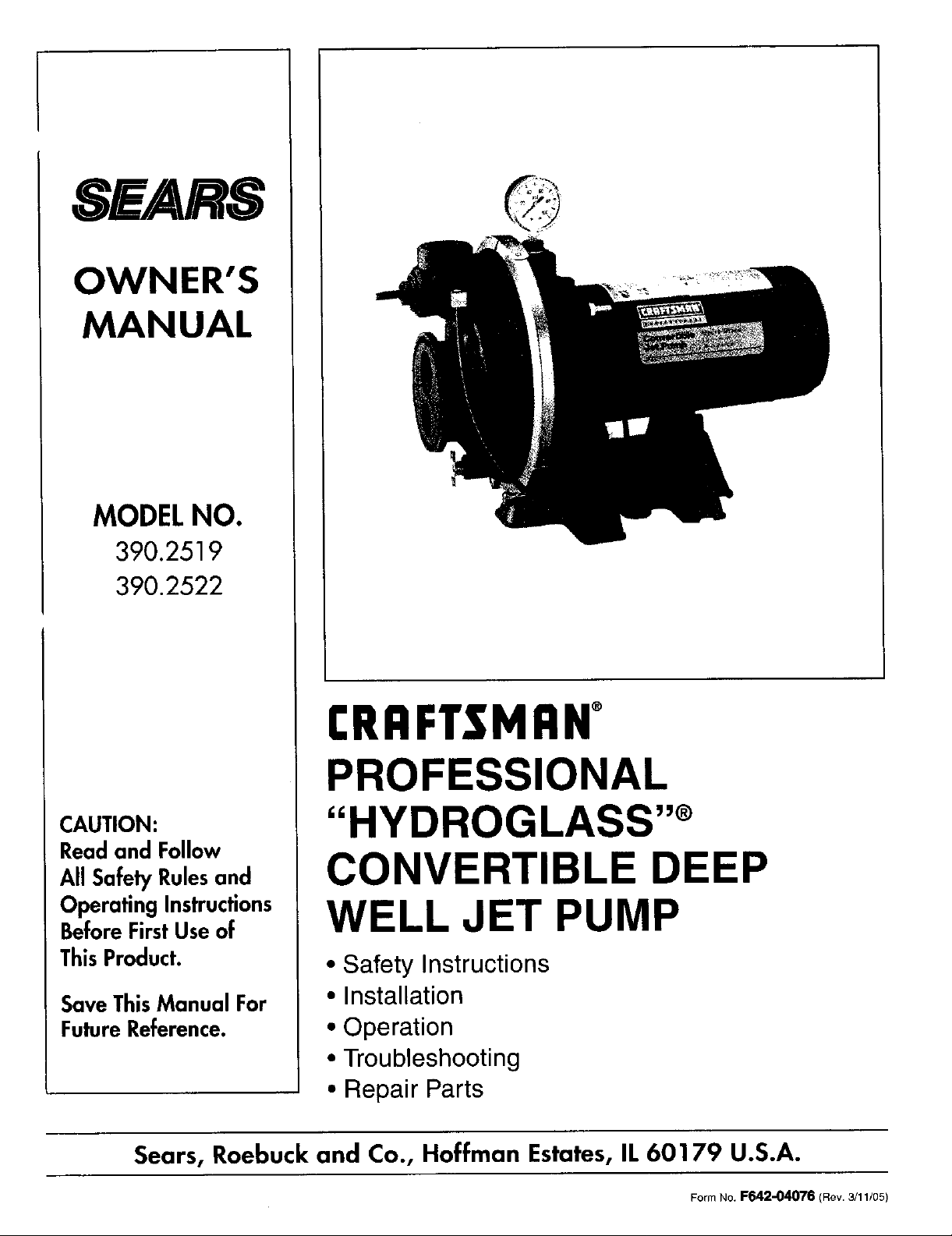

Craftsman 3902522, 390252281, 3902519 Owner’s Manual

SEARS

OWNER'S

MANUAL

MODELNO.

390.2519

390.2522

@

CAUTION:

Read and Fallow

All Safety Rulesand

Operating Instructions

BeforeFirstUseof

ThisProduct.

Save ThisManual For

FutureReference.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

I:RRFTSMRN°

PROFESSIONAL

"HYDROGLASS ''®

CONVERTIBLE DEEP

WELL JET PUMP

• Safety Instructions

• Installation

• Operation

• Troubleshooting

• Repair Parts

Form No. F642-04076 (Rev. 3/11/05)

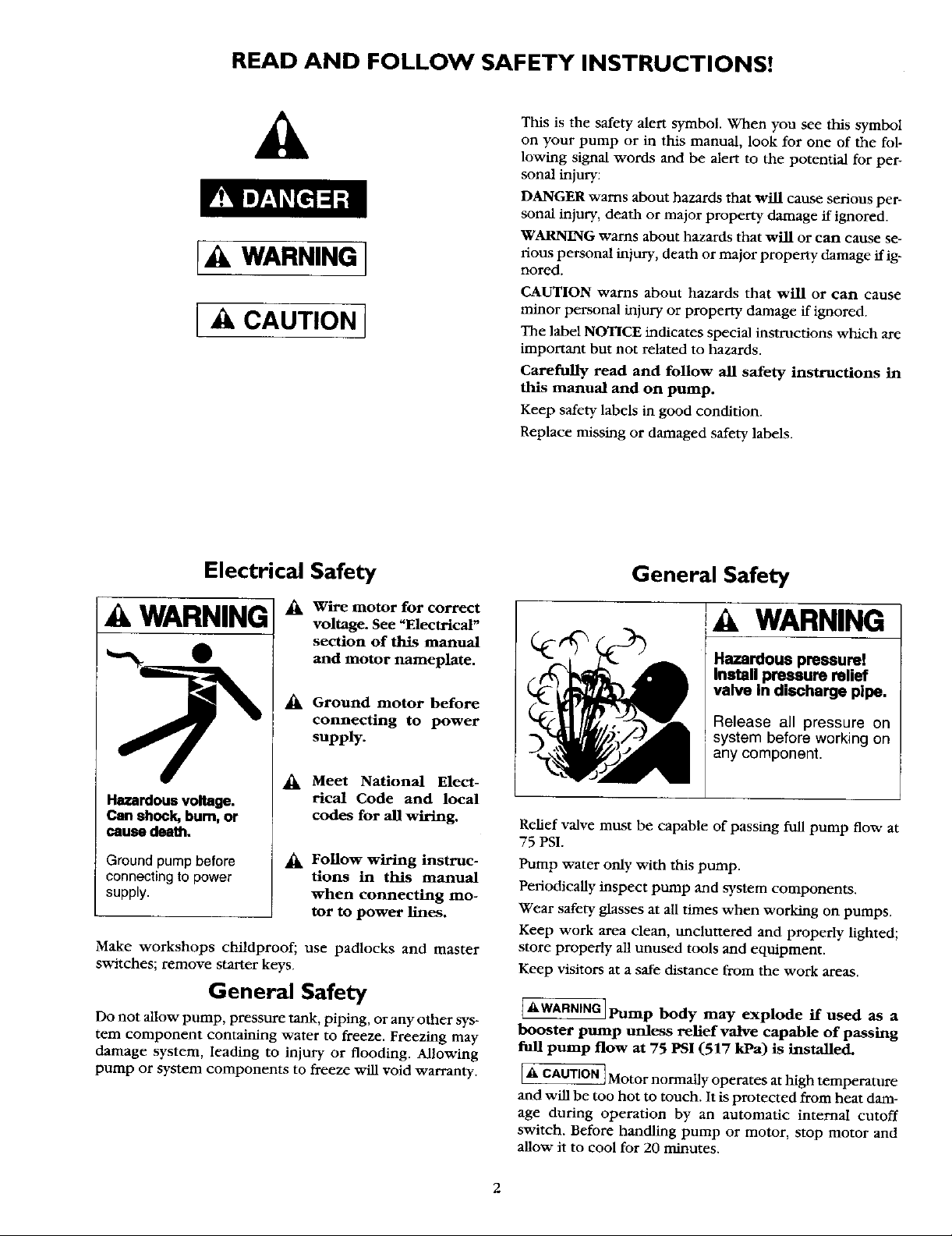

READ AND FOLLOW SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this symbol

A

WARNING 1

A CAUTION 1

on your pump or in this manual, look for one of the fol-

lowing signal words and be alert to the potential for per-

sonal injury:

DANGER warns about hazards that will cause serious per-

sonal injury, death or major property damage if ignored.

WARNING warns about hazards that will or can cause se-

rious personal injury, death or major property damage if ig-

nored.

CAUTION warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which are

important but not related to hazards.

Carefully read and follow all safety instructions in

this manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

Electrical Safety

A WARNING

Hazardous voltage.

Can shock, bum, or

cause death.

Ground pump before

connecting to power

supply.

Make workshops childproof; use padlocks and master

switches; remove starter keys.

_k Wire motor for correct

voltage. See "Electrical"

section of this manual

and motor nameplate.

_k Ground motor before

connecting to power

supply.

Meet National Elect-

rical Code and local

codes for all wiring.

Follow wiring instruc-

tions in this manual

when connecting mo-

tor to power lines.

General Safety

Do not allow pump, pressure tank, piping, or any other sys-

tem component containing water to freeze. Freezing may

damage system, leading to injury or flooding. Allowing

pump or system components to freeze v_dl void warranty.

General Safety

WARNING

Hazardous pressure!

Install pressure relief

valve In discharge pipe.

Release all pressure on

system before working on

any component.

Relief valve must be capable of passing full pump flow at

75 PSI.

Pump water only with this pump.

Periodically inspect pump and system components.

Wear safety glasses at all times when working on pumps.

Keep work area clean, tmclunered and properly lighted;

store properly all unused tools and equipment.

Keep visitors at a safe distance from the work areas.

AWARNINGIPump body may explode if used as a

booster pump unless relief valve capable of passing

full pump flow at 75 PSI (517 kPa) is installed.

[_ CAUTION]Motor normally operates at high temperature

and will be too hot to touch. ]t is protected from heat dam-

age during operation by an automatic internal cutoff

switch. Before handling pump or motor, stop motor and

allow it to cool for 20 minutes.

I

2

CONTENTS

Safety .................................................................................. 2

Warranty/Introduction ....................................................... 3

Installation ....................................................................... 4-8

Electrical ........................................................................ 9-10

Operation ......................................................................... 11

Maintenance ..................................................................... 11

Service ......................................................................... 12-13

Troubleshooting .......................................................... 14-15

Pump Performance .......................................................... 15

Repair Parts ................................................................. 16-19

of charge.

During the Second year and third year from purchase date, a free pump part will be supplied for a defective one.

You must pay the labor cost if you wish to have it installed.

Warranty service is available by returning this product to place of purchase for replacement, or by calling

1-800-4-MY-HOME ®to arrange for part replacement or product repair.

This warranty is VOID if this pump is used for commercial or rental purposes.

Sears is not liable for loss or damage to property, nor for any incidental or consequential loss or expense from

property damage, that results directly or indirectly from the use of this product.

This warranty gives you specific legal rights, and you may also have other fights which vary from state to state.

Sears Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

INTRODUCTION

We suggest you take a few minutes to read the instructions

contained in this manual before installing and using your

pump. This viifi help you obtain the full benefits of the qual-

ity and convenience built into this equipment. It will also

help you avoid any needless service expense resulting from

causes beyond our control which naturally cannot be cov-

eredinourwarranty.

RULES FOR SAFE INSTALLATION AND OPERATION

1. Read the Owners Manual and Rules for Safe Operation

and Installation Instructions careflifiy. Failure to follow

these Rules and Instructions could cause serious bodily

injury, and/or property damage.

2. Check your local electrical wiring codes before installa-

tion. ffyour local codes are not followed, your pump will

not work to its full rated capacity. If in doubt, contact

your local Power Company.

3. Be certain your pump installation meets all local plumb-

hag, pump and well codes.

4. While installing the pump, always keep the well covered

to prevent leaves and foreign matter from falling into the

well and contaminating the water and/or causing possi-

ble serious damage to the mechanical operation of the

pump.

5. Always test the well water for purity before using. Check

with local health department for testing procedure.

6. Before installing or servicing your pump, BE CERTAIN

pump power source is disconnected.

7. Be sure your pump electrical circuit is properly gruunded.

8. Complete pump and piping system MUST be protected

against below freezing temperature. Failure to do so could

cause severe damage and voids the Warranty.

9. Make sure the line voltage and frequency of the electrical

circuit supply agree with the motor wiring. If motor is

dual voltage type, BE SURE it is wired correctly for your

power supply.

10. The correct fusing and wiring sizing is essential to proper

motor operation. Recommended flWmg and v/ire size data

is in the manual.

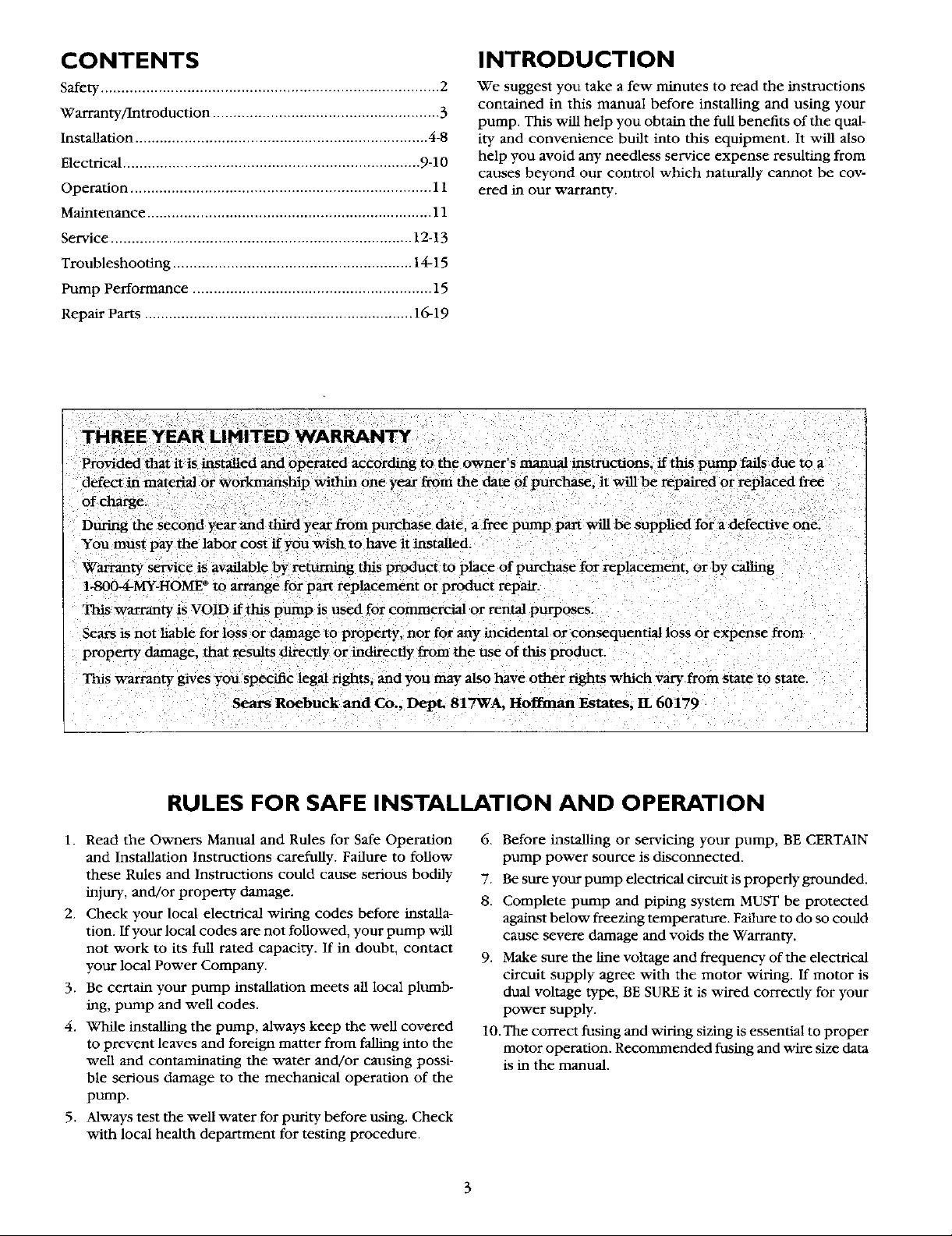

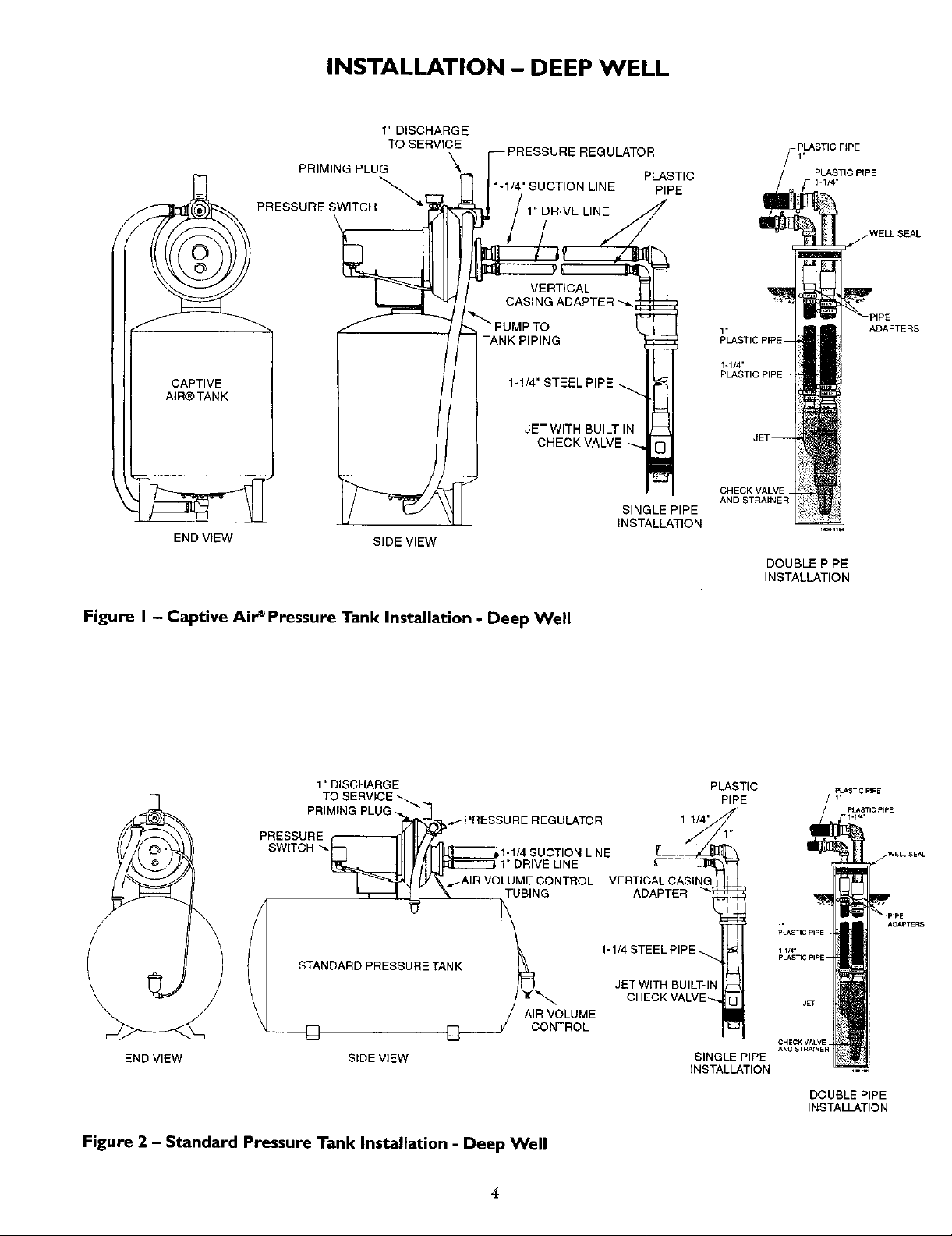

INSTALLATION - DEEP WELL

1" DISCHARGE

TO SERVICE

PRIMING PLUG

PRESSURE SWITCH !

_ 1-1/4" SUCTION LINE PIPE

\

\

IE REGULATOR

LINE

PLASTIC

1,

PLASTIC PIPE

WELLSEAL

CAPTIVE

AIR_ TANK

END VIEW

SIDE VIEW

1-1/4"

CHECK\

Figure I - Captive Air'Pressure Tank Installation - Deep Well

SINGLE PIPE

INSTALLATION

1.

PLASTIC PIPE--

1-1/4"

PLASTIC PIP

CHECKVALVE_

AND STRAINER

DOUBLE PIPE

INSTALLATION

ADAPTERS

1" DISCHARGE

TO SERVICE _.

PRIMING PLUG

_IMING PLUG

PRESSURE

SWITCH

-_ "_H_ _- PRESSURE REGULATOR 1-1/4"

1-1/4 SUCTION LINE

_._--IJl !II_:_E==_1"DRIVE LINE

.,_-AIR VOLUME CONTROL VERTICALCASING

_AIR VC TUBING ADAPTER

STANDARD PRESSURE TANK

_AIG 1-1/4 STEEL PIP

AIR VOLUME

D

END VIEW SIDE VIEW

Figure 2 - Standard Pressure Tank Installation - Deep Well

PLASTIC

PIPE

JET WITH BUILT-In

CHECK VALVE

ONTROL

SINGLE PIPE

INSTALLATION

DOUBLE PIPE

INSTALLATION

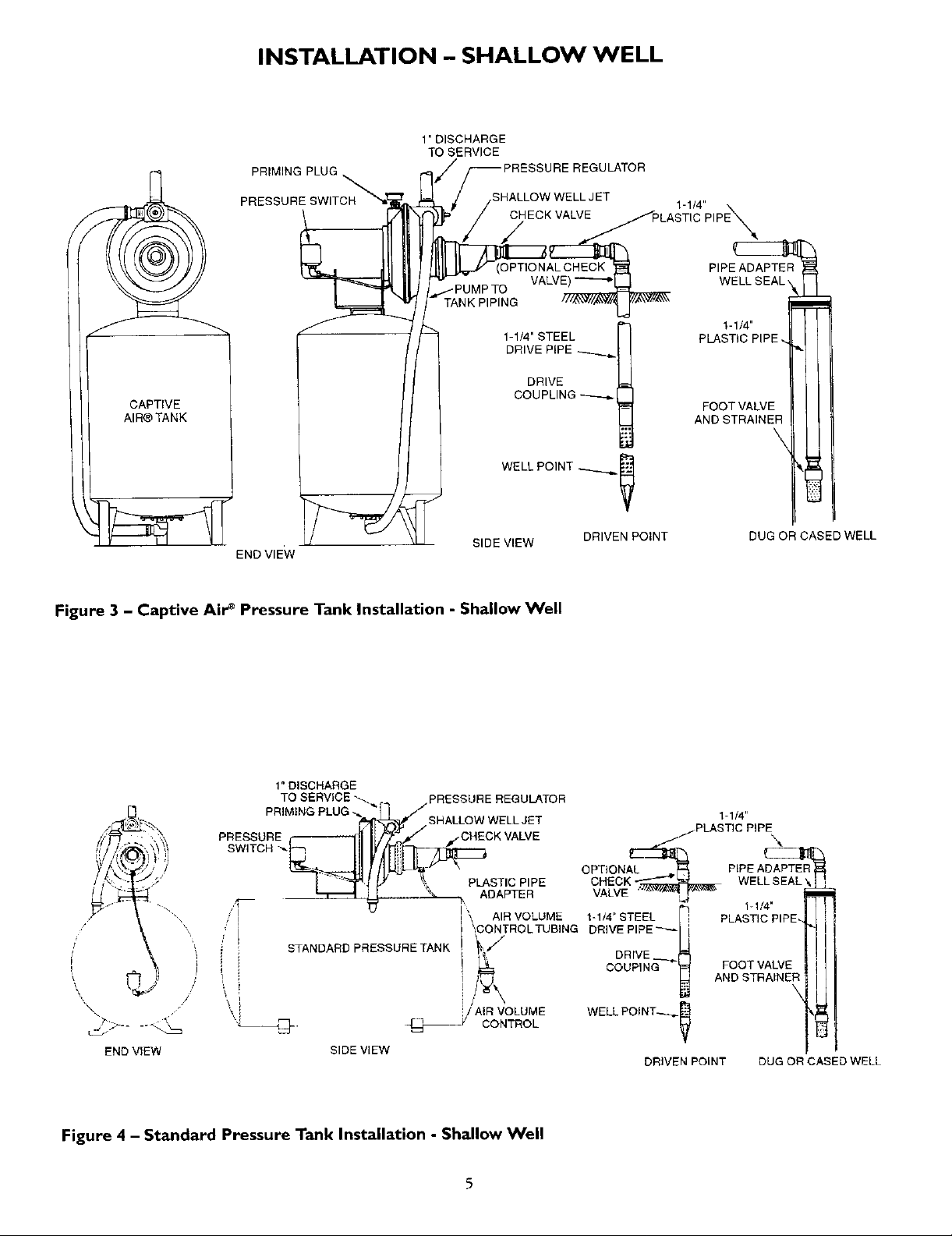

INSTALLATION - SHALLOW WELL

1" DISCHARGE

TO SERVICE

PRIMING PLUG

PRESSURE SWITCH

CHECK VALVE

ULATOR

L JET

'-"4"p,pE',

VALVE)

PING

1-1/4' STEEL

DRIVE PiPE

DRIVE

CAPTIVE

AIR®TANK

END VIEW

COUPLING

WELL POINT _._

SIDE VIEW DRIVEN POINT

Figure 3 - Captive Air _ Pressure Tank Installation - Shallow Well

PIPE ADAPTER

I

PLASTIC PIPE. •

FOOT VALVE

AND STRAIN

'-"4"l

DUG OR CASED WELL

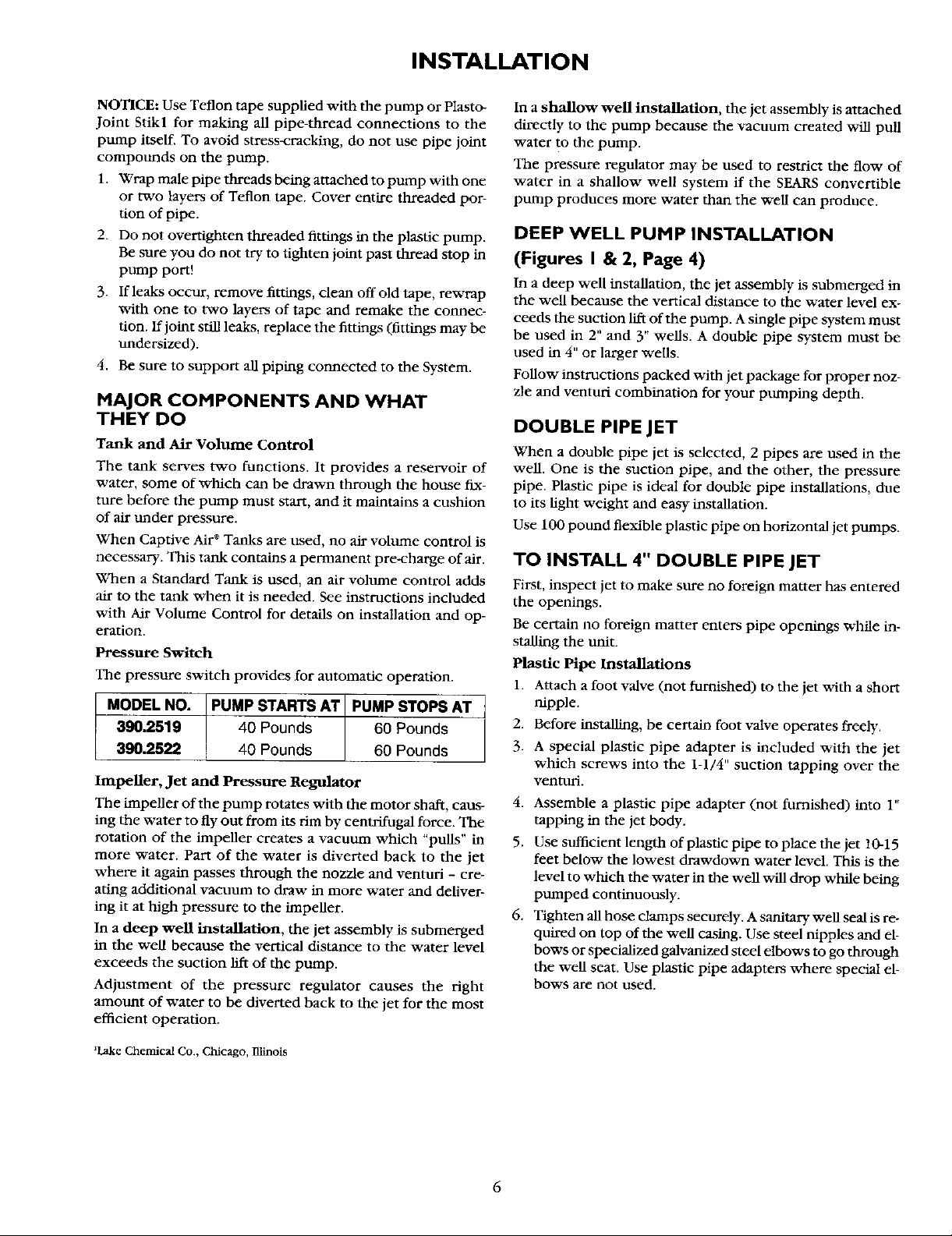

1" DISCHARGE

TO SERVICE _.. PRESSURE REGULATOR

PRIMING

PRESSURE _SNA:OHWE_K VALVE

SWITCH "__

'I

i CONTROLTUBING DRIVE PIPE_

END VIEW SIDE VIEW

PLUG

_[_f/SHALLOW WELL JET

,-, PLASTIC PIPE

STANDARD PRESSURE TANK _;; DRIVE __

ADAPTER

AIR VOLUME

i_ COUPING

/ AiR VOLUME

CONTROL

Figure 4 - Standard Pressure Tank Installation - Shallow Well

5

I-1/4"

j. PLASTIC PIPE,

OPTIONAL 4p PIPE ADAPTER

CHECK

VALVE

1-1!4" STEEL i

WELL POINT--_

DRIVEN POINT DUG OR CASED WELL

1-1/4'

PLASTIC PIPE.

FOOT VALVE

AND STRAINER

INSTALLATION

NOTICE: Use Teflon tape supplied with the pump or Plasto-

Joint Stikl for making all pipe-thread connections to the

pump itself. To avoid stress-cracking, do not use pipe joint

compounds on the pump.

1. Wrap male pipe threads being attached to pump with one

or two layers of Teflon tape. Cover entire threaded por-

tion of pipe.

2. Do not overtighten threaded fittings in the plastic pump.

Be sure you do not try to tighten joint past thread stop in

pump port!

3. If leaks occur, remove fittings, clean off old tape, rewrap

with one to two layers of tape and remake the connec-

tion. If joint still leaks, replace the fittings (fittings may be

undersized).

4. Be sure to support all piping connected to the System.

MAJOR COMPONENTS AND WHAT

THEY DO

Tank and Air Volume Control

The tank serves two functions. It provides a reservoir of

water, some of which can be drawn through the house fix-

ture before the pump must start, and it maintains a cushion

of air under pressure.

When Captive Air + Tanks are used, no air volume control is

necessary. This tank contains a permanent pre-charge of air.

When a Standard Tank is used, an air volume control adds

air to the tank when it is needed. See instructions included

with Air Volume Control for details on installation and op-

eration.

Pressure Switch

The pressure switch provides for automatic operation.

MODEL NO. PUMP STARTS AT PUMP STOPS AT

390.2519 40 Pounds 60 Pounds

390.2522 40 Pounds 60 Pounds

Impeller, Jet and Pressure Regulator

The impeller of the pump rotates with the motor shaft, caus-

ing the water to fly out from its rim by centrifugal force. The

rotation of the impeller creates a vacuum which "puns" in

more water. Part of the water is diverted back to the jet

where it again passes through the nozzle and venturi - cre-

ating additional vacuum to draw in more water and deliver-

ing it at high pressure to the impeller.

In a deep well installation, the jet assembly is submerged

in the well because the vertical distance to the water level

exceeds the suction lift of the pump.

Adjustment of the pressure regulator causes the fight

amount of water to be diverted back to the jet for the most

efficient operation.

In a shallow well installation, the jet assembly is attached

directly to the pump because the vacuum created will pull

water to the pump.

The pressure regulator may be used to restrict the flow of

water in a shallow well system if the SEARS convertible

pump produces more water than the well can produce.

DEEP WELL PUMP INSTALLATION

(Figures I & 2, Page 4)

In a deep well installation, the jet assembly is submerged in

the well because the vertical distance to the water level ex-

ceeds the suction lift of the pump. A single pipe system must

be used in 2" and 3" wells. A double pipe system must be

used in 4" or larger wells.

Follow instructions packed with jet package for proper noz-

zle and venturi combination for your ptmaping depth.

DOUBLE PIPE JET

When a double pipe jet is selected, 2 pipes are used in the

well. One is the suction pipe, and the other, the pressure

pipe. Plastic pipe is ideal for double pipe installations, due

to its light weight mid easy installation.

Use 100 ponnd flexible plastic pipe on horizontal jet pumps.

TO INSTALL 4" DOUBLE PIPE JET

First, inspect jet to make sure no foreign matter has entered

the openings.

Be certain no foreign matter enters pipe openings while in-

stalling the unit.

Plastic Pipe Installations

1. Attach a foot valve (not furnished) to the jet with a short

nipple.

2. Before installing, be certain foot valve operates freely.

3. A special plastic pipe adapter is included with the jet

which screws into the 1-1/4" suction tapping over the

venturi.

4. Assemble a plastic pipe adapter (not furnished) into 1"

tapping in the jet body.

5. Use sufficient length of plastic pipe to place the jet 10-15

feet below the lowest drawdown water level. This is the

level to which the water in the well will drop while being

pumped continuously.

6. Tighten all hose clamps securely. A sanitary well seal is re-

quired on top of the well casing. Use steel nipples and el-

bows or specialized galvanized steel elbows to go through

the well seat. Use plastic pipe adapters where special el-

bows are not used.

_Lake Chemical Co., Chicago, Blinois

6

Loading...

Loading...