Craftsman 3902655 Owner’s Manual

SEARS

OWNER'S

MANUAL

MODEL NO.

390.2655

CAUTION:

Read and Follow

All Safety Rulesand

Operating Instructions

Before FirstUse of

ThisProduct.

Save ThisManual For

FutureReference.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

I:RRFTSMRW

PROFESSIONAL

SUBMERSIBLE

UTILITY PUMP

• Safety Instructions

• Installation

• Electrical

• Repair Parts

Form No. F642-04079 (Rev. 3/22/05)

CONTENTS

INTRODUCTION/WARRANTY ......................................... 2

SAFETY .............................................................................. 2

INSTALLATION ................................................................. 3

SERVICE ............................................................................. 4

PERFORMANCE ................................................................. 5

PARTS ................................................................................ 6

INTRODUCTION

Please read our instructions before you install and use your

new pump; tins will help you obtain hall value and good ser-

vice from it. It will also help you avoid needless service costs

that result from causes we cannot control and cannot cover

in our warranty.

GENERAL SAFETY INFORMATION

NOTICE: This unit is not designed for applications involving

salt water or brine! Use with salt water or brine will void

warranty.

1. Know the pump application, limitations, and potential

hazards.

[_.WARNING]Do not use in explosive atmosphexes.

Pump water only with this pump. Failure to follow

this warning can result in personal injury and/or

property damage.

2.

Disconnect power before servicing.

3.

Release all pressure within the system before servicing

any component.

4.

Drain water from the system before servicing.

5.

Secure the discharge line before starting the pump. An un-

secured discharge line will whip, possibly causing per-

sonal injury and/or property damage.

.

Check hoses for weak or worn condition before each use,

making certain that all connections are secure.

7.

Periodically inspect pump and system components.

Perform routine maintenance as required (See

MAINTENANCE, Page 4).

8.

Provide a means of pressure relief for pumps whose dis-

charge line can be shut-off or obstructed.

9.

Personal Safety:

a. Wear safety glasses at all times when working with

pumps.

b. Keep work area clean, uncluttered and properly

lighted - replace all unused tools and equipment.

c. Keep visitors at a safe distance from the work area.

d. Make workshop child-proof - with padlocks, master

switches, and by removing starter keys.

10.When wiring an electrically driven pump, follow elec-

tricaI and safety codes, as well as the most recent National

Electrical Code.

11.This equipment is only for use on 115 volt (single

phase) and is equipped with an approved 3-con-

ductor cord and 3-prong, grounding-type plug.

[a'WARNING]To reduce the risk of electric shock,

pull plug before servicing. This pump has not been

investigated for use in swixi_g pool areas. This

pump is supplied with a grounding conductor and

grounding-type attachment plug. Be certain that it

is connected only to a properly grounded ground-

ing-type receptacle.

Where a 2-prong wall receptacle is encountered, it

must be replaced with a properly grounded 3-prong

receptacle installed in accordance with the National

Electrical Code and local codes and ordinances.

12. All wiring should be performed by a qualified electrician.

13.Make certain that the power source conforms to the

requirements of your equipment.

14.Protectelectricalcordfromsharpobjects,hotsurfaces,

oil,andchemicals.Avoidkinkingthecord•Replaceorre-

pairdamagedorworncordsimmediately.

15.Donottouch an operating motor. Modem motors can op-

erate at high temperatures.

16. Do not handle a pump or pump motor with wet hands or

when standing on a wet or damp surface, or in water.

I AxWARNING ] Risk of electric shock. If your basement

has water or moisture on the floor, do not walk on wet

area until all power has been turned off. If shut-off

box is in basement, call the electric company to shut-

off service to the house, or call your local fire depart-

ment for instructions. Remove pump and repair or

replace. Failure to follow this warning can result in

fatal electrical shock.

INSTALLATION

[_&WARNING]Do not use power cord to lift motor. Al-

ways use handle,

NOTICE: Do not use this pump in ponds containing plants

or fish.

1. Pump should be located and should rest on level solid

foundation. Do not suspend pump by means of discharge

pipe or power cord. Keep pump inlet sereen clear.

2. Thread outlet pipe into pump body carefully to avoid

stripping or crossing threads.

a. To install with 3/4" garden hose, install adapter pro- Figure A

vided vdth pump.

b. To install with rigid pipe, use plastic pipe. Wrap thread

with Teflon tape or use Plasto Joint Stik*. Screw pipe

into pump hand tight +1 - 1-1/2 turns.

NOTICE: Do not try to disassemble pump farther than re-

moving inlet screen. Any evidence of tampering v_ill void

warranty.

3. Power Supply: Pump is designed for 115V, 60 Hz opera-

tion and requires a circuit of 15 amperes or more capac-

ity. It is supplied with a 3-wire cord set with

grounding-type plug for use in a 3-wire, grounded outlet.

3 wire extension cord, of at least 14 AWG (2mm z) size is

suggested, with larger sizes for runs over 25 ft (7M). For Figure B

safety, pump should always be electrically grounded to a

suitable electrical ground such as a grounded water pipe

or a properly grounded metallic raceway, or ground wire

system. Do not cut off the round grounding prong.

The Pump has a 3-prong electric plug. The third prong is

used to ground the pump to prevent possible fatal shock.

The third prong should never be removed. Your electrical

outlet should be the 3-prong, polarized type v4th an inter-

nal ground.

A separate 15 amp GFCI branch electrical circuit is recom-

mended. DO NOT USE AN EXTENSION CORD.

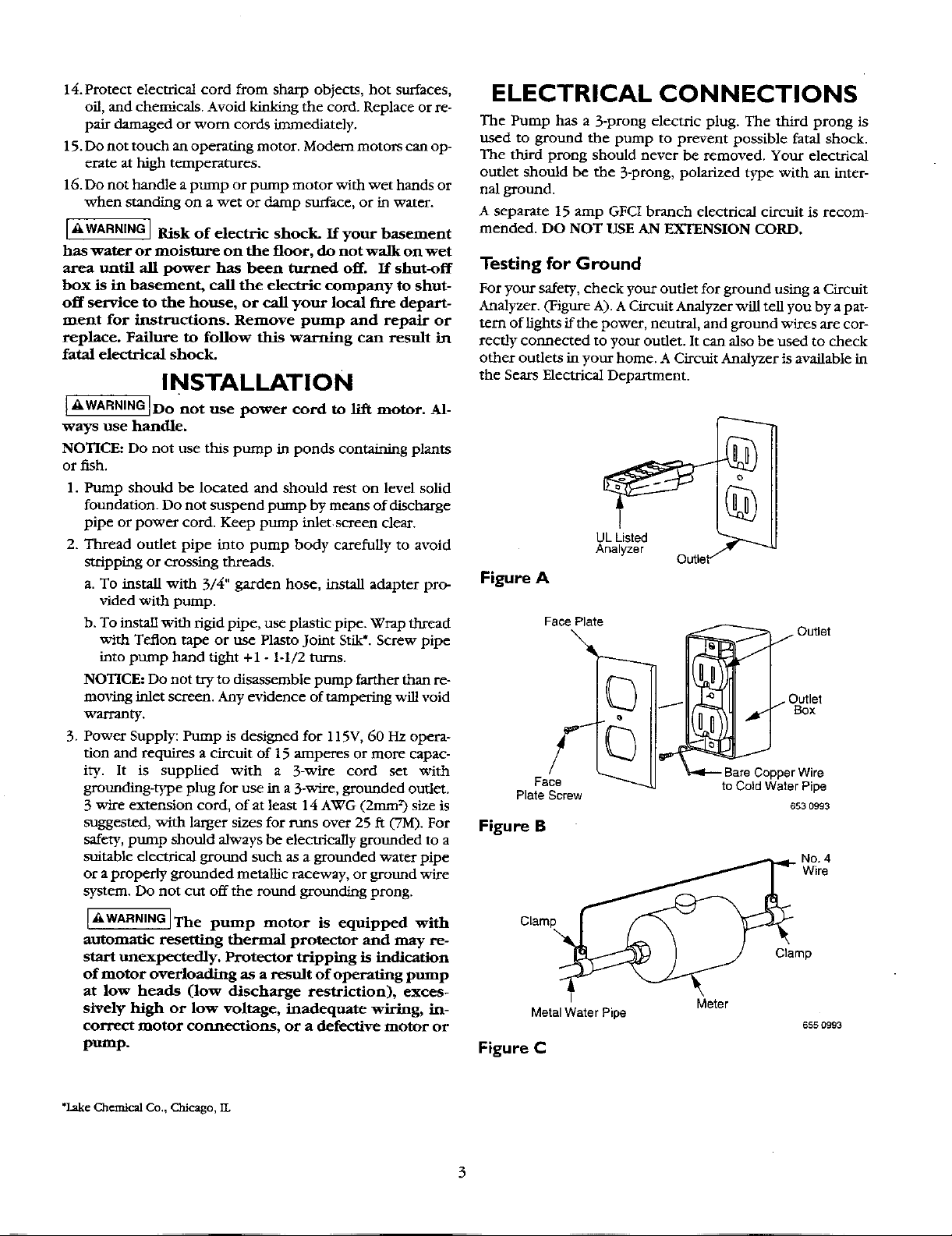

Testing for Ground

For your safety, check your outlet for ground using a Circuit

Analyzer. (Figure A). A Circuit Analyzer will tell you by a pat-

tern of llghrs ffthe power, neutral, and ground wires are cor-

rectly connected to your oudet. It can also be used to check

other outlets in your home. A Circuit Analyzer is available in

the Sears Electrical Department.

ELECTRICAL CONNECTIONS

UL Listed

Analyzer Outlet"

Face Plate

/_ _ Outlet

II ±_ IIII I /Outlet

Face to Cold Water Pipe

Plate Screw

Bare CopperWire

Box

653 0993

No. 4

[_'WARNING_The pump motor is equipped with

automatic resetting thermal protector and may re-

start unexpectedly. Protector tripping is indication

of motor overloading as a result of operating pump

at low heads (low discharge restriction), exces-

sively high or low voltage, inadequate wiring, in-

correct motor connections, or a defective motor or

pumtp.

"Lake Chemical Co., Chicago, IL

Clamp

Figure C

Metal Water Pipe

Clamp

Meter

6550993

Loading...

Loading...