Page 1

Operator's Manual

STOP

Model No. 486.248473

FRONT SCOOP TRACTOR ATTACHMENT

DO NOT RETURN TO STORE

For Missing Parts or Assembly

Ouestions Cali 1-866-576-8388

CAUTION:

Before using this product, read

this manual and follow all Safety

Rules and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

WWW. sea rs. com/crafts man

PRINTED IN U.S.A.

• Safety

• Assembly

• Operation

• Maintenance

• Parts

FORM NO, 40967 (02/22/08)

Page 2

TABLE OF CONTENTS

WARRANTY...................................................................2

SAFETY RULES

FULL SIZE HARDWARE CHART......................................4

CARTON CONTENTS

ASSEMBLY....................................................................7

OPERATION

................................................................

...................................................

.....................................................................

17

WARRANTY

ONE YEAR FULL WARRANTY

MAINTENANCE...........................................................18

3

6

TROUBLESHOOTING

REPAIR PARTS ILLUSTRATION

REPAIR PARTS LIST

SLOPE GUIDE.............................................................23

PARTS ORDERING/SERVICE

.................................................

.................................

.................................................

........................

Back Page

19

20

21

When operated and maintained according to the instructions supplied with it, if this Front Scoop Tractor Attachment fails

due to a defect in material or workmanship within one year from the date of purchase, call 1-800-4-MY-HOME® to arrange

for free repair (or replacement if repair proves impossible).

If this product is used tor commercial or rental purposes, this warranty applies for only 90 days from the date of purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., D817WA, Hoffman Estates, IL 60179

The model number and serial number will be found on a

decal attached to the bucket.

You should record both the serial number and the date of

purchase and keep in a safe place for future reference.

MODEL NUMBER: 486.248473

SERIAL NUMBER:

DATE OF PURCHASE:

Page 3

Any power equipment can cause injury if operated improperly or if the user does not understand how to operate the equipment.

Exercise caution at all times when using power equipment.

Read this operator's manual before attempting to

assemble or operate the scoop attachment.

Read the vehicle owner's manual and know how

to operate your vehicle before using the scoop

attachment.

Never carry passengers in the scoop bucket, it has

not been designed to carry passengers.

Never allow children to operate the vehicle or the

scoop attachment.

Do not allow adults to operate the vehicle or scoop

attachment without proper instructions.

Always begin with the transmission in first (low) and

gradually increase speed as conditions permit.

Drive the tractor at reduced speed over rough terrain

and hillsides or near creeks and ditches to prevent

tipping over and loss of control. Do not drive too close

to a creek or ditch.

Look for this symbol to point out important safety precautions. It means -

A

alert!! Your safety is involved.

Never ram the scoop into material at high speed.

Vehicle braking and stability may be affected with

the attachment of this scoop. Do not fill the scoop

to maximum weight capacity without checking the

capability of the vehicle to safely drive and stop with

the scoop attached.

Before operating vehicle on any grade (hill) refer

to the safety rules in the vehicle owner's manual

concerning safe operation on slopes. Refer also to the

slope guide on page 23 of this manual. Stay off steep

slopes!

Follow maintenance and lubrication instructions as

outlined in this manual.

-Attention!! Become

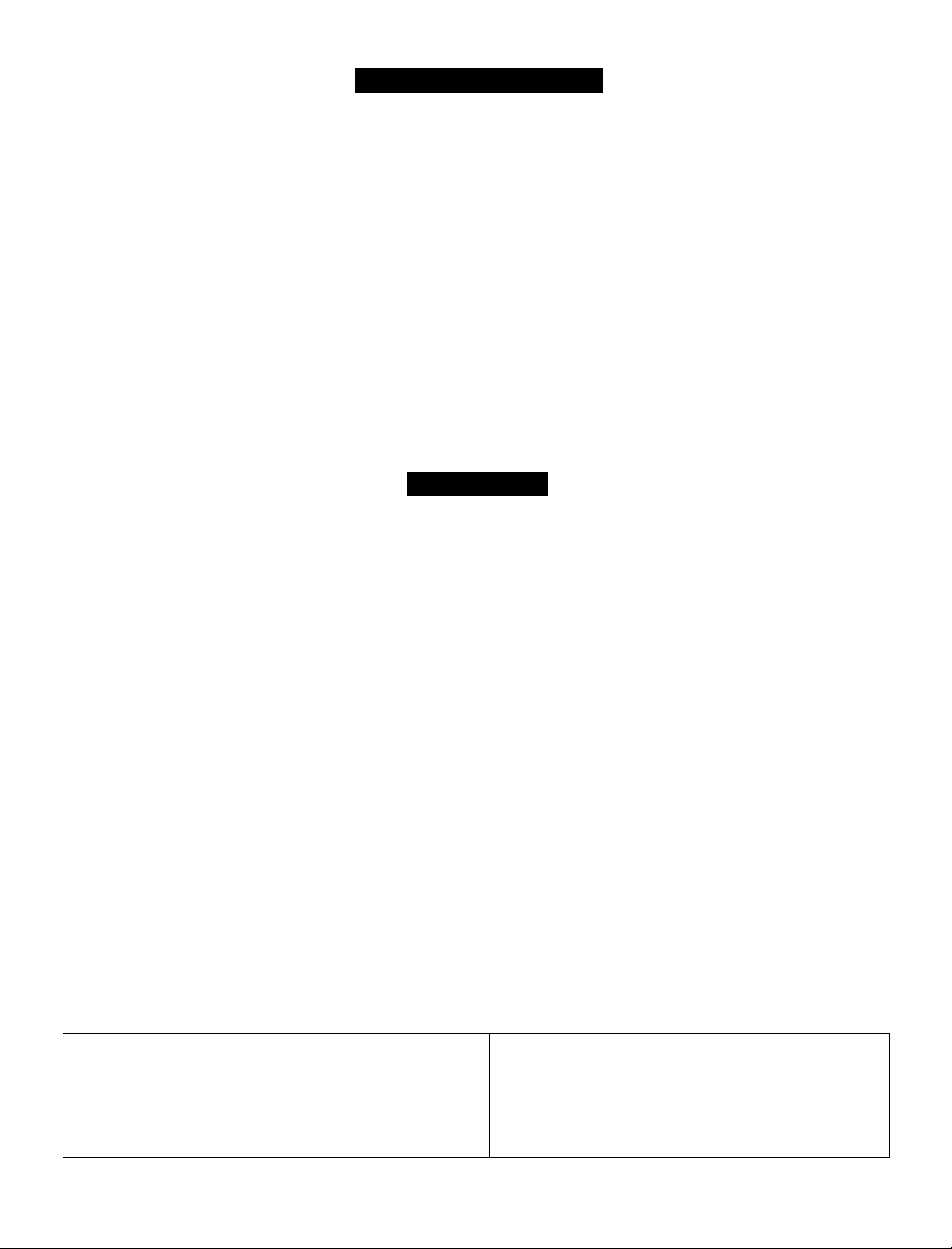

ACCESSORIES AND ATTACHMENTS

These and other accessories are recommended for use with your unit. Call 1-800-4-MY-HOME® to find out if they are available,

if available, they may be purchased at most Craftsman outlets or by calling 1-800-4-MY-HOME®.

Page 4

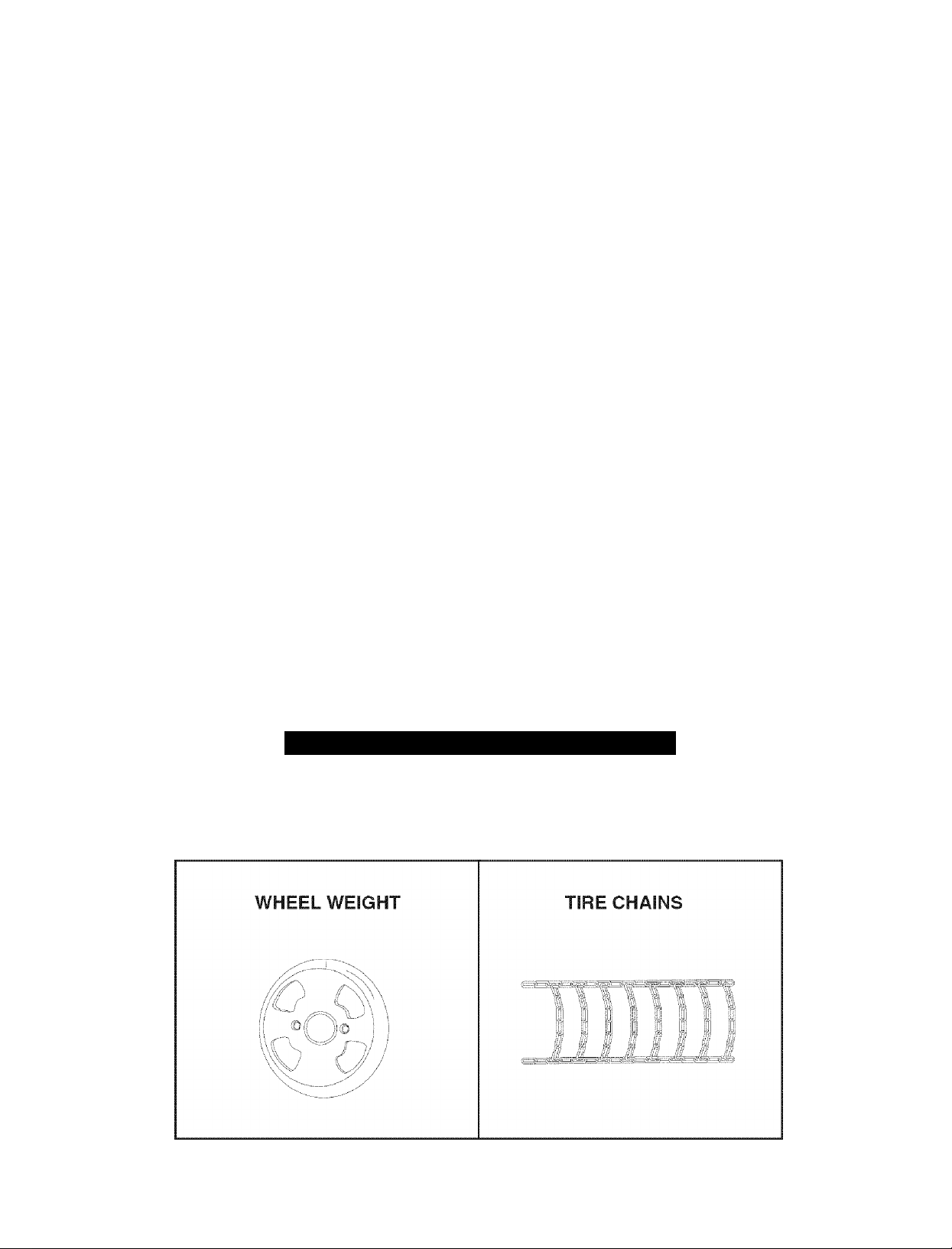

FULL SIZE HARDWARE CHART

Page 5

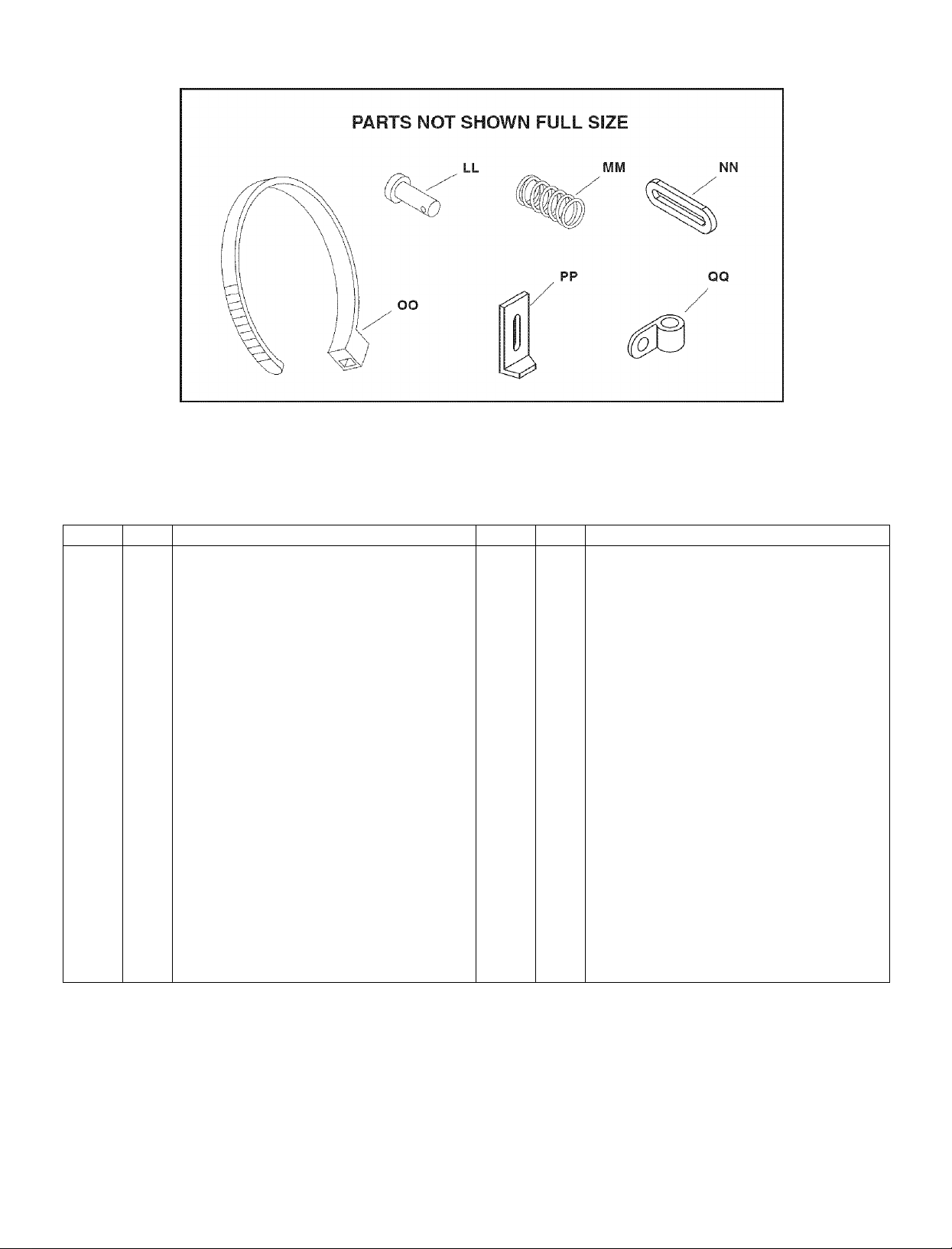

PARTS BAG CONTENTS

Not all parts will be needed for fit-up to any one tractor.

Discard unneeded parts after assembly is finished.

REF QTY DESCRIPTION REF QTY DESCRIPTION

A 2 Hex Bolt, 5/8" X 1-1/2" W 4 Spacer, 1/2" Long

В 2 Hex Bolt, 1/2" X 1 -3/4" X 3 Hairpin Cotter, Long

c 3 Hex Bolt, 1/2" X 1" Y 4 Hairpin Cotter, Short

D 2 Hex Bolt, 3/8" X 1-1/4" 6 Cotter Pin, 1/8" x 1-1/4"

E 6 Hex Bolt, 3/8" X 1" AA 2 Cotter Pin, 1/8" X 1-1/2"

F 4 Hex Bolt, 5/16" X 1" BB 6 Lock Washer, 3/8"

G 5 Hex Bolt, 5/16" X 1-3/4" CC 2 Washer, 1/4"

H 2 Hex Bolt, 1/4" X 1 -3/4" DD 8 Washer, 5/16"

1

J 8

К 2

1 Hex Bolt, 1/4" X 2" EE 8 Washer, 3/8" (Small)

Carriage Bolt, 3/8“ x 1"

Carriage Bolt, 5/16" x 1"

FF 4 Washer, 1/2" (Small)

GG 2

Washer, 3/8" (Large)

L 1 Slotted Truss Head Bolt, 10-32 x 5/8" HH 6 Washer, 5/8"

M 2 Nylock Nut, 5/8" II 8

N 1

О 2 Nylock Nut, 1/2" KK 2 Washer, 1"

P 2

Q

Hex Lock Nut, 1/2"

Nylock Jam Nut, 1/2"

2 Hex Nut, 3/8" MM 1 Compression Spring

JJ 2 Washer, 3/4"

LL 2

Washer, 1/2" (Large)

Clevis Pin

R 10 Nylock Nut, 3/8" NN 1 Slotted Stop Bracket

S 12 Nylock Nut, 5/16" OO 6

Cable Tie

T 3 Nylock Nut 1/4" PP 2 Tilt Stop Bracket

u

V 1 Spacer, 1" Long

1 Nylock Nut, #10-32

QQ

1

Hose Clip

Page 6

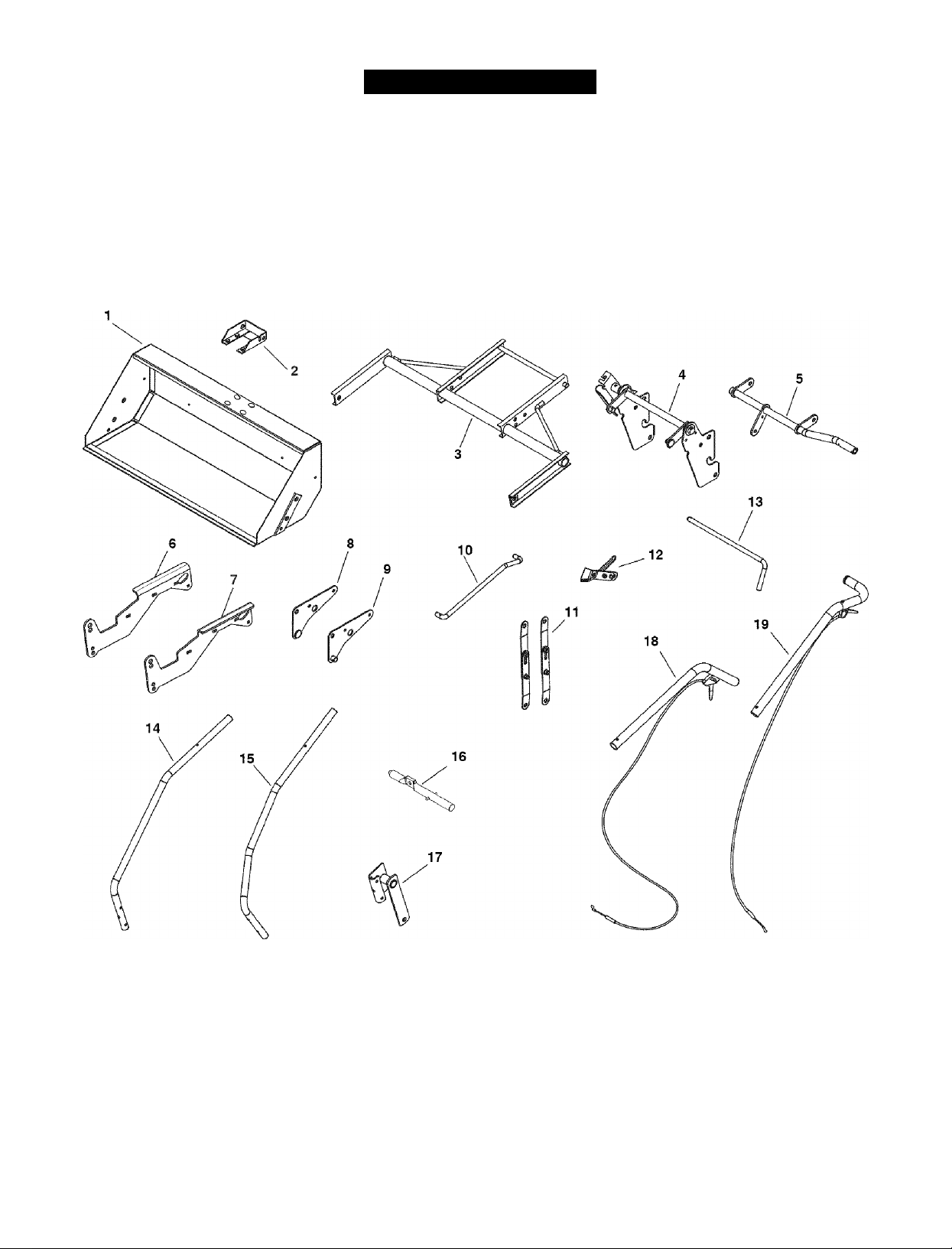

CARTON CONTENTS

1. Bucket Assembly 8. Right (Short) Side Plate

2. Pin Stop Bracket

3. Lift Frame Assembly 10. Dump Control Rod 17. Dump Pivot Bracket

4. Lift Bracket Assembly 11. Lift Strap Assembly (2) 18. Dump Handle Tube Extension

5. Tilt Anchor Assembly 12.Tilt Bracket Assembly 19. Lift Handle Tube Extension

6. Right (Long) Side Plate 13. Attachment Rod

7. Left (Long) Side Plate 14. Dump Handle Tube

9. Left (Short) Side Plate

15. Lift Handle Tube

16. Dump Control Pin

Page 7

TOOLS REQUIRED FOR ASSEMBLY

(1)

(2)

(2)

(2)

(2)

(2)

(1)

Standard Screwdriver

15/16" Wrenches (one

3/4" Wrenches

9/16" Wrenches

1/2" Wrenches

7/16" Wrenches

3/8" Wrench

should be box-end)

ADDITIONAL ITEMS NEEDED

Ruler or Tape Measure

Grease

REMOVE PARTS FROM CARTON

• Remove the hardware pack and all loose parts from

the carton.

• Lay cardboard on floor to help prevent scratching of

painted parts.

• Lay out and identify all the parts and hardware as

shown on pages 4 through 6.

ASSEMBLE SCOOP

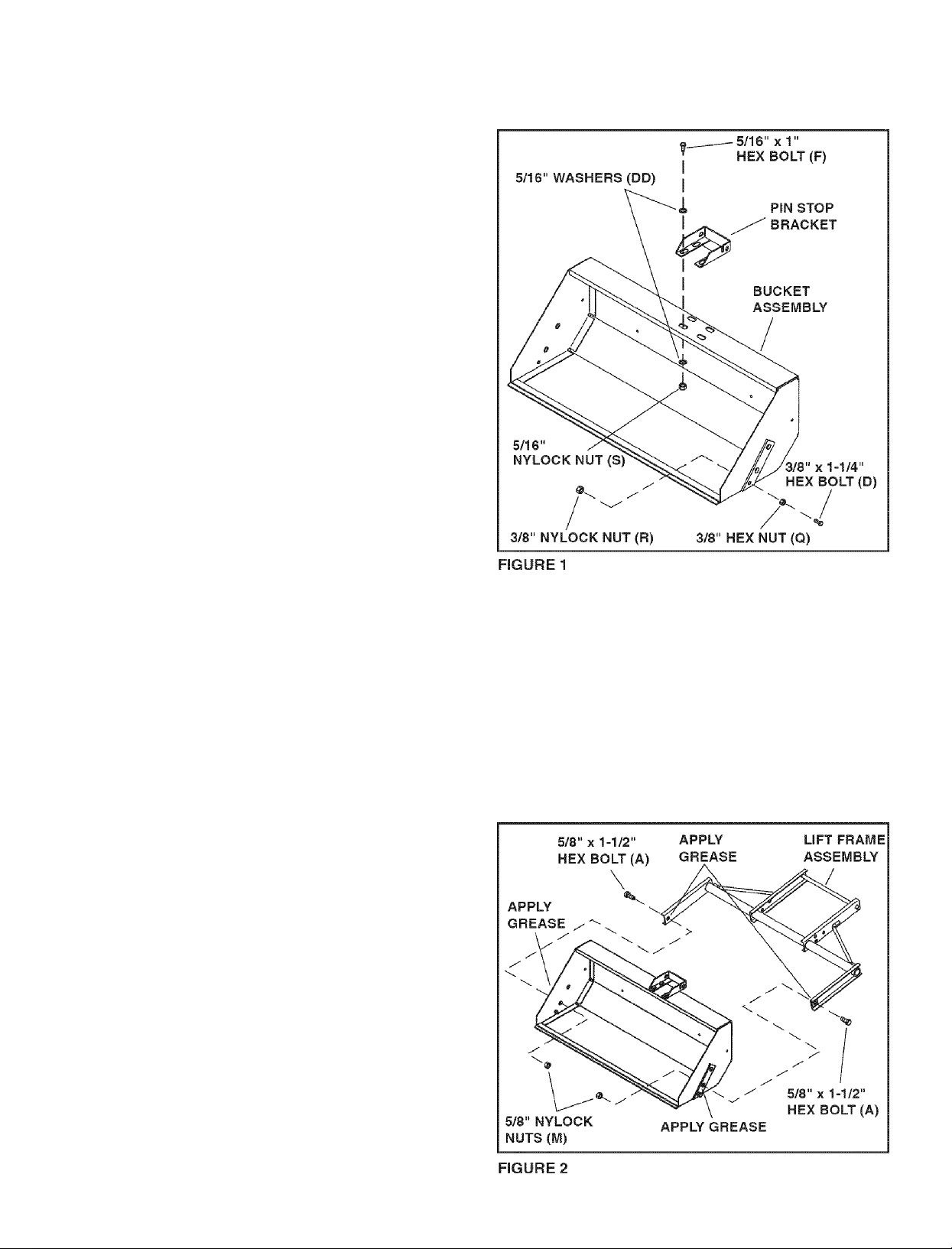

STEP 1: INSTALL TWO BOLTS

(SEE FIGURE 1)

• Assemble two 3/8" x 1 -1/4" hex bolts (D) and 3/8" hex

nuts (Q), threading the nut all the way onto the bolt

until it is tight against the head of the bolt.

* Install a nut/bolt assembly into the bucket assembly

and fasten using a 3/8" nylock nut (R). Tighten.

Repeat for the other side.

STEP 2: INSTALL PIN STOP BRACKET (SEE FIGURE 1)

• install the pin stop bracket to the top of the bucket

assembly using four 5/16" x 1" hex bolts (F), eight

5/16" washers (DD) and four 5/16" nylock nuts (S).

Leave the bolts loose enough that the position of the

pin stop bracket can be adjusted later.

STEP 3: INSTALL LIFT FRAME ASSEMBLY

(SEE FIGURE 2)

* Apply grease to the mounting surface of the bucket

assembly and the inside of the lift frame arms.

• Assemble the lift frame assembly to the bucket

assembly using two 5/8" x 1-1/2" hex bolts (A) and

5/8" nylock nuts (M). Tighten, then loosen the nuts

1/4 turn, or until the lift frame pivots freely.

Page 8

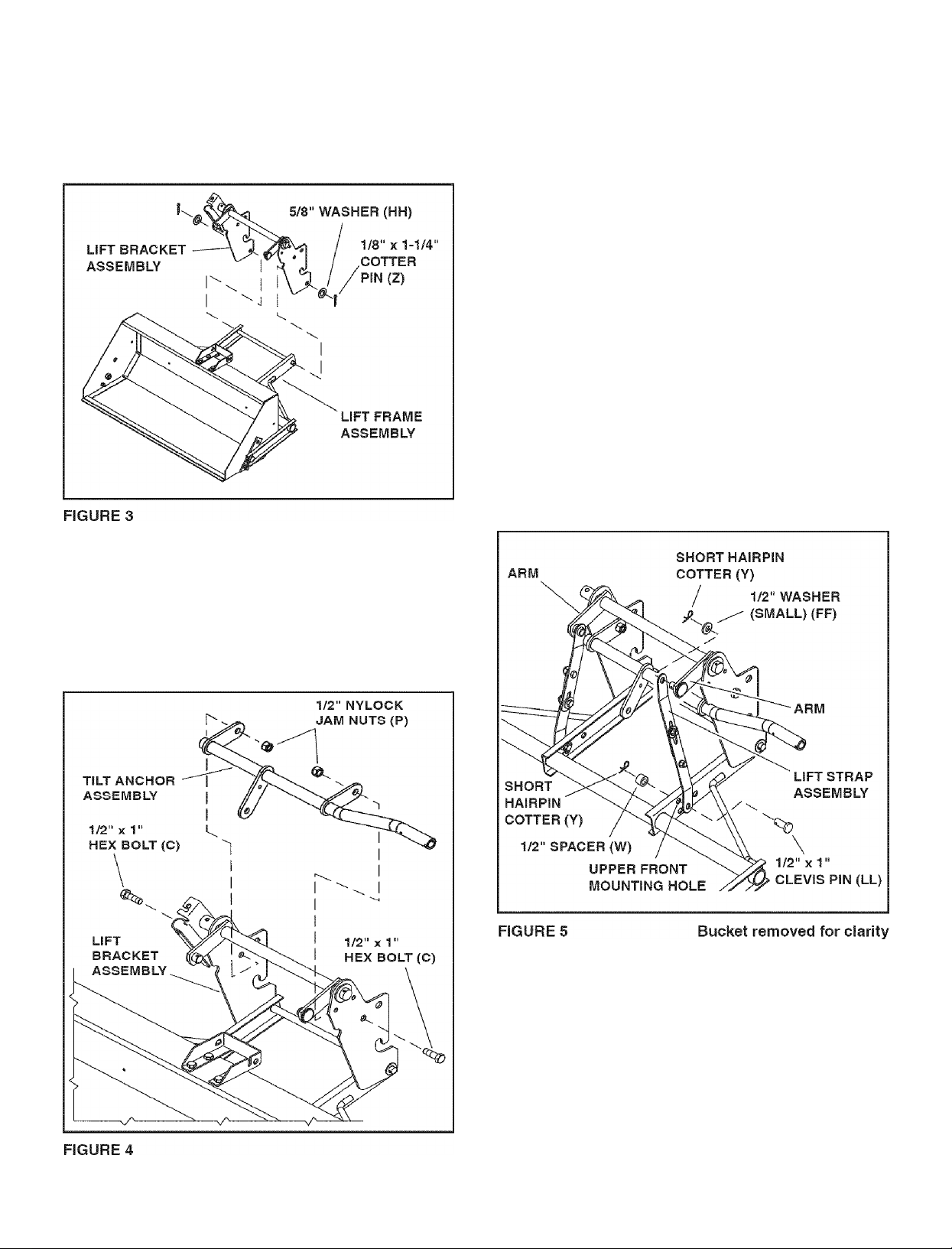

STEP 4; INSTALL LIFT BRACKET ASSEMBLY

(SEE FIGURE 3)

• Assemble the lift bracket assembly to the lift frame

assembly using two 5/8" washers (HH) and 1/8" x

1-1/4" cotter pins (Z).

STEP 6: INSTALL LIFT STRAP ASSEMBLIES (SEE FIGURE 5)

• Loosen the bolts and nuts on the lift strap

assemblies 1/4 turn or until the straps will slide back

and forth. You will retighten them later in step 26.

• Turn the lift strap assemblies as shown, install each lift

strap assembly to an arm of the lift bracket assembly

and then secure with a small 1/2" washer (FF) and a

short hairpin cotter (Y).

• Position the lower end of each lift strap assembly to

the outside of the lift frame. Fasten to the upper front

holes in the lift frame using a 1/2" x 1" clevis pin (LL),

1/2" long spacer (W) and short hairpin cotter (Y) for

each assembly.

NOTE: The lift strap assemblies may be installed in the

rear mounting holes of the lift frame to increase the lift

height, but this will also increase the lifting effort. The

front holes give a lift height of about 6-1/2" and require 28

lbs. of force to lift a 150 lb load. The rear holes will give a

lift height of about 8-1/2" and require 35 lbs. of force.

STEP 5: INSTALL TILT ANCHOR ASSEMBLY (SEE FIGURE 4)

• Assemble the tilt anchor assembly to the lift bracket

assembly using two 1/2" x 1" hex bolts (C) and 1/2"

nylock jam nuts (P). Tighten.

Page 9

STEP 7; INSTALL TILT BRACKET ASSEMBLY

(SEE FIGURE 6 ON NEXT PAGE)

• Loosen the bolts and nuts on the tilt bracket

assembly 1/4 turn or until the two plates of the

assembly will slide back and forth. You will retighten

them later in step 25.

• Lightly apply grease to the end of the arm on the tilt

anchor assembly and install the tilt bracket assembly

to the arm using a 1/2" x 1" hex bolt (C) and 1/2" hex

lock nut (N). Tighten then loosen the nut 1/4 turn, or

until the tilt bracket assembly pivots freely.

• Install the 1/4" x 2" hex bolt (I) through a 1/4" washer

(CC), the 1" long spacer (V) and then through the end

of the extension spring on the tilt bracket assembly.

Next, insert the end of the bolt into the hole in the arm

of the tilt anchor assembly and install the slotted stop

bracket (NN), a 1/4" washer (CC) and a 1/4" nylock

nut (T) onto the bolt. Tighten.

STEP 8; INSTALL DUMP PIVOT BRACKET (SEE FIGURE 7)

• Install a 1/8" x 1-1/2" cotter pin (AA) to the inside hole

In the shaft shown in figure 7, and then install a 1"

washer (KK) onto the shaft. Apply grease to the end of

the shaft and install the dump pivot bracket assembly

onto the shaft. Install a 1" washer (KK) onto the shaft

and secure it using a 1/8" x 1 -1/2" cotter pin (AA).

STEP 9: INSTALL DUMP CONTROL ROD

(SEE FIGURE 8)

• Install a 1/8" x 1 -1/4" cotter pin (Z) into the inside hole

in each end of the dump control rod. Spread the ends

of the cotter pins and wrap around the rod. Install a 5/8"

washer (HH) onto each end of the control rod.

• Install the dump control rod to the dump pivot bracket

and bucket. Fasten using two 5/8" washers (HH) and

1/8" x 1 -1/4" cotter pins (Z). Spread the ends of the

cotter pins and wrap around the rod.

Page 10

STEP 10: INSTALL TILT STOP BRACKETS

(SEE FIGURE 9)

• install a tilt stop bracket (PP) to each side of the

bucket using a 3/8" x 1" carriage bolt (J), 3/8" washer

(EE) and 3/8" nylock nut (R). Do not tighten the nuts

until step 27.

STEP 12: INSTALL LIFT HANDLE TUBE EXTENSION (SEE FIGURE 11)

• Install the lift handle tube extension on the lift handle

tube using a 1/4" x 1 -3/4" hex bolt (H) and 1/4" nylock

nut (T).

STEP 13: INSTALL LIFT CABLE (SEE FIGURE 12)

• Connect the hooked end of the lift cable Into the Index

rod, and install the threaded cable adjuster into the

notch in the top of the index bracket, placing a nut on

each side of the notch.

STEP 11: INSTALL LIFT HANDLE TUBE (SEE FIGURE 10)

• install the lift handle tube into the index bracket using

two 5/16" x 1 -3/4" hex bolts (G) and 5/16" nylock nuts

(S).

Adjust the cable adjustment nuts so that when the lift

trigger is squeezed, the bottom of the index rod raises

enough to release from the latched position. The index

rod should also lower far enough to lock in the latched

position when the trigger is released.

Attach the lift cable to the lift handle using three cable

ties (OO).

10

Page 11

STEP 14: INSTALL DUMP HANDLE TUBE

(SEE FIGURE 13)

• Install the dump handle tube to the dump pivot bracket

assembly using three 5/16" x 1 -3/4" hex bolts (G) and

5/16" nylock nuts (S).

STEP 16: INSTALL DUMP CONTROL PIN

(SEE FIGURE 15)

• Install a small 1/2" washer (FF) and then the

compression spring (MM) onto the dump control pin.

Install the dump control pin into the pin stop bracket.

Make sure the flat side of the pin faces to the front

when finished.

• Connect the hooked end of the dump cable into the

hole in the dump control pin. install the threaded cable

adjuster down into the notch in the pin stop bracket,

placing a nut on each side of the notch. Adjust and

tighten the adjuster nuts so that the tapered end of

the dump control pin extends 3/4" through the side of

the pin stop bracket.

STEP 15: INSTALL DUMP HANDLE TUBE EXTENSION

(SEE FIGURE 14)

• Install the dump handle tube extension on the dump

handle tube using a 1/4" x 1 -3/4" hex bolt (H) and 1/4"

nylock nut (T).

* Attach the dump cable to the dump handle tube using

three cable ties (OO).

11

Page 12

STEP 17: INSTALL HOSE CLIP AND SPACER

(SEE FIGURE 16)

• Secure the dump cable to the back of the bucket

using a hose clip (QQ), a #10 x 5/8" truss-head bolt

(L) and a #10-32 nylock nut (U).

LAWN TRACTORS AND GARDEN TRACTORS

WITH SINGLE SUSPENSION BRACKETS

STEP 19: INSTALL SIDE PLATES (SEE FIGURE 18)

• Remove any bolts present in the mounting holes on

the left side of the tractor frame. Do not remove bolts

from right side of frame until left side plate has been

installed.

• Install the left (long) side plate on the tractor frame

using three 3/8" x 1" carriage bolts (J), three 3/8"

nylock nuts (R), one 5/16" x 1" carriage bolt (K), one

5/16" nylock nut (S) and three large 1/2" washers (II) if

needed (see note). Do not tighten yet. Repeat for the

right side plate.

NOTE: If an engine mounting plate is present (shown with

dotted lines) that prevents the side plate from resting flat

against the tractor frame, place 1/2" washers (II) on the

front two 3/8" bolts and on the rear 5/16" bolt to serve as

shims between the side plate and the frame.

INSTALL FRONT SCOOP ON TRACTOR

STEP 18: IDENTIFY YOUR TRACTOR TYPE (SEE FIGURE 17)

* Look underneath the front axle of your tractor. If there

is a single mower deck suspension bracket located

under the middle of the front axle, continue on to

step 19. If your tractor does not have a mower deck

suspension bracket underneath the middle of the

front axle, skip to step 21 on page 13 or step 23 on

page 14 for tractors with dual suspension brackets.

12

Page 13

STEP 20: INSTALL FRAME BRACE

(SEE FIGURE 19)

• install the frame brace to the inside of the side plates

using two 1/2" X 1 -3/4" bolts (B), large 1/2“ washers

(It), 1/2" spacers (W) and 1/2" nylock nuts (O).

install the brace in the bottom holes for Garden (GT)

Tractors and the second from bottom holes for Lawn

(LT) Tractors. Do not tighten yet.

LAWN TRACTORS WITH DUAL SUSPENSION BRACKETS

STEP 21: INSTALL SIDE PLATES

(SEE FIGURE 20)

• Remove any bolts present in the mounting holes on

the left side of the tractor frame. Do not remove bolts

from right side of frame until done with left side plate.

• Tighten all nuts on side plates and frame brace.

• Skip to step 24 on page 15.

* Fasten the left (long) side plate to the tractor frame

using three 3/8" x 1" hex bolts (E), 3/8" small washers

(EE), and 3/8" lock washers (BB). if there is a bracket

like the one shown with dotted lines, use a 3/8" large

washer (GG) as a shim on the rear bolt. Do not

tighten yet. Repeat for the right (long) side plate.

13

Page 14

STEP 22: INSTALL FRAME BRACE

(SEE FIGURE 21)

• install the frame brace between the side plates using

two 1/2" X 1 -3/4" bolts (B), large 1/2" large washers

(It), 1/2" spacers (W) and 1/2" nylock nuts (O). Fasten

the brace to the second from bottom holes in the side

plates. Tighten.

• Tighten 3/8" bolts (E) in side plates only until they are

snug and the lock washers are flattened.

• Skip to step 24 on page 15.

GARDEN TRACTORS WITH DUAL

SUSPENSION BRACKETS

STEP 23: INSTALL SIDE PLATES

(SEE FIGURE 22)

• Remove any bolts present in the mounting holes on

the left side of the tractor frame. Do not remove bolts

from right side of frame until left side plate has been

installed.

• Install the left (short) side plate with the pin to the

outside using two 3/8" x 1" hex bolts (E) and 3/8" lock

washers (BB). Tighten only until bolts are snug and

lock washers are flattened. Repeat for the right side

plate.

• Install a 3/4" washer (JJ) and a long hairpin cotter

(X) to the pin in each side plate. Remove them while

mounting the scoop.

LEFT (GT)

SIDE PLATE

§

LONG \

HAIRPIN 3/4" WASHER (JJ)

COTTER (X)

FIGURE 22

(2) 3/8" LOCK

WASHERS (BB)

\2) 3/8" X 1"

HEX BOLTS (E)

14

Page 15

INSTRUCTIONS FOR ALL TRACTORS

STEP 24: MOUNT SCOOP TO TRACTOR

(SEE FIGURE 23)

• Align the scoop with the side plates on the front of the

tractor. Lift the rear of the scoop and slide the notches

in the scoop frame onto the bolts or pins in the tractor

side plates. Stand on the left side of the tractor and

push down on the scoop dump handle until the holes

in the scoop frame and the holes in the side plates are

aligned, install the attachment rod through the holes

from the left side and secure it with a long hairpin

cotter (X).

STEP 25: ADJUSTTILT BRACKET AND PIN STOP BRACKET

(SEE FIGURE 24)

• Lower the scoop assembly onto a smooth level surface.

For normal use, let the bottom of the bucket rest flat on

the ground. For more aggressive scraping action, place

1/4" shims under the rear of the bucket at each end.

• If they are tightened, slightly loosen the two smaller

bolts in the tilt bracket. If they are tightened, slightly

loosen the four bolts in the pin stop bracket.

• Swing the tilt bracket forward and position the pin stop

bracket so the end of the dump control pin inserts into

the hole in the tilt bracket.

• Adjust the pin stop bracket so that it is square with the

bucket leaving a small gap between the pin stop bracket

and the tilt bracket. The taper on the end of the pin

should now extend all the way through the tilt bracket.

TIGHTEN the bolts and nuts in the pin stop bracket

• TIGHTEN the two bolts and nuts in the tilt bracket.

15

Page 16

STEP 26; ADJUST LIFT STRAPS

(SEE FIGURE 25)

• Make sure the nuts and bolts in the lift straps are

loose enough to turn by hand. Stand beside the right

side of the scoop and hold the lift handle as far

forward as it will go until you tighten one of the nuts

in the lift straps. Let go of the lift handle and tighten

the other three nuts in the lift straps.

STEP 28: ADJUST SLOTTED STOP BRACKET (SEE FIGURE 27)

• Keep the scoop locked in the TRANSPORT position.

Push the tilt bracket forward against the dump control

pin and then slide the slotted stop bracket forward

against the tilt bracket. SECURELY TIGHTEN the bolt

and nut that fasten the slotted stop bracket.

STEP 27: ADJUST TILT STOP BRACKETS (SEE FIGURE 26)

• Raise the scoop until it locks in the TRANSPORT

position. Push the tilt stop brackets (PP) on each side

of the bucket down against the lift frame arms, and

tighten the nuts.

STEP 29: CHECK DUMPING OPERATION

• With the scoop in the transport position, squeeze the

dump trigger and push down on the dump handle

to dump the bucket. Release the dump trigger and

lift up on the handle to lock the bucket in the upright

position. If the dump control pin does not lock into the

tilt bracket, repeat step 28. If it still does not lock Into

the tilt bracket, repeat steps 25, 26, 27 and 28.

16

Page 17

OPERATION

KNOWYOUR FRONT END SCOOP

Read this owner's manual and safety rules before

operating your front end scoop.

Compare the illustration below with your front end scoop

to familiarize yourself with the various controls and their

locations.

Always test to make sure your vehicle has adequate

power and braking capabilities whenever hauling a

substantial amount of weight in your front end scoop.

Use extra caution when operating on slopes.

For best handling and traction, distribute the weight of

the load evenly in the bucket.

CAUTION: NEVER RAM THE SCOOP INTO

A

Keep the lift handle locked in the raised position when

tilting the scoop bucket forward to dump.

The lift handle must be locked in the raised position to

allow the dump handle to lock the scoop bucket back

in the upright position after dumping.

Do not scrape or push material with the scoop bucket

while it is tilted forward.

Add wheel weights for improved traction when using

the scoop.

MATERIAL AT HIGH SPEEDS.

DUMP TRIGGER LEVER Press to release the dump pin.

DUMP HANDLE Press down to dump the bucket.

LIFTTRIGGER LEVER Press to release the index pin.

LIFT HANDLE Press down to lift the bucket assembly.

HOWTO USE YOUR SCOOP

DO NOT EXCEED 200 LB. CAPACITY OF BUCKET

One cubic foot of dirt weighs approximately 80 ibs.

One cubic foot of dry sand or gravel weighs

approximately 100 Ibs.

CAUTION: VEHICLE BRAKING AND

STABILITY MAY BE AFFECTED WITH THE

ADDITION OF AN ACCESSORY OR AN

A

REFER TO THE VEHICLE OWNER'S MANUAL

FOR INSTRUCTIONS ON SAFE OPERATION ON

SLOPES.

USE THE SLOPE GUIDE PROVIDED ON PAGE

23 OF THIS MANUAL TO DETERMINE WHETHER

SLOPE ANGLE IS TOO STEEP FOR SAFE

OPERATION.

ATTACHMENT. BE AWARE OF CHANGING

CONDITIONS ON SLOPES.

17

To dump material from the bucket, squeeze the dump

trigger and push the dump tube handle down. Release

the trigger before returning the bucket to the upright

position.

To lower the bucket, squeeze the lift trigger and

then lift up on the lift handle. If the trigger is hard

to depress, you may need to push down on the lift

handle while squeezing, and then lift up. Release

the trigger before retuning the bucket to the raised

position.

Do not exceed mowing speed (3 mph) when the front

end scoop is attached to the tractor.

CAUTION: TO AVOID POSSIBLE INJURY,

MAKE SURE THAT NO ONE IS NEAR

A

A

THE BUCKET BEFORE DUMPING THE

BUCKET.

CAUTION: ALWAYS LOWER THE SCOOP

BUCKET TO THE GROUND BEFORE

LEAVING THE TRACTOR.

Page 18

MAINTENANCE

CUSTOMER RESPONSIBILITIES

* Read and follow the maintenance schedule and the maintenance procedures listed in this section.

MAINTENANCE SCHEDULE

Fill in dates as you

complete regular service. Service Dates

Check for loose fasteners

Cleaning X

Lubrication X

X

CHECK FOR LOOSE FASTENERS

• Before each use make a thorough visual check of

the front end scoop for any bolts and nuts which may

have loosened. Retighten any loose bolts and nuts.

CLEANING

• After each use, clean off any dirt and debris from the

scoop bucket lift frame.

• Before storing at the end of each season, rinse off

the scoop bucket and scoop lift frame. Allow to dry

thoroughly. Paint any exposed metal surfaces to

protect from rust.

• Store in a clean, dry area.

LUBRICATION

• Lightly oil all pivot points on the scoop lift mechanism.

• Lightly oil the surface on the scoop bucket where the

attachment lift frame pivots.

• Apply a good grade of spray lubricant to the trigger

assemblies on the lift handle and dump handle.

18

Page 19

TROUBLESHOOTING

PROBLEM CAUSE CORRECTION

Scoop won’t lock into

raised/transport position.

Scoop bucket won’t lock into level

position after dumping.

Lift handle trigger won’t release

scoop from the transport position.

Dump handle trigger won't

release bucket to dump.

Bucket is becoming more difficult

to tilt up or down.

1. Index rod is jamming.

2. Frame is hitting tilt stop

brackets.

1. Dump control pin does not align

with the tilt bracket.

1. Index rod is jamming.

2. Lift cable is not adjusted properly.

1. Dump control cable is not adjusted

properly.

2. Latch mechanism is not adjusted

properly.

1. Debris is lodged between bucket

assembly and lift frame.

1. Apply grease to the bottom slot in the

lift bracket, where the index rod slides

2. Adjust the tilt stop brackets as

instructed on page 16.

1. Adjust the tilt bracket and lift straps as

instructed on page 16.

2. Adjust the slotted stop bracket as

instructed on page 16.

1. Apply grease to the bottom slot in the

lift bracket, where the index rod slides.

2. Adjust cable nuts as instructed on page

10.

1. Adjust parts as instructed for figure 15

on page 11.

2. Adjust parts as instructed for figure 16

on page 12.

1. Remove all debris from between the

bucket assembly and the lift frame.

19

Page 20

REPAIR PARTS FOR MODEL 486.248473

Page 21

REPAIR PARTS FOR MODEL 486.248473

REF PART NO. QTY DESCRIPTION REF PART NO. QTY DESCRIPTION

1 1509-69 2 Hex Bolt, 1/4-20 x 1 -3/4" (Grade 5) 43 43093 3 Cotter Pin, 1/8" X 1-1/2"

2 726-0178 6

3 49265 1 Lift Handle Extension 45 R19212016 6 Flat Washer, 5/8" x 1-1/4" x 16 Ga.

4 49266 2 Oval Screw, 10-24 x 1-1/2" 46 25852 1 Tilt Bracket Extension Strap

5 47674 2

6 46699 1 Hex Bolt, 1/4-20x2" 48 HA6441 1 Hex Bolt, 3/8-16 X 2" (Grade 5)

7 47135 2 Washer, .28" x .875" x .063" 49 43350 8 Bolt, Carriage 3/8-16x1" (Grade 5)

8 46053 1 Spacer, .28" x .50" x .95" L 50 64963 1

9 49912 1

10 47189 3 Nylock Nut, 1/4" 52 43010 6 Cotter Pin, 1/8" X 1-1/4"

11 47369 1 Roll Pin, 3/16" X 1 -3/4" 53 64968 1 Dump Pivot Bracket

12 47368 1 Roll Pin, 5/16" X 1 -3/4" 54 49273 1 Dump Control Rod

13 47810 14 Nylock Nut, 5/16-18 55 49268 1 Dump Control Pin

14 HA21362 16 Nylock Nut, 3/8-16 56 48905 1 Compression Spring

15 43070 14 Flat Washer, 3/8" 57 46055 1 Spring Pin, 1/8" X 1"

16 25350 4 Lift Strap 58 25335 1 Pin Stop Bracket

17 43063 6 Hex Bolt, 5/16-18x1" (Grade 5) 59 47171 1 Nylock Nut, #10-32

18 25343 1 Lift Bracket 60 HA23761 1

19 741-0192 2

20 R19171616 4 Flat Washer, 1/2" x 1" (Small) 62 64962 1 Bucket Assembly

21 43055 4 Hairpin Cotter, 3/32" x 1.8" 63 43015 3 Hex Nut, 3/8-16

22 43001 10 Hex Bolt, 3/8-16 X 1" (Grade 5) 64 43087 3 Hex Bolt, 3/8-16 X 1 -1/4" (Grade 5)

23 25773 1 Slotted Stop Bracket 65 44950 2 Carriage Bolt, 1/4-20 x 3/4" (Grade 5)

24 43262 1 Hex Lock Nut, 1/2-13 66 26481 2 Tilt Stop Bracket

25 64964 1 Tilt Anchor Assembly 67 25722 1

26 48115 2 Nylock Jam Nut, 1/2-13 68 43081 8 Flat Washer, 5/16"

27 63675 1 Lift Arm Assembly 69 44326 2 Carriage Bolt, 5/16" x 1" (Grade 5)

28 25510 2 Mounting Bracket 70 710-0367 2 Hex Bolt, 5/8-11 X 1 -1/2" (Grade 5)

29 43343 3 Hairpin Cotter, 3/32" x 2-5/16" 71 736-0235 2 Washer, .375" x 1.26" x .172"

30 R74780828 2 Hex Bolt 1/2-13x1-3/4" (Grade 5) 72 43000 1 Extension Spring

31 R19172410 8 Flat Washer, 1/2" x 1-1/2" (Large) 73 44062 2 Clevis Pin, 1/2" X 1"

32 24817

33 712-3083 2 Nylock Nut, 1/2-13 75 R19131316 2 Flat Washer, 3/8" x 13/16" x 1/16"

34 43003 6 Lock Washer, 3/8" 76 63773 1 Index Bracket Assembly

35 712-0261 2 Nylock Nut, 5/8-11 77 48049 1 Index Rod

36 63568 1 Right (Short) Side Plate 78 732-0306 1 Spring, Compression

37 63569 1 Lett (Short) Side Plate 79 49264 1

38 49270 1 Dump Handle Tube Extension 80 43009 2 Flat Washer, 3/4"

39 47066 1 Attachment Rod 81 25562 1 Right (Long) Side Plate

40 49271 1 Dump Handle Tube 82 25563 1 Left (Long) Side Plate

41 40173 1 Dump Control Cable 48205 1

42 43601 3 Washer, 1.59" x 1.032" x 0.60"

Cable Tie

Plastic Plug, 1-1/4" O.D.Tube

Cable, Lift

Flange Bearing with Flats

4

Spacer, 0.52" x 0.75" x 0.5"

44 710-0865 3 Hex Bolt, 1/2-13 X 1" (Grade 5)

47 25851 1 Tilt Bracket

Lift Frame Assembly

51 43084 5 Hex Bolt, 5/16-18 X 1 -3/4" (Grade 5)

Hose Clamp

61 43346 1 Truss-Head Bolt #10-32 x 5/8"

Frame Brace

74

142 1 Cotter Pin, 1/8" x 3/4"

Lift Handle Tube

Owner's Manual

Purchase Common Hardware Locally

21

Page 22

Page 23

SUGGESTED GUIDE FOR SIGHTING SLOPES FOR SAFE OPERATION

OF TRACTOR WITH ATTACHMENT

■ ^^S£.0P£" ~ ^ ^

*

f

iL

t , , . .'VVVVVVVVV'

'VVVi'A-VVV VVV'I'VV'

■

i'r

VV VVVVWWWVVVVVVV Vvvvvvvvvvvvvvvvv vvvvvvvvvvvvv

i

ONLY RIDE UP AND DOWN HILL,

r/ '

NOT ACROSS HILL

CO

CM

10 DEGREES MAX.

•vv vv vv vv vv vv vv vv v vvv v vv vv vv vv vv vv vv vv vv vv vv vv v vv vv vv vv vv vv vv vv vv vv vv vv v vvv vv v vv vv vv vv vv vv vv vv vv vv vv vv v vv vv vv vv vv vv vv vv vv vv vv vv vv vv v vv vv vv vv vv vv vv v?

WARNING; To avoid serious injury, operate your tractor up and

down the face of slopes, never across the face. Do not operate

on slopes greater than 10 degrees. Make turns gradually to

A

1. Fold this page along dotted line indicated above.

2. Hold page before you so that its left edge is vertically parallel to a tree

trunk or other upright structure.

3. Sight across the fold in the direction of hill slope you want to measure.

4. Compare the angle of the fold with the slope of the hill.

prevent tipping or loss of control. Exercise extreme caution

when changing direction on slopes. Braking may be affected by

tractor attachment. Reduce speed on slopes.

+

Page 24

Get it fixed, at your home or ours!

Your Home

For repair - in your home - of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner’s manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME® (1-800-469-4663)

Call anytime, day or night (U.S.A. and Canada)

www.sears.comwww.sears.ca

For expert home solutions advice: www.managemyhome.com

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call or go on-line for the location of your nearest

Sears Parts & Repair Service Center

1 -800-488-1222 (u s A) 1 -800-469-4663 (Canada)

Call anytime, day or night

www.sears.comwww.sears.ca

To purchase a protection agreement on a product serviced by Sears:

1-800-827-6655 (U.S.A.) 1-800-361-6665 (Canada)

Para pedir servicio de reparación

a domicilio, y para ordenar piezas:

1-888-SU-HOGAR®

(1-888-784-6427)

Au Canada pour service en français:

1-800-LE-FOYER“'=

(1-800-533-6937)

www.sears.ca

® Registered Trademark / ™ Trademark / Service Mark of Sears Brands, LLC

® Marca Registrada / ™ Marca de Fábrica / Marca de Servicio de Sears Brands, LLC

Marque de commerce / Marque déposée de Sears Brands, LLC

© Sears Brands, LLC

Loading...

Loading...