Craftsman 390284021, 390284041, 390284061, 390284071, 390284081 Owner’s Manual

...

SEARS

OWNER'S

MANUAL

3 WIRE

3-WIRESUBMERSIBLE

PUMPMODELNos.

390.284021 390.284071

390.284031 390.284081

390.284041 390.28409]

390.284051 390.284370

390.284061 390.284380

390.284390

CONTROLCENTERNos.

390.284121 390.284251

390.284131 390.284261

390.2841 390.284271

2-WIRESUBMERSIBLE

PUMPMODELNos.

390.285511

390.2855

390.2853

CONTROL CENTER

I:RRFTSMRN°

TWO and THREE WIRE

CAUTION:

Read and Follow

All Safety Rulesand

Operating Instructions

Before FirstUse of

ThisProduct.

SaveThisManual For

FutureReference.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

PRINTED IN U.S.A. Form No. F642-04078 (7/21/04)

SUBMERSIBLE PUMPS

• Safety Instructions

• Installation

• Operation

• Troubleshooting

• Repair Parts

CONTENTS

Safety ................................................................................... 2

Pump Performance/General Information ........................... 3

Before You Start/Tools/Materials ........................................ 4

Installation

Piping .................................................................... 4-5, 8-12

Electrical ........................................................................ 6-8

Helpful Hints ................................................................. 11-12

Parts .............................................................................. 13-15

INTRODUCTION

Please take a few minutes to read our instructions before in-

stalling your submersible pump. It vffll help to assure per-

fect installation and help you avoid needless service

expenses.

RULES FOR SAFE INSTALLATION AND OPERATION

Carefully read and follow all safety instructions in this man-

ual or on pump.

_1, This is the safety alert symbol. When you see this sym-

bol on your pump or in this manual, look for one of

the following signal words and be alert to the potential for

personal injury!

_ warns about hazards that will cause serious

personal injury, death or major property damage if ignored.

[AWARNING] warns about hazards that can cause serious

personal injury, death or major property damage if ignored.

[_ CAUTION ] warns about hazards that will or can cause

minor personal in jury or property damage if ignored.

The word NOTICE indicates special instructions which are

important but not related to hazards.

To avoid risk of serious bodily injury and property

damage, read safety instructions carefully before in-

stalling pump.

1. _kWARNING Under certain conditions, submersible

Hazardous

pressure pumps can develop extremely high pres-

of passing entire pump flow at 75 PSI (517kPa).

_kDo not allow pump, pressure tank, piping, or

any other system component containing water

to freeze. Freezing may damage system, leading to in-

jury or flooding. Allowing pump or system compo-

sure. Install a pressure relief valve capable

nents to freeze will void warranty.

2. Follow local and/or national plumbing and electrical

codes when installing pump.

3. Keep well covered while installing pump to prevent

leaves and other foreign material from falling into well,

contaminating the well and possibly damaging the pump.

4. Protect pump and piping system from freezing. Allowing

pump or water system to freeze could severely damage

pump and voids warranty.

5. To protect system against over-pressure, install a pressure

relief valve (Stock No. 2729).

6. With a new well, test well water for purity before using.

Constflt your local Health Department for procedure.

LAWARNING[Hazardous voltage. Can shock, burn,

cause death, or start fires.

7. Disconnect electrical power source before installing or

working on pump.

8. Use pump only in a well application.

9. Correct fusing, vdring and grounding are essential to

proper operation. See Page 6 for electrical instructions.

10. Line voltage and frequency listed on motor nameplate

must agree with line voltage and frequency of electrical

power supply.

11. Use of fuses or wire smaller than size recommended in

owner's manual can cause overheating, possible fires,

and will void warranty.

2

GENERAL INFORMATION

NOTICE: Model Number of your pump is located on the

pump shell. Record this number and keep in a safe place for

future reference in the event service is needed.

The most important things you should know about your well

are: (l) its total depth; (2) depth to water; (3) draw down

water level.

1. The well total depth is the distance from the ground

level to the well bottom.

Record the following information at the time of

installation and retain R for future reference:

Pump Model No.

Control Center Model No.

Horsepower

Volts

Phase

2. Depth to water is measured from the ground level to the

water level in the well when the pump is not running.

3. Draw down water level is the distance from ground

level to the water level while water is being pumped. In

most wells, the water level drops when water is being

pumped.

Usually you can obtain this information from your well

driller. Enter it in box at fight.

Hertz

Full Load Amps

Well Casing Diameter

Wetl Depth

Depth to Water

Draw Down Water Level

Table I - Pump Performance Chart (In Gallons Per Minute)

Residential Pumps with 1-1/4" Discharge

Model Pressure

Number H.P. Voltage Stages P.SJ, 20 40 60 80 100 125 150 175 200

390.285511 1/2 115 6 40 13.6 12.6 11.5 10.1 8.6

390.2855 1/2 230 6 40 13.6 12.6 11.5 10.1 8.6

390.284021 1/2 230 6 40 13.6 12.6 11.5 10.1 8.6

390.2853 3/4 230 8 40 13.5 12.7 11.9 10.7 9.4 7.9

390.284031 3/4 230 8 40 13.5 12.7 11.9 10.7 9.4 7.9

390.284041 1 230 10 40 - 13.5 12.9 11.9 10.9 9.8

390.284051 1-1/2 230 14 40 - 13.5 12.9

390.284061 1 230 7 40 26,4 24.7 22.7 20.7 18.4

390.284071 1-1/2 230 9 40 - 25,8 24.3 22,9 21.0 18,8 15.4

390,284081 2 230 12 40 26.4 25.1 23.7 22.2 20.8 17.2 -

390,284091 3 230 17 40 - 26.7 25.5 23.8 21.7

390.284370 1-1/2 230 6 40 36.0 93.5 30.8 - -

390.284380 2 230 8 40 - 36.6 34.8 32.8 29.8

390.284390 3 230 12 40 - - 38.8 37.3 35.9 34.5 32.6 28.3

*Pumping depth in feet is the maximum distance to water from ground level. This maximum distance (drawdown water level) occurs while pump is operating.

In most cases, when pump is not running, the water level will dse to a higher point in the well.

Discharge Pumping Depth in Feet *

250 300 350 400

7.4 - - -

11.7 10.4 8.9 7.1

High Capacity Pumps with 1-1/4" Discharge

Extra-High Capacity Pumps with 1-1/4" Discharge

19.6 16.8

Model

Number

390.285511

390.2855

390.2853

390.284021

390.284031

390.284041

390.284061

390.284051

390.284071

390.284370

390.284081

390.284380

390.284091

390.284390

TABLE II - Fusing, Wiring and Cable Selection (Copper Conductors Only)

Type

2-Wire

2-Wim

2-Wim

3-Wim

3-Wire

3-Wire

3-Wire

3-Wire

3-Wire

3-Wire

3-Wire

3-Wire

3-Wire

3-Wire

Circuit

Control

Box

No.

390.284121

390.264131 3/4 230 8.0 20 480

390.2841 1 230 9.8 25 400

390.2841 1 230 9.8 25 400

390.284251 1-1/2 230 11.5 30 310

390.284251 1-1/2 230 11.5 30 310

390.284251 1-1/2 230 11.5 30 310

390.284261 2 230 13.2 25 250

390.284261 2 230 13.2 25 250

390.284271 3 230 17.0 40 190

390.284271 3 230 17.0 40 190

HP Volts Amps (Amps)

1/2 115 12.0 30

1/2 230 6.0 15

3/4 230 8.0 20

1/2 230 6.0 15

Max Breaker

Load Rating

12 10

160 250

650 1020

480 760

650 1020

AWG

Cable Size

76O

630

63O

48O

48O

48O

39O

39O

3OO

300

8

Max. Cable

Length in Feet-

1610

390 }

1200

1610

1200

990

990 _, Max. Cable

770 Disconnect

770 _k Length in Feet -

770 switch to motor

620

620

47O

470

Disconnect

switch to motor

INSTALLATION

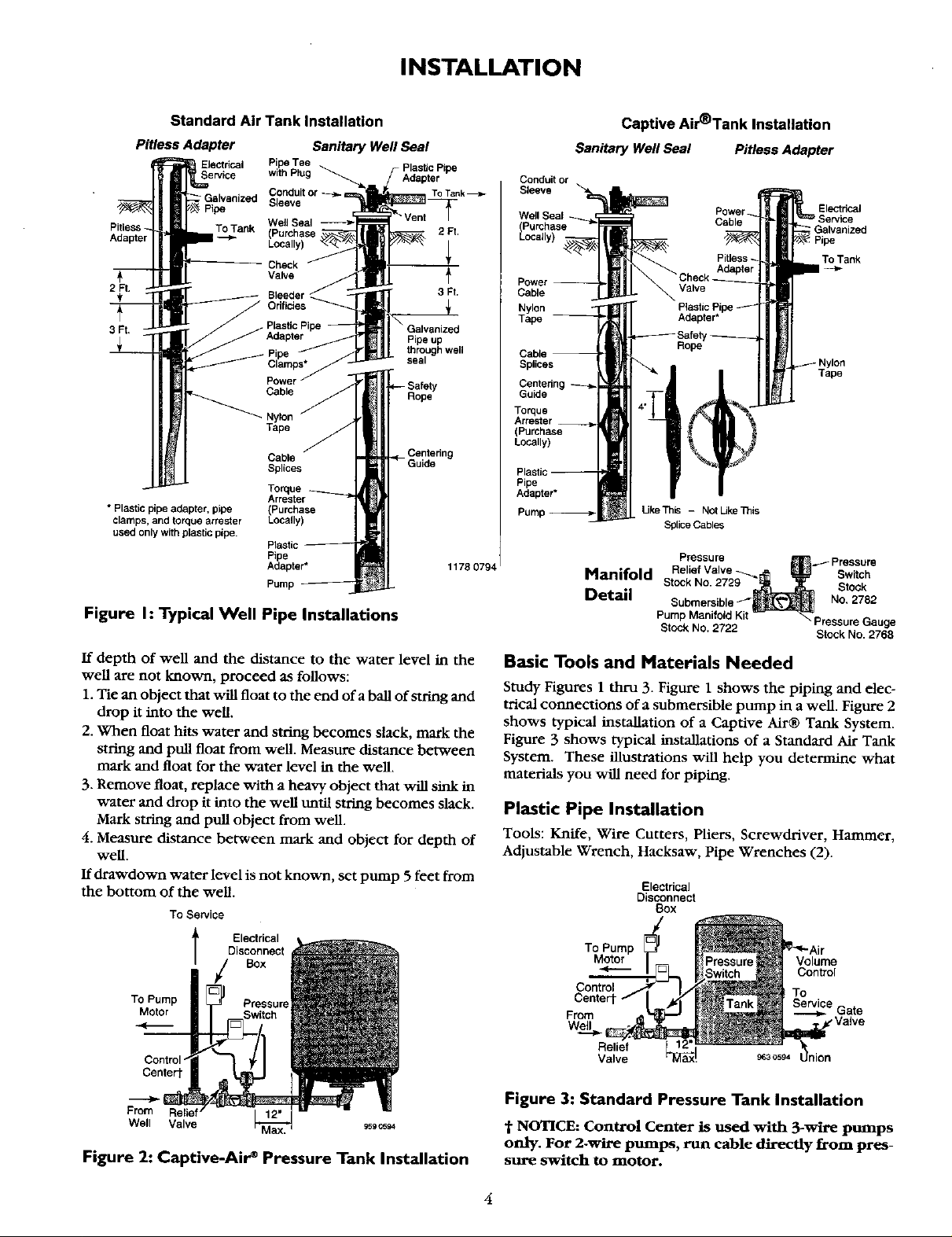

Standard Air Tank Installation

Pitless Adapter

Service with Plug

El_p_ _ctrical Pipe Tee

Galvanized Sleeve

ipe

Pitless ToTank (Purchase ,

_'_ --'- Locally)

2 Ft.

3 Ft, _ Plastic Pipe

• Plastic pipe adapter, pipe

clamps, and torque arrester

used only withplastic pipe.

-- Check

Sanitary Well Seal

Conduit or

WellSeal

Valve

Bleeder_-

Oriticies

Adapter

Clamps*

Cable

Ny_n

Tape

Splices Guide

Torque

Cable sa__ Centenng

Arrester

(Pumha

TO Tank ---_

2 Ft,

3 Ft.

\ Galvanized

Pipe up

through well

seal

Looal,y,IJll

Pipe

Adapter* t 178 0794

Plastic r_

Pump

Figure I: Typical Well Pipe Installations

If depth of well and the distance to the water level in the

well are not known, proceed as follows:

1. Tie an object that will float to the end of a ball of string and

drop it into the well.

2. When float hits water and string becomes slack, mark the

string and pull float from well. Measure distance between

mark and float for the water level in the well.

3. Remove float, replace with a heavy object that will sink in

water and drop it into the well until string becomes slack.

Mark string and pull object from well.

4. Measure distance between mark and object for depth of

well.

If drawdown water level is not known, set pump 5 feet from

the bottom of the well.

To Sewice

Captive Air'Tank Installation

SanitaryWellSeal PitlessAdapter

Conduit or

Sleeve

Well Seal

(Purchase

Locally)

Power

Cable

Nylon

Tape --

Splices

Torque

Arrester

(Purchase

Locally)

Pipe

Adapter•

Manifold

Detail

UkeTh_ - NotUkeTnis

Splice Cables

• ._ Pressure

Relief Valve _ Sw tch

Stock No. 2729 Stock

Pressure

Submersible/" No, 2782

P_cP Marlin2 dKit Pressure Gauge

• Stock No. 2768

Electrical

; Galvanized

To Tank

Tape

Basic Tools and Materials Needed

Study Figures 1 thru 3. Figure 1 shows the piping and elec-

trical connections of a submersible pump in a well. Figure 2

shows typical installation of a Captive Air® Tank System•

Figure 3 shows typical installations of a Standard Air Tank

System• These illustrations will help you determine what

materials you will need for piping.

Plastic Pipe Installation

Tools: Knife, Wire Cutters, Pliers, Screwdriver, Hammer,

Adjustable Wrench, Hacksaw, Pipe Wrenches (2).

Electrical

Disconnect

(3ox

Disconnect

l Ele_dcal

Box

To Pump Pressure

Motor

Control"

Centert

From

Well Valve

Figure 2: Captive-Air* Pressure Tank Installation

To Pump

Motor

Control

Centert

Volume

Control

From e Gate

Wel_l ,Valve

Relief

Valve ss3c594

Figure 3: Standard Pressure Tank Installation

"i"NOTICE: Control Center is used with 3-wire pumps

only. For 2-wire pumps, run cable directly from pres-

sure switch to motor.

4

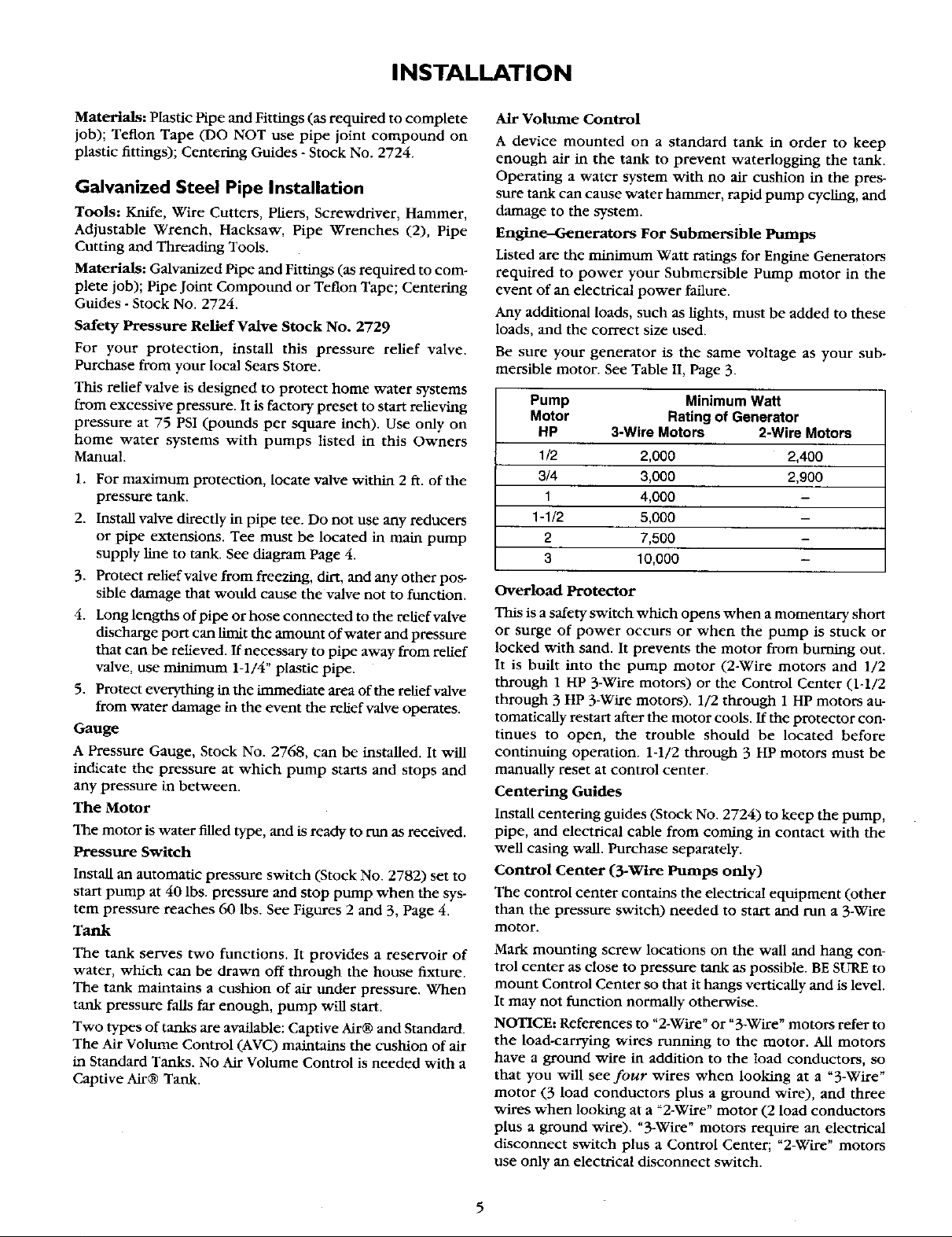

INSTALLATION

Materials: Plastic Pipe and Fittings (as required to complete

job); Teflon Tape (DO NOT use pipe joint compound on

plastic fittings); Centering Guides - Stock No. 2724.

Galvanized Steel Pipe Installation

Tools: Knife, Wire Cutters, Pliers, Screwdriver, Hammer,

Adjustable Wrench, Hacksaw, Pipe Wrenches (2), Pipe

Cutting and Threading Tools.

Materials: Galvanized Pipe and Fittings (as required to com-

plete job); Pipe Joint Compound or Teflon Tape; Centering

Guides - Stock No. 2724.

Safety Pressure Relief Valve Stock No. 2729

For your protection, install this pressure relief valve.

Purchase from your local Sears Store.

This relief valve is designed to protect home water systems

from excessive pressure. It is factory preset to start relieving

pressure at 75 PSI (pounds per square inch). Use only on

home water systems with pumps listed in this Owners

Manual.

1. For maximum protection, locate valve within 2 ft. of the

pressure tank.

2. Install valve directly in pipe tee. Do not use any reducers

or pipe extensions. Tee must be located in main pump

supply line to tank. See diagram Page 4.

3. Protect relief valve from freezing, dirt, and any other pos-

sible damage that would cause the valve not to function.

4. Long lengths of pipe or hose connected to the relief valve

discharge port can limit the amount of water and pressure

that can be relieved, ff necessary to pipe away from relief

valve, use minimum 1-1/4" plastic pipe.

5. Protect everything in the immediate area of the relief valve

from water damage in the event the relief valve operates.

Gauge

A Pressure Gauge, Stock No. 2768, can be installed. It will

indicate the pressure at which pump starts and stops and

any pressure in between.

The Motor

The motor is water filled type, and is ready to run as received.

Pressure Switch

Install an automatic pressure switch (Stock No. 2782) set to

start pump at 40 lbs. pressure and stop pump when the sys-

tem pressure reaches 60 lbs. See Figures 2 and 3, Page 4.

Tank

The tank serves two functions. It provides a reservoir of

water, which can be drawn off through the house fixture.

The tank maintains a cushion of air under pressure. When

tank pressure falls far enough, pump will start.

Two types of tanks are available: Captive Air® and Standard.

The Air Volume Control (AVC) maintains the cushion of air

in Standard Tanks. No Air Volume Control is needed with a

Captive Air® Tank.

Air Volume Control

A device mounted on a standard tank in order to keep

enough air in the tank to prevent waterlogging the tank.

Operating a water system with no air cushion in the pres-

sure tank can cause water hammer, rapid pump cycling, and

damage to the system.

Engine--Generators For Submersible Pumps

Listed are the minimum Watt ratings for Engine Generators

required to power your Submersible Pump motor in the

event of an electrical power failure.

Any additional loads, such as lights, must be added to these

loads, and the correct size used.

Be sure your generator is the same voltage as your sub-

mersible motor. See Table II, Page 3.

Pump Minimum Watt

Motor Rating of Generator

HP 3-Wire Motors 2-Wire Motors

1/2 2,000 2,400

3/4 3,000 2,900

1 4,000 -

1-1/2 5,000 -

2 7,500 -

3 10,000 -

Overload Protector

This is a safety switch which opens when a momentary short

or surge of power occurs or when the pump is stuck or

locked with sand. It prevents the motor from burning out.

It is built into the pump motor (2-Wire motors and 1/2

through 1 HP 3-Wire motors) or the Control Center (1-1/2

through 3 HP 3-Wire motors). 1/2 through 1 HP motors au-

tomatleally restart after the motor cools. If the protector con-

tinues to open, the trouble should be located before

continuing operation. 1-1/2 through 3 HP motors must be

manually reset at control center.

Centering Guides

Install centering guides (Stock No. 2724) to keep the pump,

pipe, and electrical cable from coming in contact with the

well casing wall. Purchase separately.

Control Center (3-Wire Pumps only)

The control center contains the electrical equipment (other

than the pressure switch) needed to start and run a 3-Wire

motor.

Mark mounting screw locations on the wall and hang con-

trol center as close to pressure tank as possible. BE SURE to

mount Control Center so that it hangs vertically and is level.

It may not function normally otherwise.

NOTICE: References to "2-Wire" or "3-Wire" motors refer to

the load-carrying wires running to the motor. All motors

have a ground wire in addition to the load conductors, so

that you will see four wires when looking at a "3-Wire"

motor (3 load conductors plus a ground wire), and three

wires when looking at a _2-Wire" motor (2 load conductors

plus a ground wire). "3-Wire" motors require an electrical

disconnect switch plus a Control Center; "2-Wire" motors

use only an electrical disconnect switch.

Loading...

Loading...