Page 1

MODEL 47089

COMPRESSION TEST KIT

JAN - 04 Section

Form 823451

- MV19

Page

- 1

Page 2

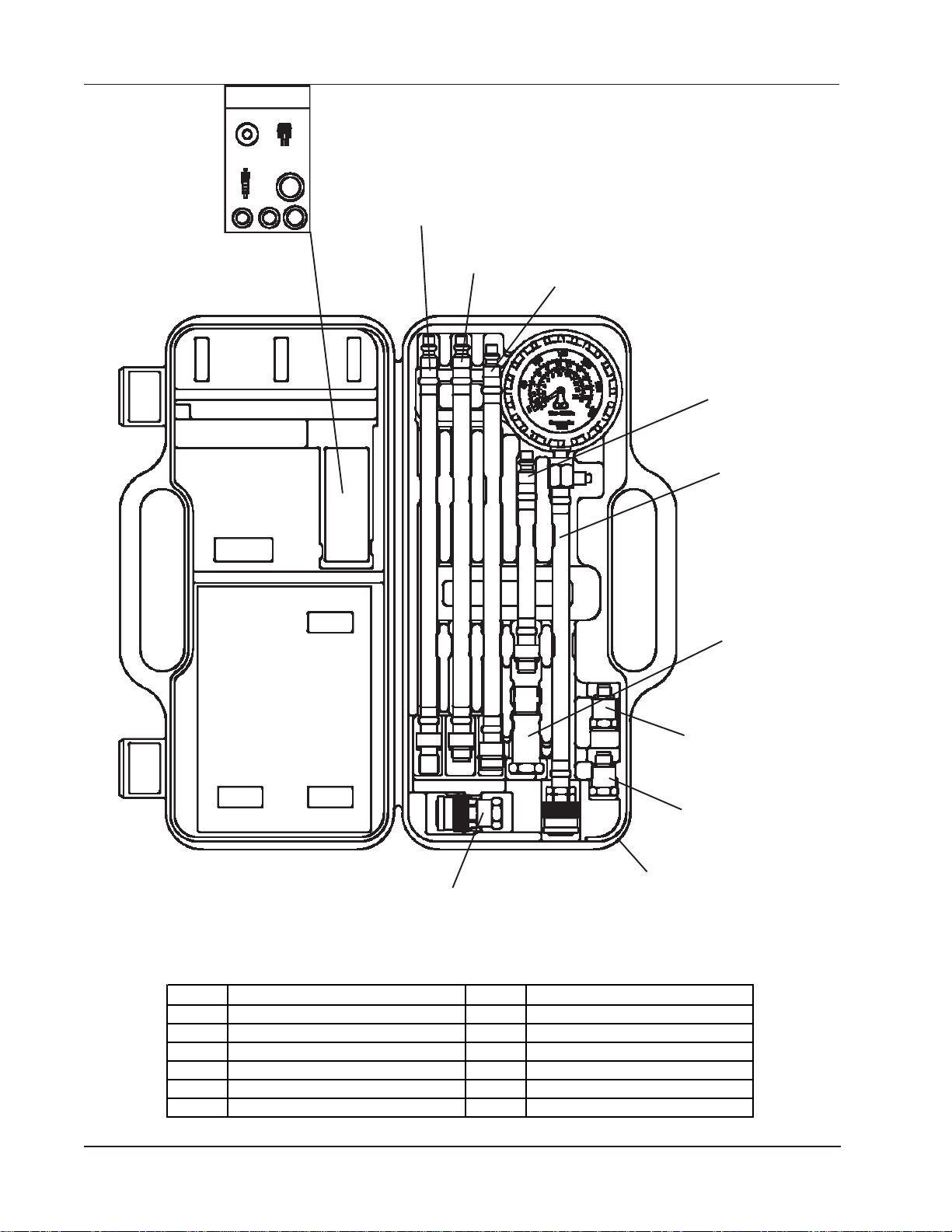

823437

Hose 14MM Long Reach

823441

Field Service Kit

823436

Hose 14MM Short Reach

823438

Hose 18 MM Short Reach

823435

Hose 14MM

Short Reach

823449

Gauge, Valve

and Hose

823433

14MM - 18MM

Adapter

Part No. D es cripti on Part No. D es cripti on

823431 10MM Adapt er 823438 Hose Long reach 18MM x 11.625

823432 12MM Adapt er 823440 Pressure Hold Adapter

823433 14MM Female - 18MM M a le Adapt er 823441 Field S er vice Kit

823435 Hose Short R eac h 14 MM x 6.05 823442 Case

823436 Hose Short R eac h 14 MM x 11.625 823448* Gauge

823437 Hose Long Reach 14MM x 11.951 823449 Gaug e Assembly

Page Number - 2

* Not Shown

823440

Pressure Hold Adapter

823431

10MM Adapter

823432

12 MM Adapter

823442

Plastic Case

Form 823451

Page 3

Always read instructions carefully prior to use.

Dry Compression Test Procedures:

Included in this Kit

• Heavy duty 2 ¾” (70 mm) gauge with high impact lens,

rubber boot, and three (3) scales of measure (psi, kg/cm

bar), attached to 10" (250 mm) hose and quick release

coupler

• Four (4) extension hoses:

• 6 ½” (165 mm) long x 14 mm thread, short

• 12" (305 mm) long x 14 mm thread, short

• 12" (305 mm) long x 14 mm thread, long

• 12" (305 mm) long x 18 mm thread, short

• One (1) adapter: 14 mm thread, short x 18 mm thread, long

• Two (2) small engine adapters

• 10 mm thread

• 12 mm thread

• One (1) quick release air hold adapter

• Custom blow-molded case

• Field service kit

2

,

Applications

The Craftsman Professional Compression Test Kit can perform

dry or wet compression tests to determine the amount of

pressure produced in the cylinder of an engine. It can also be

used as a tool for pressurizing an engine cylinder to hold the

valves closed while performing repairs.

How to Perform a Comression Test

Precautions & Diagnostic Notes:

WARNING: DO NOT use the ignition switch during the

compression test on fuel-injected vehicles. Use of a

remote starter switch to crank the engine is recommended. Fuel injectors on many late model vehicles

are triggered by the ignition switch during the cranking

mode, this could result in a fire hazard or contamination

of the engine’s oil with fuel.

Always use eye protection when performing compression tests.

An engine in good operating condition will produce a certain

amount of pressure in each cylinder. Normally, the cylinders

should be within 10 percentage points of one another and

within the manufacturer’s specifications. The pressure should

rise smoothly on each stroke of the engine, until it reaches a

peak.

If the pressure reading fails to rise, or it remains the same for

several strokes of the engine and begins to rise, the likely

cause of the problem is a sticking valve.

If two adjacent cylinders show pressure readings of 20 or

more pounds below the other cylinder readings, suspect a

blown head gasket.

If a cylinder shows a pressure reading of 15 or more pounds

higher than the other cylinders, the probable cause is carbon

build-up inside the cylinder.

The Craftsman Professional Compression Test Kit can perform

two tests: the dry compression test and the wet compression

test. The result of performing these tests will provide an

indication of the condition of the piston rings, the cylinders, and

valve-train.

1. Refer to the appropriate service manual for the compression

specifications specific to the engine you are testing.

2. Start engine and allow engine to run until it reaches normal

operating temperature (usually about 15 minutes.) Turn

engine OFF .

3. Install an auxiliary starter switch in the starting circuit.

4. While wearing eye protection, use compressed air to

carefully remove dirt and debris from the area around the

spark plugs.

5. Remove spark plugs one at a time, marking the number of

the cylinder they were removed from, and place them on a

clean flat surface. This will aid you in identifying problem

cylinders by allowing the comparison of spark plug appearance to the compression level of a given cylinder.

NOTE: When testing engines with two spark plugs per

cylinder, it is only necessary to remove the spark

plugs located on the exhaust side.

6. On vehicles with standard distributors, disconnect the coil

wire (high tension lead) from the distributor cap and secure

it to a suitable ground, or disable the ignition by disconnecting the positive (BAT) terminal from the ignition coil.

7. On vehicles with a distributorless ignition (DIS), disable the

ignition system by removing the electronic ignition (control)

module fuse, or disconnect the crank angle sensor.

NOTE: Refer to the appropriate service manual to

determine which fuse or component to temporarily

remove or disconnect.

8. Remove air cleaner from carburetor or throttle body and

secure throttle linkage in wide-open throttle (WOT) position.

NOTE: NEVER place anything inside the throttle body;

internal damage to the engine could result. On

vehicles equipped with port fuel injection, remove

throttle linkage covers (as necessary) and secure

throttle linkage in the wide-open throttle (WOT)

position.

9. Crank engine several times to ensure removal of any foreign

matter that may have fallen into the cylinders during preparation for test.

10. Select the appropriate adapter fitting (14mm, 18mm short

reach or 14mm, 18mm long-reach), and thread adapter into

spark plug hole of cylinder head.

11. Connect the appropriate test hose or adapter to the gauge

assembly.

12. Crank the engine at least five compression strokes or until

the pressure reading stops increasing on gauge.

13. Read the pressure level on the gauge and record the

reading along with the cylinder number being tested.

Example: #1-150 psi, #2-145 psi, etc.

14. Repeat this test on each cylinder. If any of the cylinder

readings are found to be low or uneven, perform wet

compression test.

Form 823451

Page Number - 3

Page 4

15. When compression test is complete, return the spark plugs

to their respective cylinders and the throttle and ignition

components to their normal positions.

Wet Compression Test Procedure

CAUTION: DO NOT perform the wet compression test on

any diesel engine. The higher compression in a diesel

engine may cause engine damage or injury to the

technician.

The wet compression is a way to remove the influence of the

piston rings, pistons and cylinders from the compression test.

After completing the dry compression test, squirt approximately

one teaspoon of engine oil into the spark plug holes and crank

the engine several times to seal the piston rings. Repeat the dry

compression test outlined above. NOTE: If the readings during

the wet compression test are greater, then air is leaking around

worn or damaged piston rings. If the reading is approximately

the same for both wet and dry tests then the valves, valve lifters

or the camshaft lobes are worn. Any low reading of cylinder

compression indicates worn or damaged parts.

Small Engine Compression Testing

The Craftsman Professional Compression Test Kit has two (2)

adapters, 10mm and 12mm, that allow it to be used on small

engines found in lawn mowers, chain saws and line trimmers.

To use these adapters:

5. Attach the Air Hold Adapter to the extension hose.

6. Attach a shop air hose to the Air Hold Adapter, this will

maintain air pressure in the cylinder to hold the valves

closed while performing repairs. (It may be necessary to

rotate the engine until all valve are closed and air is holding

in the cylinder)

Note: The air hold quick connector does not come with

a compressed air line fitting to adapt to your air source.

This will have to be purchased separately to fit your

system.

For answers to technical questions, or to

order replacement parts, call or fax:

Phone: (314) 679-4200 Ext. 4782

Fax: (314) 679-HELP (4357)

Full One Year Warranty

If this Craftsman® Compression Test Kit is defective in material or

workmanship within one (1) year from the date of purchase,

return it to your nearest Sears store in the United States, and it will

be replaced free of charge.

Sear, Roebuck and Co., Dept. 817WA,

Hoffman Estates, IL 60179

1. Disconnect the spark plug wire and remove the spark plug.

2. Thread the appropriate size adapter onto the compression

tester main hose end until the o-ring seats (do not use a

wrench to tighten).

3. Thread the assembly into the cylinder spark plug hole until

the o-ring on the adapter seats firmly (do not use a wrench

to tighten).

4. Ensure the spark plug is grounded to the cylinder head or is

insulated in a way that will prevent an electric shock

hazard.

5. Crank the engine over using the pull cord (or starter if

electric) a minimum of 5 revolutions. This will allow the

cylinder to build sufficient compression to be measured.

6. Refer to the manufacturer’s data to determine the correct

reading

Using the Pressure Hold Adapter

The Craftsman Professional Compression Tester comes with a

pressure hold adapter. This adapter is used to perform valve

seal replacement on an engine without removing the cylinder

head(s). To use the adapter:

1. Remove the spark plug from the desired cylinder.

2. Select the appropriate extension hose that will fit the spark

plug hole.

TO A VOID PERSONAL INJURY AND/OR VEHICLE

DAMAGE:

While some precautions are specified in this manual, and

should be noted to avoid personal injury or vehicle damage,

it is not possible for these cautions to cover all conceivable

ways in which service or testing might be done, or all

possible hazardous consequences of each way, nor could

Lincoln possibly know or investigate all such ways. It is

therefore the responsibility of anyone using this manual or

any other Mityvac product, to satisfy him or herself

completely that neither personal safety nor vehicle safety

will be jeopardized by the service methods selected. Any

such injury or damage is entirely the user’s responsibility.

This device is not to be used in any manner on the human

body.

3. Using the valve core tool (from the field service kit included),

remove the valve core from the end of the hose and lay it

aside.

4. Thread the extension hose into the spark plug hole until the

o-ring seats; do not use pliers or a wrench to tighten.

Page Number - 4

Form 823451

Page 5

TEST DE COMPRESSION PROFESSIONNEL

P/N 05530

Prenez soin de toujours lire les instructions avant

utilisation.

Descriptif Général

Le Testeur de Compression Professionnel Craftsman mesure

le niveau de pression qu’un cylindre de moteur peut produire. La

face frontale de la jauge du testeur possède trois échelles de

mesure : livre par pouce carré (psi), bar et kilogramme par

centimètre carré (kg/cm).

Pour tester le niveau de compression d’un cylindre donné,

enfiler le tuyau du test de compression approprié dans la fente

de la bougie d’allumage du cylindre à tester.

Le Test de Compression Professionnel Craftsman peut être

utilisé pour le test de compression sèche et le test de compression mouillée. Les résultats de ces tests donneront une

indication sur l’état des anneaux du piston, des cylindres, et de

la train de valve.

Remarques : Précautions et Diagnostic

AVERTISSEMENT : NE PAS utiliser l’interrupteur pendant

le test de compression sur des véhicules à injection de

combustible. L’utilisation d’un démarreur télécommandé pour mettre le moteur en marche est recommandé. Les systèmes d’injection de carburant sur de

nombreux modèles récents sont déclenchés par

l’interrupteur pendant la mise en marche, cela peut

provoquer un incendie ou la contamination de l’huile

moteur par du carburant.

Prenez soin de toujours utiliser une protection pour les

yeux lorsque vous faites des tests de compression.

Un moteur en bon état de fonctionnement produira un certain

niveau de pression sur chaque cylindre. Normalement, les

cylindres doivent rester dans une fourchette de dix points (pour

cent) l’un de l’autre, et respecter les caractéristiques du

fabricant. La pression doit augmenter doucement à chaque

sursaut du moteur, jusqu’à ce qu’elle atteigne un pic.

Si la pression ne parvient pas à monter, ou si elle reste la même

après plusieurs sursauts du moteur puis augmente, la cause du

problème est probablement une valve collante.

Si, sur deux cylindres adjacents, l’un montre un niveau de

pression de 20 livres ou plus de moins que l’autre, on peut

suspecter une tête de garniture cassée.

Si un cylindre montre une pression supérieure de 15 livres ou

plus aux autres cylindres, c’est qu’il y a certainement un amas

de carbone dans le cylindre.

Procédures pour le Test de Compression

Sèche :

1. Se reporter au manuel d’entretien approprié pour les

caractéristiques de compression spécifiques au moteur que

vous testez.

2. Démarrez le moteur et laissez lui le temps d’atteindre une

température normale de fonctionnement (environ 15 minutes

habituellement). Arrêtez le moteur.

3. Installez un interrupteur de starter auxiliaire dans le circuit

de démarrage.

4. En gardant toujours vos protections oculaires, utilisez de l’air

comprimé pour évacuer avec soin poussière et débris de la

zone environnante des bougies d’allumage.

5. Retirez les bougies une après l’autre, en notant le numéro

de cylindre duquel chaque bougie a été retirée, et disposezles sur une surface plane et propre. Cela vous aidera à

identifier les cylindres à problème en vous permettant de

comparer l’aspect de la bougie au niveau de compression

d’un cylindre donné.

À NOTER : En testant les moteurs à deux bougies par

cylindre, il n’est nécessaire d’enlever que les bougies

situées du côté de l’échappement.

6. Sur les véhicules à distributeur standard, branchez la

bobine (tête haute tension) du capot du distributeur et

mettez-la en sureté sur une surface adaptée ou bien

désactivez l’allumage en débranchant le terminal positif

(BAT) de la bobine d’allumage.

7. Sur les véhicules à allumage sans distributeur (DIS),

désactivez le système d’allumage en ôtant le fusible

d’allumage électronique (commande) ou désactivez le

capteur d’angle de mise en marche.

À NOTER : Se reporter au manuel d’entretien approprié pour

savoir quel fusible ou composant ôter ou déconnecter de

façon temporaire.

8. Ôtez le filtre à air du carburateur ou le corps du régulateur

et placez le lien du régulateur en position régulateur grand

ouvert (WOT).

À NOTER : NE JAMAIS placer quoique ce soit dans le

corps du régulateur ; le moteur pourrait subir des

dégâts internes. Sur les véhicules équipés

d’injection gauche de carburant, ôtez les couvercles

de liens du régulateur (si nécessaire) et placez le

lien du régulateur en position régulateur grand

ouvert (WOT).

9. Mettre en marche le moteur plusieurs fois pour s’assurer

que tout corps étranger qui serait tombé dans les cylindres

pendant la préparation du test ait été évacué.

10. Sélectionnez la taille de l’adaptateur (14mm, 18mm extension

courte ou 14mm, 18mm extension longue, et faire passer

l’adaptateur dans le trou de la bougie de la tête de cylindre.

11. Branchez le tuyau de test approprié ou l’adaptateur à la

jauge.

12. Faire faire au moteur au moins cinq coups de compressions

ou jusqu’à ce que la pression cesse d’augmenter sur la

jauge.

13. Lire le niveau de pression sur la jauge et enregistrez cette

lecture ainsi que le numéro de cylindre testé. Exemple : #1-

150 psi, #2-145 psi, etc.

14. Répétez ce test sur chaque cylindre, si les résultats

constatés sur les cylindres semblent bas ou irréguliers,

faites le test de compression mouillée.

15. Lorsque le test de compression est terminé, replacez les

bougies sur leur cylindre respectif, remettez le régulateur et

les composants de l’allumage en position normale.

Form 823451

Page Number - 5

Page 6

Procédures pour le Test de Compression

Mouillée

(Il pet s’avérer nécessaire de faire tourner le moteur jusqu’à

ce que toutes les soupapes soient fermées et que l’air soit

maintenu dans le cylindre).

ATTENTION : NE PAS faire de test de compression

mouillée sur les moteurs diesel. La compression plus

élevée sur un moteur diesel peut causer des dégâts au

niveau du moteur ou des blessures pour le mécanicien.

La compression mouillée permet d’enlever l’influence des

anneaux de piston, des pistons et cylindres du test de compression. Après avoir terminé le test de compression sèche,

verser environ une cuillère à café d’huile de moteur dans les

fentes de bougies et faire démarrer le moteur plusieurs fois

pour sceller les anneaux de pistons. Répétez les étapes du test

de compression sèche mentionnées ci-dessus.

À NOTER : Si les résultats pendant le test de compression

mouillée sont plus élevés, c’est que de l’air fuit autour des

anneaux de pistons usés ou endommagés. Si les résultats

sont à peu près les mêmes pour les deux tests, c’est que les

valves, les valves poussoirs ou l’arbre à cames sont usés.

Tout résultat faible au niveau du cylindre de compression

indique que des pièces sont usées ou endommagées.

Test de Compression d’un Petit Moteur

Le Testeur de Compression Professionnel Craftsman possède

deux (2) adaptateurs, 10mm et 12mm qui permettent de l’utiliser

sur des petits moteurs tels que ceux des tondeuses, des

tronçonneuses et des outils de taille. Pour utiliser ces adaptateurs :

1. Débranchez le câble de la bougie et ôtez la bougie.

2. Placez l’adaptateur de taille appropriée à l’extrémité du tube

principal du testeur de compression jusqu’à ce que l’anneau

se place (ne pas utiliser de clé pour serrer).

3. Faites le passer dans la fente de bougie du cylindre jusqu’à

ce que l’anneau de l’adaptateur se place et tienne fermement

(ne pas utiliser de clé pour serrer).

4. Vérifiez que la bougie soit fixée à la tête de cylindre ou soit

isolée de façon à éviter tout danger de choc électrique.

5. Démarrez le moteur en utilisant la courroie de démarrage (ou

le starter si c’est électrique) en attendant au moins le temps

de 5 révolutions. Cela permettra au cylindre de créer

suffisamment de compression à mesurer.

6. Se reporter aux données du fabricant pour connaître les

résultats corrects à obtenir.

Utilisation de l’Adaptateur de Maintien de

Pression

À NOTER : Le connecteur rapide Air Hold n’est pas

livré avec un tube à air comprimé à adapter à votre

source d’air. Il devra être acheté séparément pour

s’adapter à votre système.

Pièces

• Jauge de 2 ¾’’ à grand rendement avec lentille à haut

impact, boot en caoutchouc et trois échelles de mesure

différentes : PSI, kg/cm² et Bar, un tube fouet fixe de 10’’ et

un Quick Coupler pour une installation rapide.

• Une soupape de décompression montée sur le cou de la

jauge pour un accès facile.

• Quatre tubes d’extension : 6 1/2’’ 14mm extenseur court,

12’’14mm extenseur court, 12’’14mm extenseur long et

12’’18mm extenseur court

• Un adaptateur d’extenseur long 14mm femelle x 18mm male

• Deux adaptateurs pour petit moteur : 12mm et 10mm

• Un adaptateur de maintien d’air à évacuation rapide pour

l’entretien de joint de soupape sur véhicule

• Boîte moulée pour assurer protection et facilité de rangement

• Kit d’entretien de terrain, comprenant des joints, des

soupapes de Schrader et un outil d’enlèvement de noyau

utilisé pour maintenir votre kit.

Si vous avez des questions techniques ou si vous désirez

commander des pièces de rechange, appelez ou envoyez un

fax :

Téléphone : (314)679-4200

Fax : (314) 679-HELP (4357)

Garantie pendant Une Année Complète

Si ce Kit d’Essais à la Compression Craftsman® s’avère

défectueux, vice de matériau ou de fabrication durant une

période d’un (1) an après la date d’achat, retournez-le à votre

magasin Sears le plus proche (aux Etats Unis), et il sera

remplacé gratuitement.

Cette garantie vous donne des droits légaux précis. Il est

possible que vous ayez aussi d’autres droits, ceux-ci peuvent

différer d’un état à un autre.

Sears, Roebuck and Co., Département 817WA

Hoffman Estates, IL 60179

Le testeur de Compression Professionnel Craftsman est livré

avec un adaptateur de maintien de pression. Cet adaptateur est

utilisé lors du remplacement des joints de valves sur un moteur

sans enlever la ou les têtes de cylindre. Pour utiliser

l’adaptateur :

1. Ôtez la bougie du cylindre désiré.

2. Choisissez l’extenseur adéquat qui s’adaptera à la fente de

la bougie.

3. Otez el coeur de la poupape à l’extrémité du tuyau en

utilisant l’outil compris dans le kit d’entretien. Posez le de

côté.

4. Faites passer l’extenseur dans la fente de bougie jusqu’à ce

que l’anneau se place, ne pas utiliser de pinces ou de clé

pour serrer.

5. Fixez le connecteur rapide Air Hold à l’extenseur.

6. Fixez un tube de chambre à air à l’Adaptateur Air Hold, cela

maintiendra suffisamment d’air dans le cylindre pour

maintenir les soupapes fermées pendant les réparations.

Page Number - 6

POUR ÉVITER LES BLESSURES ET/OU LES

DÉGÂTS DE VÉHICULE :

Alors que certaines précautions sont spécifiées dans ce

manuel, et devraient être notées pour éviter les blessures

personnelles ou les dégâts de véhicule, il n’est pas possible

de couvrir toutes les possibilités d’utilisation d’entretien ou

de test, ou une éventuelle conséquence dangereuse de

ces possibilités ; Lincoln ne pourrait non plus connaître ou

enquêter sur ces possibilités. La responsabilité de

quiconque utilisant ce manuel ou tout autre produit Craftsman, est donc engagée pour son entière satisfaction,

sachant qu’aucune des méthodes d’utilisation sélectionnées

ne peut mettre en danger la sécurité des personnes ou des

véhicules. L’utilisateur est entièrement responsable de toute

blessure ou dommage. Cet appareil ne doit en aucun cas

être utilisé sur le corps humain.

Form 823451

Page 7

EQUIPO PROFESIONAL PARA PRUEBAS DE COMPRESIÓN

NÚMERO DE PARTE 05530

Siempre lea las instrucciones cuidadosamente antes de

usarlo.

Descripción General

El Probador de Compresión Profesional Craftsman mide cuanta

presión producirá un cilindro del motor. La carátula del probador

tiene tres escalas de medición: libras por pulgada cuadrada

(psi), bares y kilogramos por centímetro cuadrado (kg/cm2).

Al probar el nivel de compresión de un cilindro determinado,

atornille el conjunto apropiado de la manguera de prueba de

compresión en el agujero de la bujía de encendido del cilindro

que vaya a probarse.

El Equipo Profesional de Pruebas de Compresión Craftsman

puede hacer dos pruebas: la prueba de compresión en seco y

la prueba de compresión en condiciones húmedas. El resultado

de la ejecución de estas pruebas proporcionará una indicación

del estado de los anillos de los pistones, los cilindros y el tren

de válvulas.

Precauciones y Notas Diagnósticas:

ADVERTENCIA: NO use el interruptor de encendido

durante la prueba de compresión en los vehículos con

inyección de combustible. Se recomienda el uso de un

interruptor remoto del motor de arranque para hacer

girar el motor sin que arranque. Los inyectores de

combustible en muchos vehículos de modelo reciente

son activados por el interruptor de encendido durante

la modalidad de hacer girar el motor sin que arranque;

esto podría resultar en un riesgo de incendio o en la

contaminación del aceite del motor con combustible.

Siempre use protección para los ojos cuando haga

pruebas de compresión.

Un motor en buen estado de funcionamiento producirá cierta

cantidad de presión en cada cilindro. Por lo general, los cilindros

deben tener una diferencia de no más de 10 puntos porcentuales entre sí y estar dentro de las especificaciones del fabricante. La presión debe aumentar suavemente con cada carrera

de los pistones del motor, hasta que alcance un valor máximo.

Si la lectura de presión no aumenta o permanece igual durante

varias carreras de los pistones del motor y empieza a subir, la

causa probable del problema es una válvula pegada.

Si dos cilindros adyacentes muestran lecturas de presión de 20

o más libras debajo de las lecturas de los demás cilindros, se

debe sospechar que hay un empaque de la culata quemado.

Si un cilindro muestra una lectura de presión de 15 o más libras

más alta que los demás cilindros, la causa probable es la

acumulación de carbón dentro del cilindro.

Procedimientos de la Prueba de Compresión en Seco:

1. Consulte el manual de servicio apropiado para las especificaciones de compresión específicas del motor que esté

probando.

2. Arranque el motor y déjelo funcionar hasta que alcance la

temperatura normal de trabajo (por lo general alrededor de

15 minutos.) Apague el motor.

3. Instale un interruptor auxiliar de arranque en el circuito

correspondiente.

4. Utilizando algún tipo de protección para sus ojos, use aire

comprimido para eliminar cuidadosamente la suciedad y los

desechos del área alrededor de las bujías de encendido.

5. Quite las bujías de encendido una por una, marcando el

número del cilindro del que fueron quitadas y colóquelas

sobre una superficie plana limpia. Esto le ayudará a

identificar los cilindros problema al per-mitirle hacer una

comparación de la apariencia de la bujía de encendido con

el nivel de compresión de un cilindro determinado.

NOTA: Al probar motores con dos bujías de encendido por cilindro, sólo es necesario quitar las bujías de

encendido localizadas del lado del escape.

6. En los vehículos con distribuidores convencionales,

desconecte el cable de la bobina (el conductor de alta

tensión) de la tapa del distribuidor y fíjelo a una tierra

apropiada o inactive el encendido desconectando la terminal

positiva (BAT) de la bobina del sistema de encendido.

7. En los vehículos con un sistema de encendido sin distribuidor (DIS), inactive el sistema de encendido quitando el

fusible del módulo (de control) del encendido electrónico o

desconecte el sensor del ángulo del cigüeñal.

NOTA: Consulte el manual de servicio apropiado

para determinar cuál fusible o componente debe

quitarse o desconectarse temporalmente.

8. Quite el filtro de aire del carburador o el cuerpo del estrangulador y asegure el varillaje del estrangulador en la

posición del estrangulador totalmente abierto (ETA).

NOTA: NUNCA coloque alguna cosa dentro del cuerpo

del estrangulador pues esto podría resol-tar en

daños internos en el motor. En los vehículos equipados con inyección de combusti-ble en los puertos,

quite las cubiertas del varillaje del estrangulador

(según sea necesario) y asegure el varillaje del

estrangulador en la posición del estrangulador

totalmente abierto (ETA).

9. Haga girar el motor varias veces, sin arrancarlo, para

asegurar la eliminación de cualquier materia extraña que

pueda haber caído dentro de los cilindros durante la

preparación para la prueba.

10. Seleccione la conexión adaptadora apropiada (14 mm, 18

mm de corto alcance o 14 mm, 18 mm de largo alcance) y

atorníllela en el agujero de la bujía de encendido de la culata

de cilindros.

11. Conecte la manguera de prueba o la conexión adaptadora

apropiada al conjunto de la carátula del compresómetro.

12. Haga girar el motor, sin arrancarlo, por lo menos cinco

carreras de compresión o hasta que la lectura de presión

deje de aumentar en la carátula del compresómetro.

13. Lea el nivel de presión en el compresómetro y regístrela

junto con el número del cilindro que esté probando. Ejemp-

lo: #1150 psi, #2145 psi, etc.

14. Repita esta prueba en cada cilindro. Si se encuentra que

cualquiera de las lecturas de los cilindros es baja o

desigual, haga la prueba de compresión en condiciones

húmedas.

15. Cuando la prueba de compresión esté completa, vuelva a

colocar las bujías de encendido en sus respectivos cilindros

y vuelva a colocar los componentes del varillaje y el

encendido en sus posiciones normales.

Form 823451

Page Number - 7

Page 8

Procedimiento de la Prueba de Compresión

en Condiciones Húmedas

PRECAUCIÓN: NO haga la prueba de compresión en condiciones húmedas en ningún motor diesel. La mayor

compresión en un motor diesel puede causar daños al

motor o lesiones al técnico.

La compresión en condiciones húmedas es una manera de

eliminar la influencia de los anillos de los pistones, los pistones y

los cilindros de la prueba de compresión. Después de hacer la

prueba de compresión en seco, inyecte con la aceitera un chorro

de aproximadamente una cucharadita de aceite para motores en

los agujeros de las bujías de encendido y haga girar el motor

varias veces, sin arrancarlo, para sellar los anillos de los pistones. Repita los pasos de la prueba de compresión en seco

mencionados arriba. NOTA: Si las lecturas durante la prueba de

compresión en condiciones húmedas son mayores, entonces hay

escapes de aire alrededor de los anillos de los pistones gastados o dañados. Si la lectura es aproximadamente igual para las

pruebas en condiciones húmedas y las pruebas en seco,

entonces las válvulas, los levantaválvulas o los lóbulos del árbol

de levas están gastados. Cualquier lectura baja de compresión

de los cilindros indica partes gastadas o dañadas.

Pruebas de Compresión de Motores

Pequeños

El Probador de Compresión Profesional Craftsman tiene dos (2)

adaptadores, de 10 mm y 12 mm, que permiten usarlo en los

motores que se encuentran en las podadoras de césped, las

cadenas de motosierras y las recortadoras de cable. Para usar

estos adaptadores:

1. Desconecte el cable de la bujía de encendido y quite ésta.

2. Atornille el adaptador de tamaño apropiado en la manguera

principal del compresómetro hasta que asiente el anillo en “O”

(no use una llave para apretarlo).

3. Atorníllelo en el agujero de la bujía de encendido del cilindro

hasta que el anillo en “O” del adaptador se asiente firmemente

(no use una llave para apretarlo).

4. Asegúrese que la bujía de encendido esté conectada a tierra

con la culata del cilindro o que esté aislada de tal manera que

evite un riesgo de choque (toque) eléctrico.

5. Haga girar el motor utilizando el cordón de arranque (o el motor

de arranque si es eléctrico) un mínimo de 5 revoluciones. Esto

permitirá que el cilindro acumule una compresión suficiente

para que pueda medirse.

6. Consulte los datos del fabricante para determinar la lectura

correcta.

Como Usar el Adaptador de Retención de

Presión

El Probador de Compresión Profesional Craftsman viene con un

adaptador de retención de presión. Este

adaptador se usa cuando los sellos de las válvulas de un motor

son reemplazados sin quitar la culata o culatas del cilindro o

cilindros. Para usar el adaptador:

1. Quite la bujía de encendido del cilindro deseado.

2. Seleccione la manguera de extensión apropiada que se adapte

al agujero de la bujía de encendido.

3. Utilizando la herramienta de remoción del pivote core de válvula

(del equipo de servicio de campo incluido), quite el pivote core

de válvula del extremo de la manguera y póngalo aparte.

4. Atornille la manguera de extensión en el agujero de la bujía de

encendido hasta que asiente el anillo en “O”; no use pinzas ni

una llave para apretarla.

5. Fije el conector rápido de Retención de Aire a la manguera de

extensión.

6. Conecte una manguera de aire comprimido del taller al Adaptador de Retención de Aire, esto proporcionará aire continuo en

el cilindro para mantener las válvulas cerradas mientras se

hacen las reparaciones. (Podría ser necesario hacer girar el

motor hasta que todas las válvulas estén cerradas y el aire

esté retenido en el cilindro).

Nota: El conector rápido de Retención de Aire no viene

con una conexión para línea de aire comprimido que

pueda adaptar a su fuente de aire comprimido. Ésta

tendrá que comprarse por separado para adaptarla a

su sistema.

Lista de Partes

• Manómetro de 2¾” para servicio pesado con vidrio de alta

resistencia al impacto, cubrepolvos de hule y tres diferentes

escalas de medición: PSI, kg/cm2 y bares, una manguera de

conexión flexible de 10” fija y un Acoplador Rápido para

rapidez en la preparación

• Válvula de alivio de presión montada en el cuello del compresómetro para fácil acceso

• Cuatro mangueras de extensión: 6½ “ de 14 mm de corto

alcance, 12” de 14 mm de corto alcance, 12” de 14 mm de

largo alcance y 12” de 18 mm de corto alcance

• Un adaptador de largo alcance con conexión hembra de 14 mm

y conexión macho de 18 mm

• Dos adaptadores para motores pequeños: de 12 mm y 10 mm

• Un adaptador de retención de aire de desconexión rápida para

dar servicio a los sellos de las válvulas en el vehículo

• Estuche especial moldeado por soplado para protección y fácil

almacenamiento

• Equipo de servicio de campo, que incluye sellos, válvulas

Schrader y la herramienta de remoción del pivote core usada

para mantener su equipo.

Para obtener respuestas a preguntas técnicas, o para pedir

piezas de repuesto, llame o envíe un fax:

Teléfono: (314)679-4200

Fax: (314)679-HELP (4357)

Garantía completa de un año

Si este juego de prueba de compresión Craftsman® tiene defectos

de materiales o fabricación en un plazo de un (1) año contado a

partir de la fecha de compra, devuélvalo a su tienda Sears más

próxima en Estados Unidos, y se le reemplazaremos de forma

gratuita.

Esta garantía le da derechos legales específicos, y también puede

tener otros derechos que varían de un estado a otro.

Sear, Roebuk and Co., Dept. 817WA

Hoffman Estates, IL 60179”

P ARA EVIT AR LESIONES PERSONALES Y/O DAÑOS AL

VEHÍCULO:

Aunque en este manual se especifican algunas precauciones

y éstas deben tomarse en cuenta para evitar las lesiones

personales o los daños al vehículo, no es posible que estas

precauciones cubran todas las formas imaginables en las que

podrían hacerse el servicio o las pruebas, o todas las posibles

consecuencias peligrosas de cada forma, ni tampoco Lincoln

posiblemente podría conocer o investigar todas esas formas.

Por lo tanto, es responsabilidad de cualquier persona que use

este manual o cualquier otro producto Craftsman, convencerse

por completo que ni la seguridad personal ni la seguridad del

vehículo se pondrán en peligro por los métodos de servicio

seleccionados. Cualquier lesión o daño de ese tipo es totalmente responsabilidad del usuario. Este dispositivo no debe

usarse de ninguna manera en el cuerpo humano.

Page Number - 8

Form 823451

Loading...

Loading...