Craftsman 3902509 Owner’s Manual

SEARS

OWNER'S

MANUAL

MODEL NO.

390.2509

I:RRFTSMRN°

CAUTION:

Read and Follow

All Safety Rulesand

Operating Instructions

Before FirstUse of

ThisProduct.

Save ThisManual For

FutureReference.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

PRtNTED IN U.S.A, Form No. F642-04074 (8/3/04)

1/2 HP SHALLOW WELL

WATER SYSTEM

• Safety Instructions

• Installation

• Electrical

• Maintenance

• Repair Parts

CONTENTS

INTRODUCTION/WARRANTY ..................................................... 2

MAJOR COMPONENTS ................................................................. 3

INSTALLATION .......................................................................... 3-4

PUMP PERFORMANCE .................................................................. 4

ELECTRICAL ............................................................................... 5_5

OPERATION .................................................................................. 7

M.MNTENANCE ........................................................................ 7-10

HELPFUL HINTS .......................................................................... 11

REPAIR PARTS ........................................................................ 12-14

TROUBLESHOOTING GUIDE ..................................................... 15

INTRODUCTION

Please read our instructions before installing and using your Shallow

Well Water System. This will help you obtain the full benefits of the

quality and convenience built into this equipment. It will also help

you avoid any needless service expense resulting from causes be-

yond our control which are not covered by our warranty.

READ AND FOLLOW SAFETY INSTRUCTIONS!

Carefully read and follow all safety instructions in this man- 1. To avoid risk of serious bodily injury and property damage,

ual or on pump. read safety instructions carefldiy before installing pump.

_This is the safety alert symboL When you see this symbol

on your pump or in this manual, look for one of the follow-

ing signal words and be alert to the potential for personal injury!

_ warns about ILazards that will cause serious per-

sonal injury, death or major property damage if ignored.

r I

[ ..XWARNING ]warns about hazards that will or can cause serious

personal injury, death or major property damage if ignored.

P

[A CAUTION Iwarns about hazards that will or can cause minor

personal injury or property damage if ignored.

The word NOTICE indicates special instructions which are im-

portant but not related to hazards.

r

i

[_ CAUTION [Never rtm pump dry. Running pump without water

may cause pump to overheat, damaging seal and possibly causing

burns to persons handling pump. Fill pump with water before

starting.

P

L_kWARNING_ Never run pump against closed discharge. TO do

so can boil water inside pump, causing hazardous pressure in

unit, risk of explosion and possibly scalding persons handling

pump.

F

lax CAUTIONJ Motor normaUy operates at high temperature and

will be too hot to touch. It is protected from heat damage during

operation by an automatic internal cutoff switch. Before handling

pump or motor, stop motor and allow to cool for 20 minutes.

2. Follow local and/or national plumbing and electrical codes

when installing pump.

3. Keep well covered while installing pump to prevent leaves and

other debris from falling into well, contaminating well and pos-

sibly damaging pump.

4. Protect pump and piping system from freezing. Allowing pump

or water system to freeze could severely damage pump and

voids warranty.

LAWARNINGJTo avoid serious injury and equipment

damage, limit system pressure to 75 pounds per sqlmre

inch (PSI) or below at all times. Over-pressure can cause

explosion; install relief valve capable of passing full

pump volume at 75 PSI.

5. With a new well, test well for purity before use. Consult local

Health Department for procedure.

F _

LAWARNINGJHazardous voltage. Can shock, burn,

cause death, or start fires.

6. Disconnect electrical power source before installing or work-

ing on pump.

7. Ground pump with a ground wire run from grounding lug on

motor to a grounded lead in the service panel.

8. Line voltage and frequency of electrical power supply must

agree with motor nameplate.

9. Use of fuses or wire smaller than size recommended in

owner's manual can cause overheating, possible fires, and will

void warranty.

2

BASIC TOOLS

AND MATERIALS NEEDED

Plastic Pipe Installation

Tools

Pipe Wrenches Knife or Saw to Cut Plastic Pipe

Screwdriver Tire Pressure Gauge

Materials

Plastic Pipe and Firings (as required to complete job).

Teflon Tape (DO NOT use joint compound on plastic fittings).

Galvanized Steel Pipe Installation

Tools

Pipe Wrenches Pipe Cutting and Threading Tools

Screwdriver Tire Pressure Gauge

Materials

Galvanized Pipe and Fittings (as required to complete job).

Pipe Joint Compound or Teflon Tape

MAJOR COMPONENTS AND

WHAT THEY DO

Impeller and Jet

Impeller turns with motor shaft, causing water to fly out from its

rim by centrifugal force. Impeller rotation creates a vacuum which

pulls in more water. Part of the water is diverted back to the jet

where it passes through the nozzle and venturi. This creates more

vacuum to draw in more water.

In shallow webs (less than 20 feet deep), the vacuum created at the

pump is enough to pull water to the pump. Therefore, for shallow

web use the jet is built into the pump.

Pre-Charged Tank

The tank serves two functions. It provides a reservoir of water

under pressure and maintains a cushion of air pressure to prevent

pipe hammering and possible damage to plumbing components.

When water is drawn off through the house fixtures, the pressure

in the tank is lowered and the pump starts.

Pressure Switch

The pressure switch provides for automatic operation. Pump starts

when pressure drops to 30 pounds and stops when pressure

reaches 50 pounds.

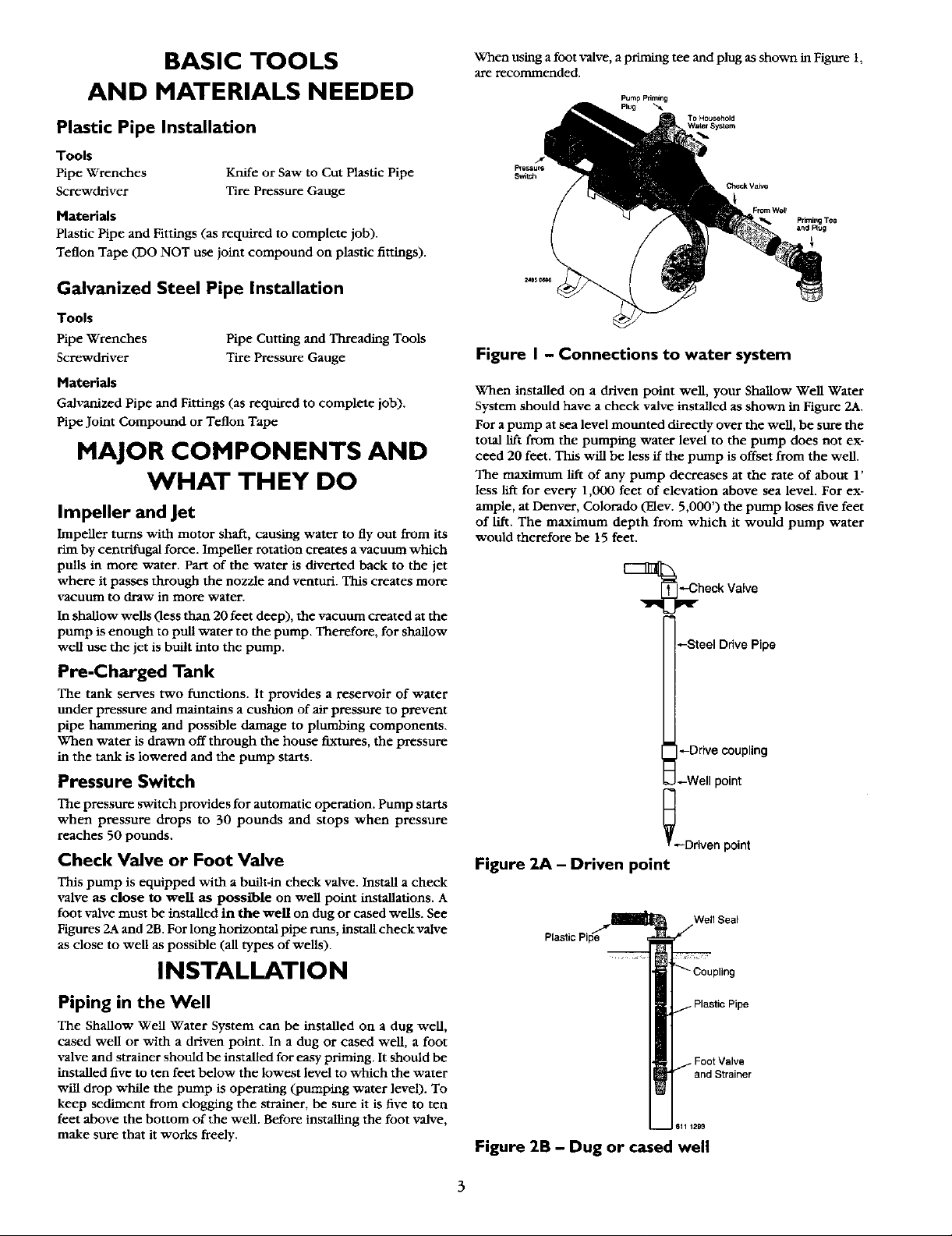

Check Valve or Foot Valve

This pump is equipped with a built:m check valve. Install a check

valve as close to well as possible on web point installations. A

foot valve must be installed in the well on dug or cased wells. See

Figures 2A and 2B. For long horizontal pipe runs, install check valve

as close to web as possible (all types of wells).

INSTALLATION

When using a foot valve, a priming tee and plug as shown in Figure 1,

are recommended.

Figure I - Connections to water system

When installed on a driven point well, your Shallow Well Water

System should have a check valve installed as shown in Figure 2A.

For a pump at sea level mounted directly over the well, be sure the

total lift from the pumping water level to the pump does not ex-

ceed 20 feet. This will be less if the pump is offset from the weB.

The maximum lift of any pump decreases at the rate of about 1'

less lift for every 1,000 feet of elevation above sea level. For ex-

ample, at Denver, Colorado (Elev. 5,000') the pump loses five feet

of lift. The maximum depth from which it would pump water

would therefore be 15 feet.

C_heck Valve

_Steel Drive Pipe

_Drive coupling

_Well point

_Ddven point

Figure 2A - Driven point

Well Seal

Plastic PilSe

Piping in the Well

The Shallow Well Water System can be installed on a dug well,

cased well or with a driven point. In a dug or cased well, a foot

valve and strainer should be installed for easy priming. It should be

installed five to ten feet below the lowest level to which the water

will drop while the pump is operating (pumping water level). To

keep sediment from clogging the strainer, be sure it is five to ten

feet above the bottom of the well. Before installing the foot valve,

make sure that it works freely.

Foot Valve

and Strainer

Figure 2B - Dug or cased well

3

INSTALLATION

PUMP/TANK INSTALLATION

Pump

NOTICE: Use Teflon tape supplied with the pump or Plasto-Joint Stik _

for making all pipe-thread connections to the pump itself. To avoid

stress-cracking, do not use pipe joint compounds on the pump.

1. Wrap male pipe threads being attached to pump with one or

two layers of Teflon tape. Cover entire threaded portion of

pipe.

2. Do not overtighten threaded fittings in the plastic pump. Be

sure you do not try to tighten joint past thread stop in pump

port!

3. If leaks occur, remove fittings, clean off old tape, rewrap with

two to three layers of tape and remake the connection, ff joint

still leaks, replace the fittings (fittings may be undersized).

4. Be sure to support all piping connected to the System.

Horizontal Piping from Well to Pump

When the pump is offset more than 25 feet from the well, hori-

zontal suction pipe size should be increased to reduce friction

losses. Never install a suction pipe that is smaller than the suction

tapping of the pump.

1-114" 1-1/2" 2"

Up to 25 Ft. 25 to 50 Ft. 50 to 200 Ft.

Discharge Pipe Sizes

When the pump is some distance from the house or point of water

use, the discharge pipe size should be increased to reduce pressure

losses caused by friction.

1" 1-114" 1-1/2"

Up to 25 Ft. 25 to 100 Ft. 100 to 600 Ft.

'Lake Chemical Co., Chicago, IlIinois

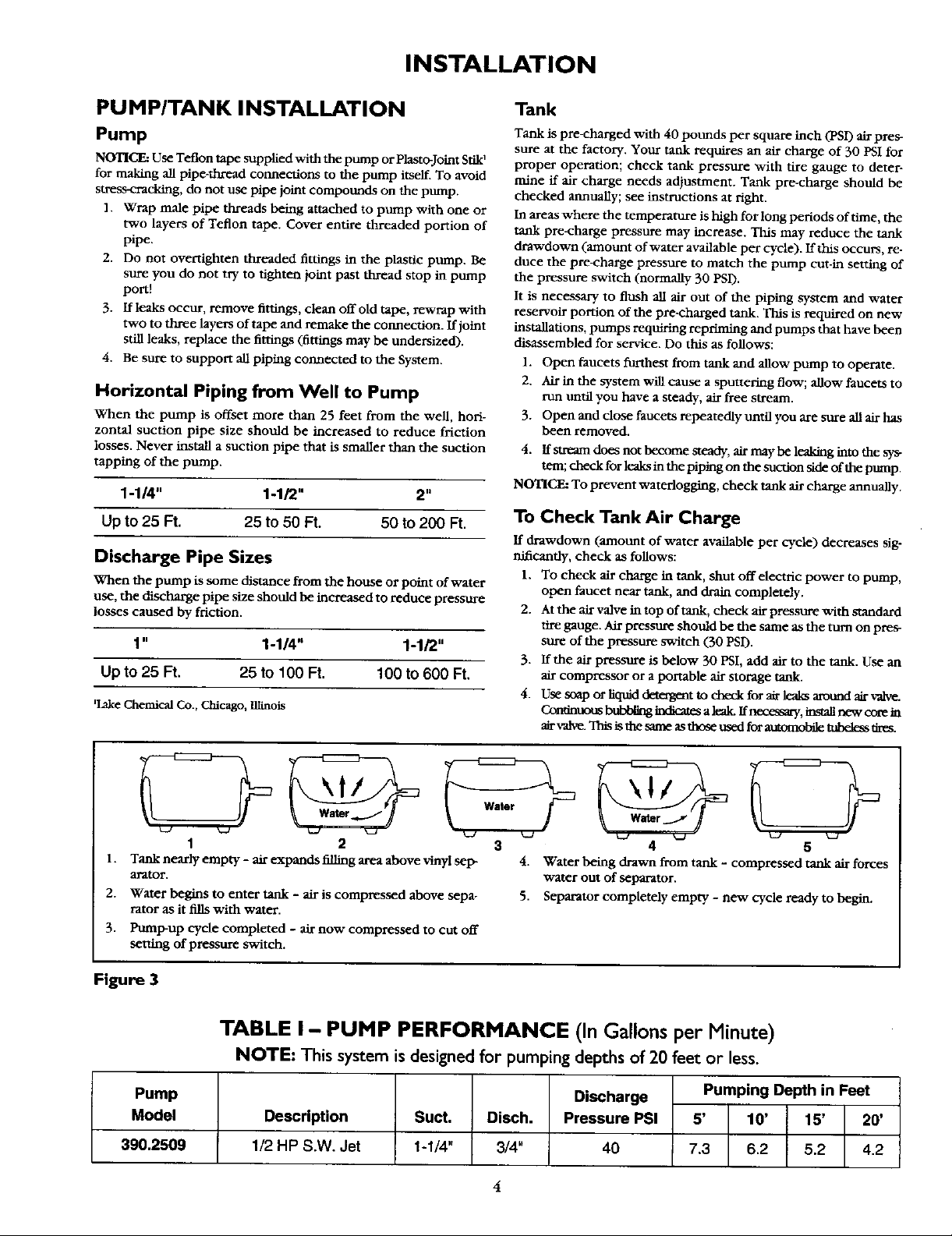

Tank

Tank is pre-charged with 40 pounds per square inch (PSI) air pres-

sure at the factory. Your tank requires an air charge of 30 PSI for

proper operation; check tank pressure with tire gauge to deter-

mine if air charge needs adjustment. Tank pre-charge should be

checked annual!y; see instructions at right.

In areas where the temperature is high for long periods of time, the

tank pre-charge pressure may increase. This may reduce the tank

drawdown (amount of water available per cycle). If this occurs, re-

duce the pre-charge pressure to match the pump cut-in setting of

the pressure switch (normally 30 PSI).

It is necessary to flush aL! air out of the piping system and water

reservoir portion of the pre-charged tank. This is required on new

installations, pumps requiring repriming and pumps that have been

disassembled for service. Do this as follows:

1. Open faucets furthest from tank and allow pump to operate.

2. Air in the system will cause a sputtering flow; allow faucets to

run until you have a steady, air free stream.

3. Open and close faucets repeatedly until you are sure all air has

been removed.

4. If stream does not become steady, air may be leaking into the sys-

tem; check for leaks in the pipio_ on the suction side of the pump.

NOTICE: To prevent waterlogging, check tank air charge annually.

To Check Tank Air Charge

If drawdown (amount of water available per cycle) decreases sig-

nificantly, check as follows:

1. To check air charge in tank, shut off electric power to pump,

open faucet near tank, and drain completely.

2. At the air valve in top of tank, check air pressure with standard

tire gauge. Air pressure should be the same as the turn on pres-

sure of the pressure switch (30 PSI).

3. If the air pressure is below 30 PSI, add air to the tank. Use an

air compressor or a portable air storage tank.

4. Use soap or liquid detergent to check for air leaks around air valve.

Continuous b_ _ a lealc If necessary, install new core in

air valve. This is tiae same as those used for amons3b_le tabeless tires.

1.

Tank nearly empty - air expands filling area above vinyl sep-

arator.

2. Water begins m enter tank - air is compressed above sepa-

rator as it fills with water.

3. Pump-up cycle completed - air now compressed to cut off

setting of pressure switch.

Figure 3

TABLE I - PUMP PERFORMANCE (In Gallons per Minute)

NOTE: This system is designedfor pumping depthsof 20 feet or less.

Pump

1 2

Model

390.2509

Description Suct. Disch, Pressure PSI 5' 10' 15' 20'

112HP S.W. Jet 1-1/4" 3/4" 40 7.3 6.2 5.2 4.2

x-d L_d X_d "_d

3 4 5

4. Water being drawn from tank - compressed tank air forces

water out of separator.

5. Separator completely empty - new cycle ready to begin.

Discharge Pumping Depth in Feet

4

ELECTRICAL

Disconnect power before working on pump, motor, pressure switch, or wiring.

Motor Switch Settings

lfthe motor can operate at either 115 or 230 volts, it is set at the

factory to 230 volts. Do not change motor voltage setting if line

voltage is 230 volts, or if you have a single voltage motor.

NOTICE: Never wire a 115 volt motor to a 230 volt line.

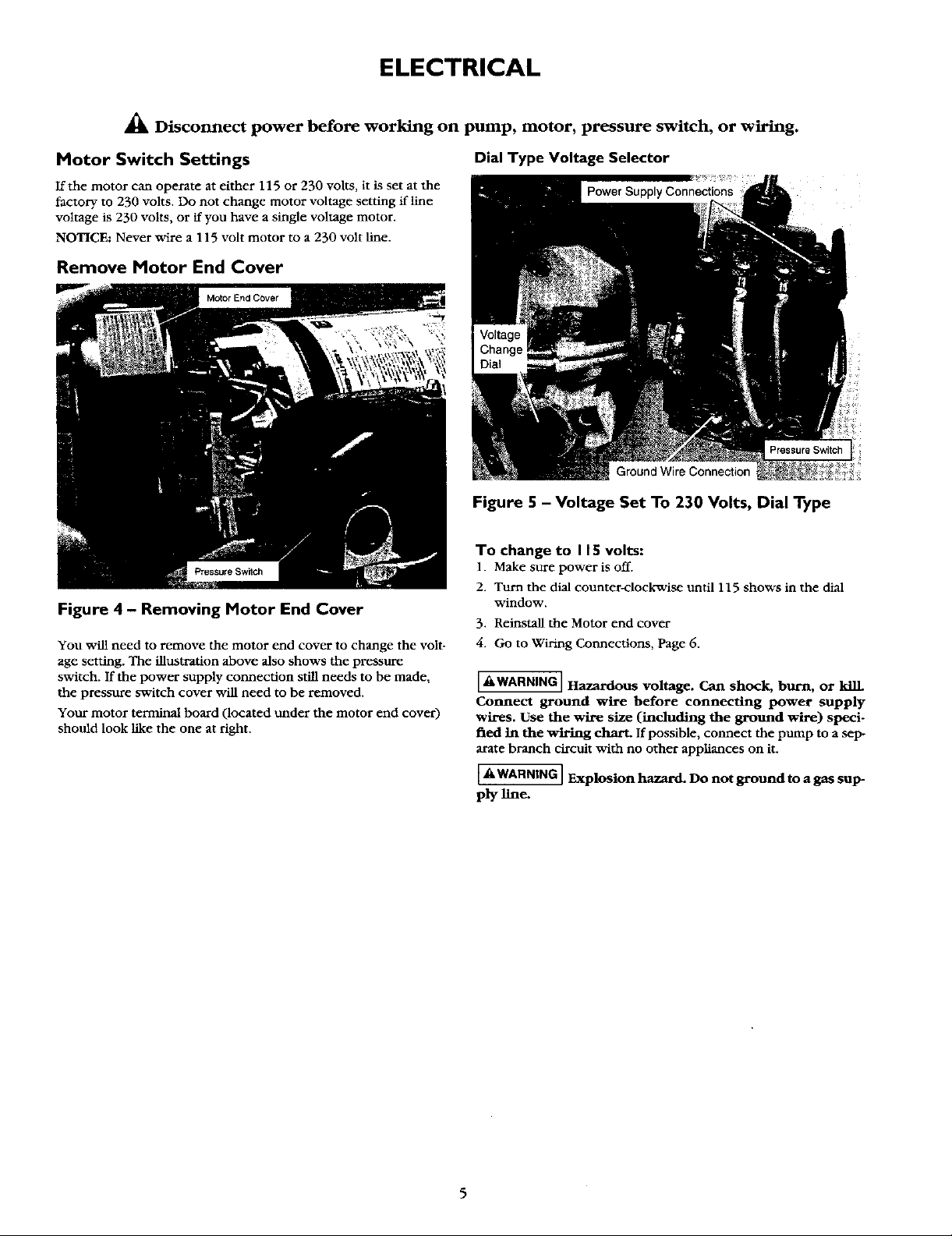

Remove Motor End Cover

Figure 4 - Removing Motor End Cover

You will need to remove the motor end cover to change the volt-

age setting. The illustration above also shows the pressure

switch. If the power supply connection still needs to be made,

the pressure switch cover v_di need to be removed.

Your motor terminal board (located under the motor end cover)

should look like the one at right.

Dial Type Voltage Selector

rConnections

Ground Wire Connection

Figure 5 - Voltage Set To 230 Volts, Dial Type

To change to I 15 volts:

1. Make sure power is off.

2. Turn the dial counter-clockwise until 115 shows in the dial

window.

3. Reinstall the Motor end cover

4. Go to Wiring Connections, Page 6.

[_,WARNING] Hazardous voltage. Can shock, burn, or kill

Connect ground wire before connecting power supply

wires. Use the wire size (including the ground wire) speci-

fied in the wiring chart. If possible, connect the pump to a sep

arate branch circuit with no other appliances on it.

_ Explosion hazard. Do not ground to a gas sup-

ply line.

Loading...

Loading...