Craftsman 486250131 Owner’s Manual

Operator's IVlanuai

CRAFTSMAH°

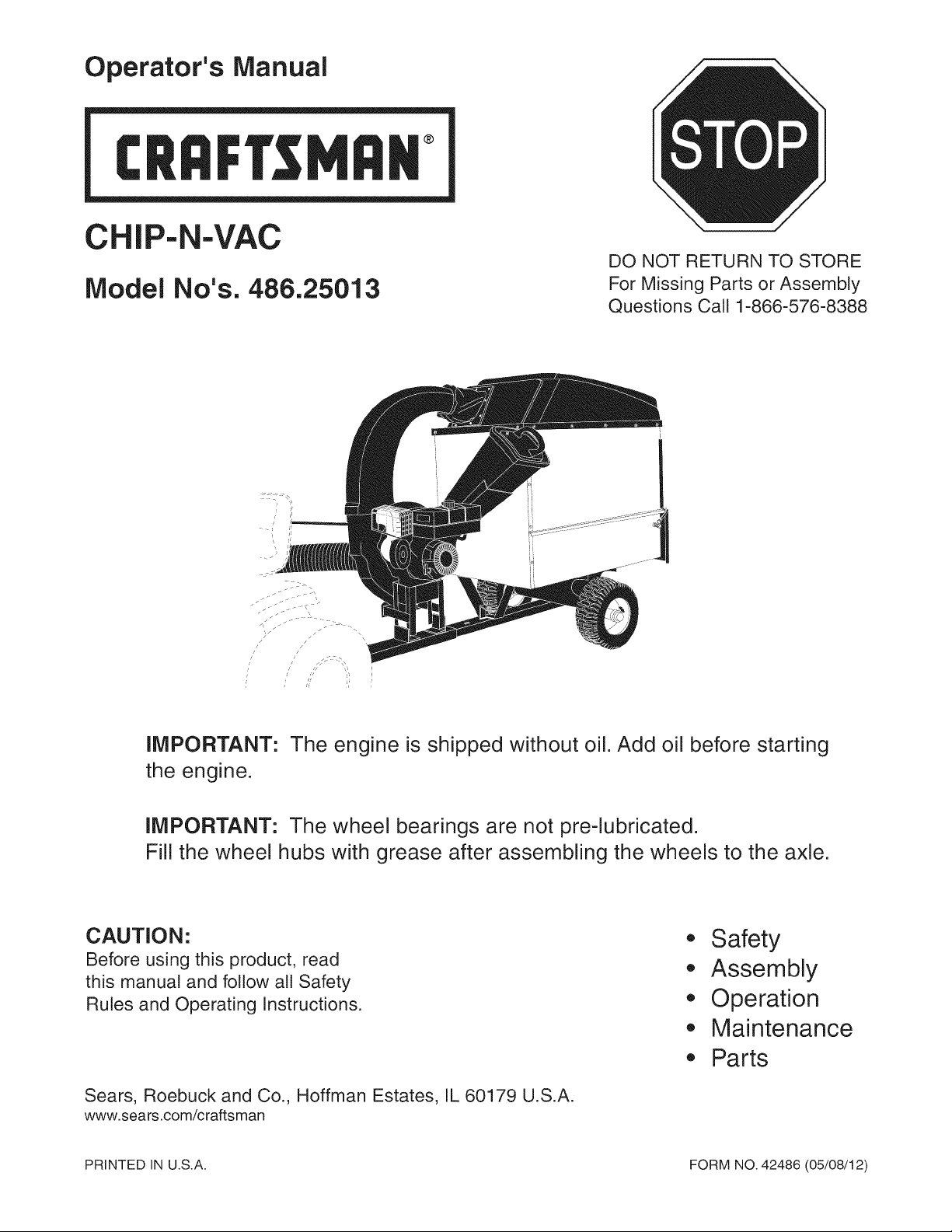

CHIP-N-VAC

Model No's. 486.25013

DO NOT RETURN TO STORE

For Missing Parts or Assembly

Questions Call 1-866-576-8388

IMPORTANT: The engine is shipped without oil. Add oil before starting

the engine.

IMPORTANT: The wheel bearings are not pre-lubricated.

Fill the wheel hubs with grease after assembling the wheels to the axle.

CAUTION:

Before using this product, read

this manual and follow all Safety

Rules and Operating Instructions.

,, Safety

,, Assembly

,, Operation

,, Maintenance

,, Parts

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www.sears.com/craftsman

PRINTED IN U.S.A. FORM NO. 42486 (05/08/12)

WARRANTY ................................................................ 2

SAFETY RULES .......................................................... 3

FULL SIZE HARDWARE CHART ................................ 6

CARTON CONTENTS ................................................. 7

ASSEMBLY .................................................................. 8

OPERATION .............................................................. 16

MAINTENANCE ........................................................ 18

CRAFTSMAN FULL WARRANTY

FOR ONE YEAR from the date of purchase, this product is warranted against defects in material or workmanship. A

defective product will receive free in-home repair or replacement if repair is unavailable.

WARRANTY SERVICE

For warranty coverage details to obtain free repair or replacement, call 1-800-659-5917 or visit the web site: www.

craftsman.corn

All of the above warranty coverage is void if this riding equipment is ever used while providing commercial services or if

rented to another person.

SERVICE AND ADJUSTMENTS ............................... 19

STORAGE ................................................................. 19

TROUBLESHOOTING ............................................... 20

REPAIR PARTS ILLUSTRATIONS ................. 23,24,26

REPAIR PARTS LISTS .................................... 23,25,26

SLOPE GUIDE .......................................................... 27

PARTS ORDERING/SERVICE .................... Rear Cover

This warranty covers ONLY defects in material and workmanship. Warranty coverage does NOT include:

* Expendable parts that can wear out from normal use within the warranty period, including but not limited to spark

plugs, air cleaners, belts, and oil filters.

* Standard maintenance servicing, oil changes, or tune-ups.

* Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or glass.

* Tire or wheel replacement or repair resulting from normal wear, accident, or improper operation or maintenance.

* Repairs necessary because of operator abuse, including but not limited to damage caused impacting objects that

bend the frame, axle assembly or crankshaft, or over-speeding the engine.

* Repairs necessary because of operator negligence, including but not limited to, electrical and mechanical damage

caused by improper storage, failure to use the proper grade and amount of engine oil, failure to keep the product clear of

flammable debris, or failure to maintain the equipment according to the instructions contained in the operator's manual.

* Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or oxidized (stale). In general,

fuel should be used within 30 days of its purchase date.

* Normal deterioration and wear of the exterior finishes, or product label replacement.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

The model and serial numbers will be found on a decal

attached to the engine base.

You should record both the serial number and the

date of purchase and keep in a safe place for future

reference.

MODEL NUMBER:

SERIAL NUMBER:

DATE OF PURCHASE:

486.25013

Any power equipment can cause injury if operated improperly or if the user does not understand how to operate the equipment. Exercise

caution at all times, when using power equipment.

• Read and follow all instructions in this manual before attempting

to assemble or operate this equipment. Failure to comply

with these instructions may result in personal injury. Keep this

manual in a safe place for future reference and for ordering

replacement parts.

Read this operating and service instruction manual carefully.

Be thoroughly familiar with the controls and proper use of this

power vacuum.

Read the vehicle owners manual and vehicle safe operation

rules before using this equipment.

Never allow children under 16 to operate this Chipper Vac.

Children 16 years and older should only operate under close

parental supervision.

Do not allow anyone to operate this equipment without proper

instructions.

Do not allow passengers to ride on this equipment or on the

towing vehicle.

Keep the area of operation clear of all persons, particularly

small children. Also keep area clear of pets.

Check fuel before starting engine. Do not fill fuel tank indoors,

or when engine is running, or while engine is hot. Wipe off any

spilled fuel before starting engine.

Engine and muffler get hot. Do not touch! To avoid fire hazard,

keep clean of debris and other accumulations.

Never store Chipper Vac with fuel in tank. Allow engine to coot

before storing in any enclosure.

Do not change engine governor settings.

Do not operate engine if air cleaner or cover is removed,

except for adjustment. Removal of these parts could create a

fire hazard.

Before cleaning, repairing or inspecting, make certain all moving

parts come to a complete stop. Disconnect spark plug wire and

keep wire away from plug to prevent accidental starting. Keep

throttle control lever in stop position.

If the Chipper Vac should become blocked with debris at any

point, shut engine off and wait until the impeller comes to a

complete stop before attempting to remove the obstruction.

Disconnect spark plug wire to prevent accidental starting.

If the cutting mechanism strikes a foreign object, or if your

ChipperVac should start to vibrate abnormally, stop the engine

immediately, disconnect the spark plug wire and move the wire

away from the spark plug. Allow the machine to stop and take

the following steps.

a. Inspect for damage.

b. Repair or replace any damaged parts.

c. Check for loose parts and tighten to assure

continued safe operation.

Check all bolts for tightness at frequent intervals to help insure

safe operation.

Check vinyl hard top boot frequently for wear. Replace if worn

or damaged.

Never operate Chipper Vac unless deck adapter, hose, hose

adapter (nozzle), discharge chute (elbow), chipper chute and

top cover are properly attached in their place.

Do not remove top cover or attempt to empty contents of cart

while engine is running.

Never attempt to change hose adapter (nozzle) or to install

remote hose attachment when engine is running.

Keep all shields and guards (e.g. chipper chute, discharge

chute (elbow) and hose adapter (nozzle) in place and securely

attached.

Keep hands, feet, face, long hair and clothing out of inlet and

discharge area. There are ROTATING BLADES inside these

openings.

Always wear safety glasses or other suitable eye protection

when operating or maintaining this equipment.

Wear protective gloves when feeding material into the chipper

chute. Avoid loose fitting clothing.

Keep face and body clear of the chipper chute to avoid accidental

bounce back of any material.

When feeding material into this equipment, be extremely careful

that pieces of metal, rocks, bottles, cans or other foreign objects

are not included. Personal injury or damage to the machine

could result.

Do not stand behind cart in exhaust discharge area while

engine is running.

Do not operate this equipment while intoxicated or while taking

drugs or medication that impairs the senses and reactions.

When using this equipment, start with the vehicle transmission

in first (low) gear and then gradually increase speed only as

conditions permit.

Operate this equipment at reduced speed on rough terrain,

along creeks and ditches and on slopes to prevent tipping or

loss of control. Do not drive too close to a creek or ditch.

Vehicle braking and stability are affected by the addition of

this equipment. Do not fill the Chipper Vac to its full capacity

without checking the capability of the towing vehicle to safely

pull and stop with the Chipper Vac attached.

Before operating on any grade (hilt) refer to the safety rules

in the vehicle owner's manual concerning safe operation on

slopes. Also refer to the SLOPE GUIDE on page 27 of this

owner's manual. Do not operate on slopes in excess of 10

degrees. STAY OFF STEEP SLOPES.

Follow the maintenance instructions outlined in this manual.

Look for this symbol to point out important safety precautions. It means-- Attention!! Become alert!! Your safety

is involved.

DANGER: This Chipper Vac was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This unit is capable of amputating fingers and hands and throwing objects.

Failure to observe the following safety instructions could result in serious injury or death.

TO AVOID SERIOUS iNJURY

• Read Owner's Manual and all safety labels on machine before starting and using machine.

• Do Not remove top cover or attempt to empty contents of cart while engine is running.

• Do Not stand behind cart in exhaust discharge area while engine is running.

• Keep hands, feet, face, long hair and clothing out of chipper inlet, vac inlet, and discharge

area. There are ROTATING BLADES inside these openings.

• Wear approved safety glasses and gloves. Avoid loose fitting clothes.

• Keep the area of operation clear of all persons, particularly small children and pets.

• Keep all shields and guards (e.g. upper chipper chute extension, discharge chute, nozzle

assembly) in place and securely attached.

• Check discharge boot frequently for wear. Replace if worn or damaged.

• if unit becomes clogged or jammed, shut off engine right away. Do Not attempt to clear

clog or jam with engine running.

• Muffler and engine get hot and can cause burns. Do Not Touch. To avoid a fire hazard,

keep leaves, grass and other combustible debris off hot muffler and engine.

• Do Not attempt to remove or attach vac nozzle or optional Hose Kit with engine running.

• Do Not operate unit unless nozzle or optional Hose Kit is secured in place.

• Do Not fill gas tank while engine is running. Allow engine to cool at least 2 minutes

before refueling.

ROTATING CUTTING BLADES.

KEEP HANDS AND FEET OUT

OF OPENINGS WHILE MACHINE

iS RUNNING.

WA I

This unit is equipped with an internal combustion engine and should not be used on or near unimproved forest-covered, or

grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable local or state

laws (if any). If a spark attester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other

states may have similar laws. Federal laws apply on federal lands. A spark attester muffler is available at your nearest

engine authorized service center.

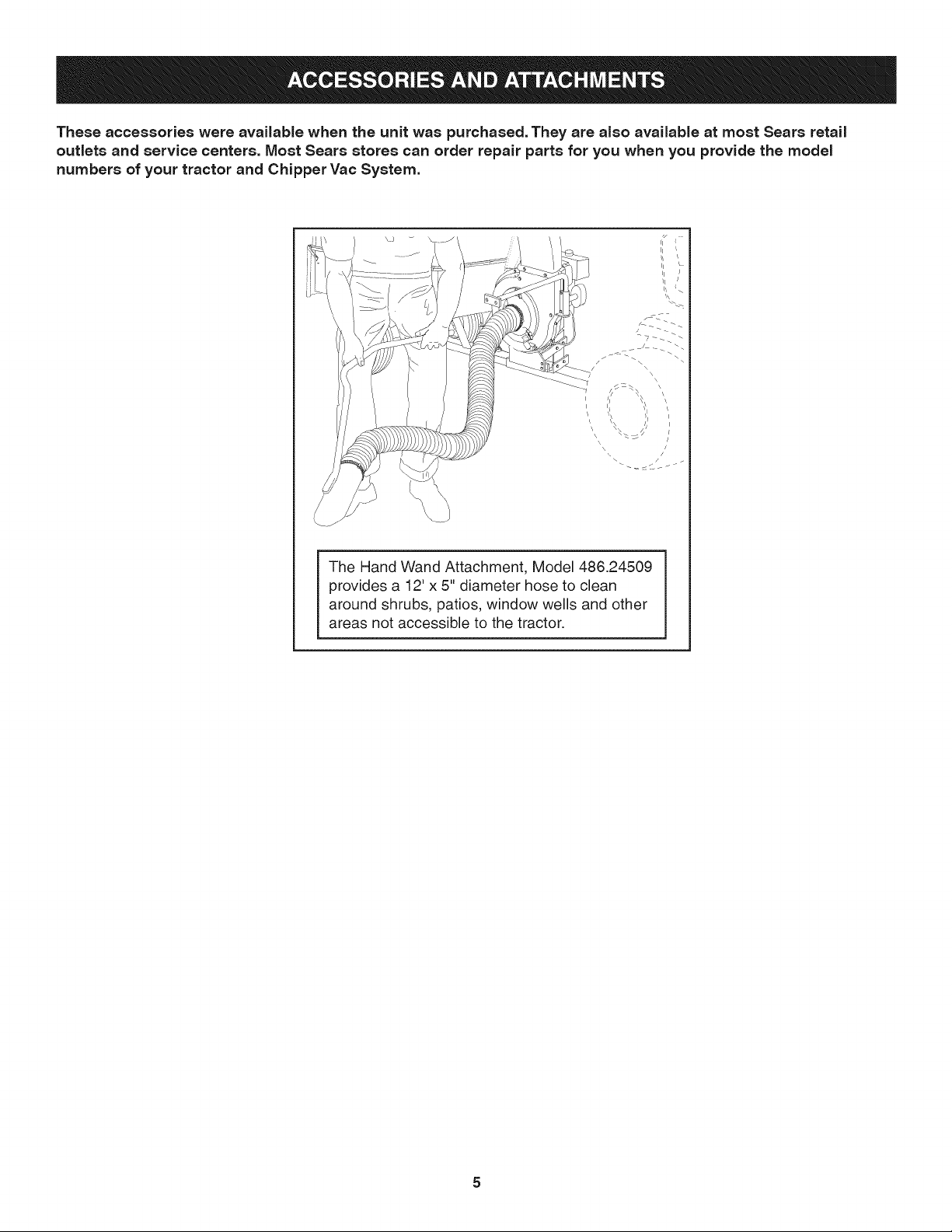

These accessories were available when the unit was purchased. They are also available at most Sears retail

outlets and service centers. Most Sears stores can order repair parts for you when you provide the model

numbers of your tractor and Chipper Vac System.

\

\

/

\

\

The Hand Wand Attachment, Model 486.24509

provides a 12' x 5" diameter hose to clean

around shrubs, patios, window wells and other

areas not accessible to the tractor.

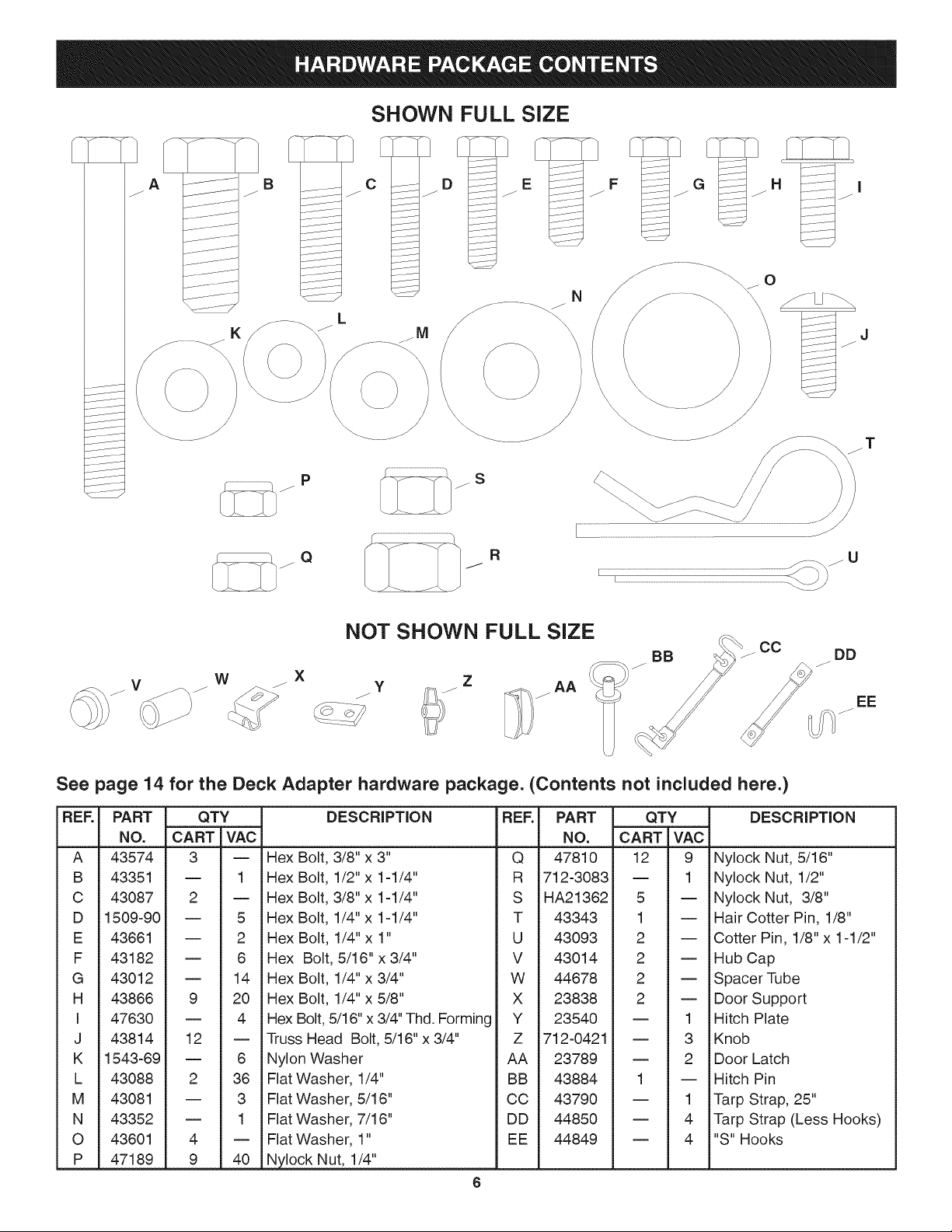

SHOWN FULL SIZE

A -J B

J J J

j ........

K

W J X y Z AA

C D E I---:--:--_ F G H i

..... J

p S

Q R

NOT SHOWN FULL SIZE

_.._ -.............._

/

N

0

\

\

r..................................................................................................................................................................................................................._=%_j U

CC

J

DD

J

EE

See page 14 for the Deck Adapter hardware package. (Contents not included here.)

RER PART QTY

NO. CART VAC

A 43574 3 --

B 43351 -- 1

C 43087 2 --

D 1509-90 -- 5

E 43661 -- 2

F 43182 -- 6

G 43012 -- 14

H 43866 9 20

I 47630 -- 4

J 43814 12 --

K 1543-69 -- 6

L 43088 2 36

M 43081 -- 3

N 43352 -- 1

O 43601 4 --

P 47189 9 40

Hex Bolt, 3/8" x 3" Q 47810 12 9

Hex Bolt, 1/2"x 1-1/4" R 712-3083 = 1

Hex Bolt, 3/8"x 1-1/4" S HA21362 5 =

Hex Bolt, 1/4" x 1-1/4" T 43343 1 --

Hex Bolt, 1/4" x 1" U 43093 2 --

Hex Bolt, 5/16" x 3/4" V 43014 2 --

Hex Bolt, 1/4" x 3/4" W 44678 2 --

Hex Bolt, 1/4" x 5/8" X 23838 2 --

Hex Bolt, 5/16" x 3/4" Thd. Forming Y 23540 -- 1

Truss Head Bolt, 5/16" x 3/4" Z 712-0421 -- 3

Nylon Washer AA 23789 --

Flat Washer, 1/4" BB 43884 1

Flat Washer, 5/16" CC 43790 --

Flat Washer, 7/16" DD 44850 --

Flat Washer, 1" EE 44849 --

NyiockNut,1/4"

DESCRIPTION REF. PART QTY

NO. CART VAC

DESCRiPTiON

Nylock Nut, 5/16"

Nylock Nut, 1/2"

Nylock Nut, 3/8"

Hair Cotter Pin, 1/8"

Cotter Pin, 1/8" x 1-1/2"

Hub Cap

Spacer Tube

Door Support

Hitch Plate

Knob

2 Door Latch

-- Hitch Pin

1 Tarp Strap, 25"

4 Tarp Strap (Less Hooks)

4 "S" Hooks

1

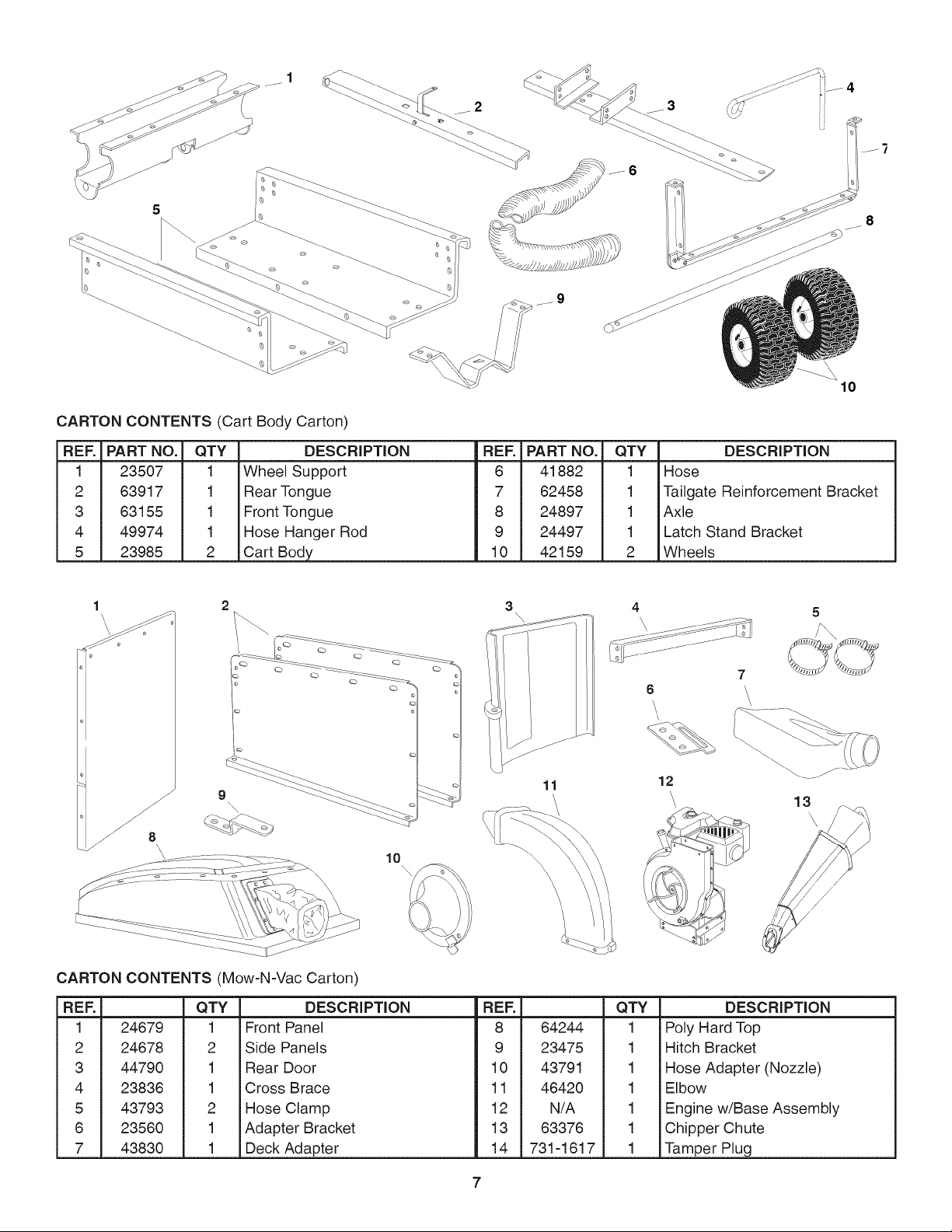

CARTON CONTENTS (Cart Body Carton)

REF. PART NO. QTY DESCRIPTION

1 23507 1 Wheel Support

2 63917 1 Rear Tongue

3 63155 1 Front Tongue

4 49974 1 Hose Hanger Rod

5 23985 2 Cart Body

REF.

6

7

8

9

10

_9

PART NO.

41882

62458

24897

24497

42159

QTY

1

1

1

1

2

10

DESCRIPTION

Hose

Tailgate Reinforcement Bracket

Axle

Latch Stand Bracket

Wheels

1

\

\

CARTON CONTENTS (Mow-N-Vac Carton)

REF.

1 24679 1 Front Panel

2 24678 2 Side Panels

3 44790 1 Rear Door

4 23836 1 Cross Brace

5 43793 2 Hose Clamp

6 23560 1 Adapter Bracket

7 43830 1 Deck Adapter

8

9

10

11

12

13

14

3

11

\

64244

23475

43791

46420

N/A

63376

731-1617

7

6

12

1

Poly Hard Top

1

Hitch Bracket

1

Hose Adapter (Nozzle)

1

Elbow

1

Engine w/Base Assembly

1

Chipper Chute

1

Tamper Plug

\

5

\,

13

\

ThisunitisshippedWITHOUTGASOLINEorOIL.After

assembly,seeseparateenginemanualforproperfuel

andengineoilrecommendations.

TOOLS REQUIRED FOR ASSEMBLY

(1)Screwdriver

(!) Pliers

(2)7/16"Wrenches

(2)1/2"Wrench

(2)9/16"Wrenches

(2)3/4"Wrenches(onlyiffigure23onpage12isused)

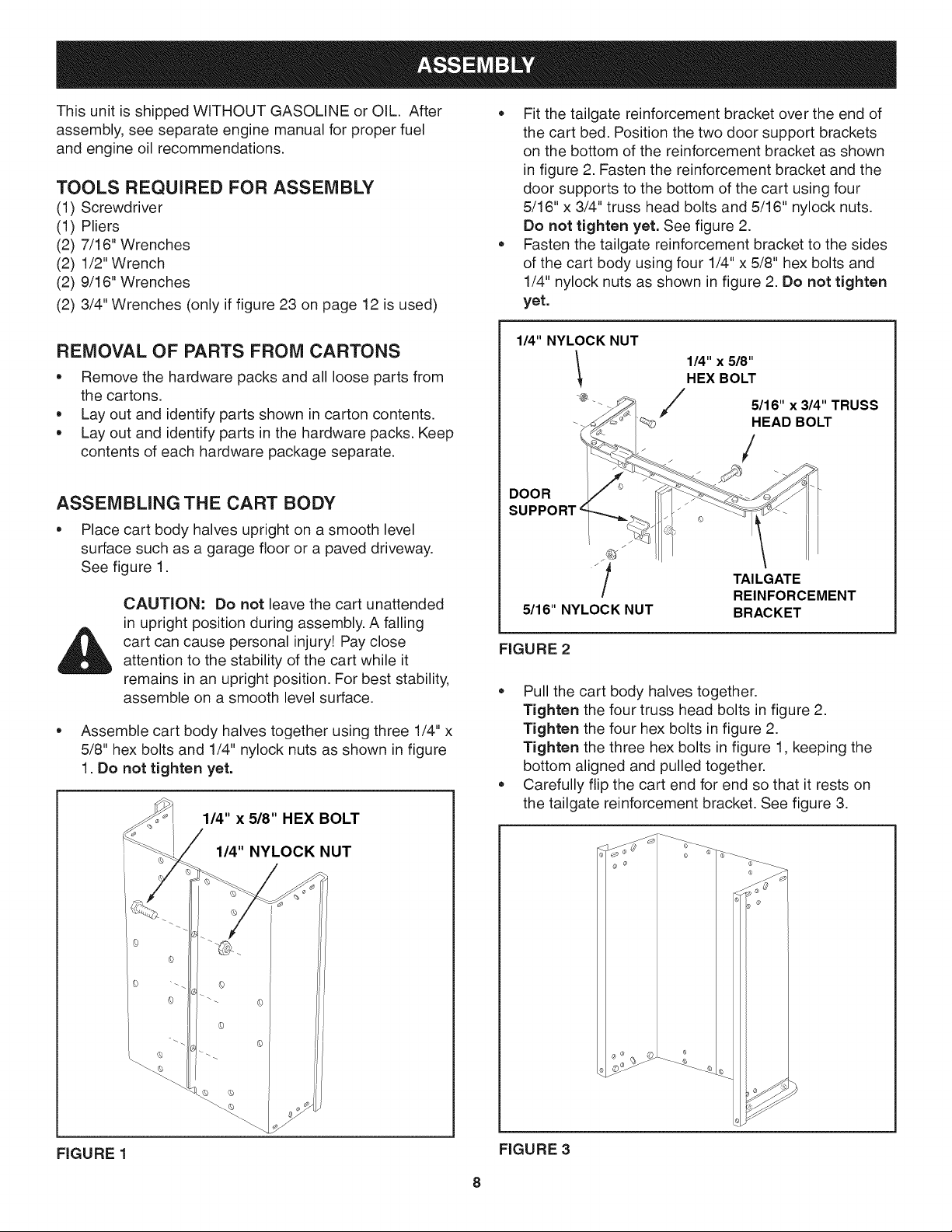

• Fitthetailgatereinforcementbracketovertheendof

thecartbed.Positionthetwodoorsupportbrackets

onthebottomofthereinforcementbracketasshown

infigure2.Fastenthereinforcementbracketandthe

doorsupportstothebottomofthecartusingfour

5/16"x3/4"trussheadboltsand5/16"nylocknuts.

Donottightenyet.Seefigure2.

• Fasten the tailgate reinforcement bracket to the sides

of the cart body using four 1/4" x 5/8" hex bolts and

1/4" nylock nuts as shown in figure 2. Do not tighten

yet.

REMOVAL OF PARTS FROM CARTONS

Remove the hardware packs and all loose parts from

the cartons.

Lay out and identify parts shown in carton contents.

Lay out and identify parts in the hardware packs. Keep

contents of each hardware package separate.

ASSEMBLING THE CART BODY

Place cart body halves upright on a smooth level

surface such as a garage floor or a paved driveway.

See figure 1.

CAUTION: Do not leave the cart unattended

in upright position during assembly. A falling

cart can cause personal injury! Pay close

attention to the stability of the cart while it

remains in an upright position. For best stability,

assemble on a smooth level surface.

Assemble cart body halves together using three 1/4" x

5/8" hex bolts and 1/4" nylock nuts as shown in figure

1. Do not tighten yet.

1/4" x 5/8" HEX BOLT

1/4" NYLOCK NUT

1/4" x 5/8"

HEX BOLT

/ 5116"x 314"TRUSS

p-

-_' HEAD BOLT

/

DOOR

SUPPORT

t TAILGATE

/

5116"NYLOCK NUT BRACKET

FIGURE 2

Pull the cart body halves together.

Tighten the four truss head bolts in figure 2.

Tighten the four hex bolts in figure 2.

Tighten the three hex bolts in figure 1, keeping the

bottom aligned and pulled together.

Carefully flip the cart end for end so that it rests on

the tailgate reinforcement bracket. See figure 3.

REINFORCEMENT

FIGURE 1

1/4" NYLOCK NUT

FIGURE 3

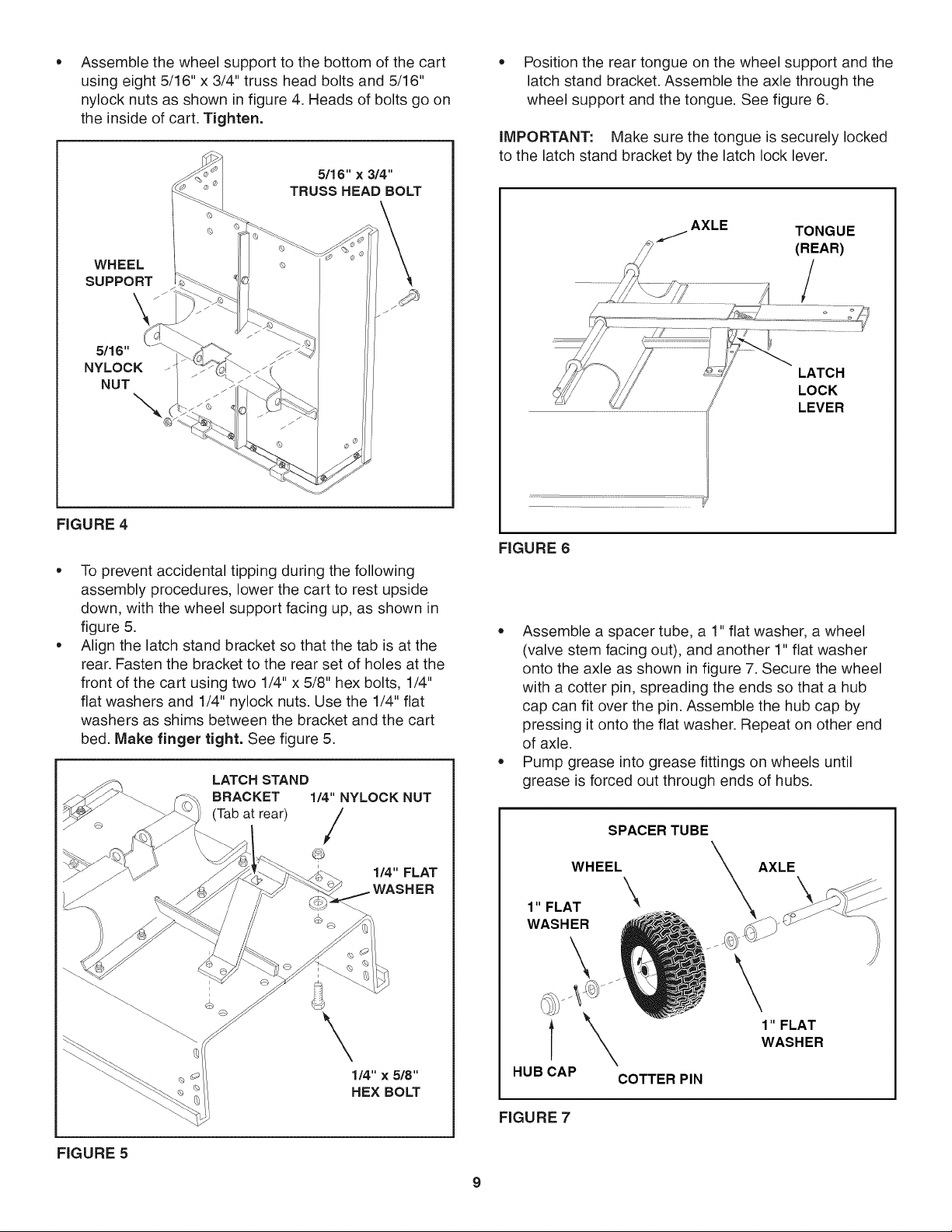

Assemble the wheel support to the bottom of the cart

using eight 5/16" x 3/4" truss head bolts and 5/16"

nylock nuts as shown in figure 4. Heads of bolts go on

the inside of cart. Tighten.

5/16" x 3/4"

TRUSS HEAD BOLT

• Position the rear tongue on the wheel support and the

latch stand bracket. Assemble the axle through the

wheel support and the tongue. See figure 6.

iMPORTANT: Make sure the tongue is securely locked

to the latch stand bracket by the latch lock lever.

WHEEL

SUPPORT

\

5/16"

NYLOCK __

NUT

\

FIGURE 4

To prevent accidental tipping during the following

assembly procedures, lower the cart to rest upside

down, with the wheel support facing up, as shown in

figure 5.

Align the latch stand bracket so that the tab is at the

rear. Fasten the bracket to the rear set of holes at the

front of the cart using two 1/4" x 5/8" hex bolts, 1/4"

flat washers and 1/4" nylock nuts. Use the 1/4" flat

washers as shims between the bracket and the cart

bed. Make finger tight. See figure 5.

LATCH STAND

BRACKET 1/4" NYLOCK NUT

AXLE

FIGURE 6

Assemble a spacer tube, a 1" fiat washer, a wheel

(valve stem facing out), and another 1" flat washer

onto the axle as shown in figure 7. Secure the wheel

with a cotter pin, spreading the ends so that a hub

cap can fit over the pin. Assemble the hub cap by

pressing it onto the flat washer. Repeat on other end

of axle.

Pump grease into grease fittings on wheels until

grease is forced out through ends of hubs.

TONGUE

FIGURE 5

(Tab at rear) /

\

1/4" FLAT

1/4" × 5/8"

HEX BOLT

1" FLAT \

WASHER

T

HUBCAP

FIGURE 7

SPACER TUBE

WHEEL

\

\

1" FLAT

WASHER

COTTER PIN

Loading...

Loading...