Craftsman 3902532 Owner’s Manual

SEARS

OWNER'S

MANUAL

MODEL NO.

390.2.532

I:RRFTIMRN °

CAUTION:

Read and Follow

All Safety Rulesand

Operating Instructions

BeforeFirstUseof

ThisProduct.

Save ThisManual For

FutureReference.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

PRINTED IN U.S.A. Form No. F642-040T7 (8/6/04)

MULTI-STAGE JET PUMP

• Safety Instructions

• Installation

• Electrical

• Operation

• Maintenance

• Repair Parts

CONTENTS

INTRODUCTION/WARRANTY .................................. 2

MAJOR COMPONENTS .............................................. 3

PUMP PERFORMANCE ............................................... 4

INSTALLATION ........................................................ 4-8

ELECTRICAL ............................................................ 8-9

OPERATION ........................................................ 10-11

HELPFUL HINTS / MAINTENANCE ..................... 11-14

TROUBLESHOOTING GUIDE .................................. 15

REPAIR PARTS ..................................................... 16-19

INTRODUCTION

Please read our instructions before installing and using

your Deep WellJet Pump. This will help you obtain the

full benefits of the quality and convenience built into

this equipment. It will also help you avoid any needless

service expense resulting from causes beyond our con-

trol which are not covered by our warranty.

RULES FOR SAFE INSTALLATION AND OPERATION

Carefully read and follow all safety instructions in this

manual or on pump

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury!

Warns about hazards that will cause seri-

ous personal injury, death or major property damage if

ignored.

[AWARNING] Warns about hazards that will or can

cause serious personal injury, death or major property

damage if ignored.

[_ CAUTION ] Warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The word NOTICE indicates special instructions

which are important but not related to hazards.

1. To avoid risk of serious bodily injury and property

damage, read safety instructions carefully before in-

stalling pump.

2. Follow local and/or national plumbing and electri-

cal codes when installing pump.

3. Keep well covered while installing pump to prevent

leaves and other debris from falling into well, con-

taminating well and possibly damaging pump.

4. Protect pump and piping system from freezing.

Allowing pump or water system to freeze could

severely damage pump and voids warranty.

[AWARNING] To avoid serious injury and equip-

ment damage, limit system pressure to 100

pounds per square inch (PSI) or below at all

times. Over-pressure can cause tank blowup; in-

stall relief valve capable of passing full pump vol-

ume at 100 PSI.

5. With a new well, test well for purity before use.

Consult local Health Department for procedure.

[AWARNING_Hazardous voltage. Can shock, burn,

cause death, or start fires.

6. Disconnect electrical power source before in-

stalling or working on pump.

7. Ground pump with a ground wire nan from ground-

ing lug on motor to a grounded lead in the service

panel.

8. Line voltage and frequency of electrical power sup-

ply must agree with motor nameplate.

9. Use of fuses or wire smaller than size recommended

in owner's manual can cause overheating, possible

fires, and will void warranty.

10. This pump is a deep well jet pump. It is not de-

signed or intended for shallow well use. Use in a

deep well (more than 25' depth to water).

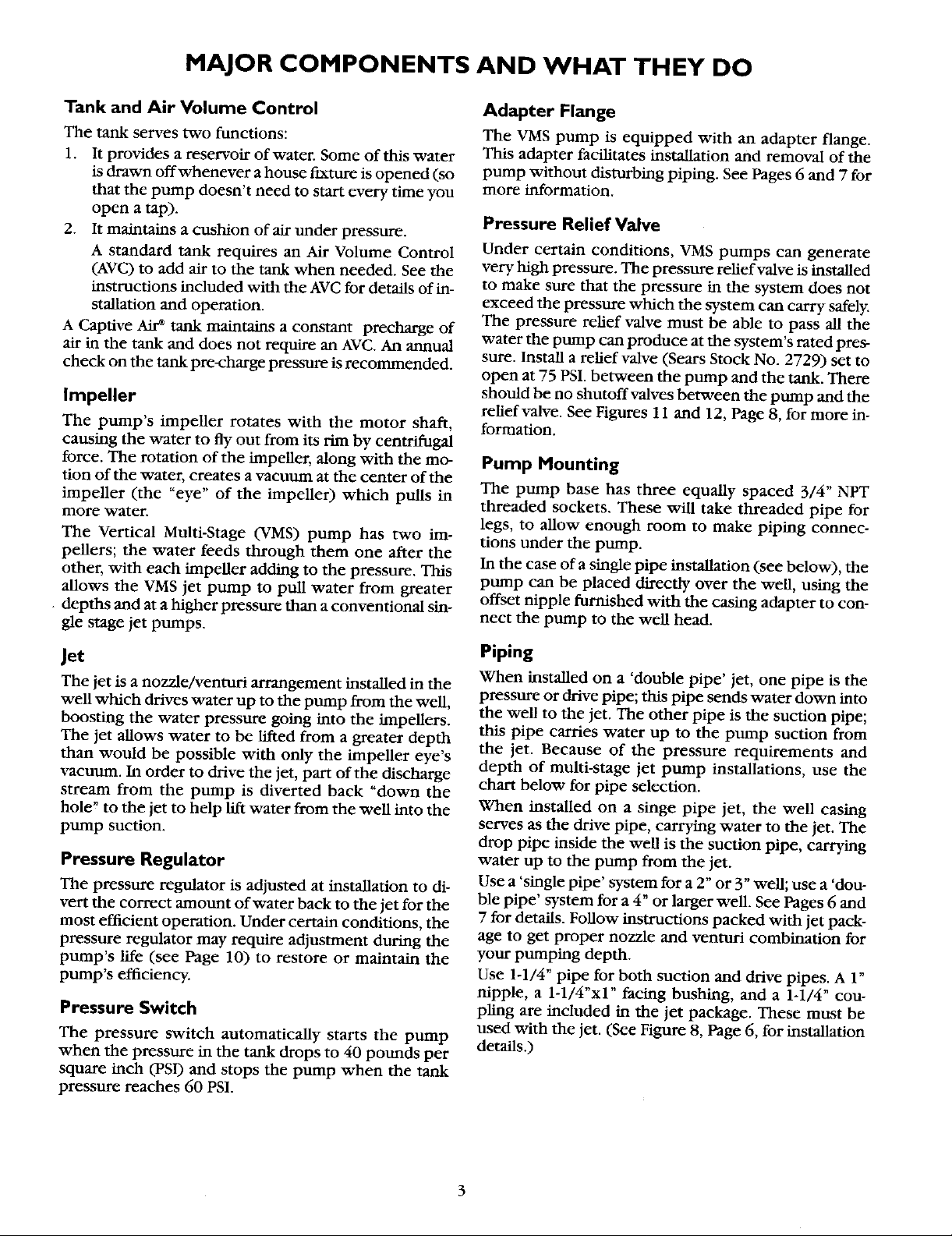

MAJOR COMPONENTS AND WHAT THEY DO

Tank and Air Volume Control

The tank serves two functions:

1. It provides a reservoir of water. Some of this water

is drawn offwhencver a house ftxture is opened (so

that the pump doesn't need to start every time you

open a tap).

2. It maintains a cushion of air under pressure.

A standard tank requires an Air Volume Control

(AVC) to add air to the tank when needed. See the

instructions included with the AVC for details of in-

stallation and operation.

A Captive Air* tank maintains a constant precharge of

air in the tank and does not require an AVC. An annual

check on the tank pre-charge pressure is recommended.

Impeller

The pump's impeller rotates with the motor shaft,

causing the water to fly out from its rim by centrifugal

force. The rotation of the impeller, along with the mo-

tion of the water, creates a vacuum at the center of the

impeller (the "eye" of the impeller) which pulis in

more water.

The Vertical Multi-Stage (VMS) pump has two im-

pellers; the water feeds through them one after the

other, with each impeller adding to the pressure. This

allows the VMS jet pump to pull water from greater

depths and at a higher pressure than a conventional sin-

gle stage jet pumps.

Jet

The jet is a nozzle/ventllri arrangement installed in the

well which drives water up to the pump from the well,

boosting the water pressure going into the impellers.

The jet allows water to be lifted from a greater depth

than would be possible with only the impeller eye's

vacuum. In order to drive the jet, part of the discharge

stream from the pump is diverted back "down the

hole" to the jet to help lift water from the well into the

pump suction.

Pressure Regulator

The pressure regulator is adjusted at installation to di-

vert the correct amount of water back to the jet for the

most efficient operation. Under certain conditions, the

pressure regulator may require adjustment during the

pump's life (see Page 10) to restore or maintain the

pump's efficiency.

Pressure Switch

The pressure switch automatically starts the pump

when the pressure in the tank drops to 40 pounds per

square inch (PSI) and stops the pump when the tank

pressure reaches 60 PSI.

Adapter Flange

The VMS pump is equipped with an adapter flange.

This adapter facilitates installation and removal of the

pump without disturbing piping. See Pages 6 and 7 for

more information.

Pressure Relief Valve

Under certain conditions, VMS pumps can generate

very high pressure. The pressure relief valve is installed

to make sure that the pressure in the system does not

exceed the pressure which the system can carry safely.

The pressure relief valve must be able to pass all the

water the pump can produce at the system's rated pres-

sure. Install a relief valve (Sears Stock No. 2729) set to

open at 75 PSI. between the pump and the rank. There

should be no shutoff valves between the pump and the

relief valve. See Figures 11 and 12, Page 8, for more in-

formation.

Pump Mounting

The pump base has three equally spaced 3/4" NPT

threaded sockets. These will take threaded pipe for

legs, to allow enough room to make piping connec-

tions under the pump.

In the case of a single pipe installation (see below), the

pump can be placed directly over the well, using the

offset nipple furnished with the casing adapter to con-

nect the pump to the well head.

Piping

When installed on a 'double pipe' jet, one pipe is the

pressure or drive pipe; this pipe sends water down into

the well to the jet. The other pipe is the suction pipe;

this pipe carries water up to the pump suction from

the jet. Because of the pressure requirements and

depth of multi-stage jet pump installations, use the

chart below for pipe selection.

When installed on a singe pipe jet, the well casing

serves as the drive pipe, carrying water to the jet. The

drop pipe inside the well is the suction pipe, carrying

water up to the pump from the jet.

Use a 'single pipe' system for a 2" or 3" well; use a 'dou-

ble pipe' system for a 4 _ or larger well. See Pages 6 and

7 for details. Follow instructions packed with jet pack-

age to get proper nozzle and venturi combination for

your pumping depth.

Use 1-1/4" pipe for both suction and drive pipes. A 1"

nipple, a 1-1/4"xl" facing bushing, and a 1-1/4 _ cou-

pling are included in the jet package. These must be

used with the jet. (See Figure 8, Page 6, for installation

details.)

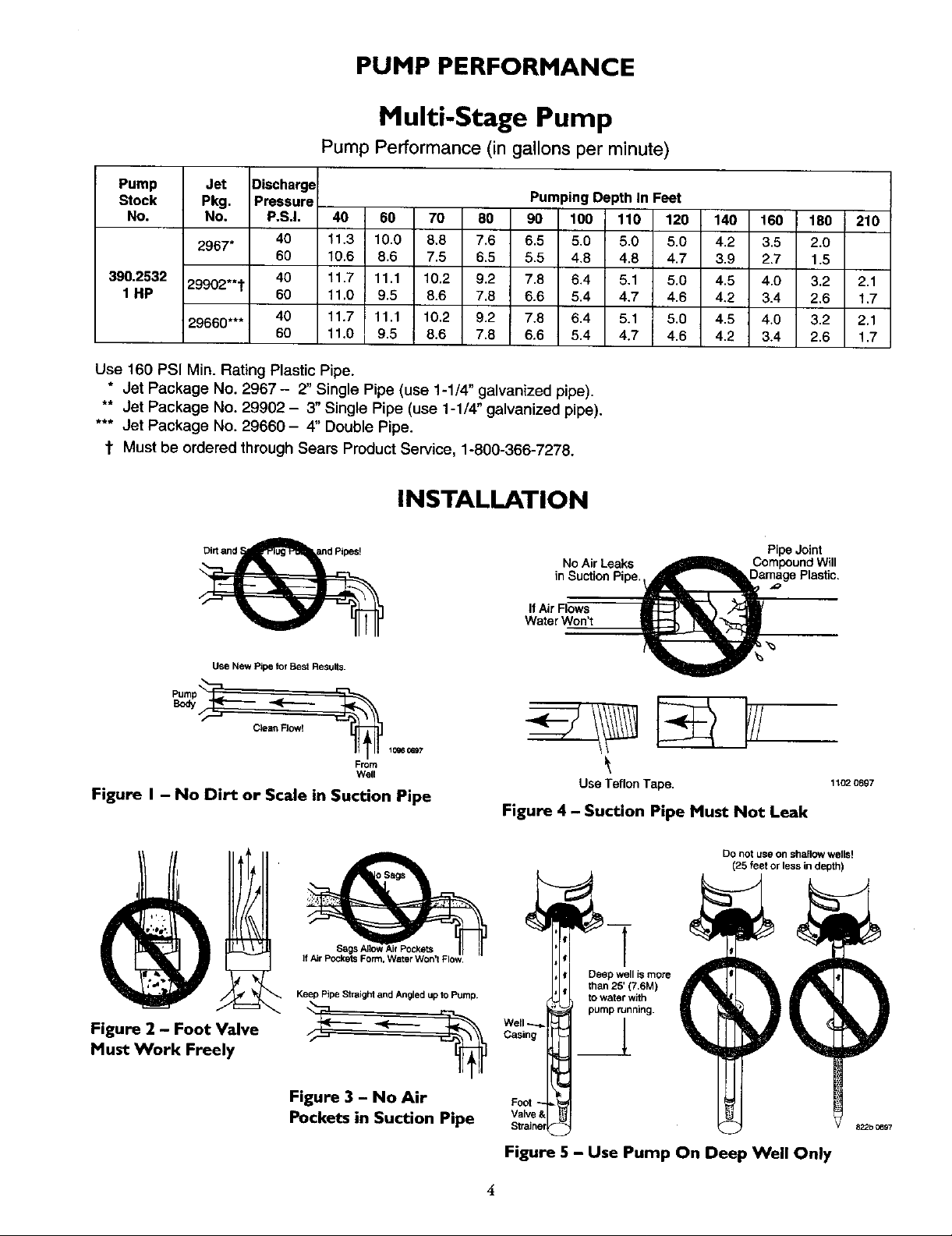

PUMP PERFORMANCE

Multi-Stage Pump

Pump Performance (in gallons per minute)

Pump Jet Discharge

Stock Pkg. Pressure Pumping Depth In Feet

No. No. P.S,I, 40 60 70 80 90 100 110 120 140 160 180 210

2967* 40 11.3 10,0 8.8 7,6 6,5 5,0 5,0 5,0 4.2 3,5 2.0

390.2532 29902**t 40 11.7 11.1 10.2 9.2 7.8 6,4 5.1 5.0 4.5 4.0 3.2 2.1

1 HP 60 11.0 9.5 8.6 7.8 6.6 5.4 4.7 4.6 4,2 3.4 2.6 1.7

29660*** 40 11.7 11.1 10.2 9.2 7.8 6.4 5,1 5.0 4.5 4,0 3.2 2.1

Use 160 PSI Min. Rating Plastic Pipe.

* Jet Package No. 2967- 2" Single Pipe (use 1-1/4" galvanized pipe).

** Jet Package No. 29902 - 3" Single Pipe (use 1-1/4" galvanized pipe).

*** Jet Package No. 29660 - 4" Double Pipe.

t Must be ordered through Sears Product Service, 1-800-366-7278.

60 10.6 8.6 7.5 6.5 5.5 4,8 4.8 4.7 3.9 2.7 1.5

60 11.O 9.5 8.6 7.8 6.6 5.4 4.7 4.6 4.2 3,4 2,6 1.7

INSTALLATION

Use New Pipe for Best Results.

Clean FJow!

1096 0697

From

Well

Figure I - No Dirt or Scale in Suction Pipe

!

NoAir Leaks _ Compound Will

PipeJoint

in Suction Pipe. _amage Plastic.

IfAir Flows

Water Won't

Use TeflonTape.

Figure 4 - Suction Pipe Must Not Leak

1102 0697

Figure 2 - Foot Valve

Must Work Freely

Figure 3 - No Air

Pockets in Suction Pipe _,_

Figure 5 - Use Pump On Deep Well Only

INSTALLATION

NOTICE: For proper performance, pump MUST be

matched to ejector and to well depth. Use this pump

on wells 25' to 210' deep.

1. Long runs and many fittings increase friction and re-

duce flow. Locate pump as close to well as possible:

use as few elbows and fittings as possible.

2. Be sure well is clear of sand. Sand will plug the

pump and void the warranty.

3. Protect pump and all piping from freezing. Freezing

will split pipe, damage pump and void the warranty.

Check locally for frost protection requirements

(usually pipe must by 12 _ below frost line and

pump must be insulated).

4. Be sure all pipes and foot valve are clean and in

good shape.

5. No air pockets in suction pipe.

6. No leaks in suction pipe. Use Teflon tape or Plasto-

Joint stik to seal pipe joints.

7. Match pump to well.

IMPORTANT: Flow into well must at least equal

flow out through pump!

8. Unions installed near pump and well will aid in ser-

vicing. Leave room to use wrenches.

I_, CAUTION]Motor normally operates at high temper-

ature and will be too hot to touch. It is protected from

heat damage during operation by an automatic internal

cutoff switch. Before handling pump or motor, stop

motor and allow it to cool for 20 minutes.

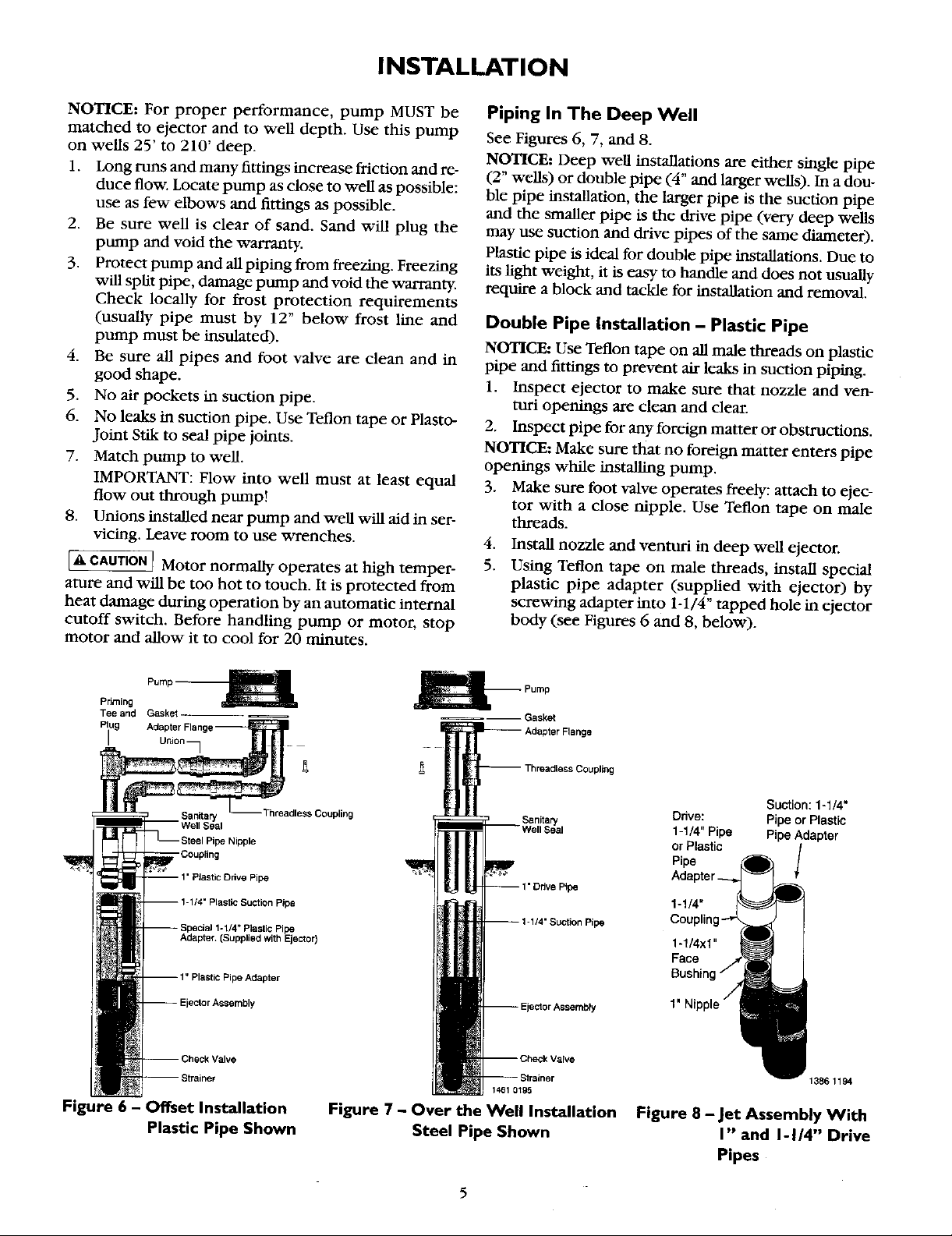

Piping In The Deep Well

See Figures 6, 7, and 8.

NOTICE: Deep well instaUations are either single pipe

(2" wells) or double pipe (4" and larger wells). In a dou-

ble pipe installation, the larger pipe is the suction pipe

and the smaller pipe is the drive pipe (very deep wells

may use suction and drive pipes of the same diameter).

Plastic pipe is ideal for double pipe instaUations. Due to

its light weight, it is easy to handle and does not usually

require a block and tackle for instaUation and removal.

Double Pipe Installation - Plastic Pipe

NOTICE: Use Teflon tape on all male threads on plastic

pipe and fittings to prevent air leaks in suction piping.

1. Inspect ejector to make sure that nozzle and ven-

turi openings are clean and clear.

2. Inspect pipe for any foreign matter or obstructions.

NOTICE: Make sure that no foreign matter enters pipe

openings while installing pump.

3. Make sure foot valve operates freely: attach to ejec-

tor with a close nipple. Use Teflon tape on male

threads.

.

Install nozzle and venturi in deep well ejector.

5.

Using Teflon tape on male threads, install special

plastic pipe adapter (supplied with ejector) by

screwing adapter into 1-1/4" tapped hole in ejector

body (see Figures 6 and 8 below).

Pnming

Tee and Gasket

Piug

)e Nipple

_Coppling

Adapter.(SuPplied with Ejector)

Ipe Adapter

heckValve

trainer

Figure 6 - Offset Installation

Plastic Pipe Shown

Gasket

Suction: 1-1/4"

Ddve: Pipe or Plastic

1-1/4" Pipe Pipe Adapter

Pipe

or Plastic J

1-1/4"

pe

1461 O_g5

Figure 7 - Over the Well Installation

Steel Pipe Shown

pe

1-1/4x1"

Face

1' Ni

1386 1194

Figure 8 - Jet Assembly With

I" and I-I/4" Drive

Pipes

5

INSTALLATION

6. Thread a 1" plastic pipe adapter or a 1" nipple into

the 1" tapped hole in ejector body (see lfigure 8).

7. Install sufficient plastic pipe in well casing to place

ejector at the proper depth. (Your well driller

should supply this information.)

NOTICE: As a guide, the ejector should be set at least

10 to 20 feet below the lowest water level with pump

running, if possible, but always at least five feet from

the bottom of the well.

8.

Tighten all hose clamps securely on plastic pipe.

Use two clamps per joint to prevent air leaks into

suction pipe. Clamp screws should be on opposite

sides of the pipe. Fill pipes with water to make sure

that foot valve and connections do not leak.

9. Install sanitary well seal on top of well casing; use

steel nipple through well seal as shown in Figure 6.

NOTICE: Align locating lugs on adapter flange and

pump base so that pump discharge will be aligned with

piping.

10. Install 1" nipple in one side of adapter flange. Slide

threadless coupling down over drive pipe from

well. Thread adapter flange onto suction pipe from

well and align nipple and drive pipe.

11. Slide threadless coupling up and secure nipple to

drive pipe.

12. Remove paper backing from adhesive gasket. Apply

gasket to adapter flange, making sure that holes line

up.

13. Align locating lugs on pump base with locating lugs

on adapter flange; attach pump to flange with cap

screws provided.

14. See "Discharge Pipe Sizes" for information regard-

hag correct discharge pipe size.

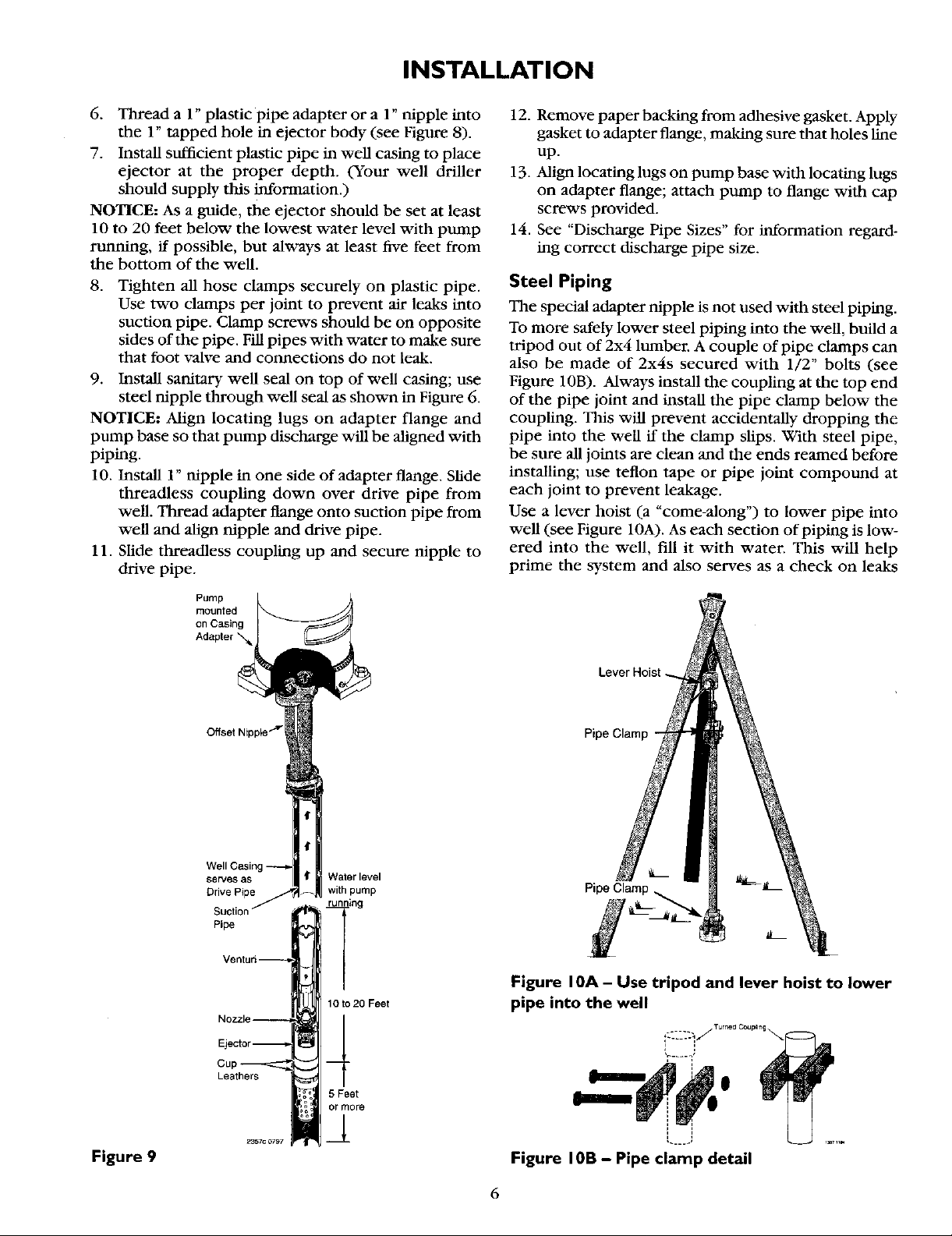

Steel Piping

The special adapter nipple is not used with steel piping.

To more safely lower steel piping into the well, build a

tripod out of 2x4 lumber. A couple of pipe clamps can

also be made of 2x4s secured with 1/2" bolts (see

Figure 10B). Always install the coupling at the top end

of the pipe joint and install the pipe clamp below the

coupling. This will prevent accidentally dropping the

pipe into the well if the clamp slips. With steel pipe,

be sure all joints are clean and the ends reamed before

installing; use teflon tape or pipe joint compound at

each joint to prevent leakage.

Use a lever hoist (a "come-along") to lower pipe into

well (see Figure 10A). As each section of piping is low-

ered into the well, fill it with water. This will help

prime the system and also serves as a check on leaks

Pump

mounted

on Casing

serves as

Drive Pipe

Pipe

Waterlevel

with pump

riiing

1Oto20 Feet

Lever Hoist

Pipe Clamp -

Pipe Clamp _ _ll_-L

Figure I0A - Use tripod and lever hoist to lower

pipe into the well

Figure 9

Leathers

5 Feet

or mere

i ,

Figure I0B - Pipe clamp detail

Loading...

Loading...