Craftsman 390304551, 390304611, 390304691 Owner’s Manual

SF.A/ $

OWNER'S

MANUAL

MODELNO.

390.304551

390.304611

390.304691

Model No. 390.304551 - 1/4 HP

CAUTION:

Read and Follow

All SafetyRulesand

Operating Instructions

BeforeFirstUseof

ThisProduct.

Save ThisManual For

FutureReference.

CRAFTSMANModel

No. 390.304611 - 1/3 HP

SUBMERSIBLE

SUMP PUMP

• Safety Instructions

• Installation

• Electrical

• Service

• Repair Parts

CRAFTSMANModel

No. 390.304691 - 1/3 HP

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

PRINTED IN U.S.A. Form No. F642-9612 (Rev. 12/6/96)

CONTENTS

INTRODUCTION

INTRODUCTION/WARRANTY .......................................... 2

SAFEI'Y ............................................................................... 2

INSTALLATION ................................................................... 3

ELECTRICAL .......................................................................4

SERVICE .............................................................................. 5

PARTS ............................................................................... 6-7

FULL ONE YEAR WARRANTY ON SEARS SUBMERSIBLE SUMP PUMPS

During the first year after the date of purchase, Sears will repair or replace this pump, free of charge, if defective in materials or

workmanship.

This warranty does not cover repairs on replacement-parts necessary because of abuse or negligence includingfailureto in-

stall, adjust and operate this pump according to the instructionsin the owner's manual.

LIMITED WARRANTY ON CRAFTSMAN SUBMERSIBLE SUMP PUMPS

During the second year after the date of purchase, Sears will furnish,free of charge, a replacement part for any defective part.

You pay for labor.

LIMITATION OF LIABILITY

SEARS WILL NOT BE LIABLE FOR LOSS OR DAMAGE TOPROPERTY OR ANY INCIDENTAL OR CONSEQUENTIAL LOSS

OR EXPENSE FROM PROPERTY DAMAGE DUE DIRECTLY OR INDIRECTLY FROM THE USE OF THIS PRODUCT.

Some states do not allow the exclusion or limitationof incidentalor consequential damages, so the above limitatJ6nor exclu-

sion may not apply to you.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERVICE CENTER/DEPART-

MENTIN THEUNITED STATES ofAMERICA. For serviceoutsidethe U.S.A., contactyour localSears Service Center or store.

This warranty gives you specific legal rights, and you may also have otherdghts which vary from state to state.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

Please read our instructions before you install and use your

new pump; this will help you obtain full value and good ser-

vice from it. It will also help you avoid needless service costs

that result from causes we cannot control and cannot cover

in our warranty.

RULES FOR SAFE INSTALLATION AND OPERATION

Carefully read and follow all safety instructions in this

manual or on pump.

_, This is the safety alert symbol Xgqlenyou see this _m-

bol on your pump or in this manual, look for one of the

following signal words and be alert to the potential for personal

injury'.

_wams about hazards that will cause serious per-

sonal injury,, death or major property damage ff ignored.

IAWARNING Iwams about hazards that will or can cause seri-

ous personal injury,, death or major property damage ffignored.

iA CAO'rlONiwarns about hazards that will or can cause

minor personal injury, or property, damage ff ignored.

The word NOTICE indicates special instructions which are im-

portant but not related to hazards.

Electrically powered sump pumps normally give many years of

trouble-free service when correctly installed, maintained, and

used. However, unusual circumstances (interruption of power

to the pump, dirt/debris in the sump, flooding that exceeds the

pump's capacity, electrical or mechanical failure in the pump,

etc.) may prevent your pump from functioning normally. To pre-

vent possible water damage due to flooding, consult your local

Sears store about installing a secondary sump pump or a DC

backup sump pump. See _Service", Page 5, for information

about common sump pump problems and remedies.

1. To avoid risk of serious bodily injury, and property damage,

read safety, instructions carefully before installing pump.

2. FoUow local and/or national plumbing and electrical codes

when installing pump.

3. [AWARN|NG ]To avoid fatal shocks, proceed as follows

if pump needs servicing:

A.Disconnect power to pump outlet box before

pulling pump cord plug. After plug is pulled, let pump

cool for 20 minutes before attempting to work on it.

Modem motors are designed to operate at high tempera-

totes.

B. Take extreme care when changing fuses. To reduce

the chance of fatal electrical shocks, DO NOT stand in

water or put your finger in the fuse socket.

C. Ground the electrical outlet box,

D.Use ordT a Ground Fault Circuit Interrupter (GFCI)

protected grounded oudet for cord plug.

4. Never run pump dry. To do so can damage internal parts,

overheat the pump (which can cause burns to people han-

dling or servicing the pump), and will void the warrant_.

5. DO NOT attempt to oil the pump motor. A special oil has

been put into the motor housing at the factory; use of any

other oil will void the warranty and could damage the pump.

6. This pump is recommended for use in permanent installa-

tions only. Pump water only with this pump.

ADDITIONAL INSTALLATION

HATERIALS

SEARS Sump/Utility Pump Hose Kit, Stock No. 27909, con-

taining 24' ('7.3M) of 1-1/4" flexible plastic pipe, a 1-1/4" plas-

tic adapter and a stainless steel clamp.

Check Valve, SEARS Stock No. 2789.

INSTALLATION

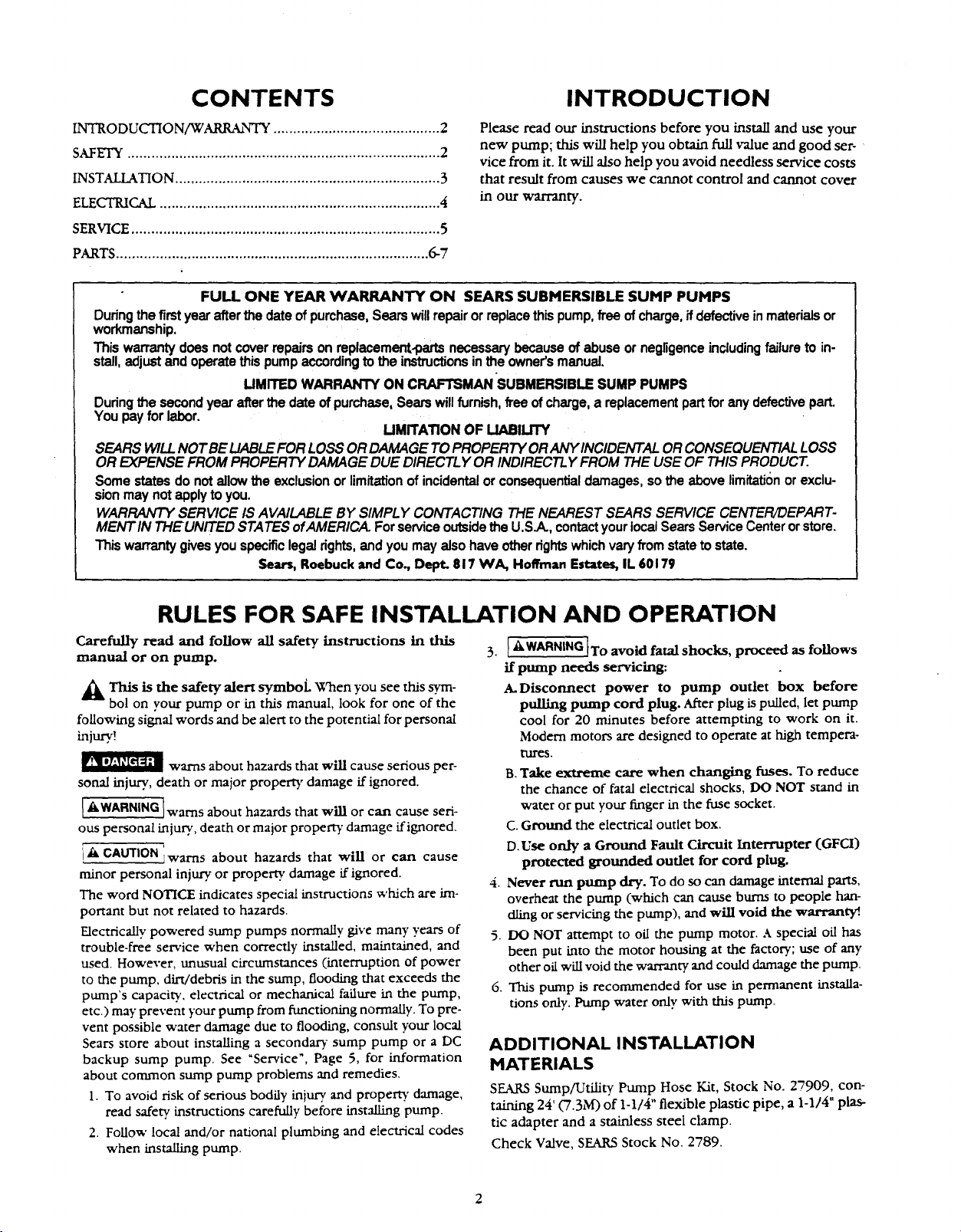

THE SUMP

The sump should be located at the lowest place in the base-

ment or area to be drained. Floor drains from other areas in

the basement may be tiled into the sump. Drain tile around

a house foundation can also be tiled into the sump, effec-

tively removing water and relieving pressure from tiffs area.

A suitable sump can be a 20" or 24" (500-610ram) sewer tile.

The minimum size is 12" (305ram) in diameter for Models

390.304551 and 390.304611; 10" (254mm) for Model

390.304691.

A sump cover is desirable to exclude refuse from the sump.

Consult local code for sump cover specifications.

NOTICE: Periodically inspect pump, system comporlents,

and sump for debris and foreign objects. Keep sump free of

all refuse. Perform routine maintenance as required.

PUMP INSTALLATION

Set the pump on the bottom of the sump, making sure that

is sits solidly and is level. Be sure there is enough space

around the pump to allow the switch free movement as the

sump water level changes. Pump should not be installed on

clay, earth, or sand surfaces.

[A CAUTION]Risk of flooding. If a flexible discharge hose

is used, pump may move around in sump when motor starts.

If it moves far enough so that the switch hits the side of the

sump, the switch may stick and prevent pump from starting.

Make sure that pump is secured so that it cannot walk

around in sump.

Hose Kit No. 27909 includes 1-1/4" flexible plastic pipe for

the discharge pipe. Run discharge pipe to the nearest sewer

outlet or other point of disposal. Use the most direct route

and the fewest turns and elbows possible. Make sure that

pump cannot move around in sump pit.

Use teflon tape to seal threads in plastic pipe. Hand tighten

only.

NOTE: To avoid backflow into sump when pump shuts off,

install a SEARS Check Valve, Stock No. 2789, in threaded dis-

charge port of pump. Be sure arrow on check valve body

points away from the pump. This Sears check valve is

equipped with an air bleed hole to prevent airlocking pump.

If using any other check valve, drill 1/8" (3.2ram) hole in

dishcharge pipe just above pump body but below check

valve to prevent air locks.

FLOAT SWITCH

INSTALLATION AND OPERATION

(Models 390.304551 and 390.304611;

For Model 390.304691, see Page 7)

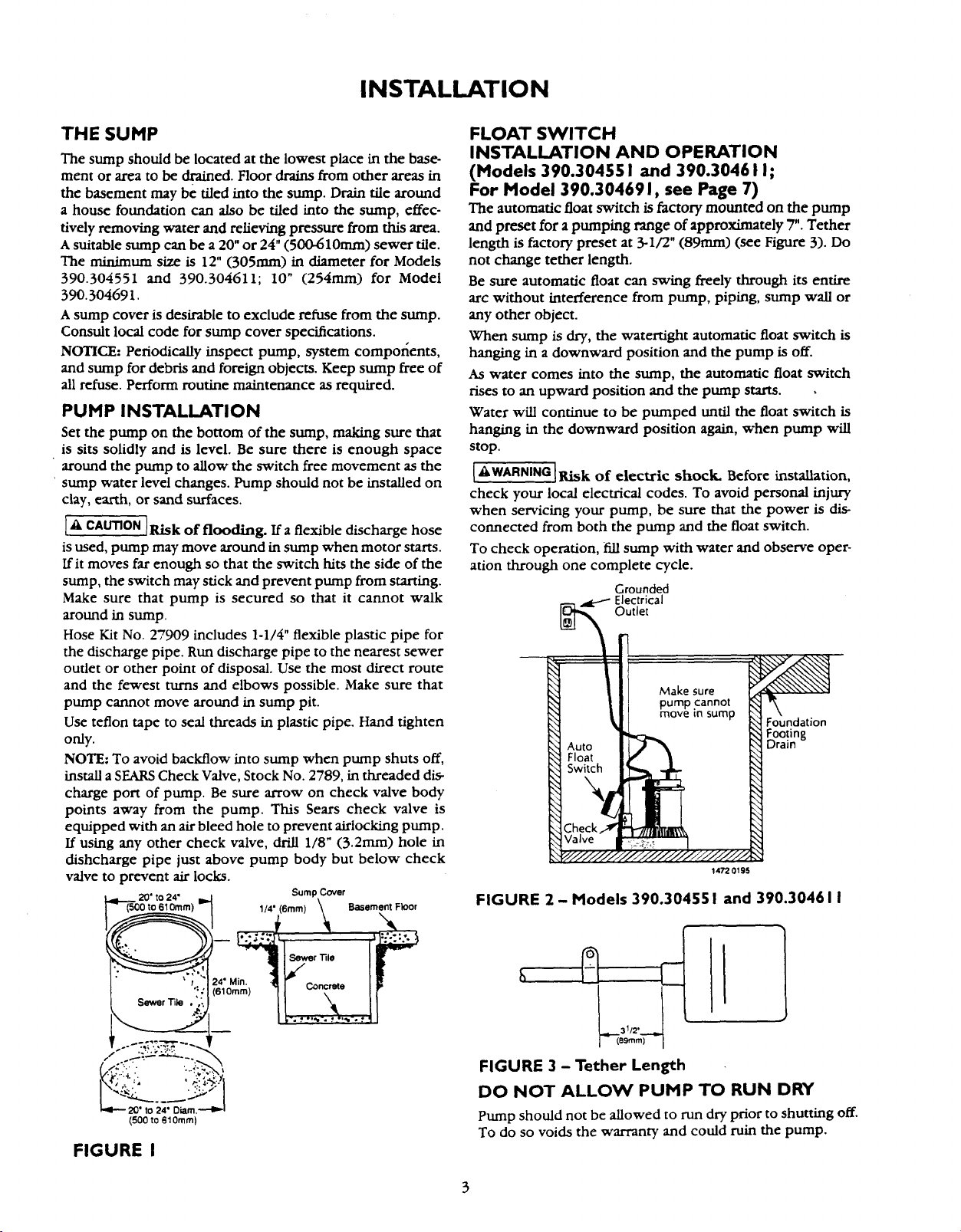

The automatic float switch is factory mounted on the pump

and preset for a pumping range of approximately 7". Tether

length is factory preset at 3-1/2" (89ram) (see Figure 3). Do

not change tether length.

Be sure automatic float can swing freely through its entire

arc without interference from pump, piping, sump wall or

any other object.

When sump is dry, the watertight automatic float switch is

hanging in a downward position and the pump is off.

As water comes into the sump, the automatic float switch

rises to an upward position and the pump starts. ,

Water will continue to be pumped until the float switch is

hanging in the downward position again, v-hen pump will

stop.

I _xWARNING1Risk of electric shock. Before installation,

check your local electrical codes. To avoid personal injury

when servicing your pump, be sure that the power is dis-

connected from both the pump and the float switch.

To check operation, fill sump with water and observe oper-

ation through one complete cycle.

Grounded

lectrical

Outlet

Make sure

pump cannot

Auto

Float

Switc

move m sump

Foundation

Footing

Drain

\

Check

Valve

1472 0195

FIGURE 2 - Models 390.304551 and 390.30461 I

L:.:. -- ;"" "" ":"""'""

'°'°ram'

l <5... ....,.'._'

(500 to 610mini

FIGURE I

._,.__ 31/2"__._

(SSmm)

FIGURE 3 - Tether Length

DO NOT ALLOW PUMP TO RUN DRY

Pump should not be allowed to run dry prior to shutting off.

To do so voids the warranty and could ruin the pump.

3

Loading...

Loading...