Craftsman 47099 Operator's Manual

Operator’s Manual

Lever Grease Gun

Model 47099

CAUTION: Before using this

product, read this manual

and follow all its Safety Rules

and Operating Instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

www.craftsman.com

404669

• SAFETY

• ASSEMBLY

• OPERATION

• MAINTENANCE

• PARTS

• ESPANOL p. 7

TABLE OF CONTENTS GENERAL SAFETY RULES SIGNAL WORDS FOR SAFETY

Safety ........................................... 2

Operating Instructions ................... 3

Install Cartridge ............................ 3

Fill From Bulk Container ................ 4

Expell Air Pockets .......................... 5

Capacities ..................................... 6

Service Parts List .......................... 6

CRAFTSMAN LIMITED WARRANTY

FOR ONE YEAR from the date of sale,

this product is warranted against defects in

material or workmanship.

WITH PROOF OF SALE, a defective

product will be replaced free of charge.

For warranty coverage details to obtain free

replacement, visit the web page:

www.craftsman.com/warranty.

This ONE YEAR warranty is void if this product is ever used while providing commercial

services or if rented to another person.

For 90 DAY commercial and rental use

terms, see the Craftsman warranty web

page.

This warranty gives you specific legal rights,

and you may also have other rights which

vary from state to state.

Sears Brands Management Corporation,

Hoffman Estates, IL 60179.

Read and carefully observe these

installation instructions before installing,

operating or troubleshooting the

assembly. The assembly must be

installed, maintained and repaired

exclusively by persons familiar with the

instructions.

Use the equipment only after safety

instructions and this guide have been

read and are completely understood.

Adequate personal protection must be

used to prevent splashing of material on

the skin or in the eyes.

This equipment generates very high

grease pressure. Extreme caution should

be used when operating this equipment

as material leaks from loose or ruptured

components can inject fluid through the

skin and into the body. If any fluid

appears to penetrate the skin, seek

attention from a doctor immediately.

Do not treat injury as a simple cut. Tell

attending doctor exactly what type of fluid

was injected.

Any other use not in accordance with

instructions will result in loss of claim for

warranty or liability.

• Do not misuse, over-pressurize,

modify parts, use incompatible

chemicals, fluids, or use worn and/or

damaged parts.

• Do not exceed the stated maximum

working pressure of the pump or of the

lowest rated component in your

system.

• Always read and follow the fluid manu-

facturer’s recommendations regarding

fluid compatibility, and the use of pro-

tective clothing and equipment.

• Failure to comply may result in death

or serious injury.

This is the safety alert symbol. It is used

to alert you to potential physical injury

hazards. Obey all safety messages that

follow this symbol to avoid possible

injury or death.

SAFETY INSTRUCTION

Safety instruction signs indicate specific

safety-related instructions or

procedures.

DANGER

Indicates a hazardous situation which,

if not avoided, will result in death or

serious injury.

WARNING

Indicates a hazardous situation which,

if not avoided will result in death or

serious injury.

CAUTION

Indicates a hazardous situation which,

if not avoided, could result in minor or

moderate injury.

2

10

1

3

6

OPERATING INSTRUCTIONS

1 Wipe fittings clean before lubricating.

2 Push coupler (1) onto fitting at slight

angle and then center coupler (1) on

the fitting

3 Operate lever handle (3) to lubricate.

Notice

!

Do not damage seals of

equipment being lubricated by excessive

pressure or lubricant volume.

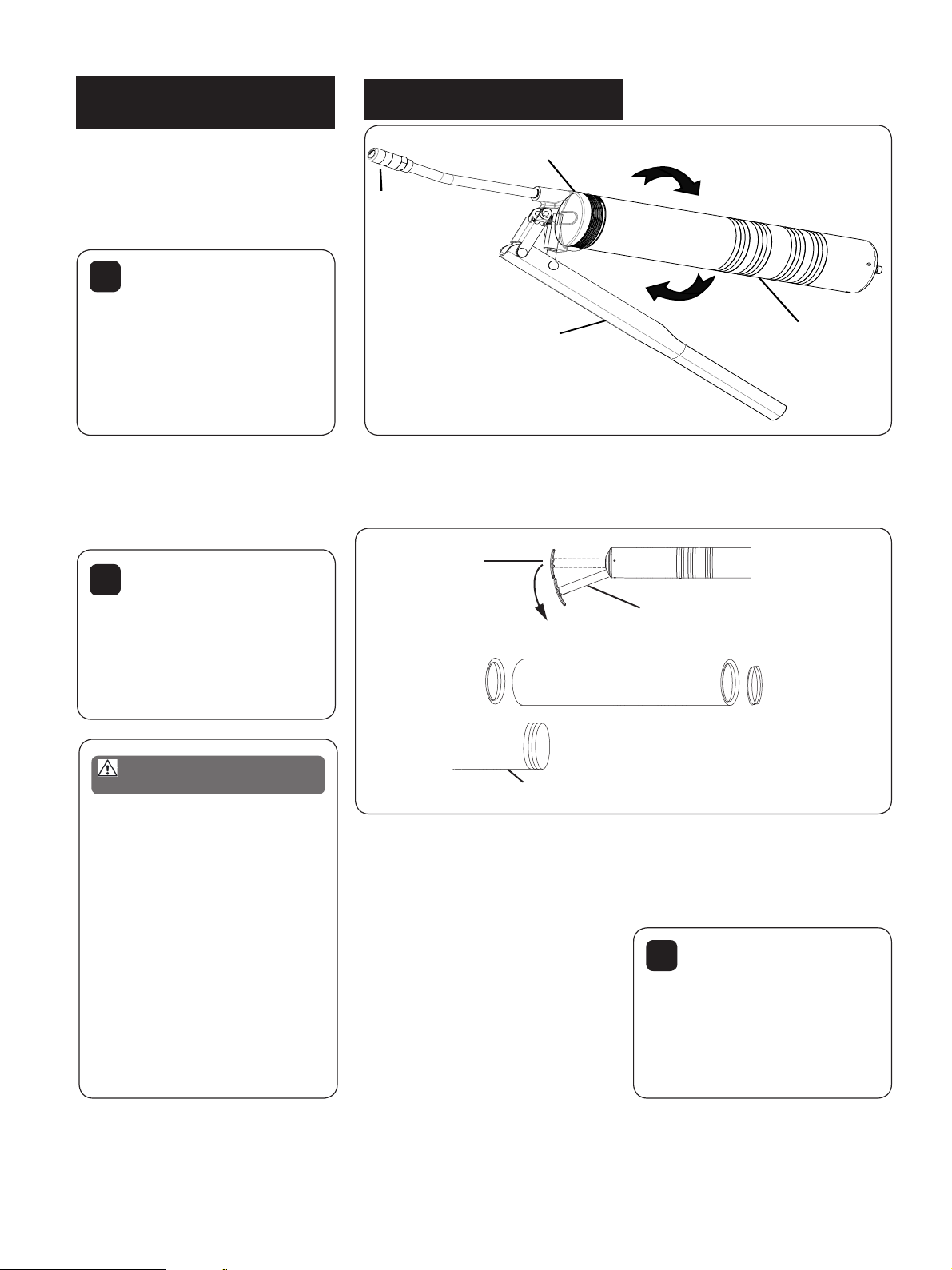

INSTALL CARTRIDGE

4 After lubricating turn coupler (1) at a

slight angle to release grip of the

coupler jaws from the fitting.

!

Notice

Failure to clean and inspect grease gun

will cause it to lose prime.

Air pockets in cartridge will cause lever

gun to lose prime.

1 While holding grease gun container

tube (6), loosen grease gun head (10)

two turns.

8

Large cap

11 Turn T-handle (8) 90° and push into

container tube (6)

5

Grease cartridge

Pull tab

WARNING

Do not over pressurize grease gun.

Extreme pressure may cause nozzle

extension to burst.

Use only identical part nozzle extension replacement. See Service Parts list

on page 6.

Keep hands clear of the extension

during operation of the grease gun.

Grease gun can develop high pressure

up to 10,000 psi (689 bar). Use safety

glasses and gloves for protection during

operation.

Failure to comply with this warning

may result in death or serious injury.

2 Pull T-handle (8) to extend follower rod

(5) fully and slide into slot.

3 Unscrew container tube (6) from

grease gun head (10).

4 Remove empty grease cartridge (if

present) from container tube (6).

5 Remove large cap from top end of new

grease cartridge.

6 Insert new grease cartridge top end

first into container tube (6).

7 Remove pull tab from bottom end of

new grease cartridge.

8 Screw container tube (6) back onto

grease gun head (10) and tighten.

9 Pull lever handle (3) away from

container tube (6).

10 Pull back and remove follower rod (5)

from slot.

6

12 Loosen grease gun head (10) two turns

to expel air and retighten.

Notice

!

If grease does not come out of

coupler (1) after ten strokes of lever

handle (3), refer to Expel Air Pockets

section on page 5.

3

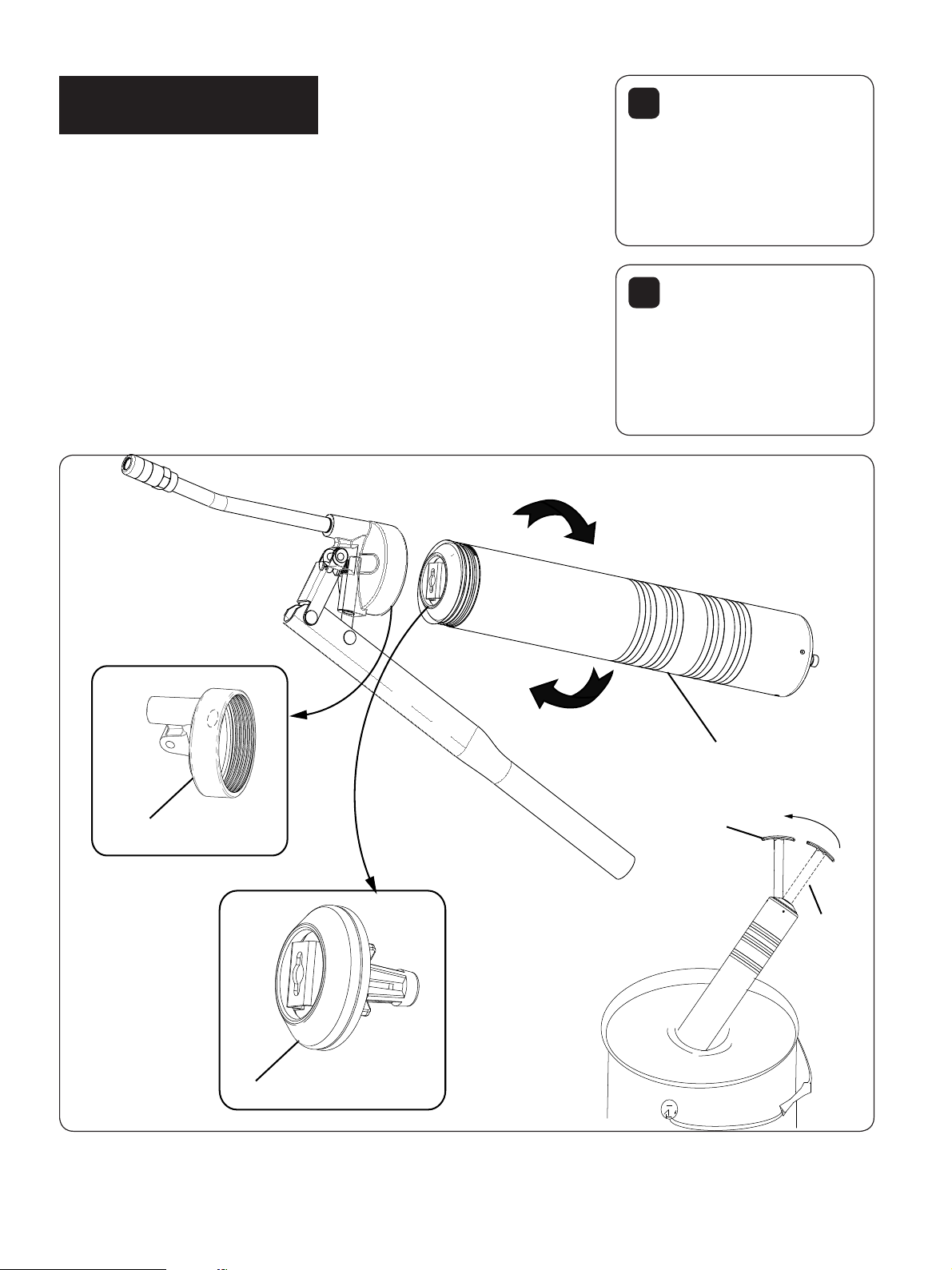

FILL FROM A BULK

LUBRICANT CONTAINER

1 While holding grease gun container

tube (6), loosen grease gun head (10)

two turns.

2 Pull T-handle (8) to extend follower rod

(5) fully and slide into slot.

3 Unscrew container tube (6) from

grease gun head (10).

4 Remove empty cartridge (if present)

from container tube (6).

5 Pull T-handle (8) back and remove

follower rod (5) from slot.

6 Pack lubricant into cavity of the grease

gun head (10) and onto surface of the

follower assembly (4).

7 Insert the open end of the container

tube (6) into lubricant.

8 Pull T-handle (8) back while pushing

container tube (6) deeper into lubricant

to prevent air pockets from being

pulled into container tube (6).

9 Pull T-handle (8) to extend follower rod

(5) fully and slide into slot.

10 Thread grease gun head (10) onto filled

container tube (6).

11 Pull lever handle (3) away from

container tube (6).

12 Pull T-handle (8) back and remove

follower rod (5) from slot.

13 Turn T-handle (8) 90° and push into

container tube (6)

14 Loosen grease gun head (10) two turns

to expel air and retighten.

Notice

!

Failure to clean and inspect

grease gun will cause it to lose prime.

Air pockets in cartridge will cause lever

gun to lose prime.

Notice

!

If grease does not come out of

coupler (1) after ten strokes of lever

handle (3), refer to Expel Air Pockets

section on page 6.

10

6

8

5

4

4

Loading...

Loading...