Page 1

Operator's lianual

42"- 2 STAGE SNOW THROWER

TRACTOR ATTACHMENT

Model No. 486.24837

STOP

DO NOT RETURN TO STORE

For Missing Parts or Assembly

Questions Call 1-866-576-8388

FOR TRACTORS WITH MODEL NUMBERS BEGINNING WITH 917.

CAUTION:

Before using this product, read

this manual and follow all Safety

Rules and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www.sears.com/craftsman

PRINTED IN U.S.A.

• Safety

• Assembly

• Operation

• Maintenance

• Parts

FORM NO. 41361 rev. (07/30/10)

Page 2

TABLE OF CONTENTS

ACCESSORIES..................................................................2

SAFETY RULES.................................................................3

FULL SIZE HARDWARE CHART

CARTON CONTENTS........................................................6

ASSEMBLY.........................................................................7

OPERATION.....................................................................26

MAINTENANCE................................................................27

......................................

SERVICE AND ADJUSTMENTS

STORAGE.........................................................................29

4

TROUBLESHOOTING

REPAIR PARTS ILLUSTRATION...........................30,32,34

REPAIR PARTS LIST

SLOPE GUIDE..................................................................35

PARTS ORDERING/SERVICE......................BACK COVER

......................................................

.............................................

......................................

31,33,34

28

29

WARRAN

j

ONE YEAR FULL WARRANTY

When operated and maintained according to the instructions suppiied with it, if this Snow Thrower faiis due to a defect in

materiai or workmanship within one year from the date of purchase, caii 1-800-4-MY-HOME® to arrange for free repair (or

repiacement if repair proves impossible).

If this product is used for commerciai or rentai purposes, this warranty appiies for only 90 days from the date of purchase.

This warranty gives you specific iegai rights, and you may aiso have other rights which vary from state to state.

Sears, Roebuck and Co., D817WA, Hoffman Estates, IL 60179

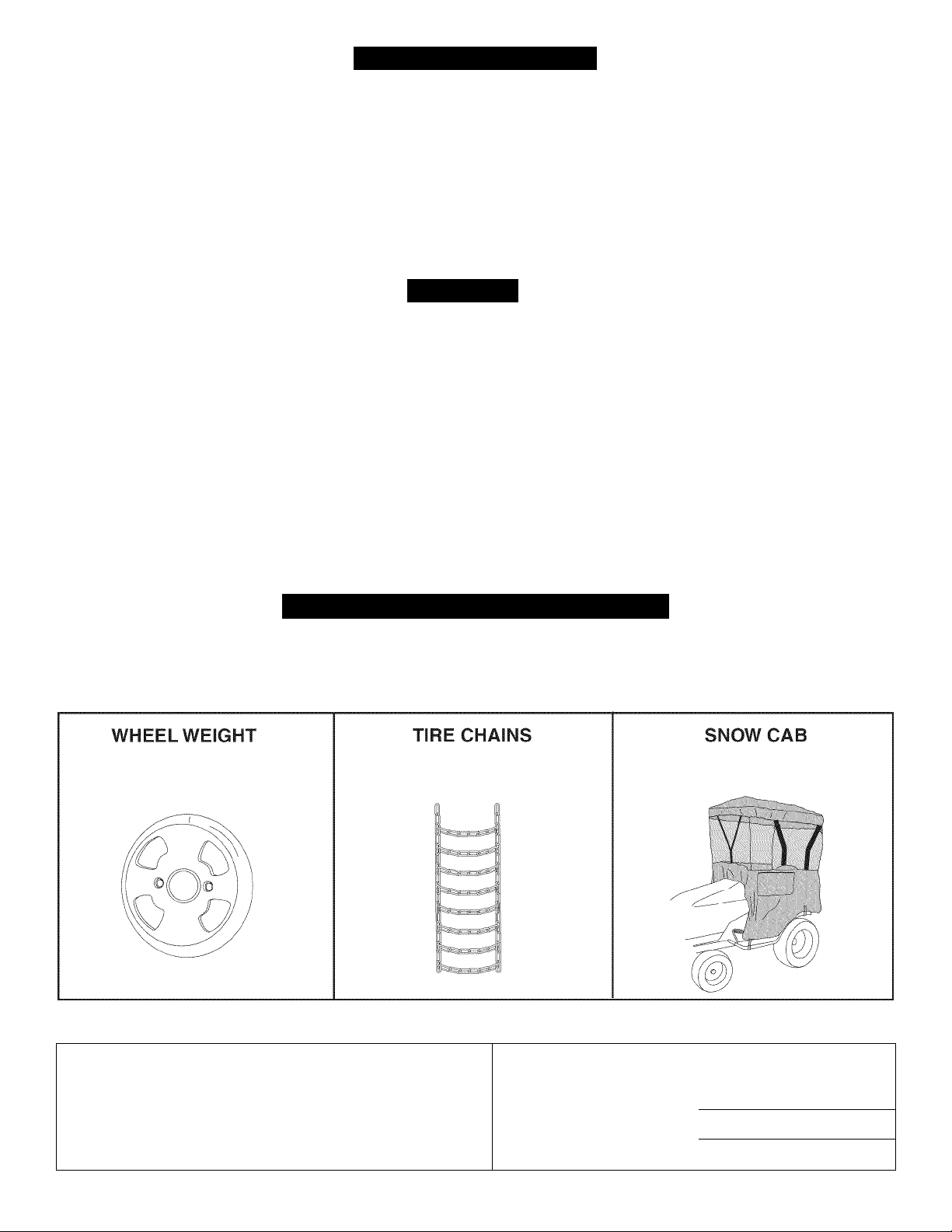

ACCESSORIES AND ATTACHMENTS

These and other accessories are recommended for use with your unit. Caii 1-800-4-MY-HOME® to find out if they are avaiiable.

If available, they may be purchased at most Craftsman outlets or by calling 1-800-4-MY-HOME®.

The modei number and seriai numbers wiii be found on a

decai attached to the snow thrower.

You shouid record both the seriai number and the date of

purchase and keep in a safe pi ace for future reference.

MODEL NUMBER: 486.24837

SERIAL NUMBER:

DATE OF PURCHASE:

Page 3

A

Any power equipment can cause injury if operated improperiy or if the user does not understand how to operate the equipment.

Exercise caution at aii times, when using power equipment.

SAFETY

A

Read this owner's manuai carefuliy and know how to

operate your snow thrower and how to stop the unit

and disengage the controis quickiy.

Never aiiow chiidren to operate the equipment.

Never aiiow adults to operate the equipment without

proper instruction.

Keep the area of operation clear of all persons,

especially small children, and pets.

Thoroughly inspect the area where the equipment is

to be used and remove all door mats, sleds, boards,

wires and other foreign objects.

Disengage all clutches and shift into neutral before

starting engine.

Do not operate equipment without wearing adequate

winter outer garments.

Wear substantial footwear which will protect feet and

improve footing on slippery surfaces.

Check fuel before starting the engine. Do not remove

the fuel cap or fill the fuel tank while the engine

is running or hot. Do not fill the fuel tank indoors.

Gasoline is an extremely flammable fuel.

Make sure the snow thrower height is adjusted to

clear the type surface it will be used on.

Do not use the snow thrower without wheel weights

attached to the tractor.

Never make any adjustments while the engine is

running.

Always wear safety glasses or eye shield during

operation or while performing adjustment or repair.

Do not place hands or feet near rotating parts. Keep

clear of the discharge opening at all times.

Use extreme caution when operating on or crossing

gravel surfaces.

Do not carry passengers.

After striking a foreign object, stop the engine, remove

the wire from the spark plug and then thoroughly

inspect the snow thrower for damage. Repair any

damage before restarting and operating the snow

thrower.

If the snow thrower starts to vibrate abnormally, stop

the engine immediately and check for the cause.

Vibration is generally a warning of trouble.

Stop the engine whenever you leave the operating

position, before unclogging the snow thrower or

making any adjustments or inspections.

Take all possible precautions when leaving the unit

unattended. Disengage the attachment clutch lever or

switch, lower the snow thrower, shift into neutral, set

the parking brake, stop the engine and remove the

key.

When cleaning, repairing or inspecting, make certain

all moving parts have stopped. Disconnect the spark

plug wire and keep it away from the plug to prevent

accidental starting.

Do not run engine indoors except when transporting

the snow thrower in or out of the building. Open the

outside doors. Exhaust fumes are dangerous.

Do not clear snow across the face of slopes. Exercise

extreme caution when changing direction on slopes.

Do not attempt to clear steep slopes. Refer to the

slope guide on page 35 of this manual.

Never operate the snow thrower without guards,

plates or other safety protection devices in place.

Never operate the snow thrower near glass

enclosures, automobiles, window wells, drop offs

etc. without proper adjustment of the snow thrower

discharge angle.

Never direct discharge at bystanders or allow anyone

in front of the snow thrower.

Never run the snow thrower into material at high

speeds.

Do not overload the machine capacity by attempting

to clear snow at too fast a rate.

Never operate the machine at high transport speed

on slippery surfaces. Look behind and use care when

backing up.

Watch for traffic and stay alert when crossing or

operating near roadways.

Disengage power to the snow thrower when

transporting or when not in use.

Use only attachments and accessories approved by

the manufacturer of the snow thrower (such as wheel

weights, counter weights, cabs etc.)

Never operate the snow thrower without good visibility

or light.

A

Look for this symbol to point out important safety precautions. It means—Attention!! Become

alert!! Your safety is involved.

Page 4

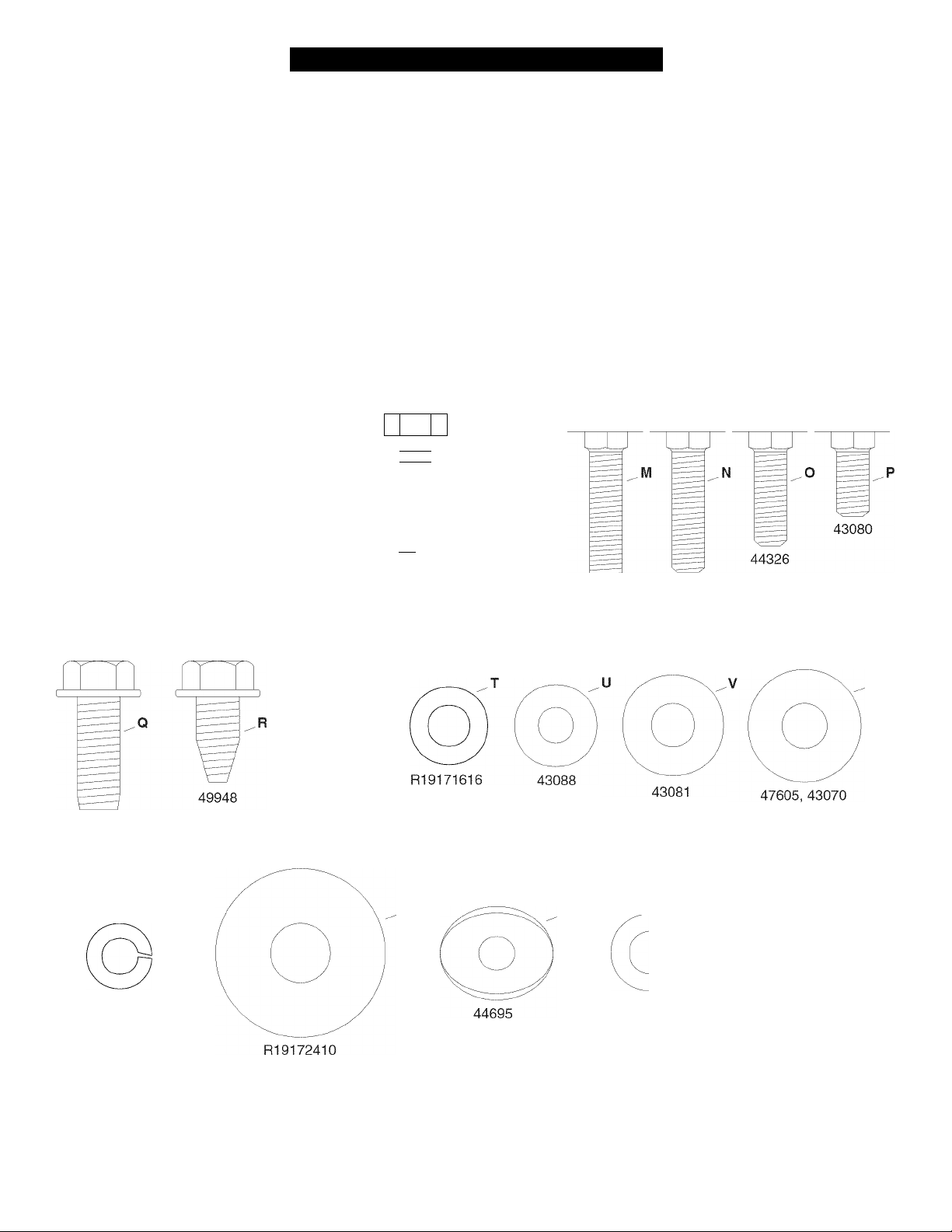

HARDWARE PACKAGE CONTENTS

SHOWN ACTUAL SIZE

43063

43182

43661

43020

48106

43351

43084

J__L

49933 ) C

46938

710-0890A

43840

TZ

K

43350

43682

44215

w,x

47630

47631

AA

43086

7T

DD

EE

FF GG HH

43003

^ I—

□

712-3083 43019 HA21362 43082 47810 47572 46584

c

BB

II JJ KK

4

cc

24817

47598

Page 5

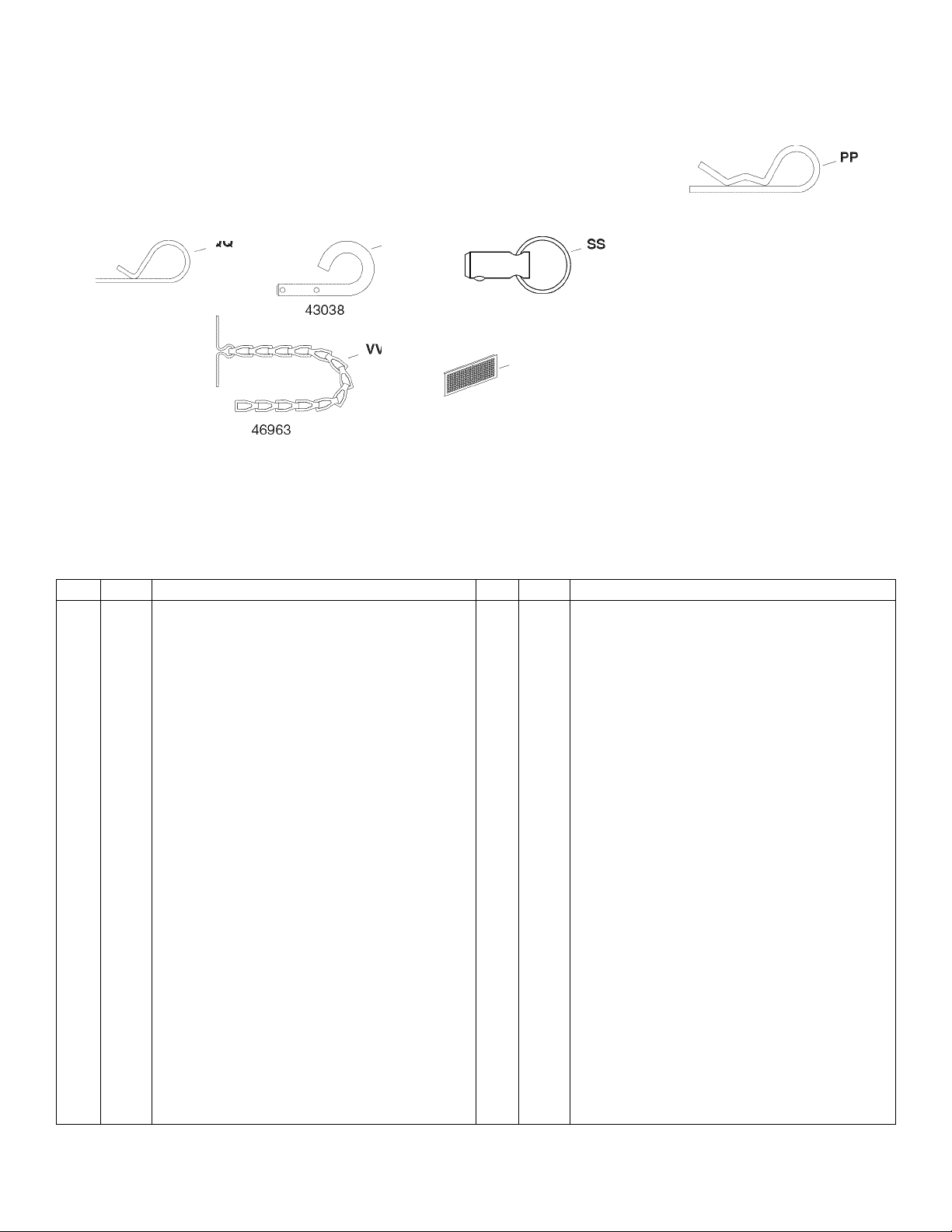

NOT SHOWN ACTUAL SIZE

46959

LL

731-0851A

MM

711-0198

RR

NN

oo

47134 43343

TT

UU

0"

43055

47788

714-04061

ww

1643-60

726-0178

23727

XX

IMPORTANT: Not all Items supplied In the hardware bag will be needed for your particular tractor. Unneeded Items may

be discarded after you have completed assembly and checked operation of unit. DO NOT DISCARD the two spare shear

bolts (K) and 5/16" nylock nuts (HH). Refer to the Service and Adjustments section on page 28.

REF. QTY. DESCRIPTION REF. QTY. DESCRIPTION

A 2 Hex Bolt, 1/2" X 1-1/2" AA 2

B 2 Hex Bolt, 1/2" X 1-1/4" BB 7 Lock Washer, 3/8"

C 1 Hex Bolt, 3/8" X 3-1/4" CC 2 Spacer, 1/2"

D 2 Hex Bolt, 5/16" X 1-3/4" DD 4 Nylock Nut, 1/2"

E 2 Hex Bolt, 5/16" X 1-1/4" EE 4 Jam Nut, 1/2"

F 4 Hex Bolt, 5/16" x1" FF 6 Nylock Nut, 3/8"

G 8 Hex Bolt, 5/16" X 3/4" GG 2 Hex Lock Nut, 3/8"

H 6 Hex Bolt, 1/4" X 1" HH 21 Nylock Nut, 5/16" (2 spare parts)

1 4 Shoulder Bolt, Hex Head II 10 Flanged Nut, 3/8"

J 2 Shoulder Bolt, Round Head JJ 1 Flanged Nut, 5/16"

K 2

Shear Bolt (spare parts)

KK 6 Flanged Nut, 1/4"

L 6 Carriage Bolt, 3/8" x 1" LL 1 Spring

M 2 Carriage Bolt, 5/16" x 1-3/4" MM 3

N 2 Carriage Bolt, 5/16" x 1-1/4" NN 1 Trunnion

0

4 Carriage Bolt, 5/16" x 1"

OO

P 2 Carriage Bolt, 5/16" x 3/4" PP 4 Hairpin Cotter, 1/8"

Q

6 Hex Bolt, 3/8" X 1" (Thread Forming)

OO

R 2 Hex Bolt, 3/8" X 3/4" (Thread Forming) RR 2 Lock Pin

S

T

u

V 22

2 Hex Bolt, 5/16" X 3/4" (Thread Forming)

4 Washer, 1/2" x 1"

7 Washer, 1/4"

Washer, 5/16" (Extra washers Included)

SS

TT

UU

VV 2 Chain, Tensioning

w 1 Washer, 3/8" (Thin) WW 2 Tall Reflector

X 3 Washer, 3/8" Standard XX 2 Nylon Tie

Y 2 Lock Washer, 5/16"

Z

8 Washer, 1/2" x 1-1/2"

Bowed Washer

Chute Keeper

4 Hairpin Cotter, 5/64"

1 Hairpin Cotter, 3/32"

2 Oulck Release Pin

1 Plastic Cap

1 Spacer, 3/8"

Page 6

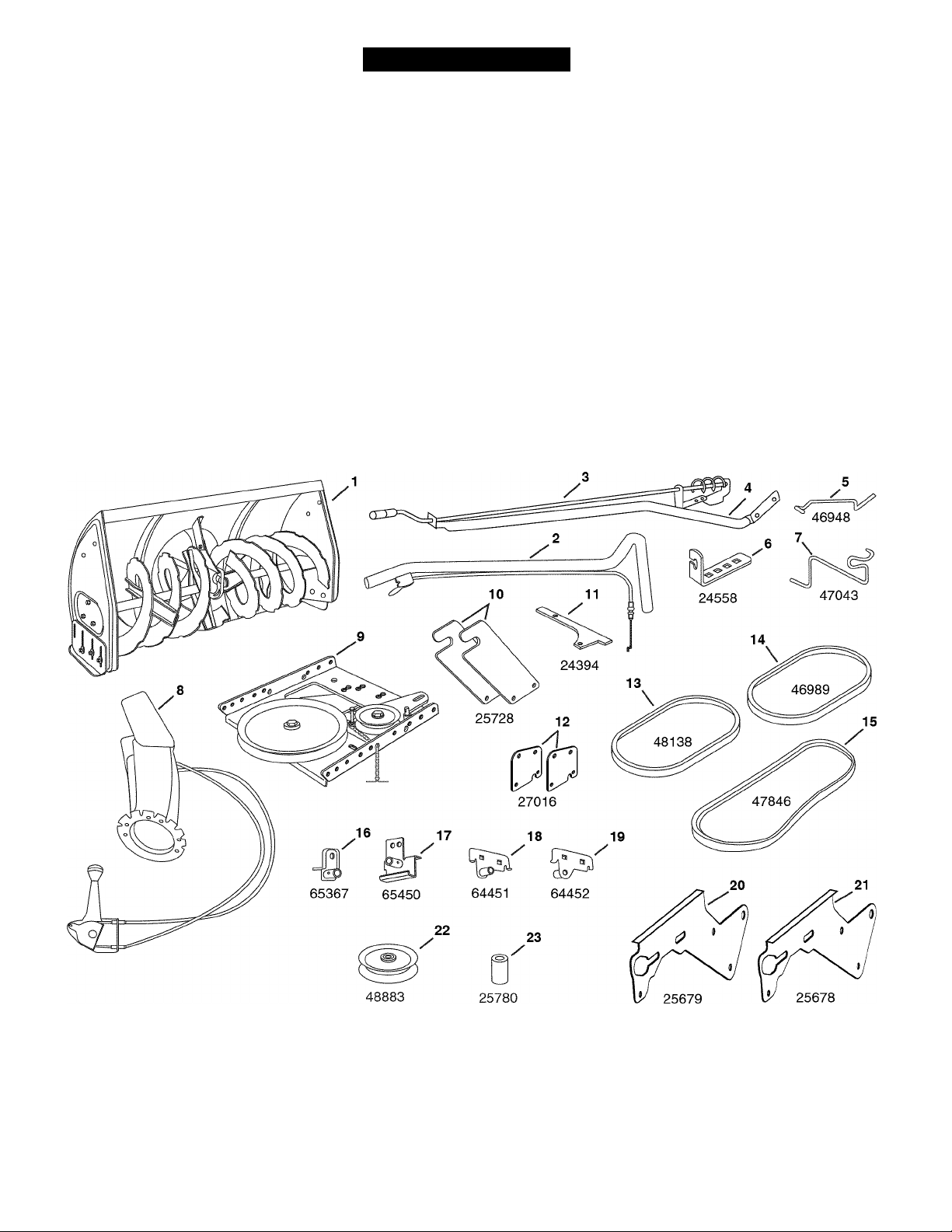

CARTON CONTENT

1. Housing Assembly 12. Front Pulley Frame Bracket (2)

2.

Lift Handle and Cable

3. Chute Crank Rod Assembly 14. V-Belt, Drive 55" (#46989)

4. Support Tube, Crank Rod 15. V-Belt, Auger (Attached to Housing Assembly)

5.

Engagement Rod (Not used on some models)

6. Cable Bracket 17. R.H. Hanger Bracket (Outside Mounting)

7.

Engine Pulley Keeper (Not used on some models)

8.

Chute and Control Cable Assembly

9. Clutch Idler Assembly 20.

10. Rear Pulley Frame Bracket (2) 21.

11. Anti-rotation Bracket. 22.

13. V-Belt, Drive 56" (#48138)

16. L.H. Hanger Bracket (Outside Mounting)

18. L.H. Hanger Bracket (Inside Mounting)

19. R.H. Hanger Bracket (Inside Mounting)

Left Hand Side Plate

Right Hand Side Plate

Pulley

23. Spacer, 3/8"

]

ONLY ITEMS NEEDED FOR MODEL 917.

TRACTORS ARE SHOWN

Page 7

ASSEMBLY

LOCATE TRACTOR'S MODEL LABEL

Look under your tractor seat to locate the model number

label shown below. This manual If for tractors with model

numbers that start with 917 as shown below.

917 MODEL TRACTORS

CRAFTSMAN ^ =

CONFORMS TO ANSI B71.1-2003 SAFETY STANDARDS

ill

FOR PARTS AND SERVICE CALL 1-800-4MY-HOME.

SEARS, ROEBUCK AND CO,, Hoffman Estates, IL 60179

IMPORTANT: If your model number starts with 247, use

the owner's manual and the parts that are contained In

the other parts bag.

C MODEL 917. 000000 J

IliilliniigBaiiiii Miali 11

SERIAL OOOOOOAOOOOOO

193653

J

CAUTION: Before starting to assemble the

snow thrower, remove the spark plugwlre(s),

set the parking brake and remove the key

A

from the tractor Ignition.

TRACTOR PREPARATION

Before performing these Instructions, refer to the Service

and Adjustments section of your tractor owner's manual

for specific safety Instructions.

• Allow engine, muffler and exhaust deflector to cool

before beginning.

• Remove any front or rear attachment which Is

mounted to your tractor.

• Remove the mower deck. Refer to your tractor owner's

manual for removal Instructions. Mark all loose parts

and save for reassembly.

• Remove the tractor hood. Refer to your tractor owner's

manual for removal Instructions.

TOOLS REQUIRED FOR ASSEMBLY

(2) 7/16" Wrenches

(2) 1/2" Wrenches

(2) 9/16" Wrenches

(2) 3/4" Wrenches

(1) Screw Driver

(1) Knife

ADDITIONAL ITEMS REOUIRED

General Purpose Grease

REMOVAL OF PARTS FROM CARTON

• Remove all loose parts, parts bags and hardware

bags from the carton. Lay out and Identify parts and

hardware using the Illustrations on pages 4, 5 and 6.

The parts bag labeled for 247 model tractors will not

be needed.

IMPORTANT: Not all Items supplied In the hardware

bag will be needed for your particular tractor. Unneeded

Items may be discarded after you have completed

assembly and checked operation of unit. DO NOT

DISCARD the two spare shear bolts and 5/16" nylock

nuts. Refer to the Service and Adjustments section on

page 28.

IMPORTANT: Right hand (R.H.) and left hand (L.H.) side

of the tractor are determined from the operators position

while seated on the tractor.

Page 8

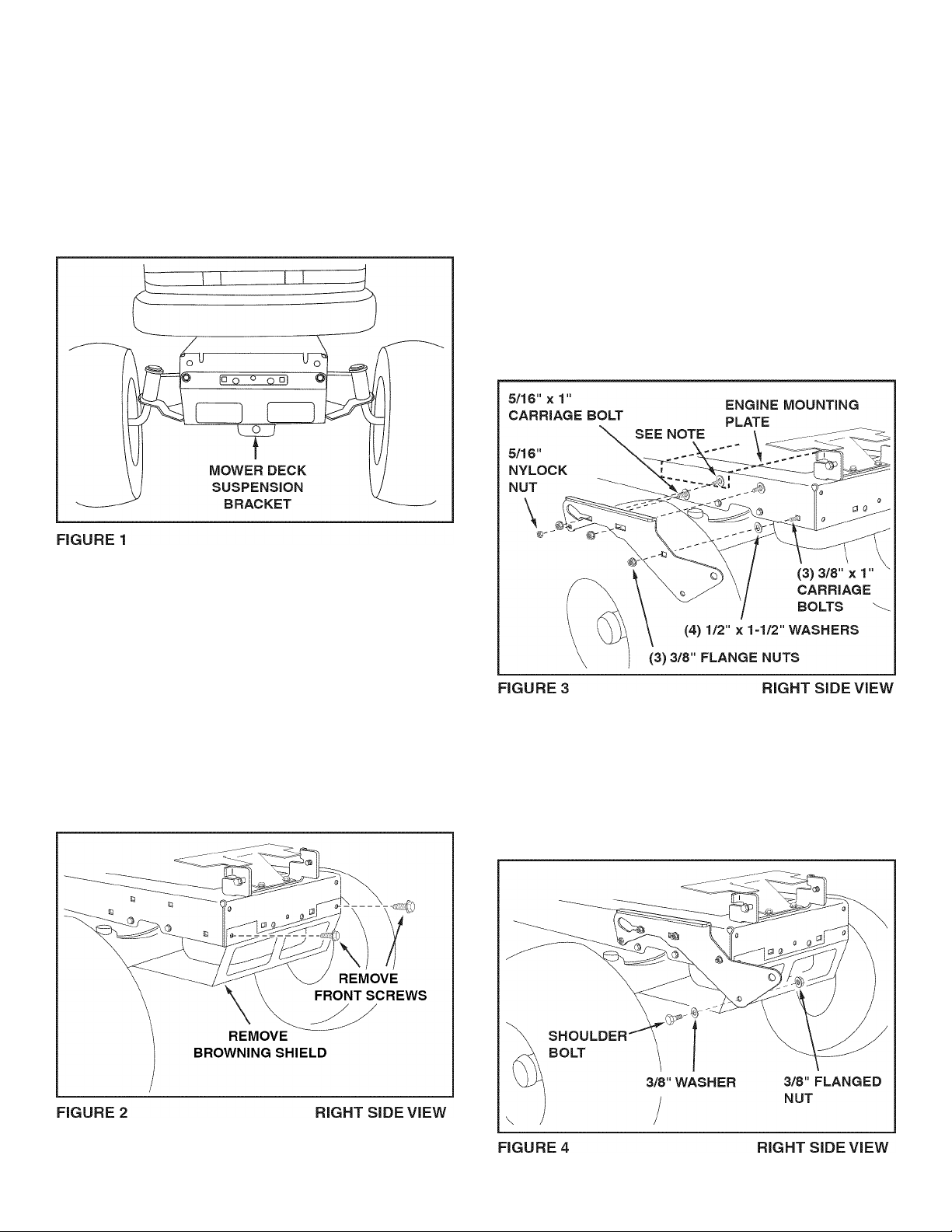

IDENTIFY YOUR TRACTOR

INSTALL SIDE PLATES

STEP 1: (SEE FIGURE 1)

• Look under the front of your tractor. If there is a single

mower deck suspension bracket located underneath

the middle of the front axle, continue on to step

2. If your tractor does not have a mower deck

suspension bracket underneath the middle of the

front axle, skip to step 21 on page 14 for tractors

with dual suspension brackets.

STEP 3: (SEE FIGURE 3)

• Fasten the R.H. Side Plate (bend facing out) to the

front three holes in the tractor frame using three 3/8"

X 1" carriage bolts, three 1/2" x 1-1/2" washers (see

note) and three 3/8" flange nuts. For the rear hole, use

a 5/16" X 1" carriage bolt, a 1/2" x 1-1/2" washer and

a 5/16" nylock nut Place the washers between the

tractor frame and the side plate. Repeat for L.H. side

plate.

• Reinstall the browning shield onto the tractor frame

using the original screws.

NOTE: If there is an engine mounting plate (shown with

dotted lines) leave the washer off the bolt that goes

through the plate.

INSTRUCTIONS FOR TRACTORS WITH

SINGLE FRONT DECK SUSPENSION

BRACKET

STEP 2: (SEE FIGURE 2)

• Remove the browning shield from the front of the

tractor as shown. Hold onto the shield as you remove

the second screw to prevent it from falling.

• Be sure to reinstall the browning shield when so

instructed in step 3.

STEP 4: (SEE FIGURE 4)

• Assemble a shoulder bolt and a 3/8" washer to the

outside of R.H. side plate, securing it with a 3/8"

flanged nut. Repeat for L.H. side plate.

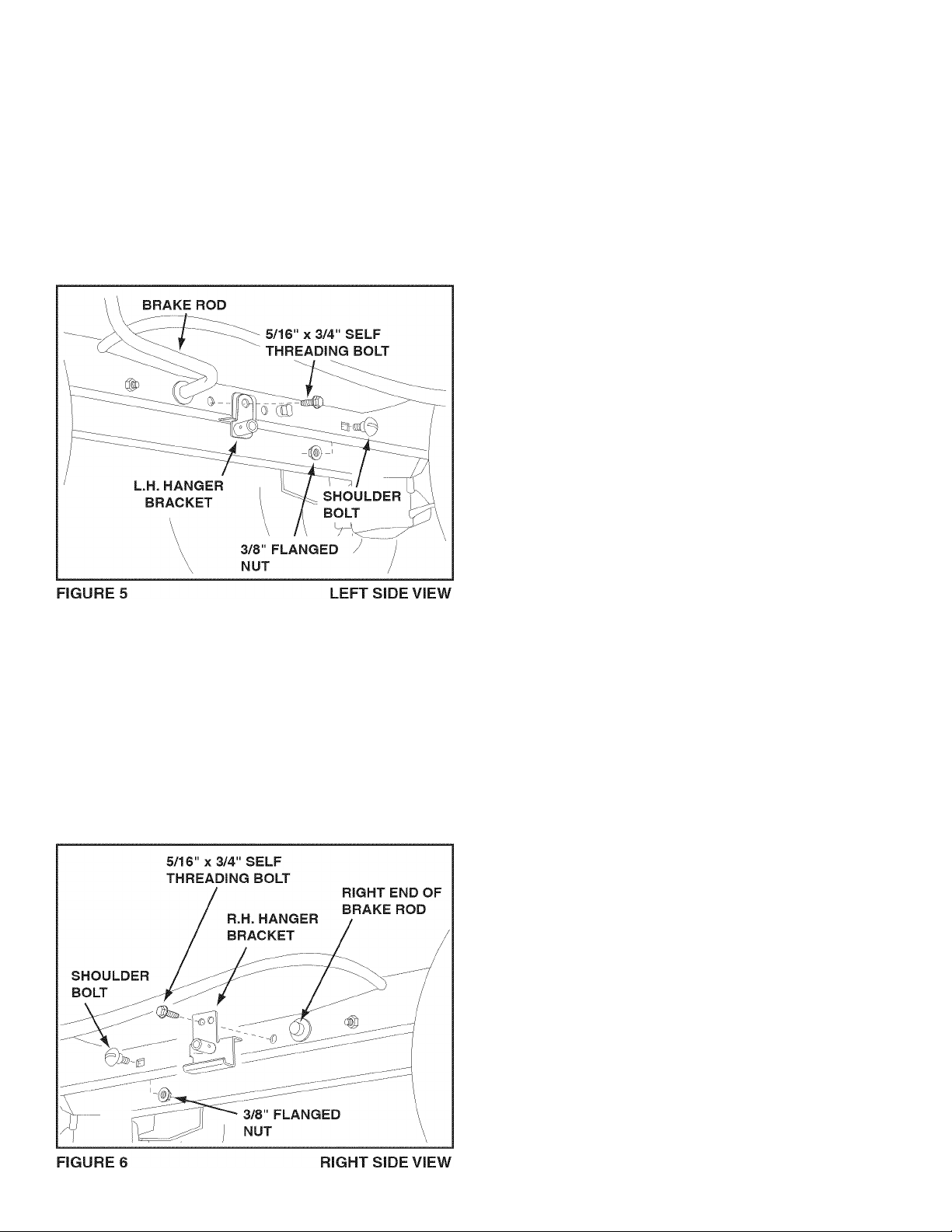

Page 9

INSTALL HANGER BRACKETS AND SHOULDER

BOLTS TO OUTSIDE OF FRAME

STEP 5: (SEE FIGURE 5)

• Remove the bolt, if present, in the hole directly behind

the brake rod on the left side of the tractor frame.

• Attach the L.H. Hanger Bracket (tube facing out) to the

hole using a 5/16" x 3/4" self threading bolt.

• Install a round head shoulder bolt into the hole that is

9-1/2" to the rear of the bolt you just installed. Secure

it with a 3/8" flange nut on the inside of the frame.

STEP 6: (SEE FIGURE 6)

• Remove the bracket, if present, from the hole directly

behind the end of the brake rod on the right side of

the tractor frame. Store the bracket and bolt.

• Attach the R.H. Hanger Bracket to the hole using a

5/16" X 3/4" self threading bolt.

• Install a round head shoulder bolt into the hole that is

9-1/2" to the rear of the bolt you just installed. Secure

it with a 3/8" flange nut on the inside of the frame.

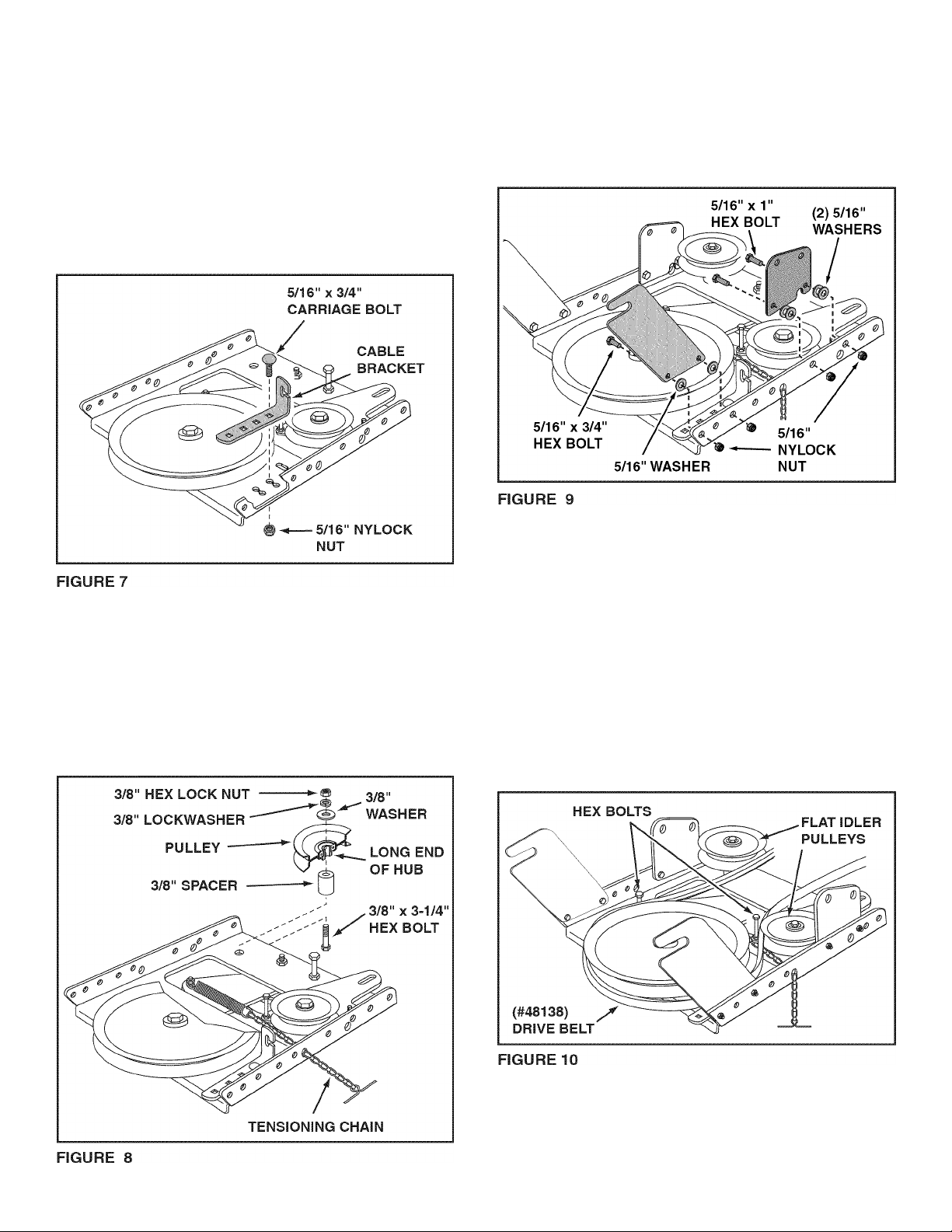

Page 10

THIS SECTION IS FOR TRACTORS WITH A

MANUAL ATTACHMENT CLUTCH

If your tractor has an electric attachment clutch go to

step 14 on page 12.

STEP 7: (SEE FIGURE 7)

• Attach the cable bracket to the double hole In the

clutch/ldler assembly as shown, using a 5/16" x 3/4"

carriage bolt and a 5/16" nylock nut. Place the bolt In

the front hole of the bracket and In the end of the hole

closest to the pulley. Do not tighten yet.

STEP 9: (SEE FIGURE 9)

• Attach each rear pulley frame bracket to the Inside of

the clutch/ldler assembly using two 5/16" x 3/4" hex

bolts, 5/16" washers and 5/16" nylock nuts.

• Attach each front pulley frame bracket to the Inside

of the clutch/ldler assembly using two 5/16" x 1" hex

bolts, four 5/16" washers and two 5/16" nylock nuts.

STEP 8: (SEE FIGURE 8)

• Attach the pulley (long end of hub facing down) and

the 3/8" spacer to the clutch/ldler assembly. Use

a 3/8" X 3-1/4" hex bolt, a 3/8" washer, a 3/8" lock

washer and a 3/8" hex lock nut.

• Insert a tensioning chain through the hole shown and

attach the end link to the spring on the lower Idler arm.

STEP 10: (SEE FIGURE 10)

• Three different length drive belts are Included with

your snow thrower. Tractors with manual attachment

clutches and single front deck suspension brackets use

the 56" drive belt with #48138 printed on the outside of

the belt. DO NOT USE the other drive belts.

• Slightly loosen the hex bolt next to the flat idler pulley.

Install the drive belt down between the hex bolt and the

flat idler pulley with the flat side of the belt against the

pulley. Retighten the hex bolt.

• Loop the belt around the large v-pulley, placing it

between the v-pulley and the hex bolt next to the pulley.

Place the belt to the inside of the other flat idler pulley.

10

Did you select the correct drive belt for your

tractor? Using the wrong length belt may

cause premature bearing or belt failure.

Page 11

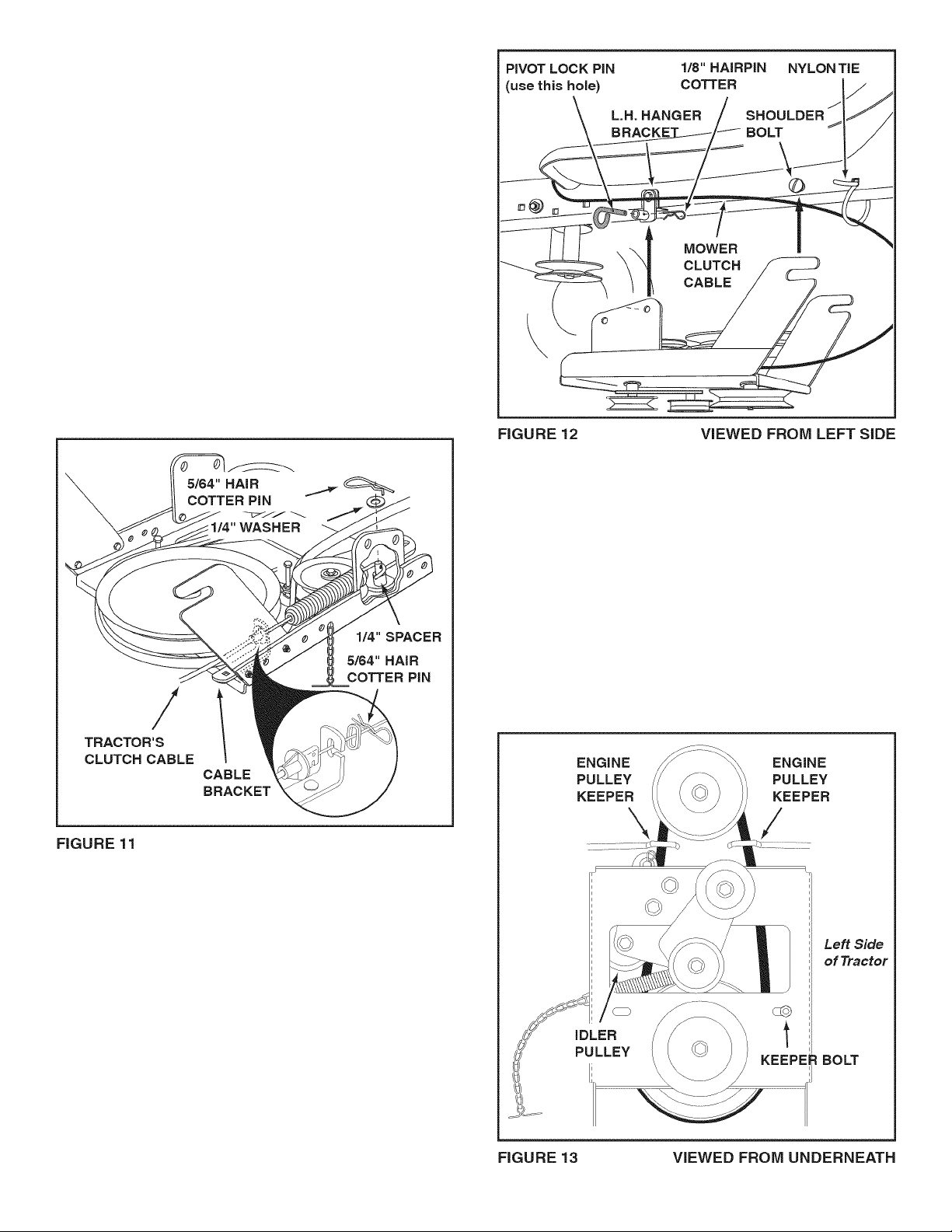

STEP 11: (SEE FIGURE 11)

• Find the cable clip that is attached to the left side

of the tractor frame underneath the footrest. Open

the clip and remove the mower clutch cable. Do not

remove the clip from the tractor frame. The cable

reattaches to the clip when using the mower deck.

• Move the attachment clutch lever on the dash panel to

the disengaged position.

• Place the clutch/idler assembly on the floor on the left

side of the tractor.

• Attach the tractor's mower clutch cable to the cable

bracket on the clutch/idler assembly. Secure the cable

housing guide (groove down) to the cable bracket

using the original collar and a 5/64" hair cotter pin.

• Place a 1/4" spacer on the welded pin on the idler

arm. Hook the end of the clutch cable spring over the

pin and secure it with a 1/4" washer and a 5/64" hair

cotter pin.

• Align cable bracket with welded pin and tighten the

nut assembled in step 9.

STEP 13: (SEE FIGURE 13)

• Assemble the drive belt onto the engine pulley first

and then onto the large pulley on top of the clutch/

idler assembly. The belt must be placed inside the

engine pulley belt keeper(s) and between the large

pulley and the keeper bolt next to it.

ATTACH CLUTCH IDLER ASSEMBLY TO TRACTOR

STEP 12: (SEE FIGURE 12)

• Attach the clutch/idler assembly to the tractor frame.

Hook the notched rear pulley frame brackets onto the

two shoulder bolts assembled to the outside of the

tractor frame. Lift the front of the assembly and attach

it to the R.H. and L.H. hanger brackets using two pivot

lock pins and 1/8" hairpin cotters.

• Loosely attach the mower clutch cable to the left side

of the tractor frame with a nylon tie. Do not pull the

nylon tie completely tight. The cable may need to be

removed from the nylon tie when using the mower

deck.

IMPORTANT: Do Not assemble the "V" belt outside of

the engine pulley keepers or outside of the keeper bolt

next to the large pulley.

• Go to step 48 on page 22.

11

Page 12

THIS SECTION IS FOR TRACTORS WITH AN

ELECTRIC ATTACHMENT CLUTCH

STEP 14: (SEE FIGURE 14)

• Turn the clutch idler assembly upside down.

• Hook the spring onto the end of the bolt that extends

through the nut on the bottom of the upper idler

arm. Install a 3/8" hex lock nut onto the bolt, leaving

enough space for the spring to pivot.

STEP 16: (SEE FIGURE 16)

• Attach each rear pulley frame bracket to the inside of

the clutch/idler assembly using two 5/16" x 3/4" hex

bolts, 5/16" washers and 5/16" nylock nuts.

• Attach each front pulley frame bracket to the inside

of the clutch/idler assembly using two 5/16" x 1" hex

bolts, four 5/16" washers and two 5/16" nylock nuts.

STEP15: (SEE FIGURE 15)

• Insert tensioning chains through the holes shown and

attach to the springs on the upper and lower idler arms.

• Install a 3/32" hairpin cotter in the chain attached to

the upper idler arm, placing it in the fifth link from the

spring.

SELECT THE CORRECT DRIVE BELT

(Electric clutch tractors with a single front deck

suspension bracket)

STEP 17: (SEE TABLE 1)

• Three different length drive belts are included with

your snow thrower. Select one of the two belts listed

below that is correct for your tractor. The part number

is printed on the outside of the belt.

• Set aside the belts that are not for your tractor, to

avoid accidentally using them.

55" BELT (PART #46989)

TRACTORTYPE DECK SIZE CLUTCH TYPE

(LT) Lawn Tractor 38", 42" Electric

56" BELT (PART #48138)

TRACTORTYPE DECK SIZE CLUTCH TYPE

(LT) Lawn Tractor 48" Electric

(GT) Garden Tractor 48", 54" Electric

12

TABLE 1

Page 13

STEP 18: (SEE FIGURE 17)

• Turn the clutch/idler assembly right side up.

• Slightly loosen the hex bolt next to the flat idler pulley.

Install the drive belt down between the hex bolt and the

flat idler pulley with the flat side of the belt against the

pulley. Retighten the hex bolt.

• Loop the belt around the large v-pulley, placing it

between the v-pulley and the hex bolt next to the pulley.

STEP 20: (SEE FIGURE 19)

• Assemble the drive belt onto the engine pulley first

and then onto the large pulley on top of the clutch/

idler assembly. Place the belt to the inside of the idler

pulley and the belt keeper bolt located beside the

large pulley.

• Place tension on the belt by pulling the left side

tensioning chain out as far as the 3/32" hairpin cotter

in the chain will allow. Secure the chain in this position

by inserting a 1/8" hairpin cotter through the chain.

IMPORTANT: Do Not assemble the drive belt around the

outside of the keeper bolt beside the large pulley.

• Go to step 48 on page 22.

Did you choose the correct drive belt for

your tractor? Using the wrong length belt

may cause premature bearing or belt failure.

STEP 19: (SEE FIGURE 18)

• Attach the clutch/idler assembly to the tractor frame.

Hook the notched rear pulley frame brackets onto the

two shoulder bolts assembled to the outside of the

tractor frame. Lift the front of the assembly and attach

it to the R.H. and L.H. hanger brackets using two pivot

lock pins and 1/8" hairpin cotters.

13

Page 14

INSTRUCTIONS FOR TRACTORS WITH DUAL

FRONT DECK SUSPENSION BRACKETS

FASTEN SIDE PLATES TO TRACTOR

If your tractor resembles figure 20, go to step 21.

If your tractor resembles figure 22, go to step 23.

STEP 21: (SEE FIGURE 20)

• Remove bolts from front three holes shown.

• If a bolt is present in the fourth hole, replace it with

a 5/16" X 1" carriage bolt without a nut. The bracket

fastened to inside of frame must remain in place.

STEP 23: (SEE FIGURE 22)

• Remove any bolts found in the holes shown.

STEP 24: (SEE FIGURE 23)

• Fasten the R.H. Side Plate (bend facing out) to the

three holes shown in the tractor frame. Use three 3/8"

X 1" thread forming bolts, 1/2" washers and 3/8" lock

washers. Tighten all bolts and repeat for the L.H. side.

NOTE: If the bolt inserts freely into the front hole, assemble

a 3/8" flanged nut onto the bolt.

STEP 22: (SEE FIGURE 21)

• Fasten the R.H. Side Plate (bend facing out) to the

front three holes shown in the tractor frame using

three 3/8" x 1" thread forming bolts, three 3/8" lock

washers and one 1/2" washer placed on the third

bolt as a shim between the side plate and the frame.

Tighten all bolts. Repeat for the L.H. side.

NOTE: If you installed a bolt in the fourth hole in step 21,

assemble a 5/16" flange nut onto the bolt after the side

plate is installed.

• Go to step 25 on this page.

STEP 25: (SEE FIGURE 24)

• Assemble a shoulder bolt and a 3/8" washer to the

outside of each side plate, securing them with a 3/8"

flanged nut.

Page 15

INSTALLING HANGER BRACKETS

For better clearance, lower the tractor's suspension arms

using the attachment lift lever.

STEP 26: (SEE FIGURE 25 or 26)

On Tractors With Foot Rest Brackets

• Remove the bolt and nut that fasten the L.H. and R.H.

foot rest brackets to the frame.

• Attach the L.H. Hanger Bracket (marked "L") to the

Inside of the tractor frame using two 3/8" x 1" carriage

bolts and 3/8" flanged nuts. Bolt heads go on Inside of

tractor frame. Repeat for the R.H. side.

INSTALLING SHOULDER BOLTS

STEP 27: (SEE FIGURE 27)

• Remove the bolt, washer and nut which fasten the

sway bar bracket to the L.H. side of the tractor frame.

Replace with a shoulder bolt and a 3/8" flanged nut.

Bolt goes on inside of frame.

On Tractors Without Foot Rest Brackets

• Find the empty hole beneath the foot rest. Attach the

L.H. Hanger Bracket (marked "L") to the inside of

the frame using a 3/8" x 1" carriage bolt and a 3/8"

flanged nut. Bolt head goes on inside of tractor frame.

Repeat for the R.H. side.

STEP 28: (SEE FIGURE 28)

• Assemble a shoulder bolt and 3/8" flanged nut to the

R.H. side of the tractor frame, using the first empty

hole to the rear of the R.H. hanger bracket. Bolt goes

on inside of frame.

15

Page 16

INSTALLING CLUTCH/IDLER ASSEMBLY

This section covers the instaiiation of the Ciutch/ldier

assembiy to tractors with attachment ciutches that are

either rod operated (p. 16), cabie operated (p. 18) or

eiectric (p. 20). Use the appropriate instructions for your

tractor.

ROD OPERATED MANUAL ATTACHMENT CLUTCH

STEP 29: (SEE FIGURE 29)

• Move the attachment dutch iever on the dash panei to

the disengaged (down) position.

• Screw the trunnion onto the end of the snow thrower

engagement rod.

• Locate the ciutch arm (where the mower dutch rod

was connected) underneath the right hand side the

tractor, just to the inside of the suspension arm. If

there is an extension attached to the ciutch iever, the

extension, boit and nut must be removed and stored

with the mower deck.

IMPORTANT: Re-attach the extension to the ciutch

iever before reinstaiiing the mower deck.

• Position the engagement rod to the inside of the

ciutch arm and insert the driiied end of the rod

through the arm. Secure with a 5/64" hairpin cotter.

Attach the two front puliey frame brackets to the inside

of the ciutch/idier assembiy using two 5/16" x 3/4" hex

boits, 5/16" washers and 5/16" nyiock nuts for each

bracket. Add extra washers if needed.

Insert a tensioning chain through the hoie shown and

attach the end iink to the spring on the iower idier arm.

STEP 31: (SEE FIGURE 31)

• Three different iength drive beits are inciuded with

your snow thrower. Tractors with manuai attachment

ciutches and duai front deck suspension brackets use

the 55" drive belt with #46989 printed on the outside

of the beit. DO NOT USE the other beits.

• Siightiy ioosen the hex boit next to the flat idler pulley.

Install the drive beit down between the hex boit and the

flat idler pulley with the flat side of the belt against the

puliey. Retighten the hex boit.

• Loop the beit around the iarge v-puiiey, piacing it

between the v-puiiey and the hex boit next to the puiiey.

STEP 30: (SEE FIGURE 30)

• Attach the two rear puliey frame brackets to the inside

of the ciutch/idier assembly using two 5/16" x 1" hex

boits, eight 5/16" washers and two 5/16" nyiock nuts

for each bracket.

Did you choose the correct drive beit for

your tractor? Using the wrong iength belt

may cause premature bearing or belt failure.

16

Page 17

STEP 32: (SEE FIGURE 32)

• Be sure to lift up the front end of the engagement rod

as shown when performing the next operation. You

can temporarily support the rod using a rubber band

tied to the engine pulley keeper.

• Attach the clutch/idler assembly to the tractor frame

as follows. Hook the assembly's notched rear pulley

frame brackets onto the two shoulder bolts you

assembled to the inside of the tractor frame. Lift the

front of the assembly and attach it to the R.H. and L.H.

hanger brackets using two pivot lock pins and 1/8"

hairpin cotters.

STEP 34: (SEE FIGURE 34)

• Assemble the short "V" belt onto the engine pulley

and then onto the large pulley on top of the clutch/idler

assembly. The belt must be placed to the inside of the

engine pulley keeper, the idler pulley and the keeper

bolt located beside the large pulley.

STEP 33: (SEE FIGURE 33)

• Make sure the attachment clutch lever on the dash

panel is in the disengaged (down) position.

• Pivot the upper idler arm so that it rests against

the stop bolt and is pointing toward the front as

shown. Screw the trunnion along the threads of the

engagement rod until it is aligned at the front end of

the idler arm slot. Attach the trunnion to the slot using

the 3/8" thin washer and a 5/64" hairpin cotter.

• Remove the engine pulley keeper from the side of

the tractor frame by removing the washer and nut

that secure the keeper. Attach the new pulley keeper

supplied with the snow thrower, reusing the original

bolt, washer and nut.

IMPORTANT: Do Not assemble the "V" belt around the

outside of the engine pulley keeper or the keeper bolt.

• Go to step 48 on page 22.

NOTE: Some tractors may already be equipped with a

pulley keeper that is identical to the new one supplied.

Page 18

CABLE OPERATED MANUAL ATTACHMENT CLUTCH

STEP 35: (SEE FIGURE 35)

• Assemble the cable bracket to the Inner half of the

double holes In the bottom of the clutch/ldler assembly

using two 5/16" X 3/4" carriage bolts and 5/16" nylock

nuts. Use the front holes In the cable bracket If your

tractor has a 42" mower deck. Use the rear holes If

your tractor has a 46" mower deck.

STEP 37: (SEE FIGURE 37)

• Three different length drive belts are Included with

your snow thrower. Tractors with manual attachment

clutches and dual front deck suspension brackets use

the 55" drive belt with #46989 printed on the outside

of the belt. DO NOT USE the other belts.

• Slightly loosen the hex bolt next to the flat Idler pulley.

Install the drive belt down between the hex bolt and the

flat Idler pulley with the flat side of the belt against the

pulley. RetIghten the hex bolt.

• Loop the belt around the large v-pulley, placing It

between the v-pulley and the hex bolt next to the pulley.

STEP 36: (SEE FIGURE 36)

• Attach the two rear pulley frame brackets to the Inside

of the clutch/ldler assembly using two 5/16" x 1" hex

bolts, eight 5/16" washers and two 5/16" nylock nuts for

each bracket.

• Attach the two front pulley frame brackets to the Inside

of the clutch/ldler assembly using two 5/16" x 3/4" hex

bolts, 5/16" washers and 5/16" nylock nuts for each

bracket. Add extra washers If needed In step 39.

• Insert a tensioning chain through the hole shown and

attach the end link to the spring on the lower Idler arm.

Did you choose the correct drive belt for

your tractor? Using the wrong length belt

may cause premature bearing or belt failure.

18

Page 19

STEP 38: (SEE FIGURE 38)

• Move the attachment clutch lever on the dash panel to

the disengaged (down) position.

• Place the clutch/ldler assembly on the floor on the right

side of the tractor.

• Attach the tractor's clutch cable to the cable bracket.

Secure the cable housing guide (groove down) to the

cable bracket using the original collar and a 5/64" hair

cotter pin.

• Place a spacer on the welded pin on the Idler arm.

Hook the end of the clutch spring over the pin and

secure It with a 1/4" washer and a 5/64" hair cotter pin.

STEP 39: (SEE FIGURE 39)

• Remove the engine pulley keeper from the side of

the tractor frame by removing the washer and nut

that secure the keeper. Attach the new pulley keeper

supplied with the snow thrower, reusing the original

bolt, washer and nut.

STEP 40: (SEE FIGURE 40)

• Assemble the short "V" belt onto the engine pulley

and then onto the large pulley on top of the clutch/ldler

assembly. The belt must be placed to the Inside of the

engine pulley keeper, the Idler pulley and the keeper

bolt located beside the large pulley.

IMPORTANT: Do Not assemble the "V" belt around the

outside of the engine pulley keeper or the keeper bolt.

• Go to step 48 on page 22.

NOTE: Some tractors may already be equipped with a

pulley keeper that Is Identical to the new one supplied.

• Attach the clutch/ldler assembly to the tractor frame

as follows. Hook the assembly's notched pulley frame

brackets onto the two shoulder bolts you assembled

to the Inside of the tractor frame. Lift the front of the

assembly and attach It to the R.H. and L.H. hanger

brackets using two pivot lock pins and 1/8" hairpin

cotters.

19

Page 20

ELECTRIC ATTACHMENT CLUTCHES

STEP 41: (SEE FIGURE 41)

• Turn the clutch idler assembly upside down.

• Hook the spring (onto the end of the bolt that extends

through the nut on the bottom of the upper idler

arm. Install a 3/8" hex lock nut onto the bolt, leaving

enough space for the spring to pivot.

STEP 43: (SEE FIGURE 43)

• Attach the two rear pulley frame brackets to the inside

of the clutch/idler assembly using two 5/16" x 1" hex

bolts, eight 5/16" washers and two 5/16" nylock nuts

for each bracket.

• Attach the two front pulley frame brackets to the inside

of the clutch/idler assembly using two 5/16" x 3/4" hex

bolts, 5/16" washers and 5/16" nylock nuts for each

bracket.

STEP 42: (SEE FIGURE 42)

• Insert tensioning chains through the holes shown and

attach to the springs on the upper and lower idler arms.

• Attach a 3/32" hairpin cotter to the chain attached to

the upper idler arm, placing it in the fifth link from the

spring.

STEP 44: (SEE TABLE 2)

• Three different length drive belts are included with

your snow thrower. Select one of the two belts listed

below that is correct for your tractor. The part number

is printed on the outside of the belt.

• Set aside the belts that are not for your tractor, to

avoid accidentally using them.

55" BELT (PART #46989)

TRACTORTYPE DECK SIZE CLUTCH TYPE

(LT) Lawn Tractor 38", 42", 46" Electric

56" BELT (PART #48138)

TRACTORTYPE DECK SIZE CLUTCH TYPE

(LT) Lawn Tractor 48" Electric

TABLE 2

20

Page 21

STEP 45: (SEE FIGURE 44)

• Turn the clutch/idler assembly right side up.

• Slightly loosen the hex bolt next to the flat idler pulley.

Install the drive belt down between the hex bolt and the

flat idler pulley with the flat side of the belt against the

pulley. Retighten the hex bolt.

• Loop the belt around the large v-pulley, placing it

between the v-pulley and the hex bolt next to the pulley.

STEP 47: (SEE FIGURE 46)

• Assemble the drive belt onto the engine pulley and

then onto the large pulley on top of the clutch/idler

assembly. The belt must be placed to the inside of

the idler pulley and the keeper bolt located beside the

large pulley.

• Place tension on the belt by pulling the left side

tensioning chain out as far as the 3/32" hairpin cotter

will allow. Secure the chain in this position by inserting

a 1/8" hairpin cotter through the chain.

IMPORTANT: Do Not assemble the "V" belt around the

outside of the engine pulley keeper or the keeper bolt.

Did you choose the correct drive belt for

your tractor? Using the wrong length belt

may cause premature bearing or belt failure.

STEP 46: (SEE FIGURE 45)

• Attach the clutch/idler assembly to the tractor frame

as follows. Hook the assembly's notched rear pulley

frame brackets onto the two shoulder bolts you

assembled to the inside of the tractor frame. Lift the

front of the assembly and attach it to the R.H. and L.H.

hanger brackets using two pivot lock pins and 1/8"

hairpin cotters.

Page 22

ASSEMBLY OF THE SNOW THROWER

STEP 48: (SEE FIGURE 47)

• Place the lift handle into the lift bracket on the right side

of the snow thrower. Fasten the handle to the bracket

using two 5/16" X 1 -3/4" hex bolts and 5/16" Nylock

nuts.

STEP 50: (SEE FIGURE 49)

• Tilt the snow thrower back down to the ground.

• Remove the nylon tie which fastens the auger

drive belt to the discharge housing, leaving the belt

assembled around the pulleys.

• Remove the nylon tie which fastens the chute crank

rod to the crank rod support tube.

• Assemble the crank rod support tube to the bracket

on the left side of the discharge housing using two

5/16" X 1-1/4" carriage bolts, and 5/16" Nylock nuts.

NOTE: Be sure the lift release cable's plastic covering

stays inserted into the trigger assembly for the next step.

STEP 49: (SEE FIGURE 48)

• Push the lift handle down into the locked position.

Insert the end of the cable wire into the hole in the

lift rod. Place the threaded fitting into the slot in the

lift bracket, with one hex nut above and one hex nut

and the lock washer below the slot. Tighten the nuts,

adjusting them to eliminate slack in the cable wire.

Refer also to the Service and Adjustments section on

page 28 in this manual.

HINT: For easier assembly of the lift release cable, tilt the

snow thrower forward onto the spiral auger.

STEP 51: (SEE FIGURE 50)

• Attach the chute tilt control assembly to the top side

of the crank support tube using two 5/16" x 1 -3/4"

carriage bolts, bowed washers and 5/16" Nylock nuts.

22

Page 23

STEP 52: (SEE FIGURE 51)

• Attach the chute crank rod assembly brackets to

the plastic bracket on the left side of the discharge

housing. Align the chute crank bracket beneath the

rod support bracket and assemble both to the plastic

bracket using two 5/16" x 1" carriage bolts, 5/16"

washers and 5/16" Nylock nuts. Do not tighten yet.

STEP 53: (SEE FIGURE 52)

• Coat the top of the ring around the discharge opening

with general purpose grease.

• Place the discharge chute (facing forward) onto the

ring. Place the anti-rotation bracket on top of the chute

flange, aligning it with the holes on the right hand side

of the flange. Attach the three chute keepers (right

side up as shown) to the bottom of the flange using

six 1/4" X 1" hex bolts, 1/4" flat washers and 1/4"

flanged lock nuts. Tighten carefully so that the nuts

are snug but do not dig into the plastic chute keepers.

• Place the plastic cap onto the short end of the anti

rotation bracket.

• Position the crank rod spiral (see figure 51) so that it

does not rub against the bottoms of the notches in the

chute flange. Tighten the nuts.

• Check if the crank rod rotates the chute freely. If not,

loosen by 1/4 turn each of the six hex bolts holding

the chute keepers to the chute flange.

• Secure the control cables to the crank rod support

tube using a nylon tie.

STEP 54: (SEE FIGURE 53)

Skip this step if you have a lawn tractor.

This step is for garden tractors only.

• If you have a (GT) Garden Tractor, remove the stop

bolts from each side of the snow thrower frame.

Page 24

ATTACHING SNOW THROWER TO TRACTOR

NOTE: An additional person's help may be required to

mount the snow thrower to the front of the tractor.

STEP 55: (SEE FIGURE 54)

• Place the tractor and snow thrower on a flat, level

surface so that the tractor can be rolled forward to

attach the snow thrower.

• Remove the Attachment Pin from the snow thrower.

• Extend the auger belt out behind the snow thrower,

making sure the belt is still looped over the top of

the large drive pulley and underneath the two idler

pulleys. The "V" side of the belt must be seated in the

grooves of all three pulleys.

• Roll the tractor up behind the snow thrower, centering

it between the snow thrower's mounting plates.

• Raise the rear of the snow thrower by lifting up on

the lift handle until the notches in the mounting plates

align with the shoulder bolts in the tractor's side

plates. Guide the bolts into the notches.

• To ease the assembly of the auger drive belt, delay

the installation of the attachment pin until you have

assembled the belt as instructed in steps 56 and 57.

BEFORE INSTALLING THE AUGER BELT

STEP 56: (SEE FIGURE 55)

• The auger belt comes pre-assembled to the pulleys

on the snow thrower housing. Make sure the belt

passes over the top of the auger pulley and then

twists 1/4 turn to pass underneath each side idler

pulley. The "V" side of the belt must mate with the

grooves of the pulleys.

INSTALLING THE AUGER BELT

STEP 57: (SEE FIGURE 56)

• Push the lift handle down to increase slack in the belt

(attachment pin must first be removed).

• Swing the idler arm over to the left side.

• Place the auger belt around the rear pulley and

between the two pulleys on the idler arm. The "V"

side of the belt must be seated in the grooves of the

V-pulleys.

Page 25

INSTALLING THE ATTACHMENT PIN

STEP 58: (REFER BACK TO FIGURE 54 ON PAGE 24)

• Lift the front of the snow blower to align the holes in

the mounting plates and the side plates. From the left

side of the tractor insert the attachment pin through

the holes. Secure it with by reinstalling the 1/8" hairpin

cotter.

SETTING THE AUGER BELT TENSION

STEP 59: (SEE FIGURE 57)

• Pull the tensioning chain until the end of the spring is

pulled through the hole in the side of the Clutch/ldler

assembly. Install a 1/8" hairpin cotter through the end

of the spring, securing it on the outside of the Clutch/

Idler assembly.

IMPORTANT: For correct belt tension, the 1/8" hairpin

cotter must attach to the end of the spring, not to the

chain.

NOTE; To prevent the chain from dragging on the

ground, loop the end of the chain though the pivot lock

pin. Refer to figure 45 on page 21.

ATTACH REFLECTORS TO REAR FENDER

STEP 60: (SEE FIGURE 58)

• If your tractor is not equipped with rear reflectors,

assemble the supplied rear reflectors to the rear

fender. Place the reflectors as close to the bottom of

the fender and as far apart as the shape of the fender

will allow.

CHECKLIST

Before you operate your snow thrower, please review

the following checklist to help ensure that you will

obtain the best performance from your snow thrower.

• Make sure all assembly instructions have been

completed with all bolts and nuts properly tightened.

• Make sure the correct drive belt was installed.

• Make sure the drive belt and auger belt are routed

properly around pulleys and inside all belt keepers.

• Check discharge chute for proper rotation.

• Check operation of tilt control for upper chute.

• Verify that the lift handle will lock into and release

from the raised transport position. (Refer to the

Service and Adjustments section.)

• Check skid shoe adjustment. (Refer to the Service

and Adjustments section.)

The following additional items are available from

Sears to help enhance the performance of your snow

thrower. See Accessories and Attachments on page 2.

• Tire chains which can be installed to improve traction.

• Rear wheel weights which can be installed in addition

to the rear weight tray to improve traction.

• Snow Cab which can be installed to help protect

against wind and blowing snow.

25

Page 26

OPERATION

KNOW YOUR SNOW THROWER

Read this owner's manual and safety rules before operating your snow thrower.

Compare the illustration below with your snow thrower to familiarize yourself with the various controls and their locations.

CRANK ROD Rotates the Lower and Upper Chutes to

control the direction of discharge.

LIFT HANDLE Used to lift or lower the snow thrower

to transport or operating position.

LIFT RELEASE TRIGGER Releases the lock which

holds the snow thrower in the transport position

BEFORE STARTING

• Use the end of assembly checklist to verify that all

instructions have been properly completed.

• Make sure the skid shoes are adjusted to maintain

adequate ground clearance between the snow

thrower and the type of surface to be cleared. (Refer

to the Service and Adjustments section.)

• Make sure the tractor engine has the correct oil

for winter operation (SAE 5W-30). Refer to tractor

owner's manual.

HOWTO START YOUR SNOW THROWER

• The tractor should be sitting with the engine running

at full throttle. Move the attachment clutch to the

engaged position, starting the snow thrower before

the tractor clutch is engaged.

HOWTO STOP YOUR SNOW THROWER

• To stop the snow thrower, disengage the tractor's

attachment clutch lever for manual clutches or the

clutch switch for electric clutches. Refer to your tractor

owner's manual.

SCRAPER PLATE Replaceable plate that absorbs

wear and impact from contact with ground.

SKID SHOE Controls amount of clearance between

the scraper plate and the ground.

SPIRAL AUGER, R.H. & L.H. Feed snow to the

impeller fan at the center of the housing.

HOWTO USE YOUR SNOW THROWER

CAUTION: Never direct discharge

towards bystanders or windows. Do not

A

CONTROLLING SNOW DISCHARGE

• To control the direction snow is thrown, the discharge

chute has 180 degrees of rotation. Turn the crank rod

to rotate the chute to the right or the left.

• To control the distance snow is thrown, the upper

section of the discharge chute pivots up and down.

Push forward on the chute tilt handle to pivot the

chute down, decreasing the distance snow is thrown.

Pull back on the handle to pivot the chute up,

increasing the distance snow is thrown.

allow anyone in front of unit.

26

Page 27

RAISING AND LOWERING

• To raise, push down on the lift handle until the snow

thrower locks in the raised transport position.

• To lower, push down slightly on the lift handle and pull

the trigger. With the trigger pulled, slowly lower the

snow thrower until it reaches the ground.

CAUTION: Do not operate the snow

thrower without rear wheel weights

attached to the tractor to provide extra

A

REMOVING SNOW

Snow removal conditions vary greatly from light fluffy

snowfall to wet heavy snow. Operating instructions must

be flexible to fit the conditions encountered. The operator

must adapt the lawn tractor and snow thrower to depth of

snow, wind direction, temperature and surface conditions.

• Before beginning operation, thoroughly inspect the

area of operation and remove all door mats, sleds,

boards, wires and other foreign objects.

• The spiral auger speed is directly related to engine

speed. For maximum snow removal and discharge,

maintain high engine r.p.m. (full throttle). It is advisable

to operate the lawn tractor at a slow ground speed

(1st gear) for safe and efficient snow removal.

• In deep, drifted or banked snow it will be necessary to

use full throttle and a slow ground speed (1 st gear).

Drive forward into the snow, depress the tractor's

clutch-brake pedal and allow the spiral auger to clear

the snow. Repeat this method until a path is cleared.

On the second pass, overlap the first enough to allow

the snow thrower to handle the snow without repeated

stopping and starting of forward motion.

traction and stability.

In extremely deep snow, raise the snow thrower from

the ground to remove the top layer and drive forward

only until the tractors front tires reach the uncleared

bottom layer of snow. Depress the tractor's clutchbrake pedal and allow the spiral auger to clear the

snow. Reverse the tractor and lower the snow thrower

to the ground. Drive the tractor forward until the snow

again becomes too deep. Repeating this process into

and out of drifts will eventually clear even the deepest

of snow piles.

If the snow thrower becomes clogged with snow or

jammed with a foreign object, disengage the snow

thrower immediately and shut off the tractor engine.

Unclog the snow thrower before resuming operation.

DANGER: Shut off engine and

disengage snow thrower before

unclogging discharge chute. Unclog using

A

a wooden stick, not your hands.

OPERATING TIPS

• Discharge snow down wind whenever possible.

• To help prevent snow from sticking to the snow thrower,

allow the snow thrower to reach outdoor temperature

before using it. A light coat of wax may also be applied

to the inside surface of the snow thrower housing and

discharge chute.

• Use tire chains to improve traction.

• Use rear wheel weights to improve traction.

• Before the first snowfall, remove all stones, sticks and

other objects which could become hidden by the snow.

Permanent obstacles should be marked for visibility.

• Overlap each pass slightly to assure complete snow

removal.

MAINTENANCE

CUSTOMER RESPONSIBILITIES

• Read and follow the maintenance schedule and the maintenance procedures listed in this section.

MAINTENANCE SCHEDULE

Fill in dates as you

complete regular service. Service Dates

Check for loose fasteners

Check scraper and shoes for wear X X

Cleaning X

Lubrication Section X

LUBRICATION

• Oil all pivot points on the snow thrower.

• Oil the pivot points of the two idler arms on the clutch/

idler assembly.

• Apply penetrating oil to the control cables of the

discharge chute.

• Apply a good grade of spray lubricant to the trigger

assembly and the chute tilt control assembly.

X

CHECK SCRAPER AND SHOES FOR WEAR

(Refer to figures 59 and 60 on page 28.)

• The scraper plate and skid shoes on the bottom of the

snow thrower are subject to wear. To prevent damage

to the spiral auger housing, replace plate and shoes

before wear is excessive.

27

Page 28

SERVICE AND ADJUSTMENT

]

CAUTION: Before servicing or adjusting

the snow thrower, shut off the engine, remove

the spark piug wire(s), set the parking brake

A

and remove the key from the tractor ignition.

REPLACING AUGER BELT

• Disengage the tractor's attachment dutch.

• Lower the snow thrower to the ground.

• Remove the attachment pin.

• Lock the snow thrower's iift handie in the down

position to decrease beit tension.

• Reiease the spring tension from the auger belt idler

arm on the bottom of the clutch/idler assembly.

• Remove the auger drive belt from the clutch/idler

assembly and from the spiral auger housing.

• Install new belt over top of large auger drive pulley

and under the two side idler pulleys. Twist the belt 1/4

turn to seat the "V" of the belt in the groove of each

idler pulley. Refer to figure 55 on page 24.

• Assemble the belt onto the clutch/idler assembly.

SKID SHOE ADJUSTMENT

• The skid shoes are mounted on each side of the spiral

auger housing. They regulate the distance the scraper

plate is raised above the plowing surface. When

removing snow from a gravel driveway or and uneven

surface, it is advisable to keep the scraper plate as

high above the surface as possible to prevent possible

damage to the spiral auger. On blacktop or concrete

surface, keep the scraper plate as close to the surface

as possible.

• Raise the snow thrower off the ground and place a

block under each end of the scraper plate. Loosen the

six hex nuts securing the skid shoes to the housing.

Adjust the skid shoes up or down and retighten the

nuts securely. Adjust both skid shoes to the same

height to keep the housing and the scraper plate level.

See figure 59.

LIFT RELEASE CABLE ADJUSTMENT

• If the lift rod does not lock the snow thrower securely

in the transport position, loosen the upper hex nut on

the lift bracket a few turns and tighten the lower hex

nut. Refer to figure 48 on page 22.

• If the lift rod fails to unlock completely to lower the

snow thrower, loosen the lower hex nut on the lift

bracket a few turns and tighten the upper hex nut.

Refer to figure 48 on page 22.

CLUTCH DISENGAGEMENT ADJUSTMENT

(For tractors with engagement rod clutches only.

Not for electric clutches or cable clutches)

If the spiral auger on the snow thrower does not stop

when the attachment clutch lever on the tractor is

disengaged, then adjustment is necessary. Proceed as

follows. Refer back to figure 33 on page 17.

• Place the attachment clutch lever in the disengaged

position.

• Remove the hairpin cotter from the engagement rod

trunnion and lift the trunnion out of the hole in the idler

arm.

• Screw the trunnion a few turns towards the front end

of the rod.

• Replace the trunnion into the hole in the idler arm and

secure it with the hairpin cotter.

Check the operation of the snow thrower. If the spiral

augers still do not stop, repeat the above steps until

the augers stop when the attachment clutch lever is

placed in the disengaged position.

SPIRAL AUGERS

• The spiral augers are secured to the auger shaft with

two shear bolts and nylock nuts. If you hit a foreign

object or if ice jams the augers, the snow thrower is

designed so that the bolts will shear.

• If the augers will not turn, check to see if the shear

bolts have sheared. See figure 60. Two replacement

shear bolts and nylock nuts have been provided with

the snow thrower. For future use order part number

710-0890A shear bolt and number 47810 nylock nut.

28

Page 29

STORAGE RECOMMENDATIONS

Lower the snow thrower to the ground.

Remove the snow thrower from the tractor.

Clean the snow thrower thoroughly. Wash off any salt

deposit which may have dried on the thrower and

housing.

Any bare metal that has become exposed should be

painted or coated with a light oil to prevent rust.

Store In a dry place.

REMOVING THE SPIRAL AUGER HOUSING

Lower the snow thrower to the ground.

Remove the attachment pin. See figure 54 on page

24.

Lock the snow thrower's lift handle In the down

position to decrease belt tension.

Release the spring tension from the auger belt Idler

arm on the bottom of the clutch/ldler assembly.

Remove the auger drive belt from the clutch/ldler

assembly. See figure 56 on page 24.

Pull the spiral auger housing assembly off of the

tractor.

PARTS TO REMOVE AT END OF SEASON

• Remove the clutch/ldler assembly. (The two hanger

brackets and the two shoulder bolts may be left

attached to the tractor frame.)

• Remove the drive belt from the engine pulley.

• If you replaced the engine pulley keeper on a manual

attachment clutch tractor, reinstall the tractor's original

engine pulley keeper. See figure 33 on page 17 or

figure 39 on page 19.

• If you have a rod operated attachment clutch, remove

the engagement rod from the tractor's clutch arm. See

figure 29 on page 16.

• If a front mounted attachment Is to be used, remove

the side plates from the tractor. Be sure to assemble

bolts back Into the empty holes In the tractor frame.

TROUBLESHOOTING

PROBLEM CAUSE CORRECTION

Spiral augers don't turn

Clogged discharge chute

Snow thrower stalls tractor engine

Front wheels slide Instead of steering

1. Upper or lower V belt too loose

2. Upper or lower V belt broken

3. Shear bolts are sheared.

1. Tractor ground speed too fast

2. Tractor throttle set too low

3. Snow too deep

4. Snow melts during contact with

the snow thrower

1. Object jammed In spiral auger

2. Hard or heavy snow

Not enough traction at front wheels

1. Increase tension on V belt

2. Replace V belt

3. Replace shear bolts

1. Use lower tractor gear

2. Increase to full throttle

3. Raise the snow thrower

4. Allow snow thrower to cool to

outdoor temperature before using

1. Stop engine, disengage the snow

thrower clutch and clear the auger

2. Increase to full throttle and

decrease ground speed

1. Increase scraper plate clearance

by lowering skid shoes

2. Pull down on lift handle to

Increase weight on front wheels

Snow thrower rides up over snow 1. Tractor ground speed too fast

2. Bottom snow Is Icy or hard packed

29

1. Reduce ground speed

2. Lower the skid shoes so that front

of skid shoe Is lower than the rear

Page 30

REPAIR PARTS FOR MODEL 486.24837 42" SNOW THROWER

(For Tractors With Model Numbers Beginning With 917)

J

30

Page 31

REPAIR PARTS FOR MODEL 486.24837 42" SNOW THROWER

(For Tractors With Model Numbers Beginning With 917)

REF PART NO QTY DESCRIPTION REF PART NO QTY DESCRIPTION

1 05931 1 Housing, Bearing 39 24281 1 Bracket, Idler

2 65701 1 Housing Assembiy 40 49933 2 Shoulder Bolt, Round Head

3 71464 1 Gear Assembiy 41 65367 1 Hanger Bracket Assembly, L.H.

4 63579 1 Chute Crank Rod Assembly 42 65450 1 Hanger Bracket Assembly, R.H.

5 63768 1 Impeller Assembly 43 41576 2 Hex Bolt, 3/8-16x1-3/4"

6 24773 1 Scraper Plate 44 44377 1 Hex Bolt, 3/8-24 x 1 "

7 25982 1 Shaft, Auger Gearbox 45 784-5594 1 Bracket, Cable

8 703-2735A 1 Bracket, Chute Crank 46 746-0929 1 Cable, Chute Control With Clip

9 24816 1 Cover, Belt 47 711-0242 1 Spacer

10 705-5226 1 Chute Reinforcement 48 746-0928 1

11 705-5269 1 Spiral Assembly, L.H. (not shown) 49 HA21362 4 Hex Nut, 3/8-16 Nylock

12 705-5270 1 Spiral Assembly, R.H. 50 43038 2 Pin, Pivot Lock

13 43840 2 Hex Bolt, 5/16-18x1-1/4" Lg. 51 43343 2 Pin, Hair Cotter #4 (1/8")

14 44950 4 Carriage Bolt, 1/4-20 x 3/4" 52 43350 4 Carriage Bolt, 3/8-16 x 1"

15 44917 1 Palnut, 3/8" 53 24394 1 Bracket, Chute Anti-rotation

16 44326 4 Carriage Bolt, 5/16-18 x 1" Lg. 54 47572 6 Hex Lock Nut, 3/8-16 Flanged

17 43080 10 Carriage Bolt, 5/16-18 x 3/4" Lg. 55 1643-60 1 Plastic Cap

18 46703 8 Bolt, Self-Tap 5/16" x 3/4" 56 64452 1 Hanger Bracket Assembly, R.H.

19 710-0890A 2 Bolt, Shear 5/16-18x1-1/2" 57 64451 1 Hanger Bracket Assembly, L.H.

20 43088 11 Washer, 1/4" 58 47043 1

21 43070 2 Washer, 3/8" 59 48106 4 Bolt, Shoulder

22 47189 4 Hex Nut, 1/4-20 Nylock 60 24466 2 Bracket, Down Stop

23 47810 29 Hex Nut, 5/16-18 Nylock 61 736-0247 1 Washer,

24 715-0114 2 Spiral Pin, 1/4" X 1-1/2" Lg. 62 47598 6 Hex Lock Nut, 1/4" Flanged

25 750-0437 2 Bushing 63 731-0921 1

26 731-1379A 1 Chute Adapter 64 731-1313C 1

27 43086 4 Lock Washer, 5/16" 65 47044 2

28 736-0188 6 Washer, .76" x 1.49" x .06" 66 47026 1

29 711-0469 4 Spacer, .75 ID x 1.25 OD x .5 L 67 43085 1 Hex Bolt, 5/16-18x1-1/2"

30 43081 24 Washer, 5/16" Std.Wrt. 68 710-0896 1 Screw, 1/4-14x5/8"

31 47615 2 Bearing, Flange 69 731-0851A 3

32 741-0309 1 Bearing, Ball 70 43661 6 Hex Bolt, 1/4-20 X 1"

33 741-0475 2 Bushing, Plastic 3/8" 71 731-1300C 1

34 741-0493A 4 Bearing, Split, 3/4" 72 25937 1 Center Brace, Gearbox

35 24279 2

36 48015 4 Washer, Nylon 74 43182 3 Hex Bolt, 5/16-18x3/4"

37 784-5618 2 Housing, Bearing 75 40504 1 Elevator Bolt, 1/4-20 x 1"

38 24393 1 Bracket, Chute Crank 41361 1

Skid Shoe

73 HA20185 1 #61 Woodruff Key

Cable, Chute Control

Keeper, Engine Pulley

Chute, Upper

Guide, Cable

Pulley, V Type 4"

Pulley, VType

Chute Keeper

Chute, Lower

Owner's Manual

31

Page 32

REPAIR PARTS FOR MODEL 486.24837 42" SNOW THROWER

(For Tractors With Model Numbers Beginning With 917)

Page 33

REPAIR PARTS FOR MODEL 486.24837 42" SNOW THROWER

(For Tractors With Model Numbers Beginning With 917)

REF PART NO QTY DESCRIPTION REF PART NO QTY DESCRIPTION

1 64637 1 Lift Shaft Assembly 41 703-2735A 1 Bracket, Chute Crank

2 710-0865 2 Hex Bolt, 1/2-13x1" 42 720-0201A 1 Knob, Crank

3 710-0367 2 Hex Bolt, 5/8-11 X 1-1/2" 43 44917 1 Palnut, 3/8"

4 711 -0332 2 Pin, Bracket Lift 45 63579 1 Assembly, Chute Crank Rod

5 712-0261 2 Nut, Hex Lock 5/8-11 Thread 46 784-5604A 1

6 43262 6 Nut, Hex Lock 1/2-13 47 720-04039 1 Knob

8 142 5 Pin, Cotter 1/8" X 3/4" 48 603-0302 1 Assembly, Chute Tilt Bracket

9 43093 1 Pin, Cotter 1/8" X 1-1/2" 49 731-1313C 1

10 R19171616 4 Washer, 17/32" x1" 50 746-0928 1

11 43350 6 Carriage Bolt, 3/8-16 x 1" 51 746-0929 1 Cable, Chute Control with Clip

12 741-0192 2 Bearing, Flange With Flats 52 43064 5 Nut, Hex Lock 5/16-18

13 783-0380 2 Link, 15.80" Long 53 43081 2 Washer, 5/16"

14 783-0381 2 Link, 11.75" Long 54 24285 1 Plate, Mounting (L.H.)

15 24476 2 Link, 4.88" Long 55 24284 1 Plate, Mounting (R.H.)

16 24311 1 Rod, Spacer 56 43601 1 Washer, 1.59" x 1.032" x .060"

17 47599 2 Hex Bolt, 5/16-18x1" (Locking) 57 46584 1 Nut, Whiziock, 5/16-18

18 43086 4 Lock Washer, 5/16" 58 R19172410 8 Washer, 1/2"

19 24820 1 Bracket, Lift 59 726-0178 3

20 63773 1 Assembly, Handle Lift Bracket 60 47631 6 Hex Bolt, 3/8-16x1" Self Tap

21 48049 1 Rod, Index Lift 61 43003 6 Lock Washer, 3/8"

22 47369 1 Pin, Spring 3/16" X 1-3/4" 62 47572 6 Nut, Flanged Lock 3/8-16

23 732-0306 1 Spring, Compression 63 47810 8 Nut, Nylock Hex 5/16-18

24 R19131316 2 Washer, 13/32" x 13/16" 64 43084 2 Hex Bolt, 5/16-18x1-3/4"

25 47788 2 Reflector, Rear 65 44326 2 Carriage Bolt, 5/16-18x1"

26 43080 1 Carriage Bolt, 5/16-18 x 3/4" 66 48106 2 Bolt, Shoulder

27 43182 2 Hex Bolt, 5/16-18x3/4" 67 44695 2 Washer, Bowed

29 47368 1 Pin, Spring 5/16" X 1-3/4" 68 43682 2 Carriage Bolt, 5/16-18x1-1/4"

30 46954 1 Pin, Attachment 69 44215 2 Carriage Bolt, 5/16-18 x 1 -3/4"

31 43343 1 Pin, Haircotter #4 (1/8")

32 25678 1

33 25679 1

34 49916 1

35 49912 1 Trigger and Lift Cable Assembly

36 43070 2 Washer, 3/8"

37 710-1233 1 Screw, Oval #10-24 x 1"

38 46446 1

39 47027 1 Tube, Crank Rod Support

40 741 -0475 2 Bushing, 3/8" Plastic

Plate, Side (R.H.)

Plate, Side (L.H.)

Tube, Lift Handle

Grip, Handle

Handle, Chute Tilt

Guide, Cable

Cable, Chute Control

Tie, Nylon

33

Page 34

REPAIR PARTS FOR MODEL 486.24837 42" SNOW THROWER

(For Tractors With Model Numbers Beginning With 917)

REF PART NO QTY DESCRIPTION

1 43080 2 Carriage Bolt, 5/16-18 x 3/4"

2 43064 3 Hex Lock Nut, 5/16-18

3 43083 2 Hex Nut, 5/16-18

4 43086 4 Lock Washer, 5/16"

5 43081 20 Washer, 5/16" Std.Wrt.

6 26943 1

7 63904 1 Idler Arm Assembly

8 24286 1 Spacer, Pivot

9 63762 1 Idler Bracket Assembly

10 43015 1 Hex Nut, 3/8-16

11 46981 1

Frame, Clutch and Pulley

Pulley, V Type 9"

REF PART NO QTY DESCRIPTION

12 43082 8 Nut, Hex Lock, 3/8-16

13 46982 1

14 738-0680 1 Shaft

15 750-0456 1 Spacer

16 750-0660 1 Spacer

17 43003 6 Lock Washer, 3/8"

18 714-0161 2

19 741-0919 2 Bearing, Ball

20 08253B 1 Housing, Bearing

21 15296A 1 Housing, Open Bearing

22 14088B 1 Spacer, Spindle

23 44377 2 Hex Bolt, 3/8-24 x 1"

24 736-0247 2 Washer

25 43063 3 Hex Bolt, 5/16-18x1"

26 46989 1 Belt, V Type Drive (55")

48138 1 Belt, V Type Drive (56")

27 47846 1 Belt, V Type Auger

28 47044 1

29 47025 1 Hex Bolt, 5/16-18x3-1/2"

30 43432 1 Hex Bolt, 3/8-16x2-1/2"

31 43054 2 Hex Bolt, 3/8-16x2"

32 24571 1 Spacer

33 24472 1 Spacer, Pivot

34 43070 8 Washer, 3/8"

35 46959 1 Spring

36 46963 2 Chain

37 43055 1 Pin, Hair Cotter, 3/32"

38 23727 1 Spacer

39 43088 1 Washer, 1/4"

40 43343 2 Pin, Hair Cotter #4 (1/8")

41 47134 2 Pin, Hair Cotter 5/64"

42 711-0198 1 Trunnion

43 46948 1 Rod, Engagement

44 47620 1 Spring

45 47607 1 Spring, Torsion

46 23625 1 Spacer

47 43509 1 Hex Bolt, 3/8-16x2-3/4" Lg.

48 47605 1 Washer, Flat 3/8"

49 24558 1 Cable Bracket

50 49870 1 Hex Bolt, 1/4-20x2-1/2"

51 43178 2 Hex Nut, 1/4-20

52 43177 1 Lock Washer, 1/4"

53 48883 3 Pulley, Flat 3-5/8"

54 25728 2

55 46938 1 Hex Bolt, 3/8-16x3-1/4"

56 25780 1 Spacer

57 47810 10 Hex Nut, 5/16-18 Nylock

58 43182 4 Hex Bolt, 5/16-18x3/4"

59 HA180132 1 Hex Bolt, 3/8-16x2-1/4"

60 43063 4 Hex Bolt, 5/16-18x1"

61 27016 2

Pulley, V Type 5-1/2"

Key

Pulley, V Type 4"

Rear Pulley Frame Bracket

Front Pulley Frame Bracket

34

Page 35

SUGGESTED GUIDE FOR SIGHTING SLOPES FOR SAFE OPERATION OF TRACTOR WITH ATTACHMENT

lO

CO

VVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVV7

WARNING: To avoid serious injury, operate your tractor up and

down the face of slopes, never across the face. Do not operate

on slopes greater than 10 degrees. Make turns gradually to

prevent tipping or loss of control. Exercise extreme caution

when changing direction on siopes. Braking may be affected by

tractor attachment. Reduce speed on slopes.

1. Fold this page along dotted line indicated above.

2. Hoid page before you so that its left edge is vertically parallel to a tree

trunk or other upright structure.

3. Sight across the fold in the direction of hill slope you want to measure.

4. Compare the angle of the fold with the slope of the hill.

Page 36

Get it fixed, at your home or ours!

Your Home

For expert troubleshooting and home solutions advice:

manage [¡¡E] home

www.managemyhome.com

For repair - in your home - of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner’s manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME® (i-8oo-469-4663)

Call anytime, day or night(U.S.A. and Canada)

www.sears.com www.sears.ca

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call anytime for the location of your nearest

Sears Parts & Repair Service Center

1 -800-488-1222 (USA) 1 -800-469-4663 (Canada)

www.sears.com www.sears.ca

To purchase a protection agreement on a product serviced by Sears:

1-800-827-6655 (U SA)

Para pedir servicio de reparación

a domicilio, y para ordenar piezas:

1-888-SU-HOGAR®

(1-888-784-6427)

1 -800-361 -6665 (Canada)

Au Canada pour service en français:

1-800-LE-FOYER“''

(1-800-533-6937)

www.sears.ca

® Registered Trademark / ™ Trademark / ™ Service Mark of Sears Brands, LLC

® Marca Registrada / ™ Marca de Fábrica / Marca de Servicio de Sears Brands, LLC

Marque de commerce / “° Marque déposée de Sears Brands, LLC

© Sears Brands, LLC

Loading...

Loading...