Craftsman 390304692 Owner’s Manual

SEARS

OWNER'S

MANUAL

MODELNO.

390.304692

CAUTION:

Read and Follow

All SafetyRulesand

Operating Instructions

Before FirstUseof

ThisProduct.

Save ThisManual For

FutureReference.

Sears, Roebuck and Co., Haffman Estates, IL 60179 U.S.A.

I:RRFTSMRN°

SUBMERSIBLE

SUMP PUMP

• Safety Instructions

• Installation

• Electrical

• Maintenance

• Repair Parts

Form No. F642-05004 (3/22/05)

CONTENTS

INTRODUCTION/WARRANTY ......................................... 2

SAFETY ........................................................................... 2-3

INSTALLATION ............................................................... 3-4

ELECTRICAL ...................................................................... 4

MAINTENANCE ................................................................. 5

SERVICE ............................................................................. 5

PARTS ................................................................................ 6

INTRODUCTION

Please read our instructions before you install and use your

new pump; this will help you obtain full value and good ser-

vice from it. It vdll also help you avoid needless service costs

that result from causes we cannot control and cannot cover

in our warranty.

GENERAL SAFETY INFORMATION

Carefully read and follow all safety instructions in this

manual or on pump.

_k This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one

of the following signal words and be alert to the potential

for personal injury!

_ warns about hazards that will cause serious

personal injury, death or major property damage if ignored.

WARNING

A ]warns about hazards that will or can cause se-

rious personal injury, death or major property damage if ig-

nored.

I& CAUTION ]warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The word NOTICE indicates special instructions which are

important but not related to hazards.

Electrically powered sump pumps normally give many years

of trouble-free service when correctly installed, maintained,

and used. However, unusual circumstances (interruption of

power to the pump, dirt/debris in the sump, flooding that ex-

ceeds the pump's capacity, electrical or mechanical failure in

the pump, etc.) may prevent your pump from functioning

normally. To prevent possible water damage due to flooding,

]

consult your local Sears store about installing a secondary

sump pump or a DC backup sump pump. See "Service", Page

6, for information about common sump pump problems and

remedies.

l,

To avoid risk of serious bodily injury and property dam-

age, read safety instructions carefully before installing

pump.

2.

Follow local and/or national plumbing and electrical

codes when installing pump.

3.

[&WARNING]To avoid fatal shocks, proceed as fol-

lows if pump needs servicing:

A.Disconnect power to pump outlet box before

pulling pump cord plug, After plug is pulled, let

pump cool for 20 minutes before attempting to work

on it. Modern motors may operate at high temperatures.

B. Take extreme care when changing fuses. To re-

duce the chance of fatal electrical shocks, DO NOT

stand in water or put your finger in the fuse socket.

C. Ground the electrical outlet box.

D.Use only an individual branch circuit with a

grounded outlet for cord plug.

2

SAFETY / INSTALLATION

4. Never run pump dry. To do so can damage internal

parts, overheat the pump (witich can cause burns to peo-

ple handling or servicing the pump), and will void the

warranty!

5. DO NOT attempt to oil the pump motor. A special off has

been put into the motor housing atthe factory; use of any

other oil will void the warranty and could damage the

pump.

6. This pump is recommended for use in permanent instal-

lations only. This pump has not been invenstigated for use

in swimming pool areas.

7. Know the pump application, limitations, and potential

hazards. Not for use with salt water or brine.

[&WARNING]Do not use in explosive atmospheres.

Pttmp water only with this pump. Failure to follow

this warning can result in personal injury and/or

property damage.

8. Release all pressure within the system before servicing

any component.

9. Drain water from the system before servicing.

10. Secure the discharge line before starting the pump. An un-

secured discharge line v(ill whip, possible causing per-

sonal injury and/or property damage.

11. Periodically inspect pump and system components. Perform

rouOne maintenance as required (See MAINTENANCE).

12. Provide a means of pressure relief for pumps whose dis-

charge line can be shut-off or obstructed.

13. Personal Safety:

a. Wear safety glasses at all times when working with

pumps.

b. Keep work area clean, uncluttered and properly

lighted - replace all unused tools and equipment.

c. Keep visitors at a safe distance from the work area.

d. Make workshop child-proof - with padlocks, master

svdtcbes, and by removing starter keys.

14. This equipment is only for use on 115 volt (single phase)

and is equipped with an approved 3-conductor cord and

3-prong, grounding-type plug.

[AWARNING]To reduce the risk of electric shock,

pull plug before servicing. This pump has not been

investigated for use in swimming pool areas. This

pump is supplied with a grounding conductor and

grounding-type attachment plug. Be certain that it

is connected only to a properly grounded ground-

ing-type receptacle,

Where a 2-prong wall receptacle is encountered, it

must be replaced with a properly grounded 3-prong

receptacle installed in accordance with the National

Electrical Code and local codes and ordinances.

15. Protect electrical cord from sharp objects, hot surfaces,

oil, and chemicals. Avoid kinking the cord. Replace or re-

pair damaged or worn cords immediately.

16. Do not handle a pump or pump motor with wet hands or

when standing on a wet or damp surface, or in water.

[AWARNING_Risk of electric shock. If your basement

has water or moisture on the floor, do not walk on wet

area until all power has been turned off. If shut-off

box is in basement, call the electric company to shut-

off service to the house, or call your local fire depart-

ment for instructions. Remove pump and repair or

replace. Failure to follow this warning can result in

fatal electrical shock.

ADDITIONAL INSTALLATION

MATERIALS (Purchase Separately)

Sump Pump Hose Kit, SEARS Stock No. 27909, containing

24' (7.3M) of 1-1/4" flexible plastic pipe, 1-1/4" plastic

adapter and stainless steel clamp. We recommend a Check

Valve, SEARS Stock No. 2789 or 2792.

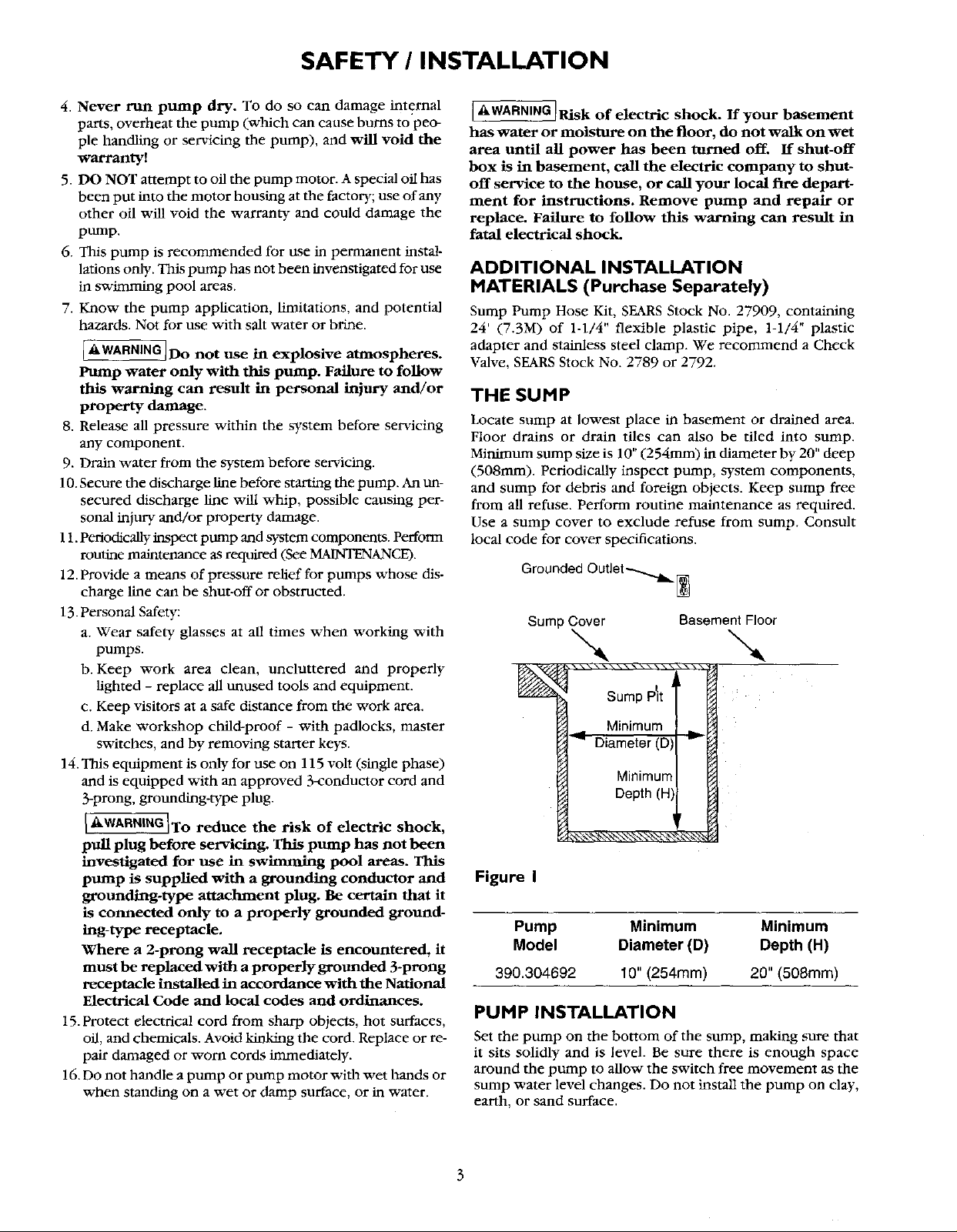

THE SUMP

Locate sump at lowest place in basement or drained area.

Floor drains or drain tiles can also be tiled into sump.

Minimum sump size is 10" (254mm) in diameter by 20" deep

(508ram). Periodically inspect pump, system components,

and sump for debris and foreign objects. Keep sump free

from all refuse. Perform routine maintenance as required.

Use a sump cover to exclude refuse from sump. Consult

local code for cover specifications.

Grounded Outlet -_..jb,,. _

Sump Cover Basement Floor

_xx\xxxx\-. \\-, \\ ,\\\

Sump P_t '

Minimum

_" Diameter (D) --

Minimum

Depth (H)

_r

Figure I

Pump Minimum Minimum

Model Diameter (D) Depth (H)

390.304692 10" (254mm) 20" (508ram)

PUMP INSTALLATION

Set the pump on the bottom of the sump, making sure that

it sits solidly and is level. Be sure there is enough space

around the pump to allow the switch free movement as the

sump water level changes. Do not install the pump on clay,

earth, or sand surface.

Loading...

Loading...