Craftsman 3902508 Owner’s Manual

I

SEARS

OWNER'S

MANUAL

MODEL NO.

390.2508

CAUTION:

Read andFollow

All Safety Rulesand

Operating Instructions

Before FirstUse of

ThisProduct.

CRAFTSMAN°

HYDROGLASS ®

SHALLOW WELL

JET PUMP

• Safety Instructions

• Installation

Save ThisManual For

FutureReference.

Sears, Roebuck and Co., Hoffman Estates, IL60179 U.S.A.

PRINTED IN USA. Form No F642-04072 (Rev 2/15/05)

• Operation

• Troubleshooting

• Repair Parts

CONTENTS

WaL'ranty .............................................................................. 2

Pump Performance .............................................................. 3

Major Components .............................................................. 3

Piping ................................................................................ 3-4

Installation ........................................................................... 4

Electrical .............................................................................. 5

Operation/Maintenance ................................................... 6-9

Helpful Hints ....................................................................... 9

Troubleshooting Guide ..................................................... 10

Repair Parts ........................................................................ 11

INTRODUCTION

Please read our instructions before installing and using your

pump. This will help you obtain the full benefits of the qual-

ity and convenience binh into this equipment. It will also

help you avoid any needless service expense resulting from

causes beyond our control which are not covered by our

waiTanty.

RULES FOR SAFE INSTALLATION AND OPERATION

1. Read the Owners Manual and Rules for Installation and

Safe Operation carefully. Failure to follow these Rules and

Instructions could cause serious bodily injury, and/or

property damage.

2. Check your local electrical wiring codes before installa-

tion. ffyour local codes are not followed, your pump will

not work to its full rated capacity and could present a fire

hazard, ff in doubt, contact your local power company.

3. BE SURE your pump installation meets all local plumb-

ing, pump and well codes.

4. While installing your pump, always keep the well covered

to prevent leaves and foreign matter from falling into the

well, contaminating the water and/or causing possible se-

rious damage to the mechanical operation of the pump.

5. Always test the water from well for purity before using.

Check with local health department for testing procedure.

6. Before installing or servicing your pump, BE SURE pump

power source is disconnected.

7. BE SURE your pump electrical circuit is properly

grounded.

8. Complete pump and piping system MUST be protected

against below freezing temperature. Allov_mg the pump

or piping to freeze could cause severe damage and voids

the Warranty.

9. BE SURE the llne voltage and frequency of the electrical

current supply agree with the motor wiring as shown on

motor nameplate.

10. The correct fusing and vdring sizing is essential to proper

motor operation. Recommended fusing and wire size data

is in the manual (Page 5).

11. Pump water only with this pump.

12. Periodically inspect pump and system components.

IA CAUTION 1Motor normally operates at high temperature

and wilt be too hot to touch. It is protected

from heat damage during operation by an automatic inter-

nal cutoff switch. Before handling pump or motor, stop

motor and allow it to cool for 20 minutes.

GENERAL INFORMATION

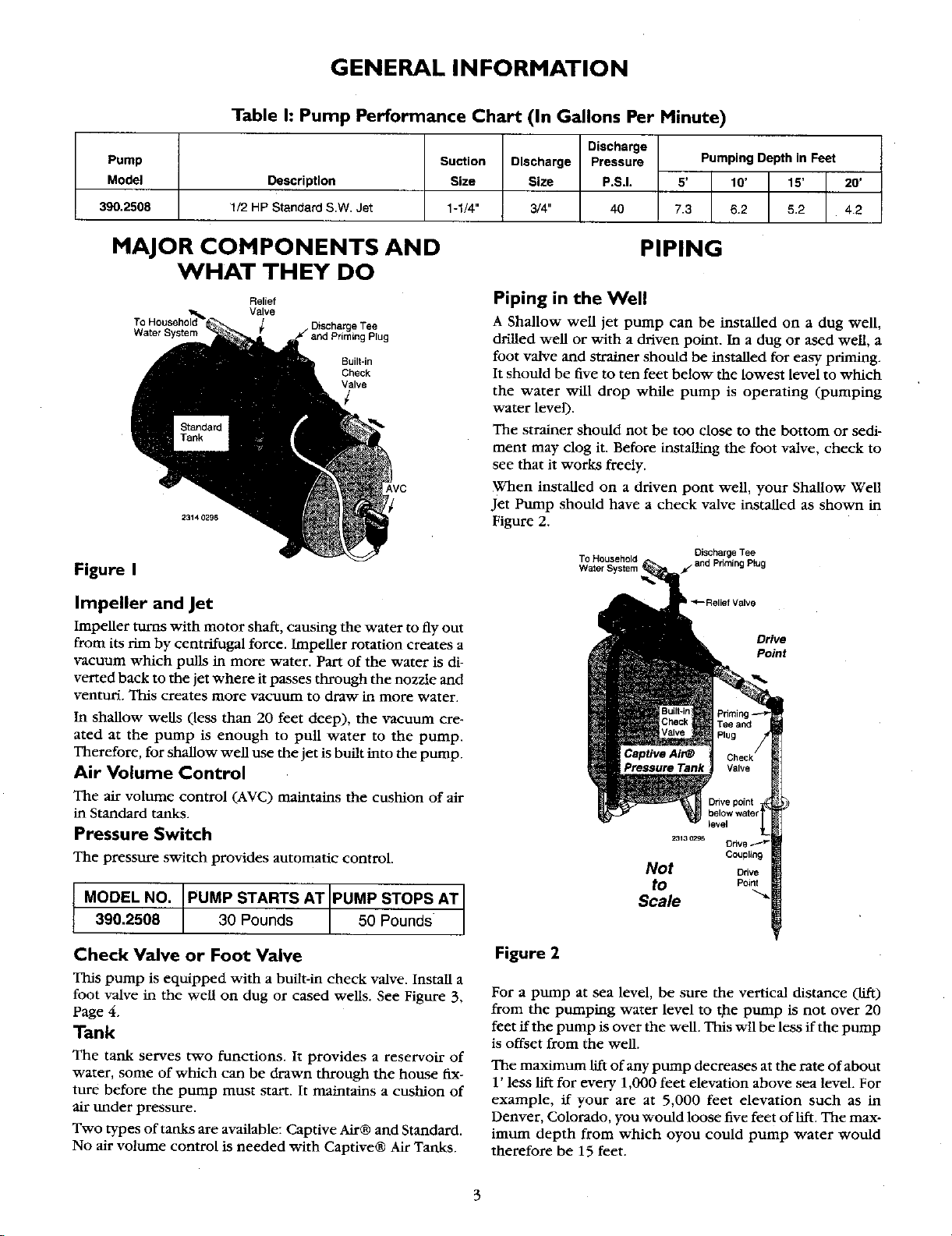

Table h Pump Performance Chart (In Gallons Per Minute)

Pump Suction Discharge Pressure Pumping Depthin Feet

Model Description Size Size P.S.I. 5' 10' 15' 20'

390.2508 1/2 HP Standard S.W. Jet 1-1/4" 3/4" 40 7.3 6.2 5.2 4.2

MAJOR COMPONENTS AND

Discharge

PIPING

WHAT THEY DO

Relief

Valve

Water System and Priming Plug

23140E96

ieTee

Built-in

Check

Valve

Figure I

Impeller and Jet

Impeller turns with motor shaft, causing the water to fly out

from its rim by centrifugal force. Impeller rotation creates a

vacuum which puUs in more water. Part of the water is di-

verted back to the jet where it passes through the nozzle and

venturi. This creates more vacuum to draw in more water.

In shallow wells (less than 20 feet deep), the vacuum cre-

ated at the pump is enough to pull water to the pump.

Therefore, for shallow well use the jet is built into the pump.

Air Volume Control

The air volume control (AVC) maintains the cushion of air

in Standard tanks.

Pressure Switch

The pressure switch provides automatic control.

MODEL NO. PUMP STARTS AT [PUMP STOPS AT

390.2508 _ / _

Piping in the Well

A Shallow well jet pump can be installed on a dug well,

drilled well or with a driven point. In a dug or ased well, a

foot valve and strainer should be installed for easy priming.

It should be five to ten feet below the lowest level to which

the water will drop while pump is operating (pumping

water level).

The strainer should not be too close to the bottom or sedi-

ment may clog it. Before installing the foot valve, check to

see that it works freely.

When installed on a driven pont well, your Shallow Well

Jet Pump should have a check valve installed as shown in

Figure 2.

To Household Discharge Tee

Water System f- and Priming Plug

II _--Relief Valve

Drive

Point

Couplin9

Not Orive

to Point

Scale

Check Valve or Foot Valve

This pump is equipped with a built-in check valve. Install a

foot valve in the well on dug or cased wells. See Figure 3,

Page 4.

Tank

The tank serves two functions. It provides a reservoir of

water, some of which can be drawn through the house fix-

ture before the pump must start. It maintains a cushion of

air under pressure.

Two types of tanks are available: Captive Air® and Standard.

No air vohtme control is needed with Captive® Air Tanks.

Figure 2

For a pump at sea level, be sure the vertical distance (lift)

from the pumping water level to the pump is not over 20

feet ifthe pump is over the well. This wll be less if the pump

is offset from the well.

The maximum lift of any pump decreases at the rate of about

1' less lifx for every 1,000 feet elevation above sea level. For

example, if your are at 5,000 feet elevation such as in

Denver, Colorado, you would loose five feet of llfx. The max-

imum depth from which oyou could pump water would

therefore be 15 feet.

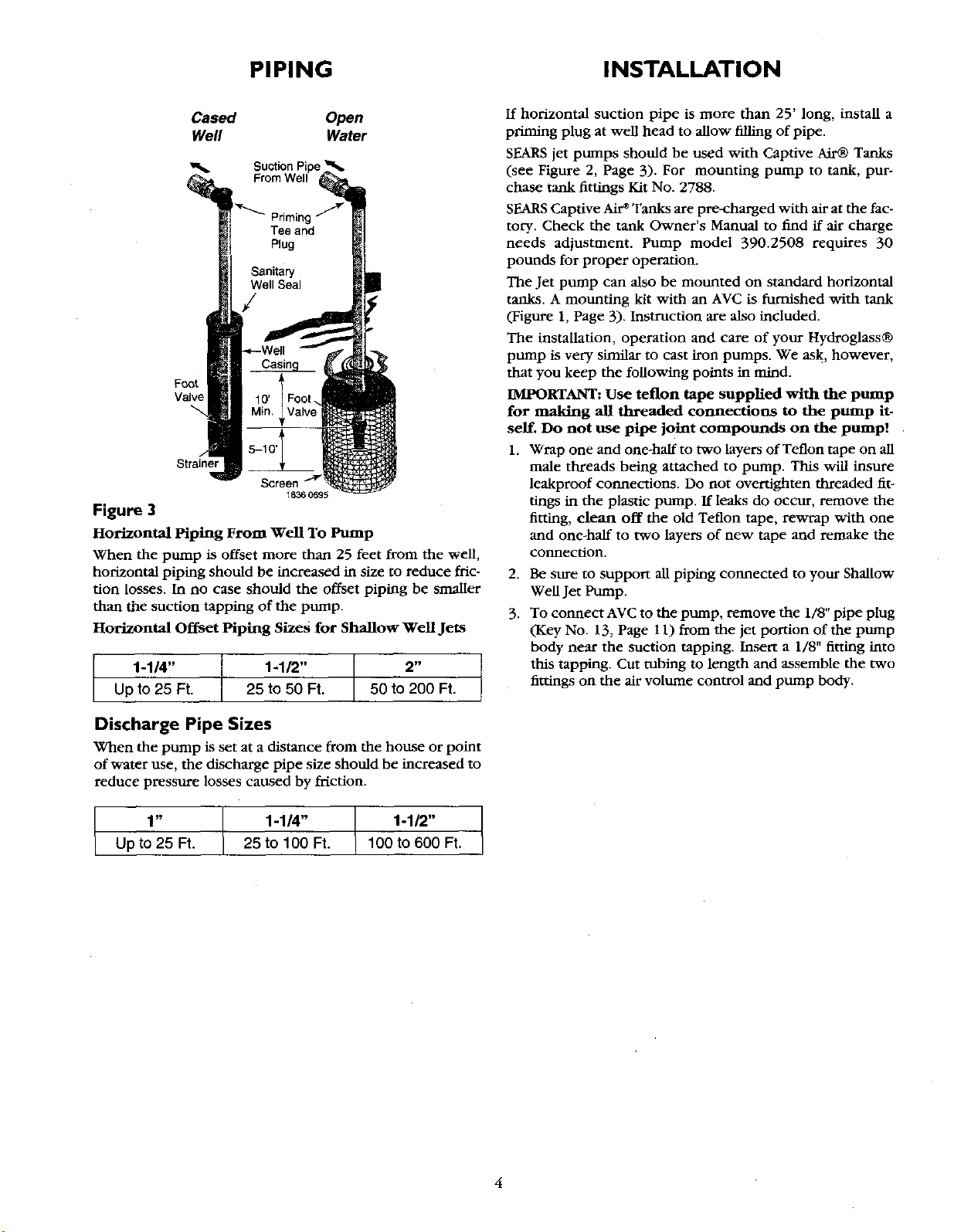

PIPING INSTALLATION

Cased Open

Well Water

Foot

Valve

Strainer

Screen

18360695

Figure 3

Horizontal Piping From well To Pump

When the pump is offset more than 25 feet from the well,

horizontal piping should be increased in size to reduce fric-

tion losses. In no case should the offset piping be smaller

than the suction tapping of the pump.

Horizontal Offset Piping Sizes for Shallow Well Jets

2 _

50 to 200 Ft.

t 1-1/4"

Up to 25 Ft.

1-1/2"

25 to 50 Ft.

ff horizontal suction pipe is more than 25' long, install a

priming plug at well head to allow filling of pipe.

SEARS jet pumps should be used vdth Captive Air® Tanks

(see Figure 2, Page 3). For mounting pump to tank, pur-

chase tank fittings Kit No. 2788.

SEARS Captive Air* Tanks are pre-charged with air at the fac-

tory. Check the tank Owner's Manual to find if air charge

needs adjustment. Pump model 390.2508 requires 30

pounds for proper operation.

The Jet pump can also be mounted on standard horizontal

tanks. A mounting kit with an AVC is furnished with tank

(Figure 1, Page 3). Instruction are also included.

The installation, operation and care of your Hydroglass®

pump is very similar to cast iron pumps. We ask, however,

that you keep the following points in mind.

IMPORTANT: Use teflon tape supplied with the pump

for making all threaded connections to the pump it-

self. Do not use pipe joint compounds on the pump!

1. Wrap one and one-half to two layers of Teflon tape on all

male threads being attached to pump. This vdll insure

leakproof connections. Do not overtighten threaded fiv

tings in the plastic pump. If leaks do occur, remove the

fitting, clean off the old Teflon tape, rewrap with one

and one-half to two Myers of new tape and remake the

connection.

2.

Be sure to support all piping connected to your Shallow

Well Jet Pump.

3.

To connect AVC to the pump, remove the 1/8" pipe plug

(Key No. 13, Page 11) from the jet portion of the pump

body near the suction tapping. Insert a 1/8" fitting into

this tapping. Cut tubing to length and assemble the two

fittings on the air volume control and pump body.

Discharge Pipe Sizes

When the pump is set at a distance from the house or point

of water use, the discharge pipe size should be increased to

reduce pressure losses caused by friction.

1" l 1-1/4" 1-1/2"

Up to 25 Ft. _ 25 to 100 Ft. 100 to 600 Ft.

ELECTRICAL

Disconnect power before working on pump, motor, pressure switch, or wiring.

Motor Switch Settings

If the motor can operate at either 115 or 230 volts, it is set

at the factory to 230 volts. Do not change motor voltage

setting if line voltage is 230 volts, or if you have a single

voltage motor.

NOTICE: Never wire a 115 volt motor to a 230 volt line.

Remove Hotor End Cover

Figure 4 - Removing Motor End Cover

You will need to remove the motor end cover to change

the voltage setting. The illustration above also shows the

pressure switch. If the power supply connection still

needs to be made, the pressure svdtch cover v/ill need to

be removed.

Your motor terminal board (located under the motor end

cover) should look like the one at right.

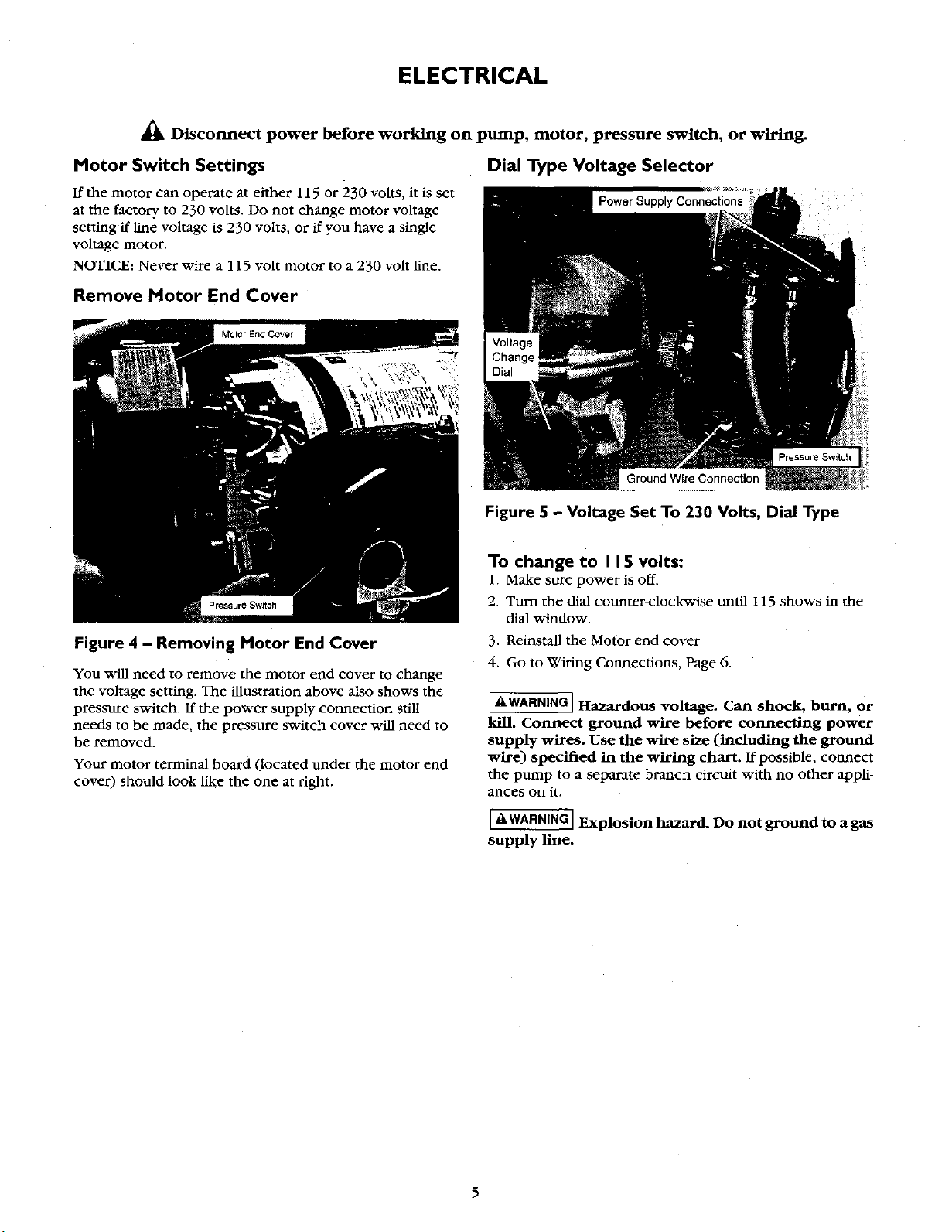

Dial Type Voltage Selector

Figure 5 - Voltage Set To 230 Volts, Dial Type

To change to I 15 volts:

1. Make sure power is off.

2. Turn the dial counter-clockwise until 115 shows in the

dial window.

3. Reinstall the Motor end cover

4. Go to Wiring Connections, Page 6.

I_,WARNING] Hazardous voltage. Can shock, burn, or

kill. Connect ground wire before connecting power

supply wires. Use the wire size (including the ground

wire) specified in the wiring chart. If possible, connect

the pump to a separate branch circuit with no other appli-

ances on it.

[_.WARNING] Explosion hazard. Do not ground to a gas

supply line.

Loading...

Loading...