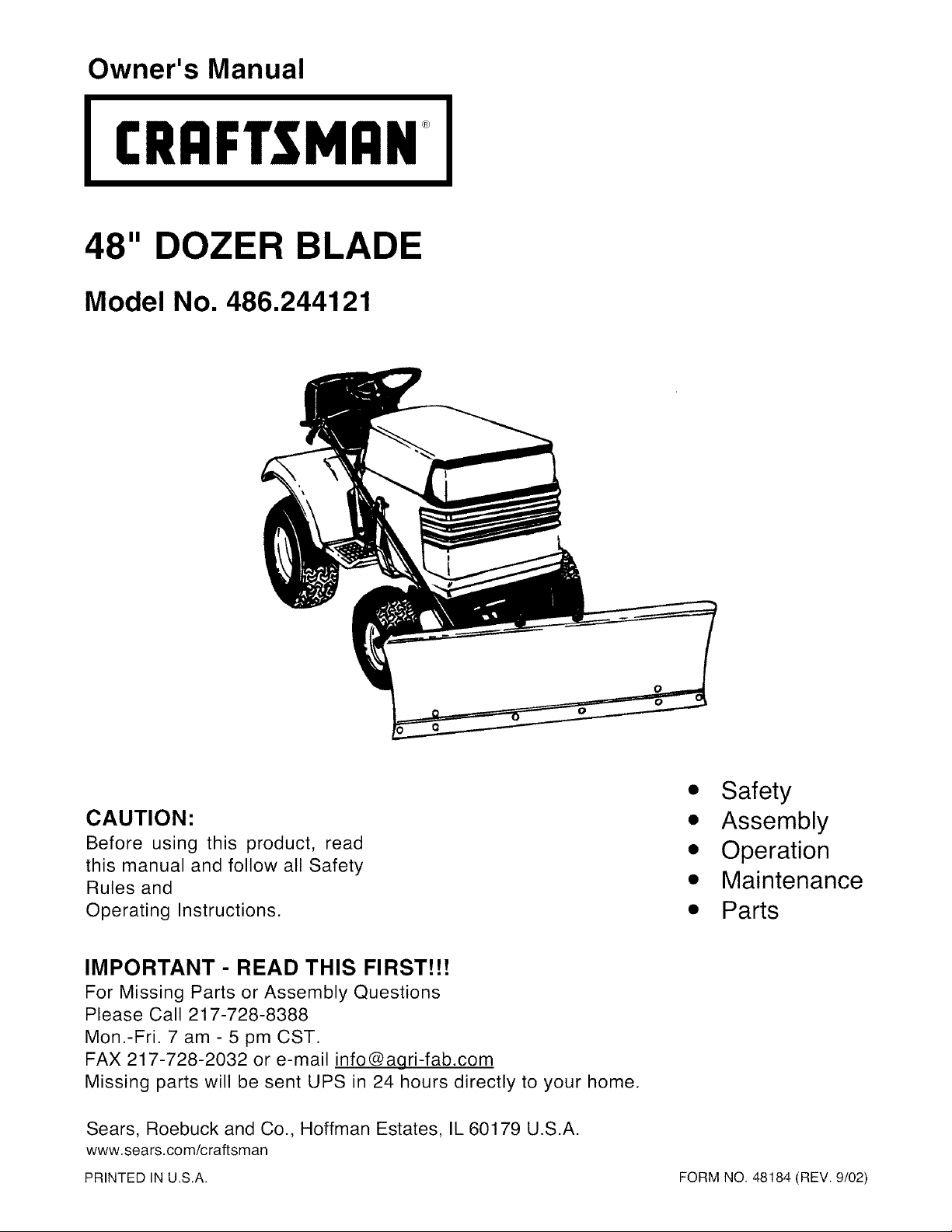

Craftsman 486244121 Owner’s Manual

Owner's Manual

CRAFTSMAN+

48" DOZER BLADE

Model No. 486.244121

• Safety

CAUTION:

Before using this product, read

this manual and follow all Safety

Rules and

Operating Instructions.

IMPORTANT - READ THIS FIRST!!!

For Missing Parts or Assembly Questions

Please Call 217-728-8388

Mon.-Fri. 7 am - 5 pm CST.

FAX 217-728-2032 or e-mail info@agri-fab.com

Missing parts will be sent UPS in 24 hours directly to your home.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www.sears.com/craftsman

PRINTED IN U.S.A. FORM NO. 48184 (REV. 9/02)

• Assembly

• Operation

• Maintenance

• Parts

SAFETY

Any power equipment can cause injury if operated improperly or if the user does not understand how to operate the

equipment. Exercise caution at all times, when using power equipment.

1. Read the tractor and dozer blade owners manuals and know how to operate your tractor before using the tractor with

the dozer blade attachment.

2. Never operate the tractor and dozer blade without wearing proper clothing suited to weather conditions and

operation of controls.

3. Never allow children to operate the tractor and dozer blade. Do not allow adults to operate without proper instructions.

4. Always begin with transmission in first (low) gear and gradually increase speed as required.

Look for this symbol to point out important safety precautions. It mean--Attention!!

Become alert!! Your safety is involved.

LIMITED ONE YEAR WARRANTY ON 48" DOZER BLADE

For one year from the date of purchase, when this Dozer Blade is maintained and lubricated according to the

operating and maintenance instructions in the owner's manual, Sears will repair any defect in material or

workmanship free of charge. If this Dozer Blade is used for commercial or rental purposes, this warranty applies for

only 90 days from the date of purchase.

This warranty does not cover repairs necessary because of operator negligence or abuse, including the failure to

maintain the equipment according to instructions contained in the owner's manual.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER/DEPART-

MENT IN THE UNITED STATES.

This warranty applies only while this product is in the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co. D/817 WA. Hoffman Estates, Chicago, IL 60179

7

14

11

/

12

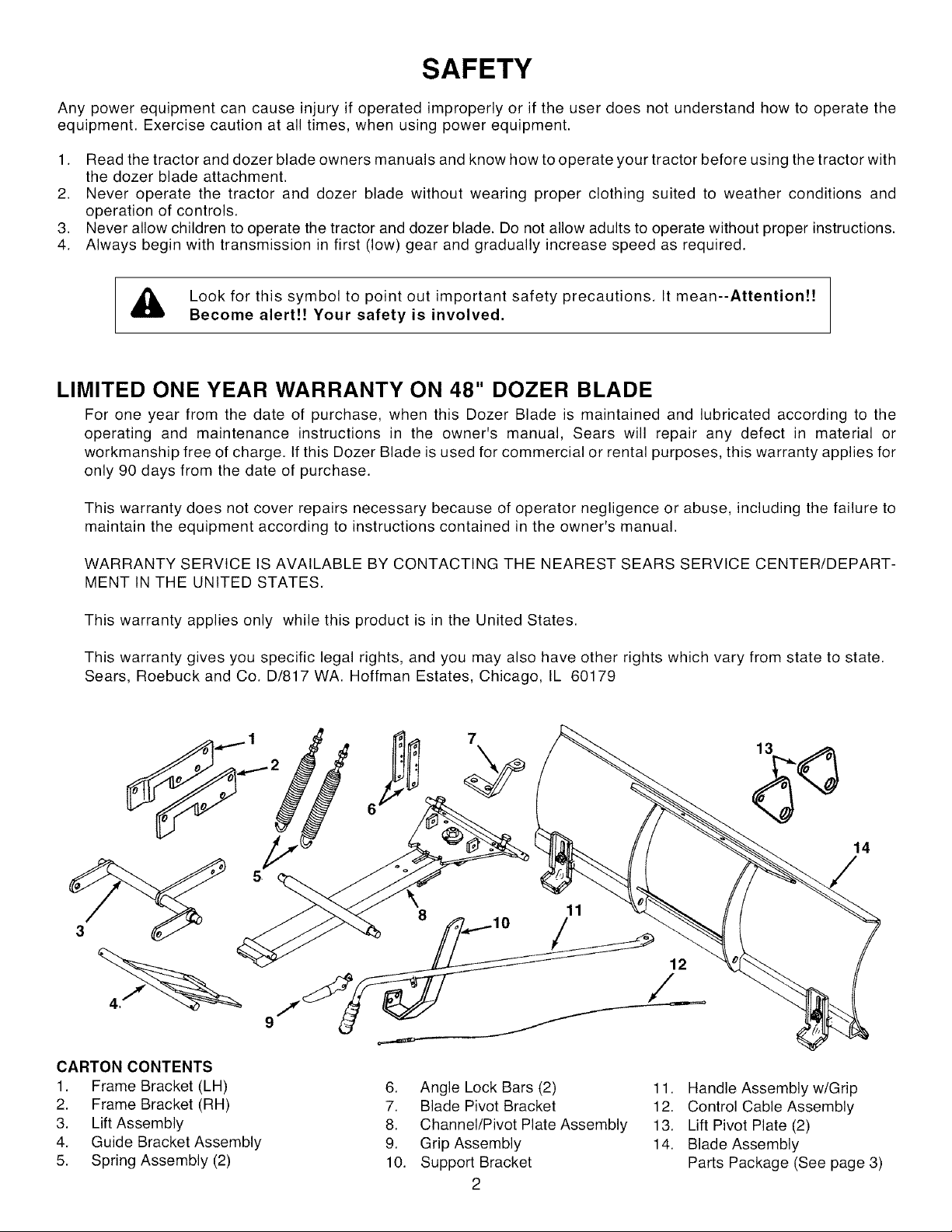

CARTON CONTENTS

1. Frame Bracket (LH)

2. Frame Bracket (RH)

3. Lift Assembly

4. Guide Bracket Assembly

5. Spring Assembly (2)

6. Angle Lock Bars (2)

7. Blade Pivot Bracket

8. Channel/Pivot Plate Assembly

9. Grip Assembly

10. Support Bracket

2

11. Handle Assembly w/Grip

12. Control Cable Assembly

13. Lift Pivot Plate (2)

14. Blade Assembly

Parts Package (See page 3)

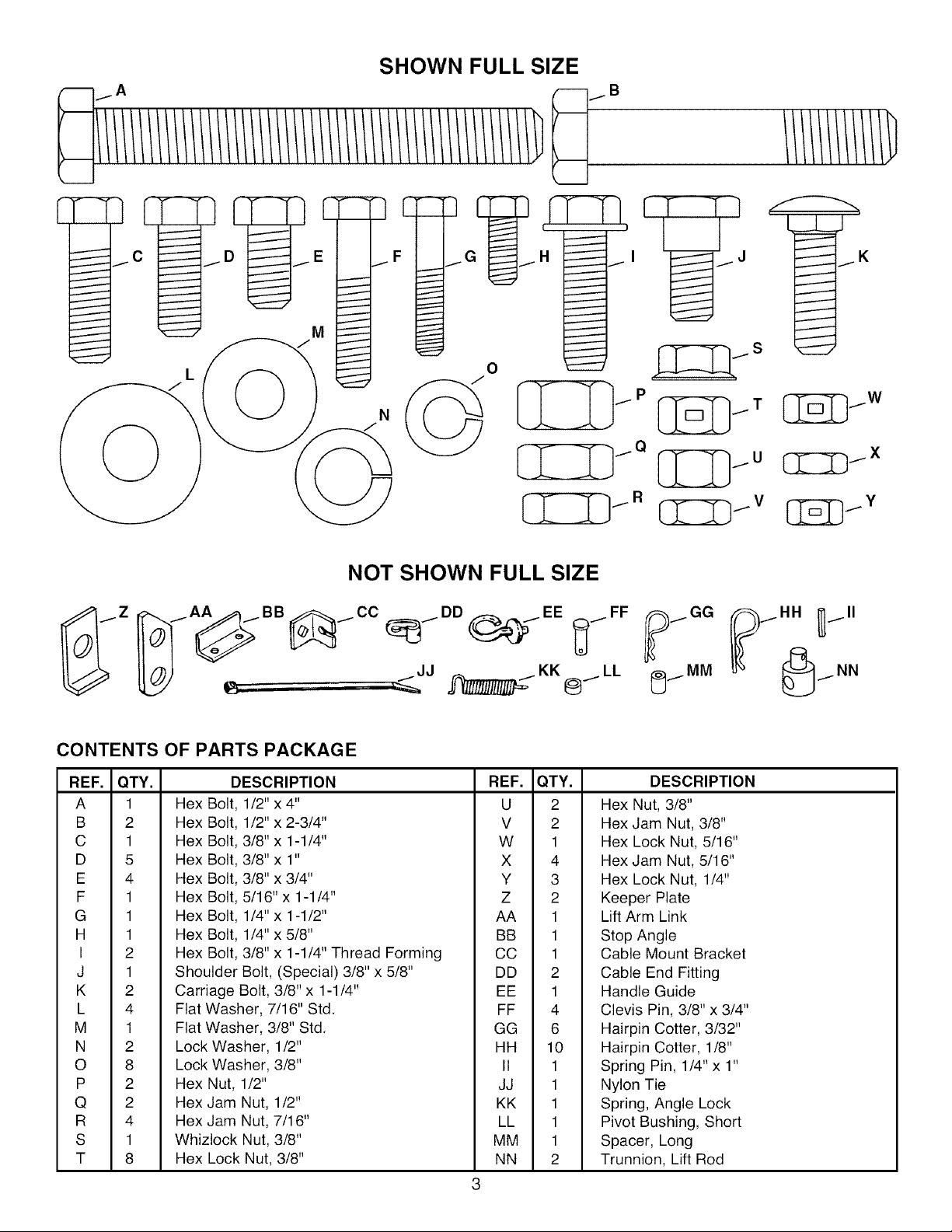

SHOWN FULL SIZE

;===.*..,.,=_

t

I

I

I

M

I

N

C[ZD Ix

CONTENTS OF PARTS PACKAGE

REF. QTY.

A 1

B 2

C 1

D 5

E 4

F 1

G 1

H 1

I 2

J 1

K 2

L 4

M 1

N 2

O 8

P 2

Q 2

R 4

S 1

T 8

Hex Bolt, 1/2" x 4" U 2

Hex Bolt, 1/2" x 2-3/4" V 2

Hex Bolt, 3/8" x 1-1/4" W 1

Hex Bolt, 3/8" x 1" X 4

Hex Bolt, 3/8" x 3/4" Y 3

Hex Bolt, 5/16" x 1-1/4" Z 2

Hex Bolt, 1/4" x 1-1/2" AA 1

Hex Bolt, 1/4" x 5/8" BB 1

Hex Bolt, 3/8" x 1-1/4" Thread Forming CC 1

Shoulder Bolt, (Special) 3/8" x 5/8" DD 2

Carriage Bolt, 3/8" x 1-1/4"

Flat Washer, 7/16" Std.

Flat Washer, 3/8" Std.

Lock Washer, 1/2"

Lock Washer, 3/8"

Hex Nut, 1/2"

Hex Jam Nut, 1/2"

Hex Jam Nut, 7/16"

Whizlock Nut, 3/8"

Hex Lock Nut, 3/8"

DESCRIPTION REF. QTY.

NOT SHOWN FULL SIZE

EE 1

FF 4

GG 6

HH 10

II 1

JJ 1

KK 1

LL 1

MM 1

NN 2

DESCRIPTION

Hex Nut, 3/8"

Hex Jam Nut, 3/8"

Hex Lock Nut, 5/16"

Hex Jam Nut, 5/16"

Hex Lock Nut, 1/4"

Keeper Plate

Lift Arm Link

Stop Angle

Cable Mount Bracket

Cable End Fitting

Handle Guide

Clevis Pin, 3/8" x 3/4"

Hairpin Cotter, 3/32"

Hairpin Cotter, 1/8"

Spring Pin, 1/4" x 1"

Nylon Tie

Spring, Angle Lock

Pivot Bushing, Short

Spacer, Long

Trunnion, Lift Rod

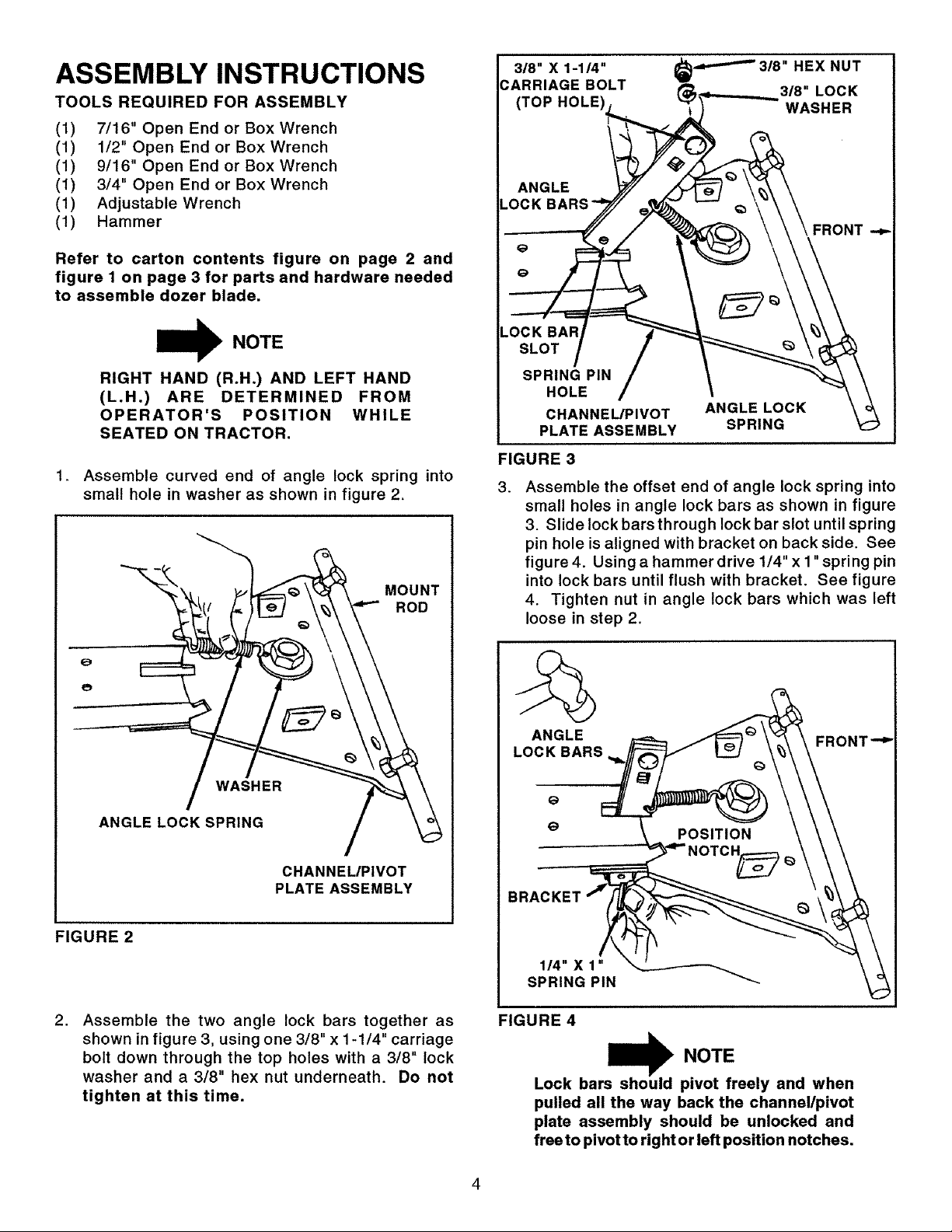

ASSEMBLY INSTRUCTIONS

TOOLS REQUIRED FOR ASSEMBLY

(1) 7/16" Open End or Box Wrench

(1) 1/2" Open End or Box Wrench

(1) 9/16" Open End or Box Wrench

(1) 3/4" Open End or Box Wrench

(1) Adjustable Wrench

(1) Hammer

Refer to carton contents figure on page 2 and

figure I on page 3 for parts and hardware needed

to assemble dozer blade.

3/8" X 1-114"

DARRIAGE BOLT

(TOP HOLE

ANGLE

LOCK BARS

_,_.--''_3_"HEX NUT

(_ 3/8"LOCK

WASHER

NOTE

RIGHT HAND (R.H.) AND LEFT HAND

(L.H.) ARE DETERMINED FROM

OPERATOR'S POSITION WHILE

SEATED ON TRACTOR.

.

Assemble curved end of angle lock spring into

small hole in washer as shown in figure 2.

.OCK BAR

SLOT

SPRING PIN

HOLE

CHANNEL/PIVOT

PLATE ASSEMBLY

FIGURE 3

.

Assemble the offset end of angle lock spring into

small holes in angle lock bars as shown in figure

3. Slide lock bars through lock bar slot until spring

pin hole is aligned with bracket on back side. See

figure 4. Using a hammer drive 1/4" x 1"spring pin

T

into lock bars until flush with bracket. See figure

4. Tighten nut in angle lock bars which was left

loose in step 2.

ANGLE LOCK

SPRING

/

ANGLELOCKSPR,NG /

CHANNEL/PIVOT

PLATE ASSEMBLY

FIGURE 2

,

Assemble the two angle lock bars together as

shown in figure 3, using one 3/8" x 1-1/4" carriage

bolt down through the top holes with a 3/8" lock

washer and a 3/8" hex nut underneath. Do not

tighten at this time.

FIGURE 4

rs_ NOTE

Lock ba pivot freely and when

pulled all the way back the channel/pivot

plate assembly should be unlocked and

free to pivot to right or left position notches.

4,

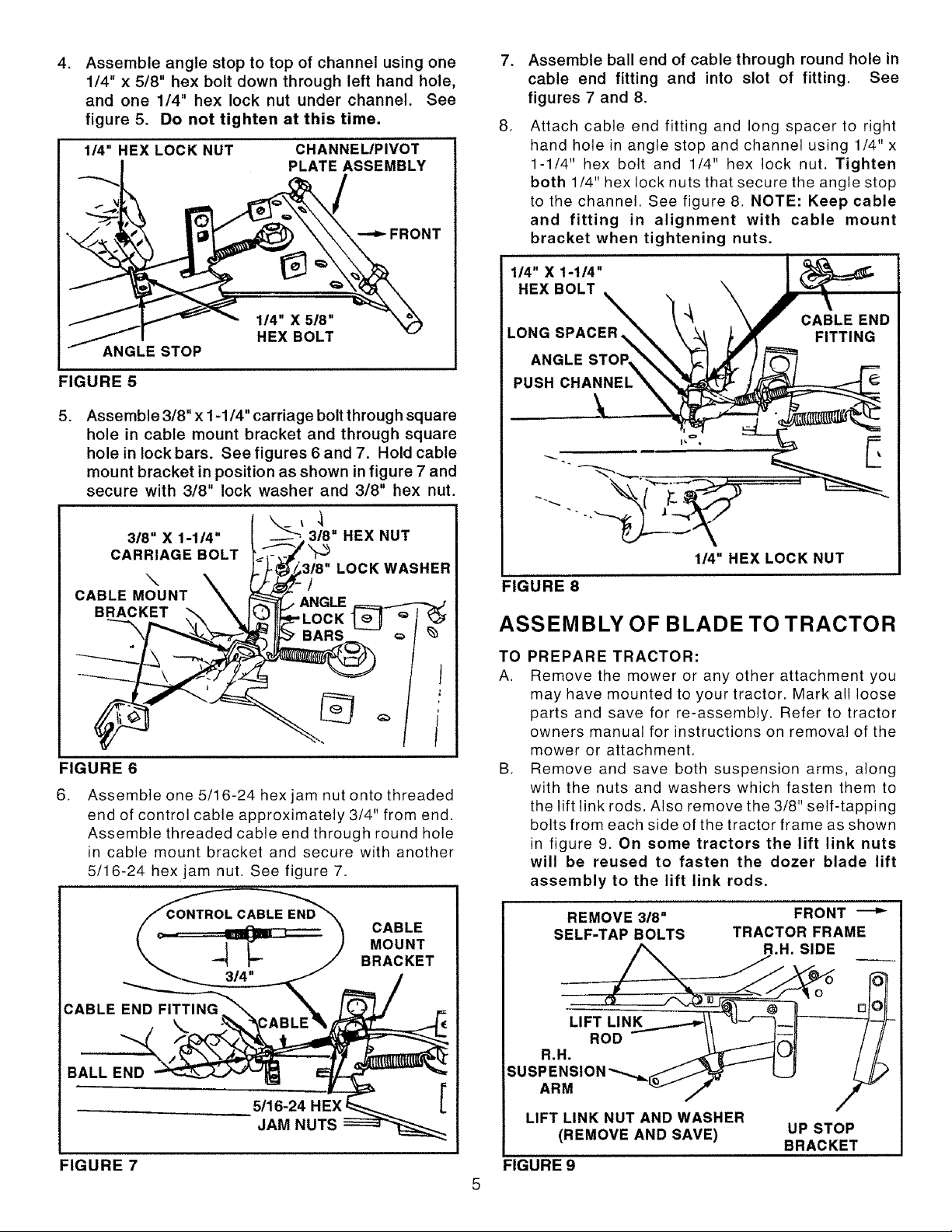

Assemble angle stop to top of channel using one

1/4" x 5/8" hex bolt down through left hand hole,

and one 1/4" hex lock nut under channel. See

figure 5. Do not tighten at this time.

114" HEX LOCK NUT

CHANNEUPIVOT

PLATE ASSEMBLY

FRONT

7,

Assemble ball end of cable through round hole in

cable end fitting and into slot of fitting. See

figures 7 and 8.

.

Attach cable end fitting and long spacer to right

hand hole in angle stop and channel using 1/4" x

1-1/4" hex bolt and 1/4" hex lock nut. Tighten

both 1/4" hex lock nuts that secure the angle stop

to the channel. See figure 8. NOTE: Keep cable

and fitting in alignment with cable mount

bracket when tightening nuts.

1/4" X 1-1/4"

HEX BOLT

1/4" X 518"

HEX BOLT

ANGLE STOP

FIGURE 5

.

Assemble 3/8" x 1-1/4" carriage bolt through square

hole in cable mount bracket and through square

hole in lock bars. See figures 6 and 7. Hold cable

mount bracket in position as shown in figure 7 and

secure with 3/8" lock washer and 3/8" hex nut.

,1

3/8" X 1-114" 3/8" HEX NUT

CARRIAGE BOLT

\ /

CABLE MOUNT ANGLE

BRACKET

FIGURE 6

6. Assemble one 5/16-24 hexjam nut onto threaded

end of control cable approximately 3/4" from end.

Assemble threaded cable end through round hole

in cable mount bracket and secure with another

5/16-24 hex jam nut. See figure 7.

LOCK WASHER

CABLE END

LONG SPACER%

ANGLE

PUSH CHANNEL

FITTING

-'% _

1/4" HEX LOCK NUT

FIGURE 8

ASSEMBLY OF BLADE TO TRACTOR

TO PREPARE TRACTOR:

A. Remove the mower or any other attachment you

may have mounted to your tractor. Mark all loose

parts and save for re-assembly. Refer to tractor

owners manual for instructions on removal of the

mower or attachment.

B. Remove and save both suspension arms, along

with the nuts and washers which fasten them to

the lift link rods. Also remove the 3/8" self-tapping

bolts from each side of the tractor frame as shown

in figure 9. On some tractors the lift link nuts

will be reused to fasten the dozer blade lift

assembly to the lift link rods.

BALL E__ _

5/16"24 HE _ [

JAM NUTS _

FIGURE 7

CABLE

MOUNT

J BRACKET

REMOVE 3/8"

SELF-TAP BOLTS

TRACTOR FRAME

FRONT

R.H. SIDE

ARM

'

LIFT LINK NUT AND WASHER

(REMOVE AND SAVE)

FIGURE 9

UP STOP

BRACKET

Loading...

Loading...