Drop a flat washer into each counterbored hole.

6. Start 1-3/4" long pan head screw through

center hole and into U-clip, but do not fully

tighten.

7. Start cup point set screw through leveling

hole and into tee nut, but do not fully tighten.

8. Put 1" long pan head screw in each of

four remaining holes and through matching

holes in table supports. On end of each

screw, put lockwasher then nut and tighten

with screwdriver.

Make Front Table Flat

1. Place rear table on its edge, across center of front tabl e. Check for gap between surfaces.

If there is less than 1/32" gap, tighten cup

point set screw unt il it touches frame (look

underneath table), then tighten center (1-3/4"

long pan head screw.

If there is more than 1/32" gap, close gap

by raising or lowering center of front table:

1/4-20 x 1-3/4"

Pan Hd. Screw

Rear Table

Board

Assembly/Adjustments

1

1/4-20 x 1"

Cup Point

Set Screw

Hold Down

Screw

17/64"

Lockwasher

Leveling

Set Screw

1/4-20 x 1"

Pan Hd. Screw

Front Table

Lockwasher

Hex Nut

to raise center, tighten cup point set screw

against frame;

to lower center, tighten center (1-3/4" long)

pan head screw.

2. When gap is closed, mak e sure cup poi nt

set screw touches frame (look underneath

table), and center (1-3/4" long) pan head

screw is tightened.

NOTE:

Rip fence scale is no longer correct.

Measure distance between fence and blade

for correct distance when in rip mode.

Front Table

17

Page 18

Alignment

The saw and blade mus t be aligned correctly

for two reasons:

1) To prevent binding of the blade and workpiece, which can cause jams, kickbacks, or

thrown workpieces;

2) To make accurate cuts.

Alignment and Adjustment Steps

The following alignments and adjustments

must be made in order. If you miss an

adjustment, you must go back, make the

missed adjustment, and repeat all steps

from that point on.

These adjustments are like fine tuning a

piece of equipment. Often, a series of steps

must be repeated more than o nce in order to

get the adjustment right. There are many

adjustments to make. Because some adjustments may be awkward, you may want to

ask someone to help you.

Before you start, make sure the framing

square is true.

WARNING

Plugging in saw during alignment could

result in accidental start-up and severe

cuts from contact with spinning blade.

Do not plug in saw at anytime during

alignment or adjustment.

Plug in saw only when it is to be used.

Check Framing Square

This edge must

be straight

Draw light

line on board

along this edge

Should be no gap or overlap here when

square is filipped over to dotted position.

Square Crosscut Travel

The goal of this adjustment is to make accurate crosscuts. To do so , the radi al arm must

be square to the fence, otherwise, there will

be a slight miter angle in all crosscuts.

Squaring cross cut travel.

1. Index but do not lock arm at 0° miter.

2. Install saw blad e as shown. Motor shaft

has left hand threads.

Note: Do not overtighten arbor nut. Use the arbor

wrench to just "snug" it.

Blade

Rotation

Sawblade

Outer

Collar

Arbor

Nut

Shaft Wrench

End of arbor wrench

resting on table

Motor

Inner

Collar

18

Page 19

Alignment

3. Lower arm until saw blade just clears the

front table. Tighten the yoke lock lever and

bevel lock lever.

4. Place a framing square on the table, as

shown, with one leg of square firmly against

rear edge of front table. Position the blade

and square until the leg of the square just

contacts a tooth of the blade. Ma rk this

tooth.

5. When the carriage is moved slowly back

and forth on the arm, the marked tooth

should just touch the square at all points. If

marked tooth moves into or away from

square, follow the adjustments as described

in your saws original owners manual. If you

no longer have your saws owners man ual

call Customer Service at 1-800-325-1184.

Have y our saws model number ready when

you call.

Yoke Lock

Lever

Miter/Arm Lock Lever

Bevel Index

Lever

Bevel Lock

Marked

Tooth

Lever

Install New Table Clamps

1. Insert fence, then spacer table, then rear

table.

2. Tilt clamp forward and snap into place in

opening at rear of table support.

3. Tighten thumbscrews to clamp table sections in place.

Front

Table

Fence

Spacer

Table

Rear

Table

19

Page 20

Assembly

Replacing Handle

1. Remove screw “A” from handle assembly.

2. Remove trim handle “B”.

3. Remove screw “C” and lockwasher “D”.

Yoke handle “E” should then be removed.

OLD HANDLE ASSEMBLY

4. Remove the bevel indicator and screw

attached to the yoke handle (“E”). Reinstall

these pieces on the new handle.

5. Attach new handle reusing scre w “C” and

lockwasher “D”.

NEW HANDLE ASSEMBLY

E

D

C

B

A

D

C

20

Page 21

Install Guard

The guard is a v ery important safet y feature.

It covers a large part of the blade and helps

protect against severe cuts. Always use the

guard

1. Lock motor at 0° bevel (blade vertical).

Alignment

2. Use one hand to lift clear plastic guard;

use other hand to grasp rear o f guard (belo w

dust elbow). Position guard so riving knife

faces front of saw.

3. Tilt front of guard down about 45°; place

over blade; rotate guard to level position.

NOTE:

Make sure two screw heads on back

of guard are resting on top of motor housing.

This will prevent movement of guard about

motor. Squeeze handle trigger to make sure

it fully raises clear plastic guard. If it does

not, remove and r einstall guard, making sur e

that trigger mechanism engages pull link on

guard.

4. Tighten guard clamp screw.

Riving

Knife

Parallel

21

Page 22

Alignment

Align Riving Knife to Blade

The goal of this adjustment is to position the

riving knife directly in line with the blade.

Riving knife alignment is an important safety

factor. The riving knife rides in the kerf of t he

cut workpiece during ripping to keep the two

sides of the workpiece from pinching on the

blade. Blade p inc hing is a cause of kickback.

1. Lock yok e in in-rip position (b lade towards

column, motor towards front of arm).

2. Lower arm until blade just clears table.

3. Unlock rip lock while holding up lower

plastic guard, move yoke back unt il blade

touches fence . Lock rip lock.

4. Loosen pawls/riving knife knob. Lower riving knife to the table and tighten knob. The

riving knife should rest flat against fence.

5. If adjustment is needed:

Wrong

Correct

Wrong

a.) loosen riving knife bracket screw.

b.) slide riving knife so it rests against

fence.

c.) secure riving knife bracket screw .

6. Raise riving knife and tight en pawls/riving

knife knob.

Riving Knife

Bracket Screw

22

Page 23

Bevel Index Lever

Controls

Miter/Arm Lock Lever

On-Off Switch

Yellow Key

Control Function Operation/Comments

Miter/Arm Lock Frees radial arm to move; locks in

any desired position; pre-set

indexed positions at 0°, 45°L, 45°R

Pull lever forward to release index

then swing arm left or right.

Hold in unlocked posi tion while moving arm

On-Off Switch Turns motor on/off Pull on, push off

Requires yellow key

Yellow Key Allows saw to be switched on Insert into on-off switch

Remove after turning saw off

Bevel Index Lev er Index es th e sawb lade t o 0°, 45°, or

90° pre-set indexed positions

Move bevel index lever to the left

while positioning the blade, then

release it

23

Page 24

Controls

Table Clamp

Yoke Index

Lever

Bevel Lock Lever

Elevation

Crank

Control Function OperationlComments

Bevel Lock Lever Frees motor to rotate; locks in any

desired position

Pull lever to release and push to lock

Support motor before unlocking

because it can swing do wn quickly

Bevel index lever must be unindexed

before moving motor

Elevation Crank Raises/lowers radial arm

Turn clockwise to raise, counterclockwise to lower

Table Clamp Frees table sections to allow

changing fence position

Yoke Index Lever Frees yoke to rotate between rip

and crosscut positions

Turn clockwise to tighten, counterclockwise to loosen

Pull the spring loaded yoke pivot

latch forward to release this pin

24

Page 25

Saw Handle

Controls

Rip Scale &

Rip Indicator

Rip Lock

Yoke Lock

Handle

Bevel Lock Lever

Control Function OperationlComments

Yoke Lock Handle Locks yoke in rip or crosscut posi-

tion

Pull handle forward to release; push

handle rearward to tighten

Yoke index lever must be un indexed

before rotating yoke

Rip Lock Locks carriage to radial arm for rip-

ping

Rotate counterclockwise to release

carriage; turn clockwise to lock carriage in position

Lock before ripping

* Rip Scale & Rip

Indicators

Saw Handle Provides gras ping surface so car-

Tells approximate distance

between blade and fence when

saw is in in-rip or out-rip position

riage can be moved.

Contains trigger mechanism to

raise clear plastic guard when

Move blade carriage along arm to

align line on indicator with desired

number on scale

Grasp to move blade carriage

Squeeze trigger to fully r a ise clear

and plastic guard. Clear guard must

be raised over fence to crosscut

making a crosscut

* NOTE: After installing new guard and new table boards rip fence scale is no longer correct.

Measure distance between fence and blade for correct distance when in rip mode.

25

Page 26

Controls

Hold Down

Knob

Guard

Guard Clamp

Screw

Pawls/Riving

Knife Knob

Riving Knife

Bracket

Riving Knife

Hold Down

Pawls

Control Function Operation/Comments

Guard Clamp

Screw

Guard Protects against contact wi th upper

Secures guard to motor; frees

guard for removal

blade; partially protects against

contact with lower blade; acts as

sawdust deflector

Turn counterclockwise to loosen,

clockwise to tighten

Upper part remains fixed in level

position.

Notch in guard fits securely

into matching tab on motor

Clear guard is moveable: fully raise

over fence at start of crosscut;

Saw Handle

; most workpieces will

automatically rai se clear guard during

See Guard Tab

Hold Down Knob Frees hold down to move up and

down; locks hold down in place

ripping;

Turn counterclockwise to loosen,

clockwise to tighten

See

Hold Down During ripping, acts as partial bar-

rier to infeed side of blade; keeps

infeed side of workpiece from fluttering; acts as sawdust deflector

Riving Knife

Bracket

Prevents side to side movement of

riving knife and pro vides means f or

adjusting alignment

26

For ripping, lo we r hol d do wn t o top of

workpiece surface, then raise slightly

and lock in place. For crosscutti ng

lock in fully raised position

Loosen to align riving knife, then

tighten

Page 27

Pawls/Riving

Knife Knob

Pawls

Controls

Riving Knife

27

Page 28

Crosscutting

Crosscutting Defined

Crosscutting is cutting a workpiece to leng th.

The workpiece is held firmly against the

fence, and the blade is pulled through the

workpiece to make the cut. Straigh t, bevel,

miter, and compound cuts can be made.

Crosscutting Safety

Straight

Bevel

Miter

Compound

The hazards associated with crosscutting

include: exposed blade teeth, rolling carriage, and thrown workpiece. This section

explains these hazards and tel ls how to

avoid them or redu ce the risk of their happening. Read this section before making

any type of crosscut. Follow these steps

every time you make a crosscut.

Exposed Blade Teeth

WARNING

During crosscutting, blade teeth can

be exposed. To reduce risk of having

fingers, hand or arm cut off:

[Correctly install and use guard.

[Lower pawl s or riving knife to clear fence

or workpiece, whiche v er is higher, by 1/4".

Lowered pawl s or riving knif e act as partial

barrier to front of blade.

[Keep hands away from blade and out of

blade path. Keep hand holding down

workpiece at least 8" from blade.

[Blade can come off table edge be y ond 30°

left miter position. Use right miter position

whenever possible.

[Do not cut freehand. You will not be able to

control workpiece.

[ If blade jams, turn off saw, remove yellow

key, then free blade.

Rolling Carriage

WARNING

When saw is turned on, blade can suddenly come forward. To reduce risk of

this happening:

[Keep one hand on saw handle when turn-

ing saw on.

[Adjust le veling feet to make sure radial

arm slants slightly toward rear.

Thrown Workpiece

CAUTION

Workpiece could be picked up by spinning blade and thrown. You might be

hit by thrown workpiece. To reduce

risk of thrown workpiece:

[Make sure installed fence is at least half

as high as the workpiece, and never less

than 3/4".

[Start and finish cut with blade in rearmost

position, behind fence.

[Firmly hold workpiece flat on table and up

against fence . Cut only one w orkpiece at a

time.

[Pull blade through workpiece only far

enough to complete cut, and nev er more

than half the diameter of blade .

[Do not touch or move workpieces until

blade has stopped spinning.

28

[Use length stop only on end of workpiece

which is held down.

[Use table extensions to support work-

pieces that extend beyond table.

Page 29

Crosscut Kerfs

A kerf or shallow cut is needed in the table

and fence to serve as a path f o r the blade

and to ensure that the blade cuts all the way

through the workpiece. A kerf is needed fo r

each different cutting path.

To make an approximately 1/16" deep kerf:

1. Prepare table:

- put fence in front position

- tighten table clamps

2. Prepare blade:

- lock motor in crosscut position

- lock radial arm at desired miter angle

- lock motor at desired bevel angle*

- unlock carriage lock and push blade

to rearmost position, behind fence

- lower b lade* to just clear table

- lower pawls or riving knife to clear

fence by 1/4".

Crosscutting

* raise clear plastic guard before changing

bevel angle and when lowering beveled

blade, otherwise i t may jam into table.

3. Grasp saw handle, then turn saw on.

Keep one hand on saw handle through

step 6.

4. Slowly lower blade until it touches table,

then lower one more full turn of crank.

5. Squeeze handle trigger to full y raise cl ear

plastic guard so it will clear fence. Pull bl ade

through fence and across table as far as it

will go.

6. Push blade to rearmost position, behind

fence, and turn saw off. Keep hand on saw

handle until blade stops spinning.

29

Page 30

Crosscutting

Making Cr ossc uts

Follow these steps to make crosscuts.

1. Prepare table:

- put fence in front position

- tighten table clamps

2. Prepare blade:

- lock motor in crosscut position

- lock radial arm at desired miter angle

- lock motor at desired bevel angle*

- unlock carriage lock and push blade

to rearmost position, behind fence

- lower b l ade into kerf* but not touching

kerf bottom (blade should move

freely).

* raise clear plastic guard before changing

bevel angle and when lowering beveled

blade, otherwise i t may jam into table.

8"

1/4"

3. Position workpiece against fence, and

lower pawls or riving knife to clear fence or

workpiece, whichever is higher, by 1/4".

4. Grasp saw handle, then turn saw on.

Keep one hand on saw handle through

step 7.

5. Hold workpiece down and against fence.

Keep hand at least 8" away from blade.

6. Squeeze handle trigger to full y raise cl ear

plastic guard so it will clear fence and workpiece. Pull bla de thr ough w orkpiece b ut onl y

far enough to complete cut, and never more

than half the diameter of blade.

7. Push blade carriage to rearmost position,

behind fence, and turn saw off. Keep hand

on saw handle until blade stops spinning.

30

Page 31

Repetitive Crosscutting

Crosscutting

Repetitive crosscutting is the repeated and

continuous cutting of many pieces of lumber

to the same length. Carriage and length

stops can help make this type of cr osscutting

more efficient.

A carriage stop defines the distance neede d

to pull the blade through to complete each

cut. This will prevent pulling the blade

through more than the recommended distance.

To make a carriage stop use 1x2 lumber:

a) cut two pieces, each 2" long

b) clamp a piece on each side of radial arm,

so blade carriage sto ps at distance needed

to complete cut

c) check that clamps do not interfere with

hand grip on saw handle.

A length stop defines the cut length and

ensures that all pieces will be cut to the

same size. Clamp a piece of 1x2 lumber on

the fence to define the cut length. Use a

length stop only on the end of the workpiece which is held down.

Carriage

Stop

Length

Stop

Crosscutting Hints

1. To extend life of table top, buy auxiliary

table cover (see Accessories) or make one

out of 1/4" plywood or fiberboard. Clamp or

nail to original table t op, section b y section. I f

you use nails, nail in the four corners to

make sure blade will not contact nails.

2. Make several fences, so each will have

only a few kerfs (See Cutting Aides). Too

many kerfs will wea ken a fence.

3. Keep table clean of chips and sawdust.

4. Use sharp blades, and use the right blade

for each job.

5. When making miter or bevel cuts, use

extra force to hold workpiece down because

it tends to move during these types of cuts.

6. When cutting hard woods, like oak, or

making compound cuts, keep arm holding

saw handle rigid and pull blade through

slowly.

7. To keep cut line accurate, periodically

check blade alignment.

8. Do not cut severely warped, bowed or

twisted workpieces.

31

Page 32

Ripping

Ripping Defined

Ripping is changing the width of a workpiece

by cutting along its length. The workpiece is

fed into the blade, which rotates in a fixed

position, parallel to the fence and a set distance from the fence. A solid fence (no k erfs)

serves as a guide for the workpiece . Pl ace

the fence in the front positi on for narrower

workpieces, or in the rear position for wider

ones.

In-Rip and Out-Rip Posi tions

In-rip and out-rip refer to blade position.

In-rip: the blade is toward the column, and

the motor is toward the table front. In-rip is

recommended because this position allo ws

better visibility of the workpiece and your

hands. Use in-rip when you set the blade 1/ 2

to 16" from the fence.

Outfeed

Side

Front Fence

Position

-OR-

Rear Fence

Position

Out-rip: the blade is toward the table front,

and the motor is toward the column. Use

out-rip only when you set the blade 16" or

more from the fence.

Infeed and Outfeed Directions

Infeed and outfeed refer to sides of the

blade.

Infeed: the side of the blade where the

guard hold down is. Always start a rip cut

at the infeed side and push the w orkpiece

through to the outfeed side.

Outfeed: the side of the b lade where the

pawls and riving knife are. Never start a rip

cut at the outfeed side. This is wr ong way

feed. Never put ha nds on the outfee d side

of the blade when ripping because they

can be pulled back into the spinning

blade.

In-Rip Position

Out-Rip Position

Infeed

Side

Infeed

Side

Outfeed Side

Pawls/Riving

Knife

32

Page 33

Workpiece Positioning

Always set up so that the wider part of

the workpiece is between the blade and

fence. This gives you greater clearance for

push sticks, and allows better stability for

feeding the workpiece.

Ripping

8"

Push Sticks and Push Blocks

Use push sticks and push blocks instead of

the hands to push the workpiece through to

complete cuts. They help keep hands away

from the blade . A push block is used with an

auxiliary fence. (see Cutting Aides).

Use a push block and auxiliary fence

when the blade is set 1/2 to 2" from the

fence.

Use a push stic k when the b lade is set 2" or

more from the fence.

Do not set the blade closer than 1/2 " to

the fence. The radial saw is the wrong

tool for such a narro w cut. A band saw

would be more appropriate for this type

of cut.

Example: To rip 2" off a 10" wide board, set

blade in in-rip position 8" from rear fence.

Ripping Safety

The hazards associated with ripping include:

outfeed zone haza rd, kickback, and wrong

way feed. This section explai ns these hazards and tells how to avoid them or reduce

the risk of their happening. Read this sec-

tion before making any type of rip cut.

Follow these steps every time you make a

rip cut.

33

Page 34

Ripping

Outfeed Zone Hazard

DANGER

Rotational force of blade can pull

hands and fingers back into blade.

Touching, holding, or pulling on outfeed side of workpiece while blade is

still spinning will result in fingers,

hand or arm being cut off. To reduce

risk of outfeed hazard:

[Set pawls and riving knife; they act as par-

tial barrier to outfeed side.

[Start and finish cut from infeed side.

[Keep both hands on infeed side.

[Keep hands away from outfeed side.

[Push workpiece through to complete cut.

Do not reach around to pull it.

[If blade jams, turn saw off, remove yellow

key, then free blade.

Kickback

Kickback is the un controlled propell ing of the

workpiece back tow ard the user.

W ARNING

Kickback can happen when blade is

pinched or bound by workpiece.

Pinching or binding can happen when:

• pawls and riving knife are not used or not

set correctly

• riving knife is not aligned with blade

• blade is not parallel to f ence

• workpiece is twisted or warped and rocks

on table top

• pressure is put on outfeed side of workpiece

• workpiece is released before being

pushed past pawls

• user touches or tries to pull workpiece

through outfeed side before blade has

stopped spinning.

34

Page 35

Ripping

To reduce risk of kickback:

[Set pawls and riving knife according to rip-

ping set-up procedure. Cor rectly set rivin g

knife is more likely to prevent workpiece

from binding or pinching blade; correctly

set pawls are more likely to grab into workpiece to stop or slow kickback if one happens.

[Check that riving knife is in line with blade

(see Alignment: Riving Knife to Blade).

[Cut only straight workpieces so surface

will lie flat on table and edge will sta y tight

against fence. If you must cut an irregular

workpiece, attach a straigh t edge (see

Cutting Aides).

Wrong Way Feed

Wrong way feed is ripping by feeding the

workpiece into the outfeed side of the blade.

WARNING

Rotational force of bla de will pull workpiece through violently if workpiece is

fed in same direction as blade rotates

(wrong way feed). Hands and fingers

could be pulled along with workpiece

into spinning blade before you can let

go or pull back. Fingers, hand or arm

could be cut off. Propelled workpiece

could hit bystander.

To eliminate risk of wrong way feed:

[Push workpiece through from infeed to

outfeed side until it is completely past

pawls.

[Use featherboard (see Cutting Aides).

[Keep hands away from outfeed side.

[If blade jams, turn saw off, remove yellow

key, then free blade.

[When cutting composition materials, or

other materials with one smooth and one

rough side, put rough si de up so pa wls will

be more likely to grab.

[Feed workpiece against blade rotation.

[Set pawls and riving knife; they act as par-

tial barrier to outfeed side.

35

Page 36

Hold Down Function

The hold down must be set correctly during

ripping to act as barrier against the infeed

side of the blade, to help keep the workpiece

flat on the table, and to deflect workpiece

chips. It must be lowered to just clear the

workpiece.

The hold down must be ree12(cl(.)]TJ0 -)12(e )-11(t)8(a)1(b)23(( )1m)-7(t)8(a)10(t)- TD0.002 Tw[(chi)7(at)8( )-11(di w)1*-0. dur help kpiece ork4(e)23(,)-3( and to def.-14(kI)1(rr )-11(w)s1 Tw[.008 Tw[(fl)g)wpiece rw[(fl)gpi ece

36

Page 37

Ripping

Ripping Set-up Procedure

Follow these steps before ripping.

These steps must be repeated each time

a different thic kness w orkpi ece is rip ped.

A kerf must be made for each different

width cut. Also see the special notes for

bevel set-up that follow this section.

1. Prepare table:

- insert solid (no kerfs) fence (Note:

Use auxiliary fence when blade is set

1/2 to 2" from fence

Aides)

- tighten table clamps.

2. Prepare blade:

- lock radial arm at 0° miter - loc k bl ade

in in-rip position*

- lower blade to just clear table

- lock blade carriage desired distance

from fence. Note:

part of workpiece will be between

blade and fence.

*

use out-rip position for rips 16" or wider

(See Cutting

Make sure wider

W ARNING

If workpiece is pushed along fence

with kerfs, workpiece could get caught

on kerf, pinch blade and cause kickback. Do not use crosscutting fence

for ripping.

In-Rip Set-Up

3. Make ker f:

a) turn saw on

b) lower blade about 1/16" into table

c) turn saw off and remove yellow key.

4. Place workpiece parallel to and up

against blade.** Note:

Workpiece will be

between blade and table front.

5. Lower hold down** to workpiece , then

raise slightly so it just clears top surface of

workpiece. Lock in place.

6. Lower riving knife to table. Lower pawls

to workpiece surface.** Move w orkpiece

toward outfeed side until one set of pawls

rests level on workpiece surface . Lock in

place.

** bevel set-up: see special notes, next page

Setting Guard For Rip Cut

37

Page 38

Ripping

7. Remove workpiece from table.

8. Ready push stick or push block.

9. Set up table ex tension(s) and support

their outer ends. Do not use another per-

son to support workpieces because this

can cause kickbac k and it exposes helper

to potential hazards at outfeed side.

Special Notes for Bevel Set-Up

CAUTION

Bevel ripping creates unique problems

of visibility and feeding. Before cutting, check the set-up using both in-rip

and out-rip. Use the position that gives

the best combination of workpiece visibility and push stick clearanc e.

W ARNING

Bevel the edge that is not against the

fence.

1. When setting bevel angle, raise radial

arm to allow sufficient clearance for blade

and guard to not jam in table.

2. When blade is beveled manually raise

clear plastic guard before lowering blade to

table or kerf, otherwise it may jam in the

table.

3. To set hold down, place workpiece

directly under guard nose, rather than parallel to blade.

4. To set pawls, place workpiece directly

under set of pawls closer t o tab le . This se t of

pawls will keep contact with workpiece surface.

Making Rip Cu ts

Follow these steps to make in-rip cuts. For

out-rip cuts, reverse hand functions; that is,

put right hand on table and use left hand to

support and push workpiece.

In-Ripping

1. Follow ripping set-up procedure.

38

Page 39

2. Insert yellow key and turn saw on.

3. Stand at infeed side and out of line of

workpiece, in case of kic kback. Start and

finish cut from infeed side.

4. Put workpiece on table, in front of hold

down, and tight against fence. To hold workpiece in position, put left hand on tabl e, at

least 8" in front of hold down, and lightly

press fingers against workpiece. Support

workpiece with table extension or right hand.

CAUTION

For large workpieces use a feather

board in place of your hand on the

table. It gives better support. (See cutting aides)

5. With right hand, push workpiece under

hold down and into blade. Keep left hand

fixed on table, applying slight pressure to

keep workpiece against fenc e.

Out-Ripping

Ripping

Keep Hand

Back 8"

6. Use right hand to continue to apply feed

pressure to part of workpiece close to f ence .

Keep hand at least 8" in front of hold down.

Note:

Most workpieces will automatically

raise clear plastic guard as the y pass from

infeed to outfeed side. Unusually tall and

narrow workpieces may n ot raise clear

guard. When this happens, push guard tab

to raise guard, then release tab when guard

rests on top of workpiece surface.

CAUTION

Pushing guard tab means using only

one hand to control workpiece. While

pushing tab, use extra care to guide

workpiece and to keep hand at least 8"

in front of hold down.

Release tab as soon as clear guard

rests on workpiece.

7. When end of workpiece gets to tab le, us e

push stick or block, instead of hand, on part

of workpiece between blade and fence to

push until workpiece is completely past

pawls.

Guard

Tab

Keep Hand

Back 8"

In-Ripping

8. Turn saw off and wait for blade to stop

spinning before touching workpiece.

39

Page 40

Ripping

Dado Blades, Molding Heads

See Accessories for information on safety,

installation and use of dado blades and

molding heads.

Edging

Edging is the use of a dado blade or molding

head in the horizontal position. It is an

advanced technique that requires a molding

head guard and a special fence. See Accessories for information on safety, installation

and use of dado blades and molding heads

for edging. See Cutt ing Aid es f or information

on making the special fence.

Ripping Hints

1. To extend life of table top, make auxiliary

table cov er out of 1/4" plyw ood or fiberboard.

Clamp or nail to original t able top, s ection by

section. If you use nails, nail in the four comers to make sure blade will not contact nails.

2. Keep table clean of chips and sawdust.

3. Use sharp blades.

4. Use the right blade for each jo b.

5. For workpiece with one smooth and one

rough surface, such as paneling or finished

fiberboard, cut with rough surface up so

pawls will be more likely to grab in case of

kickback.

6. To keep cut line accurate, periodically

check blade alignment.

7. If you must cut an irregular workpiece,

attach a straight edge (see Cutting Aides).

40

Page 41

Cutting Aides

Before cutting any wood on your saw, study

all of the Crosscutting and Ripping Instructions found on pages 45 through 57. As y ou

learn new radial arm saw woodworking techniques, you’ll see that many types of cuts

need different support and feeding devices,

known as jigs or fixtures. They can help you

make cuts more accurately. By helping to

steady the workpiece and keep you away

from the blade, they can help you safely use

your saw for certain cuts. Many people custom build their o wn jigs and fi xtures. Ji gs and

fixtures are often designed for a particular

cut. You can use your radial saw to easi ly

make many jigs and fixtures. To get you

started, we’ve i ncluded instructi ons f or some

simple ones. After you have made a few

practice cuts, make up these jigs before

starting any projects. Make the push stick

first.

Push Sticks

Make the push stick using a piece of 1 x 2.

(see drawing top right for dimensions and

shapes)

Push Block

There are any number of ways to properly

cut your work pieces to make a push block.

The following steps describe one way you

can proceed.

Making the base:

• Start with a piece of 3/8" plywood at least

5-5/8" wide or wider and 12" long or longer.

• Make two ripcuts. Perform the first ripcut

along the long side of the 3/8" plywood to

create a 3/8" wide strip. Ne xt ripcut the 3/8"

plywood to a width of 5-1/8".

• Crosscut the 3/8" plywood to 12" long.

• Crosscut a 2-1/2" piece off of the 3/8"

wide by 3/8" thick strip and sav e this short

piece for later.

• The next cuts will create the 3/ 8" by 9-1/2"

notch in the base. Mark the long edge of

the board 2-1/2" from one end. Make a

crosscut into the edge, stopping about 3/4"

into the board. Set the saw to the in-rip

position and rip the width to 4-3/4" along

the same edge as the stopped crosscut.

Stop the ripcut where the two cuts intersect. Turn off the saw and remove the base

piece. The base should now measure as

shown.

Push Stick

Slightly Less Than Thickness

Of Workpiece Up To 3/8"

90° Notch

Material for Push Block

At Least 12"

3/8" Thick Plywood

Base

At Least 12"

3/4" Thick Plywood

Handle

Cutting Out the Base

2-1/2" (save)

4th Cut 1st Cut

2nd Cut

12"

Creating the Notch

1st Cut

2nd Cut

2-1/2"

Finished Base

12"

At Least

5-1/8"

2-1/2"

3/8"

4-3/4"

3rd Cut

At Least

5-5/8"

At Least

5"

3/8"

5-1/8"

4-3/4"

These Edges

Must Be

Parallel

41

Page 42

Making the Handle:

• Miter crosscut a piece of 3/4" thick plywood to the shape and size shown. The

mitered corners can be any size that look s

like the drawing (about 1-1/2" by 1-1/2").

Putting it together:

• Using good quality wood working glue,

glue the 2-1/2" strip sav ed earlier to the

base as shown. Important: Do not use

nails or screws. This is to prevent dulling

of the saw blade in the event you cut in to

the push block.

• Position the handle at the edge of the plywood base as shown. Fasten them

together with glue and wood screws.

Important:

Make sure the scre w heads do

not stick out from the bottom of the base .

42

Page 43

Clamp the featherboar d t o th e front tab l e , so

that the angled edge of the featherboard is

against the workpiece on the infeed side of

the blade. Do not clamp the featherboard

against the cut off part (out-feed side) of

the workpiece. If clamped to the outfeed

side, the featherboard can squeeze the

kerf closed, put binding pressure on the

blade, and cause kickback.

Straight Edge for Irregular Workpiece

WARNING

If you try to rip an irregular workpiece,

it could bind blade and cause kickback.

Cutting Aides

If the workpiece you want to rip does not

have a str aight edge, attach a strai ght-edged

board to the workpiece:

a) place irregular side of workpiece against

fence

b) put straight-edged board on top of work-

piece and against fence

c) tack straight edged board to work piece.

Note:

Straight-edged board must not e xte nd

beyond leading end of workpiece and should

cover workpiece width onl y enough to pass

between blade and fence.

Note:

Use fence at le as t as high as c ombined heights of workpiece and straightedged board.

43

Page 44

Maintenance

Replacing Pawls

Make sure the teeth of the pawls are always

sharp. If they become dull the pa wls must be

replaced:

1. Use 7/16" wrench to remove hex nut.

Remove old pawls.

2. Install new pawls. Place spacers exactly

as shown.

3. Re-install hex nut.

4. Check that pawls work freely.

Lubricating Blade Guard Assembly

If guard becomes difficult to raise:

1. Clean sawdust from the slot and slider.

2. Regrease with a small amount of light

grease applied to the slot and slider. Also

add a thin coat of grease between the Trigger and the Pull Link.

Adjusting the Trigger

If the trigger becomes loose side-to-side,

adjust the setscrews at the top of the yoke

handle. Use a 1/8" hex wrench to ti ghte n setscrews tight. Then back off one setscrew

until the trigger moves freely.

Grease

Pull Link

Here

Slider

Slot

Adjust

Screws

44

Page 45

PARTS LIST CRAFTSMAN 10" RADIAL SAW GUARD KIT

Always order by Part Number - Not by Key Number

Key

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

—

* Standard Hardware Item - May be purchased locally.

Part No. Description

820985

805548-10

STD610805

SP6311

803425

821354-1

STD601103

821410

818169

820573

824980

37384

818199

826284

SP5984

Guard Accessory

Washer 3/16 x 1/16

* Screw Plastite #8 x 1/2

Form Instructions

Screw, Locking Set 1/4-20 x 3/8

Trigger

* Screw Pan Hd Ty “T” 10-32 x 1/2

Handle, Hoke Asm

Table Rear 40"

Table Spacer 40"

Table Front 40"

Nut, Tee

Table Support

Clamp Assembly

Owners Manual (Not Shown)

No. 509347

FIGURE 1

14

13

1

2

3

5

6

7

9

4

10

8

11

Repair Parts

45

12

Page 46

46

Page 47

PARTS LIST CRAFTSMAN 10" RADIAL SAW GUARD KIT

No. 509347

Always order by Part Number - Not by Key Number

FIGURE 2

Key

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Part No. Description

821217

821313

STD551025

815865

STD601105

802392-47

808447-6

827919

STD551031

820521

820515

STD541425

815815

820517

STD512510

820512

824159

Screw, Guard Clamp

Link, Pull

* Washer, 17/64 x 5/8 x 1/16

Screw, Hex Washer Hd Type

"TT" 1/4 - 20 x 1/2

* Screw, Pan Hd Type "TT" 10-32 x 5/16

Spacer #10 x .125

Washer, Spring

Knob, 5/16-18

* Washer 21/64 x 5/8 x 1/16

Spacer

Knife, Riving

* Nut, Lock 1/4-20

Pawl, AKB

Bushing

* Screw, Pan Hd. 1/4-20 x 1

Holder, AKB

Screw, Flat Hd Type “TT” 1/4 - 20 x 9/16

Key

No.

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

* Standard Hardware Item - May Be Purchased Locally

Part No. Description

820519

STD551225

820530

808822-1

820632-3

STD533107

809019-4

820532

821310

821311

821312

821314

828139

60413

821449

824158

825756

STD551131

Nut, Slotted 1/4 - 20

* Lockwasher 1/4

Support, Knife

Nut, Push 1/4

* Ring, Retaining

* Bolt, R.H. Short Neck 5/16 - 18 x 5/8

Bolt, Rd Hd Short Neck 5/16 - 18 x 1-3/4

Bolt 1/4-20 x 1/2

Guard, Lower

Link

Guard

Hold Down

Elbow, Dust

Nut, Push 5/16

Nut, Square 5/16 - 18 Double Lead

Strap-Retainer

Screw Guard Index

* Lockwasher

Repair Parts

47

Page 48

RZQHU·V

10-INCH RADIAL SAW

PDQXDO

MODEL NO.

509347

GUARD KIT

For Customer Service Questions

or Replacement Parts Call

1-800-325-1184

NOTE:

1. This manual is intended to be used along with your

original saw manual. If you no longer have your saw’s

owners manual, call customer service at 1-800-325-1184.

Have your saw’s model number when you call.

2. If you require this manual in Spanish or French, call

1-800-511-2628.

Si usted requiere que éste manual usuario en español o

francés, llame 1-800-511-2628. Pedir formulario

SP5984S-2.

Si vous nécesstent ce mode d’emploi en espagnol ou

français, télé phonez au 1-800-511-2 628. Demander pour

forme SP5984F-2

© 2000 Emerson Electric Co.

Part No. SP5984 Form No. SP5984-2 Printed in U.S.A. 10/00

.

Loading...

Loading...