Craftsman 486244031 Owner’s Manual

owners

manual

Model No.

486.244031

42"

SNOW BLADE

CAUTION:

Read Rules for

Safe Operation

and Instructions

Carefully

42'" SNOW BLADE

Use this manual for all 502 series tractors

EXCEPT those listed here:

502.25426, 502.25428,

502.25469, 502.25928

For these models use

486.244090 snow blade.

• Assembly

• Operation

• Customer Responsibilities

• Repair Parts

Sears, Roebuck and Co., Chicago, Ill. 60684 U.S.A.

502.25429,

manual for

PRINTED IN U.S.A,

RULES FOR SAFE OPERATIONS

Any power equipment can cause injury if operated improperly or if the user does not understand how to operate

the equipment.

LOOK FOR THIS SYMBOL TO POINT OUT

IMPORTANT SAFETY PRECAUTIONS. IT

MEANS ,. ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED.

Exercise caution at all times, when using power equipment.

1. Read the tractor and snow blade owners manuals and know how to operate your tractor, before using tractor

with snow blade attachment.

2. Never operate tractor and snow blade without wearing proper clothing suited to weather conditions and

operation of controls.

3. Never allow children to operate tractor and snow blade, and do not allow adults to operate without proper

instructions.

4. Always begin with transmission in first (tow) gear and gradually increase speed as required.

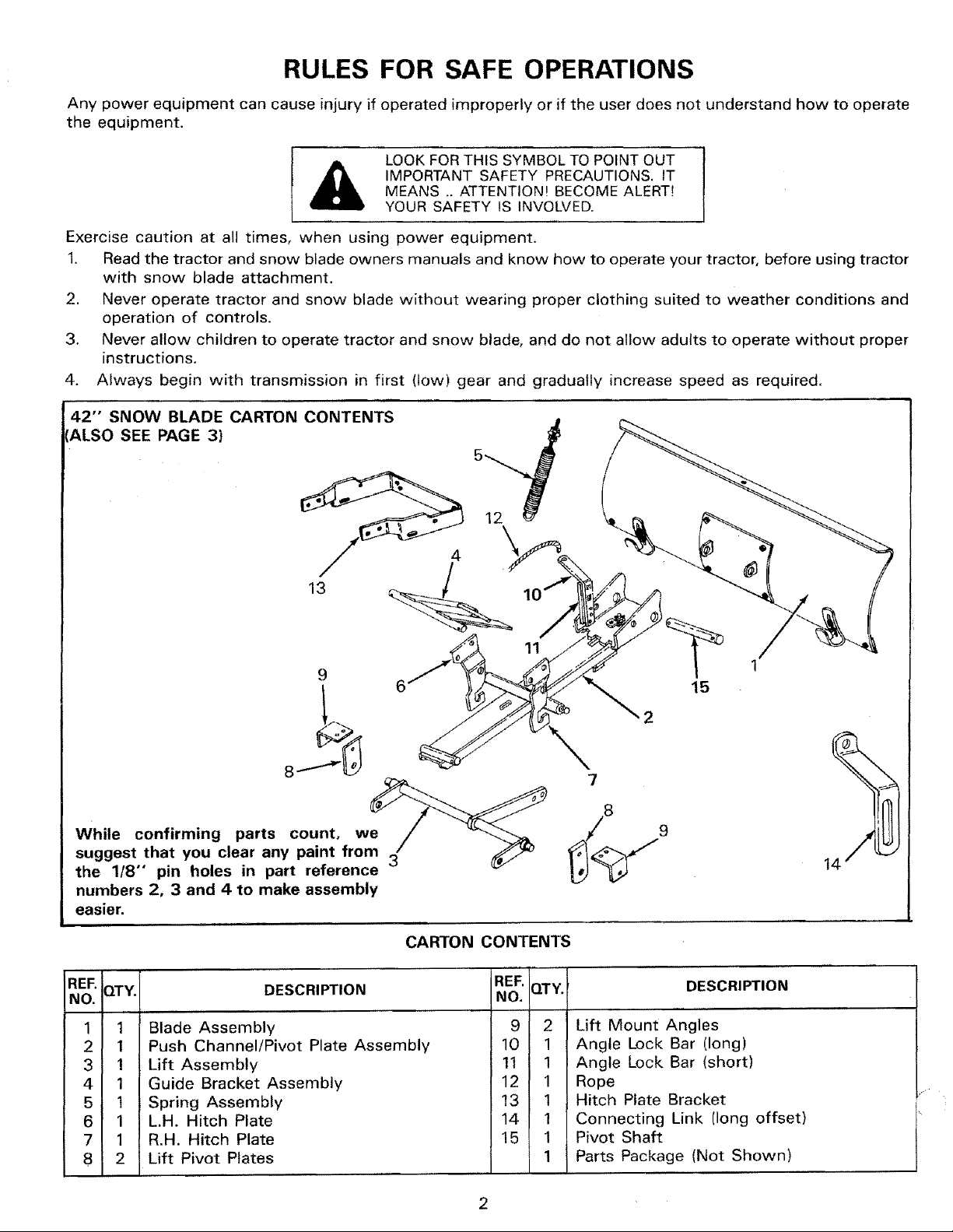

42" SNOW BLADE CARTON CONTENTS

ALSO SEE PAGE 3)

12

13

While confirming parts count, we

suggest that you clear any paint from

the 1/8" pin holes in part reference

numbers 2, 3 and 4 to make assembly

easier.

REE QTY.

NO.

1 1

2 1

3 1

4 1

5 1

6 1

7 1

8 2

Blade Assembly

Push Channel/Pivot Plate Assembly

Lift Assembly

Guide Bracket Assembly

Spring Assembly

L.H. Hitch Plate

R.H. Hitch Plate

Lift Pivot Plates

DESCRIPTION

CARTON CONTENTS

REF. QTY. DESCRIPTION

NO.

9 2 Lift Mount Angles

10 1 Angle Lock Bar (long)

11 1 Angle Lock Bar (short)

12 1 Rope

13 1 Hitch Plate Bracket

14 1 Connecting Link [long offset)

15 1 Pivot Shaft

1 Parts Package (Not Shown)

15

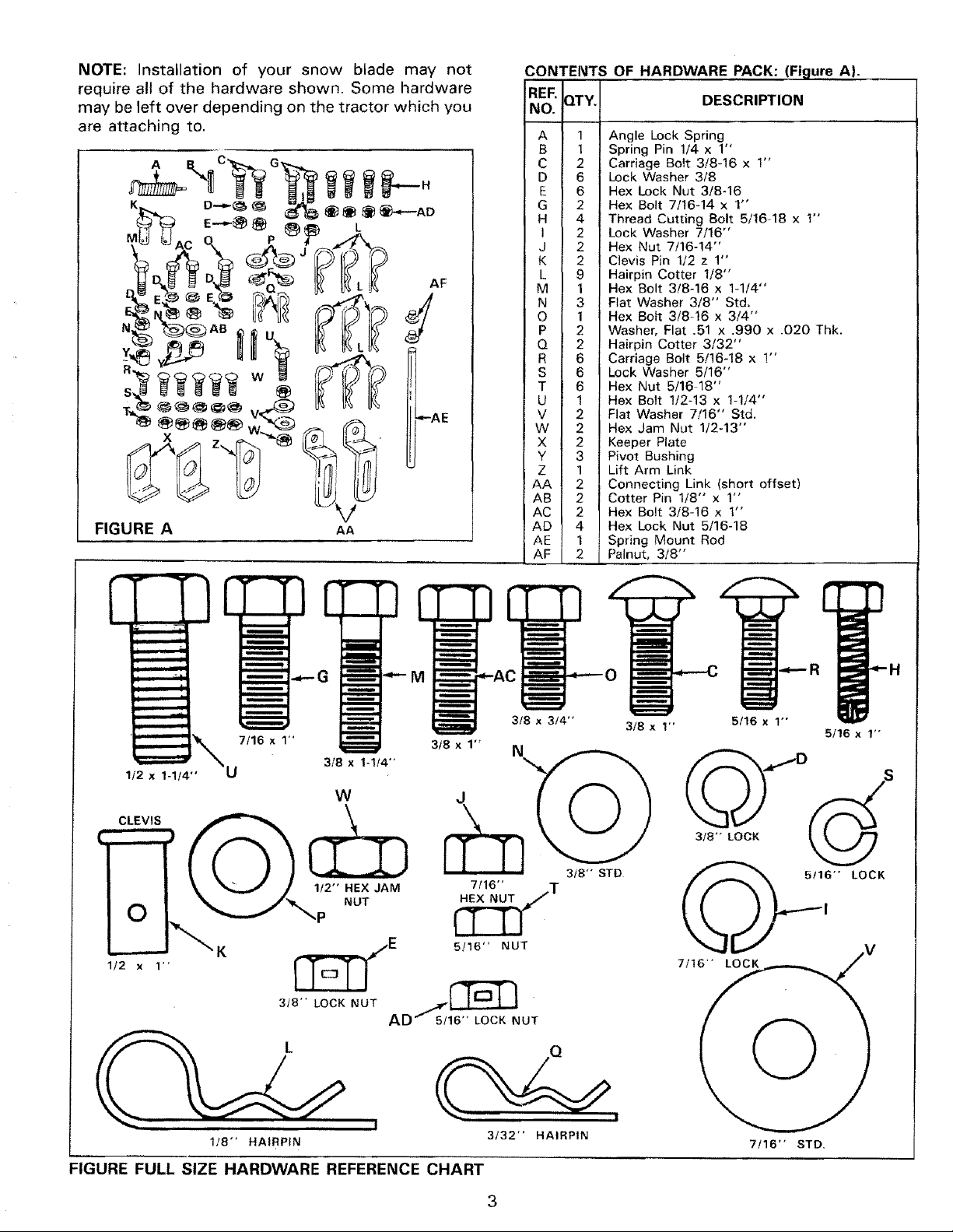

NOTE: Installation of your snow blade may not

require all of the hardware shown. Some hardware

may be left over depending on the tractor which you

are attaching to,

CONTENTS OF HARDWARE PACK: (Figure A}.

REF. QTY. DESCRIPTION

NO.

A 1 Angle Lock Spring

B 1 Spring Pin 1/4 x 1"

C 2 Carriage Bo{t 3/8-16 x !"

D 6 Lock 'Washer 3/8

E 6 Hex Lock Nut 3/8-16

G 2 Hex Bolt 7/16-14 x 1"

H 4 Thread Cutting Bolt 5/16-18 x 1"

I 2 Lock Washer 7/16"

J 2 Hex Nut 7/16-14"

K 2 Clevis Pin t/2 z 1"

L 9 Hairpin Cotter 1/8"

M 1 Hex Bolt 3/8-16 x 1-1/4"

N 3 Flat Washer 3/8" Std.

O 1 Hex Bolt 3/8-16 x 3/4"

P 2 Washer, Flat 31 x .990 x .020 Thk.

Q 2 Hairpin Cotter 3/32"

R 6 Carriage Bolt 5/16-18 x 1"

S 6 Lock Washer 5/16"

T 6 Hex Nut 5/16 18"

U 1 He× Bolt 1/2-13 x 1-1/4"

V 2 Flat Washer 7/16" Std.

W 2 Hex Jam Nut 1/2-13"

X 2 Keeper Plate

Y 3 Pivot Bushing

Z 1 Lift Arm Link

AA 2 Connecting Link (short offset)

AB 2 Cotter Pin 1/8" x 1"

AC 2 Hex Bolt 3/8-16 x 1"

AD 4 Hex Lock Nut 5/16-18

AE 1 Spring Mount Rod

AF 2 Palnut, 3/8"

CLEVIS

1/2 x 1"

H

3/8 x 1-1/4"

3/8 x 3/4"

3!8 x 1" N

3/8 x 1" 5/16 x 1"

5/16 x 1"

W

3/8"" STD

_-_ i" LOCK

K

._._E 5/16" NUT

318"

7/1 "

v

LOCKNUT AD 1[ l_-LJu"/5/1_ T

I

1/8- HAIRPIN

FIGURE FULL SIZE HARDWARE REFERENCE CHART

3/32" HAIRPIN

3

7/16" STD.

ASSEMBLY INSTRUCTIONS

TOOLS REQUIRED FOR ASSEIVIBLY

(1) Pliers

(1) Hammer

(1) Screwdriver

(1) 1/2" Open End or Box Wrench

(1) 9/16" Open End or Box Wrench

(1) 5/8" Open End or Box Wrench

(1) 3/4" Open End or Box Wrench

(1) Adjustable Wrench

Refer to carton contents figure on page 2 and figure

A on page 3 of snow blade supplement for parts and

hardware needed to assemble snow blade.

NOTE

RIGHT HAND (R.H.) AND LEFT HAND

(L.H.) ARE DETERMINED FROM

OPERATOR'S POSITION WHILE

SEATED ON TRACTOR.

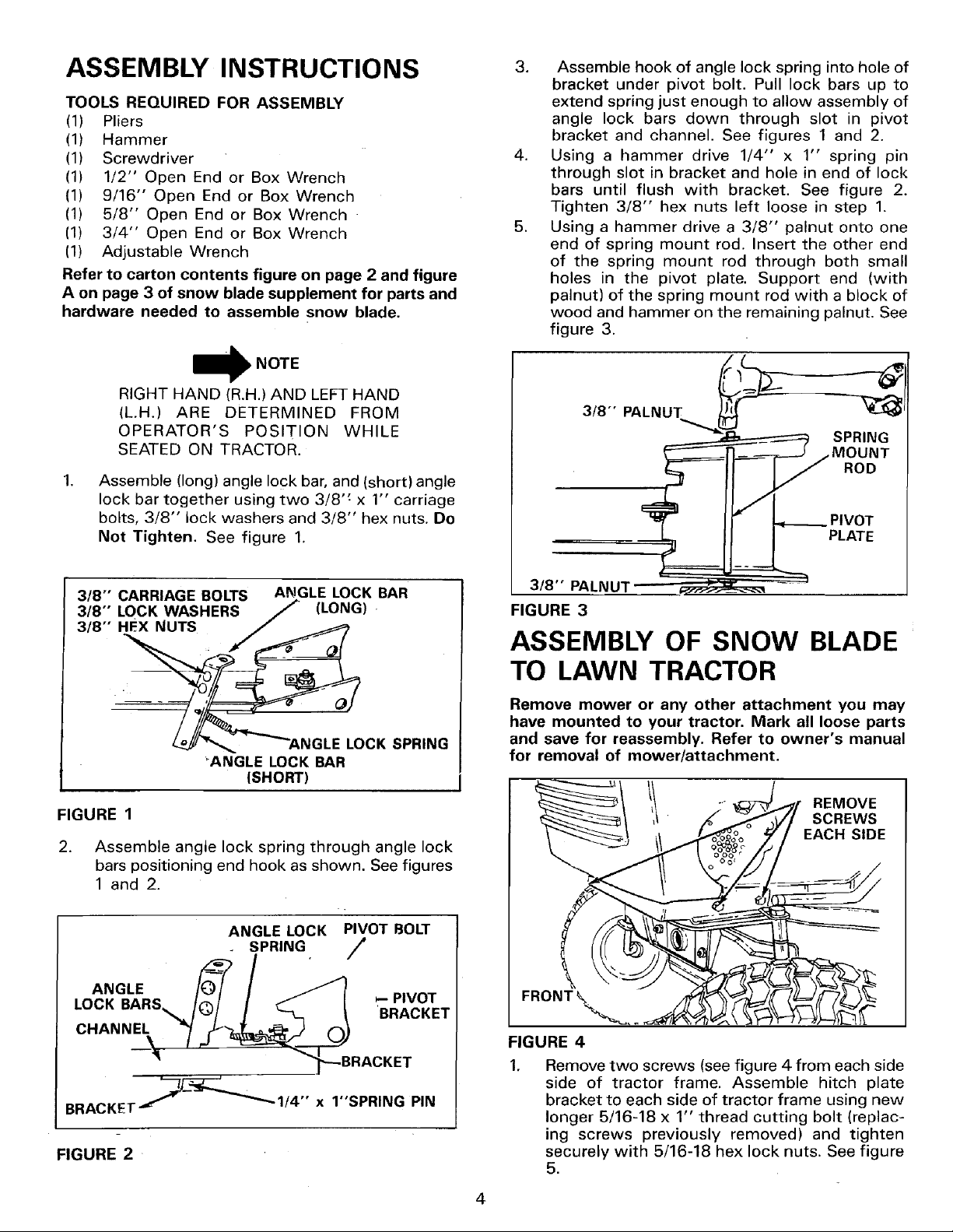

.

Assemble (long) angle lock bar, and (short) angle

lock bar together using two 3/8" x 1" carriage

bolts, 3/8" lock washers and 3/8" hex nuts. Do

Not Tighten. See figure 1.

3. Assemble hook of angle lock spring into hole of

bracket under pivot bolt. Pull lock bars up to

extend spring just enough to allow assembly of

angle lock bars down through slot in pivot

bracket and channel. See figures 1 and 2.

4. Using a hammer drive 1/4" x 1" spring pin

through slot in bracket and hole in end of lock

bars until flush with bracket. See figure 2.

Tighten 3/8" hex nuts left loose in step 1.

5. Using a hammer drive a 3/8" palnut onto one

end of spring mount rod. Insert the other end

of the spring mount rod through both small

holes in the pivot plate. Support end (with

palnut) of the spring mount rod with a block of

wood and hammer on the remaining palnut. See

figure 3.

3/8" PALNUT _l

SPRING

MOUNT

ROD

__ IVOT

PLATE

3/8"" CARRIAGE BOLTS ANGLE LOCK BAR

33188::'°cKWASHERS/ (LONG)

•

'ANGLE LOCK BAR

ISHORT)

FIGURE 1

2. Assemble angle lock spring through angle lock

bars positioning end hook as shown. See figures

1 and 2.

ANGLE LOCK PIVOT BOLT

SPRING /

ANGLE

LOCK BARS _- PIVOT

CHANNEL

BRACKET--1/4" x 1"SPRING PIN

FIGURE 2

'BRACKET

3/8'" PALNU"

FIGURE 3

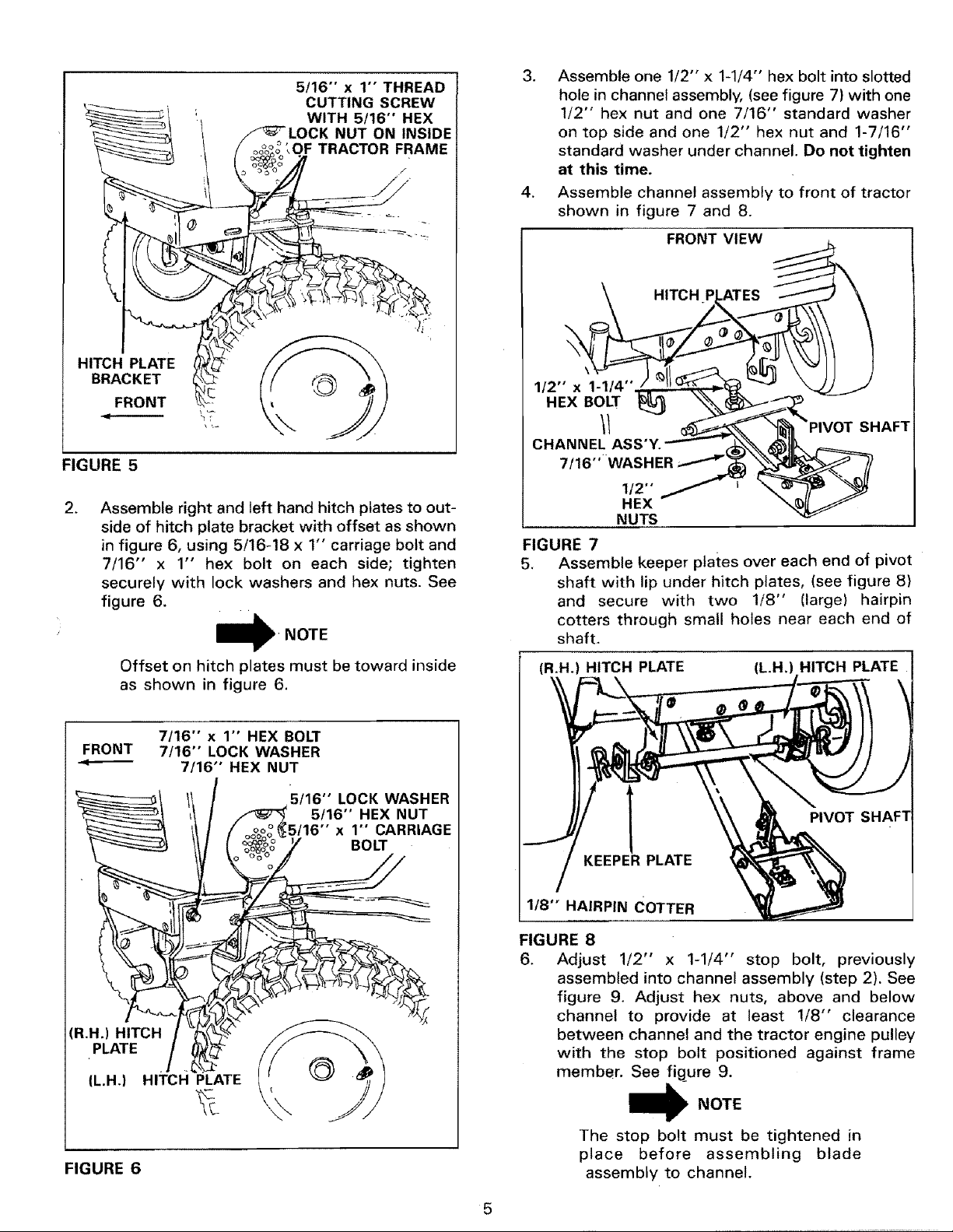

ASSEMBLY OF SNOW BLADE

TO LAWN TRACTOR

Remove mower or any other attachment you may

have mounted to your tractor. Mark all loose parts

and save for reassembly. Refer to owner's manual

for removal of mower/attachment.

REMOVE

SCREWS

FIGURE 4

Remove two screws (see figure 4 from each side

side of tractor frame. Assemble hitch plate

bracket to each side of tractor frame using new

longer 5/16-18 x 1" thread cutting bolt (replac-

ing screws previously removed) and tighten

securely with 5/16-18 hex lock nuts. See figure

5.

4

!

5/16" x 1" THREAD

CUTTING SCREW

WITH 5/16" HEX

/_ LOCK NUT ON INSIDE

'_OF TRACTOR FRAME

3. Assemble one 1/2" x 1-1/4 °' hex bolt into slotted

hole in channel assembly, (see figure 7) with one

1/2" hex nut and one 7/16" standard washer

on top side and one 1/2" hex nut and 1-7/16"

standard washer under channel. Do not tighten

at this time.

4. Assemble channel assembly to front of tractor

shown in figure 7 and 8.

FRONT VIEW

HITCH

HITCH PLATE

BRACKET

FRONT

FIGURE 5

.

Assemble right and left hand hitch plates to out-

side of hitch plate bracket with offset as shown

in figure 6, using 5/16-18 x 1" carriage bolt and

7/16" x 1" hex bolt on each side; tighten

securely with lock washers and hex nuts. See

figure 6.

\T

NOTE

Offset on hitch plates must be toward inside

as shown in figure 6.

FRONT 7/16" LOCK WASHER

"*_ 7/16" HEX NUT

7/16" x 1" HEX BOLT

5/16" LOCK WASHER

oo°I

5/16" x 1" CARRIAGE

oo %

y BOLT

5/16" HEX NUT

\

1/2" x 1-1/4"

HEX BOLT

CHANNEL ASS'Y.

7/16"-WASHER

1/2"

HEX

NUTS

FIGURE 7

5.

Assemble keeper plates over each end of pivot

shaft with lip under hitch plates, (see figure 8)

and secure with two 1/8" (large) hairpin

cotters through small holes near each end of

shaft.

(R.H.) HITCH PLATE (L.H.) HITCH PLATE

KEEPER PLATE

SHAFT

(R.H.) HITCH

PLATE

IL.H.) HITCH PLATE

FIGURE 6

1/8" HAIRPIN COTTER

FIGURE 8

6. Adjust 1/2" x 1-1/4" stop bolt, previously

assembled into channel assembly (step 2). See

figure 9. Adjust hex nuts, above and below

channel to provide at least !/8" clearance

between channel and the tractor engine pulley

with the stop bolt positioned against frame

member. See figure 9.

_NOTE

The stop bolt must be tightened in

place before assembling blade

assembly to channel.

5

Loading...

Loading...