Craftsman 390291652, 390291690, 390291552, 390291352 Owner’s Manual

F642-9301

OWNER"

MA UAL

Model No.

390.291352

390.291552

390.291652

390.291690

390.291751

CAUTION:

Read and Follow

All Safety Rulesand

Operating Instructions

BeforeFirstUseof

ThisProduct.

CAPTIVE AIR®TANK

• Safety Instructions

• Installation

• Operation

Save ThisManual For

FutureReference.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

PRINTED IN USA Form No F642-9301 (Rev 9/20/95)

• Service Hints

. Repair Parts

READ AND FOLLOW SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this sym-

bol on your tank or in this manual, look for one of the fol-

lowing signal words and be alert to the potential for

personal injury:

DANGER warns about hazards that will cause serious per-

sonal injury, death or major property damage if ignored.

WARNING warns about hazards that will or can cause se-

rious personal injury, death or major property damage if ig-

nored.

N,NGi

CAUTION warns about hazards that will or can cause

minor personal injury or property damage if ignored.

o,oT,oNI

RULES FOR SAFE INSTALLATION AND OPERATION

1. Read these Rules and the Instructions carefully. Failure

to follow them could cause serious bodily injury and/or

property damage.

&WARNING These water storage tanks are designed for

Hazardous operation on cold well water systems lira-

pressure ited to a maximum working pressure of 100

pounds per square inch (PSI). If your water system can ex-

ceed 100 P.S.I., install a Sears No. 27220 relief valve on the

system. Failure to follow these instructions can cause tank

blow-up and result in serious injury.

The label NOTICE indicates special instructions which are

important but not related to hazards.

Carefully read and follow all safety instructions in

this manual and on tank.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

NOTICE: Mthough No. 27220 Relief Valve is set to open

at 75 PSI, for your safety Captive Air@ Tanks are designed

and rated to operate at up to 100 PSI.

2. Be sure installation meets all local plumbing, pump,

electrical and well codes.

3. Always test water from well for purity before using. Call

your local health department for testing procedure.

4. Before installing or servicing your pump, BE SURE

pump power source is disconnected.

CONTENTS

INTRODUCTION

W._NTY ........... , ................. , .... ,, .... ,, ............. ,.o,.., ..... ,.2

SAFETY ............................................................................ 2

INSTALLATION ............................................................. 3-6

OPERATION ...................... :............................................. 7

SERVICE HINTS ............................................................ 7-9

REPAIR PARTS........................................................... 10-11

BASIC TOOLS AND HATERIALS NEEDED

PLASTIC PIPE INSTALLATIONS

TOOLS HATERIALS

Pipe Wrenches

Screwdriver

Knife or Saw to Cut Plastic Pipe

Tire Pressure Gauge

Plastic Pipe and Fittings (as required to complete job).

Teflon Tape (DO NOT use pipe joint compound on

plastic fittings) or Plasto-Joint Stik*

Please read our instructions before you install and use your

tank. This will help you obtain full benefits from this tank.

It will also help you avoid needless service expense that

result from causes we cannot control and cannot cover in

our Wan-anty.

GALVANIZED STEEL PIPE INSTALLATIONS

TOOLS

Pipe Wrenches

Screwdrivers

Pipe Cutting and Threading Tools

Tire Pressure Gauge

Galvanized Pipe and Fittings (as required to complete job).

Pipe Joint Compound or Teflon tape

INSTALLATION

,_kWARNING ff your system can develop more than 100

Hazardous PSI pressure, install a Sears No. 27220 re-

pressure lieve valve in system to prevent possibility

of tank blow-up.

NOTICE: DO NOT use any type of lubricant other than

water on Hose to Plastic fittings.

If rigid piping is installed to elbow on inlet flange, BE SURE

to support the piping.

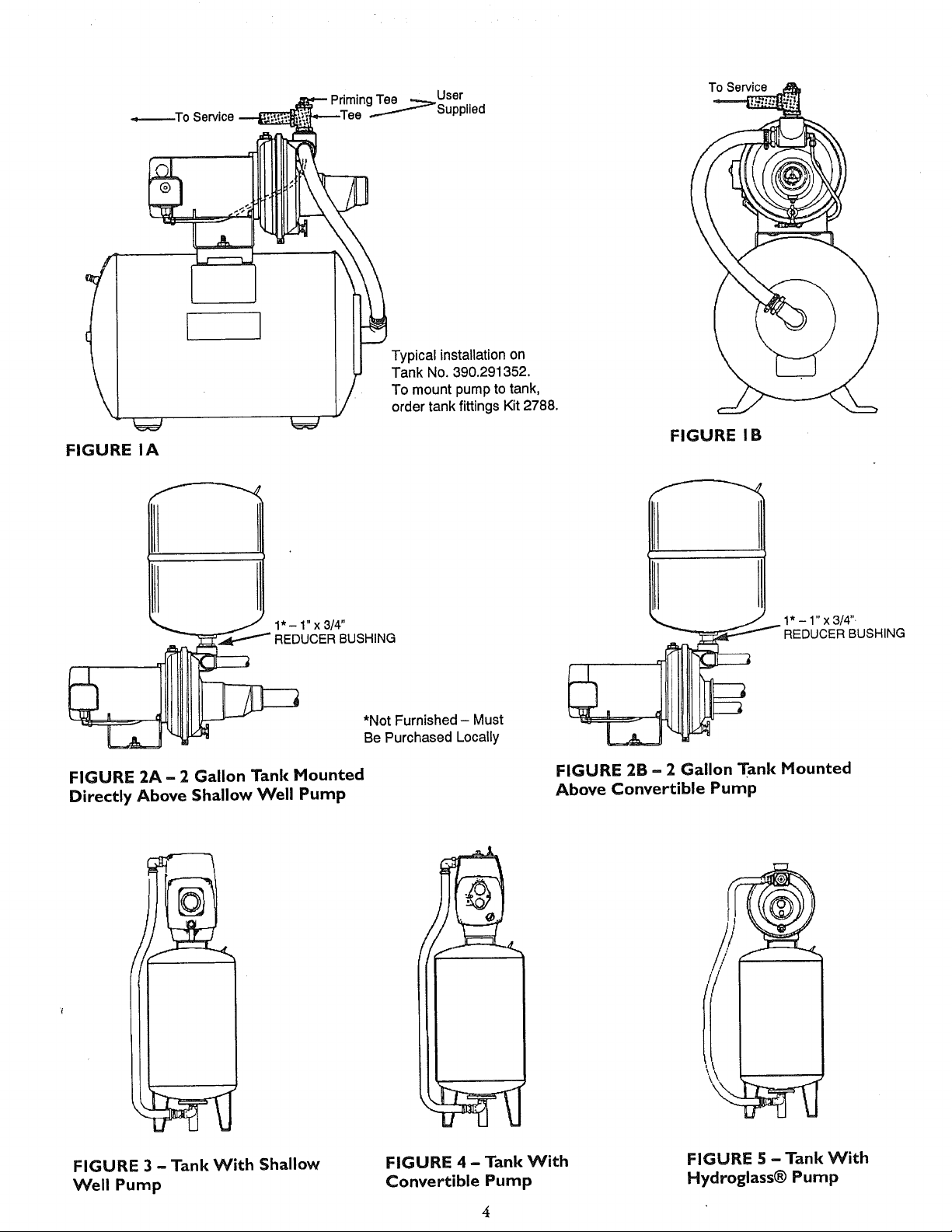

For proper installation of your pump to tank, follow one

of the typical installations on Page 4 and 5. Use Teflon tape

on all threaded connections to tank.

HATERIALS

Standard pipe fittings, such as nipples, tees and elbows

must be purchased locally. If you are using a horizontal jet

pump mounted on top of tank, Figures 3, 4 and 5, Kit No.

2788 is required. See Page 10 for contents of kit.

If your present system has an air volume control (AVC), re-

move it and plug AVC port on pump.

Complete pump, tank, and piping system MUST be pro-

tected against below freezing temperature. Failure to do

so could cause severe damage and voids the warranty.

* lake Chemical Co., Chicago, Illinois.

--To Service

Priming Tee .._= User, .

......---_- _upp eo

To Service

[

FIGURE IA

]

i

1* - 1" x 3/4"

UCER BUSHING

FIGURE 2A - 2 Gallon Tank Hounted

Directly Above Shallow Well Pump

Typical installation on

Tank No. 390.291352,

To mount pump to tank,

order tank fittings Kit 2788.

FIGURE I B

- 1" x 3/4"-

REDUCER BUSHING

•Not Furnished - Must

Be Purchased Locally

FIGURE 2B - 2 Gallon Tank Hounted

Above Convertible Pump

FIGURE 3 - Tank With Shallow

Well Pump

FIGURE 4 - Tank With

Convertible Pump

FIGURE 5 - Tank With

Hydroglass® Pump

Loading...

Loading...