Page 1

INSTRUCTIONS FOR INSTALLATION OF VERTICAL CASING ADAPTERS

FOR SINGLE PIPE JETS

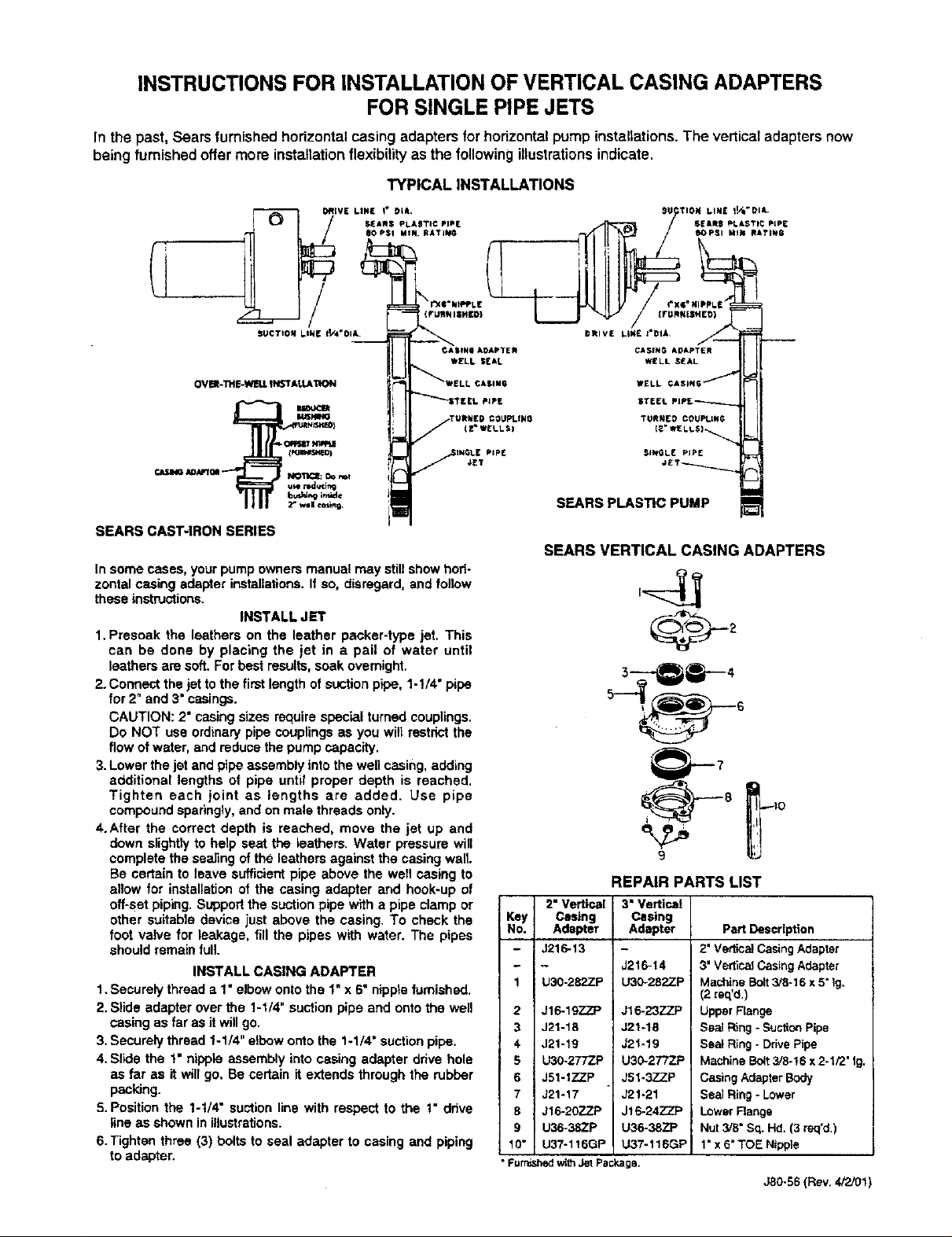

In the past, Sears furnished horizontal casing adapters forhodzonta!pump installations.The vertical adapters now

being furnished offer more installation flexibilityas the following illustrations indicate.

TYPICAL INSTALLATIONS

SEARS PLASTIC PUMP

SEARS CAST-IRON SERIES

SEARS VERTICAL CASING ADAPTERS

In some cases, your pump ownerSmanual may stillshow hori-

zontal casing adapter instaJlations.If so, disregard, and follow

these instructions.

INSTALL JET

1. Presoak the leathers on the leather packer-type jet. This

can be done by placing the jet in a pail of water until

leathers are soft. For best results, soakovernight.

2. Connect thejet to the first length ofsuction pipe, 1-1/4" pipe

for 2" and 3" casings.

CAUTION: 2" casingsizes require special turned couplings,

Do NOT use ordinary pipecouplings as you will restr;,ctthe

flow of water, andreduce the pump capacity.

3. Lower the jet and pipeassembly into the well casing, adding

additional lengths of pipe until proper depth is reached.

Tighten each joint as lengths are added. Use pipe

compound sparingly,and on male threads only.

4.After the correct depth is reached, move the jet up and

down slightly to help seat the leathers, Water pressure will

complete the sea_ng of the leatherSagainst the casing wall.

Be certain to leave sufficient pipe above the well casing to

allow for installation of the casing adapter and hook-up of

off-set piping. Supportthe suction pipe with a pipe clamp or

other suitable device just above the casing. To check the

foot valve for leakage, fill the pipes with water. The pipes

should remain full.

INSTALL CASING ADAPTER

1. Securely thread a 1"elbow onto the 1"x 6"nipple furnished.

2. Slide adapter over the 1-I/4" suction pipe and onto the well

casing as far as it willgo.

3. Securely thread 1-1/4" elbowonto the 1-1/4" suctionpipe.

4. Slide the 1" nipple assembly into casing adapter drive hole

as far as it willgo, Be certain it extends through the rubber

packing.

5. Position the 1-1/4" suctionline with respect to the t" drive

line as shown in illustrations.

6. Tighten three (3) belts to seal adapter to casing and piping

to adapter.

REPAIR PARTS LIST

2" Vert|ca[ 3" Vertical

Key Casing Casing

No. Adapter Adapter

3216-13

J216-14

U30-282ZP

J16-19ZZP

2

J21-1S

3

J21-19

4

U30-277ZP

5

J51-tZZP

6

J21-17

7

J16-20ZZP

8

U36-38ZP

9

U37-116GP

10"

• FurK_shedwith3el Packaga.

U30-282ZP

JI6-2377p

J21-18

J21-19

U30-277Zp

JS1-3ZZP

J21-21

J16-24ZZP

U36-38ZP

U37-116GP

8 _lC

Part Description

2' Vedica] CasingAdapter

3' Vertical Casing Adapter

Machine Bo_t3/8-16 x 5" Ig.

(2 req'd,)

Upper F_ange

Seal Ping -Suction Pipe

Seal Ring - Drive Pipe

Machine Bolt3/8-16 x 2-1/2"Ig,

Casing Adapter Body

Sea] Ring - Lower

Lower Range

Nut 3/8" Sq. Hd. (3 req'd,)

1"x 6" TOE Nipple

J80-56 (Rev. 4/3!01)

Page 2

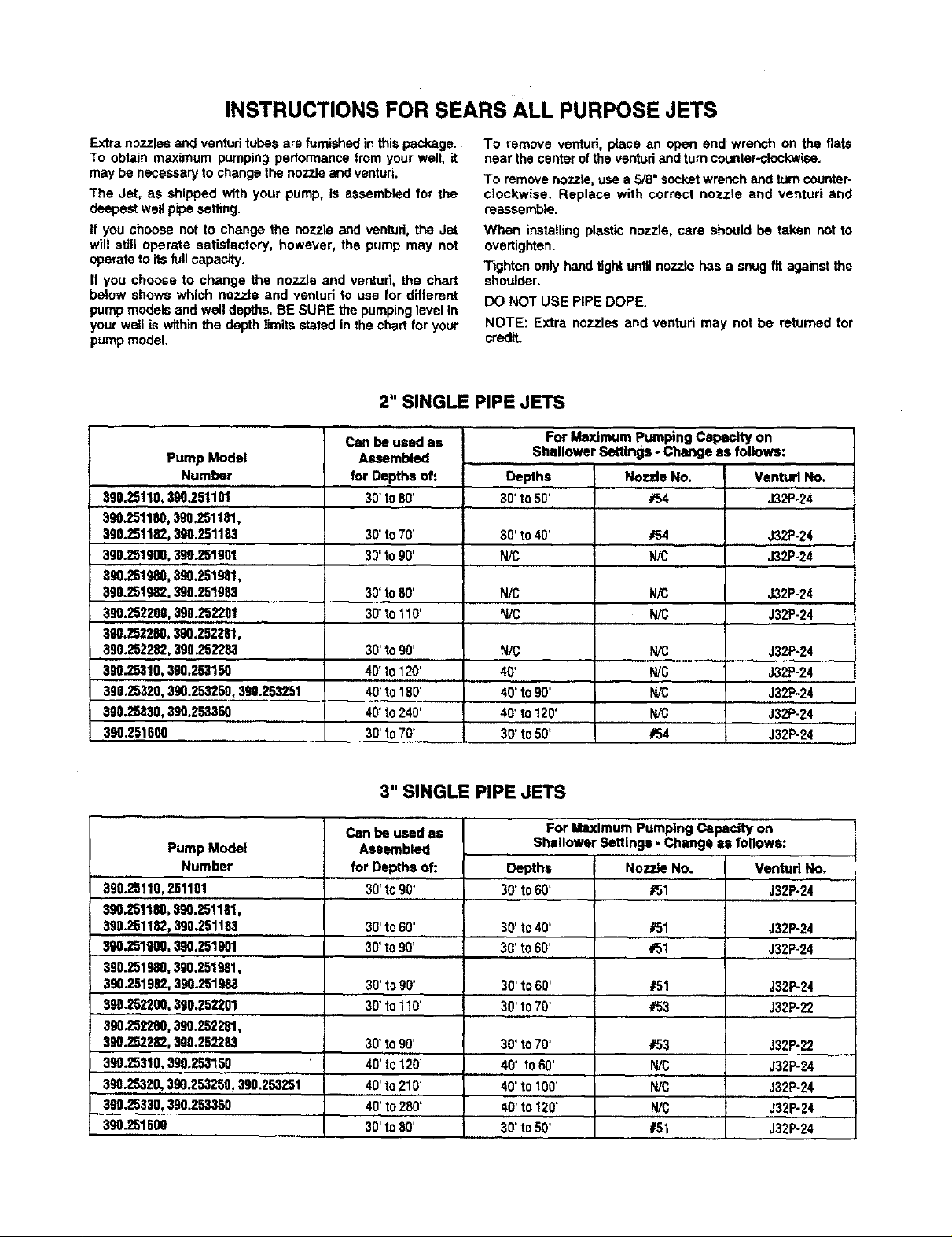

INSTRUCTIONS FOR SEARS ALL PURPOSE JETS

Extra nozzles end ventud tubes arefurnishedin thispackage.

To oblain maximum pumping performance from your wall, it

may be necessary to change the nozzle andventurL

The Jet, as shipped with your pump, is assembled for the

deepest well pipe setting.

If you choose not to change the nozzle and vantud, the Jet

will still operate satisfactory, however, the pump may not

operate to its full capacity.

If you choose to change the nozzle and venturi, the chart

below shows which nozzle and vanturi to usa for different

pump modelsand well depths. BE SURE the pumping level in

your well is within _e depth limits stated in the chart for your

pump model.

2" SINGLE PIPE JETS

Can be used as

Pump Modal

Number

390.25110,590.251101

590.251180,390.251181,

39o.2s11 ,5. 11.

590.zmg®,5. 1p1

390.251980,390.251981,

390.251982,390.251983

390.252200,590.25_01

390.252280,590.252281,

390.252282, 590.252283

390.2531o,Seo.2_lSO

590.25320, 390.253250, 390.253251

390.25330,390.253350

590.251600

Assembled

for Depths of: Depths Nozzle No. Ventud No.

30'to80' 30' to50' #54 J32P-24

30'to70' 30' to40' #54 J32P-24

30'to90' N/C N/C J32P-24

30'to80' N/C N/C J32P-24

30'to 110' N/C NIC J32P-24

30'to90' N/C N/C J32P-24

40' to120' 40' NiC J32P-24

40'to180' 40'to 90' N/C J32P-24

40'to240' 40' to 120' i'_C J32P-24

30'to70' 30' to 50' #54 J32P-24

To remove vanturi, place an open end wrench on the flats

near the canter of the ventud and turncounter-clockwise.

To remove nozzle, use a 5/8" socketwrench and turncounter=

clockwise. Replace with correct nozzle and venturi and

rea.ssembte.

When installing plastic nozzle, care should be taken not to

overtighten.

Tighten only hand tight until nozzle has a snug fit againstthe

shoulder.

DO NOT USE PIPE DOPE.

NOTE: Extranozzlesand venturimay nat be returnedfor

credit.

ForMaximumPumpingCapacityon

Shallower Settings - Change as follows:

Pump Model

Number

.......39312mlo, 11of

590. 1190,3®.,,mm,

590.251182,390.251163

390.251900,390.251901

390.251980,390.251981,

390.251962,390.251983

390.252290,390.252201

390.252280,390.252281,

390.252282,390.252283

390.25310,590.253150

390.25320,390.253250,390.253_1

590.25350,390.253350

390.251600

3" SINGLE PIPE JETS

Can be used as

Assembled

for Depths of: Depths NozTJeNo.

30'to90' 30' to_L #51

30'to 60' 30' to 40' #51 J32P-24

30'to90' 30' to 60' #51 J32P-24

30'to90' 30'to 60' #51 J32P-24

30"to 110' 30' to 70' #53 J32P-22

30'to90' 50' to70' #53 J32P-22

40'to 120' 40' to60' N/C J32P-24

40'to210' 40'to 100' WC J32P-24

40'to 280' 40' to120' N/C J32P_24

30'to80' 30'to 50' #51 J32P-24

ForM=xlmumPumpingCapacityon

ShallowerSettings.Changeas follows:

VentudNo.

J32P-24

Page 3

INSTRUCTIONS FOR SEARS ALL PURPOSE JETS

Extra nozzles and venturi tubes are furnished in this

package. To obtain maximum pumping performance from

your well, it may be necessary to change the nozzle and

ventud.

The Jet, as shipped with your pump, is assembled for the

deepest well pipesetting.

If you choose not to change the nozzle and ventud, the Jet

will still operate satisfactorY, however, the pump may not

operate to itsfull capacity.

If you choose to change the nozzle and venturi, the chart

below shows which nozzle and ventud to use for different

pump models and well depths. BE SURE the pumping level

in your we!tis within the depth limits stated inthe chad for

your pump model.

4" DOUBLE PIPE JETS

Can be used as

Pump Model

Number

390.25110 30' to 90' 30' to 60' #51 J32P-24

390.25310

390.253150

390.25320

390.253250 40' to 200' 40' to 100' NO CHANGE J32P-24

390.253251

Assembled

For Depths Of: Depths Nozzle No,

40' to 120' 40' to 60' NO CHANGE J32P-24

To remove vanturi, place an open end wrench on the flats

near the center of the ventud and turn counter-clockwise.

To remove nozzle, use a 5/8" socket wrench and turn

counter-c_ockwise.Replace w_th correct nozzle and ventud

and reassemble.

When installingplastic nozzle, cars should be taken not to

overtightan.

Tighten onlyhand tight untilnozzle has a snug fit against the

shoulder.

DO NOT USE PIPE DOPE.

NOTE: Extra nozzles end ventud may not be returned for

credit.

For Maximum Pumping Capacity On

Shallower Settings • Change As Follows:

Venturi No.

390,25330 40' to 280' 40' to 120' NO CHANGE J32P-24

390.253380

390.251600 30' to 80' 30' to 50' #51 J32P-24

390.251900 30' to 90' 30' to 60' I #51 J32P-24

390.252200 30' to 110' 30' to 70' 1 #53 J32P-22

390.251101 30' to 90' 30' to 60' #51 J32P-24

390.251901 30' to 90' 30' to 60' #51 J32P-24

390.252201 30' to 110' 30' to 70' #53 J32P-22

390,251180

390,251181 30' to 60' 30' to 40' #51 J32P-24

390.251182

390.251980

390.251981 30' to 90' 30' to 60' #51 J32P-24

390,251982

/ 390.252280

390.252281 30' to 90' 30' to 70' #53 J32P.22

390.252282

F_12J (Rev. 10/22/97

Page 4

INSTALLATION PROCEDURE FOR USING 4 INCH JETS

1-1/4" Steel-

Pipe

-1" Steel

Pipe

Pipe Pipe

1-1/4" _

Poly Pipe

Adapter

1-1/4"Pot_.

Pipe --

-- 1" Poly-

Pipe

Adapter

Poly-

Pipe

1-1/4"

x 1-1/4" Adapter

Face Bushing

1-1/4"

Poly Pipe

IMPORTANT: Use pipe thread compound on male threads and

tighten Venturi Adapter or Steel Pipe Into Jet Body.

IN WELL PIPING SIZES -ALL INSTALLATIONS

HP SUCTION DRIVE

3/4 Multi-Stage Jet PumpPiping 1-1/4" 1"

1 Multi-Stage Jet Pump Piping 1-1/4" 1-t/4"

1-1/2 Mufti-Stage Jet Pump Piping 1-1/4" 1-1/4"

All Horizontal Jet Pumps 1-1/4" 1"

1-1/4"

1-1/4"

1/4"

Face Bushing

Nipple

For long horizontal runs of piping, consult your pump owner's manual

for recommended piping size increase.

Loading...

Loading...